Whirlpool AWI-1300 Service Manual

Service Manual

Auto Washer

Model : AWI-1300

GREAT TECO WHIRLPOOL CO., LTD

WHIRLPOOL

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

WASHING MACHINE

CCoonntteennttss

1. SPECIFICATIONS

...................................................................................................................

2

2. STRUCTURE OF THE W ASHING MACHINE

........................................................................

3

3. FUNCTIONS OF THE CONTROL PANEL

.............................................................................

4

4. WASHING PR OCEDURE AND COURSE SELECTION

FULL AUT OMATIC COURSE

.........................................................................................................

5

RESERVED WASHING

...................................................................................................................

6

PARTIAL SELECTION AMONG WASH, RINSE OR SPIN

.............................................................

6

5. DIRECTIONS FOR INSTALLATION AND USE

INSTALLA TION OF THE UNDER BASE COVER

..........................................................................

7

HOW TO INSTALL ON AN INCLINED PLACE

...............................................................................

7

HOW TO CONNECT THE INLET HOSE

........................................................................................

8

HOW TO CLEAN THE FILTER

........................................................................................................

9

6. FEATURE AND TECHNICAL EXPLANATION

FEATURE OF THE WASHING MACHINE

....................................................................................

10

WATER CURRENT TO ADJUST THE UNBALANCED LOAD

.....................................................

10

FUNCTION FOR SOAK WASH

....................................................................................................

10

AUT OMATIC WATER SUPPLY SYSTEM FOR BLANKET WASH

...............................................

10

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MA CHINE

.................................................

11

AUT OMATIC DRAINING TIME ADJUSTMENT

.............................................................................

11

AUT OMATIC UNBALANCE ADJUSTMENT

.................................................................................

12

CIRCULATING-WATER COURSE AND LINT FILTER

..................................................................

12

LINT FILTER

..................................................................................................................................

13

RESIDUAL TIME DISPLAY

...........................................................................................................

13

DRAIN MOTOR

.............................................................................................................................

13

GEAR MECHANISM ASS’Y

..........................................................................................................

14

7. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

GEAR MECHANISM ASS’Y REPLACEMENT

.............................................................................

15

8. THE REPAIR METHOD OF GEAR MECHANISM FOR CLUTCH SPRING PROBLEM

THE STRUCTURE OF GEAR MECHANISM............................................................................... 18

HOW TO CHECK THE CLUTCH SPRING PR OBLEM................................................................ 19

THE PROCESS OF DISASSEMBLE............................................................................................ 20

THE RPOCESS OF ASSEMBLE.................................................................................................. 22

9. TROUBLE SHOOTING GUIDE

CONCERNING WATER SUPPLY

.................................................................................................

24

CONCERNING WASHING

...........................................................................................................

25

CONCERNING DRAINING

...........................................................................................................

26

CONCERNING SPINNING

...........................................................................................................

27

CONCERNING OPERATION

........................................................................................................

28

10. PRESENTATION OF THE P.C.B ASS’Y

.....................................................................................

29

APPENDIX

WIRING DIAGRAM

.......................................................................................................................

30

EXPLODED VIEW

.........................................................................................................................

31

PARTS LIST

...................................................................................................................................

35

CIRCUIT DIAGRAM

......................................................................................................................

37

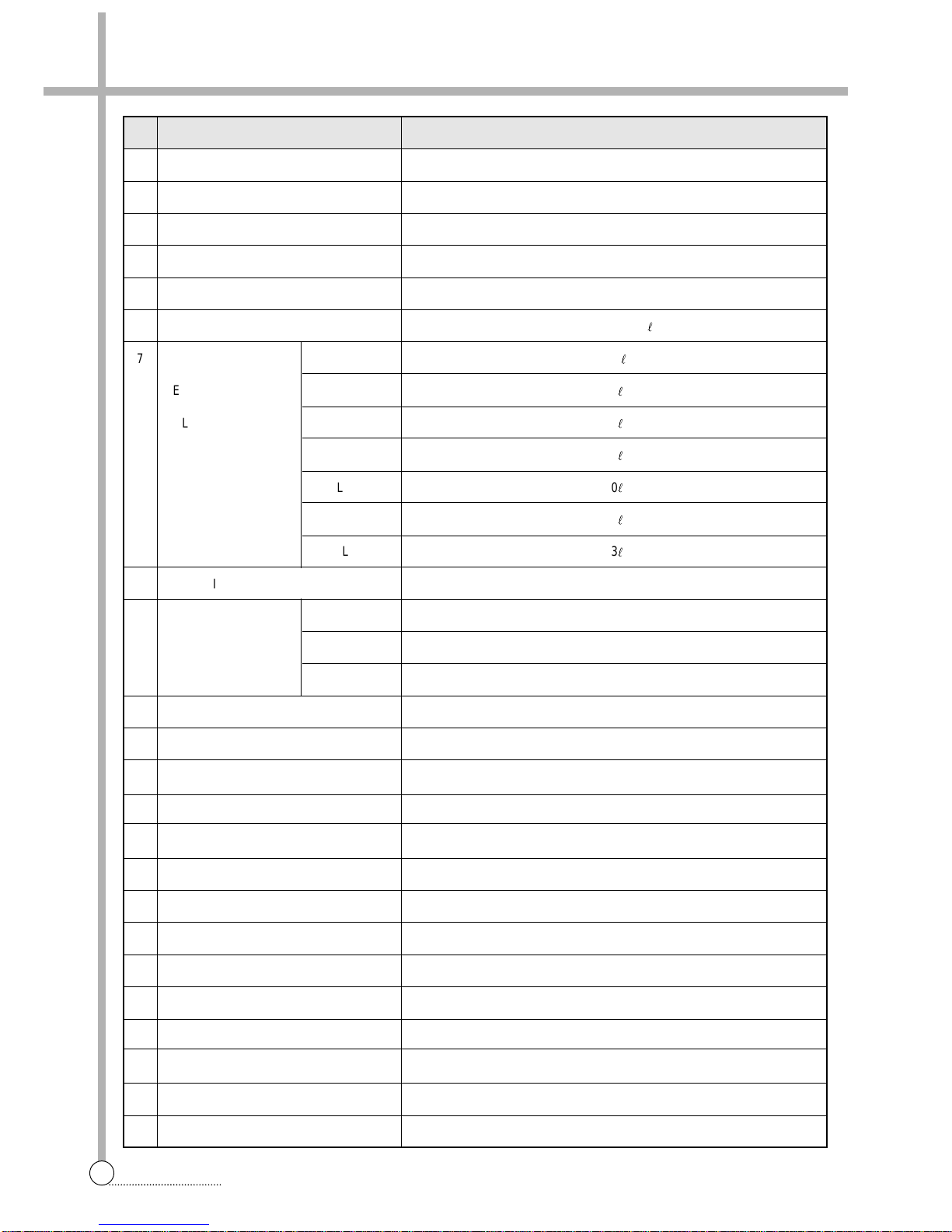

NO. ITEM AWI-1300

1 POWER SOURCE 110V, 60HZ

2 POWER CONSUMPTION 600W

3 MACHINE WEIGHT 47Kg (GROSS: 50Kg)

4 DIMENSION(WXHXD) 630 X 1010 X 670

5 WASHING COURSE

FULL AUT OMATIC 6 COURSE (ST ANDARD/BLANKET/SUIT/ECONOMY/LIGHT/HEAVY)

