Walker MC 20 HP User Manual

OWNER’S MANUAL

Safety, Assembly, Operating, and Maintenance Instructions

Model MC (20 HP)

™

Please Read and Save These Instructions |

Effective Date: 03-01-07 |

For Safety, Read All Safety and Operation |

P/N 6000-13 |

Instructions Prior to Operating Machine |

|

Foreword

Thank you. . .for purchasing a Walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied customers. If for any reason this product does not perform to your expectations, please contact us at (970) 221-5614. Every customer is important to us. Your satisfaction is our goal.

Please. . .read this manual thoroughly! This manual is to be used in conjunction with the engine manufacturer's manual for the specific engine on the mower model you have purchased. Before you operate your new mower, please read this entire manual. Some of the information is crucial for proper operation and maintenance of this mower - it will help protect your investment and ensure that the mower performs to your satisfaction. Some of the information is important to your safety and must be read and understood to help prevent possible injury to the operator or others. If anything in this manual is confusing or hard to understand, please call our service department, at (970) 221-5614, for clarification before operating or servicing this mower.

This manual covers Model MC with the Kohler Command CH20 (20.0 HP) gasoline engine.

All shields and guards must be in place for the proper and safe operation of this machine.

Where they are shown removed in this manual, it is for illustration purposes only. Do not operate this machine unless all shields and guards are in place.

Specifications given are based on the latest information available at the time this manual was produced.

Walker Mfg. Co. is continually striving to improve the design and performance of its products. We reserve the right to make changes in specifications and design without thereby incurring any obligation relative to previously manufactured products.

Sincerely,

WALKER MANUFACTURING COMPANY

Bob Walker, President

Table of Contents

General Information ________________ 1

HIGHLIGHTED INFORMATION _____________ 1

GLOSSARY ____________________________ 1

IDENTIFYING NUMBER LOCATIONS________ 1 ENGINE SERIAL NUMBER LOCATION ______ 2

SERVICING OF ENGINE AND

DRIVETRAIN COMPONENTS ______________ 2

Specifications________________________ 3

ENGINE________________________________ 3 ELECTRICAL SYSTEM ___________________ 3 TRANSMISSION_________________________ 3 BLADE DRIVE __________________________ 4 TIRE SIZE ______________________________ 4 TIRE PRESSURE ________________________ 4

DIMENSIONS (Tractor and Mower) _________ 4

MOWER DECK __________________________ 5 CURB WEIGHT__________________________ 5 DRIVE BELTS___________________________ 6

GHS SYSTEM (Optional)__________________ 6

SEAT__________________________________ 6

FRAME/BODY CONSTRUCTION ___________ 6

Component Identification___________ 7

Safety Instructions _________________ 10

BEFORE OPERATING ___________________ 10 OPERATING ___________________________ 11 MAINTENANCE ________________________ 12

SAFETY, CONTROL, AND

INSTRUCTION DECALS _________________ 14

Assembly Instructions _____________ 16

SETUP INSTRUCTIONS _________________ 16

Tire Installation (Tractor)_______________ 16

Battery Service_______________________ 16 Wet Battery Service __________________ 16 Dry Battery Service __________________ 16 Battery Charging ____________________ 17 Battery Installation ___________________ 17

Mower Deck Assembly ________________ 17

Deck Caster Wheels Installation ________ 17 Deck Discharge Chute Installation ______ 18 Deck Discharge Shield Installation ______ 18 PTO Shaft Guard Installation __________ 18 Tilt-Up Roller Wheel Installation ________ 18

Mower Deck Installation on Tractor ______ 19

Deck Installation ____________________ 19 Deck Leveling ______________________ 21

PREOPERATING CHECKLIST ____________ 22

Operating Instructions_____________ 24

CONTROL IDENTIFICATION,

LOCATION, AND FUNCTION _____________ 24

Ignition Switch _______________________ 24 Engine Choke________________________ 24 Engine Throttle ______________________ 25

