Watson-Marlow Qdos30 User Manual

WATSON-MARLOW MANUALS

m-qdos30-profibus-gb-03

Watson-Marlow qdos30

PROFIBUS pump

Contents

1 |

Declaration of conformity................................................................ |

3 |

|

2 |

Declaration of incorporation............................................................. |

4 |

|

3 |

Warranty....................................................................................... |

5 |

|

4 |

When you unpack your pump........................................................... |

6 |

|

5 |

Information for returning pumps...................................................... |

7 |

|

6 |

Safety notes.................................................................................. |

8 |

|

7 |

Pump specifications...................................................................... |

10 |

|

|

7.1 |

Dimensions.......................................................................... |

12 |

|

7.2 |

Weights............................................................................... |

12 |

8 |

Good pump installation practice..................................................... |

13 |

|

|

8.1 |

General recommendations...................................................... |

13 |

|

8.2 Do’s and do not’s.................................................................. |

14 |

|

9 |

Connecting to a power supply........................................................ |

15 |

|

10 |

Start-up check list........................................................................ |

16 |

|

11 |

PROFIBUS control wiring............................................................... |

17 |

|

|

11.1 PROFIBUS installation............................................................ |

17 |

|

|

11.2 Pin assignments at the pump.................................................. |

18 |

|

12 |

Switching on the pump for the first time...................................................... |

19 |

|

13 |

Switching the pump on in subsequent power cycles........................... |

21 |

|

14 |

Pump operation........................................................................... |

22 |

|

|

14.1 Keypad functions................................................................... |

22 |

|

|

14.2 MODE menu......................................................................... |

24 |

|

|

14.3 Manual................................................................................ |

25 |

|

|

14.4 Manual mode operation when PROFIBUS is enabled................... |

27 |

|

|

14.5 PROFIBUS mode................................................................... |

28 |

|

|

14.6 Assigning the PROFIBUS station address at the pump................. |

29 |

|

|

14.7 PROFIBUS communication errors............................................. |

30 |

|

|

14.8 PROFIBUS GSD File............................................................... |

31 |

|

|

14.9 User Parameter Data............................................................. |

33 |

|

|

14.10 PROFIBUS data exchange..................................................... |

34 |

|

|

14.11 Device Related Diagnostic Data............................................. |

36 |

|

|

14.12 Channel Related Diagnostic Data........................................... |

36 |

|

|

14.13 Flow calibration................................................................... |

37 |

|

|

14.14 Fluid recovery mode............................................................ |

39 |

|

15 |

Main menu.................................................................................. |

41 |

|

|

15.1 Fluid level monitor................................................................. |

42 |

|

|

15.2 Security settings................................................................... |

45 |

|

|

15.3 General settings.................................................................... |

48 |

|

|

15.4 MODE menu......................................................................... |

52 |

|

|

15.5 Control settings.................................................................... |

52 |

|

16 |

Troubleshooting........................................................................... |

54 |

|

|

16.1 Leak detection...................................................................... |

54 |

|

|

16.2 Error codes........................................................................... |

55 |

|

|

16.3 Technical support.................................................................. |

55 |

|

17 |

Drive maintenance....................................................................... |

56 |

|

18 |

Pumphead replacement................................................................. |

57 |

|

|

18.1 Connecting interface tubing.................................................... |

60 |

|

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

1 |

19 |

Ordering information.................................................................... |

63 |

|

19.1 Pump part numbers............................................................... |

63 |

|

19.2 Spares and accessories.......................................................... |

64 |

20 |

Performance data......................................................................... |

65 |

|

20.1 Pumping conditions............................................................... |

65 |

|

20.2 Pressure capability................................................................ |

65 |

|

20.3 Dry running.......................................................................... |

65 |

|

20.4 Pumphead life....................................................................... |

65 |

|

20.5 Performance curves............................................................... |

65 |

21 |

Trademarks................................................................................. |

66 |

22 |

Publication history........................................................................ |

