Whirlpool ATR1243SPP, ATE0943SPP, ATR0943SPP, ATE1243SPP, ATR1545SPP Technical Manual

...

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

PACKAGED

TERMINAL

AIR

CONDITIONERS

R-99

Models: ATE0743SPP, ATE0943SPP, ATE1243SPP, ATE1545SPP,

ATR0743SPP, ATR0943SPP, ATR1243SPP, ATR1545SPP

ATE0953SPP, ATE1253SPP,ATE1555SPP,

ATR0953SPP, ATR1253SPP,ATR1555SPP,

ATE0743RPP, ATE0943RPP, ATE1243RPP, ATE1545RPP,

ATR0743RPP, ATR0943RPP, ATR1243RPP, ATR1545RPP

JOB AID

Part No. 8178315

FORWARD

This Whirlpool Job Aid, “Packaged Terminal Air Conditioners” (Part No. 8178315), provides the

technician with information on the installation, operation, and service of the Packaged Terminal Air

Conditioners . It is to be used as a training Job Aid and Service Manual. For specific information

on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the

air conditioner.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Packaged Terminal Air Conditioners.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the air conditioner to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2004, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Whirlpool Model & Serial Number Designations ................................................................ 1-1

Model & Serial Number Label & Wiring Diagram Locations .............................................. 1-2

Specifications..................................................................................................................... 1-3

Whirlpool Packaged Terminal Air Conditioner (PTAC) And

Packaged Terminal Heat Pump (PTHP) Warranty ......................................................... 1-4

INSTALLATION INFORMATION ........................................................................................... 2-1

Electrical Requirements ..................................................................................................... 2-1

Drain Kit Installation ........................................................................................................... 2-2

Chassis Installation ............................................................................................................ 2-5

Remote Wall Thermostat Installation ................................................................................. 2-9

PRODUCT OPERATION ........................................................................................................ 3-1

Theory Of Operation .......................................................................................................... 3-1

Refrigeration Operation .................................................................................................. 3-1

Heat Pump Operation .................................................................................................... 3-3

Reversing Valve Operation ............................................................................................ 3-4

Remote Thermostat Operation....................................................................................... 3-5

Heat Pump Function ...................................................................................................... 3-7

Operating The Controls ..................................................................................................... 3-8

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Indoor Thermostat, Mode (System) Switch, And Heat Anticipator ............ 4-2

Removing The Power Supply Cord ................................................................................... 4-4

Removing The Defrost Thermostat.................................................................................... 4-5

Removing The Hot Start Relay And Hot Start Sensor ....................................................... 4-6

Removing The Capacitor & Fan Cycle Switch ................................................................... 4-7

Removing The Remote Control Unit Fan Switch ............................................................... 4-8

Removing The Heater & Limit Switch ................................................................................ 4-9

Removing The Fan Motor ................................................................................................ 4-10

Removing The Condensate Valve Bellows...................................................................... 4-13

Removing The Overload Protector And The Compressor ............................................... 4-14

Removing The Evaporator ............................................................................................... 4-16

Removing The Condenser ............................................................................................... 4-18

Removing The Solenoid Coil & Reversing Valve............................................................. 4-20

- iii -

COMPONENT TESTING ........................................................................................................ 5-1

Indoor Thermostat ............................................................................................................. 5-1

Mode (System) Switch ....................................................................................................... 5-2

Heat Anticipator ................................................................................................................. 5-2

Defrost Thermostat (Emergency Heat Switch) .................................................................. 5-3

Hot Start Relay .................................................................................................................. 5-4

Hot Start Sensor ................................................................................................................ 5-4

Capacitor ........................................................................................................................... 5-5

Fan Cycle Switch & Remote Control Unit Fan Switch ....................................................... 5-5

Heater & Limit Switch ........................................................................................................ 5-6

Fan Motor ......................................................................................................................... 5-6

Overload Protector............................................................................................................. 5-7

Compressor ....................................................................................................................... 5-7

Solenoid Coil...................................................................................................................... 5-8

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Diagnosing The Sealed System ........................................................................................ 6-1

Troubleshooting Charts ..................................................................................................... 6-7

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 7-1

Wiring Diagrams ................................................................................................................ 7-5

Strip Circuits .................................................................................................................... 7-10

TECH TIPS ............................................................................................................................. 8-1

Routine Maintenance ......................................................................................................... 8-1

Accessories ....................................................................................................................... 8-2

Optional Desk Control Unit ................................................................................................ 8-4

General Troubleshooting ................................................................................................... 8-5

- iv -

GENERAL

WHIRLPOOL MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER A T R 12 4 3 S P P 0

PRODUCT GROUP

A = AIR CONDITIONER

PRODUCT IDENTIFICATION

T = PTAC, WHIRLPOOL

MODEL TYPE

R = HEAT PUMP W/AUXILIARY HEAT

E = COOLING W/ELECTRIC HEAT

NOMINAL COOLING CAPACITY

07 = 7,000 BTU/HR

09 = 9,000 BTU/HR

12 = 12,000 BTU/HR

15 = 15,000 BTU/HR

ELECTRICAL CODE

4 = 208V-230V, 1 PHASE, 60 HZ

5 = 265V, 1 PHASE, 60 HZ

HEATER

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

FEATURE CODE OPTIONS

S = STANDARD ELECTROMECHANICAL

R = REMOTE WALL-MOUNTED THERMOSTAT

C = SEACOAST PROTECTION / STD. CONTROLS

B = REMOTE THERMOSTAT / SEACOAST PROTECTION

MANUFACTURING LOCATION

P = PURCHASED PRODUCT

YEAR OF INTRODUCTION

M = 2003, P = 2004, R = 2005, S = 2006, T = 2007

ENGINEERING CHANGE

0, 1, 2, ETC.

SERIAL NUMBER

SERIAL NUMBER QR P 05 21234

MANUFACTURING RESPONSIBILITY

QR = FRIEDRICH MANUFACTURING CO.

YEAR OF PRODUCTION

P = 2003, R = 2004

WEEK OF PRODUCTION

5TH WEEK

PRODUCT SEQUENCE NUMBER

1-1

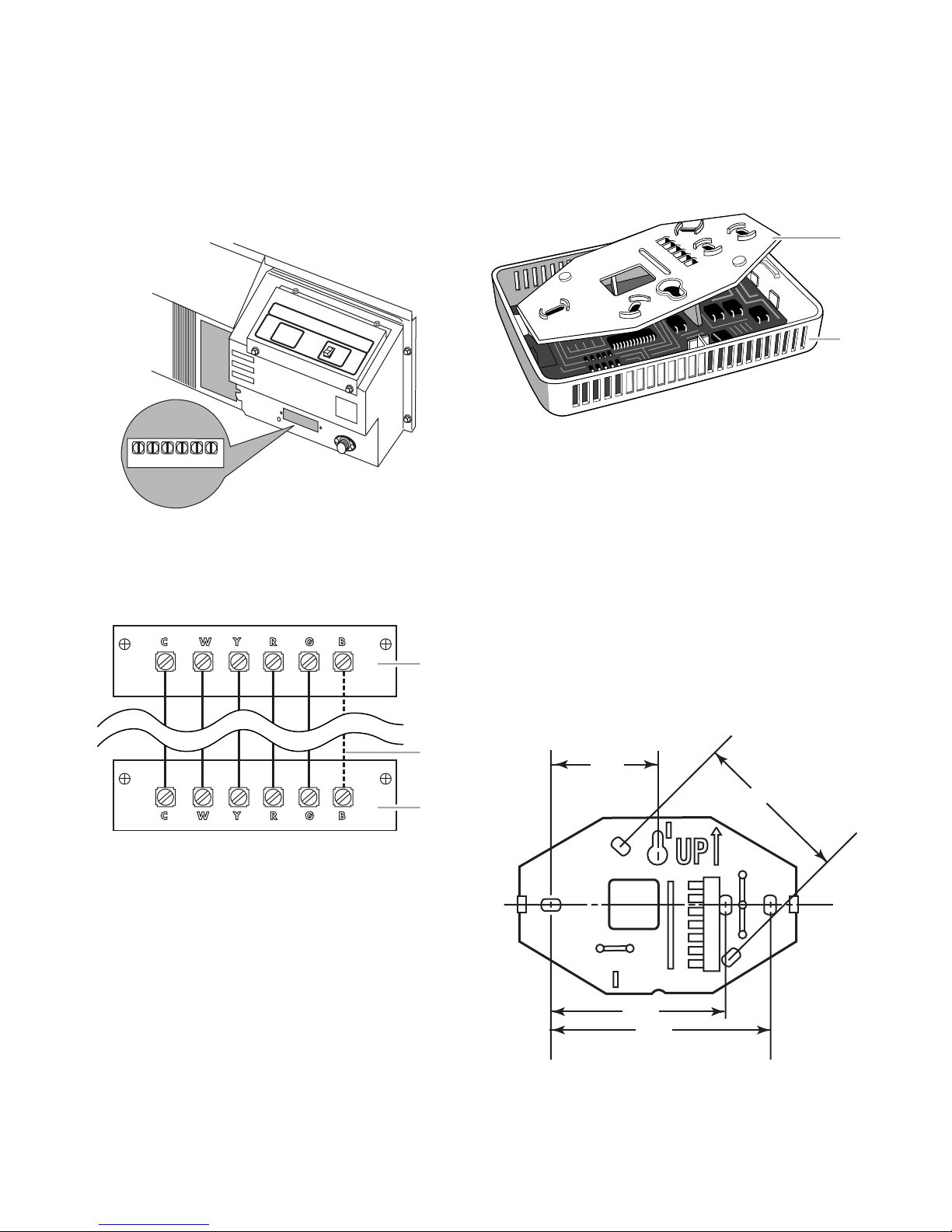

MODEL & SERIAL NUMBER LABEL &

WIRING DIAGRAM LOCATIONS

The Model/Serial Number label and Wiring Diagram locations are shown below.

Wiring Diagram Location

(Front Cover Removed)

