Whirlpool PROW 0612IIM, PROW 0614II, PROD 06SCII, PROD 06SVII Installation And Maintenance Manual

INSTALLATION AND

MAINTENANCE

PROW 0612IIM

PROW 0614II

PROD 06SCII

PROD 06SVII

WASHING MACHINE 2-17

TUMBLE DRYER 18-36

SERVICE AND GUARANTEE 37

CONTENTS – WASHING MACHINE

SAFETY 3

Transit screws

General

Child lock on Start/Stop button

Door

Overfill cut-out

Packaging

Transport/Winter storage

Scrapping

PARTS OF THE WASHING MACHINE 4

TECHNICAL INFORMATION 5

Technical data

PROGRAMME CYCLES 6

CHANGING SETTINGS 12-13

Language

Locking the programme

Wash temperature, C or F

Changing preset wash temperature

Child lock

MAINTENANCE 14-15

Emptying/cleaning trap and drain pump

Inspection holes under drum paddles

Cleaning the detergent drawer

Cleaning the outside of the machine

In areas with hard water

TROUBLESHOOTING 16-17

Door will not open

Machine will not start

MECHANICAL INSTALLATION 8-10

Transit screws

Positioning the washing machine

Adjusting the feet

Connecting to water supply

Water intake – mixed or cold water

Connecting to drain

ELECTRICAL INSTALLATION 11

Electrical installation

Connecting to coin mechanism

Error messages

The display is lighting when a

programme is selected, but no

characters or digits are shown

Wrong language displayed

WASHING MACHINE CONTENTS

2

SAFETY

TRANSIT SCREWS

Before the machine can be used the three trans-

it screws must be removed. See chapter ”Mecha-

nical Installation”.

GENERAL

• Read and keep this manual!

• Any electrical work or plumbing must be car-

ried out by qualified tradesmen.

• The machine is not designed to be used by

persons (even children) that are physically or

mentally handicapped or lack experience and

knowledge. Such persons must receive instruc-

tion in how to use the machine from the person

responible for their safety.

• Children must be watched to ensure they do

not play with the machine.

OVERFILL CUT-OUT

If the water level in the machine rises above

normal the overfill cut-out shuts off the water

intake and starts pumping out the water. The

programme resumes when the water level has

dropped.

PACKAGING

Recycle the packaging according to recommen-

dations in your area.

TRANSPORT/WINTER STORAGE

If you intend to transport the machine or store

it over winter in unheated premises, empty the

trap and the drain pump, see the chapter on

Maintenance.

Any questions? Call service.

CHILD LOCK ON

Start/Stop

BUTTON

To prevent accidental button pushes on the

Start/Stop

button you can activate the child lock

function. The

Start/Stop

button then must be held

in for three seconds to activate the machine.

DOOR

The door is opened electrically, so it cannot be

opened until the machine is connected to the

electrical supply! The door can however be ope-

ned in an emergency, see Troubleshooting.

SCRAPPING

At the end of its life the machine must be disa-

bled before being scrapped.

Contact your local recycling centre to find

out where to dispose of it or recycle it.

The machine has been built and marked to

facilitate recycling.