66 |

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

2 |

1 Declaration of conformity

EC Declaration of Conformity

Watson-Marlow Ltd

Falmouth

Cornwall

TR11 4RU

England

Description |

qdos30 peristaltic pumps |

Products |

qdos30 manual, qdos30 remote, qdos30 universal, qdos30 universal+, |

|

qdos30 PROFIBUS, qdos30 universal 110volt logic, qdos30 universal+ 110volt |

|

logic, qdos30 universal 24volt logic, qdos30 universal+ 24volt logic. |

Conformity |

Watson-Marlow Ltd declares that when this pump unit is used as a stand-alone |

|

pump it complies with Machinery Directive 2006/42/EC. |

Standards |

Watson-Marlow Limited declares that the above stated products are in |

|

conformance with the following harmonised standards and directives: |

|

Low Voltage Directive 2006/95/EC. |

|

Electro-Magnetic Compatibility Directive 2004/108/EC. |

|

Safety of Machinery-Electrical equipment of machines; BS EN 60204-1 |

|

Safety requirements for electrical equipment for measurement, control and laboratory use; |

|

BS EN 61010-1 IEC 61010-1 UL 61010-1 |

|

Safety of machinery-Basic concepts, general principals of design BS EN ISO 12100-1 and |

|

BS EN ISO 12100-2 |

|

Degrees of protection provided by enclosures (IP code) BS EN 60529 |

|

Information Technology equipment safety BS EN 60950-1 |

|

Digital Data Communication BS EN 61138-2 |

|

Conducted emissions BS EN 55011 Class A |

|

Radiated emissions BS EN 55011 Class A |

|

Electrostatic discharge immunity BS EN 61000-4-2 |

|

Radiated RF immunity BS EN 61000-4-3 |

|

Fast transient/burst immunity BS EN 61000-4-4 |

|

Surge immunity testing BS EN 61000-4-5 |

|

Conducted RF immunity BS EN 61000-4-6 |

|

Voltage dips and interruptions BS EN 61000-4-11 |

|

Mains harmonics BS EN 61000-3-2 |

Manufacturer |

Watson-Marlow Limited, TR11 4RU, England |

Date |

17th August 2012 |

Signature |

|

|

David Cole, Managing Director, Watson-Marlow Limited |

This pump is ETL listed: ETL control number 3050250. Cert to CAN/CSA std C22.2 No 61010-1. Conforms to UL std 61010A-1.

See 7 Pump specifications on page 3.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

3 |

2 Declaration of incorporation

Declaration of Incorporation

Watson-Marlow Ltd

Falmouth

Cornwall

TR11 4RU

England

In accordance with the Machinery Directive 2006/42/EC that if this unit is to be installed into a machine or is to be assembled with other machines for installations, it shall not be put into service until the relevant machinery has been declared in conformity.

We hereby declare that:

Peristaltic Pump qdos

Series: qdos 30

that the following harmonized standards have been applied and fulfilled for health and safety requirements:

Safety of Machinery - EN ISO 12100

Safety of Machinery – Electrical Equipment of Machines EN 60204-1.

Quality Management System - ISO 9001.

and the technical documentation is compiled in accordance with Annex VII(B) of the Directive.

We undertake to transmit, in response to a reasoned request by the appropriate national authorities, relevant information on the partly completed machinery identified above. The method of transmission shall be by mail or email.

The pump head is incomplete and must not be put into service until the machinery into which it is to be incorporated has been declared in conformity with the provisions of the Directive.

Person authorized to compile the technical documents:

Andrew Green

…………………………………… of Watson-Marlow Ltd.

Place and date of declaration: Watson-Marlow Ltd, 17th August 2012

Responsible person:

Mr. David Cole

Managing Director for Watson-Marlow Ltd

The information in this user guide is believed to be correct at the time of publication. However, Watson-Marlow Limited accepts no liability for errors or omissions. WatsonMarlow has a policy of continuous product improvement, and reserves the right to alter specifications without notice. This manual is intended for use only with the pump it was issued with. Earlier or later models may differ. The most up-to-date manuals appear on the Watson-Marlow website: http://www.wmpg.com

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

4 |

3 Warranty

Watson-Marlow Ltd (“Watson-Marlow”) warrants this product to be free from defects in materials and workmanship for three years from the date of shipment, under normal use and service.

Watson-Marlow’s sole responsibility and the customer’s exclusive remedy for any claim arising out of the purchase of any product from Watson-Marlow is, at WatsonMarlow’s option: repair, replacement or credit, where applicable.

Unless otherwise agreed in writing, the foregoing warranty is limited to the country in which the product is sold.

No employee, agent or representative of Watson-Marlow has the authority to bind Watson-Marlow to any warranty other than the foregoing unless in writing and signed by a director of Watson-Marlow. Watson-Marlow makes no warranty of the fitness of its products for a particular purpose.

