Wolf CRL evo max Series, CRL-iD-9000, CRL-iD-4800, CRL-iD-6200, CRL-iH-1300 Installation And Maintenance Instructions Manual

...

GB

Installation and maintenance instructions

COMFORT VENTILATION UNIT WITH THERMAL WHEEL HEAT

EXCHANGER

CRL / CRL evo max

(Translation of the original)

English | subject to modications!

3064361_201811

Table of contents

Table of contents

1 General / Safety information ................................................................... 3

2 Standards, regulations / disposal ........................................................... 5

3 CRL-iD unit layout .................................................................................. 6

4 CRL-iD appliance versions ..................................................................... 8

5 CRL-iH unit layout .................................................................................. 9

5.1 CRL-iH evo max unit layout ...................................................................11

6 CRL-iH appliance versions ................................................................... 13

7 CRL-iDH unit layout .............................................................................. 14

8 CRL-iDH appliance versions ........................................................................16

9 CRL-A unit layout ................................................................................. 17

9.1 CRL-A evo max unit layout ................................................................... 19

10 CRL-A appliance versions .................................................................... 21

11 Delivery / Handling ............................................................................... 22

12 Unit splitting for handling purposes - CRL ............................................ 24

13 Assembly - CRL evo max ..................................................................... 29

14 Installation information for external units .............................................. 32

15 Siting .................................................................................................... 33

16 Electrical connection ............................................................................ 35

17 Commissioning .................................................................................... 37

18 Maintenance shutdown ........................................................................ 46

19 Hygiene checklist ................................................................................. 47

20 Maintenance ......................................................................................... 48

21 Notes .................................................................................................... 51

2 3064361_201811

1 General / Safety information

General information These installation and maintenance instructions only apply to WOLF CRL / CRL

evo max ventilation units. Authorised personnel should read these instructions

before any commissioning or maintenance work. Comply with the specications

in this document. Installation, commissioning and maintenance work must only

be carried out by trained personnel.

These instructions should be considered an integral part of the unit

supplied, and should always be easily accessible.

Failure to observe these installation and maintenance instructions voids any

WOLF GmbH warranty.

Reference symbols The following reference symbols are used in these instructions. This

important information concerns personal and operational safety as well

as operational reliability.

“Safety information" identies instructions that must be observed to

the letter, to prevent risks and injuries to individuals and damage to the

appliance.

Danger through 'live' electrical components.

Please note: Turn off the ON/OFF switch before removing the casing.

Never touch electrical components or contacts when the ON/OFF switch

is in the ON position. There is a danger of electrocution, resulting in a

risk to health or death.

The main terminals are 'live', even when the ON/OFF switch is in the OFF

position.

Note

Safety information In addition to installation and maintenance instructions, there are notes attached

"Please note" designates technical instructions which you must observe

to prevent the unit malfunctioning or being damaged.

to the unit in the form of labels. These must also be observed.

Only qualied and trained personnel may be appointed for the installation,

commissioning, maintenance and operation of the unit.

Only qualied electricians are permitted to work on the electrical system.

VDE regulations [or local regulations] and those of your local power supply

utility are applicable to electrical installation work.

Only operate the unit within its output range, which is stated in the technical

documentation supplied by WOLF.

Only operate the appliance if it is in perfect technical condition. Any faults or

damage that impact or might impact upon the safety or correct function of the

unit must be remedied immediately by qualied personnel.

Only replace faulty components and equipment with original WOLF spare parts.

Note

It may only be used for handling air. This air must not contain any harmful,

combustible, explosive, aggressive, corrosive or otherwise dangerous

substances, as these would be distributed throughout the duct system

or building, where they could cause a risk to the health of, or even kill

the occupants, animals or plants living there.

33064361_201811

1 General / safety information

In accordance with DIN 1886, tools are required to open the unit. Wait for the

fan to reach standstill (2 minutes wait). When the doors are opened, negative

pressure may draw in loose objects, which could destroy the fan or even cause

a risk to life if items of clothing are drawn in.

Electrical connection Make the electrical connection in accordance with local regulations.

Once electrical connection work is complete, the installation must be subjected

to a safety test in accordance with VDE 0701-0702 and VDE 0700 part 500,

as otherwise there would be a risk of electric shock that could result in injury

or death.

Before working on the unit, shut it down via the isolator.

Even when the unit has been shut down, voltage will still be present at terminals

and connections of the EC fans. This means there is a risk of electric shock

that could result in injury or death.

Do not touch the EC fans for ve minutes after disconnecting the power across

all poles.

Intended use Wolf CRL / CRL evo max ventilation units are designed to heat and lter normal

air. Max. Max. air intake temperature: +40 °C. The use of these units in wet

rooms or rooms with explosive atmospheres is not permissible. Handling very

dusty or aggressive media is not permissible.

Any onsite modication or improper use of the unit is not permissible and WOLF

GmbH accepts no liability for any damage caused as a result.

Ventilation units intended for internal installation must be placed in rooms that

meet the requirements of VDI 2050 (VDI 2050, Requirements for technical

equipment rooms - Planning and execution).

Fire The unit does not present a direct risk of re.

The small numbers of seals tted inside the unit can burn away if subjected to

external inuences. Wear respiratory equipment if you ght a re. The usual

extinguishing agents such as water, extinguishing foam or extinguishing powder

can be used to extinguish res. As there are only a small number of ammable

seals, the level of pollutants that could be released in a re is minimal.

Warnings

Recommended temperatures The ventilation unit is designed for air intake temperatures between -20 °C

Other technical documents - Operating instructions WRS-K

Removal and disabling of safety and monitoring equipment is prohibited.

The system must only be operated if it is in perfect technical condition. Ensure

that any faults or damage that may impact on safety are rectied immediately.

and +40 °C. For safety reasons, the room temperature in technical equipment

rooms must not fall below 5 °C (risk of frost) or exceed 40 °C. The unit should

be operated in room conditions of between 22 °C and 28 °C at approx. 55 %

relative humidity.

- MicroMax 370W TWHE control unit operating instructions

- Wiring diagram

- Conguration assistant WRS-K

- Commissioning report / parameter list

4 3064361_201811

2 Standards, regulations / disposal

Standards and regulations - Machinery Directive 2006/42/EC

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

- ErP Directive 2009/125/EC

- EN ISO 12100 Safety of machinery; general principles

- DIN EN ISO 13857: Safety of machinery; safety distances

- DIN EN 349 Safety of machinery; minimum

- DIN EN 953 Safety of machinery; Guards

- DIN EN 1886 Ventilation for buildings; central air-

- DIN ISO 1940-1 Mechanical vibration; balance quality

- VDMA 24167 Fans; safety requirements

- DIN EN 60204-1 Safety of machinery - Electrical

for design

clearances

handling units

requirements

equipment of machines

- DIN EN 60730 Automatic electrical controls

- DIN EN 61000 -6-2+3 Electromagnetic Compatibility

In addition, ÖVE regulations and the local building code apply to Austria.

The following standards and regulations apply to installation and operation:

- DIN EN 50106 (VDE 0700-500) Safety of electrical appliances; tests

- DIN VDE 0100 Regulations regarding the installation of

high voltage systems up to 1000 V

- DIN EN 50110-1 (VDE 0105-1) Operation of electrical installations

- DIN VDE 0105-100 Operation of electrical systems; general

stipulations

Disposal and recycling When the unit reaches the end of its service life, it must only be dismantled by

qualied personnel. Before starting to dismantle the unit, disconnect the power

supply. Power cables must be removed by qualied electricians. Sort and dispose

of metal and plastic parts according to material types and in compliance with

local regulations. Dispose of electrical and electronic components as electrical

waste.