6 WATER CONSUMPTION NORMAL 270

l

7 WATER HIGH 103

l

LEVEL ● 94

l

SELECTION MIDIUM 87

l

● 77

l

LOW 70

l

● 60

l

E.LOW 43

l

8 OPERATING WATER PRESSURE 0.3~8kgf/cm2(2.94N/cm2~78.4N/cm2)

9 REVOLUTION PER WASH 125~140RPM

MINUTE SPIN 675~695RPM

SUIT COURSE WASH: 65

10 PULSATOR 6WINGS(Ø406mm)

11 WATER LEVEL CONTROL ELECTRONICAL SENSOR

12 ANTI-NOISE PLATE ❍

13 GEAR MECHANISM HELICAL GEAR

14 LINT FILTER ❍

15 SOFTENER INLET ❍

16 FUNCTION FOR SOAK WASH ❍

17 ALARM SIGNAL ❍

18 RESIDUAL TIME DISPLAY ❍

19 AUTO. WATER SUPPLY ❍

20 NEW WATER FLOW WATER FLOW FOR ADJUST THE UNBALANCED LOAD

21 FUNCTION FOR BUBBLE AND RADICAL ❍

22 AUT O RE-FEED WATER ❍

23 AUT O POWER OFF ❍

1. SPECIFICATIONS

2

SPECIFICATIONS

(OPTION)

2. STRUCTURE OF THE WASHING MACHINE

3

STRUCTURE

B

U

B

B

L

E

W

A

S

H

I

N

G

M

A

C

H

I

N

E

W

A

T

E

R

L

E

V

E

L

RES.

W

A

S

H

WASH

S

P

IN

SPIN

R

E

M

.

R

E

S

.

C

O

U

R

S

E

ECO.

ECO.

S

T

A

R

T

H

O

L

D

P

O

W

E

R

R

IN

S

E

RINSE

C

O

U

R

S

E

FUZZY

F

E

E

D

S

O

C

K

BLANKET

LIGHT

HEAVY

SUIT

HIGHT

MEDIUM

LOW

E

.

L

O

W

DETERGENT

H

O

U

R

MIN.

MIN.

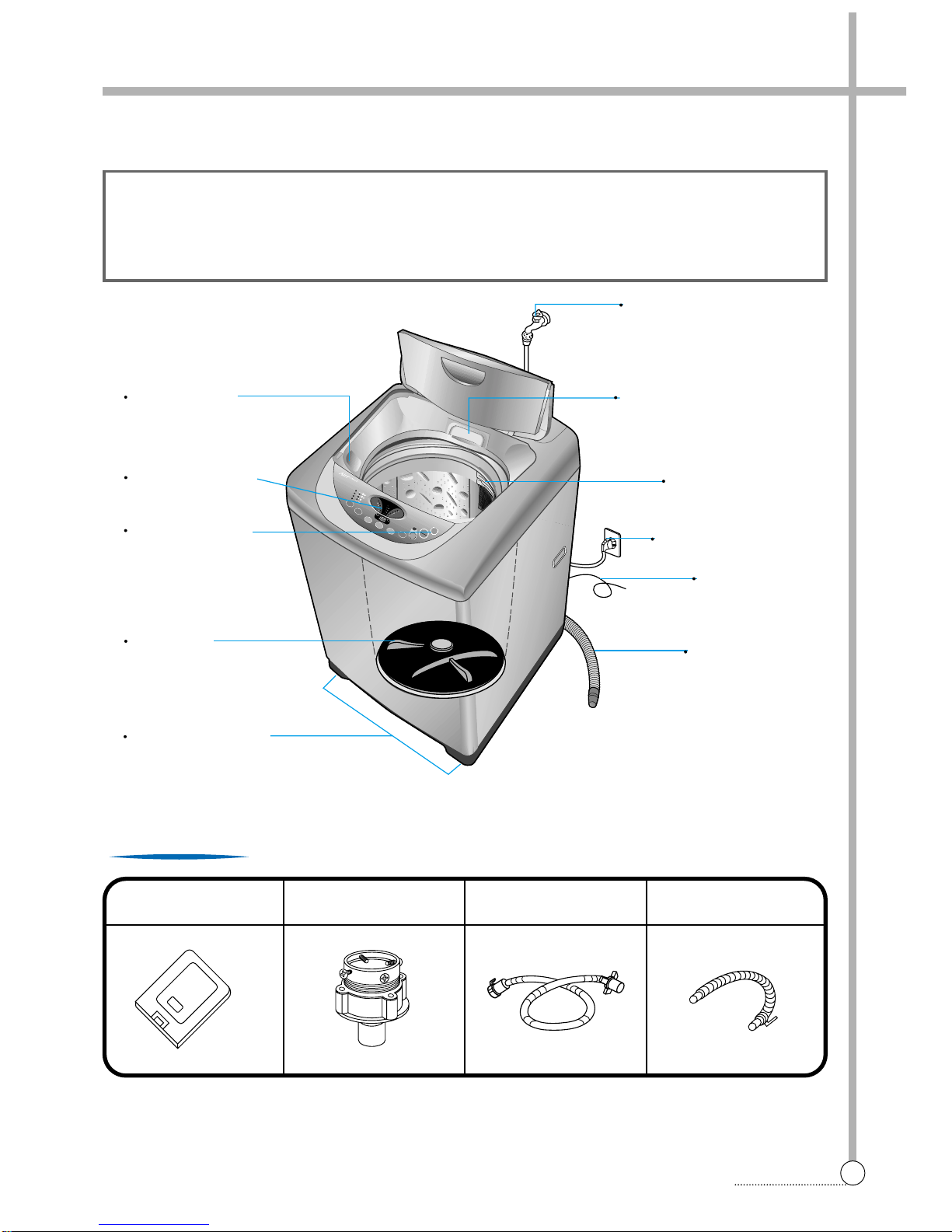

BLEACH INLET

POWER SWITCH

CONTROL PANEL

PULSATOR

ADJUSTABLE LEGS

COLD WATER TAP

After using the washer,

close the water tap.

DETERGENT CASE

LINT FILTER

GROUND WIRE

In case of 3-wire power cord

ground wire will not be provided.

POWER CORD

HOSE DRAIN

COVER UNDER [OPTION] WATER T AP ADAPTER INLET HOSE

HOSE DRAIN O AS [NON-PUMP]

Accessories

UP

The parts and features of your washer are illustrated on this page.

Be come familiar with all parts and features before using your washer.

