Watlow Electric 988, 989, 986m, 987 User Manual

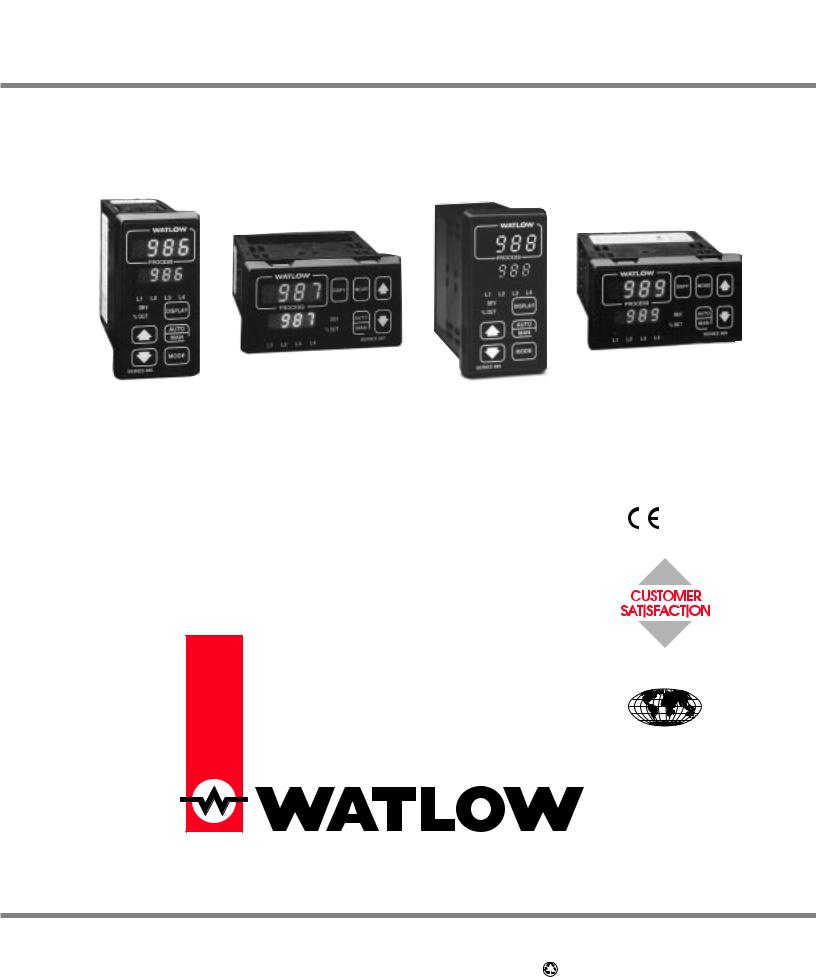

Series 988

User’s Manual

Includes 986, 987, 988 and 989

1/8 DIN Microprocessor-Based Temperature/Process Controller

User Levels: |

|

|

• New User........................... |

go to Introduction |

|

• Experienced User................... |

go to page 4.1 |

96 |

Installers: |

|

|

• Set-up..................................... |

go to page 1.1 |

|

|

|

TOTAL |

• Wiring & Installation................ |

go to page 2.1 |

|

|

|

3YearWarranty |

ISO 9001

Registered Company

Winona, Minnesota USA

Watlow Controls

1241 Bundy Blvd., P.O. Box 5580, Winona, MN, USA 55987-5580, Phone: (507) 454-5300, Fax: (507) 452-4507

0600-0009-0001 Rev V |

$10.00 |

|

December 1997 |

||

Made in the U.S.A. |

||

Supersedes: W988-XUMN Rev U00 |

||

Printed on Recycled Paper 10% Postconsumer Waste |

||

|

Series 988

User’s Manual

Includes 986, 987, 988 and 989

The Series 988 User’s Manual is copyrighted by Watlow Winona, Inc., © 1997, with all rights reserved. (1233)

Table of Contents

Introduction to the Watlow Series 988 Controllers

ii Using this Manual

iiDocument Every Step

iiiNotes, Cautions and Warnings

iiiTechnical Assistance

iiiWe Value Your Feedback

Chapter 1

Hardware Setup

1.1 Dip Switch Locations and Functions

Chapter 2

Installation and Wiring

2.1 Panel Cutout and Dimensions

2.2 Installing the Series 988

2.4 Wiring the Series 988

2.4 Input-to-output Isolation

2.4 Power Wiring

2.5 Sensor Installation Guidelines

2.6 Wiring Example

2.8 Input 1 Wiring

2.9 Input 2 Wiring

2.11 Event Input 1 Wiring

2.12 Output 1 Wiring

2.13 Output 2 Wiring

2.14 Output 3 Wiring

2.15 Output 4 Wiring

Chapter 3

Front Panel and Display Loop

3.1 Keys and Displays

3.2 Display Loop

Chapter 4

The Setup Menus

4.1 Navigating the Setup Menus

4.2 Input Menu

4.18 Output Menu

4.34 Global Menu

4.44 Communications Menu

Chapter 5

The Operation Menus

5.1 Navigating the Operation Menus

5.2 System Menu

5.9 PID A and PID B Menus

Chapter 6

The Factory Menus

6.1 Navigating the Factory Menus

6.2 Panel Lockout Menu

6.7 Diagnostics Menu

6.13 Calibration Menu

Chapter 7

Tuning, Manual Operation, Alarms and Error Codes

7.1 Auto-tuning (Heat and/or Cool)

7.2 Manual Tuning

7.4 Manual and Automatic Operation

7.5 Changing the Output 3 Alarm Jumper

7.6 Using Alarms

7.8 Error Code E1 and E2 Messages

7.9 Error Code Actions

Chapter 8 General Software

8.2 Burst Fire

8.4 Communications

8.6 Dead Band

8.8 Digital Events

8.10 Heater Current

8.12 Input Filter

8.14 Input Linearization

8.16 Ramp to Set Point

8.18 Remote Set Point

8.20 Retransmit

8.22 Slidewire Feedback

Chapter 9

Enhanced Software

9.2 |

Cascade |

9.6 |

Differential |

9.8 |

Dual PID Sets |

9.10 |

Duplex |

9.12 |

Ratio |

Appendix |

|

A.2 |

Glossary |

A.4 |

Specifications |

A.5 |

Warranty and Returns |

A.6 |

Index |

A.10 |

Menu Overview |

A.11 |

Model Number – Ordering Information |

A.12 |

Declaration of Conformity |

Table of Contents |

WATLOW Series 988 User’s Manual |

Introduction to the

Watlow Series 988 Controllers

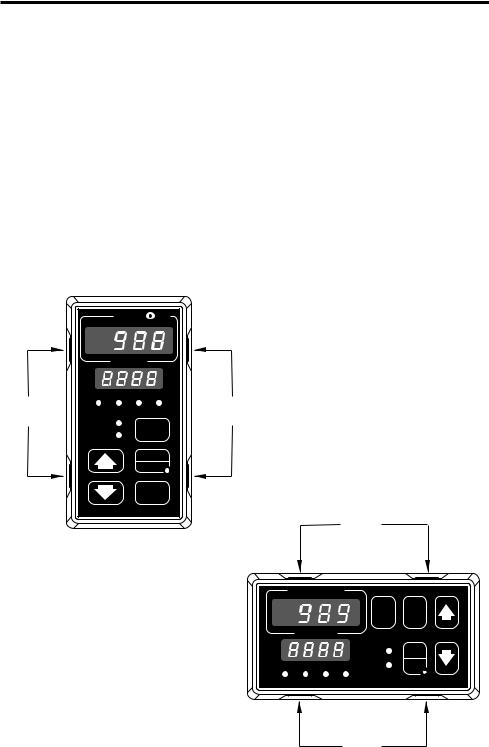

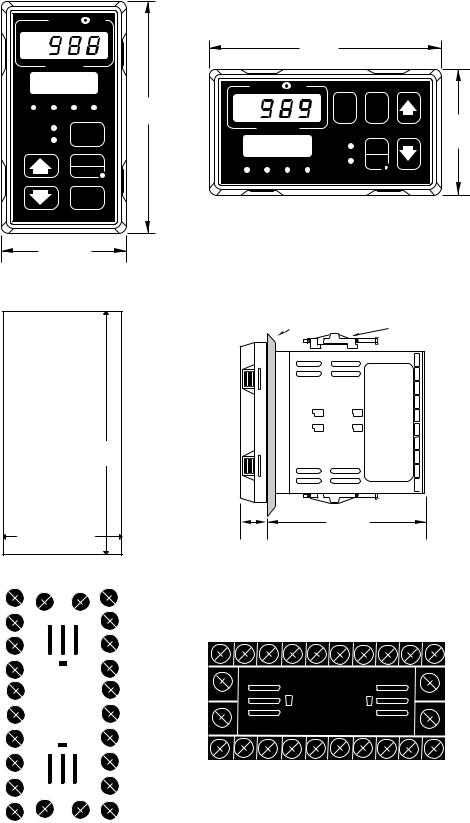

Figure Int.1 -

The Series 988 Controllers.

Watlow’s Series 988 controllers set a new standard in the controller industry by packing an impressive array of features into an 1/8-DIN package. No other controller offers the flexibility, compact size and durability of the Series 988. It can control a wide variety of temperature and process applications, with a broad range of input and output options that allow control of virtually any process variable.

The Series 988 is the only 1/8 DIN controller that can provide single-unit cascade control of a process. Its other features include heater current monitoring, remote set point input, ratio control and valve control through slidewire feedback. The Series 988 also delivers expanded auto-tuning capabilities, increased alarm functionality and several unique control algorithms.

When we refer to the “Series 988” controller, we refer also to the horizontal and low-voltage versions of the Series 988: the 986, 987, 988 and 989. We recommend that you read all of this manual’s introduction to familiarize yourself with the conventions and content of this manual and the steps to setting up a Series 988 controller. Make sure you understand the “Caution” and “Warning” symbols we use in the book.

Introduction |

WATLOW Series 988 User’s Manual |

i |

Introduction

Using this Manual

˜

NOTE:

The 12-digit number is printed on the top of the stickers on each side of the controller’s case and on the righthand or top circuit board.

˜

NOTE:

The Menu Overview in the Appendix shows all the menus and prompts.

This manual provides the information you will need to install and operate a Series 988 controller.

If you need information about Series 988 configurations and model numbers, refer to the Appendix of this manual or, for more detailed information, to Optimizing Your Process System with the Series 988 Controller: An Application Guide for the Watlow Series 988 Family.

