Wolf CGU-2-18, CGU-2-24, CGG-2-18, CGG-2-24, CGU-2 K-18 Installation And Maintenance Instructions Manual

...

Part no. 30 62 347 Subject to modications

03/09 GB

Wolf GmbH · Postfach 1380 · D-84048 mainburg · Tel. +49-8751/74-0 · Fax +49-8751/741600 · Internet: www.wolf-heiztechnik.de

Installation and

maintenance instructions

Wall mounted gas red combi boilers

and wall mounted gas red boilers

with integral cylinder connection

CGU-2-18/24

CGG-2-18/24

CGU-2 K-18/24

CGG-2 K-18/24

Illustration:

Wall mounted gas red boiler with auxiliary equipment BM

2

3062347_0309

General information

Safety instructions / Standards and regulations ............. 3-5

Installation and commissioning

Dimensions .......................................................................6

Layout / Equipment code ............................................... 7-9

Positioning information / Installation dimensions ........10-11

Installation on nished walls /

Installation on unnished walls ........................................12

General boiler installation ................................................13

Electrical connection ................................................. 14-17

Fill / Vent the system. .......................................................18

Guidelines for commissioning ..........................................19

Control / Function / Commissioning ........................... 20-21

Setting and adjusting the boiler

Displaying / Modifying control parameters ................ 22-30

DHW connection versions / Resetting control unit ...........31

Setting the eBUS address for cascade mode ..................32

Commissioning gas connection .......................................33

Conversion to other gas types / Nozzle change ..............34

Setting the control unit after converting the gas type .......35

Checking nozzle pressure .......................................... 36-37

Resetting gas valve / Setting nozzle pressure .................38

Adjusting the ue lengths CGG-2(K) ................................39

Flue gas test CGU-2(K) CGG-2(K) .................................40

Limiting the maximum output ...........................................41

Selecting the pump stage / Bypass ............................ 42-43

Checking the ue gas monitoring CGU-2(K) ....................44

Notes on planning ventilation /

Flue gas system CGU-2(K) ........................................ 45-49

Commissioning report ......................................................50

Maintenance and additional information

Inspection and maintenance steps ..................................51

Service report ...................................................................52

Maintenance .............................................................. 53-57

Wiring diagram CGU-2(K) ................................................58

Wiring diagram CGG-2(K) ................................................59

Specication ............................................................... 60-61

Fault / Cause / Remedy ...................................................62

Resistance table ..............................................................63

Notes ................................................................................64

Keyword index ........................................................... 65-67

EC declaration of conformity ............................................68

Contents

3

3062347_0309

"Safety instructions" are instructions

with which you must comply exactly, to

prevent risks and injuries to individuals

and material losses.

The following symbols and reference symbols

are used in this description. These important

instructions concern personal safety, as well as

operational reliability.

"Note" indicates technical instructions

that you must observe to prevent material

losses and boiler malfunctions.

Note

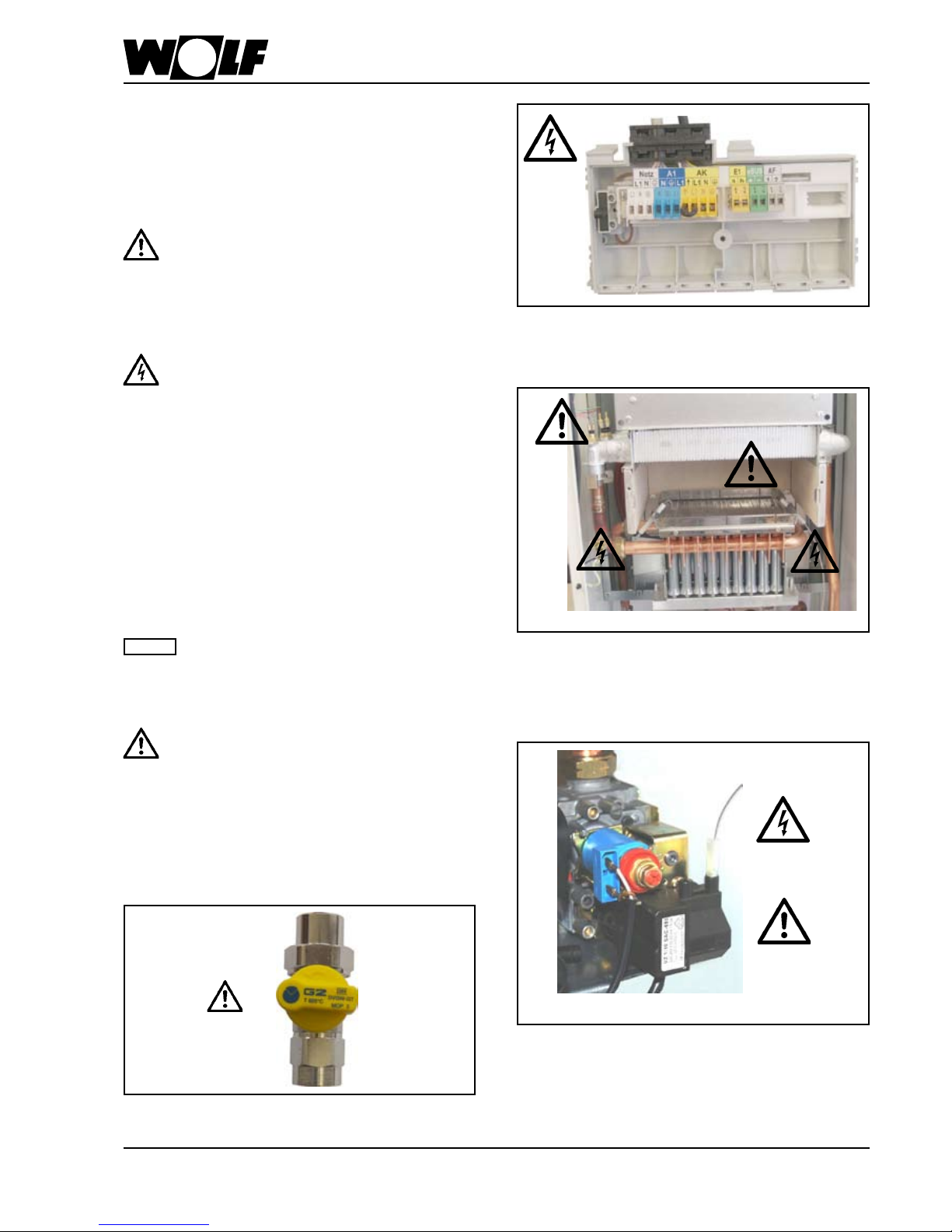

D a n g e r t h r o u g h ' l i v e ' e l e c t r i c al

components.

Please note: Switch OFF the ON / OFF

switch before removing the casing.

Never touch electrical components or

contacts when the ON / OFF switch is in

the ON position. This results in a risk of

electrocution that poses a danger of injury

or death.

The main supply terminals are 'live' even

when the ON / OFF switch is in the OFF

position.

Fig.: Terminal box: Danger from electric current

Fig.: Gas connection: Escaping gas may cause poisoning

or the risk of explosion

Fig.: Ignition transformer, high voltage ignition electrode,

combustion chamber

Risk through 'live' electrical components, risk of burning

through hot components

Fig.: Gas combination valve:

Danger from electric current

Escaping gas may cause poisoning or the risk of

explosion

Balanced flue operated gas bo i l er s

must only be installed in a room that

complies with the appropriate ventilation

requirements. Otherwise there is a risk

of asphyxiation or poisoning. Read these

installation and maintenance instructions

before installing the boiler. Also take the

technical guide into consideration.

Safety instructions / Standards and regulations

4

3062347_0309

Safety instructions / Standards and regulations

Please follow these safety instructions closely to prevent accidents and material

losses.

Commissioning - Commissioning must only be carried out by the system installer or a

commissioning engineer designated by him. All actual values must be

recorded in a commissioning/service report that should be kept with these

instructions.

Safety regulations - Observe all national safety regulations and installation requirements.

- Installation, commissioning, inspection, maintenance and repairs must

only be carried out by a competent person (heating engineer / installation

contractor).

- Before working on the equipment / heating system, switch OFF the power

supply (e.g. by removing a separate mains fuse or by means of a main

electrical isolator) and safeguard against unauthorised reconnection.

- Disconnect the system by means of an appliance that isolates all non-earthed

conductors simultaneously with at least 3 mm contact separation.

- It is not permitted to carry out repairs on parts that full a safety function.

- Use only original WOLF replacement parts or those that are equivalent and

that have been approved by the manufacturer.

Instructing the

system user

- The system installer must hand the operating instructions to the system user

and instruct them in the operation of the system.

Only use propane compliant with local regulations, otherwise

faults may arise with the starting characteristics and operation

of the wall mounted gas red boiler; this in turn, may lead to

boiler damage and risk of injury.

Poorly vented LPG tanks can lead to ignition problems. In such

cases, contact your local LPG supplier.

Note: Please read these instructions carefully before the installation

and keep them in a safe place. Please also note the technical

information in the appendix.

Any damage or loss resulting from technical modications to

the control unit or to the control components are excluded from

our liability.

Incorrect use can lead to a risk to life and limb or to a risk of

material losses.

Obtain the permission of your gas supply utility, the ue gas inspector

and the lower water authority [where appropriate] prior to the installation

of Wolf gas red boilers.

5

3062347_0309

Safety instructions / Standards and regulations

Standards and regulations

Category: II2ELL3P<DE> and

II2H3P<AT>

NOx class: 5

Efciency: *** star rating according

to 92/42/CEE) for

balanced ue operation

Flue types: CGG-2:

C12x, C32x, C42x, C52, B32

CGU-2:

B11BS

Operating mode: open / balanced ue

To be connected to: chimney, ue chimney /

balanced ue system

- Obtain the permission of your mains gas supplier

and all relevant authorities prior to the installation of

Wolf gas red combi boilers.

- Open ue gas red boilers must only be installed

in a room that complies with the appropriate

ventilation requirements.