SAFETY WASHING MACHINE

3

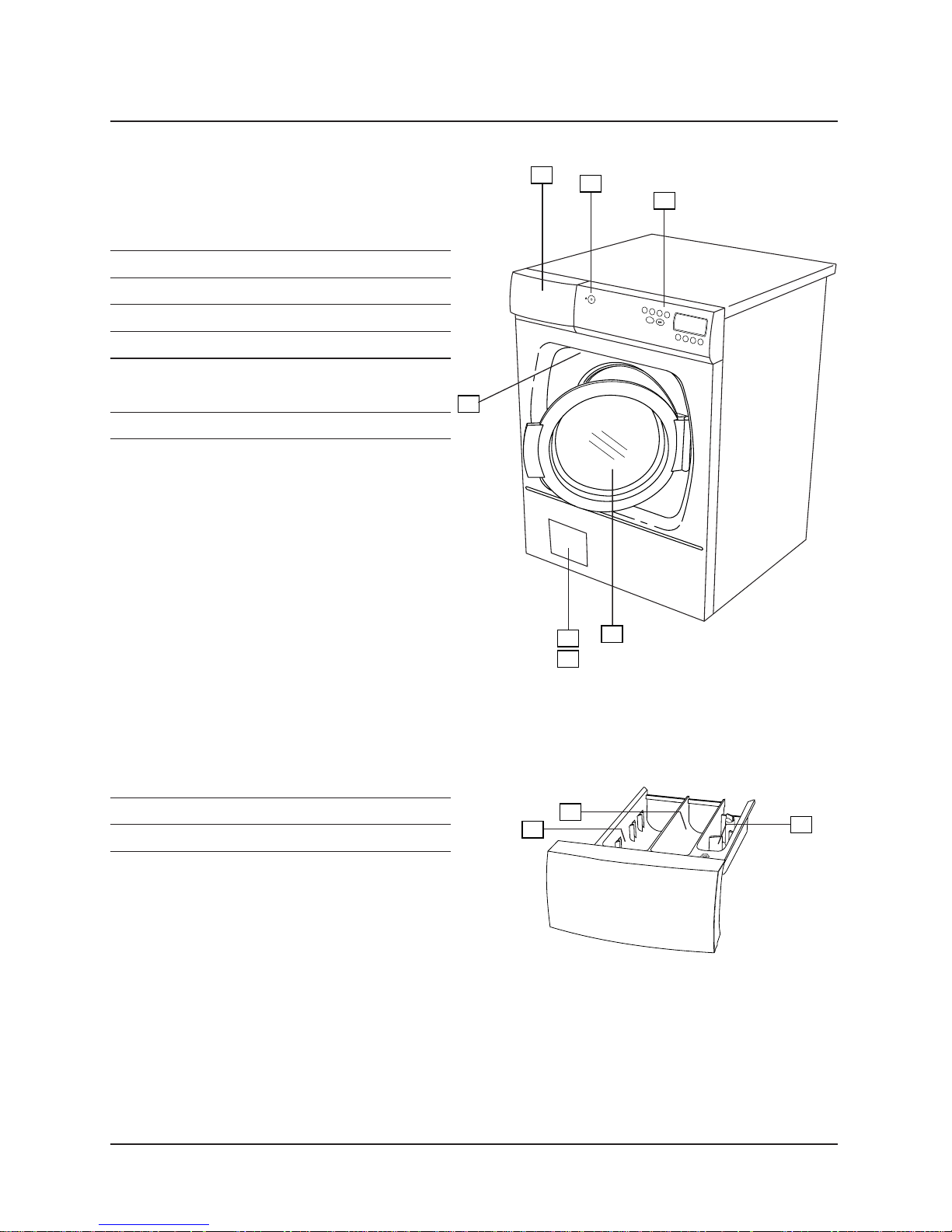

PARTS OF THE WASHING MACHINE

1. DETERGENT DRAWER

2. POWER SWITCH

3. PROGRAMME PANEL

4. RATING PLATE

5. DOOR-DRAIN PUMP/EMERGENCY OPEN

6. DRAIN PUMP/EMERGENCY OPEN (BEHIND

FLAP)

7. DOOR

1

2

3

P

1

P

2

P

3

P4

S

t

a

r

t

/

S

t

o

p

P5

P

6

P

7

P8

4

1. DETERGENT COMPARTMENT – PRE-WASH

2. DETERGENT COMPARTMENT – MAIN WASH

3. FABRIC CONDITIONER COMPARTMENT

7

5

6

1

2

3

WASHING MACHINE PARTS OF THE WASHING MACHINE

4

TECHNICAL INFORMATION

TECHNICAL DATA

Height: 850 mm.

Width: 595 mm.

Depth: 585 mm.

Weight: 73 kg.