In no event:

(i)shall the cost of the customer’s exclusive remedy exceed the purchase price of the product;

(ii)shall Watson-Marlow be liable for any special, indirect, incidental, consequential, or exemplary damages, however arising, even if Watson-Marlow has been advised of the possibility of such damages.

Watson-Marlow shall not be liable for any loss, damage, or expense directly or indirectly related to or arising out of the use of its products, including damage or injury caused to other products, machinery, buildings, or property. Watson-Marlow shall not be liable for consequential damages, including, without limitation, lost profits, loss of time, inconvenience, loss of product being pumped, and loss of production.

This warranty does not obligate Watson-Marlow to bear any costs of removal, installation, transportation, or other charges which may arise in connection with a warranty claim.

Watson-Marlow shall not be responsible for shipping damage of returned items.

Conditions

•Products must be returned by pre-arrangement to Watson-Marlow, or a WatsonMarlow approved service centre.

•All repairs or modifications must have been made by Watson-Marlow Ltd, or a

Watson-Marlow approved service centre or with the express permission in writing of Watson-Marlow, signed by a manager or director of Watson-Marlow.

•Any remote control or system connections must be made in accordance to Watson-Marlow recommendations.

•All PROFIBUS systems must be installed or certified by a PROFIBUS approved installation engineer.

Exceptions

•Consumable items including tubing and pumping elements are excluded.

•Pumphead rollers are excluded.

•Repairs or service necessitated by normal wear and tear or by lack of reasonable and proper maintenance are excluded.

•Products which, in the judgment of Watson-Marlow, have been abused, misused, or subjected to malicious or accidental damage or neglect are excluded.

•Failure caused by electrical surge is excluded.

•Failure caused by incorrect or sub-standard system wiring is excluded.

•Damage by chemical attack is excluded.

•Ancillaries such as leak detectors are excluded.

•Failure caused by UV light or direct sunlight.

•All ReNu pumpheads are excluded.

•Any attempt to disassemble a Watson-Marlow product will invalidate the product warranty.

Watson-Marlow reserves the right to amend these terms and conditions at any time.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

5 |

4 When you unpack your pump

Unpack all parts carefully, retaining the packaging until you are sure all components are present and in good order. Check against the components supplied list, below.

Packaging disposal

Dispose of packaging materials safely, and in accordance with regulations in your area. The outer carton is made of corrugated cardboard and can be recycled.

Inspection

Check that all components are present. Inspect components for damage in transit. If anything is missing or damaged, contact your distributor immediately.

Components supplied

•qdos30 pump drive unit

•ReNu pumphead

•User connection collars

•The designated power cable (attached to the pump drive unit)

•CD-ROM containing these operating instructions

•Quick start manual

•Product safety information booklet

Optional accessories

•Additional ReNu pumphead

•HMI protective cover

•Interface tubing

•Input and output (I/O) leads

Storage

This product has an extended shelf life. However, care should be taken after storage to ensure that all parts function correctly. Please observe the storage recommendations and use-by dates which apply to tubing you may wish to bring into service after storage.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

6 |

5 Information for returning pumps

In compliance with the UK Health and Safety at Work Act and the Control of Substances Hazardous to Health Regulations, you are required to declare the substances which have been in contact with product(s) you return to Watson-Marlow or its subsidiaries or distributors. Failure to do so will cause delays. Please ensure that you fax us this form and receive an RGA (Returned Goods Authorisation) before you despatch the product(s). A copy of this form must be attached to the outside of the packaging containing the product(s).

Please complete a separate decontamination certificate for each product. A copy of the appropriate decontamination certificate can be downloaded from the Watson-

Marlow website at: www.wmpg.com/decon

You are responsible for cleaning and decontaminating the product(s) before return.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

7 |

6 Safety notes

In the interests of safety, this pump and pumphead should only be used by competent, suitably trained personnel after they have read and understood this manual, and considered any hazard involved. If the pump is used in a manner not specified by

Watson-Marlow Ltd, the protection provided by the pump may be impaired.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out the work. In the UK this person should also be familiar with the Health and Safety at Work Act 1974.

This symbol, used on the pump and in this manual, means: Caution, refer to accompanying documents.

This symbol, used on the pump and in this manual, means: Do not allow fingers to contact moving parts.

This symbol, used on the pump and in this manual, means: Caution, hot surface.

