Wolf FunctionLine CHK, ComfortLine CHU, FunctionLine CHU, ComfortLine CHU-CB, FunctionLine CHU-CB Installation And Maintenance Instructions Manual

...

Installation and

maintenance instructions

ComfortLine

FunctionLine

Cast iron boilers up to 60 kW

GBPart.-No. 3060918_1203 Subject to modications

Wolf GmbH · Postfach 1380 · 84048 Mainburg · Tel. +49 8751/74-0 · Fax +49 8751/741600 · Internet: www.wolf-heiztechnik.de

2

3060918_1203

Index

Index .......................................................................................................Page

Safety instructions / Reference symbols ......................................................3

Standards / Regulations ............................................................................. 4-5

ComfortLine cast iron boilers ..........................................................................6

FunctionLine cast iron boilers .........................................................................7

Installation ................................................................................................. 8-9

Boiler installation on a plinth .........................................................................10

Boiler installation on a horizontal DHW cylinder ........................................... 11

Boiler assembly ...................................................................................... 12-15

ComfortLine decorative panel installation............................................... 16-17

FunctionLine decorative panel installation....................................................18

Flue pipe installation .....................................................................................19

Central heating to boiler connections ...........................................................20

DHW cylinder to boiler pipework ..................................................................21

Filling the heating system ....................................................................... 22-23

Draining the heating system .........................................................................24

Pressure jet oil burner installation / Electrical supply ...................................25

Initial start-up .......................................................................................... 26-27

Maintenance ........................................................................................... 28-29

Maintenance log ..................................................................................... 30-31

Specication ........................................................................................... 32-33

Dimensions ............................................................................................. 34-35

Troubleshooting ............................................................................................36

33060918_1203

Reference symbols / Safety instructions

The following symbols are used in

conjunction with these important instructions concerning personal safety

and technical reliability.

“Safety instructions“ are

instructions with which you

must comply exactly, to

prevent injury and material

losses.

Danger through “live“ elec-

trical components.

Please note: Switch OFF the

ON/OFF switch before removing the casing.

Never touch electrical com-

ponents or contacts when the

switch is in the ON position.

This creates a risk of electrocution, which may cause

injury or death.

The main supply terminals are

“live“ even when the ON/OFF

switch is in the OFF position.

This indicates technical in-

structions which you must

observe to prevent material

losses and boiler malfunctions.

In addition to the installation instructions,

operating instructions and adhesive labels

are included or tted to the boiler. These

must also be observed.

Note

General

Authorised personnel should read these

instructions before any installation, commissioning or maintenance work.

Adhere to the instructions given in this

document.

Non-observance of these installation

instructions voids any guarantee offered

WOLF.

Safety instructions

• Only use qualied and trained personnel

for the installation, commissioning and

maintenance of the boiler.

• In accordance with DIN EN 50110-1,

work on electrical components (e.g.

control units) may only be carried out

by qualied electricians.

• The regulations of VDE/ÖVE and those

of your local electricity supplier as well

as all other local regulations are applicable to electrical installation work.

• Only operate the boiler within its output

range which is stated in the specication

supplied by WOLF.

• Appropriate use of the boiler refers to

the exclusive use for hot water heating

systems in accordance with DIN 4751.

• Never remove, bypass or otherwise

disable any safety or monitoring equip-

ment.

• The boiler may only be operated in perfect technical condition. Any faults and

damage which may impact on safety

which might limit the safe use of the

equipment must be remedied immediately by a qualied contractor.

• Only replace faulty components or

equipment with original WOLF spare

parts.

4

3060918_1203

Standards / Regulations

Standards and regulations

Observe all current Building Regulations and other local requirements.

Only recognised heating contractors may

install WOLF boilers. This heating contractor will also be responsible for the proper

installation and the commissioning of the

heating system.

The boilers described in these installation

instructions are low temperature boilers

according to HeizAnlV and 92/42/EEC

(Efciency of Hot Water Boilers).

Locate the enclosed operating instructions

in a clearly visible position in the boiler

room.

Boilers may only be installed and operated in boiler rooms which are suitable

according to the Landes-FeuVo [or local

regulations].