Drum capacity: 50 l.

Max wash load: 6.0 kg.

Spin speed PROW 0612IIM: 1200 rpm.

Spin speed PROW 0614II: 1400 rpm.

Power rating: See rating plate.

Element power: See rating plate.

Water pressure: 0.1–1 MPa, 1–10 kp/cm2, 10–100 N/cm2.

Composition of drum and fluid container: Stainless steel.

Composition of casing: Powder-painted and hot-dip galvanized sheet

steel or stainless steel.

Installation: Static on four adjustable, rubber-covered feet.

Water supply: 1.5 m PEX hose.

Drain: 1.7 m polypropylene hose (pump) or 0.4 mm

EPDM rubber hose (valve).

TECHNICAL INFORMATION WASHING MACHINE

5

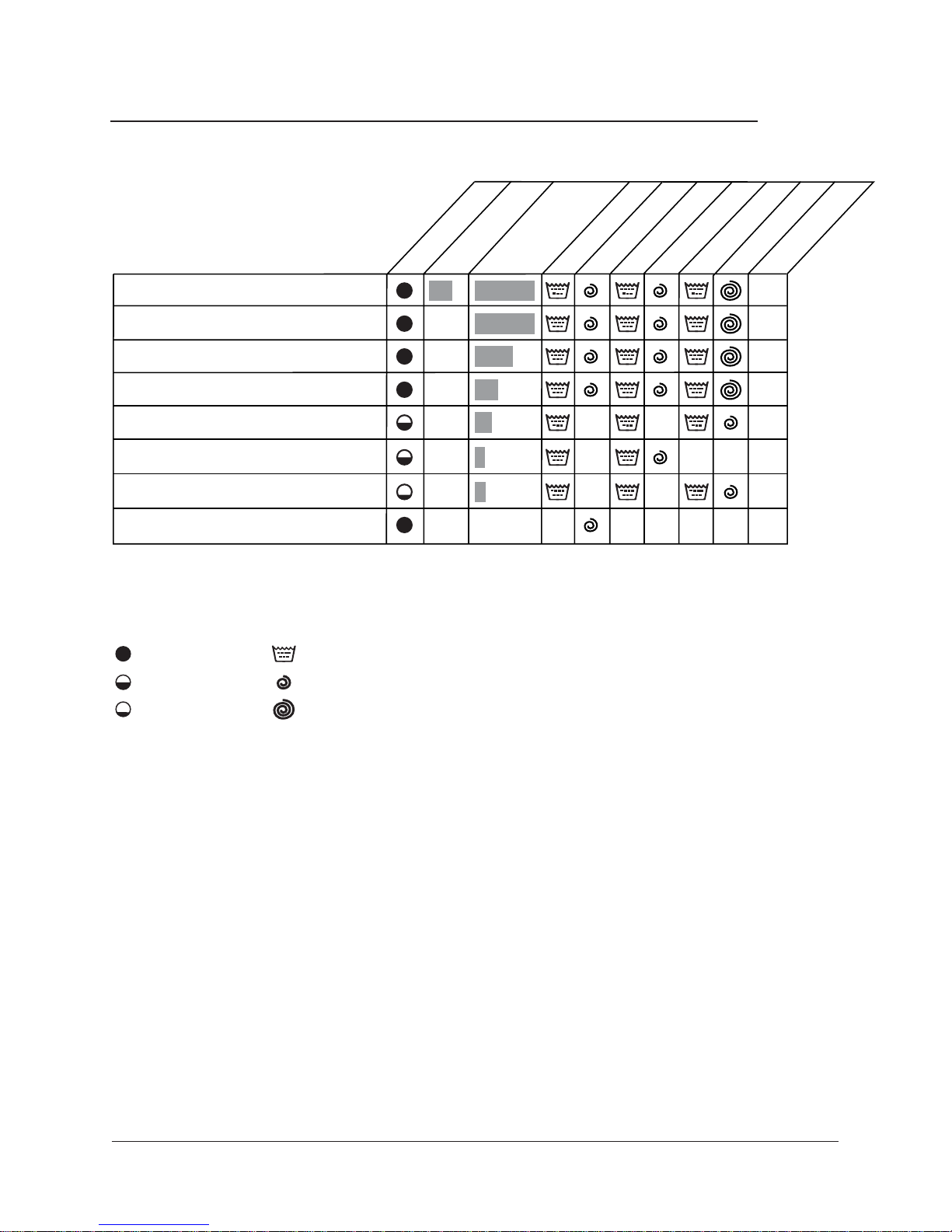

PROGRAMME CYCLES

EURO

PROGRAMMES

P1 Heavy wash 90°C

P2 Normal wash 60°C

P3 Normal wash 60°C

P4 Normal wash 40°C

P5 Synthetic wash 40°C

P6 Super quick wash 40°C

P7 Wool/hand wash 30°C (1)

P8 Spin

(1) High water level and gentle motor action.

EXPLANATIONS

1/1 (6,0 kg)

1/2 (3,0 kg)

1/3 (2,0 kg)

Rinse

Short spin (3 min)

Long spin (6 min)

Pre wash

Max .load

Main wash

Rinse

Spin

Rinse

Spin

Rinse

Spin

80

110

54

40

25

20

25

4

Length (appr. min)