If your Series 988 controller will be used for data communications, you will also need our communications manual, Data Communications with the Watlow Series 988 Family of Controllers (green cover).

Series 988 controllers are calibrated in the factory, but if you need to do periodic calibration you will need our calibration manual, Calibrating Watlow Process Controllers, (blue cover).

This manual explains the five steps of setting up a Series 988 controller:

1.Set and document all of the DIP switches, if applicable: Chapter 1.

2.Mount the controller: Chapter 2.

3.Wire and document the controller wiring: Chapter 2.

4.Configure and document the controller software: Chapters 3-6.

5.Run, test and adjust your application. Update documentation.

Chapters 7 and 8 and the Appendix provide detailed advice, definitions and specifications along with application examples to help you optimize the safety and performance of your application. Use the Table of Contents and Index to find specific information.

Document Every Step

The Series 988 provides powerful and complex features. Carefully document each step of the setup and any subsequent changes. This will make it much easier to change, adjust and troubleshoot your application.

Make the configuration documentation available to engineers and technicians, on all shifts, who may need to work with the Series 988. We provide space in this manual to record configurations. You may prefer to photocopy the blank forms and keep them in a separate binder. However you maintain your documentation, be sure to replace all old copies of the documentation with updated versions whenever the controller configuration is changed.

ii |

WATLOW Series 988 User’s Manual |

Introduction |

Introduction

Notes, Cautions and Warnings

We use note, caution and warning symbols throughout this book to draw your attention to important operational and safety information.

A bold text “NOTE” marks a short message in the margin to alert you to an important detail.

A bold text “CAUTION” safety alert appears with information that is important for protecting your equipment and performance. Be especially careful to read and follow all cautions that apply to your application.

A bold text “WARNING” safety alert appears with information that is important for protecting you, others and equipment from damage. Pay very close attention to all warnings that apply to your application.

The ç symbol (an exclamation point in a triangle) precedes a general CAUTION or WARNING statement.

The Ó symbol (a lightning bolt in a triangle) precedes an electric shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review all of your configuration information for each step of the setup to verify that your selections are consistent with your applications.

If the problem persists after checking all the steps, you can get technical assistance by calling Watlow Controls at (507) 454-5300, between 7 a.m. and 5 p.m. CST, and asking for an applications engineer. When you call have the following information on hand: the controller’s model number (the 12-digit number is printed on the top of the stickers on each side of the controller’s case and on the right-hand or top circuit board); your user’s manual; all configuration information; and the Diagnostics Menu readings.

We Value Your Feedback

Your comments and suggestions on this manual are welcome. Please send them to, Technical Writer, Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN 55987-5580 or call (507) 454-5300 or fax (507) 4524507.(1233)

Introduction |

WATLOW Series 988 User’s Manual |

iii |

Chapter 1 Hardware Setup

DIP Switch Locations and Functions

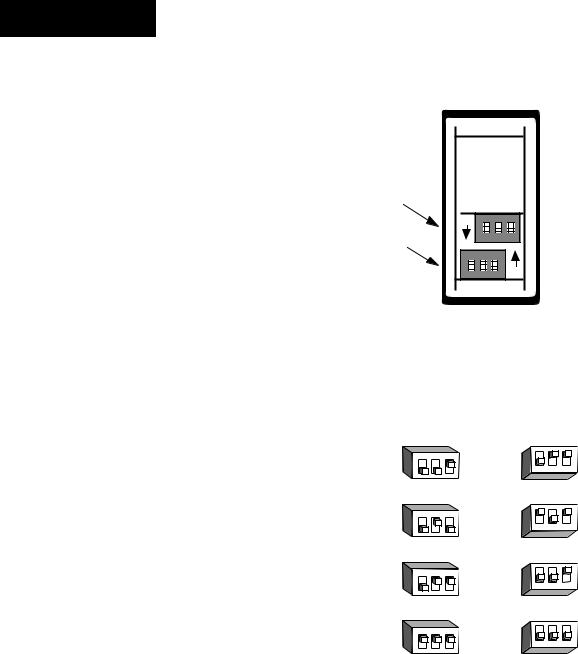

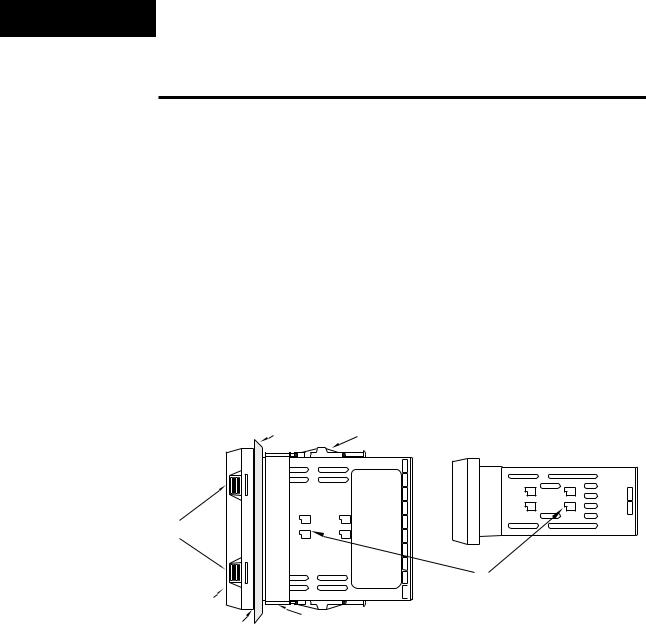

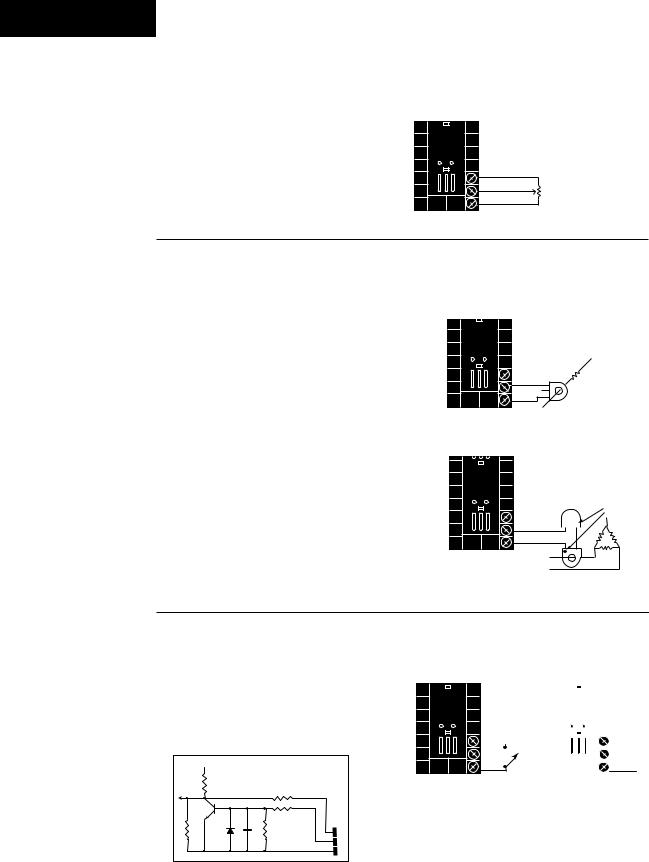

Figure 1.1 - Press the release tabs to remove the controller chassis.

The Watlow Series 988 has at least one and as many as six dual in-line package (DIP) switches inside the controller, depending on the model number. They allow users to configure the controller for a variety of input sensors, to provide power for external signal conditioners or to lockout front panel access to some functions.

To set any DIP switch:

•Remove the controller from the case by pressing firmly on the two release tabs on one side or the top of the bezel until they unsnap. Then firmly press the two release tabs on the opposite side or the bottom of the control until they unsnap. You will need to gently rock the bezel back and forth to release it from the chassis.

•Use the illustrations on the following pages to locate and set each DIP switch.

|

|

WATL W |

|

|||

|

|

PROCESS |

|

|

||

Release |

L1 |

L2 |

L3 |

L4 |

Release |

|

Tabs |

Tabs |

|||||

DEV |

|

|

|

|||

|

|

DISPLAY |

|

|||

|

% OUT |

|

|

|||

|

|

|

|

|

||

|

|

|

AUTO |

|

||

|

|

|

MAN |

|

||

|

|

|

MODE |

|

||

|

SERIES 988 |

|

|

|

||

Release

Tabs

WATL W

W

DSPY |

MODE |

PROCESS |

|

DEV |

AUTO |

% OUT |

MAN |

L1 L2 L3 L4 |

SERIES 989 |

Release

Tabs

Hardware Setup, Chapter 1 |

WATLOW Series 988 User’s Manual |

1.1 |

DIP Switches

˜

NOTE:

The Input 2 DIP switch is mounted upside down.

˜

NOTE:

Only controllers with the indicated model numbers have these DIP switches.

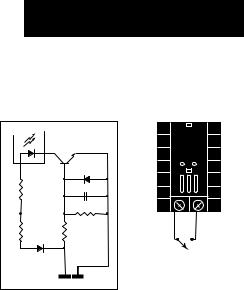

Figure 1.2 -

Input DIP switches.

1.Set the input DIP switches to match the sensors you are using in your application. Only controllers with model number 98_ _- 2_ _ _-_ _ _ _ or 98_ _- _2_ _-_ _ _ _ have an input DIP switch.

Input 2 DIP

Input 1 DIP

ON |

ON |

Controller Chassis

Rear View

Input 1 |

Input 2 |

(98 _ _-2_ _ _-_ _ _ _) (98 _ _-_2_ _-_ _ _ _)

|

O 1 |

2 |

3 |

|

|

− |

|

|

N |

|

|

|

|

|

N |

RTD (100 Ω ) |

− |

|

|

3 |

2 |

1 |

O |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

O |

1 |

2 |

3 |

|

|

− |

|

|

|

|

|

|

N |

|

|

N |

|

|

|

|

|

O |

thermocouple: R, S or B |

− |

|

|

3 |

2 |

1 |

|

|

|

|

|

|

|

|

|

|

O |

1 |

2 |

3 |

|

|

− |

|

|

|

|

|

|

N |

|

|

N |

|

|

|

|

|

O |

thermocouple: J, K, T, N, E, C, D, Pt2 |

− |

|

|

3 |

2 |

1 |

|

|

|

|

|

|

|

|

|

or 0-50mV (high impedance) |

|

|

|

|

|

|

|

|

O |

1 |

2 |

3 |

|

|

− |

|

|

|

|

|

|

N |

|

|

N |

|

|

|

|

|

O |

0-20 or 4-20mA; 0-5, 1-5 or 0-10V |

− |

|

|

3 |

2 |

1 |

|

|

|

|

|

|

|

|

|

1.2 |

WATLOW Series 988 User’s Manual |

Hardware Setup, Chapter 1 |

DIP Switches

˜

NOTE:

For other voltages or current settings contact the factory.