The following regulations, rules and guidelines must be observed during installation:

• Boiler room guidelines or Building Regu-

lations relating to the construction and

installation of central boiler rooms and

fuel storage facilities.

• Energy Savings Act (EnEG) and related

directives (Heating Systems Order).

Note: Please read these instructions

carefully before the installation

and keep them in a secure place.

• DIN standards

DIN 1988 Technical rules for DHW

installations

DIN 4701 Rules for

calculating the heat

demand of buildings

DIN 4751 Part 3 - Safety Equipment

for heating systems with ow

temperatures up to 95 °C.

DIN 18160 Domestic chimneys

• VDE requirements:

VDE 0100 General information

regarding the installation of

HV systems with rated

voltages up to 1000V.

VDE 0105 Operation of HV

systems, general

considerations.

VDE 0722 Electrical equipment of

non-electrically heated

heat generators.

VDE 0470/ Protection through

housings

EN 60529

EN 60335-1 Safety of electrical

equipment for domestic

use and similar purposes.

53060918_1203

Standards / Regulations

Cast iron boilers

acc. to DIN EN 303 as well as in accordance with EC Directive 90/396/EEC (gas

consuming equipment),

73/23/EEC (Low Voltage Directive), 89/336/EEC (EMC Directive), 92/42/EEC (Efciency of Hot Water Boilers) and 93/68/EEC (Identication Directive) for heating

systems with heating circuit pumps and ow temperatures up to 110 °C and 3 bar

permissible operating pressure in accordance with DIN 4751 and DHW cylinder pressure (max. 10 bar) in accordance with DIN 4753.