Fundamental work with regard to lifting, transportation, installation, starting-up, maintenance and repair should be performed by qualified personnel only. The unit must be isolated from mains power while work is being carried out. The motor must be secured against accidental start-up.

There is a non-replaceable fuse on the switch-mode power supply board. In some countries, the mains power plug contains a replaceable fuse. There are no user-serviceable fuses or parts inside this pump.

This pump must be used only for its intended purpose.

The pump must be accessible at all times to facilitate operation and maintenance.

Access points must not be obstructed or blocked. Do not fit any devices to the drive unit other than those tested and approved by Watson-Marlow. Doing so could lead to injury to persons or damage to property for which no liability can be accepted.

If hazardous fluids are to be pumped, safety procedures specific to the particular fluid and application must be put in place to protect against injury to persons.

The exterior surfaces of the pump may get hot during operation. Do not take hold of the pump while it is running. Let the pump cool after use before handling. The drive unit must not be run without a pumphead fitted.

This product does not comply with the ATEX directive and must not be used in explosive atmospheres.

If pumping flammable liquids, a full risk assessment should be completed prior to use.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

8 |

The exterior surfaces of the pump may get hot during operation. Do not take hold of the pump while it is running. Allow the to pump cool after use before handling. The drive unit must not be run without a pumphead fitted. The pumphead should not be run dry for extended periods of time. The pump should not be

used to pump fluids where the temperature of the fluid can reach temperatures of more than 70C.

Ensure the chemicals to be pumped are compatible with the pumphead, lubricant, tubing, pipework and fittings to be used with the pump. Please refer to the chemical compatibility guide which can be found at: www.wmpg.com/chemical If you need to use the pump with any other chemical please contact Watson-

Marlow to confirm compatibility.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

9 |

7 Pump specifications

ReNu pumphead (left hand mounted)

Mounting plate

Mounting plate

Pumphead retaining clamps

Outlet

HMI

HMI

(not Remote)

Drive unit

Drive unit

Inlet

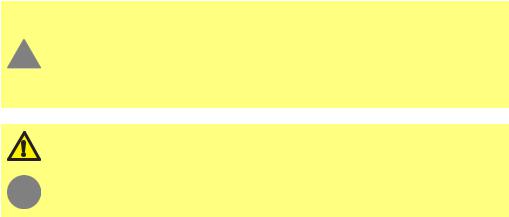

Power

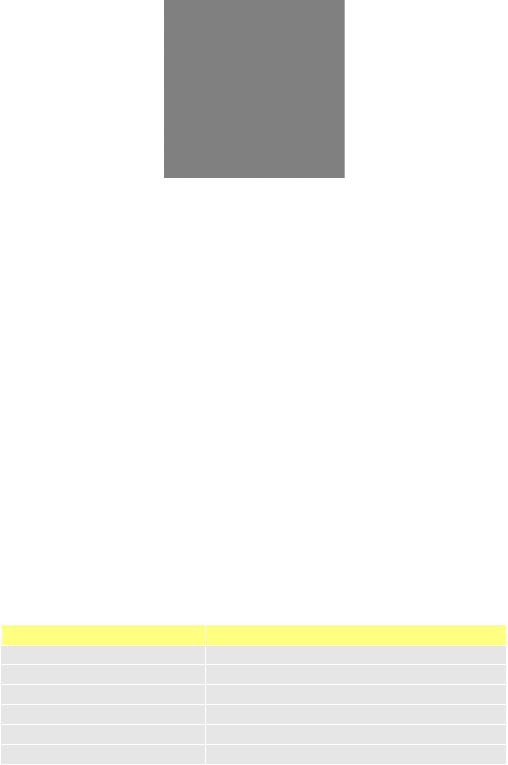

A nameplate is fixed to the rear of the pump. It contains manufacturer and contact details, product reference number, serial number and model details.