The gas red boiler meets with the following regulations

EC Directives

- 2006/95/EC Low Voltage Directive

- 2004/108/EC EMC Directive

- 90/396/EEC Gas user equipment

- 92/42/EEC Efciency directive

DIN / EN Standards

- EN 297; EN298; EN 483; EN 625;

EN 55014-2; EN 60335-1; EN 60335-2-102;

EN 60529; EN 61000-3-2; EN 61000-4-3

The following regulations, rules and guidelines must

be observed during installation:

- Boiler room guidelines or Building Regulations

relating to the construction and installation of

central boiler rooms and fuel storage facilities

- Technical regulations for gas and DHW installations

DVGW-TRGI 1996 and TRF 1996

(in the currently applicable form)

DIN / EN Standards

- EN 437 Test gases; test pressures;

appliance categories

- DIN EN 1283 Procedure for calculating the

standard heating load

- DIN EN 12828 Heating systems in buildings

- DIN EN 1717 Protection of DHW against

contaminations in DHW

installations

- DIN EN 50156-1 (VDE 0116 part 1)

Electrical equipment for

combustion systems

- On site regulatio ns from building and indust ry

regulatory agencies (mainly covered by the emission

test switch)

- On site regulations from the gas supply utility

6

3062347_0309

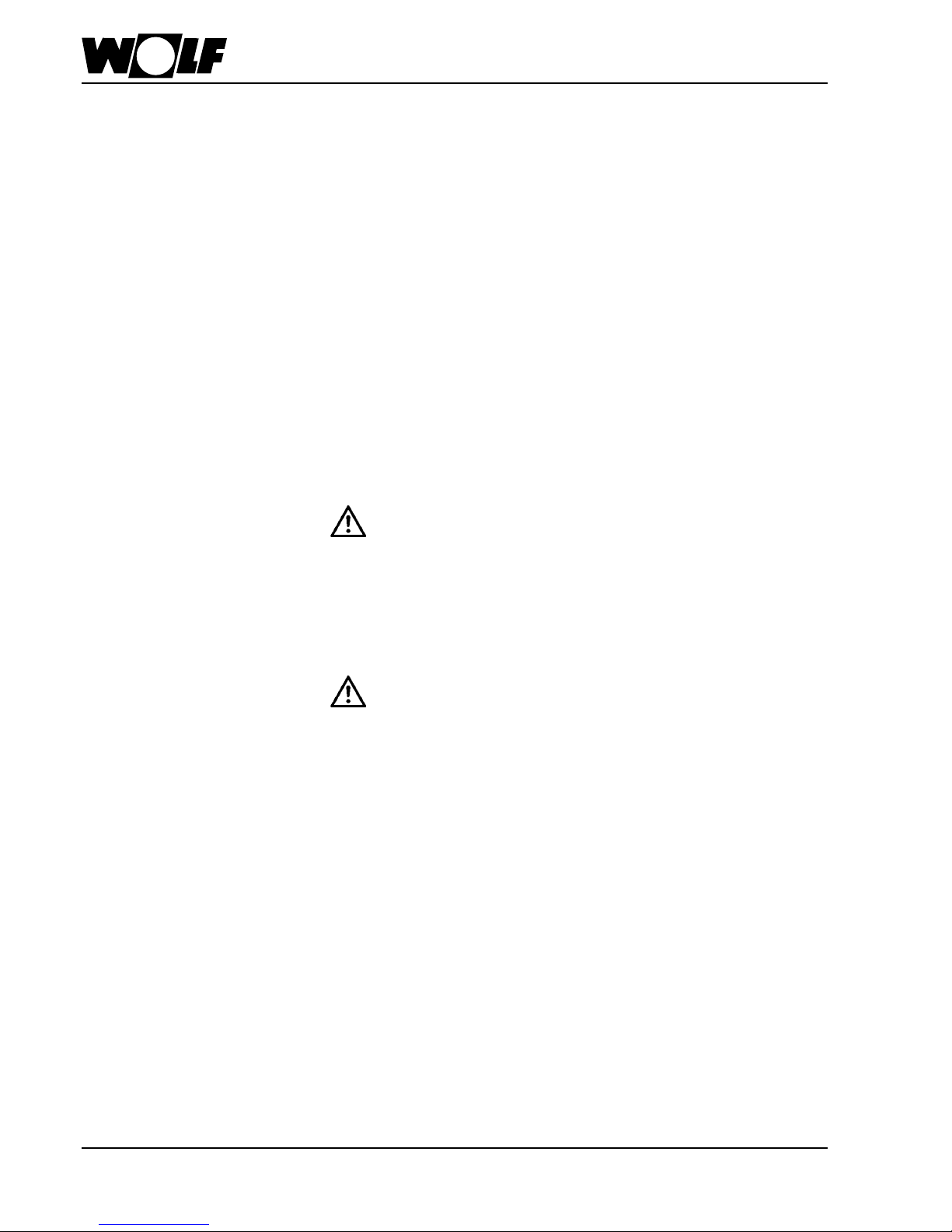

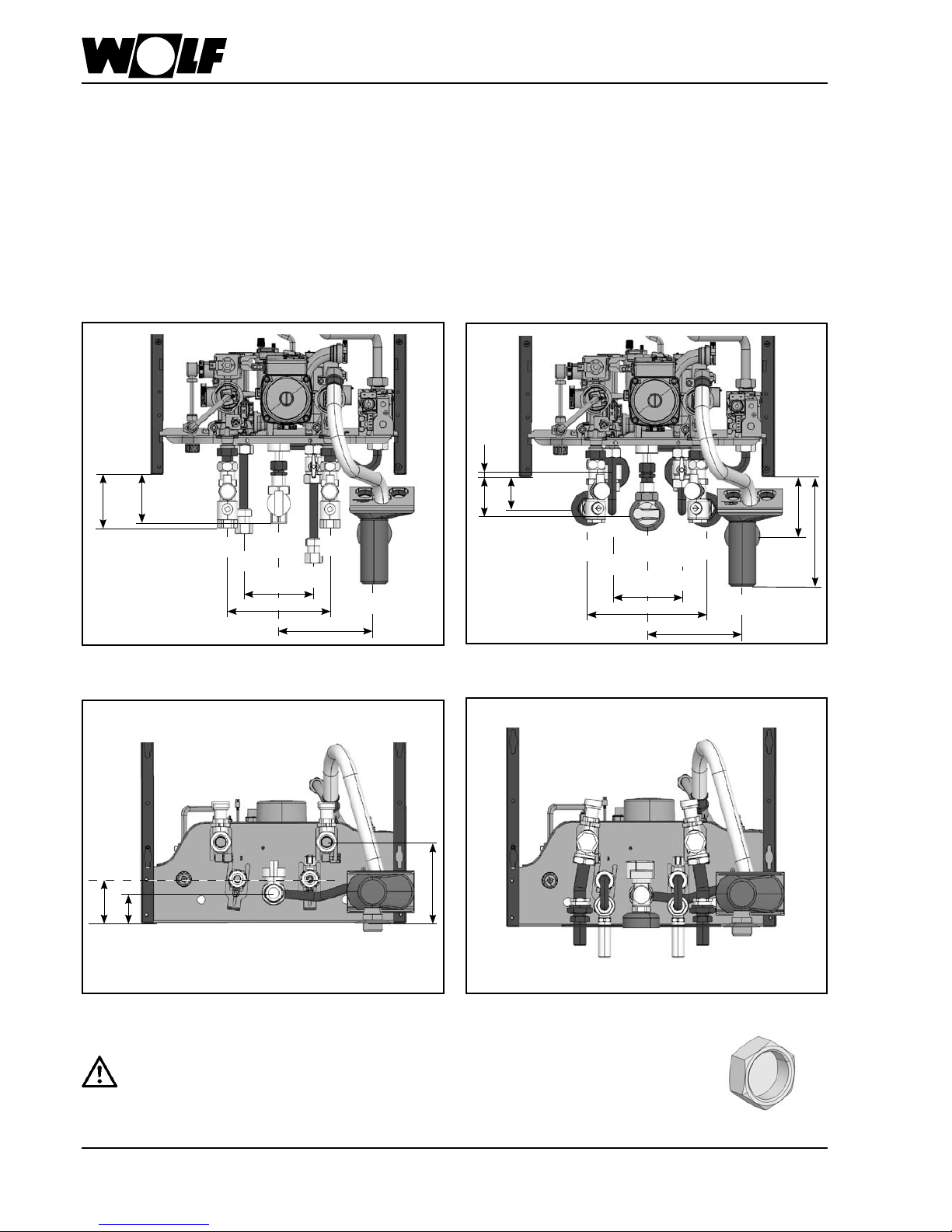

440

Dimensions

Gas red combi

boilers

Gas red boilers

1 Heating ow Heating ow

2 DHW DHW ow

3 Cold water DHW return

4 Heating return Heating return

5 Gas connection Gas connection

Installation inside a cupboard

For installation of the gas red boiler inside a cupboard

note the following:

Never install the gas red boiler on the back wall

of the cupboard, as it may not be substantial

enough to take the boiler's weight. This would

create the risk of water and gas leaks which in

turn would result in a risk of explosion

and ooding.

- Removing the rear wall of the cupboard

Minimum lateral clearance between the gas red boiler

and the cupboard sides 25 mm.