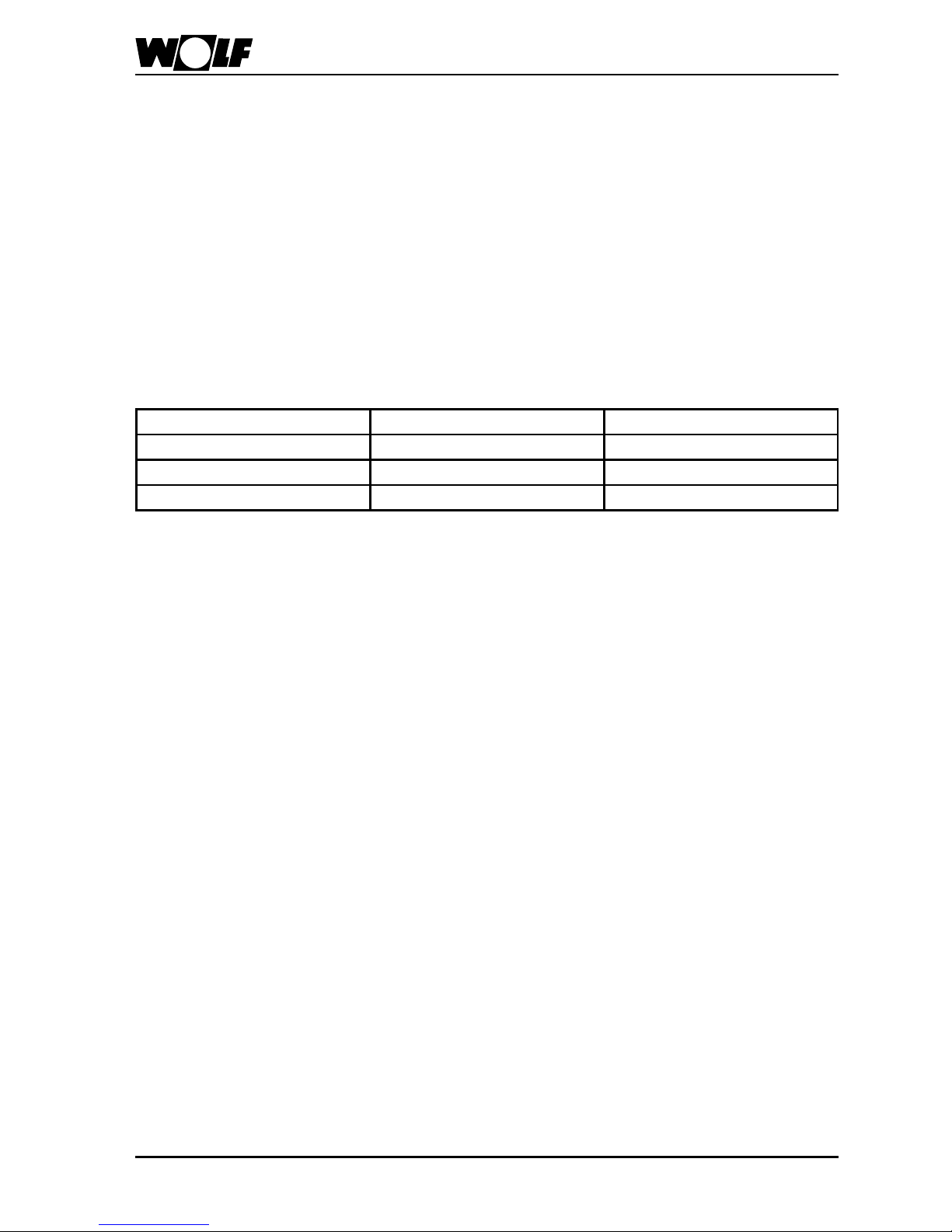

For the operation with pressure jet gas burners, the following gas device categories apply:

The NO

x

limits required by the 1st BImSchV para. 7(2) are maintained.

Country abbreviation Country Gas device category

DE Germany II

2ELL3B/P

AT Austria II

2H3B/P

LU Luxembourg I2E or I

3+

6

3060918_1203

ComfortLine cast iron boilers

Oil and gas-red cast iron boilers, type

CHK

(boiler plinth, accessory)

Oil and gas-red cast iron boilers, type

CHK-CB

incl. DHW cylinder

Oil-red cast iron Unit boiler, type CHU

incl. pressure jet oil burner

(boiler plinth, accessory)

Oil-red cast iron Unit boiler, type CHU-CB

incl. DHW cylinder

and pressure jet oil burner

73060918_1203

FunctionLine cast iron boilers

Oil and gas-red cast iron boilers, type FHK

(boiler plinth, accessory)

Oil and gas-red cast iron boilers, type

FNK-FB/FE incl. DHW cylinder

Oil-red cast iron Unit boiler, type FHU

incl. pressure jet oil burner

(boiler plinth, accessory)

Oil-red cast iron Unit boiler, type FHU-FB/FE

incl. DHW cylinder

and pressure jet oil burner

8

3060918_1203

Installation

The ventilation air supply must

be ensured and comply with

local regulations or those relating to gas installations. We

recommend that you supply the

boiler with fresh air directly from

the outside. An insufcient fresh

air supply can lead to fuel gas

escaping, which represents

a risk to life (poisoning/suffocation).

Clearances towards walls and

combustible materials must

comply with local re regulations, and should be at least

200mm, otherwise there is a

high risk of re.

General tips regarding location

• Install the boiler with or without the

DHW cylinder on a level surface which

is substantial enough to carry its weight.

• Position the boiler and DHW cylinder (if

installed) horizontally or slightly rising

towards the back to ensure adequate

venting of any trapped air (level with

adjustable feet).

Only install the boiler and DHW

cylinder (if installed) in a room

safe from the risk of frost.

Drain the boiler, the DHW

cylinder and the entire heating

system if there is a risk of frost,

when the system has been

shutdown, to prevent pipes

from bursting.

Boilers should not be installed

in areas subject to aggressive

vapours, very dusty or highly

humid conditions (workshops,

washrooms, hobby rooms etc.).

This prevents the optimum

burner function from being

achieved.

The combustion air supplied to

the pressure jet oil burner must

be free from halogenated hydrocarbons (e.g. as contained

in sprays, solvents, cleaning

uids, paints and adhesives).

Under the most unfavourable

conditions, these may lead to

pitting of the boiler and even

the ue gas system.

Never store or use combustible

material or liquids near the

boiler.