NOTE

• The drawing in this book may vary from, your washer model. They are designed to show the different features of all models covered by this book, Your model may not include all features.

• Page ref erences are included next to same features.

Refer to those pages for more information about the features .

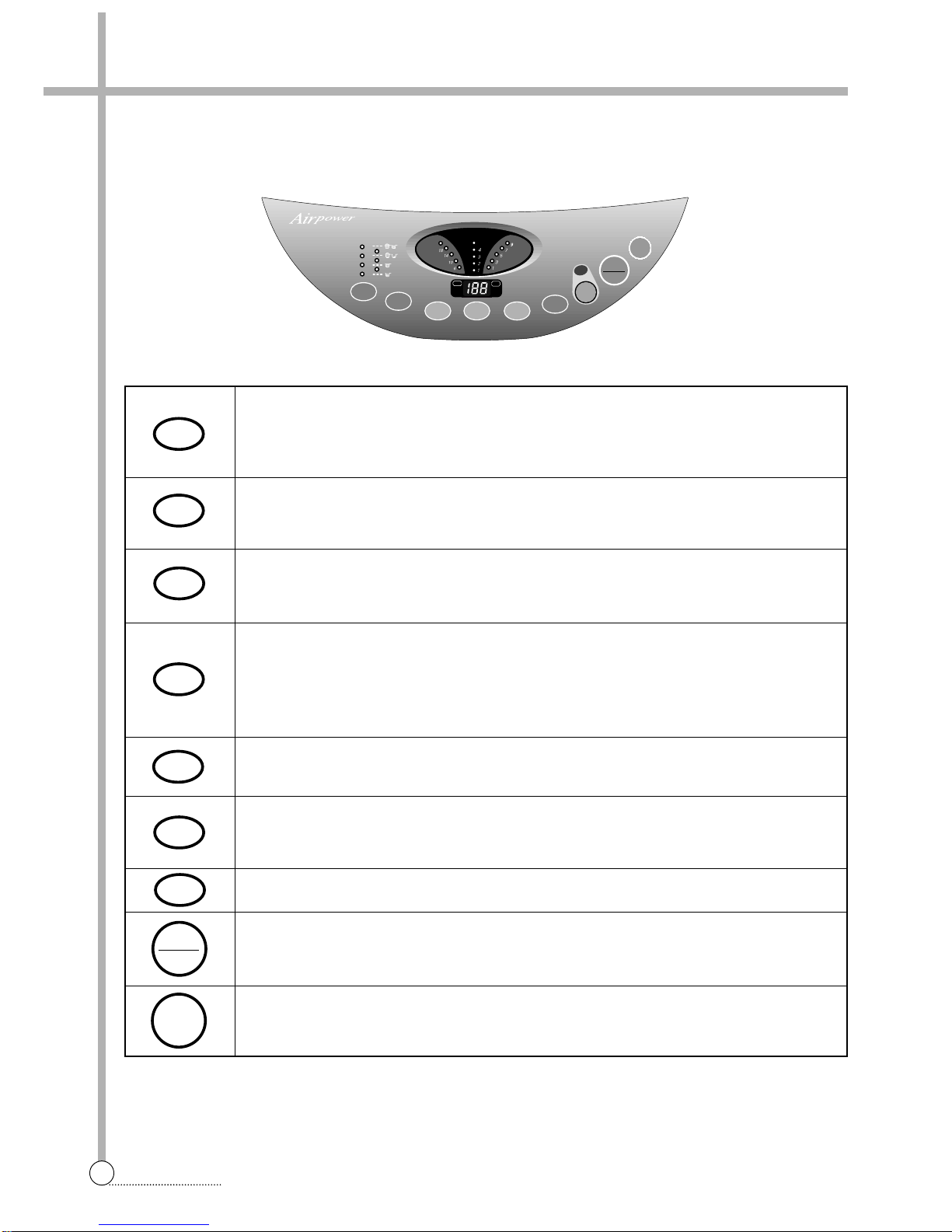

3. FUNCTIONS OF THE CONTROL PANEL

4

CONTROL PANEL

• It can be used to adjust amount of water according to the size of the load to be w ashed.

• As the button is pressed, water level is selected by MEDIUM ➔●➔HIGH ➔●➔E.LOW

➔●➔LOW ➔●➔MEDIUM

• It can be used to pre-engage time for wash

• It can be used to adjust washing time.

• As the button is pressed, you will see the repeated.

6 ➔ 10 ➔ 14 ➔ 18 ➔ SOAK

• This button selects the number of times you w ant to rinse.

• As the button is pressed, it will repeat.

• 1 time rinse ➔ 1 time feed rinse ➔ 2 times rinse ➔ 2 times feed rinse ➔ 3 times rinse ➔

3 times feed rinse ➔ 4 times rinse ➔ 4 times feed rinse.

• In case of the pump model, there is no feed rinse or spra y rinse selector function.

• It can be used to change spin time.

• As the button is pressed, it will repeat. 1 ➔ 3 ➔ 5 ➔ 7 ➔ 9.

• It can be used to select the full-automatic course.

• As the button is pressed, it will selected by following order:

FUZZY ➔ BLANKET ➔ ECONOMY ➔ LIGHT ➔ HEAVY ➔ SUIT

• It can be used to select the economic course.

• Operation and temporary stop are repeated as they are pressed.

• When you want to change course in operating; press the “START/HOLD” button ➔ Select

the course that you want to change ➔press the “START/HOLD” button again.

• Press this switch to turn the power on or off.

After turning off the power, wait for more then 3seconds and then turn it on again.

BUBBLE WASHING MACHINE

WATER

LEVEL

RES.

WASH

WASH

SPIN

SPIN

REM.

RES.

COURSE

ECO.

ECO.

START

HOLD

POWER

RINSE

RINSE

COURSE

FUZZY

FEED

SOCK

BLANKET

LIGHT

HEAVY

SUIT

HIGHT

MEDIUM

LOW

E.LOW

DETERGENT

HOUR

MIN.

MIN.

Control panel has micom sensor.

As the buttons are pressed, the lames indicating the selection of your desired washing program will light up.

WATER

LEVEL

RES.

WASH

RINSE

SPIN

COURSE

ECO.