53064361_201811

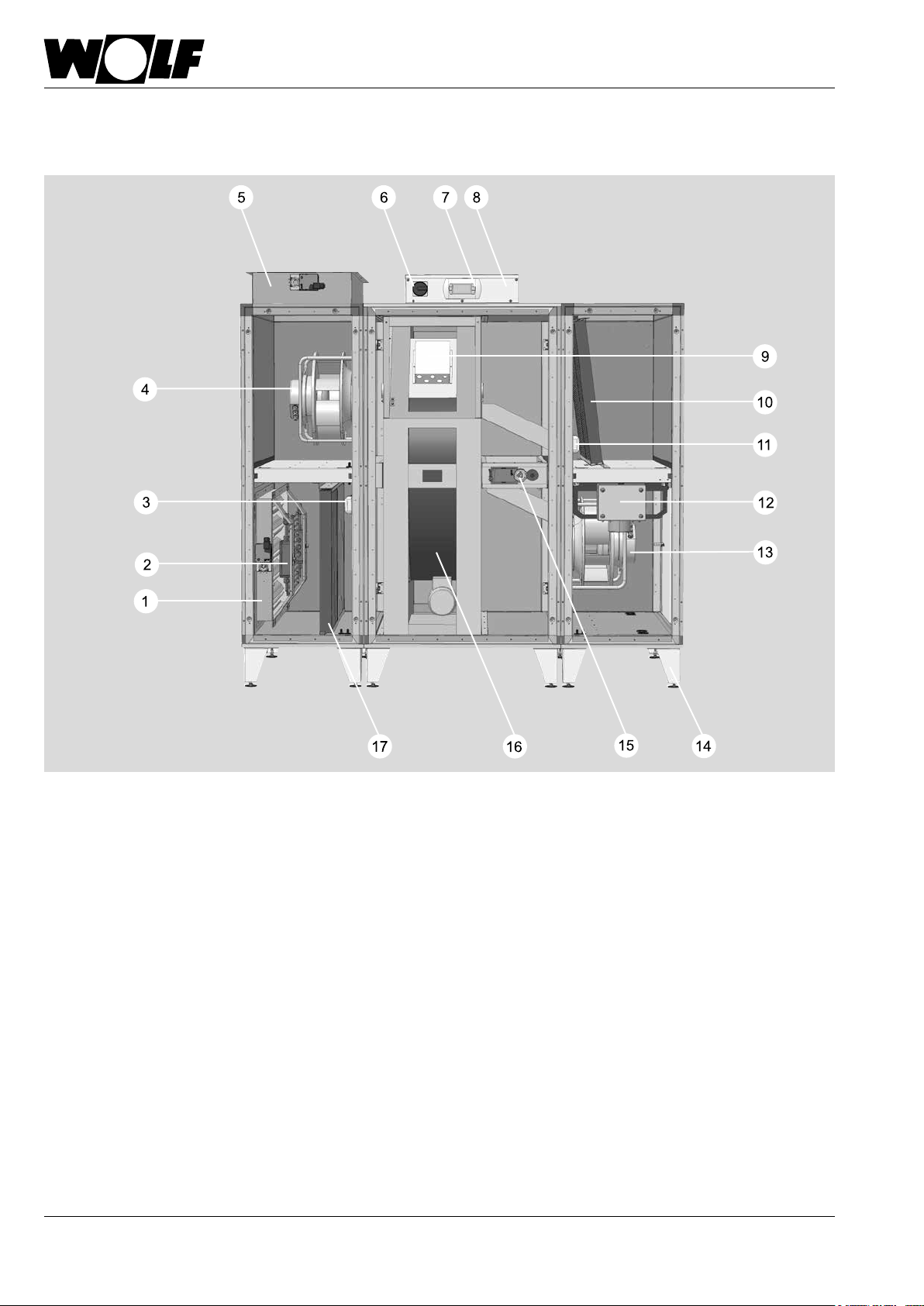

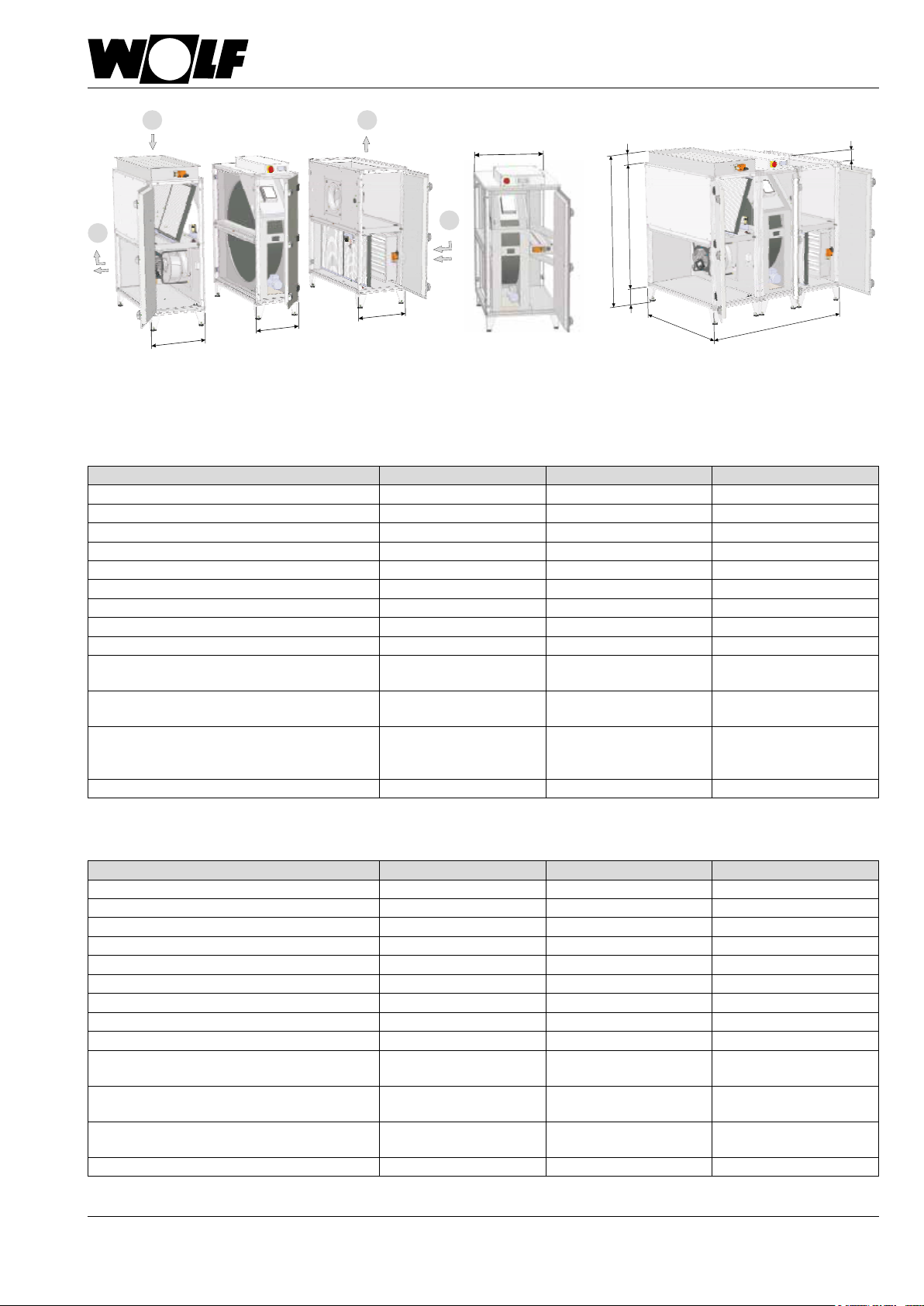

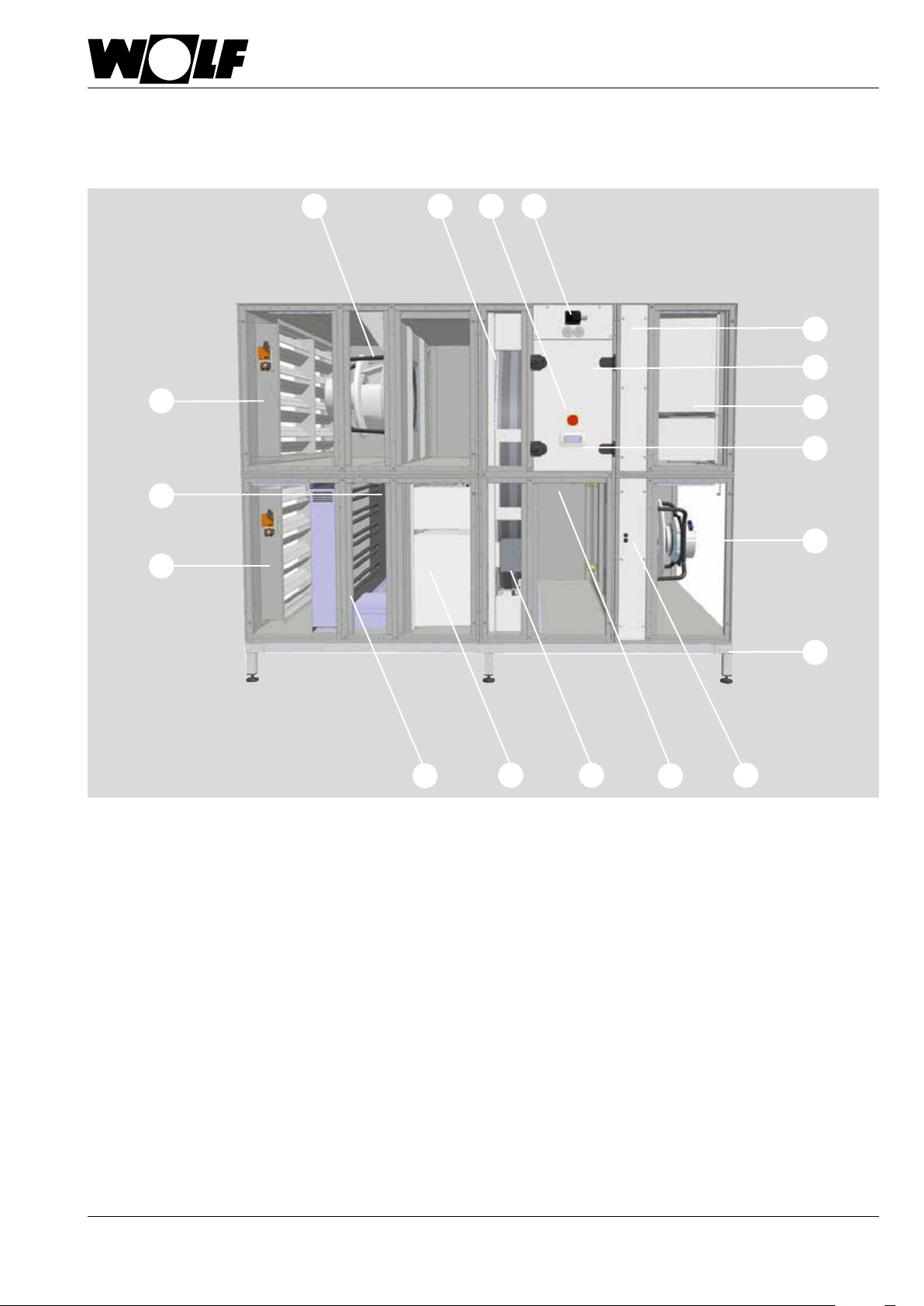

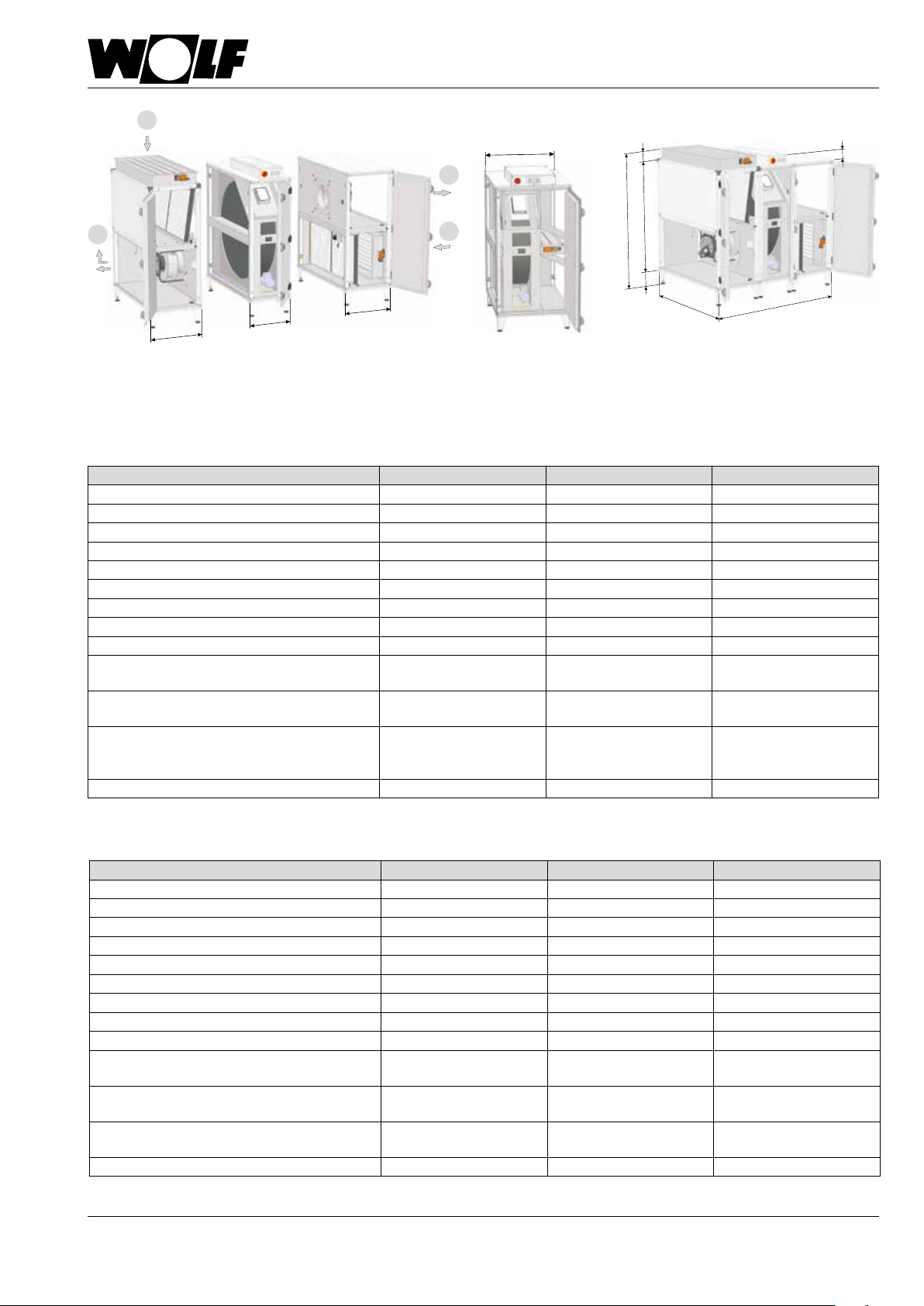

3 CRL-iD unit layout

CRL-iD Comfort thermal wheel heat exchanger ventilation unit for internal installation with vertical/

horizontal duct connection (example provided is CRL-iD-3500 with boost damper)