Note

Note

93060918_1203

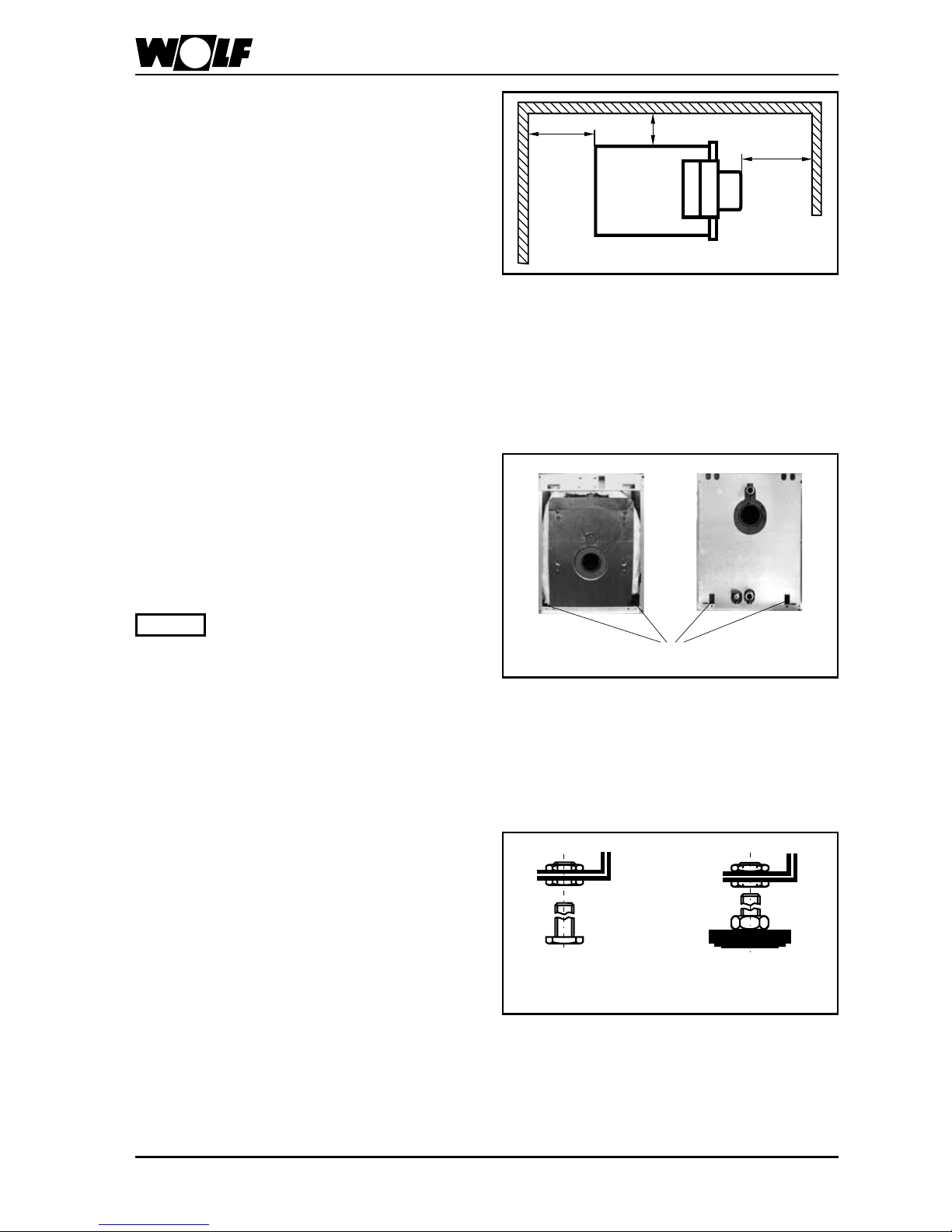

Installation

Recommended minimum wall

clearance

Maintain a minimum clearance between

the boiler sides and walls of 400 mm to

enable the boiler door with tted burner

to be opened.

Ensure that sufcient space is available

for cleaning and maintenance.

1000

900

400

Recommended minimum wall clearance

Transportation into the boiler

room

To ease the transportation into the boiler

room, lifting slings with lifting hooks are

offered as accessories.

Only lift the boiler using all four

lifting slings.

Note

Lifting eyes for lifting slings

Boiler installation on adjustable feet

At the factory the boiler is equipped with

four adjustable bolts

• Level the boiler with adjustable feet

(accessory) horizontally or with a slight

incline to the rear.