A cutout of 410 x 550 mm is required in the

cupboard top. Otherwise there is a risk of

suffocation and poisoning

With open ue gas red boilers the

ventilation grill in the cupboard door must

be installed with a free minimum diameter

of 600 cm

2

Otherwise there is a risk of suffocation

and poisoning

3

1

2

4

5

3

1

2

4

5

Min.400

Min.400

>25

694

366 CGU-2(K) 18

380 CGU-2(K) 24

258 CGG-2(K) 18/24

344

120

176

170

39

49

855

393

190

226

(CGG-2)

(CGU-2)

73

134

7

3062347_0309

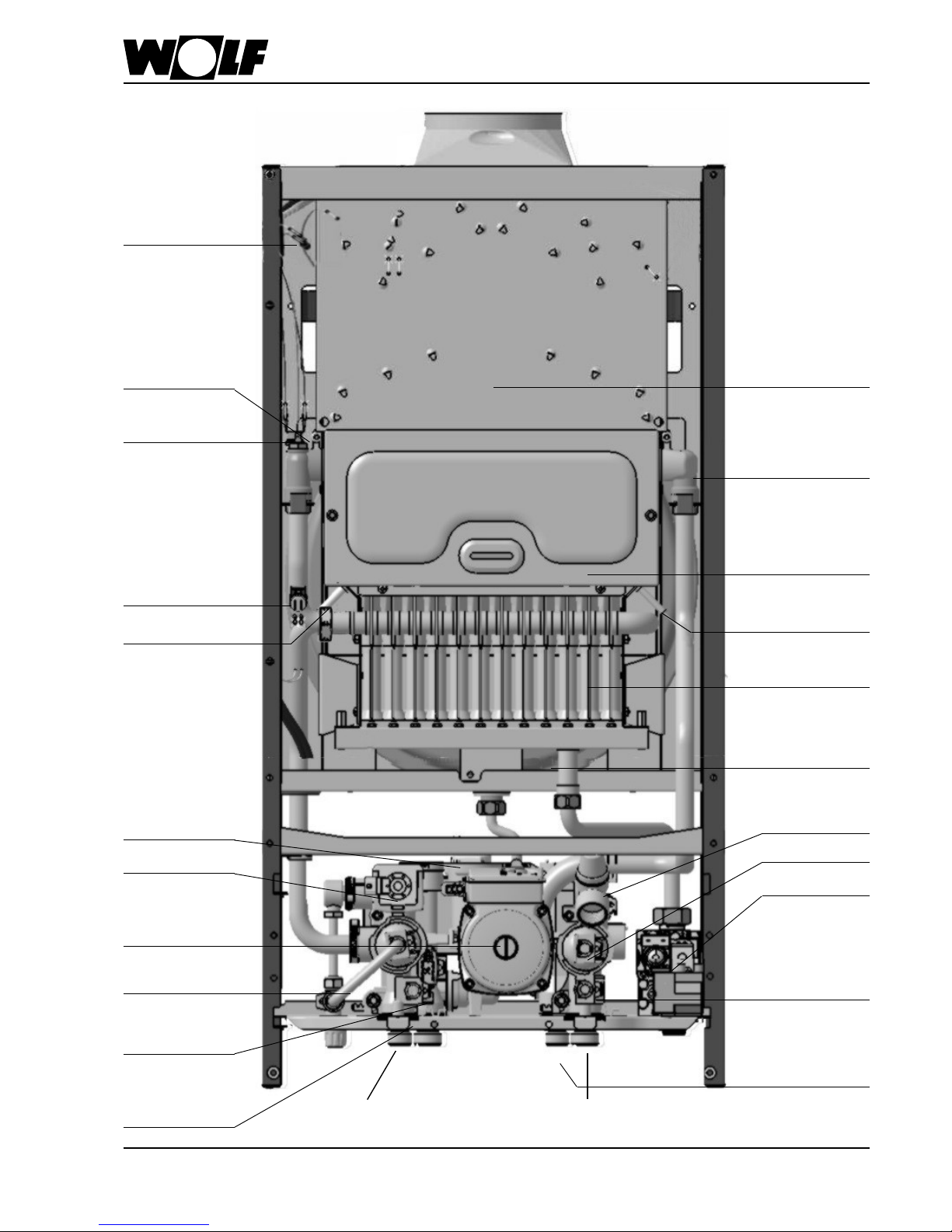

Layout CGU-2(K) 18/24

Combustion

chamber

Internal lling

equipment (optional)

not <DE><AT>

Gas combination

valve

Expansion vessel

Three-way

diverter valve

Flow sensor 2

Limit thermostat

Monitoring

electrode

Ignition electrode

Heating water heat

exchanger

Safety valve

Drain valve

DHW

Flow & temperature

sensor

Flow sensor 1

Draught hood

Gas burner

Heating circuit

strainer

Cold water strainer

with throughput

limiter

Heating circuit

pump

Air vent

Bypass

Flue gas

temperature limiter

HZ - VL

HZ - RL

8

3062347_0309

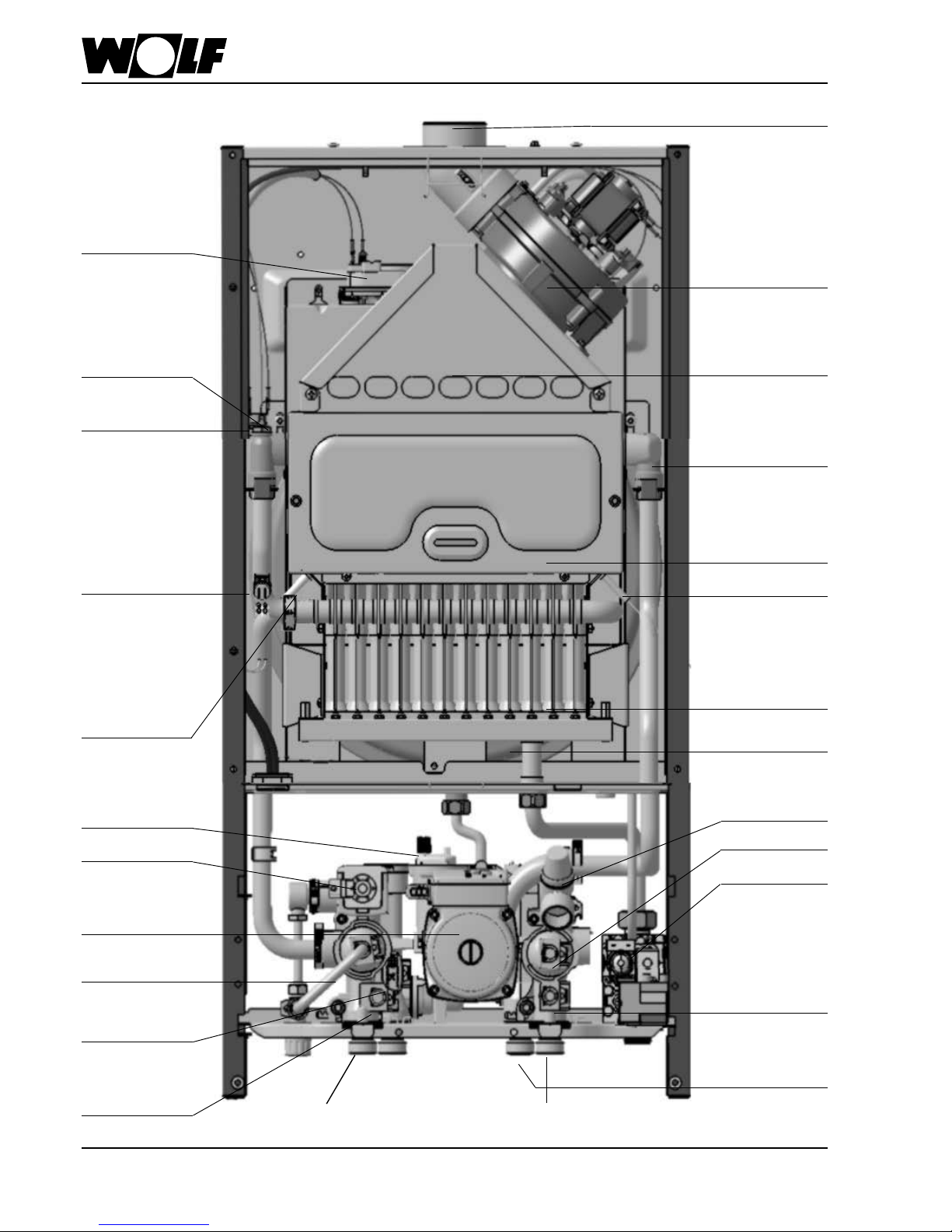

Layout CGG-2(K) 18/24

Flue gas fan

with speed

regulation

Combustion

chamber

Internal lling

equipment (optional)