START

HOLD

POWER

5

PROCEDURE

4. WASHING PROCEDURE AND COURSE SELECTION

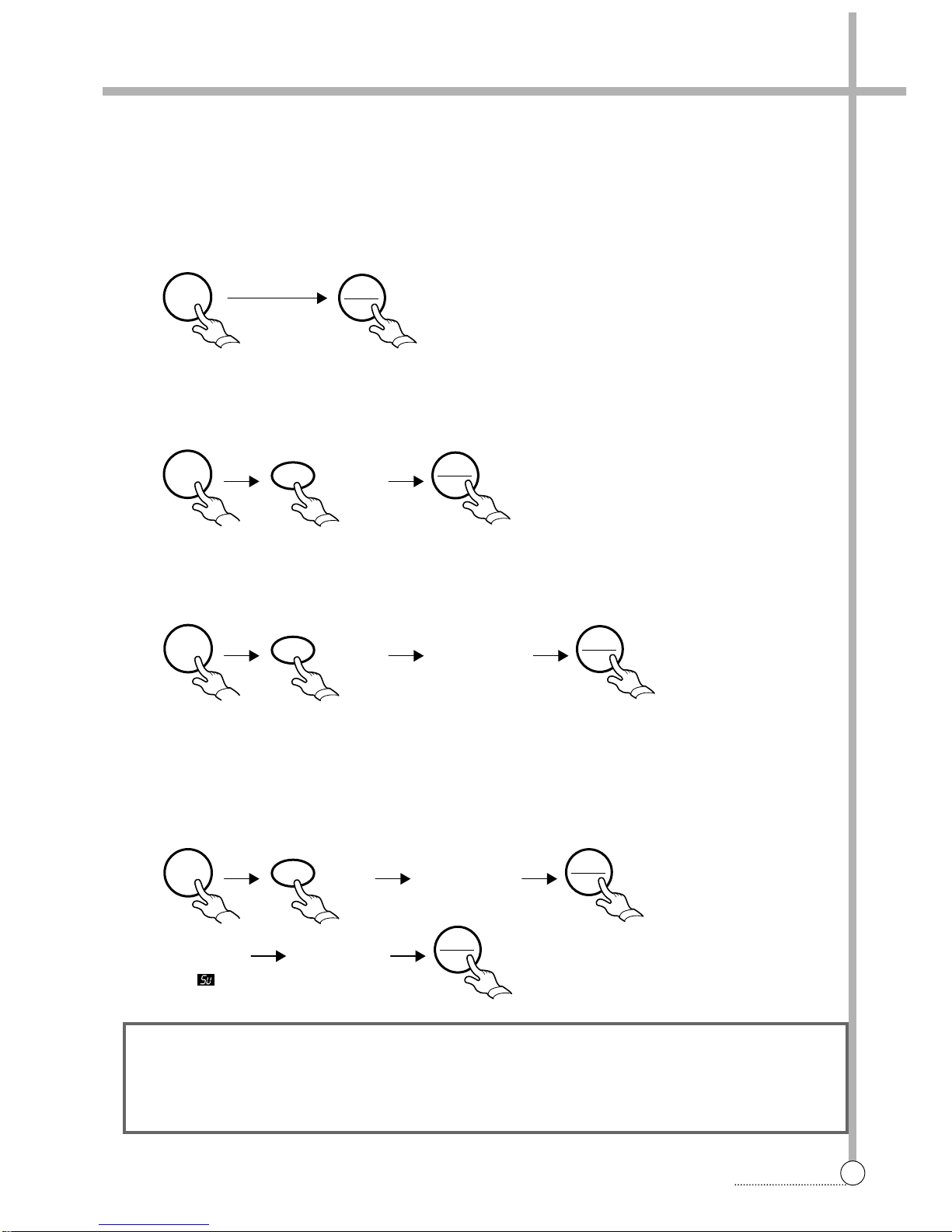

1. FUZZY COURSE (SENSOR);

• This selection is for general washing e xcept extraordinary clothes.

• Artificial brain sensor selects properly the various kind of washing condition such as washing time, rinse times, spin

time water level and washes w ell. If y ou w ant to soak, press the “WASH” button to adjust “SOAK” after the course

selection. Procedure to press the button;

2. LIGHT COURSE

• This selection is effective f or w ashing light or less dirty wash. Procedure to press the button;

3. BLANKET COURSE;

• This selection is effective f or blanket, curtain, carpet, etc ...

• Do not wash general-electric blanket absolutely (4kg’s limitation for one-time-wash). Procedure to press the button;

4. SUIT COURSE;

• This selection is effective f or high-quality sweater, underwear, wool, etc ...

• When the washer is operated, selection for water level will be selected “MEDIUM” by automatically in order to pre-

vent the laundry.

• Use detergent that is “Only for dry-cleaning”.

• 1.5kg’s limitation for one-time-wash.

NOTE

• Only cold water should be supplied for washing.

• Be sure to use only the detergent exclusively used for the w asher.

• Do not use the washer to wash leather clothes, or chamois clothes.

• Separate white color/light-colored from colorfast clothes.

■

Full Automatic Course

START/

HOLD

POWER

START/

HOLD

POWER

COURSE

adjust to

"LIGHT"

START/

HOLD

POWER

If necessary, adjust to

water level

COURSE

adjust to

"BLANKET"

START/

HOLD

START/

HOLD

POWER

Put the exclusive

detergent DRYTEN

of 26g into the tub

for dilution with water.

COURSE

adjust to

"SUIT"

(or "WOOL")

After dissolving of

detergent, lamp

will buzzer will

sound.

Put the clothes into

the tub after the

buzzer sounds.

Close the lid and press the

S/H button once again.

6

PROCEDURE

5. HEA VY COURSE;

• This selection is effective f or blue-jean, climbing clothes, ruck sack, sports wear, etc ...

• If you want to soak, press the “WASH” button to adjust to “SOAK” after the course selection.

6. ECONOMY COURSE;

• This selection is effective f or w ashing light or less dirty wash.

• Regulate the quantity of water according to load to be washed. Procedure of press the button;