Model & Serial

Number Location

1-2

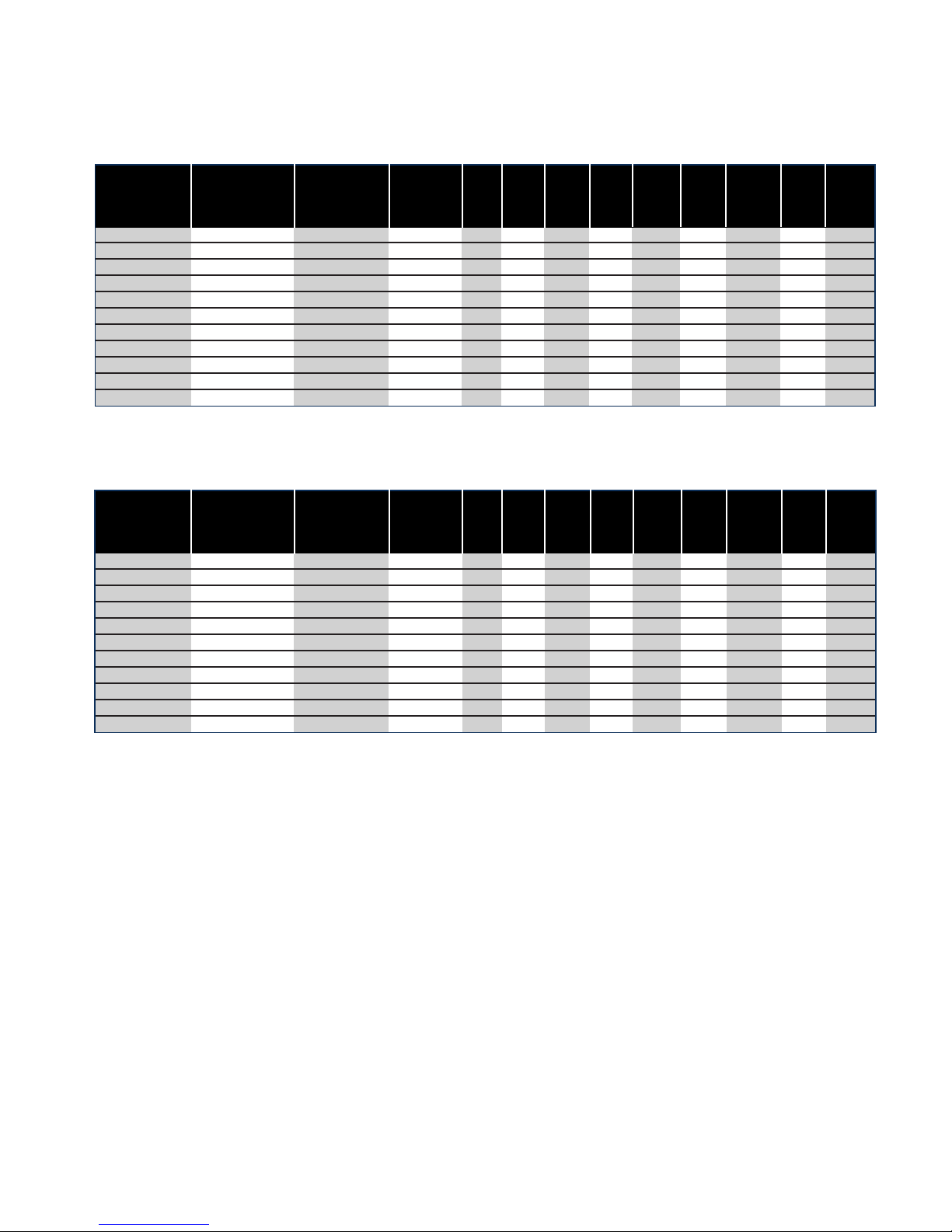

SPECIFICATIONS

ATE-SERIES PTAC W/ELECTRIC HEAT — COOLING PERFORMANCE

Whirlpool Model

ATE0743SPP Standard 7500/7000 11600 230 3.4 12.2 20 6-20 20 Amp 2.1 250 NA

ATE0943SPP Standard 9200/9000 11600 230 3.4 11.3 20 6-20 20 Amp 2.7 300 NA

ATE1243SPP Standard 12000/12000 11600 230 3.4 10.7 20 6-20 20 Amp 3.8 325 NA

ATE1545SPP Standard 15000-15000 17000 230 5.0 9.5 30 6-30 30 Amp 5.5 350 NA

ATE0953SPP Standard 9200/9000 11600 265 3.4 11.3 20 6-20 20 Amp 2.7 300 NA

ATE1253SPP Standard 12000/12000 11600 265 3.4 10.7 20 6-20 20 Amp 3.8 325 NA

ATE1555SPP Remote 15000/15000 17000 265 5.0 9.5 30 6-20 30 Amp 3.5 350 NA

ATE0743RPP Remote 7500/75000 11600 230 3.4 12.2 20 6-20 20 Amp 2.1 250 NA

ATE0943RPP Remote 9200/9000 11600 230 3.4 11.3 20 6-20 20 Amp 2.7 300 NA

ATE1243RPP Remote 12000/12000 11600 230 3.4 10.7 20 6-20 20 Amp 3.8 325 NA

ATE1545RPP Remote 15000-15000 17000 230 5.0 9.5 30 6-30 30 Amp 5.5 350 NA

Control

Type

Cooling BTU

230/208v

Heating

BTU

Electric

Volts

Heater

KW

EER

Breaker

Amps-

NEMA

Plug

Type*

Plug

Dehum-

Pts/Hr

CFM COP

ATR-SERIES PTHP W/HEATING — COOLING PERFORMANCE

Whirlpool Model

ATR0743SPP Standard 7200/7000 11600 230 3.4 12.1 20 6-20 20 Amp 2.1 250 3.3

ATR0943SPP Standard 9100/9000 11600 230 3.4 10.5 20 6-20 20 Amp 2.1 250 3.3

ATR1243SPP Standard 12000/12000 11600 230 3.4 10.5 20 6-20 20 Amp 2.1 250 3.3

ATR1545SPP Standard 15000/14700 17000 230 5.0 9.3 30 6-30 30 Amp 5.5 350 2.8

ATR0953SPP Standard 9100/9000 11600 265 3.4 11.3 20 6-20 20 Amp 3.8 325 3.1

ATR1253SPP Standard 12000/12000 11600 265 3.4 10.5 20 6-20 20 Amp 3.8 325 3.1

ATR1555SPP Standard 15000/14700 17000 265 5.0 9.3 30 6-30 30 Amp 5.5 350 2.8

ATR0743RPP Remote 7200/7200 11600 230 3.4 12.1 20 6-20 20 Amp 2.1 250 3.3

ATR0943RPP Remote 9100/9000 11600 230 3.4 11.3 20 6-20 20 Amp 2.1 250 3.3

ATR1243RPP Remote 12000/12000 11600 230 3.4 10.5 20 6-20 20 Amp 3.8 325 3.1

ATR1545RPP Remote 15000/14700 17000 230 5.0 9.3 30 6-30 30 Amp 5.5 350 2.8

Control

Type

Cooling BTU

230/208v

Heating

BTU

Electric

Volts

Heater

KW

EER

Breaker

Amps-

NEMA

Plug

Type*

Plug

Dehum-

Pts/Hr

CFM COP

* 15 Amps available on special order models

CFM = Cubic Feet per Minute

COP = Coefficient Of Performance (applies to PTHP only)

1-3

WHIRLPOOL PACKAGED TERMINAL

AIR CONDITIONER (PTAC) AND PACKAGED

TERMINAL HEAT PUMP (PTHP) WARRANTY

LENGTH OF WARRANTY:

ONE YEAR FULL WARRANTY

FIVE YEAR FULL WARRANTY

SECOND THROUGH FIFTH YEAR

LIMITED WARRANTY

WHIRLPOOL WILL PAY FOR:

For one year from the date of installation, if this PTAC/PTHP fails

when operated and maintained according to instructions attached

to or furnished with the product, Whirlpool Corporation will pay for

replacement parts and repair labor to correct defects in materials

or workmanship. Service must be provided by a Whirlpool designated service company.

For five years from the date of purchase, if this PTAC/PTHP fails

when operated and maintained according to instructions attached

to or furnished with the product, Whirlpool Corporation will pay for

replacement parts and repair labor to correct defects in materials

or workmanship in the sealed refrigeration system, including the

compressor, evaporator, condenser, reversing valve and connecting tubing. Service must be provided by a Whirlpool designated

service company.

For the second through fifth year from the date of purchase, if this

PTAC/PTHP fails when operated and maintained according to instructions attached to or furnished with the product, Whirlpool Corporation will pay for replacement parts to correct defects in materials or workmanship in the electrical or air flow systems including

the fan motor, capacitor, fan, blower wheel, switches, thermostat,

relays, frost controls, heat control, heater, heater protectors, compressor overload, solenoids, auxiliary controls, and transformer.

This is a limited parts-only warranty and does not include labor or

transportation to and from the service shop. Service must be provided by a Whirlpool designated service company.

WHIRLPOOL WILL NOT PAY FOR:

1. Service calls to correct the installation of the PTAC/PTHP, instruct you how to use the PTAC/PTHP, to replace

fuses, correct wiring, reset circuit breakers, or to clean or replace owner accessible air filters.

2. Damage resulting from accident, alteration, misuse, abuse, fire, floods, acts of God, improper installation not

in accordance with local electrical and plumbing codes, or use of products not approved by Whirlpool

Corporation, or Whirlpool Canada, Inc.

3. Replacement parts or repair labor costs for units operated outside the United States or Canada.

4. Pickup and delivery, or any transportation and reinstallation charges that may be required.

5. The removal and reinstallation of the PTAC/PTHP.

6. Repairs to parts or systems resulting from unauthorized modifications made to the PTAC/PTHP.

WHIRLPOOL CORPORATION AND WHIRLPOOL CANADA, INC. SHALL NOT BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights and you may also have other

rights which vary from state to state or province to province.

Outside the United States and Canada, a different warranty may apply. For details, please contact your

Whirlpool authorized dealer.

If you need service, first see "Troubleshooting" section of the Installation/Operation Manual. After checking

“Troubleshooting,” additional help can be found by checking the “Assistance or Service” section, or by calling the

Whirlpool Corporation Customer Interaction Center at 1-800-253-1301 (toll-free), from anywhere in the United

States. In Canada, please call 1-800-807-6777.

1-4

INSTALLATION INFORMATION

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

IMPORTANT: Connect PTAC/PTHP to a

single-outlet circuit only.

230/208 VOLT PTAC/PTHP

All 230/208 volt PTAC/PTHPs are equipped

with power cords.

230/208 volt 250 volt Receptacles and

PTAC/PTHP Overcurrent Protection

AMPS 15 20 30

RECEPTACLE

Electrical Shock Hazard

Electrically ground PTAC/PTHP.

Connect ground wire to green pigtail lead.

Use copper wire for supply connection.

Correct wire gauge is shown in the chart

below.

Failure to follow these instructions can

result in death or electrical shock.

Rating Plate Ampacity AWG

Less than 15 14

16 - 20 12

21 - 30 10

265 VOLT PTAC/PTHP

All 265 volt PTAC/PTHPs are equipped with

pigtail leads for field wiring.

IMPORTANT:

NEMA Type 6-15R 6-20R 6-30R

The field-supplied outlet must match plug on

service cord and be within reach of service

cord.

• Use copper conductors only.

• Wire sizes are per NEC.

• Use on individual branch circuit only.

• Use overcurrent protection indicated on

PTAC/PTHP’s rating plate.

• PTAC/PTHP must be grounded to branch

circuit.

• Check local codes.

2-1

DRAIN KIT INSTALLATION

LOCATION REQUIREMENTS

• Unpack and dispose of packaging materials.

• The drain kit accessory contains 10 complete drain kits.

• Locate the drain kit in the primary area for

best drainage. Maintain at least 1/2″ (1.27

cm) distance from the embossed area. If the

primary area cannot be used, locate the

drain kit in the secondary area and cut away

the foam insulation to allow access to the

drain. Do not locate the drain kit within 3″ (7.6

cm) of the indoor side of the sleeve.