not <DE><AT>

Gas combination

valve

Expansion vessel

Three-way

diverter valve

Flow sensor 2

Limit thermostat

LAF connection

Monitoring

electrode

Ignition

electrode

Heating water heat

exchanger

Differential

pressure switch

Safety valve

Drain valve

DHW

Flow & temperature

sensor

Flow sensor 1

Flue gas

collector

box

Gas burner

Heating circuit

strainer

Cold water strainer

with throughput

limiter

Heating circuit

pump

Air vent

Bypass

HZ - VL

HZ - RL

9

3062347_0309

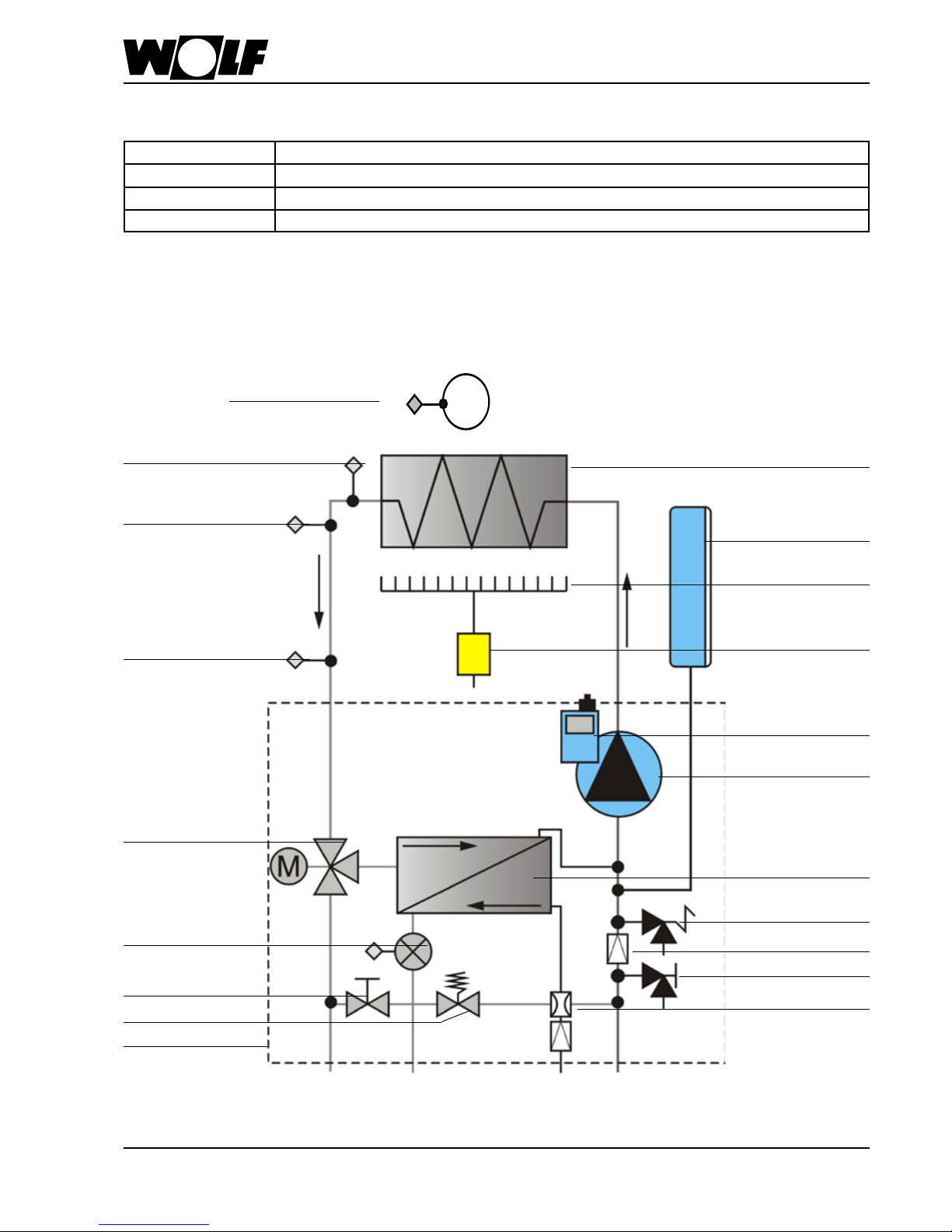

Layout / Equipment code

Heating water heat

exchanger

Gas burner

Gas

combination

valve

Expansion vessel

Air vent

Heating circuit

pump

DHW heat

exchanger

Safety valve

Drain valve

Heating circuit strainer

Cold water strainer with

throughput limiter

Limit thermostat

ow

Flow sensor 2

Flow sensor 1

Three-way

diverter valve

DHW ow

& temperature sensor

(only combi boilers)

Bypass valve

Hydro Tec system

(integrated

components)

Overow valve

Flue gas

temperature limiter

Wolf Low NOx unit with hydro tec system (plug-in technology for quick installation)

compactly designed for low emissions, high energy efciency.

DHW heat exchanger and DHW ow temperature sensor

only with combi boilers

CGU-2 - 18/24 Open ue gas red boiler with integrated cylinder connection

CGU-2 K - 18/24 Open ue gas red combi boiler

CGG-2 - 18/24 Balanced ue gas red boiler with integrated cylinder connection

CGG-2 K - 18/24 Balanced ue gas red combi boiler

Equipment codes

10

3062347_0309

Balanced ue gas red boilers must only

be installed in a room that complies with

the appropriate ventilation requirements.

Otherwise there is a risk of asphyxiation

or poisoning. Read these installation and

operating instructions before installing

the gas red boiler. Also take the technical

guide into consideration.

Sound insulation:

Under certain critical installation conditions

(e.g. installation on a drywall) additional

measures may be necessary to soundproof

the boiler. In this case use soundproof

plugs and, if necessary, rubber buffers or

insulation strips.

Positioning information /

Installation dimensions

l.h. turnbuckle

r.h. turnbuckle

Fig.: Opening the turnbuckle

- Determine the installation location for the gas red

boiler; maintain the specied minimum clearances

(see dimensions).

- Fit the supplied installation template (paper poster) to

the wall.

- Transfer the xing hole and connection positions

marked on the installation template to the wall (e.g.

with a power drill).

- Remove the installation template.

- Drill Ø 12 mm holes for the mounting bracket and

secure the bracket using the rawl plugs and screws

supplied. (Before securing the bracket, check that the

rawl plugs are suitable for the wall construction.)

- Remove the casing lid of the gas red boiler. For this,

pivot the control unit lid down, hook in the r.h. and

l.h. turnbuckle, undo the bottom of the casing lid and

unhook at the top.

- Hang the gas red boiler with the hook-in brace on the

back of the boiler onto the mounting bracket.

General

The gas red boiler may only be installed in rooms that

are protected from frost.

During the boiler installation ensure that all

xings are sufciently strong to carry its weight.

Also consider the wall consistency, otherwise

gas or water may escape which could lead to

explosions and ooding. It can also lead to

noise developing.

During the boiler installation, ensure that

no contaminants (e.g. drilling swarf) enter

the gas red boiler otherwise faults may

develop.

The combustion air supplied to the boiler must

be free from chemicals, e.g. uoride, chlorine

or sulphur. Such materials are contained in

sprays, solvents and cleaning agents. Under

the most unfavourable conditions, these

may lead to corrosion, even in the ue gas

system.

Note

500

25 25

(CGU-2-18) Ø110

(CGU-2-24) Ø130

(CGU-2) min.400

(CGG-2)

min.200

(CGG-2-18)

Ø100

1212

344

min.200

1478

11

3062347_0309

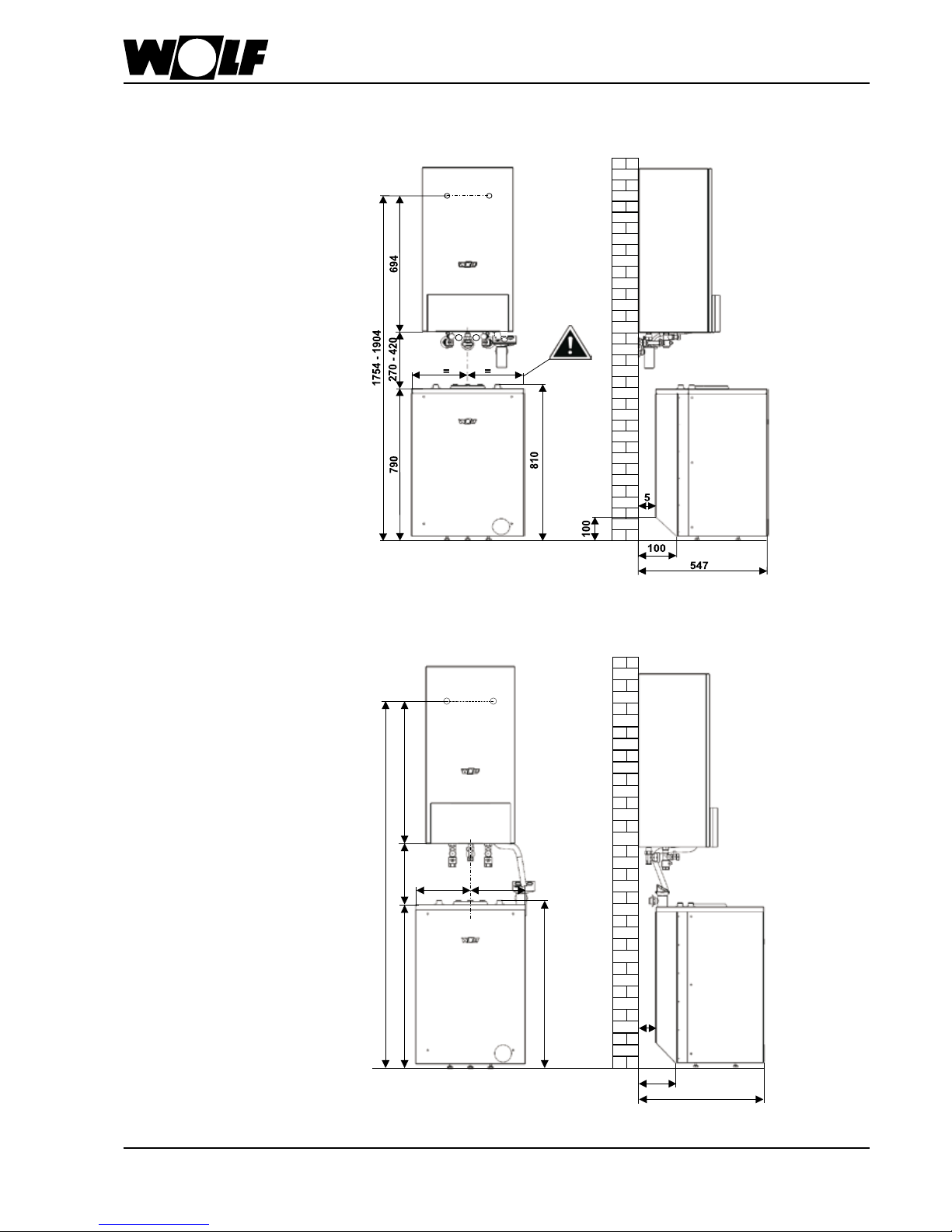

Positioning information /

Installation dimensions

270-420

790

694

1754-1904

810

5

=

=

100

547

Installation dimensions of the boiler with freestanding cylinder SW-120 / CSW-120

Installation on unnished walls

Installation dimensions of the boiler with freestanding cylinder SW-120 / CSW-120

Installation on nished walls

12

3062347_0309

Installation on nished / unnished walls

Fig.: View from below, connection set for installation on

nished walls

Installation on unnished walls (accessory)

Fig.: Front view, connection set for installation on unnished walls

Fig.: View from below, connection set for installation on

unnished walls

Installation on nished walls (accessory)

Fig.: Front view, connection set for installation on nished walls

Heating ow Rp ¾"

DHW Rp ¾" (gas combi boilers)

Cold water Rp ¾" (gas combi boilers)

Heating return Rp ¾"

Gas connection Rp ½"

Drain for safety valve R 1"

With boilers that are not used for DHW, seal the cold and DHW connections with locking

cap G ¾" (accessory).

If this is not done then the building and equipment may be damaged through uncontrolled

water leakages.