Feet

(accessory)

Adjustable

bolt

Adjustable bolt/ feet

10

3060918_1203

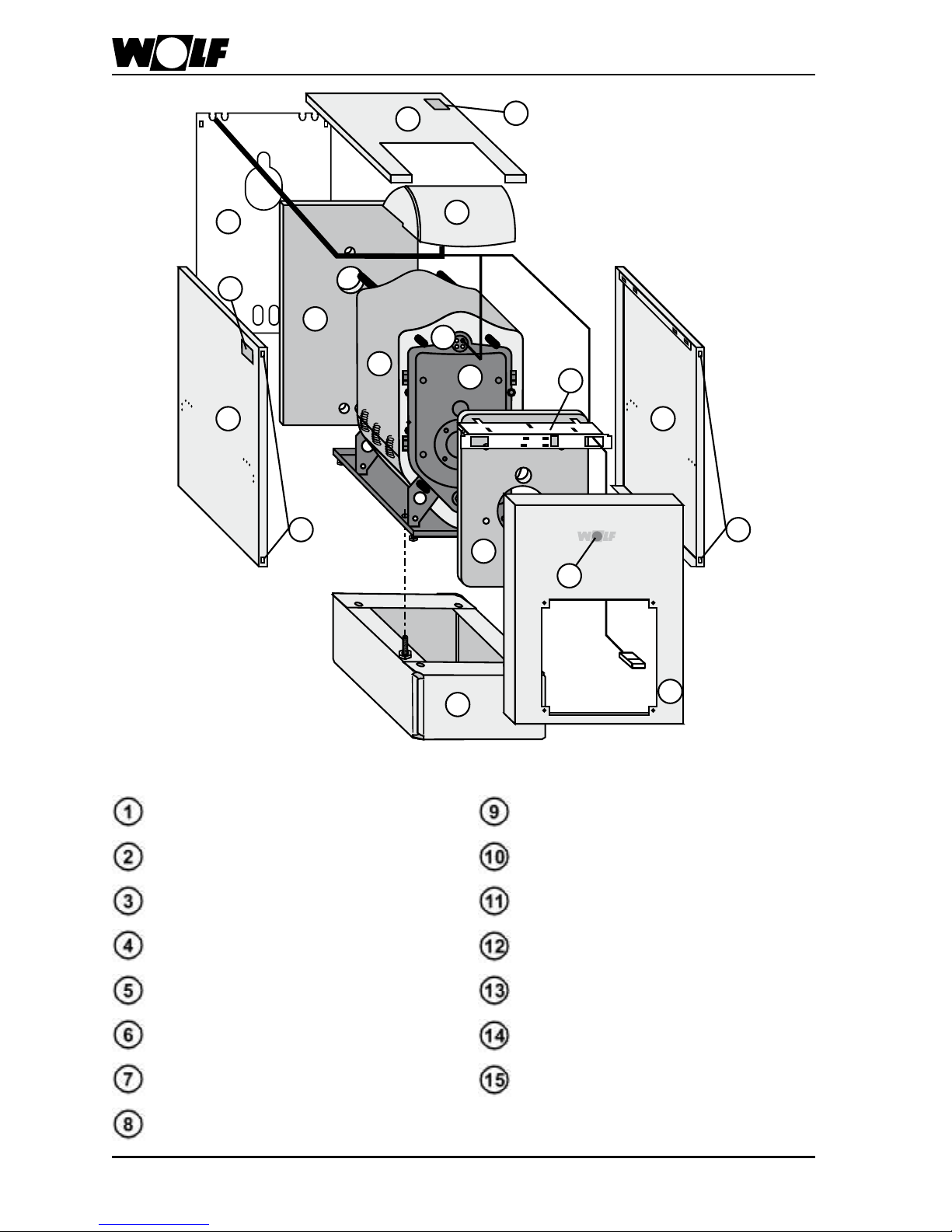

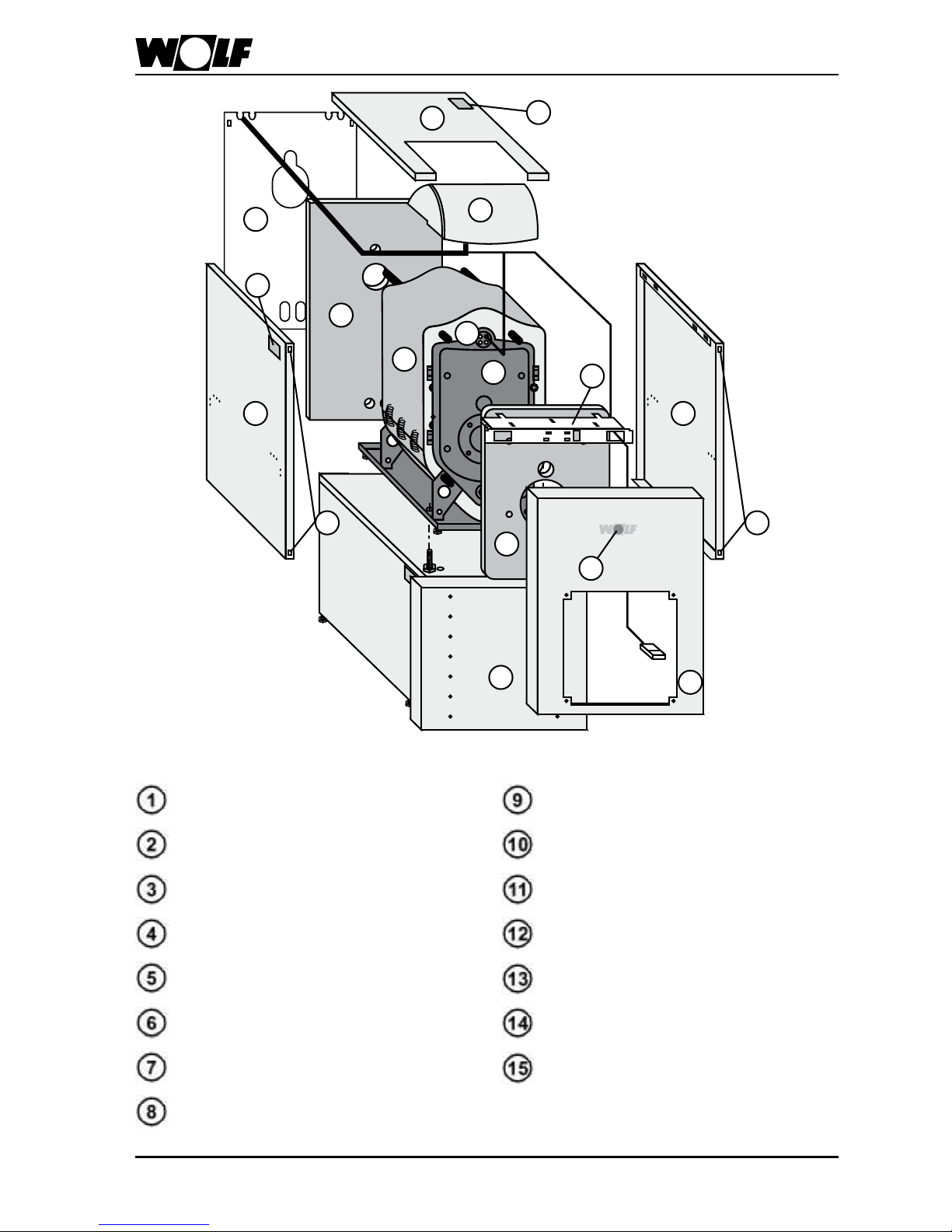

15

11 11

4

8

10

6 6

3

5

7

2

1

13

13

14

12

9

Boiler installation on a plinth

Boiler

Boiler door

Thermal insulation, boiler

Thermal insulation, boiler back

Thermal insulation, boiler front

Side casing

Control unit bracket

Back wall casing

Control unit housing

Casing cover

Spring shackles

Front casing

Type plate

Wolf logo

Plinth (accessory)

113060918_1203

15

11 11

4

8

10

6 6

3

5

7

2

1

13

13

14

12

9

Boiler installation on a horizontal

DHW cylinder

Boiler

Boiler door

Thermal insulation, boiler

Thermal insulation, boiler back

Thermal insulation, boiler front

Side casing

Control unit bracket

Back wall casing

Control unit housing

Casing cover

Spring shackles

Front casing

Type plate

Wolf logo

Horizontal DHW cylinder

Loading...

Loading...