1 Outdoor air damper with servomotor

2 Filter pre-dryer (accessory)

3 Differential pressure switch for lter monitoring

4 EC fan, extract air

5 Ventilation air damper with servomotor

6 Repair switch

7 BMK programming unit

8 control panel

9 TWHE control unit

10 Compact lter, extract air

6 3064361_201811

11 Differential pressure switch for lter monitoring

12 Electric reheating coil available for

CRL-1300/-2500/-3500 (accessory)

13 EC fan, supply air

14 Adjustable feet

15 Boost damper with servomotor optional

for CRL-1300/-2500/-3500

16 TWHE thermal wheel heat exchanger

17 Compact lter, outdoor air

3 CRL-iD unit layout

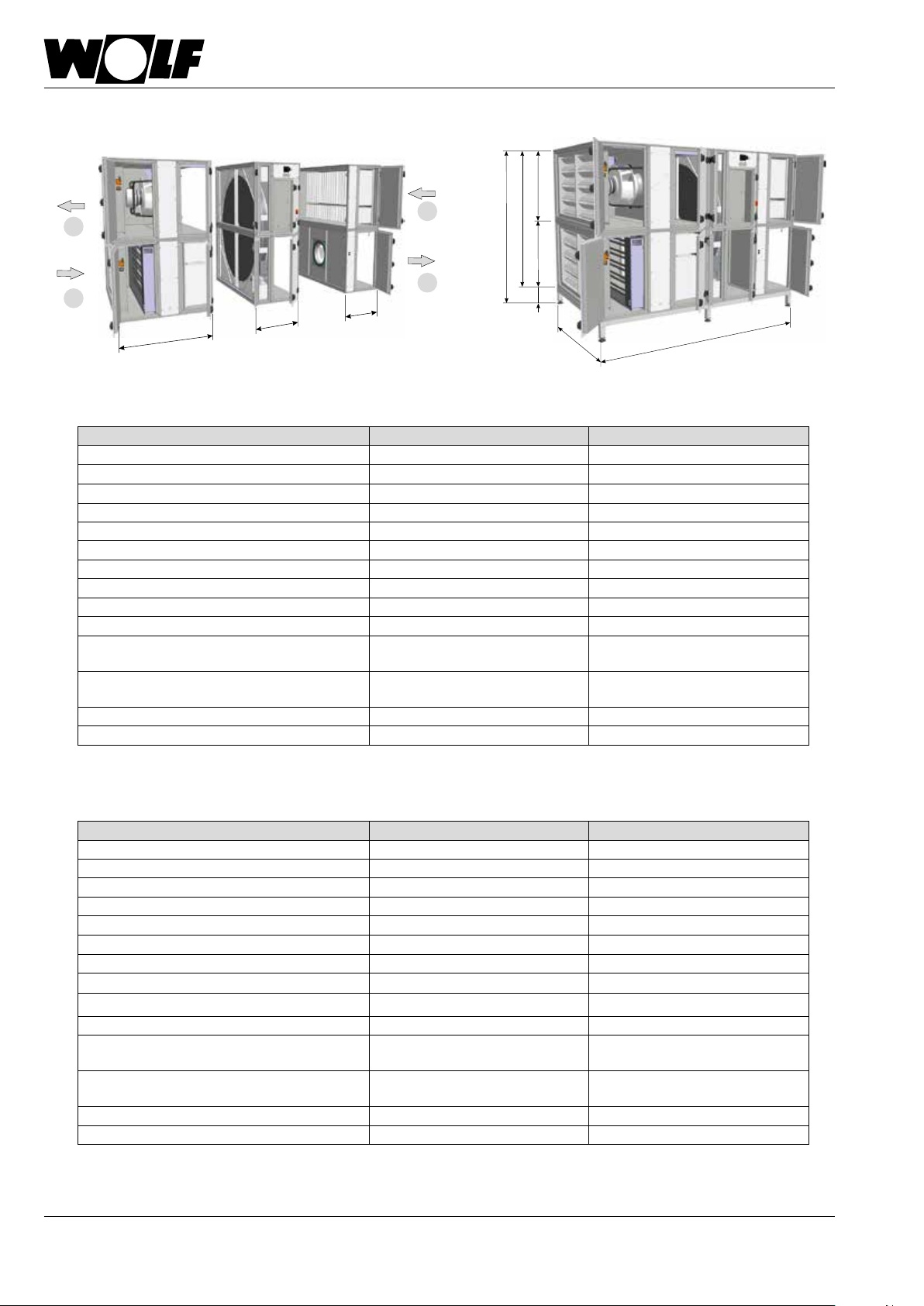

1 3

L2*

128

122

2

1 Outdoor air

2 Exhaust air

4

L1

L2

3 Supply air

L1

TWHE with boost

damper

4 Extract air

Total

H

H

170

T

L

Type CRL-iD-1300 CRL-iD-2500 CRL-iD-3500

Unit layout Single piece Single piece Three piece

Length L mm 1525 / 1525* 1626 / 1626* 1626 / 1830*

Length L1 mm - - 508

Length L2 (rotor part) mm - - 610 / 814*

Depth D (incl. locks) mm 750 950 1155

Total height mm 1315 1722 1722

Height H mm 1017 1424 1424

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

Duct connection dimensions, vertical

air routing

mm int. 612x409 Intl 815x612 Intl 1019x612

mm Intl 596x307 Intl799x307 Intl1019x408

470 / 490*

Weight kg 266 / 266* 381 / 381*

(130+210+130)

(130+230+130)*

Nominal flow rate m³/h 1300 at 460 Pa (ext.) 2500 at 600 Pa (ext.) 3500 at 980 Pa (ext.)

* with boost damper

Type CRL-iD-4800 CRL-iD-6200 CRL-iD-9000

Unit layout Three piece Three piece Three piece

Length L mm 1728 1932 2136

Length L1 mm 610 712 814

Length L2 (rotor part) mm 508 508 508

Depth D (incl. locks) mm 1360 1665 2070

Total height mm 1722 1722 1925

Height H mm 1424 1424 1627

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

Duct connection dimensions, vertical

air routing

Weight kg

mm intl 1222 x 612 intl 1527 x 612 intl 1934 x 714

mm intl 1222 x 510 intl 1527 x 612 intl 1934 x 714

590

(180+230+180)

715

(220+275+220)

845

(275+295+275)

Nominal flow rate m³/h 4800 at 450 Pa (ext.) 6200 at 680 Pa (ext.) 9000 at 1000 Pa (ext.)