■

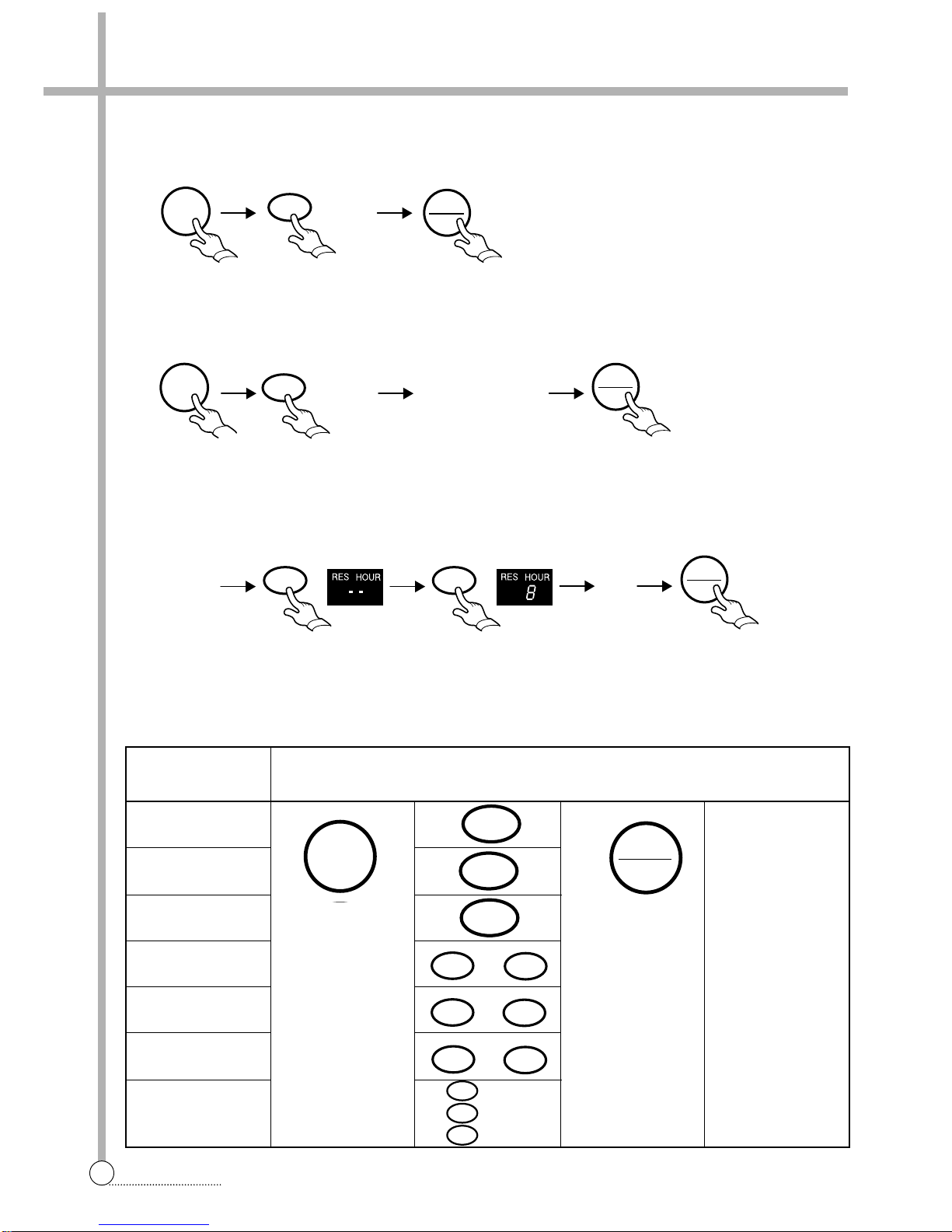

Reserved Washing

• Reservation can be made from 2 hours to 48hours.

example) To make reservation to complete washing in 8hours.

• Now the reservation is mode.

■

Partial Selection Among Wash, Rinse or Spin

Washing contents

Only Wash

Only Rinse

Only Spin

Wash & Rinse

Wash & Spin

Rinse & Spin

Wash ➔

Rinse ➔

Spin

➔

Press the “S/H” button.

If once more

Pressed, the washer

will be stopped.

For keeping

Operation continuously to the set program, press another

time.

End of washing

informed by buzzer.

After the end of the

washing, the power

switch will be turned

off automatically.

Procedure to press the button

START/

HOLD

POWER

COURSE

adjust to

"HEAVY"

START/

HOLD

POWER

COURSE

adjust to

"ECONOMY"

If necessary, adjust to

water level

(default:water

level-low, spin-1min.,

rinse-fixed 1times)

START/

HOLD

adjust to

"MEMORY"

RES.

"

--" shall blink

RES.

adjust to "8"

close

the lid

POWER

WASH

RINSE

SPIN

WASH

WASH

RINSE

RINSE

RINSE

WASH

SPIN

RINSE

SPIN

START

HOLD

➔

➔

➔

➔

➔

7

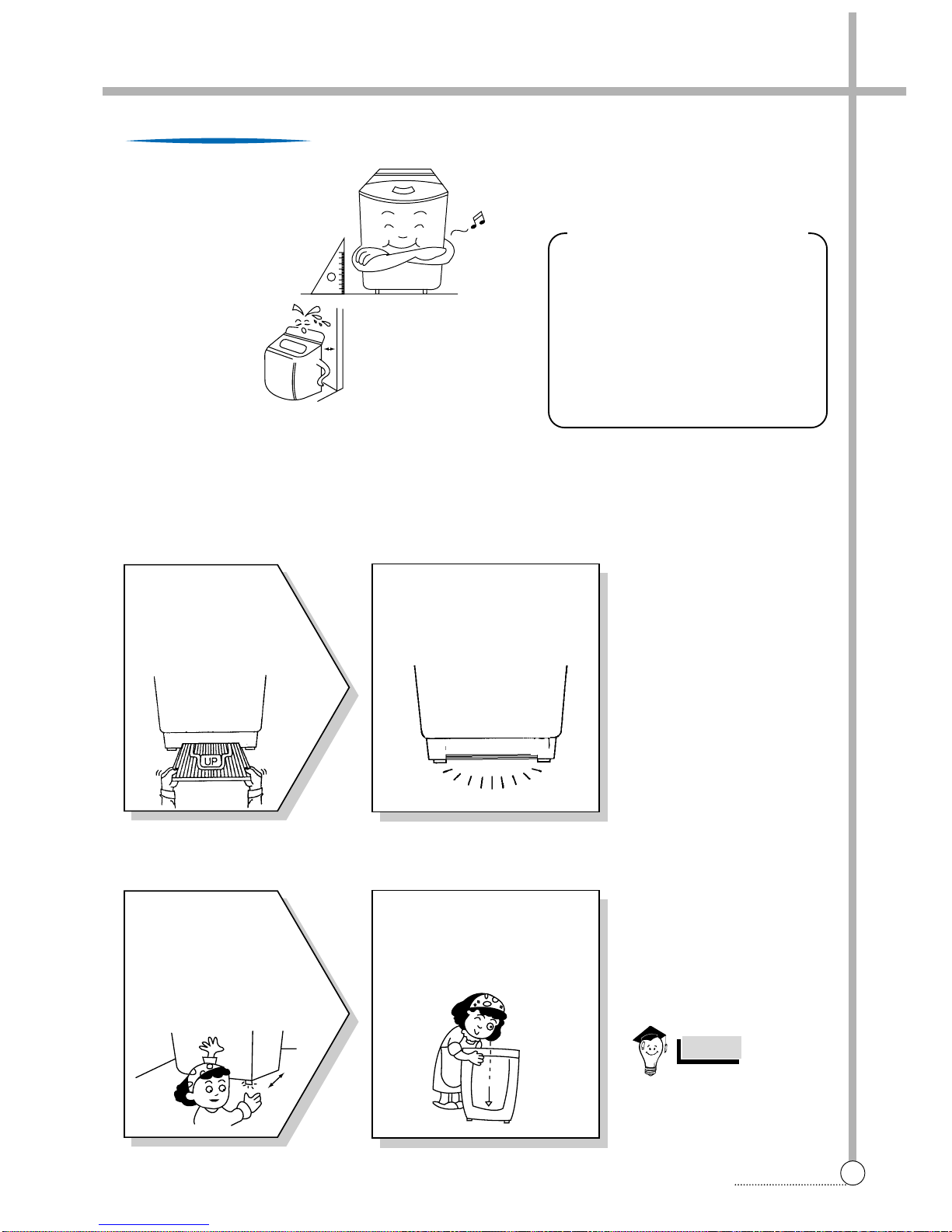

DIRECTIONS

5. DIRECTIONS FOR INSTALLATION AND USE

The openings must not

be obstructed by carpeting when the washing

machine is installed on a

carpeted floor.