Forward Speed Control (FSC) __________ 25

Steering Levers ______________________ 25 Blade Clutch (PTO) ___________________ 25 Parking Brake _______________________ 25

Transmission Lockout Levers __________ 25

Hourmeter __________________________ 26

Oil Pressure Warning Horn_____________ 26 Circuit Breaker (7 Amp) _______________ 26 Light Switch (For Optional Lights)_______ 26

STARTING THE ENGINE_________________ 28

ADJUSTING GROUND

SPEED AND STEERING _________________ 28 ENGAGING THE MOWER________________ 30

STOPPING THE MACHINE _______________ 31 ADJUSTING CUTTING HEIGHT ___________ 31 TRANSMISSION LOCKOUT ______________ 32 RECOMMENDATIONS FOR MOWING ______ 33

RECOMMENDATIONS FOR TILT-UP DECK OPERATION/TRANSPORT _______________ 34 GRASS HANDLING SYSTEM (GHS) _______ 35

General Information __________________ 36 Clogging Checklist ___________________ 37

Using the Tilt-Up Deck ________________ 38 Using the GHS Catcher ________________ 38

Powerfil ® _________________________ 38 “Full” Signal Horn ___________________ 38

Cleaning the GHS Exhaust Screen ______ 38

Dumping the Catcher _________________ 39 Tailgate Dumping ___________________ 39 Using the Dump Bag _________________ 39

Table of Contents

Maintenance Instructions__________ 41

MAINTENANCE SCHEDULE CHART _______ 41

IMPORTANT TIPS FOR CARE

OF THE KOHLER ENGINE _______________ 42

Fuel System _________________________ 42 Starting/Stopping _____________________ 42 Cooling System ______________________ 42 Air Cleaner System ___________________ 42 Oil _________________________________ 42

LUBRICATION _________________________ 43 Engine Oil ___________________________ 43 Engine Break-In Oil __________________ 43

Checking Engine Crankcase Oil Level ___ 43 Changing Engine Crankcase Oil/Oil Filter _ 43

Mower Deck Gearbox Lubrication _______ 44 DSD52 Mower Deck Lubrication _________ 45 Tractor PTO Gearbox Lubrication _______ 46

Checking Gearbox Oil Level ___________ 46 Changing Gearbox Oil ________________ 46

Gear Axle Lubrication _________________ 46 Hydrostatic Transmission Fluid _________ 46

Checking Hydrostatic

Transmission Fluid Level ______________ 46

Grease Fitting and Oil Point Lubrication __ 47

CLEANING ____________________________ 50

Engine Air Cleaner System _____________ 50

Turbine Precleaner __________________ 50

Donaldson Radialseal™ Air Cleaner _____ 51

Engine Cooling System ________________ 52

Air Intake System ___________________ 52

Cylinder Head Cooling Fins ____________ 53

Grass Buildup in Mower Housing________ 53

GHS Blower _________________________ 54 GHS Exhaust Screen __________________ 55

Hydrostatic Transmission Cooling Fins __ 55

CHECKING/SERVICING _________________ 55

Security of Air Filtration Components ____ 55

Battery______________________________ 55 Electrolyte Level ____________________ 55

Cleaning the Terminals _______________ 56

Charging the Battery _________________ 56 Tire Pressure ________________________ 56

Sharpen Mower Blades ________________ 56

Drive Belts __________________________ 57

Mower Deck Gearbox Oil Seals _________ 58

Spark Plugs _________________________ 58

Fuel Lines and Clamps ________________ 58

Blade Brake Action ___________________ 58

REPLACING/REPAIRING ________________ 58

Drive Belts __________________________ 58

Engine PTO Drive Belt _______________ 60

Jackshaft Drive Belt _________________ 61

GHS Blower Drive Belt _______________ 62 Hydrostatic Ground Drive Belt _________ 63

Fuel Filter ___________________________ 64

Blade Overload Shear Bolts ____________ 64

PTO Shear Pin _______________________ 65 Mower Blades _______________________ 65 ADJUSTMENTS________________________ 66 Steering Levers ______________________ 66

Tilt-Up Deck Adjustable Stop ___________ 66

Warranty___________________________ 67

General Information

HIGHLIGHTED INFORMATION

Walker Manufacturing recommends that any service requiring special training or tools be performed by an authorized Walker Mower Dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the operation or maintenance of a Walker Mower are caused by disregarding basic safety precautions or specific warnings. Such accidents, in most cases, can be prevented by being aware of the dangers present.