73064361_201811

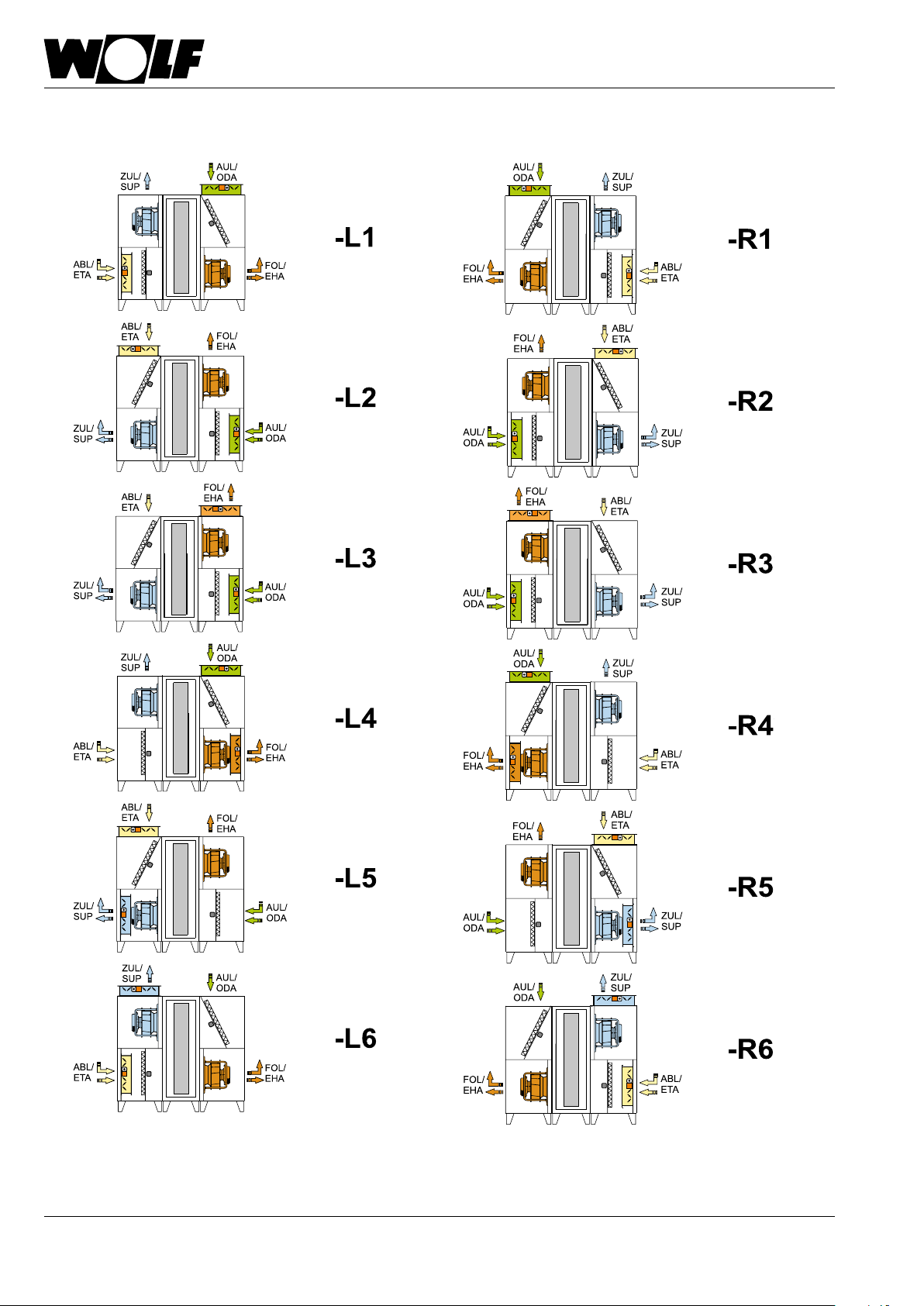

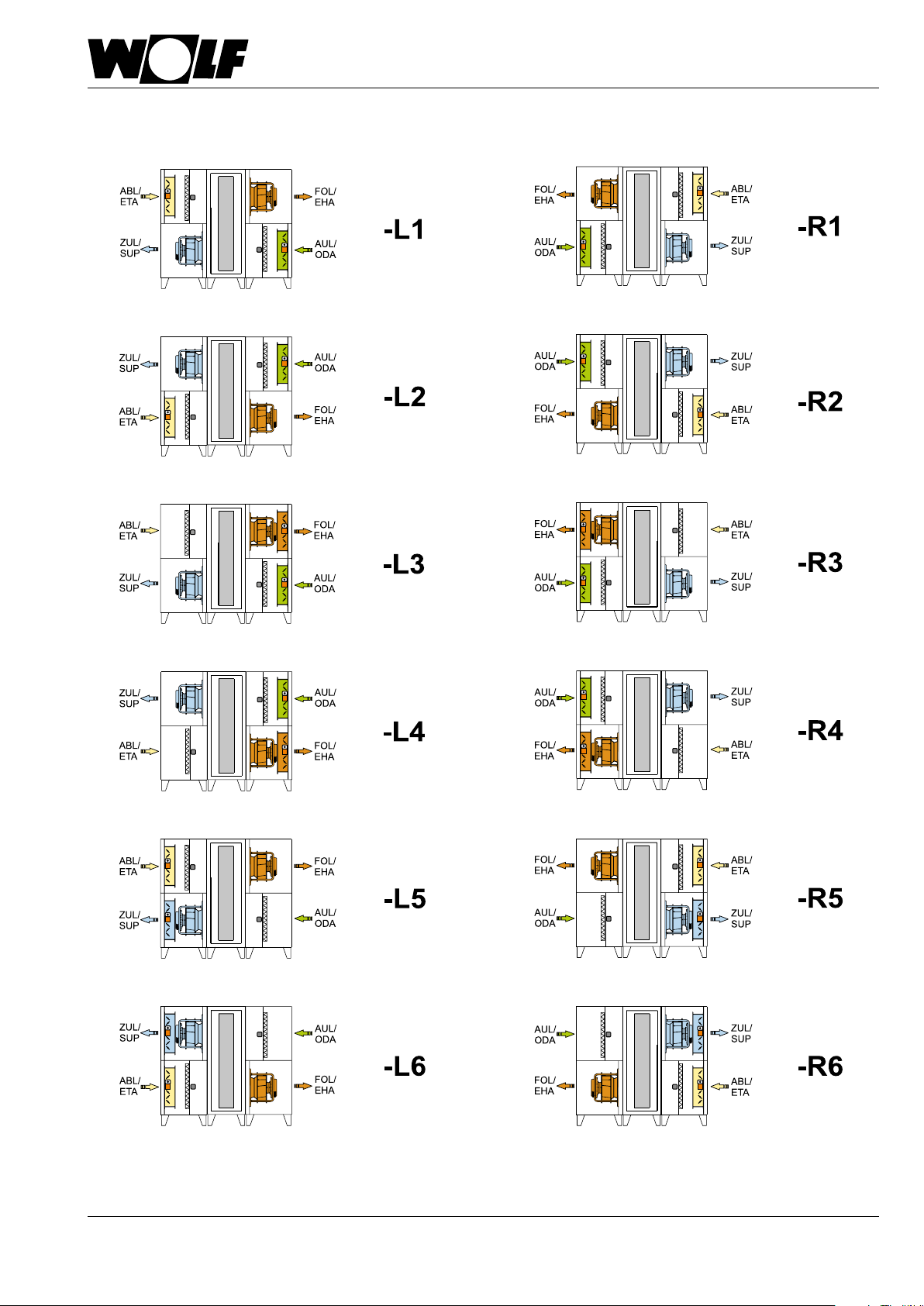

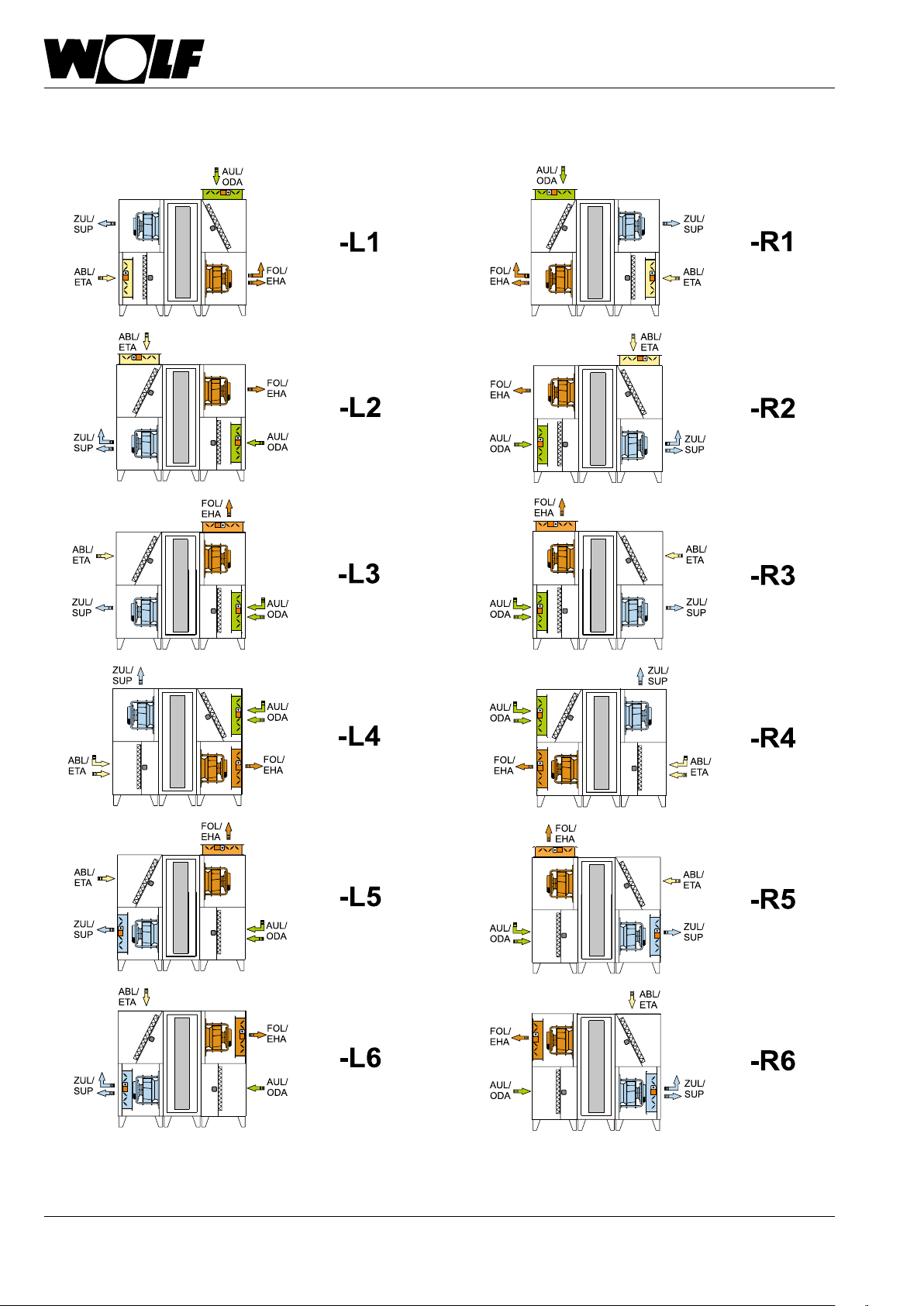

4 CRL-iD appliance versions

Access side in supply air direction, left Access side in supply air direction, right

1

1

1

1

1

For CRL-1300/-2500/-3500, these versions are available with a boost damper.

8 3064361_201811

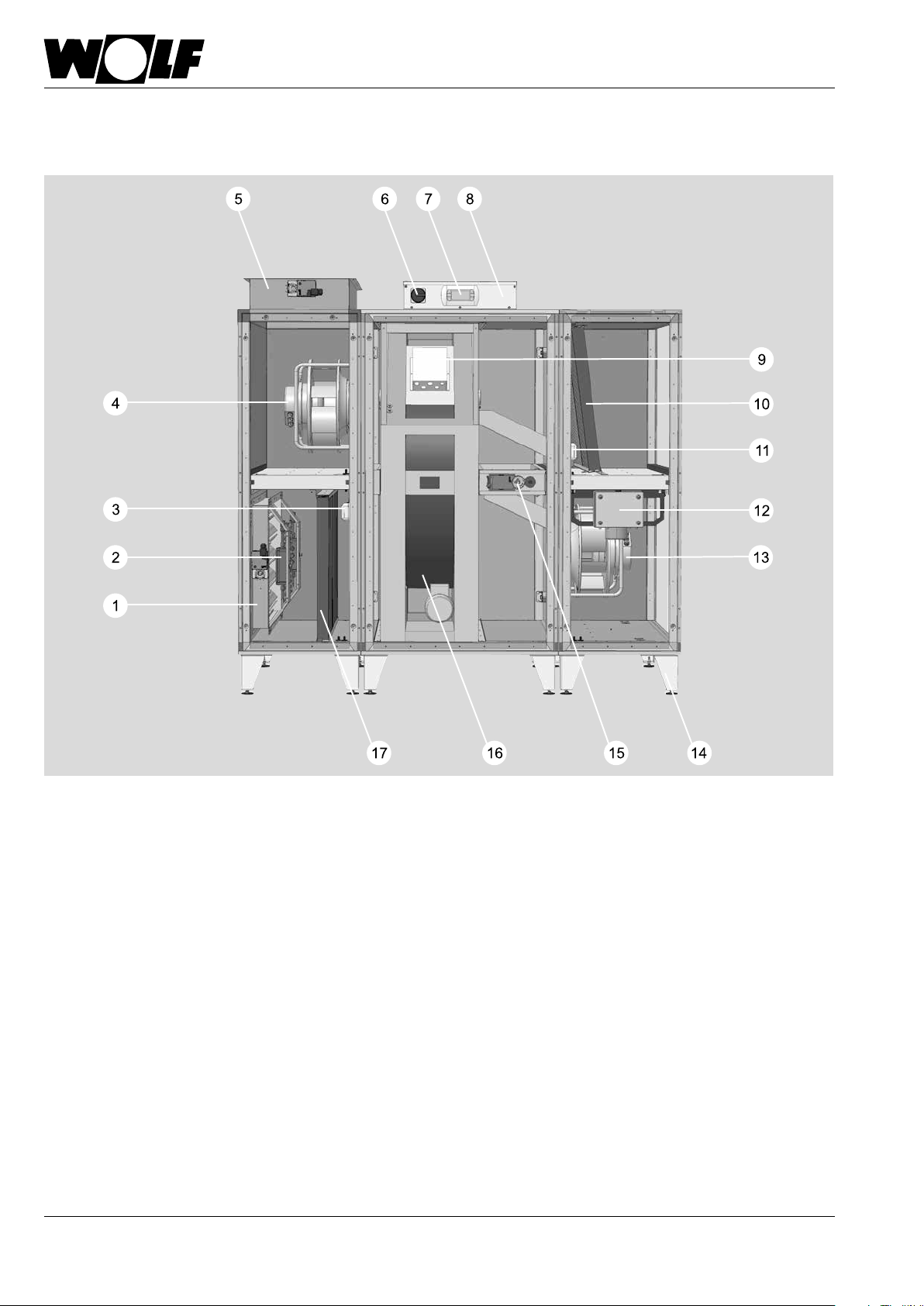

5 CRL-iH unit layout

CRL-iH Comfort thermal wheel heat exchanger ventilation unit for internal installation with horizontal duct

connection (example provided is CRL-iH-3500 with boost damper)

1 Outdoor air damper with servomotor

2 Filter pre-dryer (accessory)

3 Differential pressure switch for lter monitoring

4 EC fan, extract air

5 Ventilation air damper with servomotor

6 Repair switch

7 BMK programming unit

8 control panel

9 TWHE control unit

10 Compact lter, extract air

11 Differential pressure switch for lter monitoring

12 Electric reheating coil available for

CRL-1300/-2500/-3500 (accessory)

13 EC fan, supply air

14 Adjustable feet

15 Boost damper with servomotor optional

for CRL-1300/-2500/-3500

16 TWHE thermal wheel heat exchanger

17 Compact lter, outdoor air

93064361_201811

5 CRL-iH unit layout

L2*

4

2

1

3

H

122

Total

H

L1

L2

L1

170

T

L

TWHE with boost

1 Outdoor air

2 Exhaust air

3 Supply air

4 Extract air

damper

Type CRL-iH-1300 CRL-iH-2500 CRL-iH-3500

Unit layout Single piece Single piece Three piece

Length L mm 1525 / 1525* 1626 / 1626* 1626 / 1830*

Length L1 mm - - 508

Length L2 (rotor part) mm - - 610 / 814*

Depth D (incl. locks) mm 750 950 1155

Total height mm 1309 1716 1716

Height H mm 1017 1424 1424

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

mm int. 612x409 Intl 815x612 Intl 1019x612

470 / 490*

Weight kg

266 / 266*

381 / 381*

(130+210+130)

(130+230+130)*

Nominal flow rate m³/h 1300 at 460 Pa (ext.) 2500 at 600 Pa (ext.) 3500 at 980 Pa (ext.)