WASHING MACHINE PROGRAMME CYCLES

6

PROGRAMME CYCLES WASHING MACHINE

7

MECHANICAL INSTALLATION

2

1

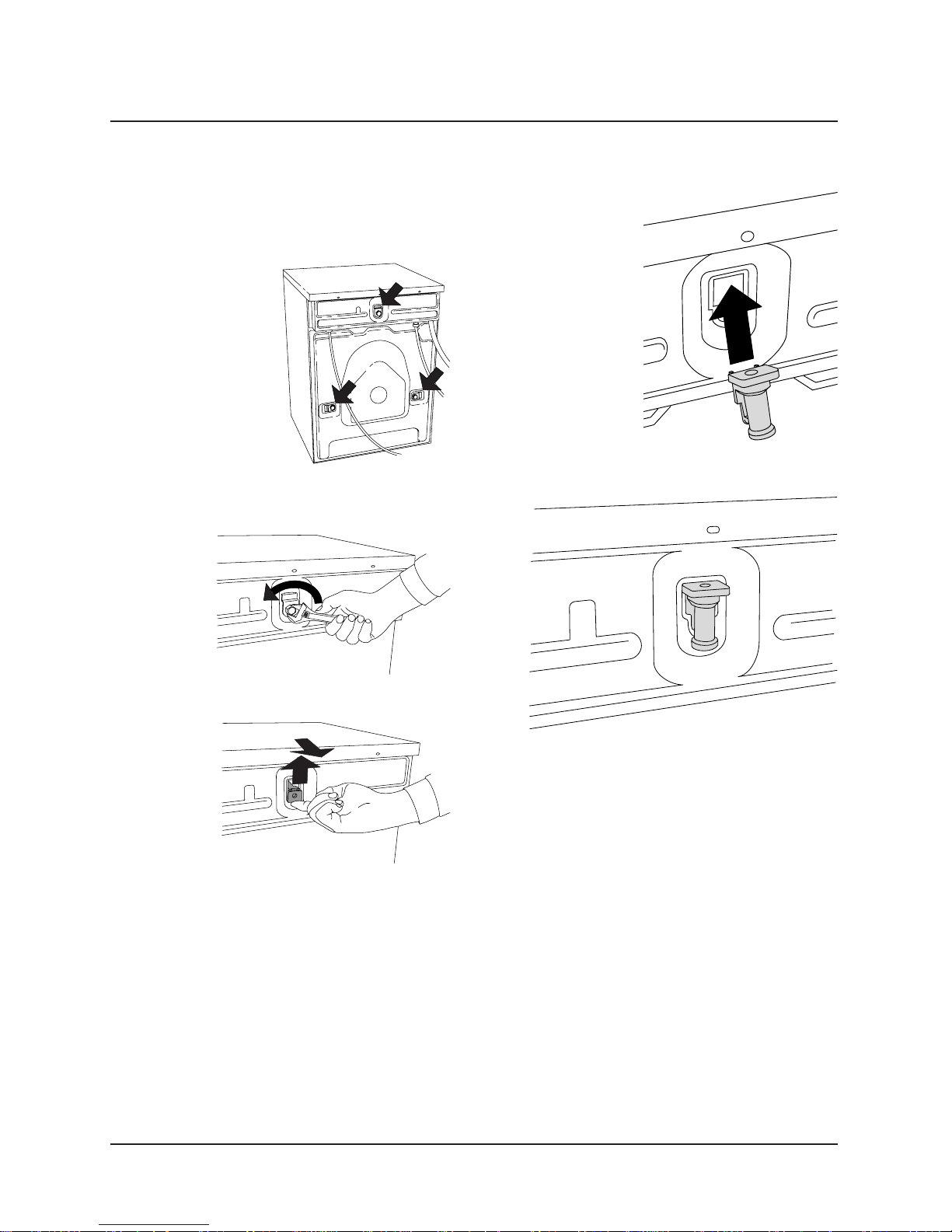

TRANSIT SCREWS

Before the machine can be used the three trans-

it screws must be removed as described below.

Each transit screw has a washer and a rubber

spacer. The rubber

spacers are used to

protect the screw ho-

les after the screws

have been removed.

1. First unscrew the screw and remove the was-

her.

3. Finally, refit the rubber spacers to cover the

transit holes.