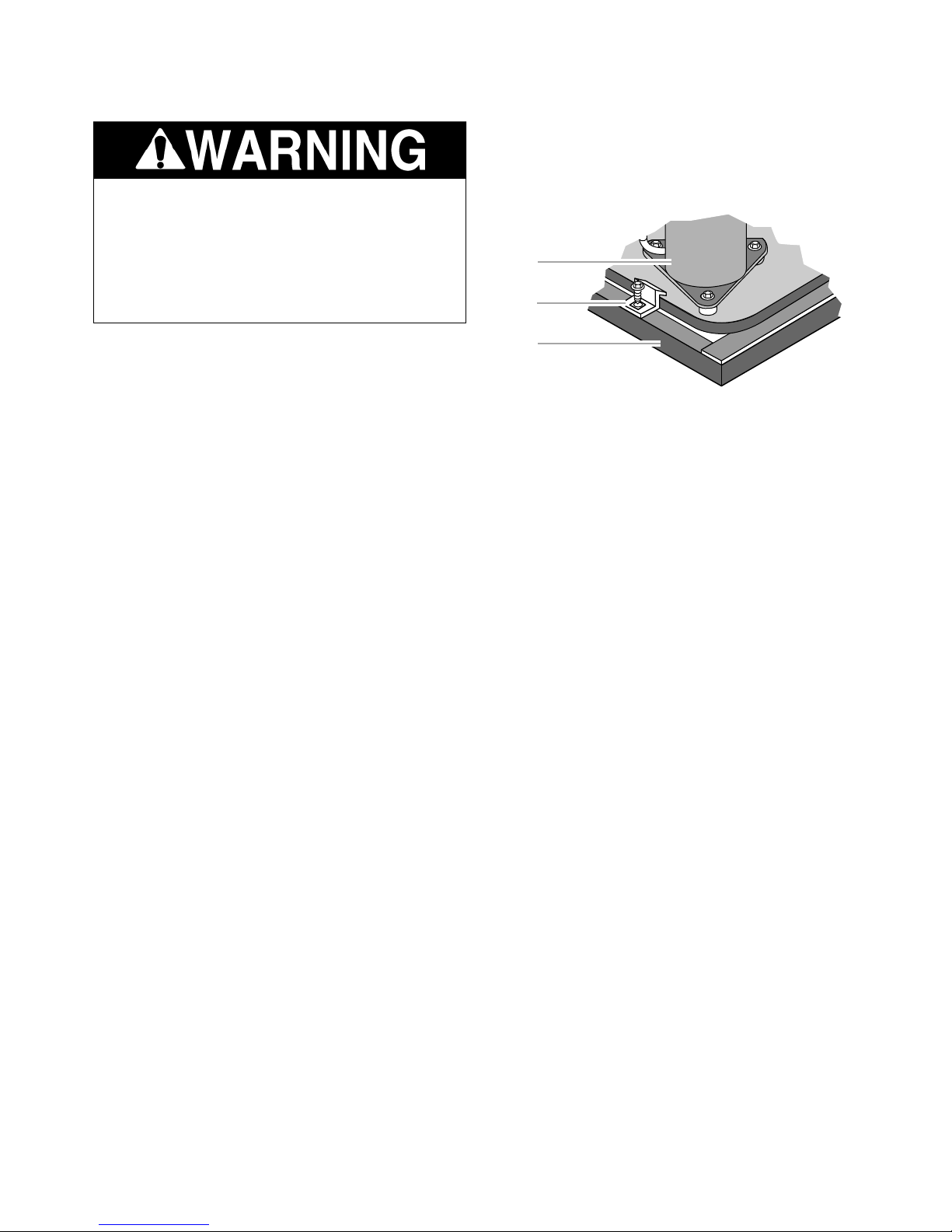

1

2

3

1. Secondary area

2. Primary area - no foam insulation

3. If the drain must be located in the secondary area,

the foam insulation must be cut away and removed

to allow access to the drain.

4. Embossed area

4

3"

(7.6 cm)

NOTES:

Determine whether the drain will be located

on the exterior of the wall, internally in the wall

cavity or internally in the room.

Internal Drain

• Drain kit located inside the room will allow

condensate to drain to a field drain located

inside the room.

• Drain kit located inside the wall cavity will

allow condensate to drain to a field drain

located inside the wall cavity.

External Drain

• Drain kit located outside will allow condensate to drain to a field drain located outside

or to drain away from the wall sleeve.

• When using an external drain system, select

the drain hole on the back of the wall sleeve

which best meets your drainage situation.

• The cover plate and external drain tube

assembly may be placed on either side of the

wall sleeve.

2-2

INTERNAL DRAIN INSTALLATION

(Located Inside The Wall Cavity Or

In The Interior Of The Room)

NOTE: If installing an internal drain, install drain

kit on the wall sleeve before the wall sleeve is

installed.

1. Using the mounting plate from the drain kit

as a template, mark and drill two 3/16″

mounting holes and a 1/2″ drain hole at the

location chosen above.

2. Remove the backing from the gasket and

mount it on the flat side of the mounting

plate. Insert the drain tube through the

hole in the gasket and mounting plate so

the tube flange will be against the wall

sleeve.

1

2

3

4

5

6

3. Position the assembly beneath the drilled

holes and secure it with #10 - 24 x 1/2″

machine screws and locknuts (provided).

Seal the tops of the screws with silicone

sealant.

4. Connect the drain tube to the drain system

in the building.

IMPORTANT: Follow all local building

codes when making this connection.

5. Attach the 2 cover plates and gaskets over

the drain holes at the rear of the wall

sleeve with #10 sheet metal screws (provided).

NOTE: Check that the 4 overflow slots at

the rear of the wall sleeve are not blocked.

1

3

4

5

1. Screw

2. Wall sleeve

3. Gasket

4. Mounting p late

5. Nut

6. Drain tube

7. Optional 4 in. (10.2 cm)

straight drain tube

1

2

1. Drain holes

2. Overflow slots

3. Gasket

4. Cover plate

5. #10 sheet metal screws

2-3

EXTERNAL DRAIN INSTALLATION

(Located On The Exterior

Of The Wall)

1. Peel the backing tape from the gaskets

and mount them on the curved side of one

cover plate and one mounting plate.

2. Place the drain tube through the gasket

and the mounting plate with the flange

toward the wall sleeve.

3. Using 2 - #10 x 1/2″ sheet metal screws

(provided), attach the drain tube assembly

to one of the 2 drain holes at the rear of the

wall sleeve.

Position the large flange at the bottom of

the sleeve facing toward the sleeve, and

partially tighten the screws. Rotate the

drain tube to a horizontal position to allow

for the wall sleeve to be installed into the

wall. Once the wall sleeve is installed,

position the drain tube to the desired angle.

Before tightening the screws, check to be

sure the tube’s position will allow the wall

sleeve to fit through the wall. Tighten screws.

1

3

8

1

2

3

4

1. Drain holes

2. Overflow slots

3. Foam gasket

4. Mounting plate

5. #10 x 1/2 in. sheet metal screws

6. 1/2 in. O.D. tube

7.

Optional 4 in. (10.2 cm) straight drain tube

Cover plate (no center hole)

8.

7

6

5

4. Using 2 - #10 x 1/2″ sheet metal screws

(provided), attach the cover plate to the

remaining drain hole. Check that the large

flange on the plate is positioned at the

bottom of the sleeve.

NOTE: Check that the 4 overflow slots at

the rear of the wall

5. Discard any unused kit parts.

2-4

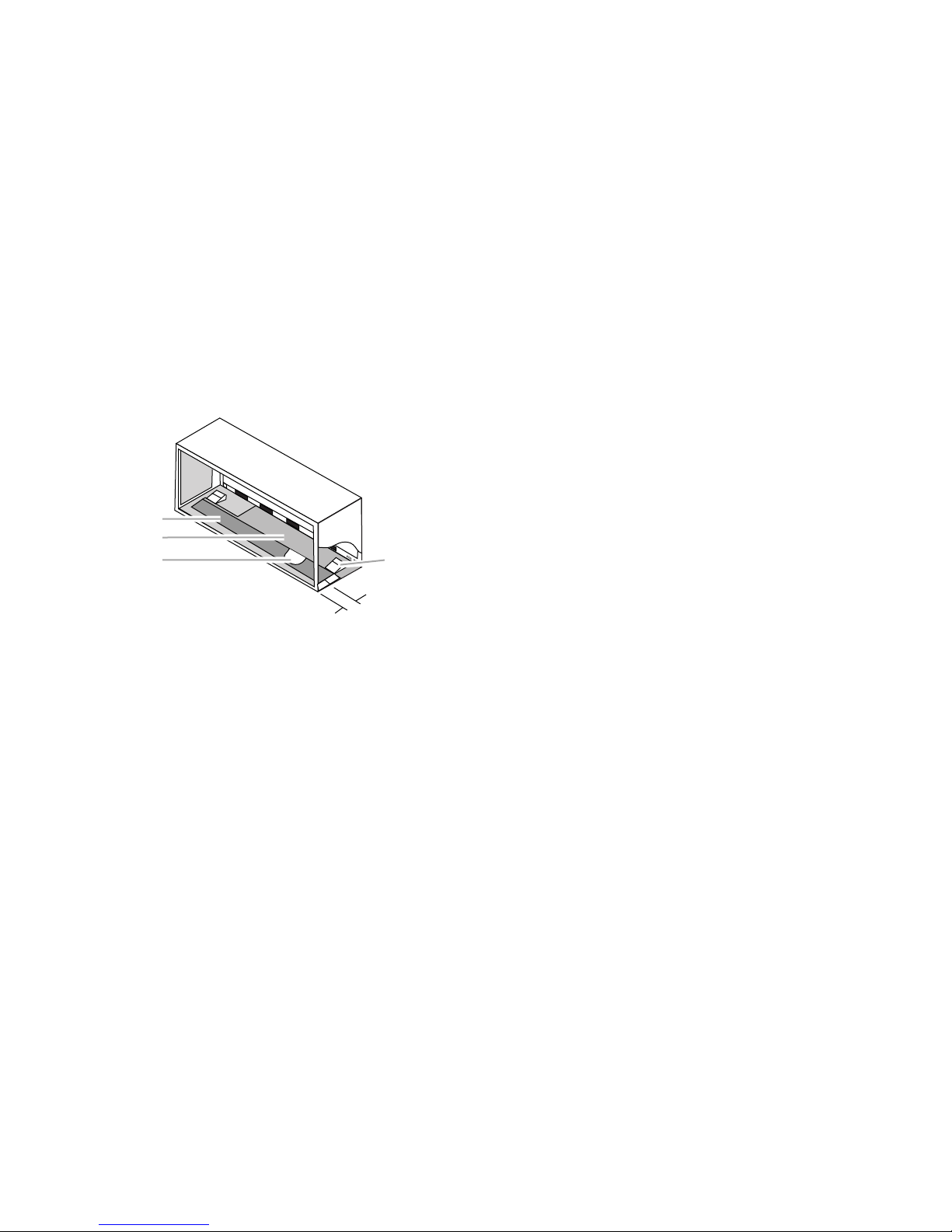

CHASSIS INSTALLATION

Excessive Weight Hazard

Use two or more people to move and

install PTAC/PTHP.

Failure to do so can result in back or other

injury.

1. Remove banding and carton.

2. Remove the 2 chassis shipping brackets

from the ends of the shipping pallet.

1

2

NOTES:

• Check to be sure wall sleeve, wall sleeve

extension (if used), wall sleeve adapter (if

used), rear grille, and drain kit are properly

installed before chassis installation.

• Locate PTAC/PTHP near the location it will

be installed.

IMPORTANT: Copper refrigerant tubes are not

handles. Product damage will occur if tubes

are used to lift or move the chassis.

3

1. Compressor

2. Chassis shipping bracket

3. Shipping pallet

3. Remove the front cover, which is contained in a protective plastic bag, from

chassis.