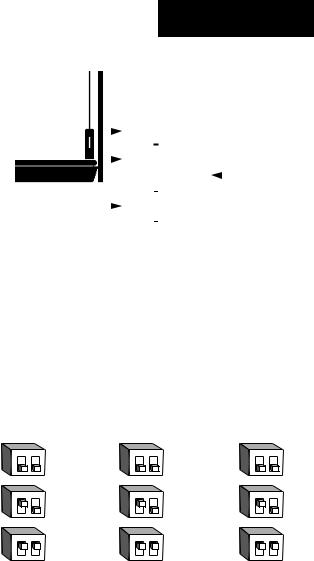

2.Set DIP switches for outputs equipped with an external signal conditioner power supply. Only controllers with model number 98_ _-_ _ _T-_ _ _ _, 98_ _-_ _ _

_-T_ _ _ or 98_ _-_ _ _

_-_T_ _ have an external signal conditioner power supply.

O utput 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Option Board |

|

|

|

|

|

|

|

|

|

|||

O utput 2 |

|

|

|

|

on |

|

off |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Option Board and DIP |

|

|

|

|

|

|

|

|

|

O utput 4 |

||

|

|

|

|

|

off |

|

on |

|

Option Board and DIP |

|||

O utput 3 |

|

|

|

|

|

|

|

|

|

|

|

|

Option Board and DIP |

|

off |

|

on |

|

|

|

|||||

Controlle r Chassis

Top V ie w (9 8 6 & 9 8 8 )

Le ft-side V ie w (9 8 7 & 9 8 9 )

˜

NOTE:

Only controllers with the indicated model numbers have these DIP switches.

Figure 1.3 - External signal conditioner power supply DIPs.

20V ± 5% @ 30mA

12V ± 5% @ 30mA

5V ± 5% @ 30mA

Output 2 |

Output 3 |

Output 4 |

|||

(98 _ _-_ _ _T-_ _ _ _) (98 _ _-_ _ _ _-T_ _ _) (98 _ _-_ _ _ _-_T_ _) |

|||||

O 1 |

2 |

O 1 |

2 |

O 1 |

2 |

N |

|

N |

|

N |

|

− |

|

− |

|

− |

|

O 1 |

2 |

O 1 |

2 |

O 1 |

2 |

N |

|

N |

|

N |

|

− |

|

− |

|

− |

|

O 1 |

2 |

O 1 |

2 |

O 1 |

2 |

N |

|

N |

|

N |

|

− |

|

− |

|

− |

|

3.When the DIP switches are set, gently insert the controller chassis into the case and push it firmly into place until all four tabs snap into place.

Hardware Setup, Chapter 1 |

WATLOW Series 988 User’s Manual |

1.3 |

DIP Switches

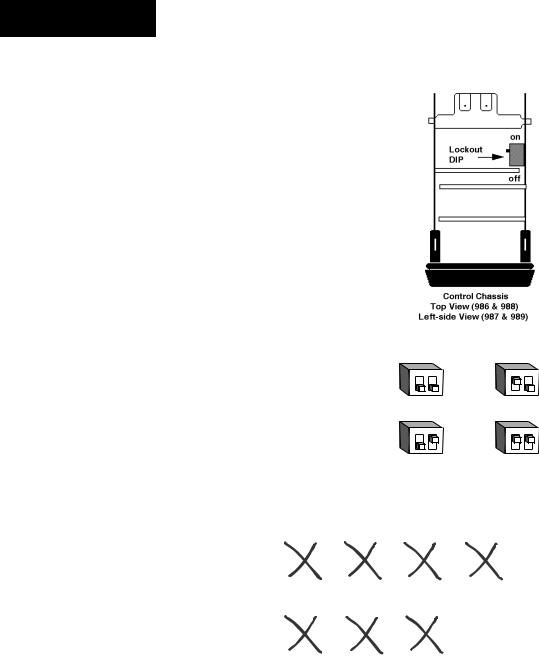

ç

CAUTION:

The lockout DIP switch makes the Setup and Factory menus unavailable. Configure all the Setup and Factory menus before locking them out. Failure to do so could result in damage to equipment in the event of a setup error.

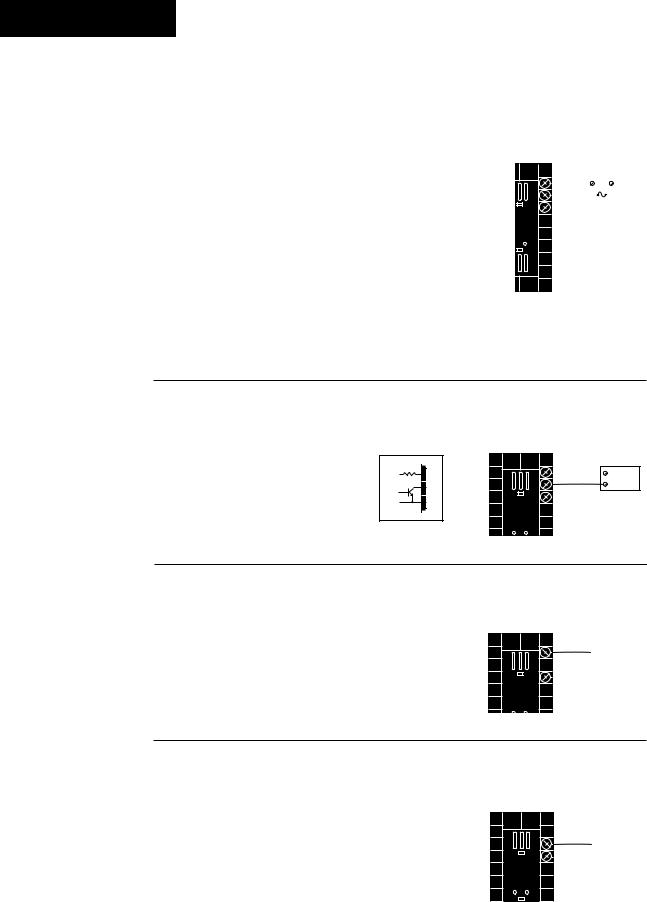

4.The lockout DIP switch hides the Setup Menus (Input, Output, Global and Communications) and the Factory Menus (Panel Lockout, Diagnostics and Calibration). All units have a lockout DIP switch.

no hardware lockout (Switch 1 has no effect.)

lockout Setup and Factory menus Figure 1.4 - (Switch 1 has no effect.)

Lockout DIP switch.

O 1 |

2 |

N |

|

− |

|

O 1 |

2 |

N |

|

− |

|

or

or

O 1 |

2 |

N |

|

− |

|

O 1 |

2 |

N |

|

− |

|

Input |

Output |

Global |

Commu- |

|

nications |

||||

|

|

|

[InPt] [OtPt] [GLbL] [COM

[`SEt] |

[`SEt] |

[`SEt] |

[`SEt] |

|

|

|

|

Panel |

Diagnostics |

Calibration |

|

|

|

||

Lockout |

|

|

|

[PLOC] [diAG][`CAL] |

|||

[Fcty] |

[Fcty] |

[Fcty] |

|

1.4 |

WATLOW Series 988 User’s Manual |

Hardware Setup, Chapter 1 |

Chapter 2 Installation and Wiring

˜

NOTE: Space panel

cutouts at least 1.66 inches (42.2mm) apart.

˜

NOTE:

Adjustable mounting brackets can be side-mounted.

˜

NOTE:

Holes can be cut in the panel using a Greenlee 1/8 DIN Hydraulic Kit #60068 (punch #60069, die #60070).

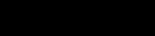

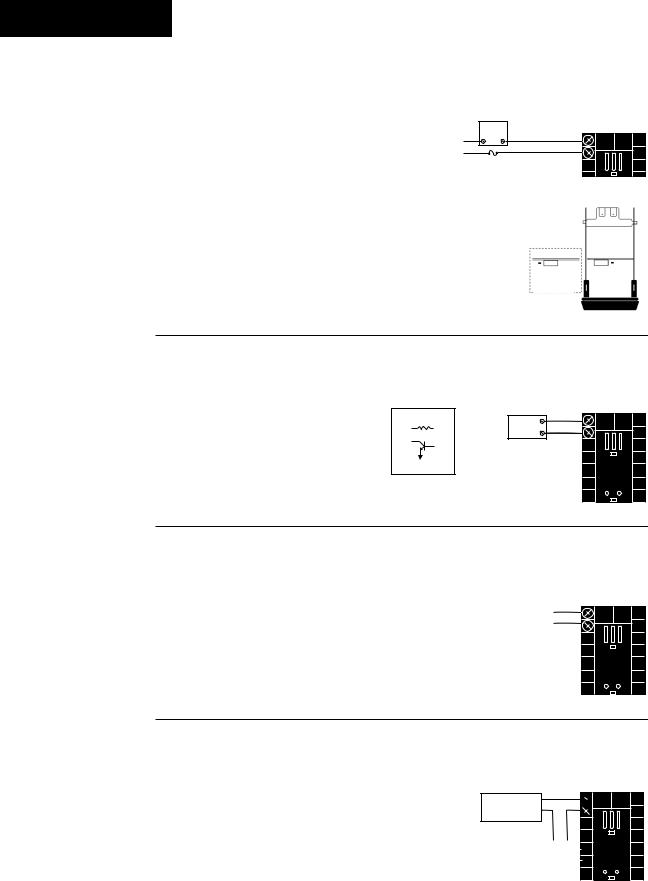

Figure 2.1 - Series 988 and Series 989 dimensions and terminal number layout.