2. Then pull out the rubber spacer.

WASHING MACHINE MECHANICAL INSTALLATION

8

S

t

a

r

t

/

S

t

o

p

P

3

P

1

P

2

P

4

P

7

P

5

P

6

P

8

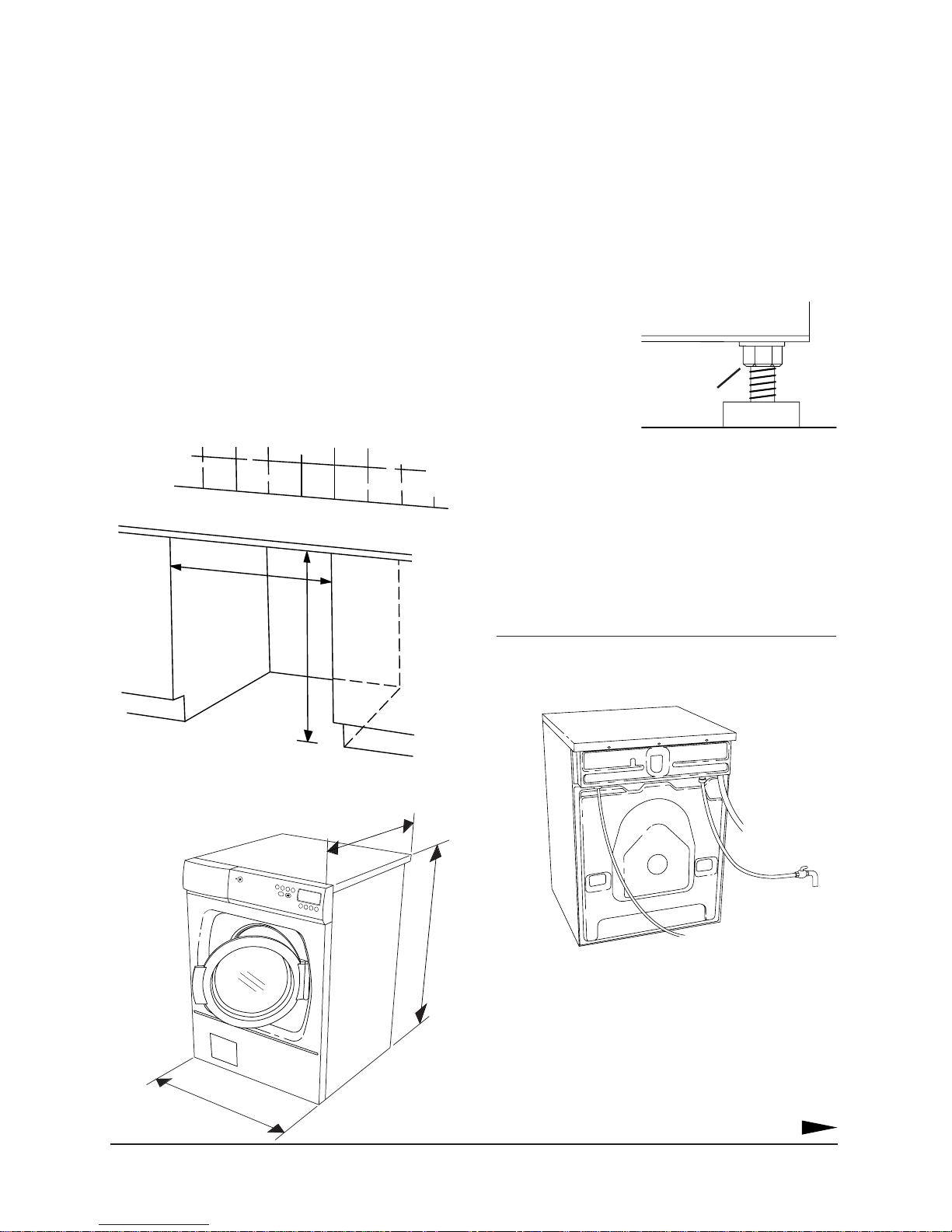

POSITIONING THE WASHING MACHINE

The washing machine can be built-in or free-

standing. It should be positioned so that there

is an electrical socket within easy reach.

The machine can be anchored to the floor, see

enclosed bag containing instructions and parts.

ADJUSTING THE FEET

Adjust the feet so that the machine is level and

A. Built-in

The washing machine can be built in under a

worktop with a working height of 850–900 mm.

Leave a 5 mm gap around the machine. This

also applies between the rear edge of the top

the machine and the wall behind.

min 600 mm

min 850 mm

steady on the floor.

Tighten the lock-

ing nuts.

Locking nut

CONNECTING TO WATER SUPPLY

The machine should be connected to the water

supply by someone who has the necessary skill.

The machine is connected using the supplied

inlet hose.

NOTE!

It is important that you use the inlet hose that

is supplied, not an old hose.

B. Free-standing

The washing machine can be placed alongside

or underneath the tumble dryer.

P

1

P

2

P

3

P

4

P

5

P

6

P

7

P

8

595 mm

MECHANICAL INSTALLATION WASHING MACHINE

585 mm

m

50 m

8

The water pressure must be 0.1–1 MPa

(about 1–10 kp/cm

2

; 10–100 N/cm2).

The water supply pipe must be fitted with a

shut-off valve.