4. Dispose of all shipping and packaging material.

2-5

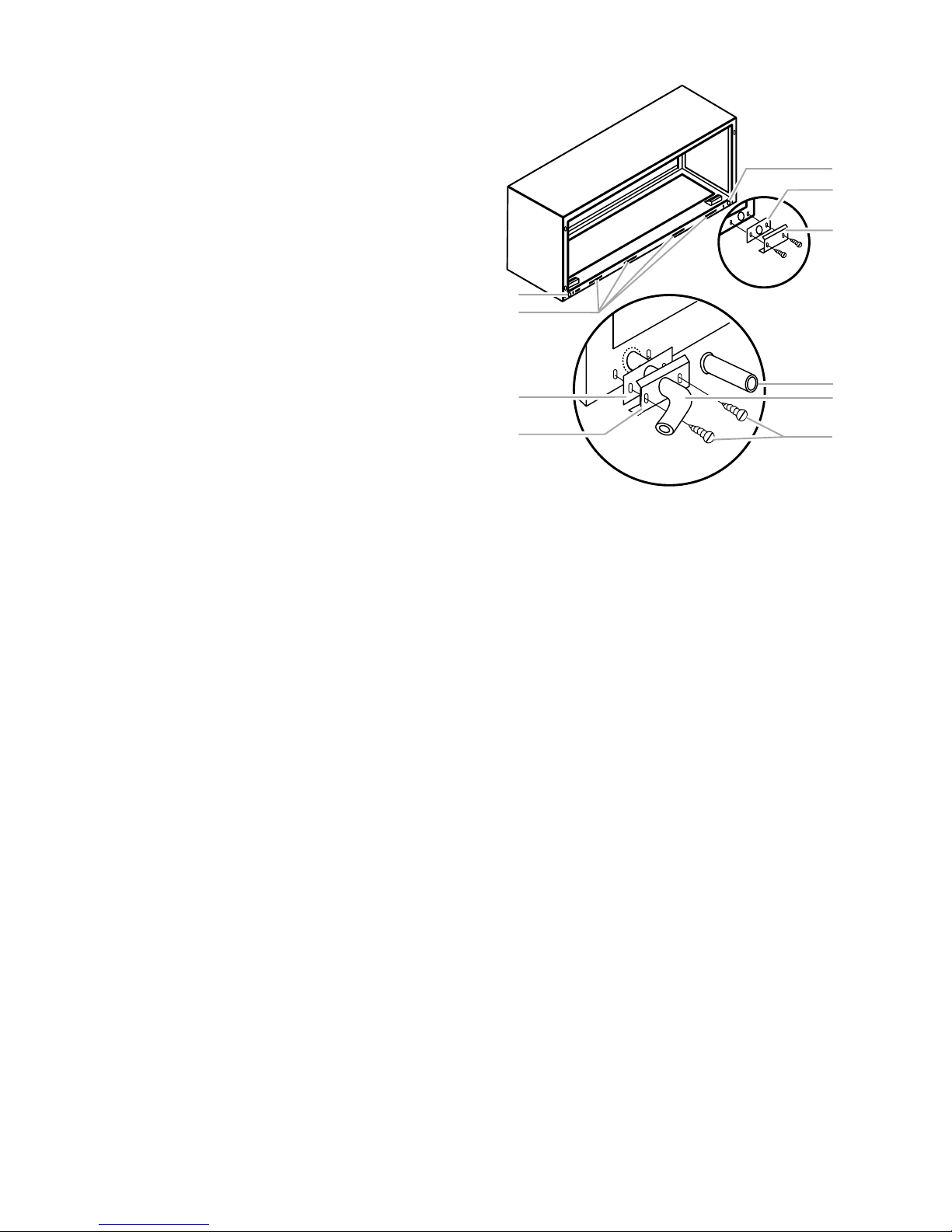

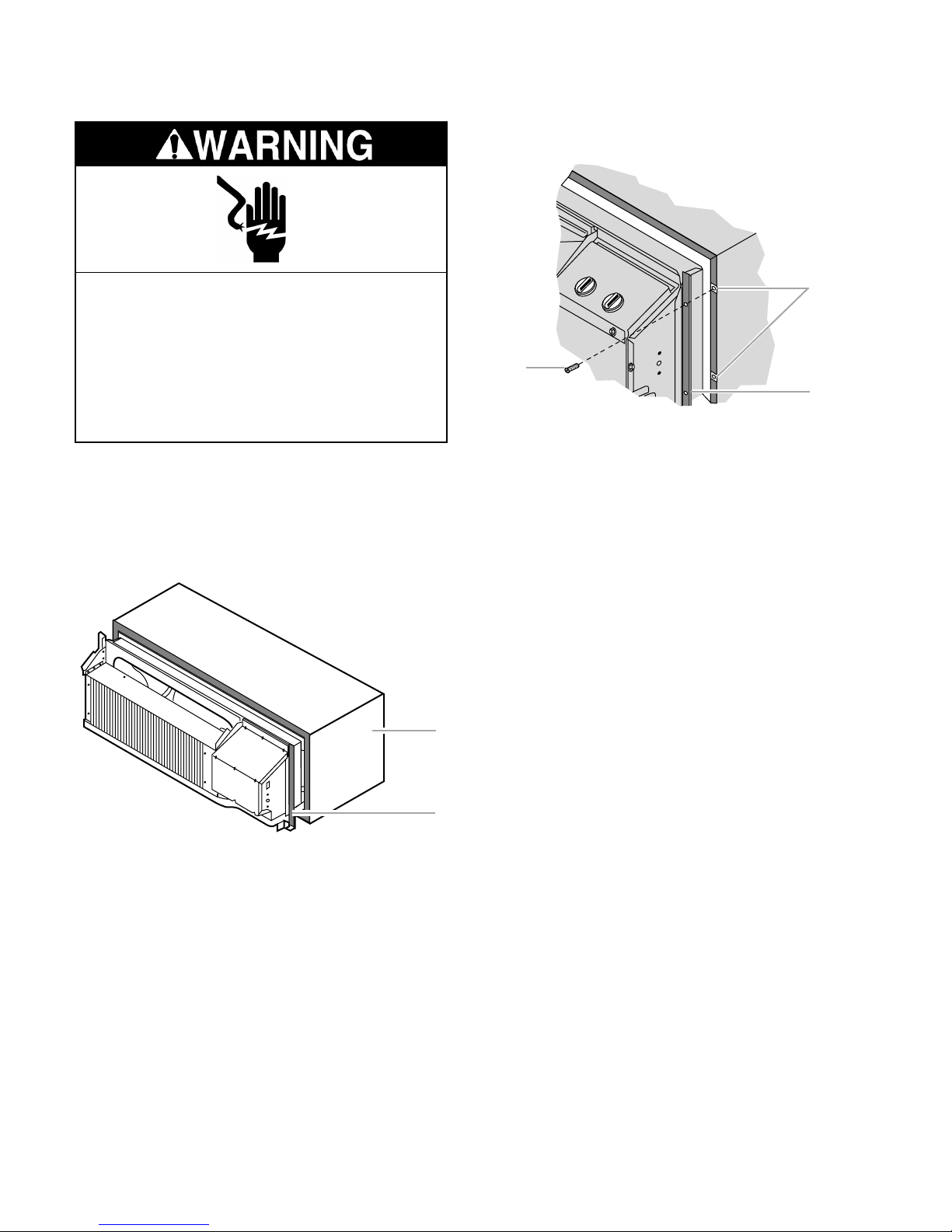

INSTALL THE CHASSIS

3. Locate the 4 - #10 x 1″ chassis mounting

screws (provided). Tighten the screws into

the wall sleeve screw clips.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Disconnect power.

2. Center the chassis in the installed sleeve

and carefully push the chassis until the

chassis flange and gasket contact the

sleeve flange.

2

1

3

1. Chassis mounting screw

2. Screw clips

3. Chassis flange

4. Install the front cover by placing the top of

the front cover onto the metal flange at the

top of the chassis. Rotate the front cover

into place. Insert the thumbscrews (provided) into the slots located at the bottom

back corners of the front cover. Tighten to

secure the cover.

NOTE: If the unit has been placed in such

a way that there is no room to insert the

thumbscrews from the bottom, a side

mounting kit may be used.

1

MAKE ELECTRICAL CONNECTIONS

1. Wall sleeve

2. Chassis flange and gasket

2

IMPORTANT: The installation of field wiring

must conform to the requirements of the National Electrical Code, ANSI/NFPA NO. 70 (latest edition) in the United States, and any state

laws and local ordinances (including plumbing

or wastewater codes). In Canada, field wiring

must conform to the Canadian electrical code

PART I, CSA STANDARD C22.1-1993 or current edition. Local authorities having jurisdiction should be consulted before installation is

made. Such applicable regulations or requirements take precedence over the general instructions in this Job Aid.

2-6

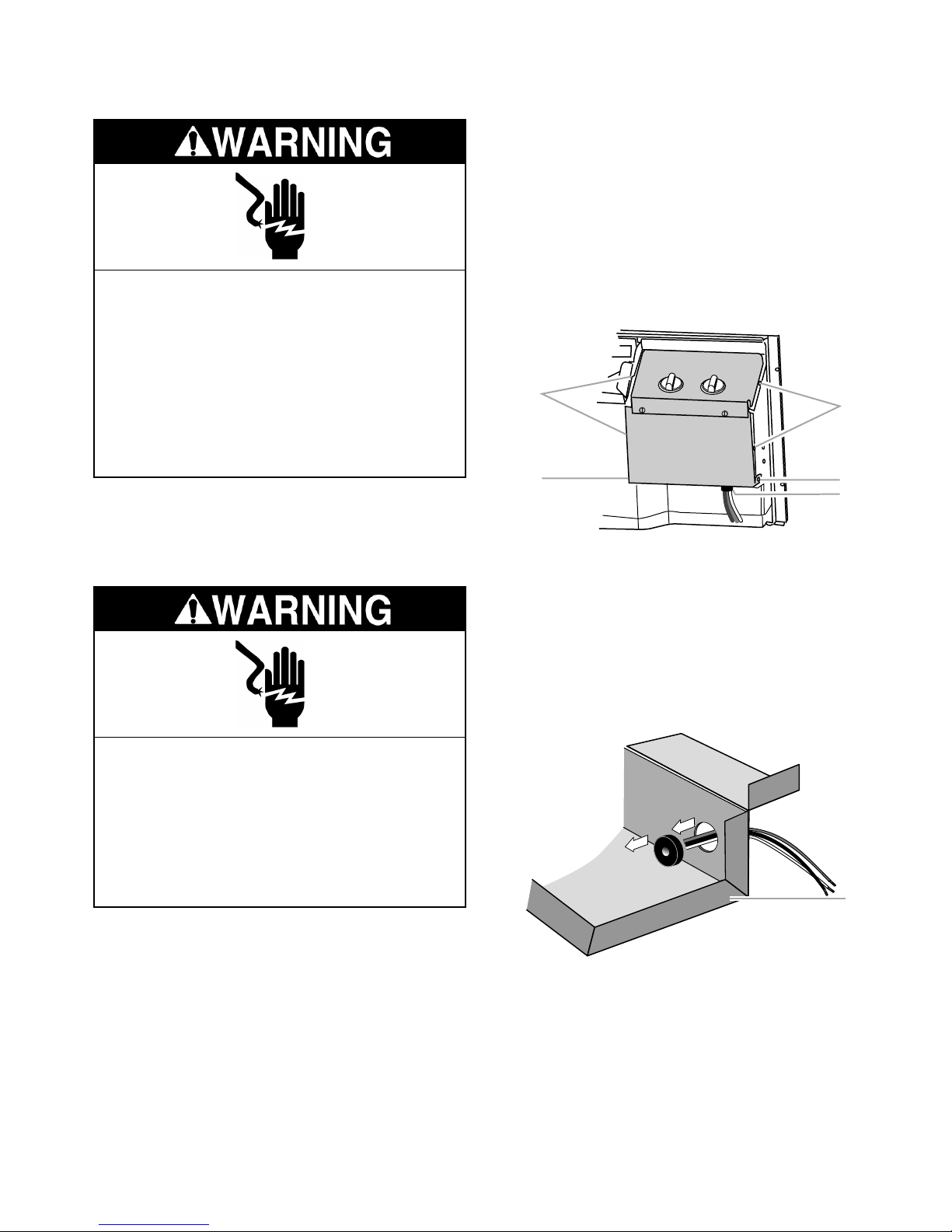

Cord Connected Models

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

FIELD WIRING CONNECTIONS

1. Disconnect power.

2. Remove the PTAC/PTHP front cover using the thumbscrews.

3. Route the incoming power supply through

suitable conduit to the PTAC/PTHP control box.

4. Remove the 4 screws holding the control

box.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

2. Reconnect power.

Direct Wired Models

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1

2

1. Remove these screws.

2. Do not remove these screws.

3. Bushing

1

2

3

5. Pivot the control box down, pull the chassis pigtail wires into the control box, and

remove the bushing from the hole. The

field-supplied wires will be routed through

this hole.