|

|

|

|

|

|

|

|

|

|

|

|

Product reference |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0M0.223L.GLU ISS 1 |

|

|

|

|

|||||||

|

|

|

|

|

|

|||||||

QDOS MANUAL 30L/HR 7BAR |

|

|

|

|

Model |

|||||||

190GPD 100PSI SANT GLYCOL |

|

|

|

|

||||||||

|

|

|

|

|

||||||||

SERIAL NUMBER |

|

|

|

|

|

|

|

Serial number |

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Manufacturer details

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

10 |

Pump specifications

Flow Range (flow control) |

0.1-500 ml/min (5000:1) |

Supply voltage/frequency |

~100-240V 50/60Hz |

±10% of nominal voltage. |

An electrical mains supply is required |

Maximum voltage fluctuation |

along with cable connections to the best |

|

practice of noise immunity |

Installation category |

II |

(overvoltage category) |

|

Power consumption |

190VA |

Enclosure rating |

IP66 to BS EN 60529 |

|

NEMA 4X to NEMA 250* |

Operating temperature range |

4C to 45C, 41F to 113F |

Storage temperature range |

-20C to 70C, -4F to 158F |

Maximum altitude |

2,000m, 6,560ft |

Humidity (non-condensing) |

80% up to 31C, 88F, |

|

decreasing linearly to 50% at 40C, 104F |

Pollution degree |

2 |

Noise |

<70dB(A) at 1m |

* Requires the fitting of the HMI protective cover

Standards

Safety requirements for electrical equipment for measurement, control and laboratory use: BS EN 61010- 1 incorporating A2 Category 2, Pollution degree 2

Degrees of protection provided by enclosures (IP code):

BS EN 60529 amendments 1 and 2

Conducted emissions:

BS EN 55011 A1 and A2, Class A, called by BS EN 61000-6-4

Radiated emissions:

BS EN 55011 A1 and A2, Class A, called by BS EN 61000-6-4

Electrostatic discharge: BS EN 61000-4-2

Radiated RF immunity:

EC harmonised BS EN 61000-4-3 A1 and A2, called by BS EN 61000-6-2 standards

Fast transient burst:

BS EN 61000-4-4 A1 and A2, Level 3 (2kV), called by BS EN 61000-6-2

Surge testing:

BS EN 61000-4-5 A1 and A2, called by BS EN 61000-6-2

Conducted RF immunity:

BS EN 61000-4-6, called by BS EN 61000-6-2

Voltage dips and interruptions:

BS EN 61000-4-11, called by BS EN 61000-6-2

Mains harmonics: BS EN 61000-3-2 A2

Pumps and pump units for liquids—common safety requirements: BS EN 809

UL 61010A-1, UL/CSA 61010-1

CAN/CSA-C22.2 No 61010-1

Other |

IEC 61010-1 |

|

standards |

|

|

Radiated emissions FCC 47CFR, Part 15 |

|

|

|

|

|

|

NEMA 4X to NEMA 250 |

|

|

NSF61 for pumphead |

|

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

11 |

|

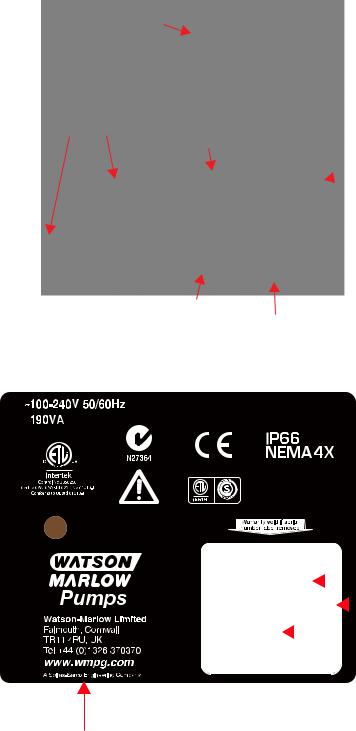

7.1 Dimensions

7.2 Weights

Model |

|

Drive |

Drive with pumphead |

|

|

kg |

lb |

kg |

lb |

Manual |

4.1 |

9lb |

5.05 |

11lb 2oz |

Remote |

4.0 |

8lb 13oz |

4.95 |

10lb 15oz |

Universal |

4.1 |

9lb |

5.05 |

11lb 2oz |

Universal+ |

4.1 |

9lb |

5.05 |

11lb 2oz |

PROFIBUS |

4.1 |

9lb |

5.05 |

11lb 2oz |

Universal 24V relay |

4.3 |

9lb 8oz |

5.25 |

11lb 9oz |

Universal+ 24V relay |

4.3 |

9lb 8oz |

5.25 |

11lb 9oz |

Universal 110V logic |

4.3 |

9lb 8oz |

5.25 |

11lb 9oz |

Universal+ 110V logic |

4.3 |

9lb 8oz |

5.25 |

11lb 9oz |

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

12 |

8 Good pump installation practice

8.1 General recommendations

Always consult an expert before installing a metering pump in a specialised system. Metering pumps should be maintained by qualified persons.