Heating ow R ¾"

DHW R ¾" (gas combi boilers)

Cold water R ¾" (gas combi boilers)

Heating return R ¾"

Gas connection R ¾"

Drain for safety valve R 1"

164

94

84

120

176

164

64

55

120

200

7

190

107

73

55

134

13

3062347_0309

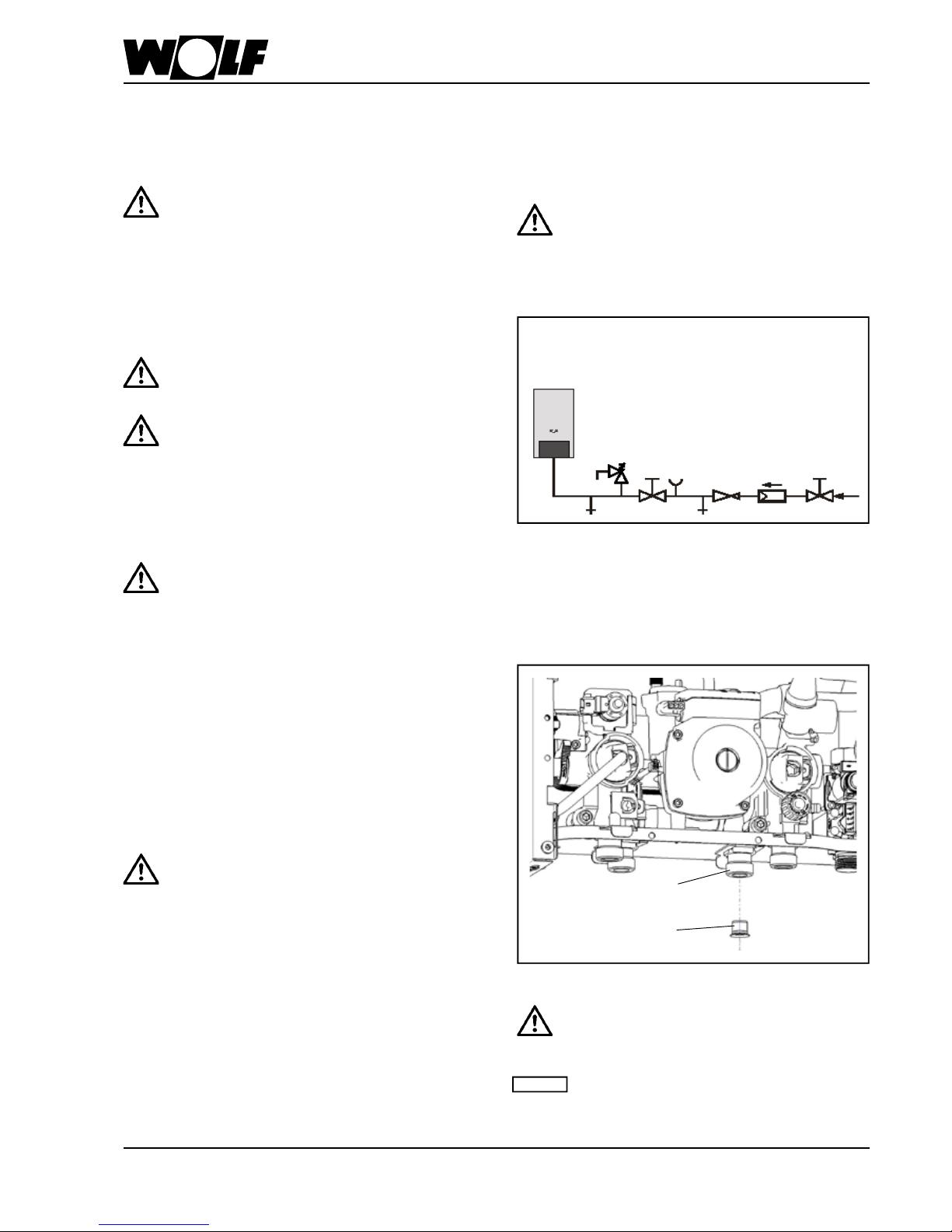

General boiler installation

Gas connection

Laying the gas pipe, as well as making the

gas connections, must only be carried out by

a licensed gas tter. Close the gas ball valve

on the gas red combi boiler to pressure test

the gas pipe.

Remove all residues from the heating pipework

and the gas pipe prior to connecting the gas

red boiler, particularly in older systems.

Prior to commissioning, test all pipe and gas

connections for leaks.

Inappropriate installation or using unsuitable

components or assemblies may lead to gas

escaping, which results in a risk of poisoning

and explosion.

The gas valve can be subj ecte d to a

maximum pressure of 150 mbar. Higher

pressure may dam age the gas valve,

resulting in a risk of explosion, asphyxiation

or poisoning. Close the gas ball valve on

the gas red boiler to pressure test the

gas pipe.

Install a tested and certified pressure

reducer, if the cold water supply pressure is

above the maximum permissible operating

pressure of 10 bar. Otherwise water could

escape resulting in a risk of ooding.

Fig.: Cold water connection

Cold water and DHW connection

For the cold water and DHW connection, we recommend

installation in accordance with the diagram below.

- Wolf connection sets (accessories) are available for

installation on nished and un nished walls. The

connection pipes are Cu 18x1.

Hydraulic connections

Note:

As standard, a combined cold water strainer

with throughput controller is tted at the cold

water connection of the boiler (see Fig.).

Fig.: Throughput controller with cold water strainer

Installation inside a cupboard

For installation of the gas red boiler inside a

cupboard note the following:

Never install the gas red boiler on the back wall

of the cupboard, as it may not be substantial

enough to take the boiler's weight. This would

create the risk of water and gas leaks which

in turn would result in a risk of explosion and

ooding.

Removing the rear wall of the cupboard

Minimum lateral clearance between the gas

red boiler and the cupboard sides 25 mm.

A cutout of 410 x 550 mm is required in the

cupboard top. Otherwise there is a risk of

suffocation and poisoning

With open ue gas red boilers the

ventilation grille in the cupboard door must

be installed with a free minimum diameter of

600 cm2.

Otherwise there is a risk of suffocation and

poisoning.

As the cold water strainer may need

to be cleaned, provide a facility for its

removal in site.

Otherwise there is a risk of faults.