1

2

Field wiring connections for direct-wired models can be done in one of 2 ways:

• Using field-supplied conduit and wires.

• Using the Conduit with Junction Box Kit

accessory.

1. Bushing

2. Control box

2-7

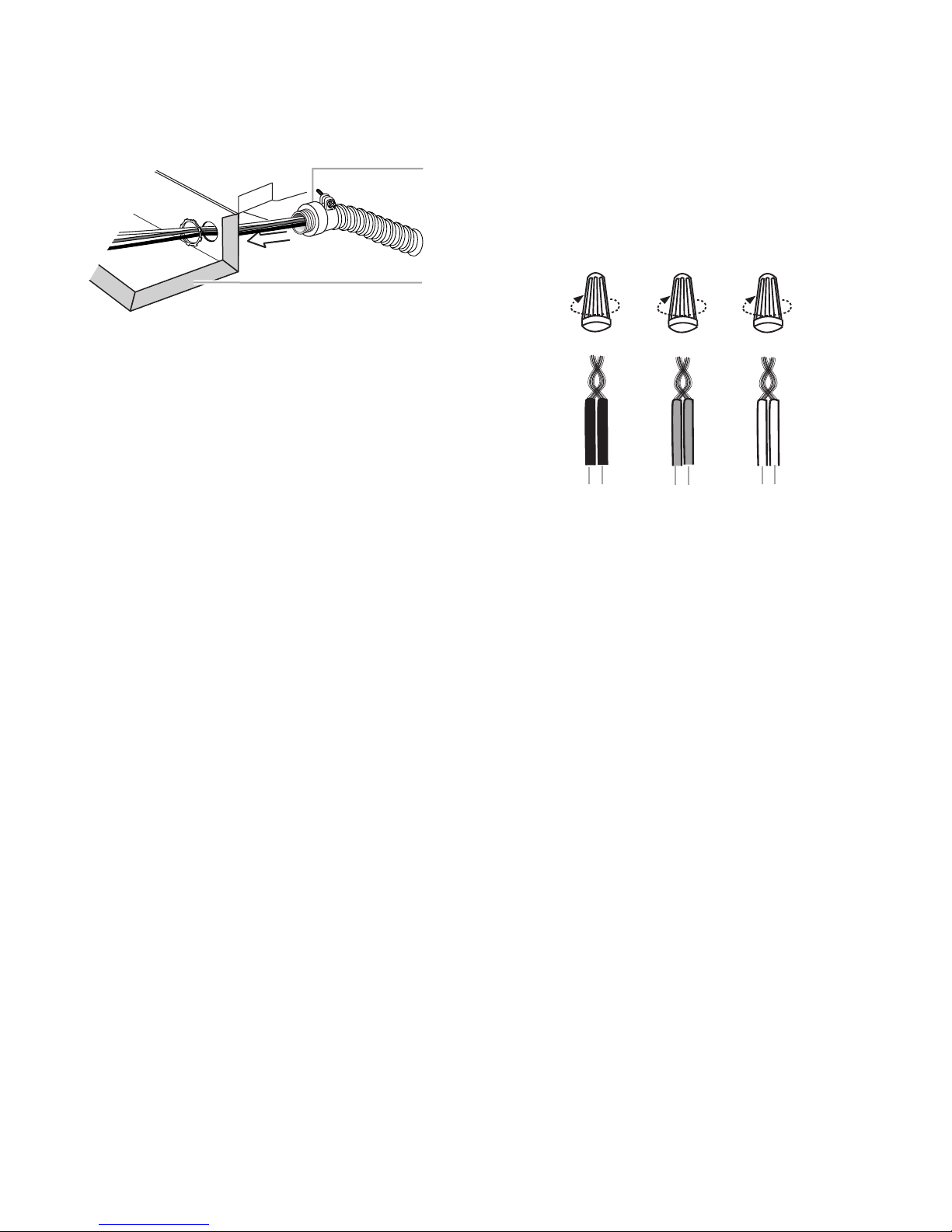

6. Install field-supplied conduit into the same

)

hole as the original bushing for the chassis

pigtail wires on the control box.

1

2

1. Field-supplied co nduit

2. Control box

7. Connect the chassis pigtail wires to the

incoming power supply wires using the UL

listed wire nuts (provided). Connect the

black wire to the incoming L1 (black) wire.

Connect the white wire to the incoming

neutral (white) wire. Connect the green

wire to the incoming ground (green or

bare) wire.

12 3

1. Black wire

2. Incoming L1 wire (black wire)

3. Green wire

4

4. Ground wire (green or bare wire

5. White wire

6. Neutral wire (white wire)

56

8. Reattach the PTAC/PTHP control panel

using the 4 screws removed earlier.

9. Reattach the PTAC/PTHP front cover using the thumbscrews removed earlier.

10. Reconnect power.

2-8

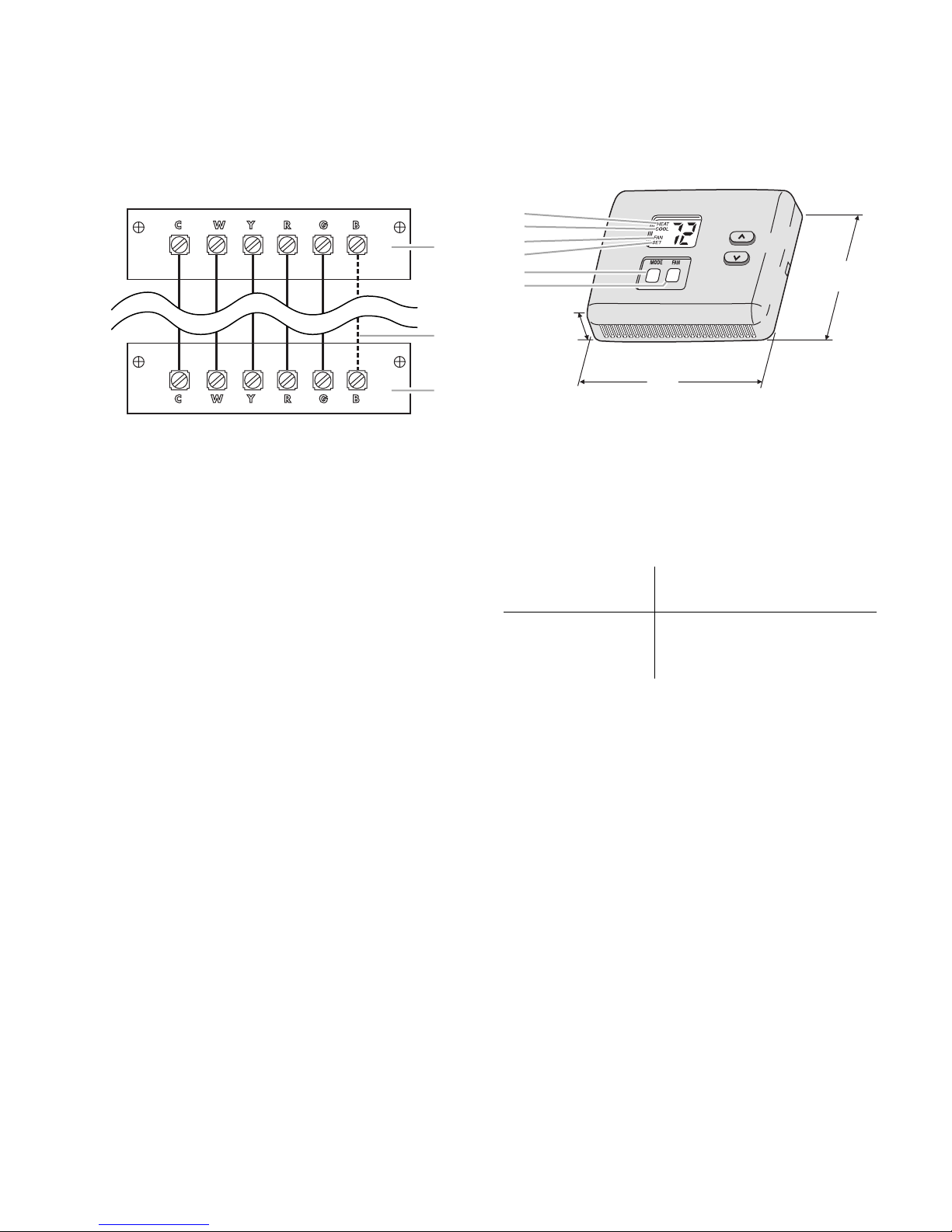

REMOTE WALL THERMOSTAT INSTALLATION

INSTALLATION REQUIREMENTS

• Unpack and dispose of packaging materials.

• This thermostat is a wall mounted, low-voltage thermostat that maintains room temperature by controlling the operation of the

PTAC/PTHP. Batteries are not required—

temperature and mode settings are preserved with the power off.

• This is not a 2-stage heat pump thermostat

with emergency heat selection. The PTAC/

PTHP turns on the electric heat automatically based on the outdoor coil temperature,

which is influenced by the outdoor temperature and humidity conditions.

• Chassis must be installed before installing

remote thermostat.

IMPORTANT: Improper wiring or installation

may cause the thermostat not to function. Wiring must conform to local and national electrical codes.

LOCATION REQUIREMENTS

For best performance, thermostat should be

mounted:

• Approximately 5 ft (152.4 cm) from floor.

• Close to or in the room with the PTAC/PTHP,

preferably on an inside partitioning wall.

• On a section of wall without pipes or duct

work.

For best performance, do not mount thermostat:

• Close to a window, on an outside wall, or

next to a door leading to the outside.

• Exposed to direct light and heat from a lamp,

the sun, a fireplace, or other heat source.

This may cause a false reading.

• Close to or in direct airflow from the PTAC/

PTHP.

• In areas with poor air circulation (behind a

door or in an alcove).

Wall Thermostat Terminal Designation

Terminal Letter Operation Contact Made

Y Cooling During call for

cooling.

W Heating During call for heat-

ing.

G Fan Continuous if the

slider is in the “Fan”

position; otherwise,

on call for cooling or

heating.

C (common) Common Constant

Terminal

R 24 V to the Constant (directly

thermostat from the transformer)

B (Heat Pump Reversing Made continuously

units Only) Valve when the mode

switch is in heating.

INSTALL THE REMOTE WALL

THERMOSTAT

Replacing Existing Thermostat

1. Disconnect power to avoid product dam-

age during removal of existing thermostat.

2. Disconnect wires from existing thermo-

stat, one at a time. Do not allow wires to fall

back into the wall.

3. As each wire is disconnected, record wire

color and terminal marking.

4. Remove existing thermostat from wall.

5. See “Installing The New Thermostat.”

IMPORTANT: Mercury is a hazardous waste

and must be disposed of properly. Contact the

Thermostat Recycling Corporation at

www.nema.org/trc for further information, or

contact your local waste management authorities.

2-9

Installing The New Thermostat

1.587

2.375

2.625

3.275

1. Disconnect power to avoid product damage during installation of new thermostat.

2. Remove the PTAC/PTHP front cover.

3. Locate the terminal strip on the front of the

control box.

Remote Control UnitRemote Control Unit

5. Route the 24 volt thermostat wire alongside the conduit or service cord to the

location chosen for the thermostat.

6. Separate the front housing and back plate

of the thermostat.

1

OFF

ON

CWY RG B

4. Connect the field supplied 5 or 6 conductor, NEC Class 2, 24 volt thermostat wire

to the terminals in accordance with the

wiring diagram.

1

2

2

1. Back plate

2. Front housing

7. Route thermostat wires through hole in

back plate. Level back plate against wall

(for aesthetic value only—thermostat need

not be leveled for proper operation) and

mark wall through any 2 of the 6 available

mounting holes.