* with boost damper

Type CRL-iH-4800 CRL-iH-6200 CRL-iH-9000

Unit layout Three piece Three piece Three piece

Length L mm 1728 1932 2136

Length L1 mm 610 712 814

Length L2 (rotor part) mm 508 508 508

Depth D (incl. locks) mm 1360 1665 2070

Total height mm 1716 1716 1919

Height H mm 1424 1424 1627

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

Weight kg

mm intl 1222 x 612 intl 1527 x 612 intl 1934 x 714

590

(180+230+180)

715

(220+275+220)

845

(275+295+275)

Nominal flow rate m³/h 4800 at 450Pa (ext.) 6200 at 680Pa (ext.) 9000 at 1000Pa (ext.)

10 3064361_201811

11

13

17

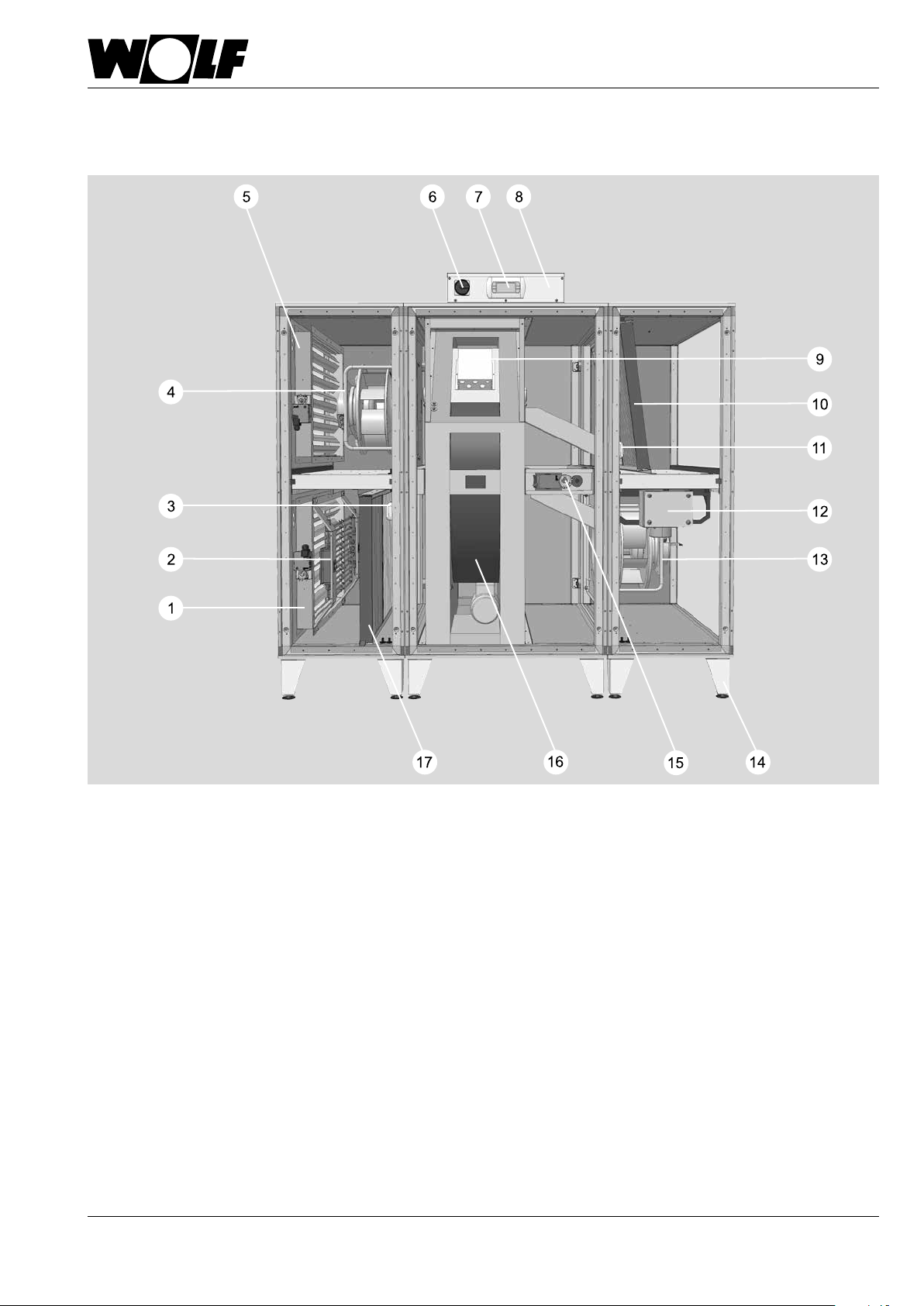

5.1 CRL-iH evo max unit layout

CRL-iH evo max Comfort thermal wheel heat exchanger ventilation unit for internal installation with

horizontal duct connection (example provided is CRL-iH-11000 evo max with boost

damper)

4

5

6 7

8

9

3

10

2

12

1

1 Outdoor air damper with servomotor

2 Differential pressure switch for lter monitoring

3 Ventilation air damper with servomotor

4 EC fan, extract air

5 TWHE thermal wheel heat exchanger

6 Repair switch

7 Panel for onsite cable entry

8 Differential pressure switch for lter monitoring

9 control panel

18

16

10 Extract air lter

11 BMK programming unit

12 EC fan, supply air

13 Base frame

14 Test connector for ow rate calculation

15 Boost damper with servomotor (optional)

16 Control TWHE

17 Outdoor air lter

18 Filter pre-dryer incl. control cabinet (accessory)

15

14

113064361_201811

5 CRL-iH evo max unit layout

H

1

1

4

H

H

Total

H

2

2

1 Outdoor air

2 Exhaust air

3

L1

L2

L3

3 Supply air

4 Extract air

250

L

T

Type CRL-iH-11000 evo max CRL-iH-13500 evo max

Unit layout Five piece Five piece

Length L mm 2950 / 2950* 2950 / 2950*

Length L1 mm 1424 1424

Length L2 (rotor part) mm 814 / 814* 814 / 814*

Length L3 mm 712 712

Depth D (incl. locks) mm 1970 1970

Total height mm 2284 2894

Height H mm 2034 2644

Internal frame (optional) mm 250 250

Height H1 / H2 mm 1017 1322

Duct connection dimensions,

horizontal air routing

Weight of standard unit kg

mm Intl 1832x917 Intl 1832x1222

1370

(590+460+320)

1550

(660+490+400)

Weight of base frame kg 60 90

Nominal flow rate m³/h 11000 at 1000 Pa (ext.) 13500 at 800Pa (ext.)

* with boost damper

Type CRL-iH-16500 evo max CRL-iH-19500 evo max

Unit layout Five piece Five piece

Length L mm 2950 / 2950* 2950 / 2950*

Length L1 mm 1424 1424

Length L2 (rotor part) mm 814 / 814* 814 / 814*

Length L3

712 712

Depth D (incl. locks) mm 2275 2580

Total height mm 2894 2894

Height H mm 2644 2644

Internal frame (optional) mm 250 250

Height H1 / H2 mm 1322 1322

Duct connection dimensions,

horizontal air routing

Weight of standard unit kg

mm Intl 2137x1222 Intl 2442x1222

1790

(710+630+450)

2020

(790+720+510)

Weight of base frame kg 110 120

Nominal flow rate m³/h 16500 at 750 Pa (ext.) 19500 at 950 Pa (ext.)