■

installation Of The Under Base Cover [Option]

■

How To Install On An Inclined Place

● The place where it would be exposed to

direct sunlight.

● The place nearby a heater or heat appliance.

● The place where it would be supposed to

be frozen in winter.

● The kitchen with coal gas and a damp

place like a bathroom.

NOTES

10Cm

Install the washer on a horizontal

solid floor. If the washer is installed

on an unsuitable floor, it could make

considerable noise and vibration.

Installing Place

Never install in these places

2

Push the noise insulation plate

into the end, which decrease

the noise made by this washer.

1

The packing box

opened, there is a

noise insulation plate.

Please insert this plate

into the bottom area on

the back side.

2

Check the Horizon

Status

Check the position of tub above

the center of the washer.

1

Horizon

Setting

After controlling the height

by turning the adjustable

leg, let the washer put

down to the ground.

Keep the machine body

more than 10cm apart from

the wall surface. It will

make easy cleaning the

drain filter which is equipped

at the back side of it. And if

it comes into contract vibration may occur.

“Back”

“Back”

8

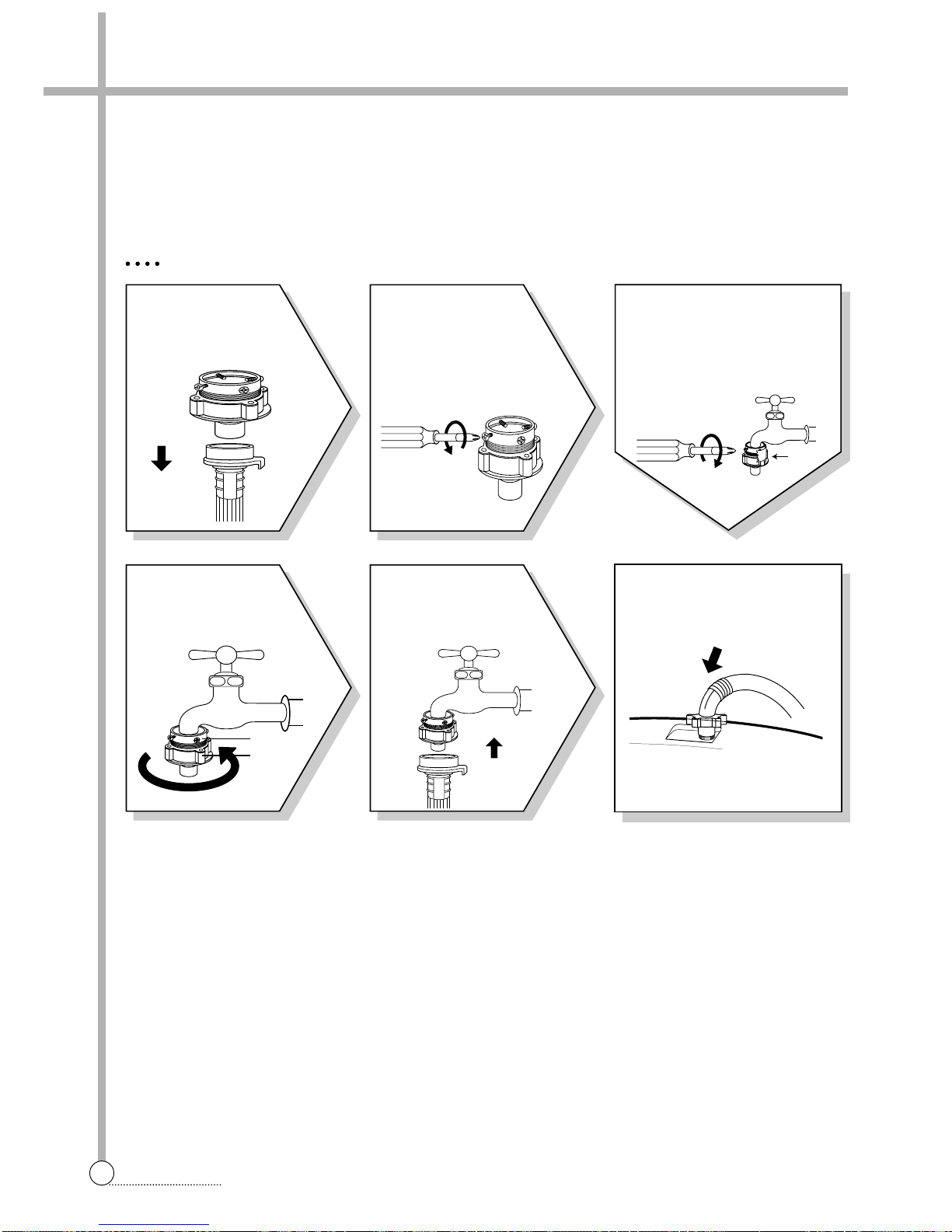

CONNECTION

FOR ORDINARY TAP

6

Connect the inlet hose adapter

of the hose to the water inlet of

the washer by turning it clockwise to be fixed tightly.

• Please check the rubber packing

inside the inlet hose adapter of

the hose.

1

Pull down the collar

of the inlet hose to

separate it from the

water tap adapter.

2

Loosen the four

screws at the water

tap adapter, but don’t

loosen the screws until

they are separated from

the water tap adapter.

4

Remove the tape,

and screw connector

B into connect A tightly.

5

Connect the inlet

hose to the water tap

adapter by puling down

the collar of the hose end.

3

Connect the water tap

adapter to the water tap tighten the four screws evenly

while pushing up the adapter

so that the rubber packing

can stick to the water tap

tightly.

■

How to Connect the Inlet Hose

Be careful not to mistake in supplying between the hot(maximum : 50˚C) and cold water.

In using only one water tap or in case of attached one water inlet valve, connect the inlet hose to the cold water inlet

valve.

Do not over tighten : this could cause damage to couplings.