8. Drill two 3/18″ mounting holes in wall where

marked.

Optional Mounting Method: Mounting holes

on thermostat are designed to fit on a

horizontally-mounted junction box.

1. Typical PTAC/PTHP unit

2. Used for PTHP only

3. Wall thermostat

3

2-10

9. Secure back plate to wall with 2 anchors

and screws (provided) making sure all

wires extend through hole in back plate.

10. Connect wires to proper terminals of the

thermostat connector block.

1

2

14. Reconnect power.

NOTE: On power up, the LCD readout will display “oP” momentarily, and then the room temperature.

1

2

3

4

5

6

(20.3 mm)

0.8"

3.30"

(83.8 mm)

3

1. Typical PTAC/PTHP unit

2. Used for PTHP only

3. Wall thermostat

11. Push any excess wire back into wall. Excess wire inside the thermostat housing

can interfere with proper airflow across

the temperature sensor. Seal hole in wall

to prevent air leaks. Air leaks can affect

operation.

12. Install thermostat housing on back plate.

13. Reattach the PTAC/PTHP front cover.

4.55"

(115.6 mm)

1. Heat display

2. Cool display

3. Fan display

4. Set display

5. Mode button

6. Fan button

WHIRLPOOL DIGITAL

THERMOSTAT OPERATION

Error Messages

E4 Internal memory failure.

Replace thermostat.

- - (two dashes) Cannot read room temperature. Replace

thermostat.

Random Restart Feature

After a power outage, the Whirlpool digital thermostat will wait between 3 and 5 minutes before allowing the unit to restart. This is to keep

multiple units from restarting at the same time

when power is restored, thus preventing a circuit overload.

2-11

— NOTES —

2-12

PRODUCT OPERATION

THEORY OF OPERATION

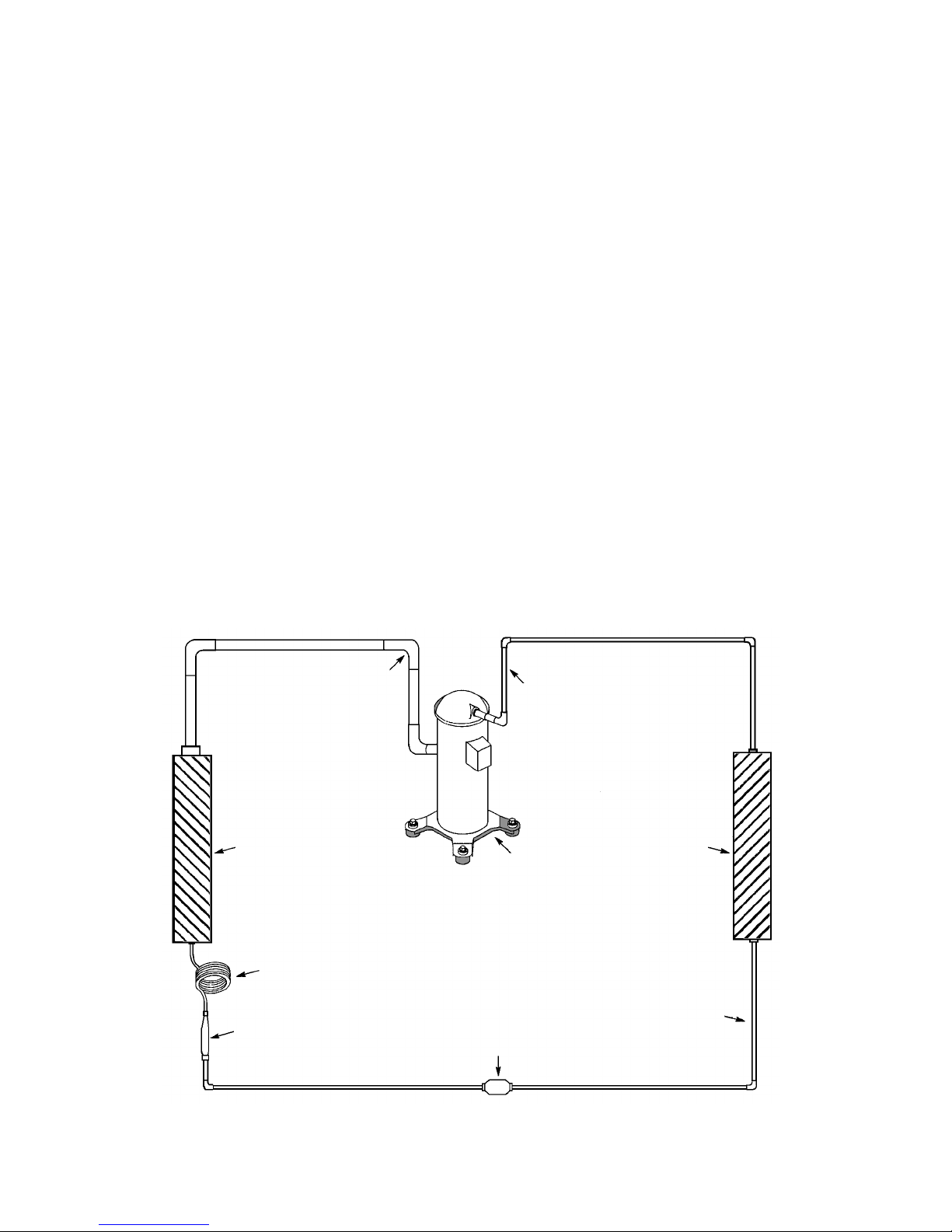

Refrigeration Operation

The refrigeration system uses the following

four basic principles in its operation:

1. Heat always flows from a warmer body to

a cooler body.

2. Heat must be added to or removed from a

substance before a change in state can

occur.

3. Flow is always from a higher pressure

area to a lower pressure area.

4. The temperature at which a liquid or gas

changes state is dependent upon the pressure.

The refrigeration cycle begins at the compressor. Starting the compressor creates a low

pressure in the suction line which draws refrigerant gas (vapor) into the compressor. The

compressor then “compresses” this refrigerant, raising its pressure, and its temperature.

The refrigerant leaves the compressor through

the discharge line as a hot, high pressure gas.

The refrigerant enters the condenser coil where

it gives up some of its heat. The condenser fan

moves air across the finned surface of the

condenser coil, and facilitates the transfer of

heat from the refrigerant to the relatively cooler

outdoor air.

When a sufficient quantity of heat has been

removed from the refrigerant gas, the refrigerant will “condense” (change to a liquid). Once

the refrigerant has been condensed to a liquid,

it is further cooled by the air flowing across the

condenser coil.

The Packaged Terminal Air Conditioner (PTAC)

design determines at exactly what point (in the

condenser) the change of state (gas to liquid)

takes place. In all cases, however, the refrigerant must be totally evaporated (changed to a

gas) before leaving the evaporator coil.

Suction Line

Evaporator Coil

Capillary Tube

(Metering)

Refrigerant

Strainer

Discharge Line

Condenser Coil

Compressor

Liquid Line

Filter/Drier

3-1

The refrigerant leaves the condenser coil as a

warm high pressure liquid. It then passes

through the filter/drier (if so equipped). It is the

function of the filter/drier to trap any moisture,

contaminants, and large particulate matter

present in the sealed system.

The liquid refrigerant next enters a metering

device called a “capillary tube” whose purpose

is to “meter” (control or measure) the quantity

of refrigerant entering the evaporator coil.

Since the blower is moving indoor air across

the finned surface of the evaporator coil, the

expanding refrigerant absorbs some of the

heat. This results in a lowering of the indoor air

temperature, hence the “cooling” effect.

The expansion and absorption of heat causes

the liquid refrigerant to evaporate, and change

back to a gas. Once the refrigerant has been

evaporated, it is further heated by the air that

continues to flow across the evaporator coil.

In the capillary tube, this is accomplished

through its size and length, and the pressure

difference present across the device.

Since the evaporator coil is under a lower

pressure than the liquid line, (due to the suction

created by the compressor), the liquid refrigerant leaves the capillary tube, and enters the

evaporator coil.

As the liquid enters the evaporator coil, the

larger area and lower pressure allows the

refrigerant to expand, and lower its temperature. This expansion is often referred to as

“boiling.”

Suction Line

The particular system design determines at

exactly what point the change of state, from a

liquid to a gas, takes place in the evaporator. In

all cases, however, the refrigerant must be

totally evaporated (changed to a gas) before

leaving the evaporator coil.

The low pressure (suction) created by the

compressor causes the refrigerant to leave the

evaporator through the suction line as a cool,

low pressure vapor. The refrigerant then returns to the compressor, where the cycle is

repeated.

Discharge Line

Evaporator Coil

Capillary Tube

(Metering)

Refrigerant

Strainer

Compressor

Condenser Coil

Liquid Line

Filter/Drier

3-2

COOLING

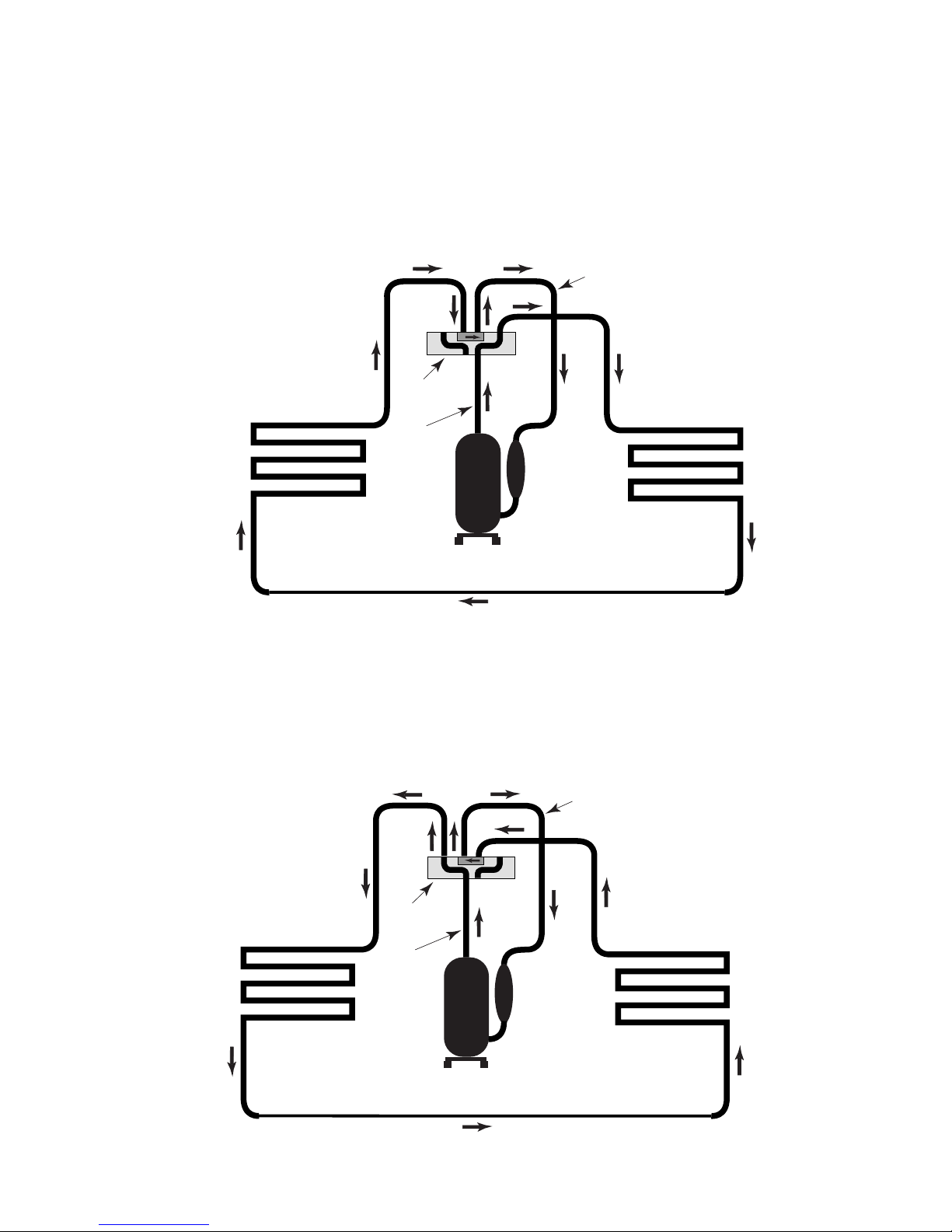

Heat Pump Operation

All air conditioners are basically heat pumps.