|

WATL W |

|

|

|

|

|

||

|

|

|

|

|

|

|

4.03" |

|

|

|

|

|

|

|

|

(102mm) |

|

|

PROCESS |

|

|

|

|

|

|

|

|

|

|

|

|

WATL W |

|

||

|

|

|

|

4.03" |

|

|

DSPY |

MODE |

L1 |

L2 |

L3 |

L4 |

(102mm) |

|

|

|

2.18" |

DEV |

|

|

|

|

PROCESS |

|

||

|

DISPLAY |

|

|

(55 mm) |

||||

% OUT |

|

|

|

|

|

|||

|

|

|

|

|

|

DEV |

AUTO |

|

|

|

|

|

|

|

|

||

|

|

AUTO |

|

|

|

% OUT |

MAN |

|

|

|

MAN |

L1 |

L2 |

L3 |

L4 |

SERIES 989 |

|

|

|

|

|

|||||

|

|

MODE |

|

|

|

|

|

|

SERIES 988 |

|

|

|

|

|

|

|

|

|

2.18" |

|

|

|

|

|

|

|

(55 mm) |

|

|

|

|

|

|

||

|

|

Panel |

Adjustable |

Panel Cutout |

|

Mounting Bracket |

|

|

|

||

|

|

|

|

Maximum Panel |

|

|

|

Thickness |

|

|

|

0.38" (9.65mm) |

|

|

|

3.62" + 0.03 -0.00 |

|

|

|

(92mm + 0.8) |

|

|

|

1.77 + 0.02 -0.00 |

0.68" |

|

4.06" |

(17 mm) |

|

(103 mm) |

|

(45mm + 0.6) |

|

||

|

|

|

1 |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

13 |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

4 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

|

|

|

||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

22 |

|

|

|

|

|

|

24 |

|

|

|

|

5 |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

16 |

|

|

|

|

21 |

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

3 |

4 |

5 |

6 |

7 |

|

|

|

|

|||

7 |

|

|

|

|

2 |

8 |

9 |

|

|

|

||||||

17 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

10 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

8 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

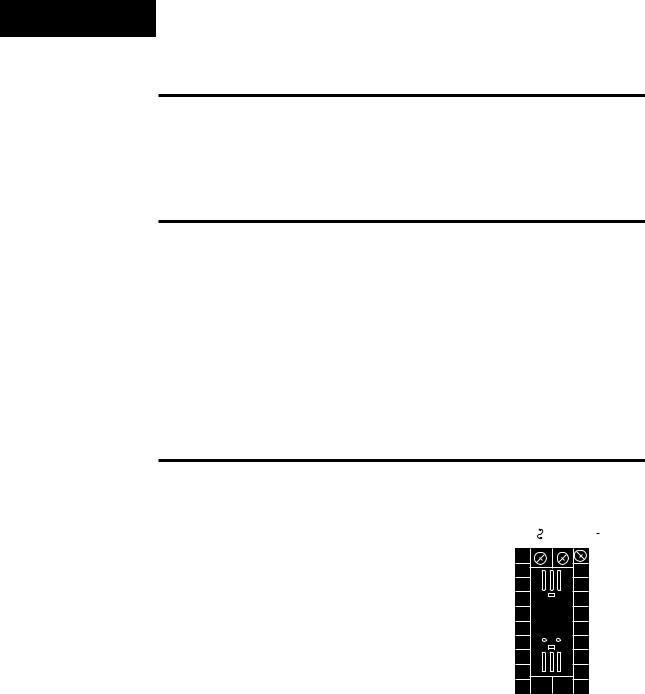

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

20 |

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual |

2.1 |

Installation

Installing the Series 988

Installing and mounting requires access to the back of the panel.

1.Make a panel cutout using the panel cutout dimensions from the previous page.

2.To remove the controller chassis from its case, press in firmly on the two tabs on one side or the top of the bezel until they unsnap, then unsnap

˜the two tabs on the opposite side or the bottom. Pull the chassis out of the case by gently rocking it.

NOTE:

Removing the controller chassis from its case makes mounting easier.

3.Slide the case into the panel cutout. Check to see that the gasket is not twisted, and is seated within the case bezel flush with the panel. Slide

Figure 2.2 -

Side and top view.

Side (986 or 988) |

|

||

or Top and Bottom (987 or 989) View |

|

||

Panel |

Adjustable |

Top and Bottom (986 or 988) |

|

or Side (987 or 989) View |

|||

|

Mounting Bracket |

||

|

|

||

Release Tabs |

|

|

|

|

|

Mounting Slots |

|

Bezel |

|

|

|

External Gasket |

Mounting Collar |

|

|

|

|

||

2.2 |

WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

Installation

the mounting collar over the back of the control.

4.Loosen the mounting bracket screws enough to allow for the mounting collar and panel thickness. Place each mounting bracket into the mounting slots (head of the screw facing the back of the controller). Push each bracket backward then down to secure it to the control case. To guarantee a proper NEMA 4X seal, Series 986 and 988 units (vertical) must have the mounting brackets located on either side of the unit. When installing Series 987 and 989 units (horizontal) the brackets must be on the top and bottom of the unit.

ç5. Make sure the case is seated properly. Tighten the installation screws firmly against the mounting collar to secure the unit. To ensure a

CAUTION:

Follow the installation procedure exactly to guarantee a proper NEMA 4X seal. Make sure the gasket between the panel and the rim of the case is not twisted and is seated properly. Failure to do so could result in damage to equipment.

NEMA 4X seal, there should be no space between the bezel and panel. Overtightening the screws will distort the case and make it difficult to remove or replace the controller.

6.Make sure the inside gasket is seated properly and not twisted. Insert the controller chassis into its case and press the bezel until all four tabs snap.

7.To release the mounting brackets, loosen the mounting bracket screws and push the brackets forward, then pull it up and out.

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual |

2.3 |

Wiring

WARNING:

To avoid potential electric shock, use National Electric Code (NEC) safety practices when wiring and connecting this unit to a power source and to electrical sensors or peripheral devices. Failure to do so could result in injury or death.

Wiring the Series 988

Wiring options depend on the model number and DIP switch settings. Check the terminal designation stickers on either side of the controller and compare your model number to those shown here and with the model number breakdown on the inside back cover of this manual.

Input-to-output Isolation

The Series 988 uses optical isolation between the analog inputs and the controller outputs/digital input. This isolation provides a 500VÅ (ac) barrier to prevent ground loops when using grounded sensors and/or peripheral equipment.

Here is a breakdown of the isolation barriers:

•Analog inputs 1 and 2 are grouped together.

•Outputs 1 through 4 and the standard event input are grouped together.

˜This does not apply to Output 4 when configured as communications.

•The digital communications output (4) is separate from the above

NOTE: Input-to-output isolation is defeated when the external signal conditioner power supply is used to power a transmitter connected to input 1 or input 2.

Figure 2.4 -

Power wiring.

groups.

Power Wiring

100 to 240V‡ (ac/dc) nominal, (85 to 264 actual) |

|

|

|

|

|

|

|

|

|

|

Vertical Package |

98 8 _ - _ _ _ _ - _ _ _ _ |

L1 |

L2 |

|

|

|

|

|||

|

|

|

|

|

|

|||||

Horizontal Package |

98 9 _ - _ _ _ _ - _ _ _ _ |

fuse |

|

+ |

|

- |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

22 |

|

|

|

|

|||

|

|

21 |

|

|

|

11 |

|

|

|

|

earth ground

24 to 28 V‡ (ac/dc) nominal, (20 to 30 actual)

Vertical Package |

98 6 _ - _ _ _ _ - _ _ _ _ |

Horizontal Package |

98 7 _ - _ _ _ _ - _ _ _ _ |

2.4 |

WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

ç

CAUTION:

The Series 988 will not function with two grounded thermocouple inputs. Avoid using a grounded thermocouple for both input 1 and input 2. Failure to follow this guideline could result in damage to equipment.

NOTE: Input-to-output isolation is defeated when the external signal conditioner power supply is used to power a transmitter connected to input 1 or input 2.

Wiring

Sensor Installation Guidelines

Maintain isolation between input 1 and input 2 to prevent a ground loop. A ground loop may cause incorrect readings, dashes across the upper display or the display of error codes.

Thermocouple input: Extension wire for thermocouples must be of the same alloy as the thermocouple itself to limit errors.

Using grounded thermocouples for both input 1 and input 2 may create ground loop problems. To correct this problem, replace at least one of the grounded thermocouples with an ungrounded thermocouple. If the application requires grounded thermocouples, use an isolated transmitter, such as a Watlow Gordon 5702 isolated transmitter.

RTD (100 Ω ) input: Each 1Ω of lead wire resistance can cause a +2°C error when using a two-wire RTD. A three-wire RTD sensor overcomes this problem. All three wires must have the same electrical resistance (i.e., same gauge, same length, multi-stranded or solid, same metal).

Process input: Isolation must be maintained between input 1 and input 2. If both input 1 and input 2 are used as process inputs, a separate power supply and transmitter must be used for each input. Output option T (external signal conditioner power supply) can be used to supply power for only one input.

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual |

2.5 |

Wiring Example

WARNING:

To avoid potential electric shock, use National Electric Code (NEC) safety practices when wiring and connecting this unit to a power source and to electrical sensors or peripheral devices. Failure to do so could result in injury or death.

ç

WARNING: Install high or low temperature limit

control protection in systems where an over temperature fault condition could present a fire hazard or other hazard. Failure to install temperature limit control protection where a potential hazard exists could result in damage to equipment, property and injury to personnel.

ç

WARNING:

To avoid damage to property and equipment, and/or injury of loss of life, use National Electric Code (NEC) standard wiring practices to install and operate the Series 988. Failure to do so could result in such damage, and/or injury or death.

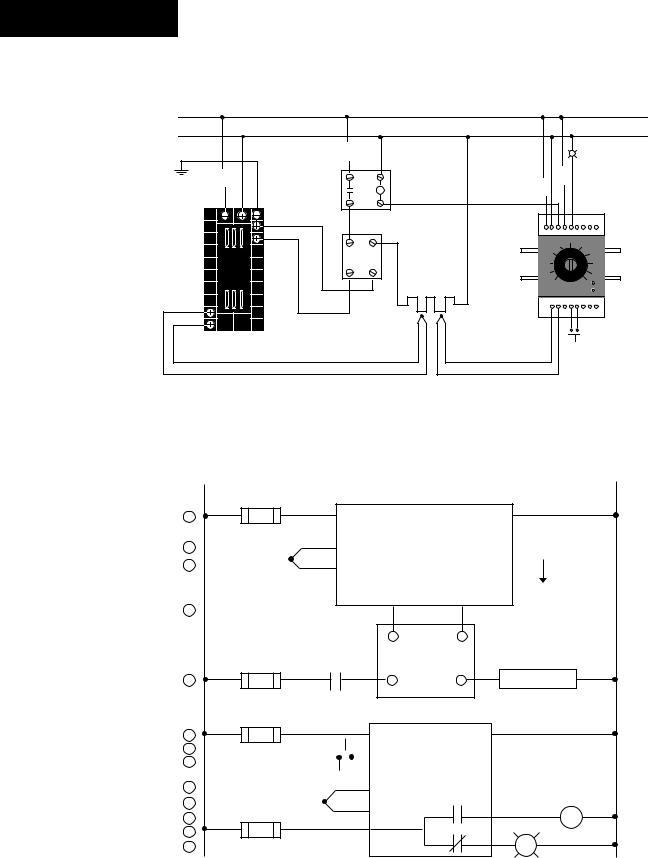

Figure 2.6 - System wiring example.