If the supply pipe has just been installed we

recommend that it is flushed out thoroughly

9

first to remove any dirt. Otherwise this could

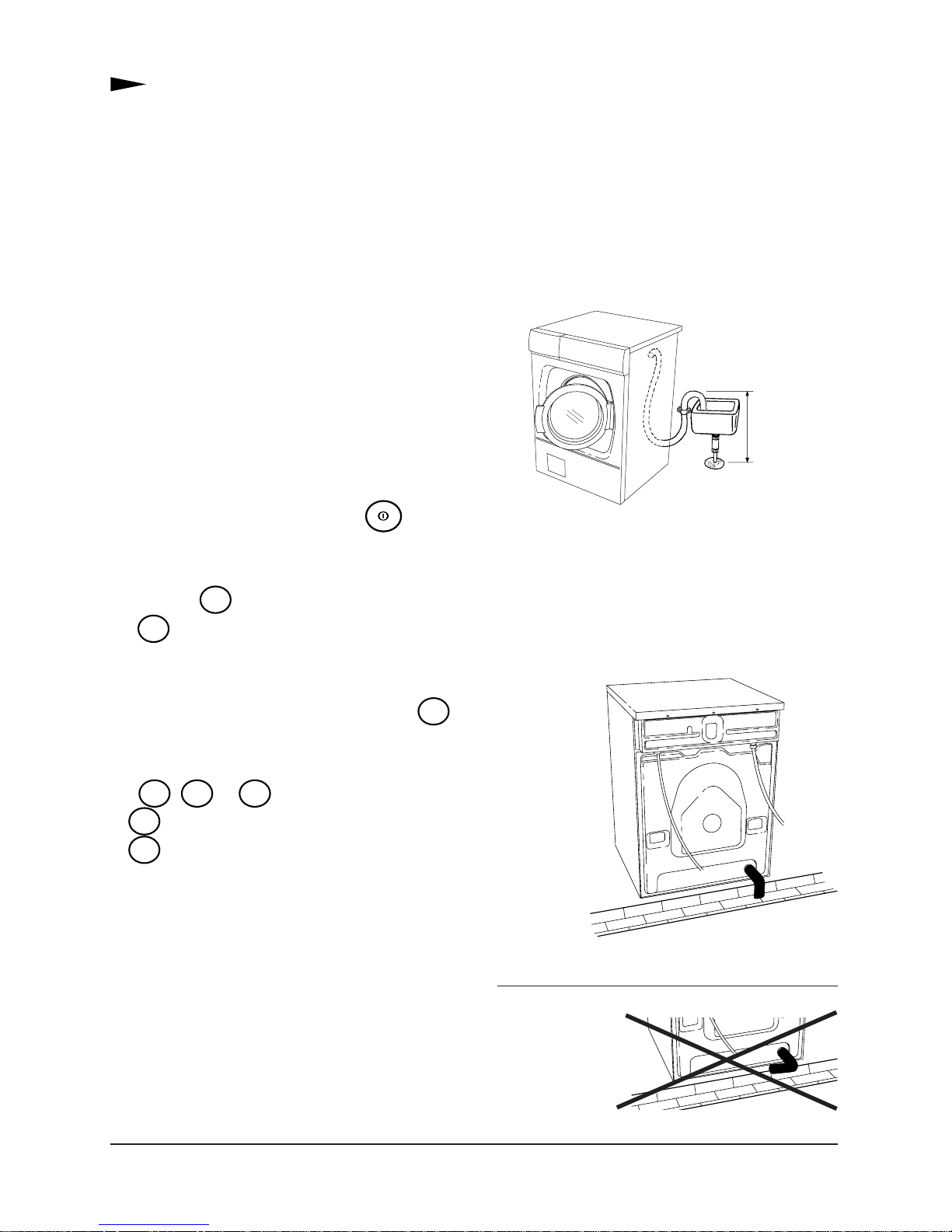

CONNECTING TO THE DRAIN

clog the intake filter in the machine and block

the water supply.

WATER INTAKE – MIXED OR COLD WATER

On delivery the machine is set to use mixed hot

and cold water (E).

The machine can be set for cold water intake

only. This setting must be made by a qualified

professional. Contact the service division.

To change the water intake setting, do as

follows:

Switch off the power switch, , then

switch it on again so that the machine is in

start-up mode.

Press the

P4

the

P8

button five times, then press

button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

P4

button for the fifth time you must then select

the type of water intake you want by pressing

the

P6, P7

or

P8

buttons.

Machine with drain pump

The machine is supplied with a drain hose al-

ready fitted and this should be connected to a

laundry sink, or the like, at a height of 600–900

mm above the floor.

600-900 mm

The lower height (600 mm) is always prefera-

ble. Make sure the drain hose is not kinked.

Machine with drain valve

An outlet hose is supplied with the machine.