Information of special importance has been highlighted in bold type in this manual. Refer to Safety Instructions for the meanings of DANGER, WARNING, CAUTION, IMPORTANT, and NOTE.

GLOSSARY

There are many terms that are either unique to this equipment or that are used as acronyms. The following terms and their definitions will help while using this manual:

•DECK is the mowing attachment mounted on the front of the tractor which includes the carrier frame, deck housing, blade drive gearboxes, and cutter blades.

•FORWARD SPEED CONTROL (FSC) controls the maximum forward speed of the tractor; functioning as a cruise control.

•GRASS HANDLING SYSTEM (GHS→) collects mowed material and deposits it in the catcher.

•GRASS-PAK→ SWITCH is mounted on the grass delivery spout (in the catcher) and activates the “full” signal horn when the grass catcher is full.

•GROUND DRIVE refers to the dual hydrostatic transmissions which drive the main wheels.

•HYDROSTATIC TRANSMISSION transmits and controls power from the ground drive belt to the main drive wheel.

•LEFT HAND (LH) refers to the left-hand side of the tractor when the operator is seated facing forward in the tractor seat.

•POWER TAKE-OFF (PTO) transmits engine power to run the cutter blades and GHS blower.

•POWERFIL→ spreads the mowed material throughout the interior of the grass catcher by an oscillating delivery spout.

•RIGHT HAND (RH) refers to the right-hand side of the tractor when the operator is seated facing forward in the tractor seat.

•SIDE DISCHARGE (SD) mows but does not collect the mowed material.

•STEERING LEVERS steer the tractor by controlling the dual hydrostatic transmissions.

•TRACTOR is the prime mover, including the engine, drive train, operator seat, and controls to operate the mower.

•TRANSMISSION LOCKOUT releases the hydrostatic transmissions to permit freewheeling the tractor.