Drain

Drain

Shut-off valve

Pressure

reducing valve

Shut-off valve

Cold water inlet

Pressure gauge port

DHW lter

Safety valve

Note

14

3062347_0309

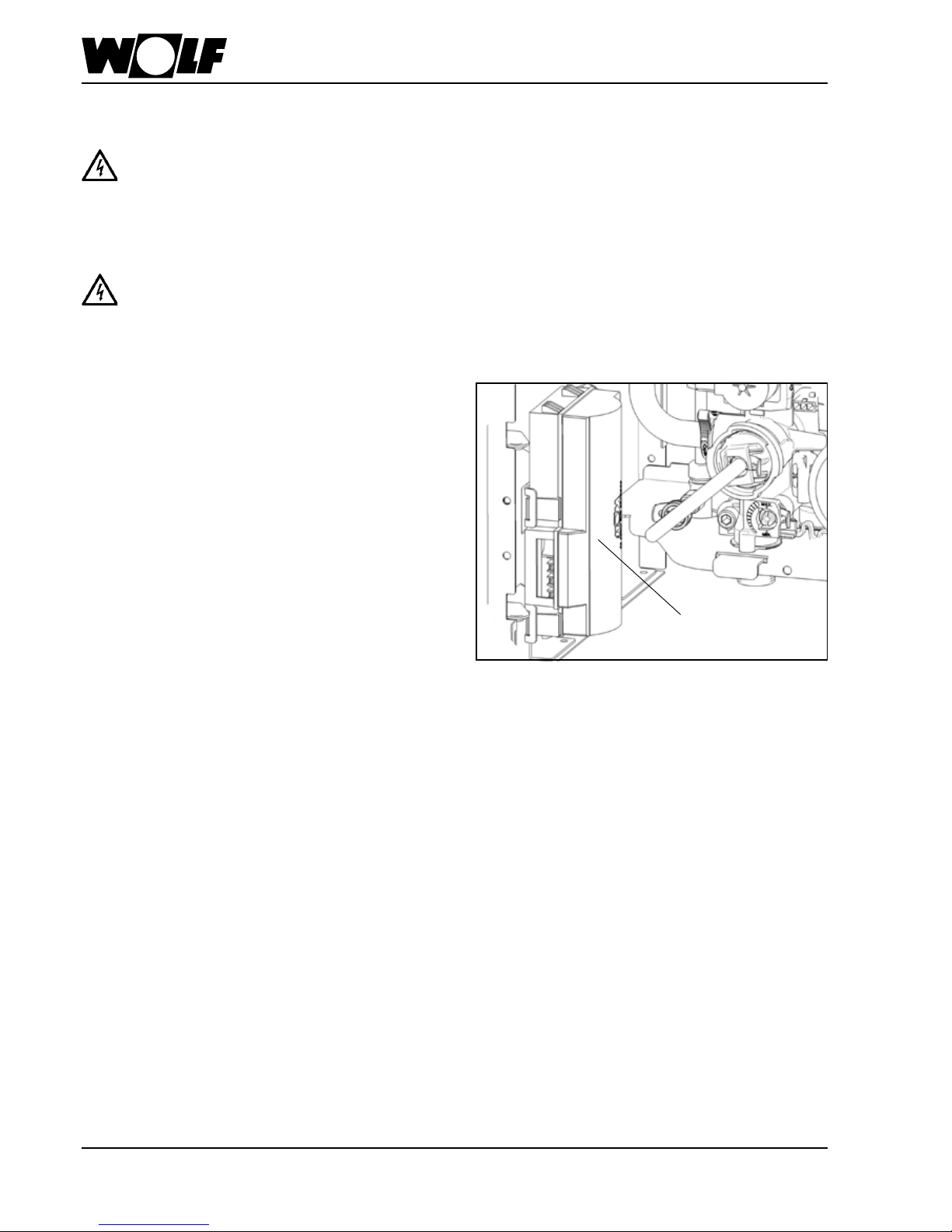

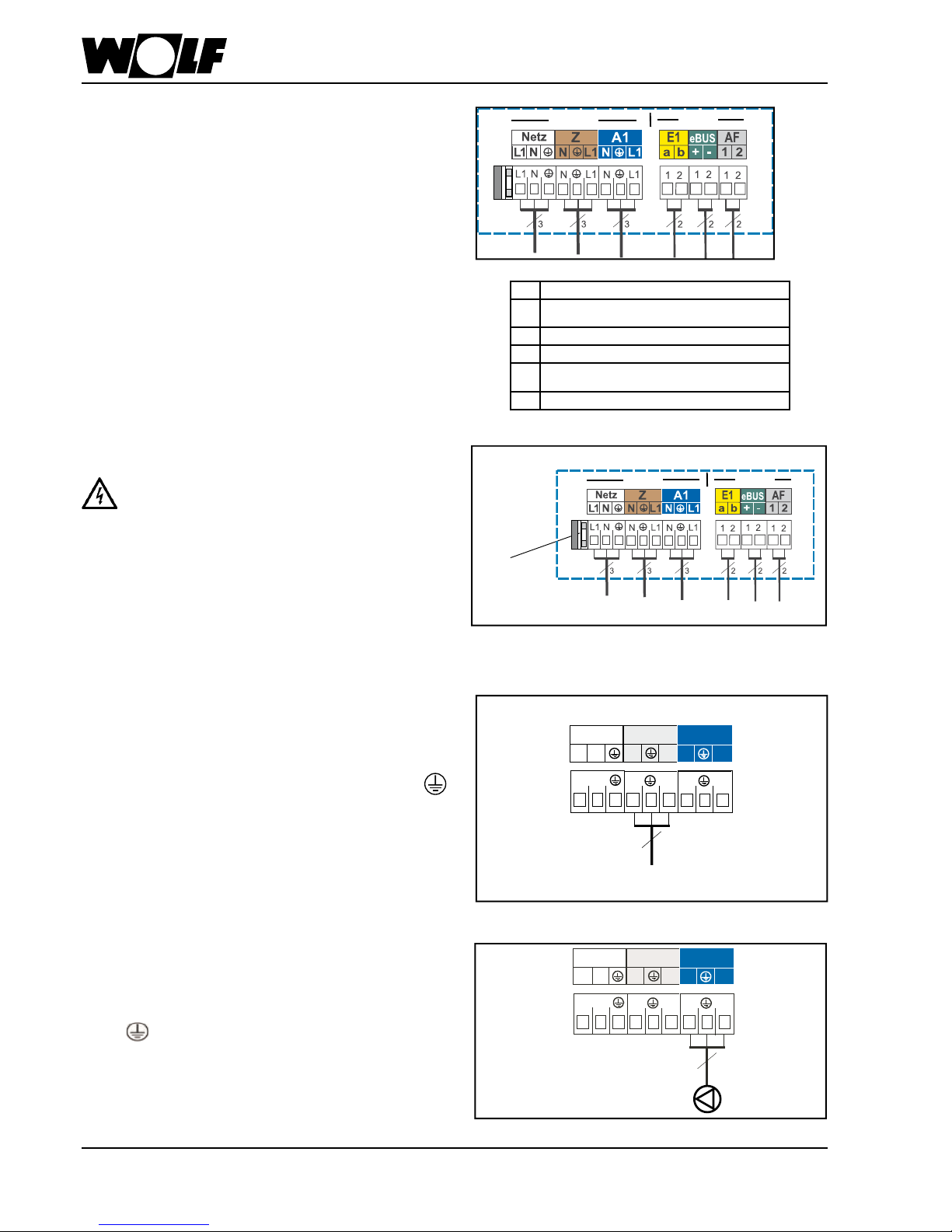

Electrical connection

CGU-2(K) / CGG-2(K)

General notes

The installation must be carried out by a

licensed electrical contractor. Observe

the regulations of the relevant authorities

and the local regulations of the power

supply company.

The power supply terminals are 'live'

even when the ON/OFF switch has been

switched OFF.

Terminal box

Terminal box

The control, regulating and safety equipment are fully

wired and tested.

You only need to connect the power supply and the

external accessories.

Power supply connection

Connect the power supply permanently or with a safety

plug (no plug connection in protective areas 1 and 2, i.e.

near a bath or shower).

Provide the power supply via a mains isolator (e.g. fuse,

heating system emergency stop), which ensures at least

3 mm contact separation for all poles.

Connection cable exible, 3 x 1.0 mm² or rigid,

max. 3 x 1.5 mm².

The plug must be accessible when using a power supply

cable with safety plug. Flexible power supply cable

3 x 1.0 mm².

15

3062347_0309

Flue gas damper connection (230 V; max.200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1, N,

and .

Fig.: Flue gas damper connection

Changing a fuse

Isolate the boiler from the main supply prior

to changing a fuse. The ON/OFF switch on

the boiler does not provide separation from

the power supply.

Danger through 'live' electrical components.

Never touch electrical components or

contacts if the boiler has not been isolated

from the power supply. Danger of death.

Fig.: Pivot the control unit forward, terminal box

cover open

Fuse

Electrical connection CGU-2(K)

Connection to Output A1 (230 VAC; max.200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1,

N and .

Fig.: Connection output A1

Installation information, electrical connection

- Isolate the system from the power supply before

opening the casing.

- Pivot the control unit to the side.

- Open the terminal box.

- Insert the strain relief into the holes provided.

- Strip approx. 70 mm off the power supply cable

insulation.

- Push the cable through the strain relief and

secure the strain relief.

- Pull the Rast-5 plug.

- Terminate the appropriate cores at the Rast-5 plug.

- Push the inserts back into the terminal box casing.

- Push the Rast-5 plugs back into the correct

positions.

A

Mains connection 230 VAC/50 Hz

C

Programmable output A1

G

Flue gas damper connection

D

Programmable input E1 zero volt

E

2-wire eBUS connection, digital Wolf control

accessories

F

Outside temperature sensor

A C G D E F

.

230 V < 24 V

230 V < 24 V

16

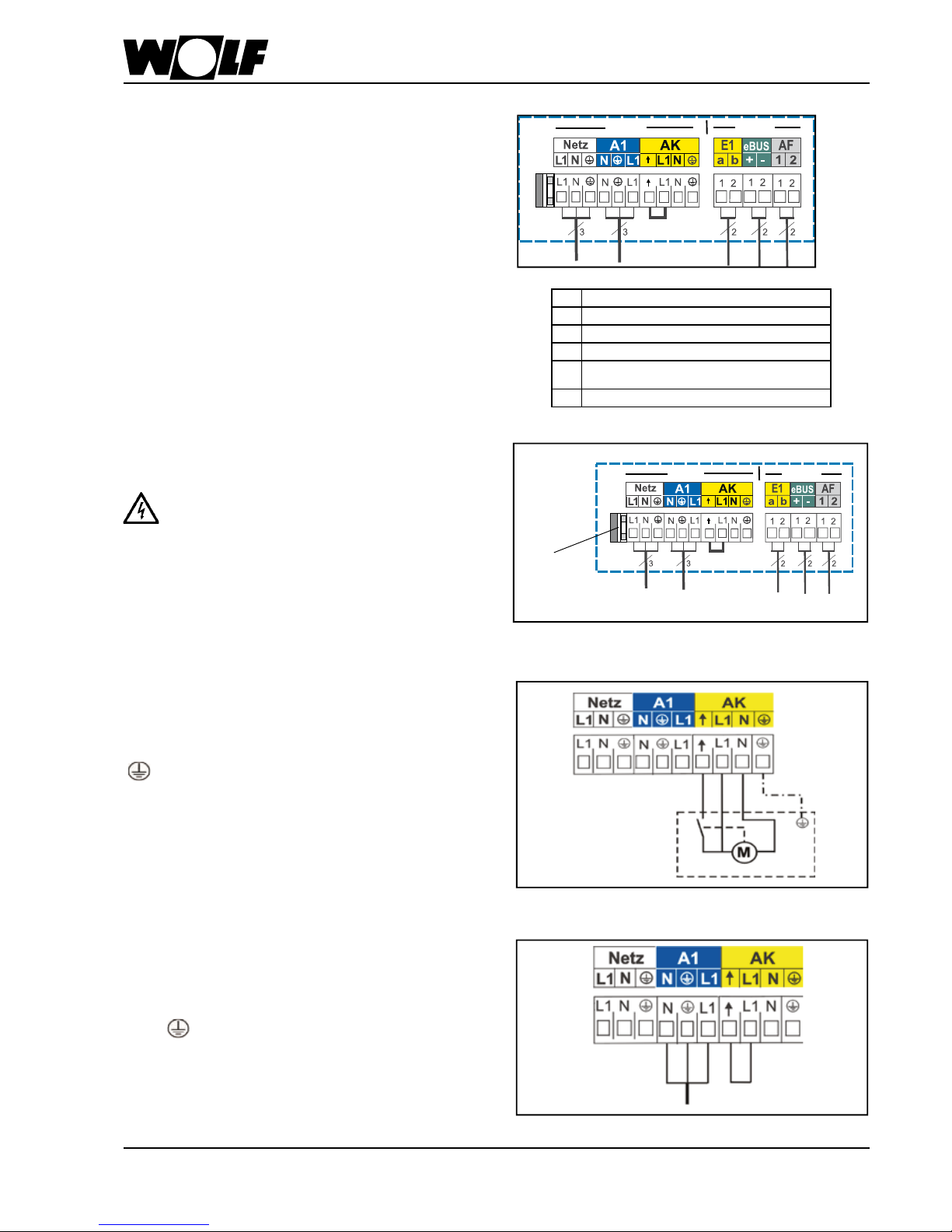

3062347_0309

Electrical connection CGU-2(K)

Fig.: Connection DHW circulation pump / external

accessories

Changing a fuse

Isolate the boiler from the main supply prior

to changing a fuse. The ON/OFF switch on

the boiler does not provide separation from

the power supply.

Danger through 'live' electrical components.

Never touch electrical components or

contacts if the boiler has not been isolated

from the power supply. Danger of death.

Fig.: Pivot the control unit forward, terminal box

cover open

Fuse

Connection to Output A1 (230 VAC; max. 200 VA)

Insert the cable glands into the terminal box. Insert

and secure the connecting cable through the cable

gland. Connect the connecting cable to terminals L1,

N and .

Fig.: Connection output A1

Installation information, electrical connection

- Isolate the system from the power supply before

opening the casing.

- Pivot the control unit to the side.

- Open the terminal box.

- Insert the strain relief into the holes provided.

- Strip approx. 70 mm off the power supply cable

insulation.