TAPE

Connector B

Connector A

9

CONVENIENCE

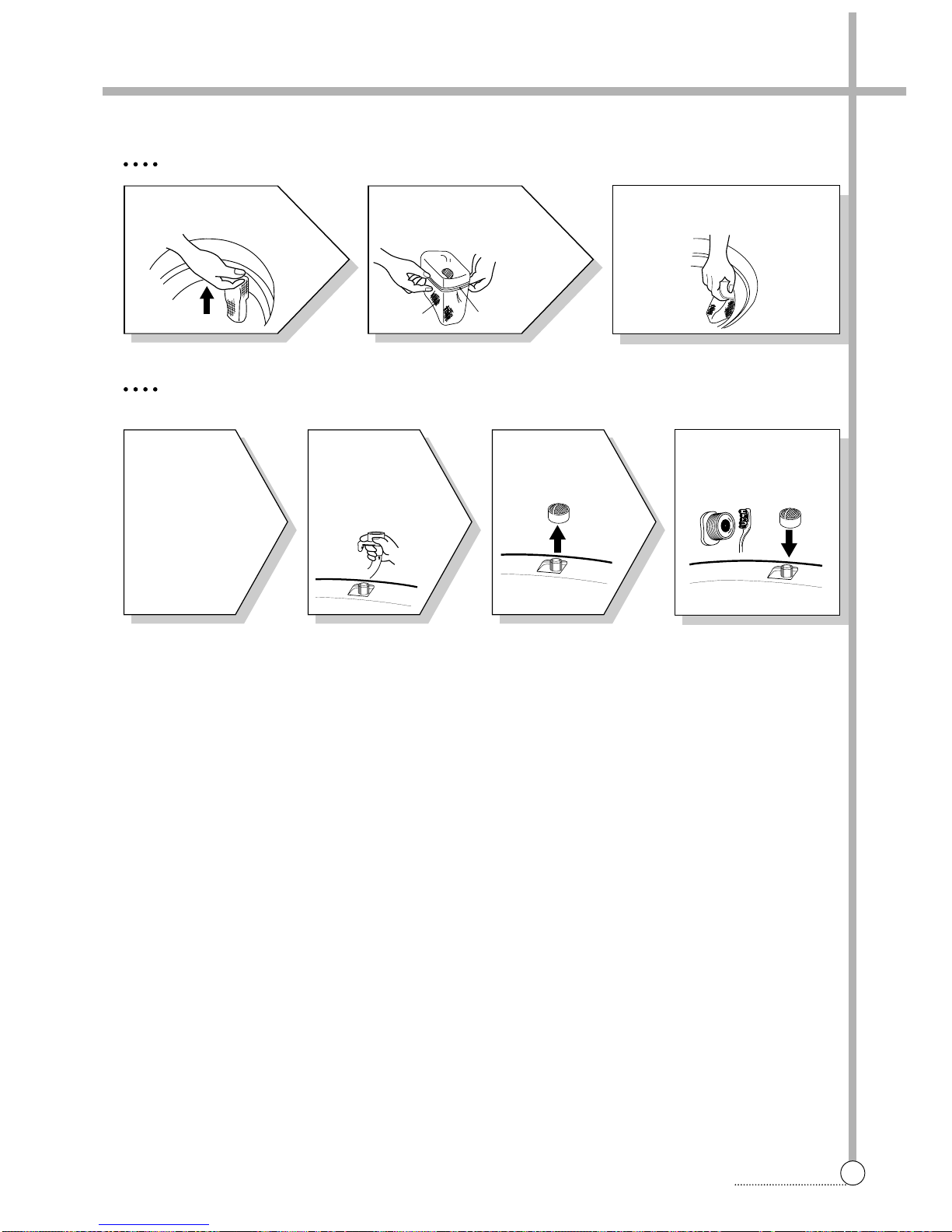

■

How To Clean The Filter

4

Remove the dirt

from the inlet filter

with a brush.

1

Pull the

power plug

out before

cleaning it.

2

Turn off the

water supply

to the washer

and sperate the

inlet hose.

3

Pull the

inlet filter out.

CLEANING THE LINT FIL TER

CLEANING THE WATER INLET FIL TER

• Clean the filter when water leaks from, the water inlet.

3

Return the filter as it was, and

insert the filter frame into the

slot.

1

Pull the Filter frame

upward.

2

Turn the lint filter

inside out, wash to

the lint off with water.

Filter Frame

Lint Filter

10

EXPLANATION

6. FEATURE AND TECHNICAL EXPLANATION

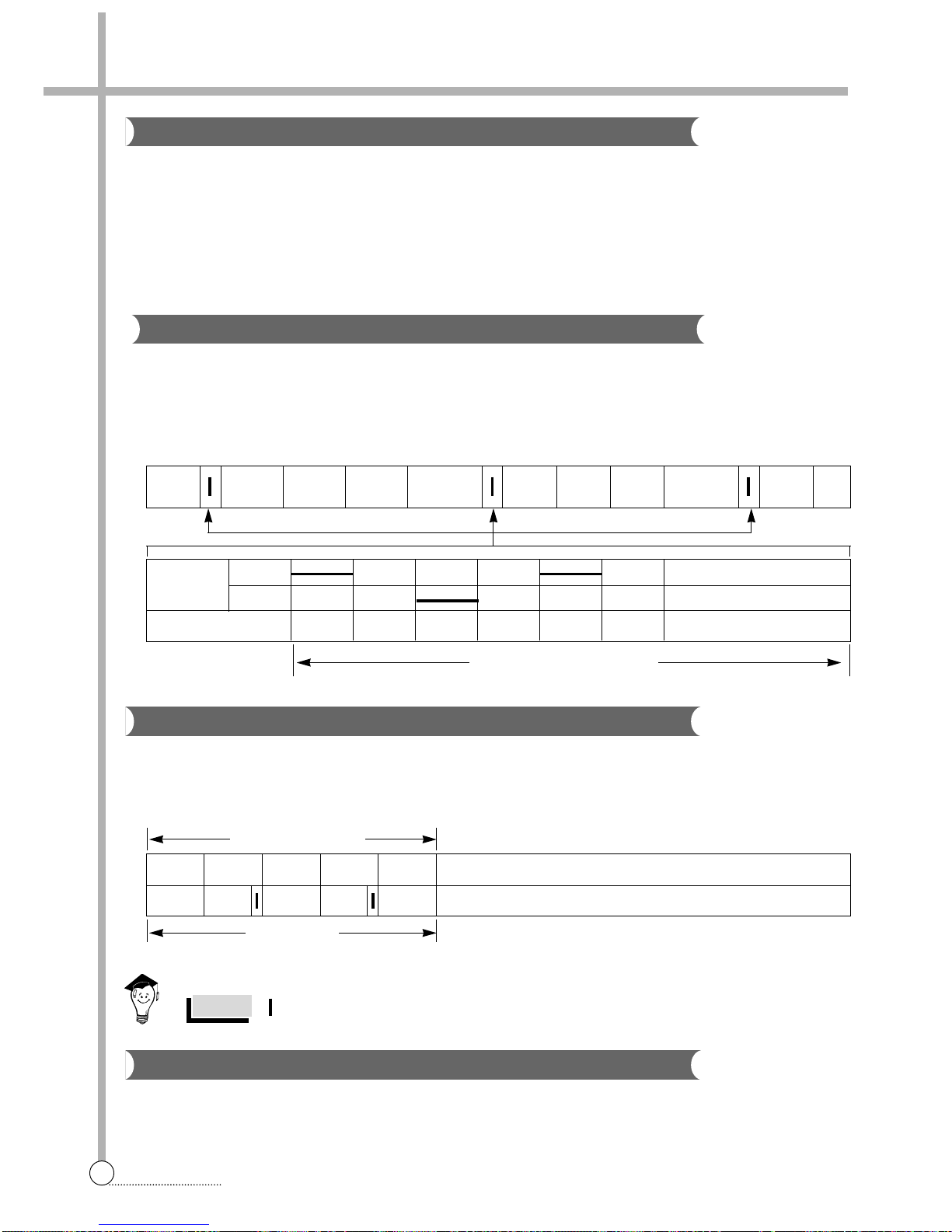

WASH DRAIN SPIN FILL RINSE 1 DRAIN SPIN FILL RINSE 2 DRAIN •••

MOT OR C.W

SINGAL C.C.W

TIME(SEC.) 0.3 0.3 0.3 0.3 0.3 0.3 •••••••

35 SEC. (About 29 Times)

FILL WASH STOP WASH STOP

• 2’ 28’ 2’ 28’

SOAK PROCESS MAIN PROCESS

60 Minute

Feature of the Washing Machine

1 The first applying Radical Technology in the world....go beyond washing, sterilize your clothes and deodorize a

bad smell.