It is recommended that the pump is bolted to a flat, horizontal, rigid surface, free from excessive vibration, to ensure correct lubrication of the gearbox and correct pumphead operation. Allow a free flow of air around the pump to ensure that heat can be dissipated. Ensure that the ambient temperature around the pump does not exceed 45C (113F).

The STOP key on pumps supplied with a keypad will always stop the pump. However, it is recommended that a suitable local emergency stop device is fitted into the mains supply to the pump.

Do not stack pumps.

This pump is self-priming and self-sealing against backflow. No valves are required in inlet or discharge lines, except as described below. Valves in the process flow must be opened before the pump operates.

Users must fit a non-return valve between the pump and the discharge pipework to avoid the sudden release of pressurised fluid in the event of a pumphead failure. This shall be fitted immediately after the discharge of the pump.

qdos30 is a positive displacement pump; therefore, it is recommended best practice that customers incorporate discharge pressure relief in their piping system. Failure to fit a pressure release valve in the discharge pipework will result in excessive build up of pressure should the discharge become blocked. This may present a safety risk, may cause damage to the system pipework or lead to premature failure of the pumphead. The pressure relief valve shall be rated at no more than 10 bar. It shall always be rated at below the users system maximum operating temperature. It shall be installed so as to provide easy access for maintenance, inspection and repair. It shall not be capable of being adjusted without the use of

a tool. The discharge opening must be located and directed so that the release material is not directed towards any person and will not deposit on parts that could cause a hazard. There must not be a shut-off valve between the overpressure safety device and the pump.

Do not block the drain port of the ReNu pumphead.

Ensure the chemicals to be pumped are compatible with the pumphead and the pipework and fittings to be used with the pump. Please refer to the chemical compatibility guide which can be found at: www.wmpg.com/chemical

If you need to use the pump with any other chemical please contact Watson-Marlow to confirm compatibility.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

13 |

8.2 Do’s and do not’s

Do not build a pump into a tight location without adequate airflow around the pump.

Do keep delivery and suction tubes as short and direct as possible - though ideally not shorter than one metre - and follow the straightest route. Use bends of large radius: at least four times the tubing diameter. Ensure that connecting pipework and fittings are suitably rated to handle the predicted pipeline pressure. Avoid pipe reducers and lengths of smaller bore tubing than the pumphead section, particularly in pipelines on the suction side. Any valves in the pipeline must not restrict the flow. Any valves in the flow line must be open when the pump is running.

Do use suction and delivery pipes equal to or larger than 6.4mm diameter bore.

When pumping viscous fluids use pipe runs with a bore several times larger than the pump tube.

Do site the pump at or just below the level of the fluid to be pumped if possible. This will ensure flooded suction and maximum pumping efficiency.

Do run at slow speed when pumping viscous fluids. Flooded suction will enhance pumping performance, particularly for materials of a viscous nature.

Do recalibrate after changing pumphead, fluid, or any connecting pipework. It is also recommended that the pump is recalibrated periodically to maintain accuracy.

Do ensure your PROFIBUS pump is installed in accordance with PROFIBUS installation guidelines.

Do not pump any chemical not compatible with the pumphead.

Do not tilt the drive with a pumphead fitted, even if it is not running.

Do not strap the control and mains cable together.

Do avoid tight bends in the PROFIBUS signal cable.

Pressure capability

qdos30 can be operated continuously at discharge pressures of up to 7 bar (100 psi). The pump can be operated at discharge pressures of up to 10 bar (145 psi), however flowrate and pumphead life will be affected.

Dry running

qdos30 will continue to operate when there is gas present in the suction line and will maintain prime in these conditions. The pump can be run dry, however flowrate and pumphead life will be affected.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

14 |

9 Connecting to a power supply

This pump is fitted with a switch mode power supply and will operate from any mains voltage in the range ~100-240V AC, 50/60Hz supplies.

Make suitable connection to an earthed, single-phase mains electricity supply.

We recommend using commercially available supply voltage surge suppression where there is excessive electrical noise.

Power cable: The pump is supplied fitted with a cable gland and approximately

1.8m (5.9ft) of power cable.

Each pump is supplied with a power cable. The connector at the pump end of the cable is IP66 rated. The mains plug at the opposite end of the cable is NOT IP66 rated.

Ensure that all power supply cables are adequately rated for the equipment.