They move, or “pump,” heat from inside a room

to the outdoors. A heat pump air conditioner

adds a component called a “reversing valve.” It

REVERSING

INSIDE COIL

VALV E

DISCHARGE

LINE

COMPRESSOR

allows heat to be transferred from the outdoors

into the room. When the reversing valve is not

energized, the system operates in the cooling

mode.

SUCTION LINE

OUTSIDE COIL

ACCUMULATOR

HEATING

When the reversing valve is energized, the

normal direction of refrigerant flow is diverted

at the valve. The outdoor coil now becomes the

low-pressure side of the system, and the inside

REVERSING

INSIDE COIL

VALV E

DISCHARGE

LINE

COMPRESSOR

coil becomes the high-pressure side. The flow

of all refrigerant past the reversing valve

changes direction, and now brings heat into the

room from the outdoors.

SUCTION LINE

OUTSIDE COIL

ACCUMULATOR

3-3

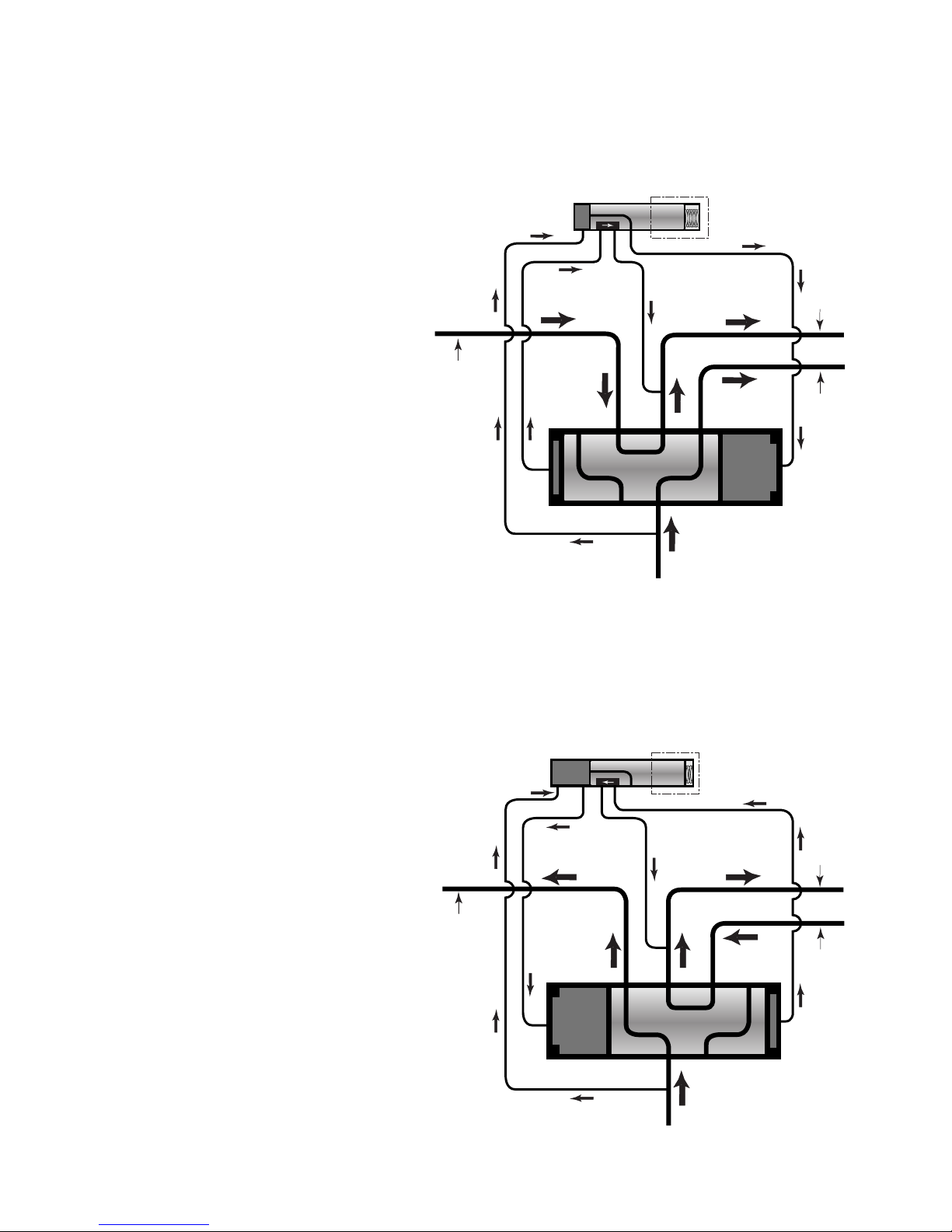

Reversing Valve Operation

PILOT VALVE SOLENOID

DE-ENERGIZED (COOLING)

The operation of the reversing valve is governed by the pilot solenoid coil. There are two

small lines going to the pilot valve, and two

lines going from the pilot valve to the main

valve body. With the solenoid de-energized,

the direction of flow is as shown, and the valve

is in the cooling mode.

TO EVAPORATOR

PILOT VALVE

(SOLENOID DE-ENERGIZED)

SUCTION LINE

TO CONDENSER

PILOT VALVE SOLENOID

ENERGIZED (HEATING)

When the solenoid is energized, refrigerant

flow from the suction and discharge lines is

redirected (reversed) through the pilot valve to

opposite ends of the main valve body. This

reverse in flow (pressure) causes the main

slide in the valve body to shift to the opposite

end, and reverses the flow of the entire system.

This reversed direction of refrigerant flow is

maintained as long as the pilot solenoid is

energized.

TO EVAPORATOR

DISCHARGE LINE

PILOT VALVE

(SOLENOID ENERGIZED)

SUCTION LINE

TO CONDENSER

DISCHARGE LINE

3-4

Remote Thermostat Operation

ROOM THERMOSTATS

Room thermostats are controlled by the use of

a remote thermostat that will cycle the air

conditioner to maintain the desired room temperature.

The fan speed switch controls the high and low

fan speed operation. The switch is located on

the control panel, and is independent of the

thermostat.

Room thermostats range from the simple bimetallic type, to the more complex electronic

setback type. No matter how simple or complex, they are simply a switch (or series of

switches) designed to turn equipment on or off

under the desired conditions.

An improperly operating, or poorly located room

thermostat, can be the source of perceived

equipment problems. A careful check of the

thermostat and wiring must be made then to

insure that it is not the source of problems.

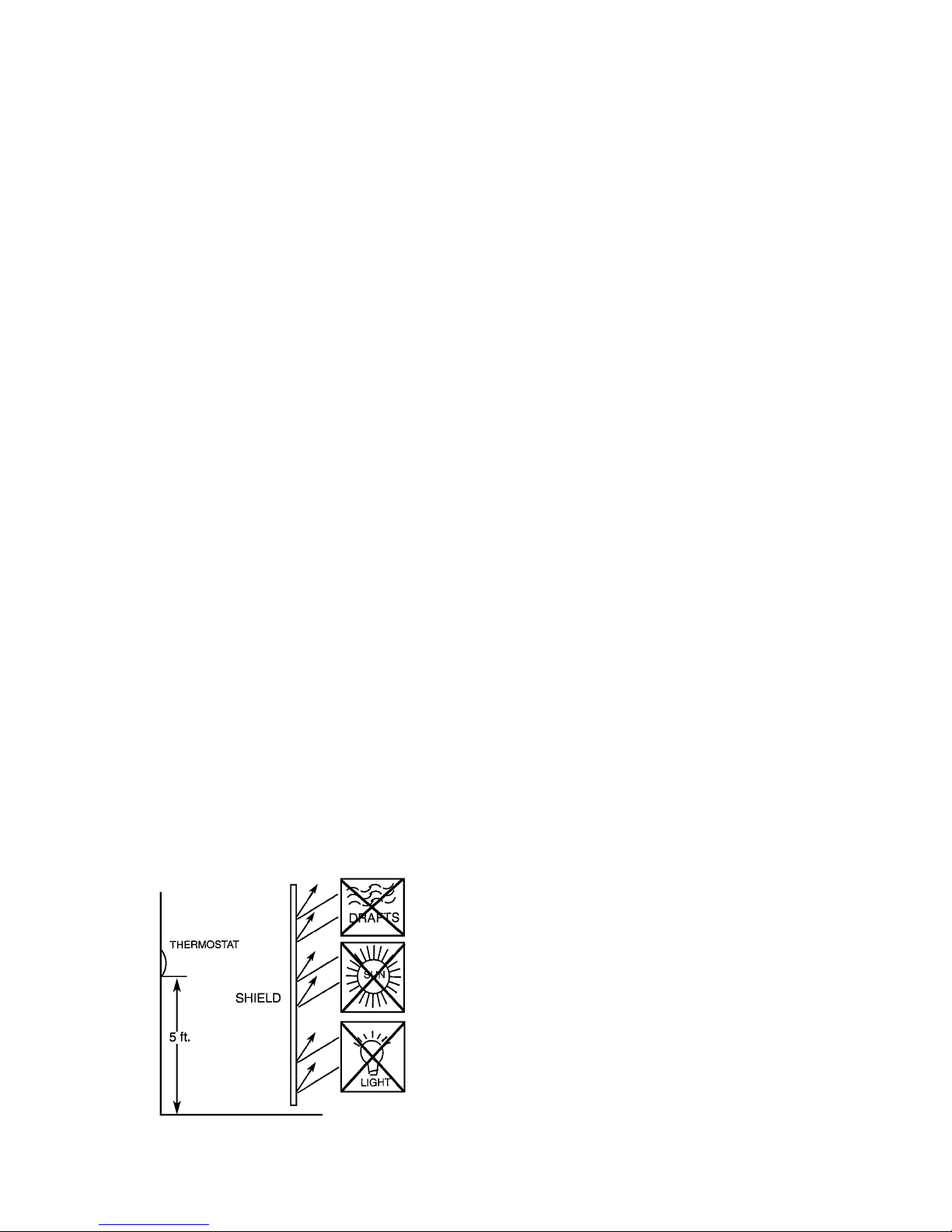

THERMOSTAT LOCATION

Thermostats should not be mounted where

they may be affected by drafts, discharge air

from registers, (hot or cold), or heat radiated

from the sun or appliances.

HEAT ANTICIPATORS

Heat anticipators are small resistance heaters

that are built into most electromechanical thermostats (wired in series with the control “W”

circuit). Their purpose is to prevent wide swings

in room temperature during system operation

in the “heating” mode. Since anticipators are

wired in series, the “W” section of the circuit will

open if one burns out, preventing the “heat”

operation.

The heat anticipator provides a small amount

of heat to the thermostat causing it to turn off

the heat source just prior to reaching the setpoint of the thermostat. This prevents exceeding the set point.

To accomplish this, the heat output from the

anticipator must be the same regardless of the

current flowing through it. Consequently, some

thermostats have an adjustment to compensate for varying current draw in the thermostat

circuits.

Electronic thermostats do not use a resistance-type anticipator. These thermostats use

a microprocessor that determines a cycle rate

based on a program loaded into it at the factory.