2 The first air bubble washing system in the world.

3 Quiet washing through the innovational low-noise design.

4 The wash effectiveness is much more enhanced because of the air bubble washing system.

5 The laundry detergent dissolves well in water because of the air bubble washing system.

6 The adoption of the water currents to adjust the unbalanced load.

7 One-touch operation system.

Water Current to Adjust the Unbalanced Load

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 35

seconds.(But, the SUIT course have no operation of the water currents to adjust the unbalnced load.)

EFFECT

It reduces vibration and noise effectively while spinning.

WATER FLOW

Function for Soak Wash

DISPLAY THE RESIDUAL TIME

When the SOAK WASH is selected, the total wash time increases because 60 minutes for soak process are added to

the time of main process.

PROGRESS

Automatic Water Supply System For Blanket Wash

The water level would be lo wered because the blanket absorbs water at the beginning of washing. Therefore, after 30

seconds, the operation is interrupted to check the water level, and then the water is supplied again until the selected

water level is reached.

‘ ’ mark indicates the operation of the water currents to adjust the unbalanced load.

NOTES

11

EXPLANATION

FUNCTIONAL PRINCIPLE

1 The micom can remember the time from the begining of drain to reset point when the pressure switch reaches to

“OFF” point

2 In case of continuous draining, residual drain time is determined by micom.

Draining time as a whole = D + 90

Residual drain time.

The time remembered by micom.

Draining

Good draining The washer begins spin process after drainage.

condition

Bad draining Draininig time is prolonged.

No draining Program is stopped and gives the alarm.

Drain Time Movement of the Program

Less than

Continue draining

15 minutes

More than

Program stops and gives the alarm with blinked on display lamp.

15 minutes

Automatic Drainning time Adjustment

This system adjusts the draining time automatically according to the draining condition.

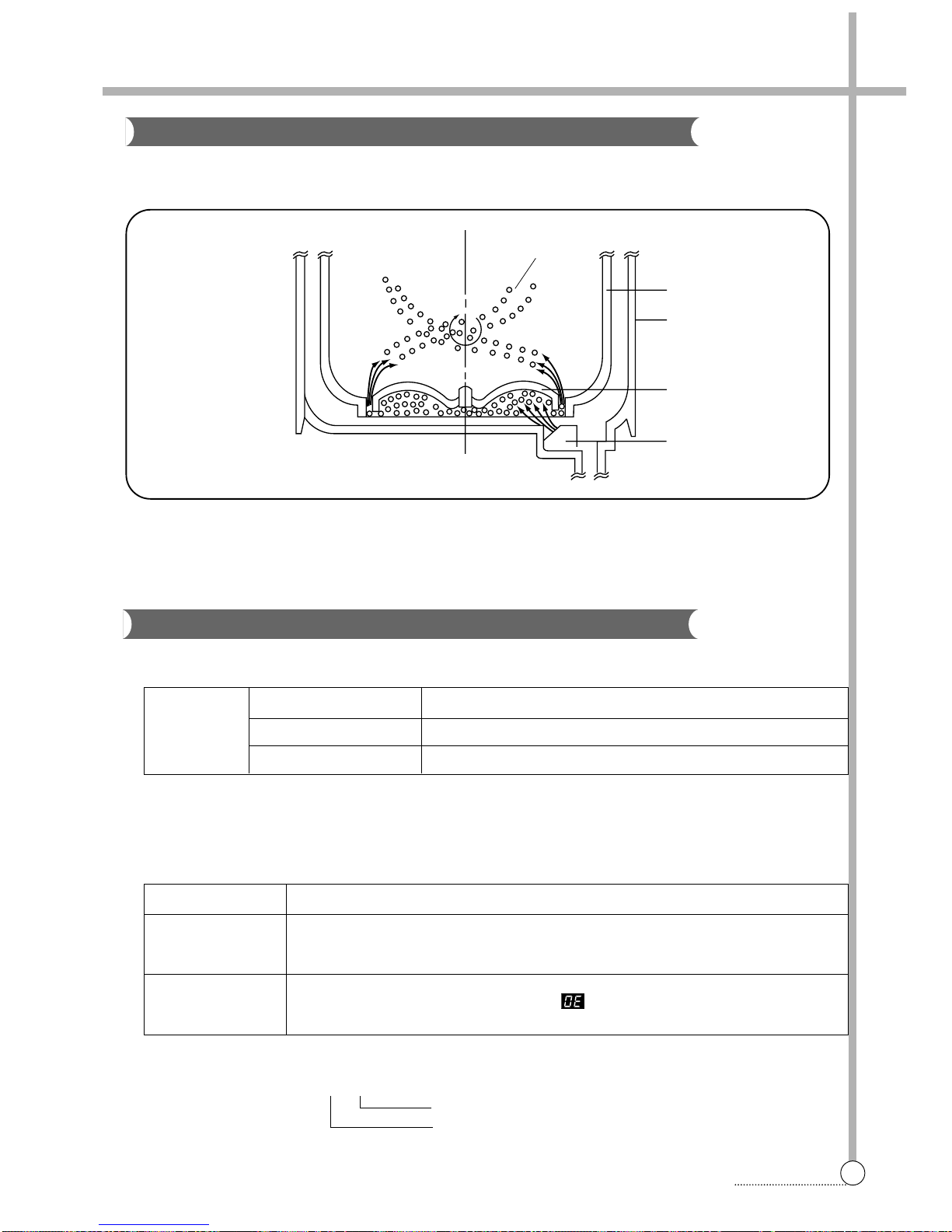

ACROSS SECTION

FUNCTIONAL PRINCIPLE

Bubble generator supplies the air from the bottom of outer tub to the inner space of pulsator, the air is dispersed by

the rotation of pulsator. Air-bubb le is created b y the centrifugal f orce , and rises up .

Air bubble

Tub

Outer tub

Pulsator

Nozzle

Functional Principle of Bubble Washing Machine

Loading...

Loading...