L1

120VÅ (ac)

L2

earth ground |

high-temperature |

light |

|

|

|

|

high-limit |

|

|

fuse |

|

|

coil |

mechanical |

|

|

|

|

|

|

contactor |

|

|

2 1 |

2 2 |

1 1 |

|

|

|

|

|

|

1 2 (+) |

SSR-240-10A-DC1 |

1 |

5 |

|

|

|

1 3 (-) |

92A3-1DJ1-0000 |

|

||

|

|

out |

dc input |

|

||

|

|

|

limit control |

|

||

|

|

1 |

2 |

SSR |

|

|

|

|

|

|

|

||

|

|

4 |

3 |

|

|

|

|

|

|

in |

|

|

|

|

|

|

|

heater |

|

|

9 (+) |

|

13 |

14 |

|

1 0 (-) |

|

|||

10 |

11 |

|

||

red |

|

|||

+ |

- |

|

||

988A-10CA-AARR |

|

|

optional |

|

rear view |

|

|

||

process sensor |

limit sensor |

|

normally open |

|

momentary switch |

||||

|

|

|||

120VÅ (ac) |

L2 |

L1 |

1 |

|

|

21 |

|

|

|

22 |

|

1 |

3 |

|

|

|

|

|

2 |

|

2 |

4 |

(+) |

9 |

|

Series 988 |

|

|

|

|

|

988A-10CA-AARR |

11 |

|||||

|

5 |

(-) |

|

|||||

3 |

10 |

temperature control |

||||||

|

||||||||

|

|

|

|

12 |

13 |

|

||

4 |

|

|

|

6 |

7 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

in |

|

SSR-240-10A-DC1 |

|

|

|

|

|

(+) 3-32VÎ (dc) |

(-) |

solid-state relay, dc input |

||

|

|

|

|

|

||||

|

|

|

1 CR-1 |

|

|

|

|

|

|

|

5 |

1 |

8 |

9 |

|

out |

10 |

|

heater |

|

2 |

|

|

24-240VÅ (ac) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

6 |

1 |

11 |

|

|

1 |

2 |

|

|

|

2 |

7 |

|

12 |

13 |

|

|

|

|

|||

|

|

|

|

Series 92 |

|

|

||||

8 |

|

|

|

13 |

|

|

|

|

||

|

|

|

14 |

|

92A3-1DJ1-0000 |

|

||||

|

|

|

|

|

|

|

||||

|

|

|

(+) |

14 |

|

|

limit control |

|

|

|

9 |

|

|

10 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

10 |

|

|

(-) |

15 |

11 |

3 |

|

|

|

|

|

|

|

|

|

|

|

1CR |

|

||

11 |

|

|

|

|

|

|

16 |

2 |

||

|

|

|

|

4 |

|

|

||||

12 |

|

|

|

|

|

|

|

|||

1 |

17 |

|

|

|

5 |

|

|

|

|

|

13 |

|

|

|

18 |

R |

|

2 |

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

high-temperature light

2.6 |

WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

|

|

|

|

|

|

|

|

|

|

|

|

Wiring Notes |

|

|

|

|

|

|

|

|

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

|

L2 |

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

earth ground |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

11 |

22 |

|

|

|

|||||

|

|

power |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

ç

WARNING:

To avoid damage to property and equipment, and/or injury of loss of life, use National Electric Code (NEC) standard wiring practices to install and operate the Series 988. Failure to do so could result in such damage, and/or injury or death.

˜

NOTE:

Sketch in your application on this page or a copy of it. See wiring examples in this chapter and in the Appendix.

Figure 2.7 -

Wiring notes.

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual |

2.7 |

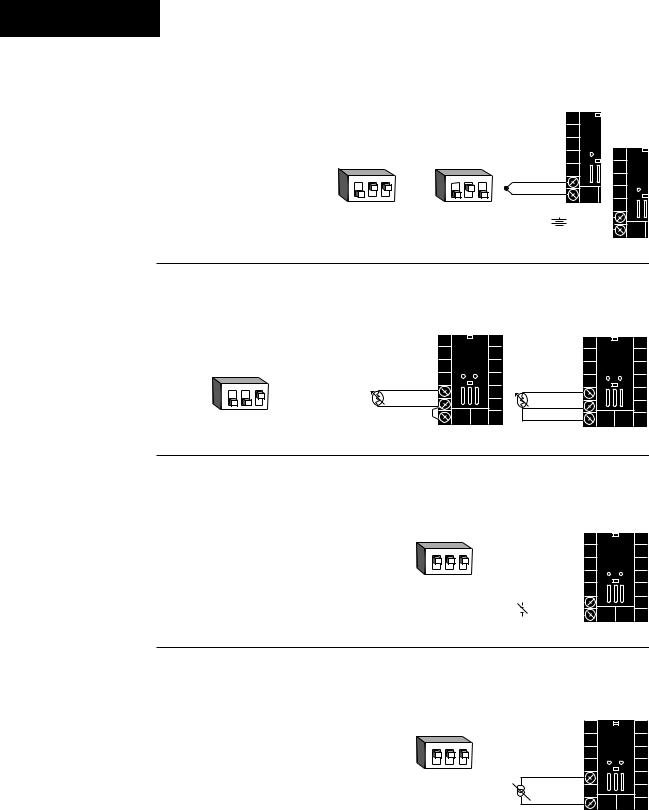

Input 1 Wiring

˜ |

Figure 2.8a — Thermocouple or 0-50mV (high impedance) |

|

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

Thermocouple only |

|

|

|

|

|

|

|

|

98 _ _ - 1 _ _ _ - _ _ _ _ |

(no DIP switches) |

|

|

|

|

|

||

Universal signal conditioner |

|

|

|

|

|

|

+ |

9 |

98 _ _ - 2 _ _ _ - _ _ _ _ |

O 1 |

2 |

3 |

O 1 |

2 |

3 |

||

N |

|

|

N |

|

|

- |

10 |

|

|

− |

|

|

− |

|

|

|

|

Input impedance: 20MΩ |

J, K, T, N, C, E, D, Pt2, |

R, S, B |

+ |

9 |

||||||

0-50mV DIP Settings |

DIP Settings |

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

10 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-50mV |

|

Figure 2.8b — RTD (2- or 3-wire) (100 Ω )

Universal signal conditioner

Jumper

#9 to #10

98 _ _ - 2 _ _ _ - _ _ _ _ for 2-wire RTD

O 1 |

2 |

3 |

S1 |

8 |

S1 |

8 |

N |

|

|

|

|

|

|

− |

|

|

S2 |

9 |

S2 |

9 |

DIP Switch |

|

10 |

S3 |

10 |

||

Setting |

|

|

|

|

||

|

|

|

|

|

||

Figure 2.8c — 0-5VÎ, 1-5VÎ or 0-10VÎ (dc) Process

Universal signal conditioner

98 _ _ - 2 _ _ _ - _ _ _ _

Input impedance: 10KΩ

O 1 2 3

N

−

DIP Switch |

|

|

|

|

Setting |

+ |

9 |

||

|

|

|||

|

|

|

- |

10 |

|

|

|

||

|

|

|

||

Figure 2.8d — 0-20mA or 4-20mA Process

Universal signal conditioner

98 _ _ - 2 _ _ _ - _ _ _ _

Input impedance: 7Ω

O 1 2 3

N

−

DIP Switch - 8

Setting

+ 10

2.8 |

WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

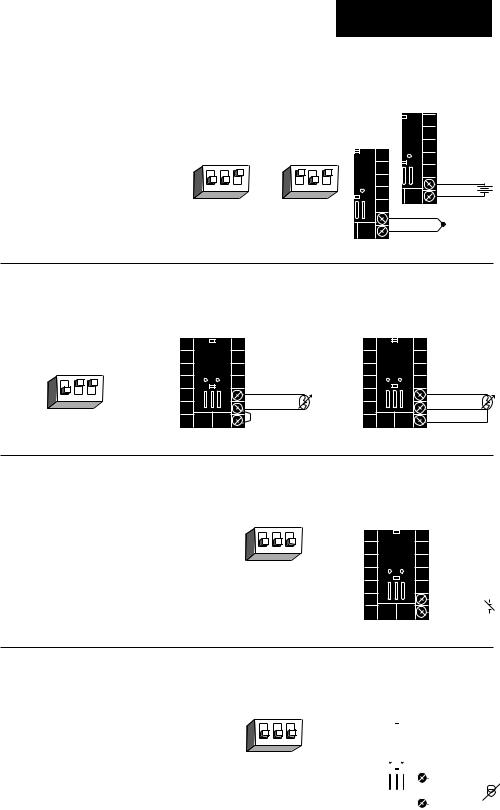

Input 2 Wiring

Figure 2.9a — Thermocouple or 0-50mV (high impedance)

Thermocouple only

98 _ _ - _ 1 _ _ - _ _ _ _ (no DIP switches)

Universal signal conditioner |

|

|

|

|

|

|

|

|

|

19 |

+ |

98 _ _ - _ 2 _ _ - _ _ _ _ |

|

|

|

N |

|

|

|

N |

|

||

|

|

|

|

− |

|

|

|

− |

|

|

|

|

3 |

2 |

1 |

O |

3 |

2 |

1 |

O |

|

20 |

- |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Input impedance: 20MΩ |

J, K, T, N, C, E, D, Pt2, |

R, S, B |

|

|

|

|

0-50mV |

||||

|

|

19 |

+ |

|

|||||||

0-50mV DIP Settings |

DIP Settings |

|

|||||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

20 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2.9b — RTD (2- or 3-wire) (100 Ω )

Universal signal conditioner |

|

Jumper |

|

|

|||

|

#19 to #20 |

|

|

||||

98 _ _ - _ 2 _ _ - _ _ _ _ |

|

|

|

||||

|

for 2-wire |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

− |

18 |

S1 |

18 |

S1 |

|

|

|

N |

||||

3 |

2 |

1 |

O |

|

|

|

|

|

19 |

S2 |

|

S2 |

|||

|

|

|

|

19 |

|||

DIP Switch |

|

20 |

|

20 |

S3 |

||

Setting |

|

|

|

|

|

||

Figure 2.9c — 0-5VÎ, 1-5VÎ or 0-10VÎ (dc) Process

Universal signal conditioner |

− |

|

N |

98 _ _ - _ 2 _ _ - _ _ _ _ |

3 |

2 |

1 |

O |

|

|

|

|

|

|

|

|

|

|

|||

|

DIP Switch |

|

|

|

|

|

||

|

Setting |

|

|

|

|

|

|

|

Input impedance: 10KΩ |

|

|

|

|

19 |

+ |

|

|

|

|

|

|

|

20 |

- |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

Figure 2.9d — 0-20mA or 4-20mA Process |

|

|

||||||||||

Universal signal conditioner |

|

|

|

|

|

|

|

− |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

98 _ _ - _ 2 _ _ - _ _ _ _ |

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

1 |

O |

|

|

|

|

||

23 |

|

|

|

|

|

|||||||

Input impedance: 7Ω |

DIP Switch |

|

|

18 |

- |

|

||||||

Setting |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

+ |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual |

2.9 |

Input 2 Wiring

NOTE:

See Chapter 8 for information on slidewire feedback.