* with boost damper

12 3064361_201811

6 CRL-iH appliance versions

Access side in supply air direction, left Access side in supply air direction, right

1, 2

1, 2

1, 2

1, 2

1For CRL-iH-1300/-2500/-3500, these versions are available with a boost damper.

2CRL-IH evo max types are available in these versions

133064361_201811

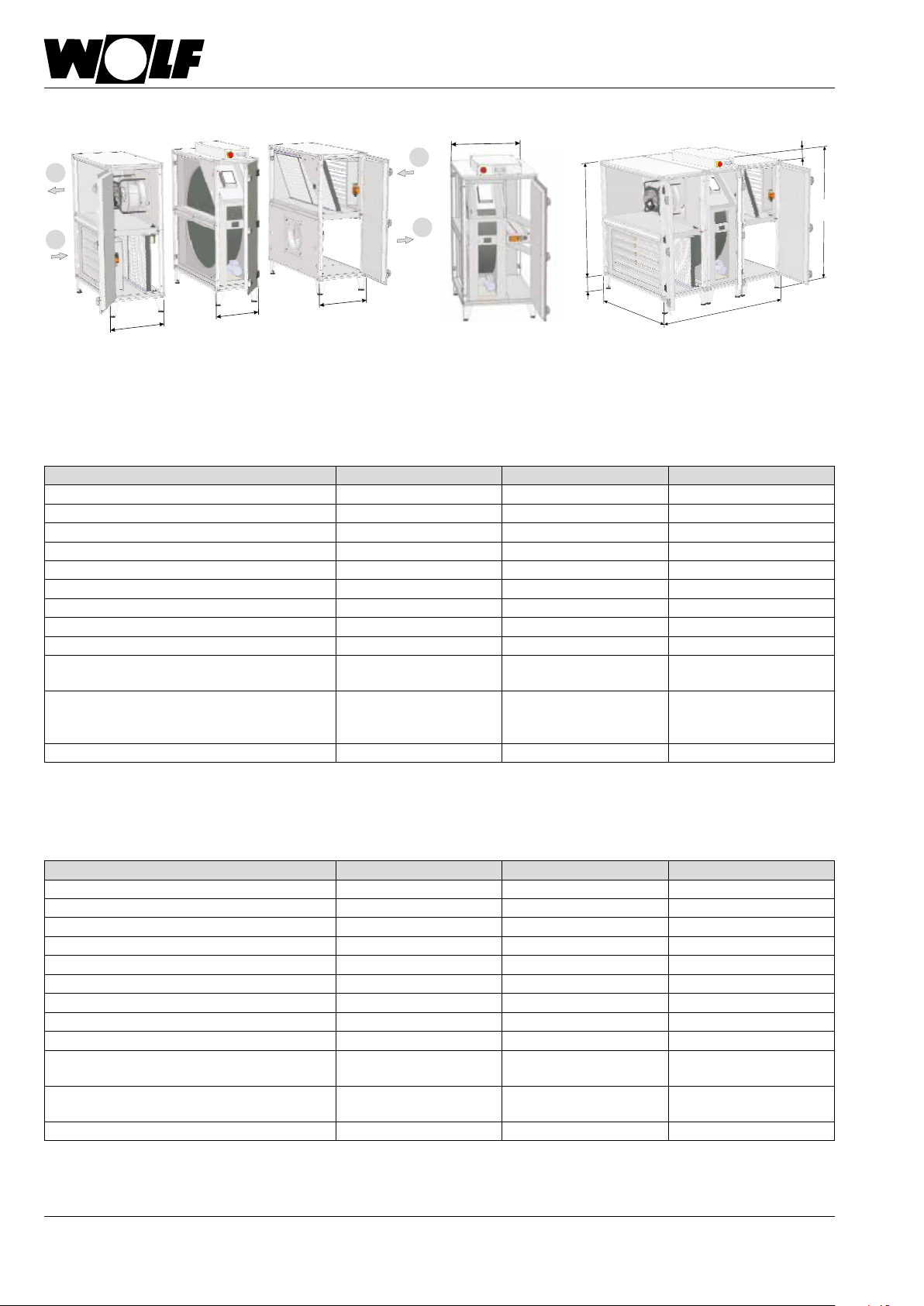

7 CRL-iDH unit layout

CRL-iDH Comfort thermal wheel heat exchanger ventilation unit energy efcient and comfortable

ventilation with vertical/horizontal duct connection (example provided is CRL-iDH-3500 with

boost damper)

1 Outdoor air damper with servomotor

2 Filter pre-dryer (accessory)

3 Differential pressure switch for lter monitoring

4 EC fan, extract air

5 Ventilation air damper with servomotor

6 Repair switch

7 BMK programming unit

8 control panel

9 TWHE control unit

14 3064361_201811

10 Compact lter, extract air

11 Differential pressure switch for lter monitoring

12 Electric reheating coil available for

CRL-1300/-2500/-3500 (accessory)

13 EC fan, supply air

14 Adjustable feet

15 Boost damper with servomotor optional for

CRL-1300/-2500/-3500

16 TWHE thermal wheel heat exchanger

17 Compact lter, outdoor air

7 CRL-iDH unit layout

L1

L2

L1

1

L2*

128

3

H

H

H

2

4

Total

170

T

L

122

1 Outdoor air

2 Exhaust air

3 Supply air

4 Extract air

TWHE with boost

damper

Type CRL-iDH-1300 CRL-iDH-2500 CRL-iDH-3500

Unit layout Single piece Single piece Three piece

Length L mm 1525 / 1525* 1626 / 1626* 1626 / 1830*

Length L1 mm - - 508

Length L2 (rotor part) mm - - 610 / 814*

Depth D (incl. locks) mm 750 950 1155

Total height mm 1315 1722 1722

Height H mm 1017 1424 1424

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

Duct connection dimensions, vertical

air routing

mm int. 612x409 Intl 815x612 Intl 1019x612

mm Intl 596x307 Intl799x307 Intl1019x408

470 / 490*

Weight kg 266 / 266* 381 / 381*

(130+210+130)

(130+230+130)*

Nominal flow rate m³/h 1300 at 460 Pa (ext.) 2500 at 600 Pa (ext.) 3500 at 980 Pa (ext.)

* with boost damper

Type CRL-iDH-4800 CRL-iDH-6200 CRL-iDH-9000

Unit layout Three piece Three piece Three piece

Length L mm 1728 1932 2136

Length L1 mm 610 712 814

Length L2 (rotor part) mm 508 508 508

Depth D (incl. locks) mm 1360 1665 2070

Total height mm 1722 1722 1925

Height H mm 1424 1424 1627

Foot height mm 170 170 170

Control unit height mm 122 122 122

Duct connection dimensions,

horizontal air routing

Duct connection dimensions, vertical

air routing

Weight kg

mm intl 1222 x 612 intl 1527 x 612 intl 1934 x 714

mm intl 1222 x 510 intl 1527 x 612 intl 1934 x 714

590

(180 + 230 + 180)

715

(220 + 275 + 220)

845

(275 + 295 + 275)

Nominal flow rate m³/h 4800 at 450 Pa (ext.) 6200 at 680 Pa (ext.) 9000 at 1000 Pa (ext.)

153064361_201811

8 CRL-iDH appliance versions

Access side in supply air direction, left Access side in supply air direction, right

1

1

1

1

Other versions available; see the WOLF sizing program.

1

For CRL-1300/-2500/-3500, these versions are available with a rapid heat-up damper.

16 3064361_201811

Loading...

Loading...