- Push the cable through the strain relief and

secure the strain relief.

- Pull the Rast-5 plug.

- Terminate the appropriate cores at the Rast-5 plug.

- Push the inserts back into the terminal box casing.

- Push the Rast-5 plugs back into the correct

positions.

Power supply for external accessories

(230 VAC; max. 200 VA)

Insert the cable glands into the terminal box. Insert and

secure the connecting cable through the cable gland.

Connect the connecting cable to terminals L1, N and .

Netz

Z

A1

N

N

N

L1

L1

L1

L1

L1

L1

N

N

N

3

Z

A1

N

N

NL1

L1

L1

L1 L1

L1

NN

N

3

Netz

A

Mains connection 230 VAC/50 Hz

B

Power supply, ext. Accessories

230 VAC/50 Hz/max. 200 VA

C

Programmable output A1

D

programmable input E1 zero volt

E

2-wire eBUS

connection, digital Wolf control accessories

F

Outside temperature sensor

A B C D E F

230 V < 24 V

230 V < 24 V

17

3062347_0309

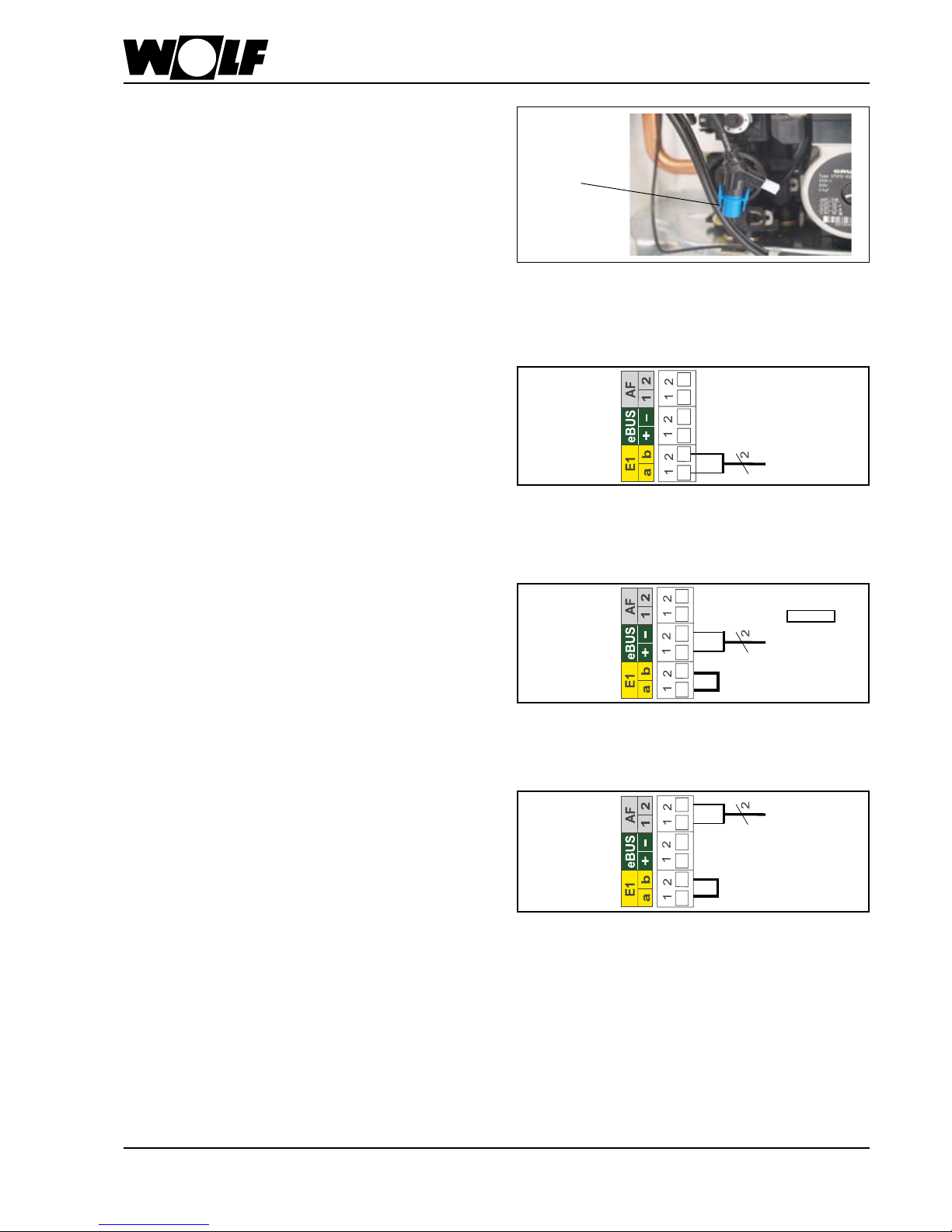

Connection, analogue outside temperature sensor

The analogue outside temperature sensor for digital

control accessory (e.g. BM) may be connected to the

terminal strip of the gas red boiler at the connection AF

or the terminal strip of the BM.

Fig.: Connection, analogue outside temperature sensor

Connection of digital Wolf control accessories

(e.g. BM, MM, SM1, SM2, KM)

Only connect control units from the Wolf accessory

range. Eac h accessory is supplied with its own

connection diagram.

Use a 2-core cable (cross-section > 0.5 mm²) as the

connecting cable between the control unit accessory

and the gas red boiler.

Fig.: Digital Wolf control accessories connection (eBUS

interface)

Electrical connection

CGU-2(K) CGG-2(K)

Fig.: Connection, programmable input

Connection, programmable input E1 (<24 V)

Connect the connecting cable for input 1 at terminals E1

in accordance with the wiring diagram; rst remove the

jumper between a and b from the respective terminals.

The functions of input E1 can only be scanned and

adjusted with Wolf control accessories with eBUS

capability.

DHW tank sensor connection

- When a cylinder is to be connected, the blue socket

of the cylinder sensor must be connected to the blue

plug of the control unit.

- Observe the cylinder installation instructions.

Fig.: Blue plug, cylinder sensor connection

Blue plug

Note

Pay attention

+ , to polarity

18

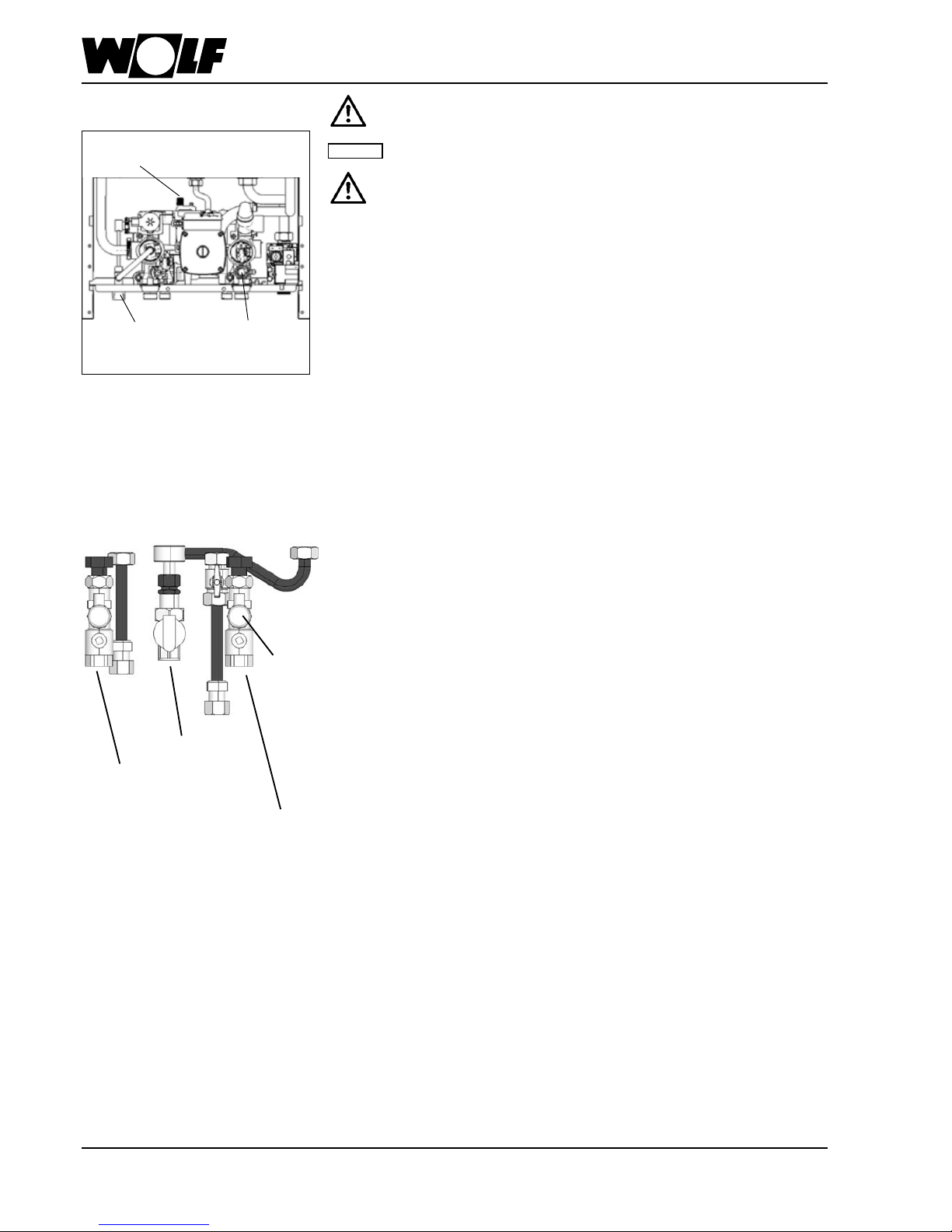

3062347_0309

Fill / vent the system

Procedure for boilers with

internal lling facility

not for <DE> <AT>

- Fill the entire heating system and boiler via the lling facility or an on-site

ll & drain valve up to approx. 0.5 - 1 bar, whilst simultaneously venting the

heating system.

- Close the shut-off valves on the heating water side of the boiler (ow and

return).

- Push the drain hose onto the drain valve of the hydraulic assembly.