˜

NOTE:

A process output cannot be installed on output 1 when using a current transformer input.

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

Figure 2.10a — Slidewire Feedback or Potentiometer Input

98 _ _ - _ 3 _ _ - _ _ _ _

18 |

CCW |

|

|

19 |

Wiper |

|

|

20 |

CW |

|

Figure 2.10b — Current Transformer Input

98 _ _ - _ 4 _ _ - _ _ _ _

The current transformer must be purchased separately. See Appendix for Watlow current transformer part numbers.

Systems that use more than 50 Amps need an interstage transformer. For example, if you use a 300A current transformer, part #16-0073, and an interstage transformer, part #160176, the 300A current transformer provides a 5A signal to the interstage transformer. In turn, the transformer sends a 20mA maximum signal to the controller.

L2

Load wire 19 CT

20

Center leg not used

L1

Single-phase

Phase dot

T1

19

19

20

T3

T2

3-phase using 2 current transformers

Figure 2.10c — Digital Event Input 2

98 _ _ - _ 5 _ _ - _ _ _ _

open 0-3VÎ (dc) Event Input 2 off closed 14-36VÎ (dc) Event Input 2 on

+5VÎ (VDC) |

|

|

|

|

Internal Circuitry |

|

|

|

|

100Ω |

|

|

|

4.7KΩ |

|

1KΩ |

.01µf |

750Ω |

18 |

|

|||

|

|

|

|

|

|

|

19 |

|

|

|

20 |

18 |

|

|

|

|

|

|

|

19 |

+ |

20 |

|

|

20 |

|

|

|

- |

||

|

|

|

|

2.10 WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

Event Input 1 Wiring

Figure 2.11a — Digital Event Input 1

Available on all units.

open 14-36VÎ (dc) Event Input 1 off closed 0-3VÎ (dc) Event Input 1 on

|

OPTO |

|

|

|

ISOLATOR |

|

|

4.99KΩ |

|

.01µf |

|

+24VÎ (dc) |

|

750Ω |

24 |

|

|

23 |

|

10KΩ |

|

+ |

- |

4.99KΩ |

|

||

Internal Circuitry |

|

|

|

|

23 |

24 |

|

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual 2.11 |

Output 1 Wiring

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

NOTE:

Switching inductive loads (relay coils, solenoids, etc.) with the mechanical relay or solid state relay output options requires using an R.C. suppressor. Watlow carries the R.C. suppressor Quencharc brand name, which is a trademark of ITW Paktron. Watlow Part No. 0804-0147- 0000.

Figure 2.12a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ _ - _ _ B _ - _ _ _ _

0.5 amps, minimum off-state impedance: 20KΩ

|

|

|

External |

|

|

||||

Electromechanical Relay with Contact Suppression |

12 |

NO |

|

Load |

|

L2 |

|||

13 |

COM |

|

|

|

|

|

|

||

(Suppression between NO and COM contacts only) |

|

|

|

|

|

|

L1 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuse |

|

|||||

98 _ _ - _ _ D _ - _ _ _ _ |

14 |

NC |

|

|

|

|

|

|

|

(#14 for D & E outputs only) |

|

||||||||

Form C, 5 amps, minimum off-state impedance: 20KΩ |

|

||||||||

|

|

|

|

|

|

|

|

|

|

Electromechanical Relay without Contact Suppression

98 _ _ - _ _ E _ - _ _ _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ _ - _ _ K _ - _ _ _ _

0.5 amps, off-state impedance: 31MΩ

Figure 2.12b — Switched DC, Open Collector

98 _ _ - _ _ C _ - _ _ _ _ |

19 to 32VÎ (dc) |

|

|

+ |

12 |

Maximum voltage: 42VÎ (dc) |

790Ω |

|

|

13 |

|

Maximum current: 1A |

|

14 |

|

Internal Circuitry |

|

12 |

+ |

External |

|

13 |

- |

||

Load |

|||

|

|

||

14 |

COM |

|

Figure 2.12c — 0-20mA and 4-20mA Process

98 _ _ - _ _ F _ - _ _ _ _

12 +

Maximum load impedance: 800Ω

14

-

Figure 2.12d — 0-5VÎ, 1-5VÎ and 0-10VÎ (dc) Process

98 _ _ - _ _ F _ - _ _ _ _

Minimum load impedance: 1KΩ

13

+

14

-

2.12 WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

NOTE:

Switching inductive loads (relay coils, solenoids, etc.) with the mechanical relay or solid state relay output options requires using an R.C. suppressor. Watlow carries the R.C. suppressor Quencharc brand name, which is a trademark of ITW Paktron. Watlow Part No. 0804-0147- 0000.

Output 2 Wiring

Figure 2.13a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ _ - _ _ _ B - _ _ _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression |

|

|

|

|

|

||||

15 |

NO |

External |

|

L2 |

|||||

(Suppression between NO and COM contacts only) |

|

Load |

|

||||||

98 _ _ - _ _ _ D - _ _ _ _ |

|

|

|

|

|

|

|

|

|

16 |

COM |

|

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

Fuse |

|

|||||

Form C, 5 amps, minimum off-state impedance: 20KΩ |

17 |

NC |

|

|

|||||

|

|

|

|

|

|

|

|||

(#17 for D & E outputs only) |

|

||||||||

Electromechanical Relay without Contact Suppression

98 _ _ - _ _ _ E - _ _ _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ _ - _ _ _ K - _ _ _ _

0.5 amps, off-state impedance: 31MΩ

Figure 2.13b — Switched DC, Open Collector

98 _ _ - _ _ _ C - _ _ _ _ |

19 to 32VÎ (dc) |

|

|

|

|

|

|

||

|

+ |

15 |

|

|

|

790Ω |

|

|

|

Maximum voltage: 42VÎ (dc) |

|

16 |

|

|

|

15 |

+ |

|

|

Maximum current: 1A |

|

External |

||

|

16 |

- |

||

|

|

17 |

|

|

|

Internal Circuitry |

|

Load |

|

|

|

|

||

|

|

17 |

COM |

|

Figure 2.13c — 0-20mA and 4-20mA Process

15 +

98 _ _ - _ _ _ F - _ _ _ _ |

17 |

- |

Maximum load impedance: 800Ω

˜

NOTE: Input-to-output isolation is defeated when the external signal conditioner power supply is used to power a transmitter connected to input 1 or input 2.

Figure 2.13d — 0-5VÎ, 1-5VÎ and 0-10VÎ (dc) Process

98 _ _ - _ _ _ F - _ _ _ _ |

16 |

+ |

|

17 |

- |

||

|

|||

|

|

||

Minimum load impedance: 1KΩ |

|

|

Figure 2.13e — External Signal Conditioner Power Supply

|

|

|

|

Loop powered |

|

98 _ _ - _ _ _ T - _ _ _ _ |

15 |

+ |

1 |

+V Transmitter |

|

16 |

- |

2 |

V- 4-20mA out |

||

|

|||||

|

|

+- |

|

|

|

|

Input |

|

|

||

|

1 or 2 |

|

|

||

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual 2.13 |

Output 3 Wiring

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

Figure 2.14a — AC Outputs

Solid-state Relay with Contact Suppression |

|

98 _ _ - _ _ _ _ - B _ _ _ |

L2 |

0.5 amps, minimum off-state impedance: 20KΩ |

L1 |

|

Electromechanical Relay without Contact Suppression

98 _ _ - _ _ _ _ - J _ _ _ _

Form A or B, 5 amps, off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ _ - _ _ _ _ - K _ _ _ _

0.5 amps, off-state impedance: 31MΩ

|

NC Form B |

|

External |

or |

|

Load |

NO Form A |

1 |

|

COM |

2 |

Fuse |

|

|

Form A or B alarm jumper settings (98__-

____-J___ only)

Form A

Form B

NOTE:

Switching inductive loads (relay coils, solenoids, etc.) with the mechanical relay or solid state relay output options requires using an R.C. suppressor. Watlow carries the R.C. suppressor Quencharc brand name, which is a trademark of ITW Paktron. Watlow Part No. 0804-0147- 0000.

NOTE: Input-to-output isolation is defeated when the external signal conditioner power supply is used to power a transmitter connected to input 1 or input 2.

Figure 2.14b — Switched DC |

|

|

|

|

|

|

98 _ _ - _ _ _ _ - C _ _ _ |

19 to 32VÎ (dc) |

+ |

1 |

|||

|

|

|

||||

|

1 |

|

|

+ |

External |

2 |

Minimum load resistance: 500Ω |

|

790Ω |

Load - |

|||

|

|

|

|

|

||

2 |

|

|

|

|

|

|

|

Internal Circuitry |

|

|

|||

Figure 2.14c — Process Retransmit |

|

|

|

0-20mA, 4-20mA, Load impedance: 600Ω max. |

+ |

1 |

|

98 _ _ - _ _ _ _ - M _ _ _ |

2 |

||

- |

|||

0-5VÎ, 1-5VÎ, 0-10VÎ (VDC), Load impedance: |

500Ω min. |

|

|

98 _ _ - _ _ _ _ - N _ _ _ |

|

|

Figure 2.14d — External Signal Conditioner Power Supply

98 _ _ - _ _ _ _ - T _ _ _ |

˜ |

|

NOTE: |

|

See Chapter 1 for |

|

power supply DIP |

|

switch information. |

Loop powered |

|

||

Transmitter |

+V |

+ |

|

- |

|||

-V |

|||

4-20mA out |

|||

|

|||

|

|

||

|

+ |

- |

|

|

Input |

||

|

1 or 2 |

||

1

2

2.14 WATLOW Series 988 User’s Manual |

Installation and Wiring, Chapter 2 |

NOTE:

Successful installation requires five steps:

•Model number and software choice (Appendix);

•DIP switch settings (Chapter 1);

•Sensor match

(Chapter 2 and Appendix);

•Sensor installation (Chapter 2); and

•Wiring (Chapter 2).