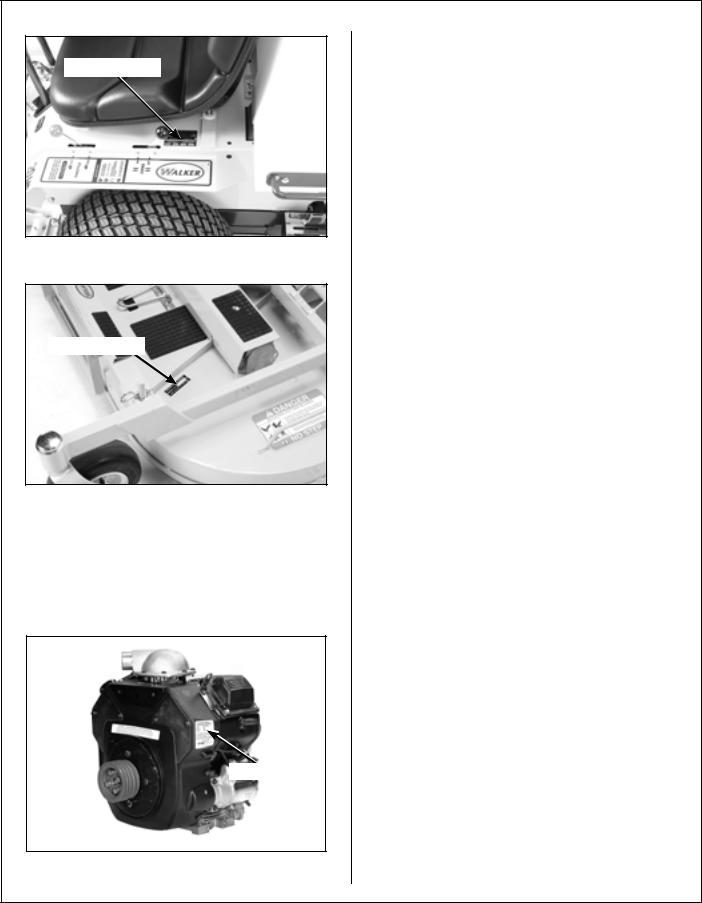

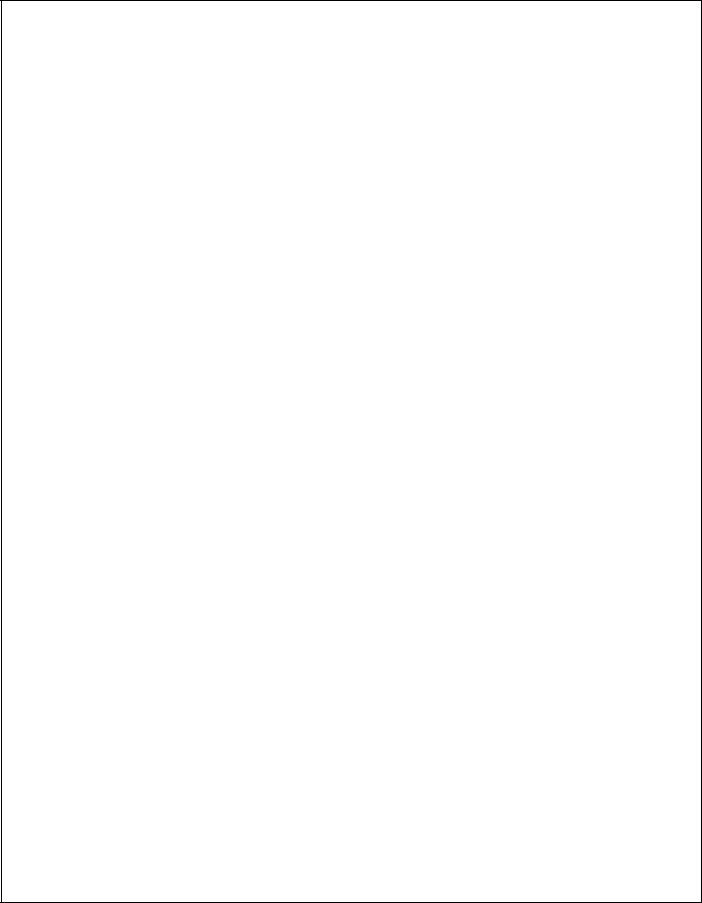

IDENTIFYING NUMBER LOCATIONS

The tractor serial number plate is affixed to the tractor body just below the left rear corner of the seat. The mower deck serial number plate is affixed alongside the angle iron framing on the LH side of the LH mower blade drive. Model and serial numbers are helpful when obtaining replacement parts and maintenance assistance. For ready reference, please record these numbers in the space provided.