- Clean the heat exchanger by opening the internal lling facility and the

drain valve simultaneously on the hydraulic assembly (make sure there is

no air remaining in the heat exchanger).

Procedure for boilers without

internal lling facility

Filling the system

Fill the system and vent it thoroughly to safeguard the perfect

function of the gas red boiler.

Otherwise there is a risk of faults.

The heating water must not be mixed with inhibitors or antifreeze;

otherwise leaks and ooding could result.

- Close the gas ball valve.

- Before connecting the gas red boiler to the heating system, ush the entire

system to remove residues such as welding pearls, hemp, putty, etc. from

the pipework and to remove air that may have collected.

- Fill the DHW system of the boiler until water ows out of a DHW draw-off point.

- To ll the heating system use the ll & drain connections. Open the cap of the

automatic air vent valve on the heating circuit pump by approx. 2 revolutions, but

do not remove the cap.

- Open all radiator valves and the shut-off valves on the heating water side of the

boiler.

- Fill the entire heating system and boiler via the ll & drain valves (Wolf

accessory) up to approx. 0.5 bar, whilst simultaneously venting the heating

system.

- Close the return shut-off valve on the heating water side of the boiler.

- Attach drain hose to the drain valve on the hydraulic assembly (alternative, if only

a ll & drain connection is provided).

- Clean the heat exchanger by opening the ll & drain valve and/or the

drain valve simultaneously on the hydraulic assembly

(make sure there is no air remaining in the heat exchanger).

- Remove the drain hose and open the boiler shut-off valve(s) on the heating water

side again.

- After venting, raise the system pressure to 2.5 bar.

- Start the boiler, set the heating water temperature selector to position "2"

(pump running, illuminated signal ring (status display) constantly green).

- Vent the pump; for this, briey open and then retighten the air vent

screw, optimum venting in pump stage 3.

Top up with water when the system pressure falls severely.

- Open the gas shut-off valve. Press the reset button.

- When in constant use the heating circuit vents automatically via the heating

circuit pump, venting optimum at pump stage 3. After venting set to pump

stage 1 or 2 for reduced noise, depending on customer preference.

- At system pressure below 1.0 bar the boiler may experience faults.

If necessary ll on heating side.

Internal lling

facility not for

<DE><AT>

Drain

valve

Fig.: Shut off valves (accessory)

Gas shut-off valve

Heating ow

(incl. ll & drain

connection)

Heating return

(incl. ll & drain

connection)

Automatic

air-vent valve

Fill & drain

Connection

Note

19

3062347_0309

- Instruct the customer about energy-saving options.Saving energy

Commissioning guidelines

Only qualied personnel must carry out the commissioning and initial

start-up of the boiler as well as instruct the user.

Guidelines for commissioning

- Flush and vent boiler (use shut-off valve with ll & drain valve from Wolf

accessory range), ll boiler and system and test for tightness. Normal

operating pressure when system is cold 1.5 bar. Prevent water leaks.

- Check location and seating of the installation.

- Check the gas supply pressure.

- Check all connections and component links for leaks.

- If tightness cannot be ensured then there is a danger of water damage.

- Check that all ue gas accessories have been correctly installed.

- Open the water and shut-off valves on ow and return.

- Open gas connection.

- Switch ON emergency heating switch and switch ON the ON/OFF switch on

the control unit.

- Check the adjustment of the ue length, resetting if required.

See chapter "Adjusting the ue length".

- Check the ignition and ame structure of the burner.

- The illuminated ring shows a yellow colour, if the boiler starts correctly.

- Instruct the customer in the operation of the boiler, with the aid of the

installation instructions.

- Complete the commissioning report and hand over the instructions to the

customer.

- Implement the "Installation" and "Electrical connection" of the boiler

and all extension and programming modules in accordance with the

instructions in the associated manuals.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 10

Step 11

Step 12

Step 13

Step 14

Step 15

Note

Otherwise there is a risk of faults.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

20

3062347_0309

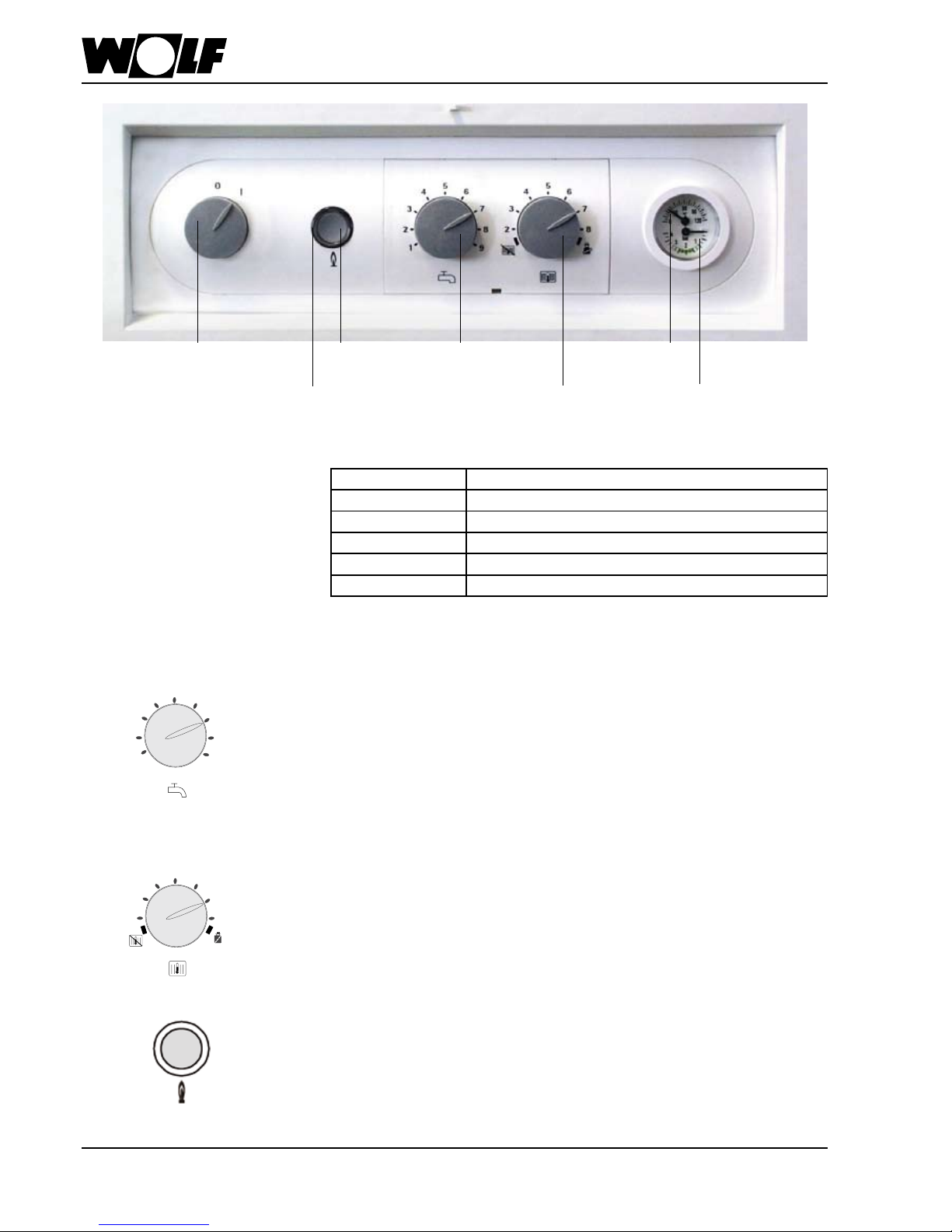

Control / Function / Commissioning

ON / OFF switch

DHW

temperature

selector

Pressure

gauge

Reset

button

Heating water

temperature

selector

Illuminated

signal ring

Thermometer

9

1

2

8

3

7

4

6

5

DHW temperature selector

Settings 1-9 correspond with a DHW temperature of 40-65 °C with gas combi

boilers, or 15-65 °C with gas boilers with a cylinder. Combined with a control

thermostat for wall mounted gas red boilers, the adjustment at the DHW

temperature selector is disabled; instead the temperature is selected at the

boiler control thermostat.

2

8

3

7

4

6

5

Heating water temperature selector

Settings 2-8 correspond to a heating water temperature of 40-80 °C. Combined

with a temperature controller for wall mounted gas red boilers, the adjustment

at the heating water thermostat is disabled; instead the temperature is selected

at the boiler temperature controller.

Signal ring as

status display

Display Explanation

Flashing green Standby (power supply ON, burner OFF)

Constant green light Heat demand: pump running, burner OFF

Flashing yellow Emissions test mode

Constant yellow light

Burner ON, ame steady

Flashing red

Fault

Reset

A fault is reset by pressing the reset button which will also restart the system.

Pressing the reset button reactivates the system, if there was no fault.

21

3062347_0309

In conjunction with the accessory controllers BM / AWT / ART, the settings at

the boiler relating to DHW and heating water are disabled.

Note:

Setting

Winter mode (position 2 to 8)

In winter mode, the boiler heats to the temperature selected at the heating water

temperature controller. According to the pump operating mode, the circulation

pump operates constantly (factory setting) or only in parallel with the burner

activation / run-on period.

Summer mode

The winter mode is deactivated by rotating the heating water temperature

selector into position . In other words, the boiler will then operate in summer

mode. Summer mode (heating OFF) means, only DHW heating. Frost protection

for the heating system and pump anti-seizing protection, however, remain

enabled.

In summer mode, the circulation pump operates for approx. 30 seconds after

a maximum idle period of 24 hours.

Anti-seizing pump protection

Thermomanometer

The current heating water temperature is displayed in the upper area.

The water pressure in the heating system is displayed in the lower area. In

normal use, the water pressure should be between 2.0-2.5 bar.

Emissions test mode

The emissions test mode is activated by rotating the heating water temperature

selector into position . The signal ring ashes yellow. After the emissions

test mode has been activated, the boiler will heat with the selected maximum

heating output. Any previous cycle block will be cancelled. The emissions test

mode terminates after 15 minutes or when the maximum ow temperature has

been exceeded. For a renewed activation, turn the heating water temperature

selector anti-clockwise and then back into position .

Control / Function / Commissioning

Loading...

Loading...