The thermostat should be located about 5′

above the floor, in an area of average temperature, with good air circulation. Close proximity

to the return air grille is the best choice.

Mercury bulb type thermostats must be level to

control temperature accurately to the desired

set-point.

3-5

CALCULATING THE

APPROXIMATE CFM

The approximate CFM actually being delivered

can be calculated by using the following formula:

Kilowatts x 3413

Temperature Rise x 1.08

Do not use the kilowatt rating of the heater, as

this will result in an incorrect airflow calculation.

Kilowatts can be calculated by multiplying the

measured voltage to the unit, times the measured current draw of all the heaters that are in

operation to obtain the wattage (watts). Kilowatts are then obtained by dividing the watts by

1000.

EXAMPLE: The measured voltage to the unit is

230 volts. The measured current draw of the

heaters is 11.0 amps.

230 x 11.0 = 2530

2530 ÷ 1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

Supply Air 95°F

Return Air 75°F

Temperature Rise 20°F

20 X 1.08 = 21.6

= CFM

8635

= 400 CFM

21.6

3-6

Heat Pump Function

THE HOT START SENSOR

Under cold room conditions, (50°F, or below),

the Hot Start Sensor turns on the heater strips

with a call for heat to distribute warm air at the

beginning of the “Heat” cycle. Once the return

air has warmed sufficiently, (above 65°F), the

heat pump mode will begin.

THE HEAT PUMP

The heat pump uses backup electric resistance heating coils. At extremely low outdoor

ambient temperatures, the heat pump is automatically disabled, and the unit operates solely

on electric resistance heat.

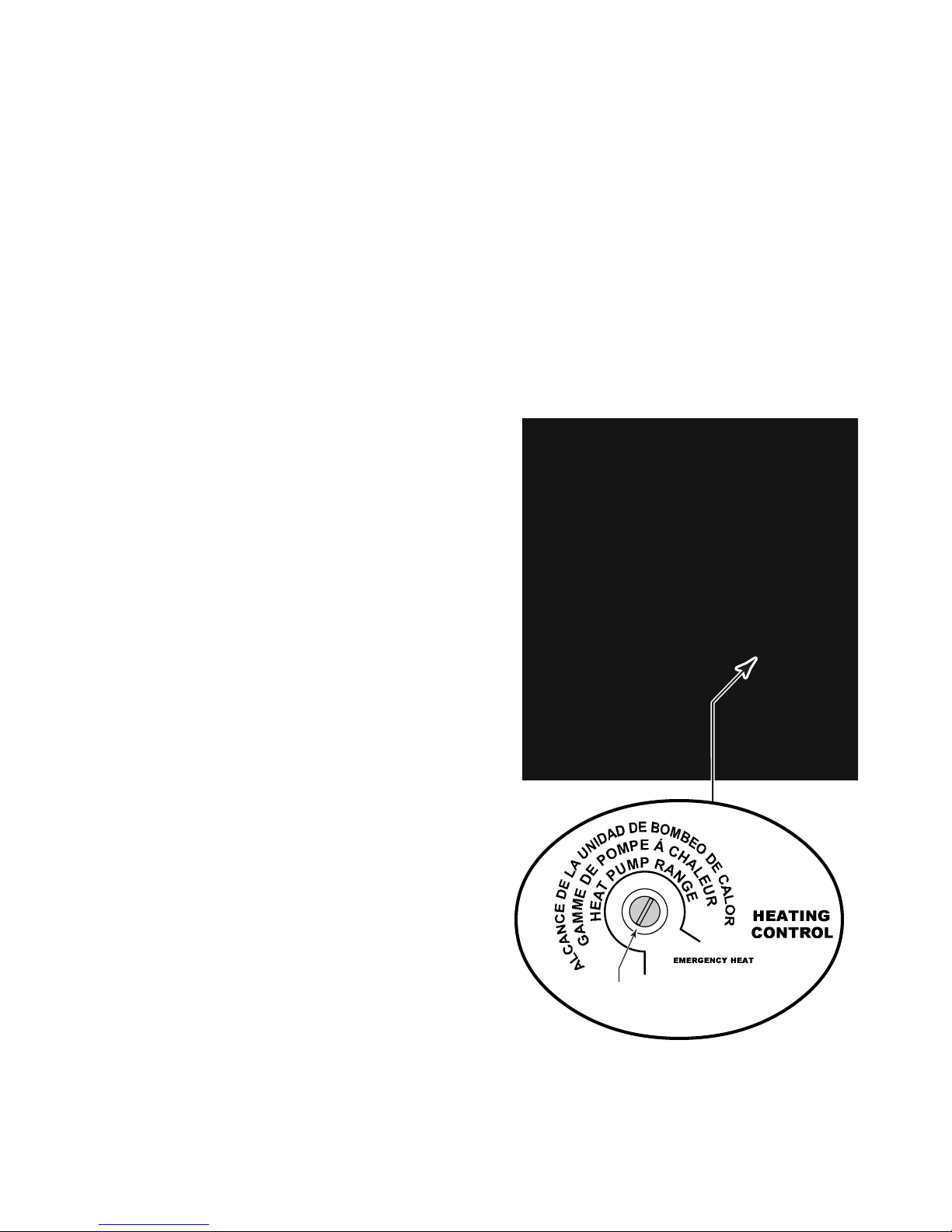

The heating control (defrost thermostat) is located behind the decorative front cover, and is

found on the right side panel of the chassis. Its

function is to allow the temperature range in

which the heat pump operates to be manually

adjusted.

Emergency Heat Operation Only: In the event

of a compressor malfunction in the “heat pump”

mode, turn the adjustment screw to the extreme counterclockwise “emergency heat” position. The heater will then cycle using electric

resistance heat only. Note that in the emergency heat position, the compressor is locked

out, disabling both the heat pump, and the

cooling operations. IMPORTANT: Do not forget to return the control to its original position

after repairs have been made. Otherwise, the

compressor will remain locked out, and will not

turn on during the “cooling” mode.

The heating control switches the unit’s heat

operation between the heat pump, and electric

resistance heat, based on the outdoor ambient

temperature. These change-over temperatures

are based on the settings of the control. The

factory set-point is at the one o’clock position.

If you wish to change the factory set-point,

insert a flat-bladed screwdriver into the slot and

turn counterclockwise to increase the changeover set-point, or clockwise to decrease it.

NOTE: Use the factory set-point for optimum

performance.

Adjustment

Screw

3-7

OPERATING THE CONTROLS

TEMPERATURE CONTROL

The temperature control is a full range thermostat that maintains room temperature at the

desired setting for both heating and cooling.

Turn the knob counterclockwise for a warmer

temperature, and clockwise for a cooler temperature.

NOTE: Always rotate the temperature control

in small increments in the warmer or cooler

direction. Moving the control more than 1/4″ at

a time may overcompensate, and result in an

extreme hot or cold condition.

MODE (SYSTEM) SWITCH

Low and High Cool

This setting operates the unit in the “cooling”

mode. Cooling will not begin if the room temperature is below 60°F (15.5°C).

Low and High Heat

This setting operates the unit in the “heating”

mode.

Fan Only

This setting operates the fan continuously at

high fan speed to circulate air within the room.

No heating or cooling functions are active in

this mode.

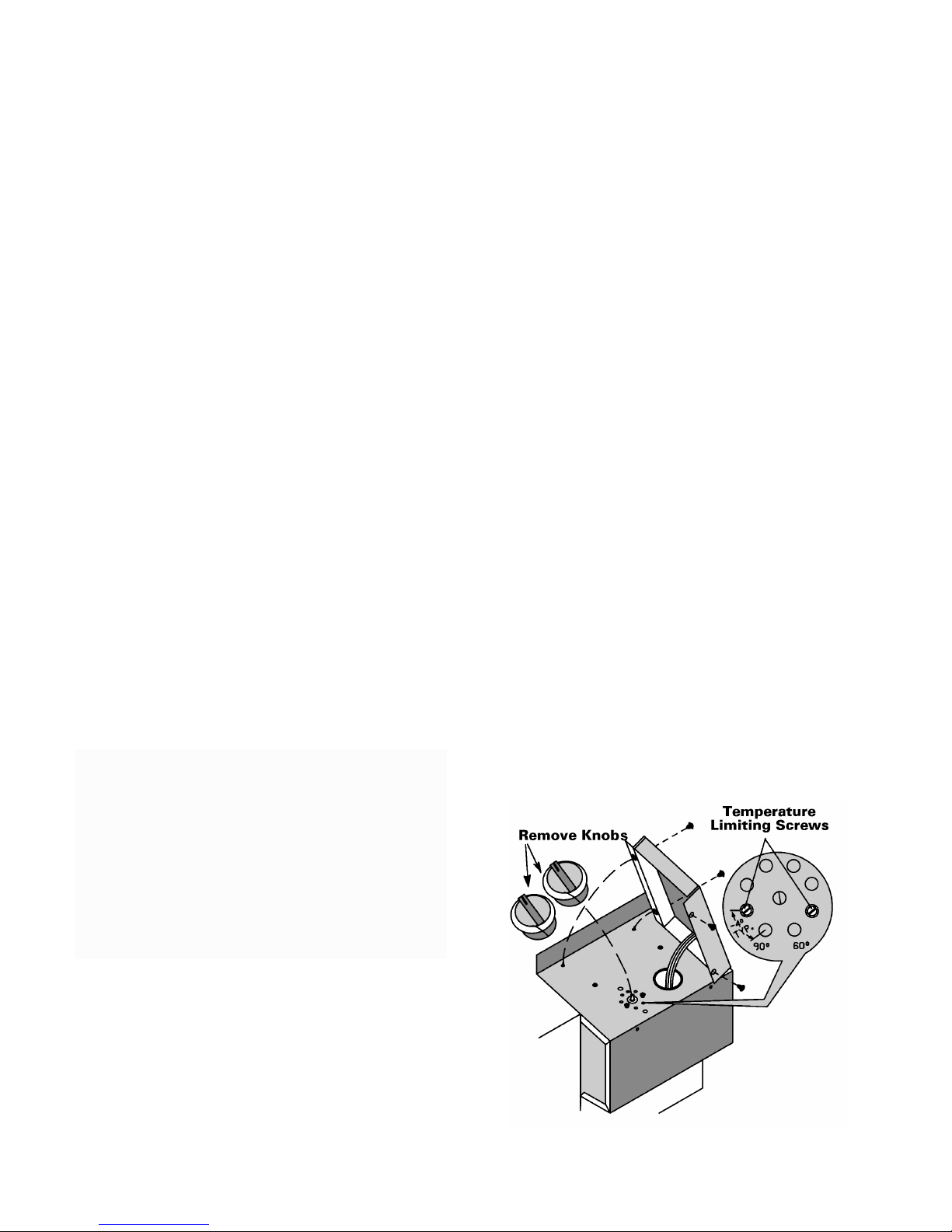

TEMPERATURE LIMITING

THERMOSTAT

The temperature limiting thermostat allows the

temperature range of the thermostat to be

varied.

To adjust the temperature range:

1. Turn the thermostat (temperature) control

to the center position.

2. Pull the two control knobs off the control

shafts and remove them.

3. Remove the four screws from the control

panel and rotate the panel up.

4. Note the location of the two temperature

limiting screws and remove the screws

from their present location. NOTE: The

screws are factory installed for a temperature range of between 60 and 90°F (15.5

to 32.2°C).

5. To adjust the temperature range, reinstall

the two screws at the desired hole locations. NOTE: Each hole represents an

approximate change of 4°. To set a maximum temperature range of approximately

64 to 86°F (17.7 to 30.0°C), install the two

screws at the hole locations shown in the

round illustration below.

6. Lower the control panel and install the two

screws, then reinstall the two control knobs.

3-8

Loading...

Loading...