NOTE:

Switching inductive loads (relay coils, solenoids, etc.) with the mechanical relay or solid state relay output options requires using an R.C. suppressor. Watlow carries the R.C. suppressor Quencharc brand name, which is a trademark of ITW Paktron. Watlow Part No. 0804-0147- 0000.

NOTE: Input-to-output isolation is defeated when the external transmitter power supply is used to power a signal conditioner connected to input 1 or input 2.

Output 4 Wiring

Figure 2.15a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ _ - _ _ _ _ - _ B _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression |

|

|

External |

|

|

|

||

(Suppression between NO and COM contacts only) |

L2 |

|

Load |

|

NO |

5 |

||

|

|

|

|

|

COM |

6 |

||

L1 |

|

|

|

|

|

|||

|

|

|

|

|

||||

98 _ _ - _ _ _ _ - _ D _ _ _ |

|

|

|

|

|

|||

|

Fuse |

|

|

|

||||

|

|

|

|

|

||||

Form C, 5 amps, minimum off-state impedance: 20KΩ |

|

|

|

|

|

|

NC |

7 |

|

(#7 for D & E outputs only) |

|||||||

Electromechanical Relay without Contact Suppression

98 _ _ - _ _ _ _ - _ E _ _ _

Form C, 5 amps, off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ _ - _ _ _ _ - _ K _ _ _

0.5 amps, off-state impedance: 31MΩ

Figure 2.15b — Switched DC, Open Collector

98 _ _ - _ _ _ _ - _ C _ _ |

19 to 32VÎ (dc) |

|

|

|

||

|

5 |

790Ω |

+ |

External |

+ |

5 |

|

|

|

||||

|

|

|

- |

6 |

||

Maximum voltage: 42VÎ (dc) |

|

|

Load |

|||

6 |

|

|

||||

|

|

|

|

|||

|

|

|

COM |

7 |

||

Maximum current: 1A |

7 |

|

|

|

||

|

|

|

|

|

||

|

Internal Circuitry |

|

|

|

||

Figure 2.15c — External Signal Conditioner Power Supply

98 _ _ - _ _ _ _ - _ T _ _

˜

NOTE:

See Chapter 1 for power supply DIP switch information.

Loop powered |

|

+ |

||

Transmitter |

+V |

|||

- |

||||

-V |

||||

4-20mA out |

||||

|

||||

|

|

|

||

|

+ |

- |

||

|

|

Input |

||

|

|

1 or 2 |

||

5

6

For data communications wiring refer to Data Communications with the Watlow Series 988 Family of Controllers.

Installation and Wiring, Chapter 2 |

WATLOW Series 988 User’s Manual 2.15 |

Chapter 3 Front Panel and Display Loop

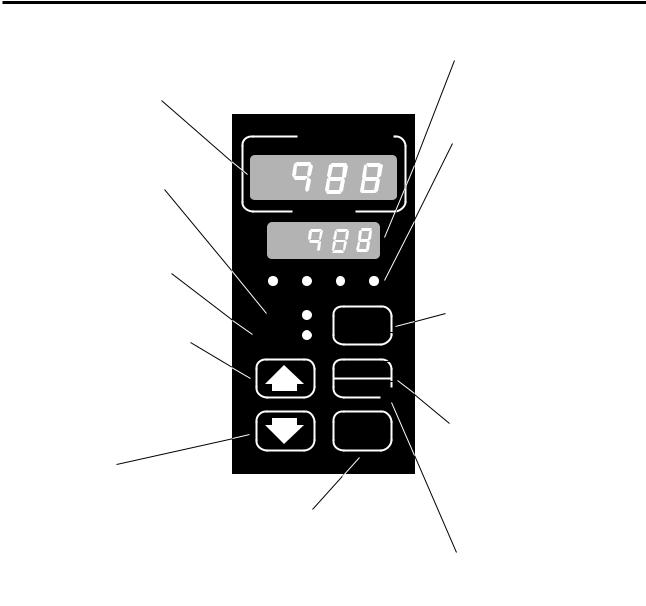

Keys and Displays

Upper Display

Indicates the actual process value, prompt parameter value or error code.

DEV LED

When lit, the lower display shows the most recent deviation unit from the set point.

% OUT LED

When lit, the lower display shows the current percent output.

Up-arrow Key

Increases the value or changes the parameter in the upper display (except for set point changes in the Display Loop, which occur in the lower display). Hold the key down to increase the value rapidly. New data takes effect in five seconds or when the Mode key or Display key is pressed.

Down-arrow Key

Decreases the value or changes the parameter in the upper display (except for set point changes in the Display Loop, which occur in the lower display). Hold the key down to decrease the value rapidly. New data takes effect in five seconds or when the Mode key or Display key is pressed.

Up + Down Keys

Press simultaneously for three seconds to go to the Setup Menu. Continue to press both keys for another three seconds to go to the Factory Menu. Access to the Setup and Factory menus can be disabled with lockout DIP switch.

WATL W

W

PROCESS

L1 |

L2 |

L3 |

L4 |

DEV

DISPLAY

% OUT

AUTO

MAN

MODE

SERIES 988

Mode Key

Enters new data and steps to the next prompt in the current menu.

Mode + Up-arrow Keys

Hold the Mode key then press the Up-arrow key to move backwards through the current menu. Scrolling stops when you reach the top of the menu.

Lower Display

Indicates the set point, deviation, percent power, temperature unit, menu prompt name or alarm code.

L1, L2, L3, L4

These LED’s indicate when output 1, 2, 3 or 4 are active. Outputs can be configured as:

Ot1 |

Control |

Ot2 |

Control or Alarm |

Ot3 |

Alarm or Retransmit |

Ot4 |

Alarm or Communications |

|

(flashes on transmit and |

|

receive) |

Display Key

Pressing this key enters the Display Loop. Press the Display key at any time to return to this loop. The next page has more information on the Display Loop.

Auto/Man Key

In Manual mode the lower display shows percent output. Pressed once, it clears any latched alarm. If pressed again within five seconds it will toggle between Auto and Manual mode.

Auto/Man LED

Lit when the control is in Manual operation. Press the Auto/Man key twice to enter Automatic operation. When blinking, press the Auto/Man key to toggle between Auto and Manual. After five seconds without pressing the Auto/Man key, the LED stops blinking and returns to its previous state.

Figure 3.1 -

Series 988 Keys and Displays

Front Panel and Display Loop, Chapter 3 |

WATLOW Series 988 User’s Manual |

3.1 |

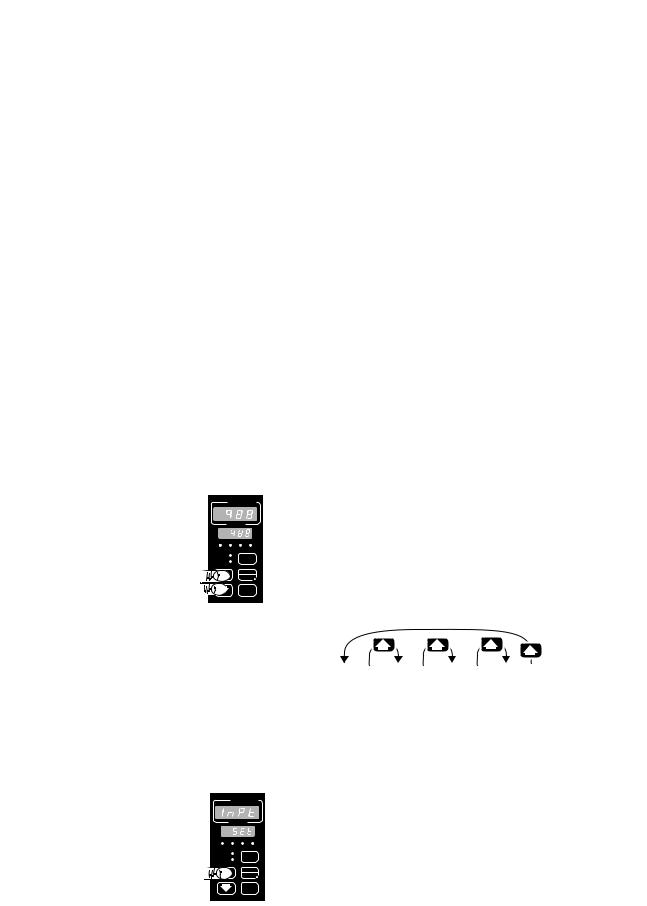

Display Loop

˜

NOTE:

For information on input 1 [`In1] and input 2 [`In2] ranges, refer to Chapter 4.

˜

NOTE:

If [``no] is selected for [`In2], in the

Input Menu, the [Pr`2] prompt will not appear.

Figure 3.2 -

The Display Loop

Display Loop

The Display Loop is the “home” state of the Series 988 controller. Pressing the Display key returns the controller to the Display Loop from any prompt in any menu. The controller automatically returns to the Display Loop from any menu when a minute passes without any keys being pressed.

|

[`988] current input 1 reading |

|

|

[`988] |

set point 1 (change with Up-arrow > or Down-arrow < key) |

DISPLAY |

[`988] |

|

|

|

current input 2 reading |

|

[Pr`2] |

input 2 process (appears only if controller equipped with input 2 hardware) |

DISPLAY |

[`988] current input 1 reading |

|

DISPLAY |

[`988] |

deviation from set point, process 1 minus set point 1 (DEV light on) |

DISPLAY |

[`988] current input 1 reading |

|

|

[`100] |

percent output (%OUT light on) |

DISPLAY |

[`988] current input 1 reading |

|

|

[``°C] |

units selected (units, °F or °C) |

3.2 |

WATLOW Series 988 User’s Manual |

Front Panel and Display Loop, Chapter 3 |

Chapter 4 The Setup Menus

NOTE:

When navigating through menus, outputs will be disabled.