This must be connected to the outlet on the

machine

and empty

into a floor

drain or

gutter drain.

P6

to use cold water intake only (C).

P8

to use mixed hot and cold water (E).

A letter C near the bottom right of the dis-

play shows that cold water is being used and

the letter E indicates mixed hot and cold.

WASHING MACHINE MECHANICAL INSTALLATION

10

NOTE!

The end of the outlet hose must be lower than

the lowest

point of the

outlet valve.

ELECTRICAL INSTALLATION

ELECTRICAL INSTALLATION

The washing machine must be connected using

a permanently installed cable through an isola-

ting switch by a qualified electrician.

Power supply

The machine is supplied as single-phase, 230 V,

50 Hz, heat output 3000W and has 16 A.

If an earth leakage circuit breaker is fitted it

must be of type A.

Reconfiguration

The machine can be reconfigured The machine

should be reconfigured as shown in the wiring

diagram underneath the top panel of the mach-

ine.

CONNECTING TO A COIN MECHANISM

Connection to a coin mechanism must be car-

ried out by a qualified electrician.

A special connecting cable is required to con-

nect the machine to a coin mechanism. This

can be ordered as a spare part, art. no. 92 090

95.

Recommendations for choice of coin mechanism

The connecting cable (92 090 95) supplies the

coin mechanism with power (230 V). The coin

mechanism must be able to short-circuit two

signal leads for a period of time (around 0–10

minutes). This is so that the user has time to

load the laundry, select the programme and start

the programme after inserting the coins.

NOTE!

Electrical connection /reconfiguring must be

carried out by a qualified electrician.

ELECTRICAL INSTALLATION WASHING MACHINE

11

CHANGING SETTINGS

Start/Stop

LANGUAGE

You can change the language of the displayed

text.

The languages you can choose from are Dansk,

Deutsch, English, Espanol, Français, Italiano,

Nederlands, Norsk, Portugués, Suomi and

Svenska.

To change language do as follows:

Switch off the power switch, , then switch

it on again so that the machine is in start-up

mode.

Press the

P1

the

P8

button five times, then press

button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

P1

button for the fifth time you should then select

Within three seconds of pressing the

P7

button for the fifth time you should hold in the

programme button for the programme you want

to lock for 5-10 seconds until the information

in the display starts flashing.

Then you can lock the programme by relea-

sing the programme button and pressing the

-button once.

Do the same to unlock the programme.

WASH TEMPERATURE - CENTIGRADE OR FAHRENHEIT

You can change the way the temperature is dis-

played from centigrade (C) to Fahrenheit (F).

To change the temperature display, do as follows:

Switch off the power switch, , then switch

it on again so that the machine is in start-up mode.

Press the

P8

button five times, then press

-

the language you want by pressing the

P7

buttons.

LOCKING A PROGRAMME

P6

or

If for some reason you want to limit the number

of programmes that can be used you can lock

one or more programmes.

No characters or digits are shown on the dis-

play when a locked programme is selected.

To lock or unlock a programme, do as follows:

Switch off the power switch, , then switch

it on again so that the machine is in start-up

mode.

Press the

P7

the

P8

-button five times, then press

-button five times. You have to com-

plete these ten button presses within fifteen se-

P2

the

button five times. You have to comple-

te these ten button presses within fifteen se-

conds.

Within three seconds of pressing the

P2

button for the fifth time you should then press

the

P6

or

P7

buttons to select centigrade

(C) or Fahrenheit (F).

CHANGING PRESET WASH TEMPERATURE

You can change the preset wash temperatures

for each of the programmes. The temperatures

you can choose from are:

Heavy wash - C, 30, 35, …, 85, 90, 95ºC.

Normal wash - C, 30, 35, …, 85, 90, 95ºC.

Light wash, Synthetic wash, Permanent Press -

C, 30, 35, …, 85, 90, 95ºC.

conds.

WASHING MACHINE CHANGING SETTINGS

12

Loading...

Loading...