The pump must be positioned so that the disconnection device

(the mains plug), is easily accessible when the equipment is in use.

When PAT testing this unit ensure that the earth bond test terminal is used.

Earth bond test terminal position

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

15 |

10 Start-up check list

•Fit the pumphead to the drive. Refer to: 18 Pumphead replacement on page 15.

•Ensure the pumphead ports are securely fitted to the interface tubing.

•Ensure proper connection has been made to a suitable power supply.

•Ensure that the recommendations in: 8.1 General recommendations on page 15 are followed.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

16 |

11 PROFIBUS control wiring

Interfacing the pump with the PROFIBUS network is by means of an M12 connector mounted on a flying lead on the front of the pump.

It is the user’s responsibility to ensure the safe and reliable operation of the pump under PROFIBUS control.

Note: The transmission speed is limited to a maximum of 1.5Mbit/s.

11.1 PROFIBUS installation

All devices in the bus system must be connected in a line. An IP66 rated T adaptor should be used to connect the pump to the PROFIBUS line. A maximum of 32 stations (to include master, slaves and repeaters) are possible and both the beginning and the end of the cable must be terminated with a terminating resistor.

The M12 socket provided for PROFIBUS installation is IP66 rated. To maintain an IP66 rated system the PROFIBUS cable, T adaptors and terminating resistors used must be fitted with IP66 rated M12 industrial connectors.

Note: To prevent low-frequency ground loops, screening which is earthed at one end shouldbeused.TocountermagneticHFpick-up,shieldingearthedatbothendsaswellas twisted conductors should be used, this will have no effect against electrical HF pick-up.

The permissible overall length of the bus cabling will vary according to the required bit rate. If a longer cable or higher bit rate are required repeaters should be used. The maximum bit rates achievable are shown in the table below.

Bit rate (Kbit/s) |

Max. length of type A bus cable (m) |

1500 |

200 |

500 |

400 |

187.5 |

1000 |

93.75 |

1200 |

19.2 |

1200 |

9.6 |

1200 |

Note: Total stub length should not exceed 6.6m

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

17 |

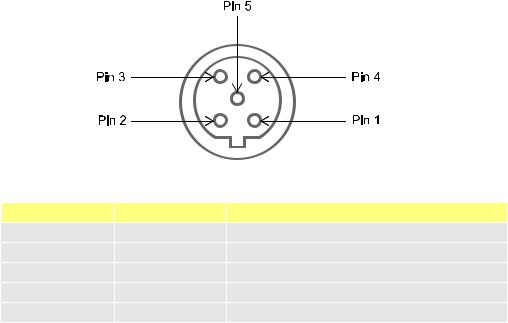

11.2 Pin assignments at the pump

Pin No. |

Signal |

Function |

1 |

VP |

+5V supply for terminating resistors |

2 |

RxD/TxD-N |

Data line minus (A-line) |

3 |

DGND |

Data ground |

4 |

RxD/TxD-P |

Data line plus (B-line) |

5 |

Shield |

Ground connection |

Note: If the pump is the last bus device connected to the PROFIBUS cable it must be terminated using terminating resistor (PROFIBUS standard EN 50170). To maintain ingress protection the resistor must be IP66 rated.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

18 |

12 Switching on the pump for the first time

Power-up the pump.

The pump displays the start-up screen with the Watson-Marlow Pumps logo for three seconds.

Selecting your chosen display language

Use the +/- keys to move the selection bar to your required language. Press SELECT to choose.

Your selected language will now be displayed on screen, choose CONFIRM to continue, all displayed text will now appear in your chosen language.

Choose REJECT to return to the language choice screen.

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

19 |

The pump is preset with operational parameters as shown in table below:

First-time start-up defaults

Flowrate |

240ml/min |

Pump status |

Stopped |

Calibration |

4 ml/rev |

Flow unit |

ml/min |

Backlight |

30 minutes |

Pump tag |

WATSON-MARLOW |

Auto restart |

Off |

|

|

This then proceeds to the home screen.

The pump is now ready to operate according to the defaults listed above.

Note: The display background colour changes according to running state as follows:

•White background indicates pump stopped

•Blue background indicates pump running

•Red background indicates error or alarm

All operating parameters may be changed by means of key-presses (see Section 14 Pump operation on page 19).

Watson-Marlow qdos30 PROFIBUS Pump User Manual |

20 |

Loading...

Loading...