˜

NOTE:

Press the Display key to return to the Display Loop from any point in any menu.

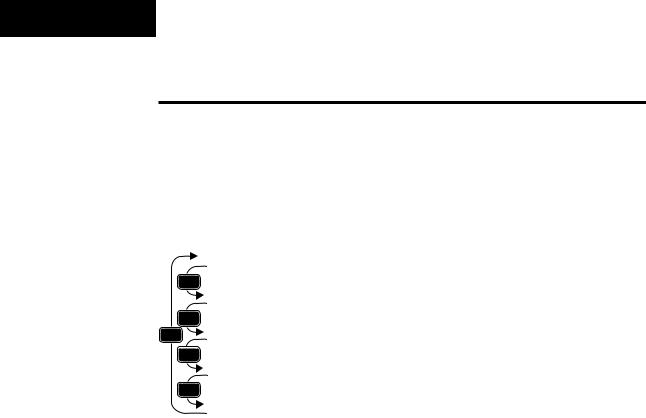

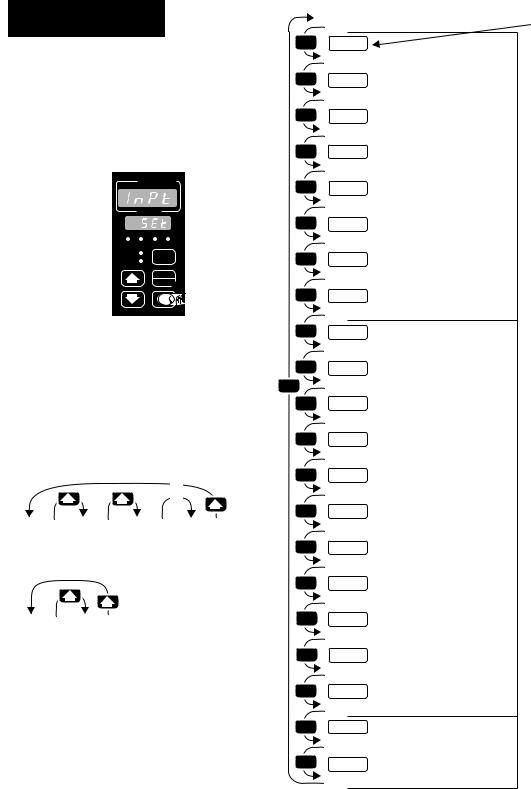

Navigating the Setup Menus

To reach the Setup Menus, begin in the Display Loop and press both the Uparrow > and Down-arrow < keys for three seconds. The Setup Menu prompt [`SEt] will appear in the lower display, and the Input Menu prompt [InPt] will appear in the upper display. The four Setup Menus are: Input [InPt]; Output [OtPt]; Global [GLbL]; and Communications [COM]. Use the Up-arrow > or Down-arrow < key to select a menu and the Mode key µ to step through a menu. The Communications Menu appears only on units equipped with the data communications option.

You will not see every prompt in any of these menus. The unit’s configuration and model number determine which prompts appear. After stepping through each menu, the Series 988 returns to the Setup Menu prompt [`SEt]. Use the Up-arrow > and Down-arrow < keys to select the next menu, or use the Mode key µ to advance through the same menu again. To move backwards through the menu hold the Mode key µ down and press the Uparrow key >. Use the Up-arrow > or Down-arrow < key to change the prompt setting.

Refer to the Appendix for model number options. For information about communications and the communications prompts, refer to the supplemental manual Data Communications with the Watlow Series 988 Family of Controllers.

Figure 4.1 -

Navigating the

Setup Menus.

˜

NOTE:

The lockout DIP switch hides the Setup Menus. See Chapter 1.

WATL W

W

PROCESS

L1 |

L2 |

L3 |

L4 |

DEV |

|

DISPLAY |

|

% OUT |

|

||

|

|

|

|

|

|

AUTO |

|

|

|

MAN |

|

|

|

MODE |

|

SERIES 988 |

|

|

|

WATL W

W

PROCESS

L1 |

L2 |

L3 |

L4 |

DEV |

|

DISPLAY |

|

% OUT |

|

||

|

|

|

|

|

|

AUTO |

|

|

|

MAN |

|

Begin in the Display Loop, and press the Up-arrow > and Down-arrow < keys simultaneously to reach the Setup Menus.

[Inpt] [OtPt] [gLbL] [COm]

[`Set] [`Set] [`Set] [`Set]

Input Output Global Communications Menu Menu Menu Menu

p.. 4.2 p. 4.18 p.. 4.34 p. 4.44

Press the Up-arrow key > to select one of the Setup Menus.

MODE

SERIES 988

Setup Menus, Chapter 4 WATLOW Series 988 User’s Manual 4.1

Setup-Input

Reaching the Input Menu

WATL W

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

AUTO

MAN

SERIES 988

Select the Input Menu, then press the Mode key µ to step through the prompts.

…

…

[```0] [```1] [```2]… [``60]

[Ftr1] [Ftr1] [Ftr1] [Ftr1]

[``no] [root]

[Lin1] [Lin1]

Press the Up-arrow key > or the Down-arrow key < to select one of the prompt values.

*Prompts may not appear, depending on controller configuration.

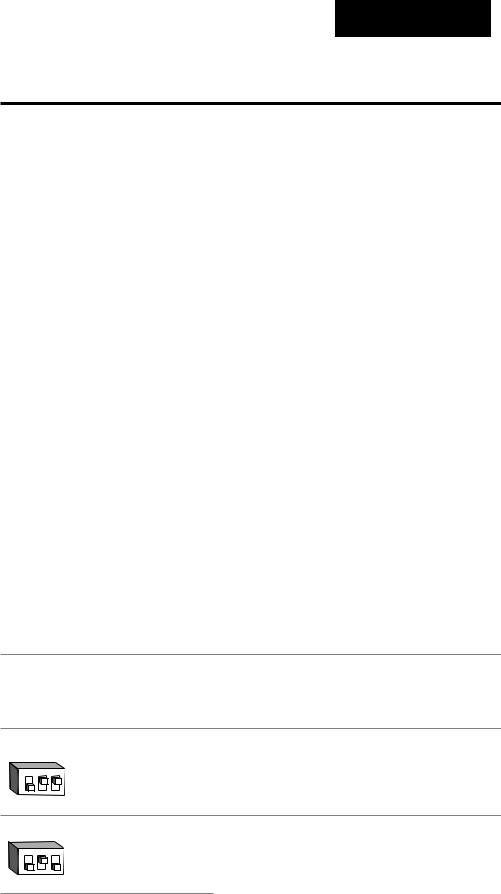

Figure 4.2 -

The Input Menu.

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

[Inpt]

[`Set] Setup Prompt

[`In1] Input 1

[deC1] *Decimal 1

[`rL1] Range Low 1

[`rH1] Range High 1

[CAL1] Calibration Offset 1

[rtd1] *RTD Calibration Curve 1

[Ftr1] Software Filter 1

[Lin1] *Linearization 1

[`ln2] *Input 2

[`rSp] *Remote Set Point

[deC2] *Decimal 2

[`RL2] *Range Low 2

[`RH2] *Range High 2

[LrnL] *Learn Low

[LrnH] *Learn High

[CAL2] *Calibration Offset 2

[rtd2] *RTD Calibration Curve 2

[Ftr2] *Software Filter 2

[Lin2] *Linearization 2

[Hunt] *Hunt

[SHYS] *Slidewire Hysteresis

Enter your settings, from the controller's upper display.

Input 1 (p. 4.3)

Input 2 (p.. 4..9)

Slidewire (pp. 4.16)

4.2 |

WATLOW Series 988 User’s Manual |

Setup Menus, Chapter 4 |

˜

NOTE:

Decimal points may not always be in the position specified below depending on the the settings in the Decimal 1 [dEC1] and Decimal 2 [dEC2] parameters in the Input Menu.

Setup-Input

Input Prompts

When you are in the Setup menus, the Series 988 displays the menu selection ( [InPt], [OtPt], [GLbL] or [COM] ) in the upper display, and [`SEt] in the lower display.

The Up-arrow > or Down-arrow key < selects another menu. Press the Mode key µ to display the prompt in the lower display and its value in the upper display. Use the Up-arrow > or Down-arrow < key to change the value in the upper display. The new value will not take effect until after a five-second delay or until you press the Mode key µ.

[`In1] Input 1

Select sensor type for input 1. This selection must match the sensor type connected to terminals 8, 9 and 10. See Appendix for more information about sensors.

•Changing the value of [`In1] changes all other prompts to the factory default values, except the Communications and Lockout menus, the

ç[`C_F] prompt in the Global Menu and the [`dFL] prompt in the

CAUTION: Changing the value of [`In1] changes most other prompts to the factory default values. Document all settings before changing sensor type. Verify the correct sensor type before making a change. Failure to follow this guideline could result in damage to equipment or property. Document all settings before changing sensor type.

[`In1]

Input 1 continued on next page.

Calibration Menu. If you change the value, the default warning [dFLt] will flash in the upper display.

•Changes do not take effect automatically after five seconds; you must press the Mode key µ to enter the sensor type change and advance to the next prompt.

[`In1] This prompt always appears.

If Default

↓↓

98_ _-1_ _ _-_ _ _ _

no DIP |

J |

K |

T |

N |

E |

W5 |

W3 |

Pt2 |

0-50mV |

thermocouple |

[```J] |

[```H] |

[```t] |

[```n] |

[```E] [```C] [```d] [`Pt2] [0-50] |

||||

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

|

only |

|

|

|

|

|

|

|

|

|

98_ _-2_ _ _-_ _ _ _

Input 1 DIP |

J |

K |

T |

N |

E |

W5 |

W3 |

Pt2 |

0-50mV |

||

O 1 |

2 |

3 |

[```J] |

[```H] |

[```t] |

[```n] |

[```E] |

[```C] |

[```d] |

[`Pt2] |

[0-50] |

N |

|

|

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

[`In1] |

− |

|

|

|||||||||

thermocouple |

|

|

|

|

|

|

|

|

|

||

Input 1 DIP |

R |

S |

B |

|

|

|

|

|

|

||

O 1 |

2 |

3 |

[```r] |

[```S] |

[```b] |

|

|

|

|

|

|

N |

|

|

[`In1] |

[`In1] |

[`In1] |

|

|

|

|

|

|

− |

|

|

|

|

|

|

|

|

|||

thermocouple

Setup Menus, Chapter 4 |

WATLOW Series 988 User’s Manual |

4.3 |

Loading...

Loading...