Tractor Model No. _______________________

Tractor Serial No. _______________________

Deck Serial No. _______________________

Engine Model No. _______________________

Engine Serial No. _______________________

Date of Purchase _______________________

Fill In By Purchaser

1

General Information

Serial Number

Tractor Serial Number Location

Serial Number

Mower Deck Serial Number Location

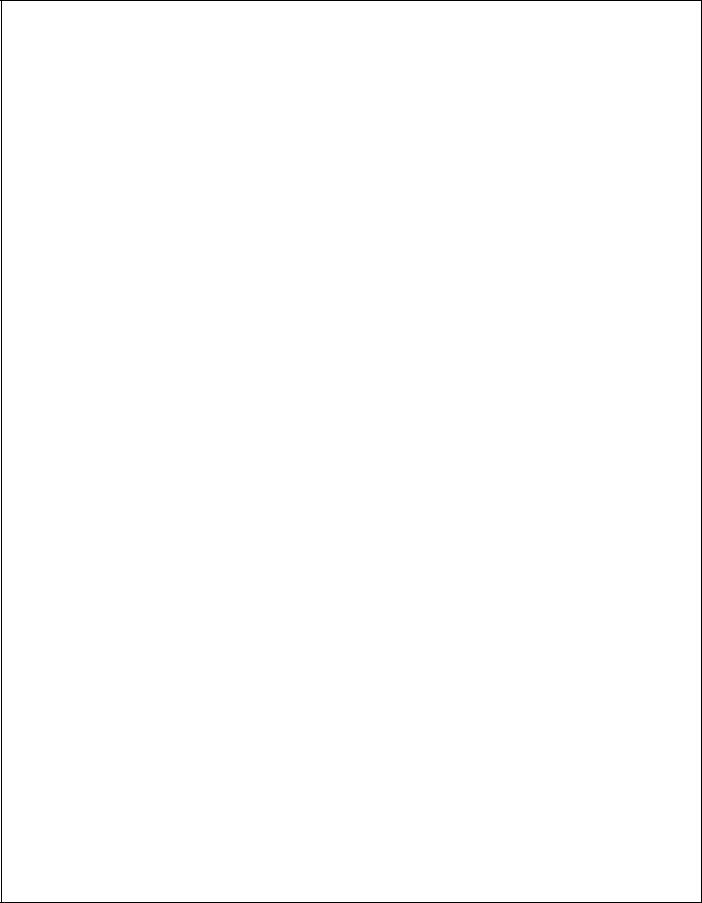

ENGINE SERIAL NUMBER LOCATION

Refer to the engine manual that accompanies this manual for the location of the engine serial number. For the mower model covered by this manual, an engine manual is available from Kohler covering the Kohler Command CH20 gasoline engine.

Serial Number

Engine Serial Number Location

SERVICING OF ENGINE AND DRIVETRAIN COMPONENTS

The detailed servicing and repair of the engine, hydrostatic transmission, and gearboxes are not covered in this manual. Only routine maintenance and general service instructions are provided. For the service of these components during the limited warranty period, it is important to find a local, authorized servicing agent of the component manufacturer. Any unauthorized work done on these components during the warranty period may void the warranty. If you have any difficulty finding an authorized outlet or obtaining warranty service, please contact our Service Department for assistance:

Walker Manufacturing Company

5925 E. Harmony Road

Fort Collins, CO 80528

1-970-221-5614

Service manuals are available for each of these components from their respective manufacturers as follows:

Kohler Engines |

Kohler Company |

|

Kohler, WI 53044 |

|

800-544-2444 |

|

www.kohlerengines.com |

Hydrostatic |

Eaton Corporation |

Transmissions |

15151 Highway 5 |

|

Eden Prairie, MN 55344 |

Gearboxes (Deck) |

Tecumseh Power Co. |

|

1555 S. Jackson Street |

|

Salem, IN 47167 |

|

812-883-3575 |

2

Specifications

MODEL |

MC |

ENGINE |

|

Manufacturer/Model |

Kohler Command CH20, 2 Cyl., Gasoline (Air-Cooled) |

Displacement |

38.1 cu. in. (624 cc) |

HP (@ 3600 RPM) |

20.0 |

Max. RPM (No Load) |

3750 |

Governed RPM |

3600 |

Max. Torque [ft-lb (N·m) @ RPM] |

32 (43) @ 2500 |

Idle RPM |

1200 ± 75 |

Spark Plug Type |

Champion® RC12YC |

Spark Plug Gap |

.030 in. (.76 mm) |

Crankcase Capacity |

2 qts (1.9 liters) |

Crankcase Lubricant |

API SG, SH, SJ or higher Grade Oil Only with 10W-30 Viscosity above |

|

0° F (-18° C), or 5W-20 or 5W-30 Viscosity below 32° F (0° C) |

Oil Filter |

28-050-01 |

Fuel Tank Capacity |

3 Gallons (11.4 liters) |

Fuel |

Regular Grade Unleaded Gasoline (87 Octane) |

Cooling System Capacity |

Air Cooled |

|

|

ELECTRICAL SYSTEM |

|

Battery |

12 Volt, 35 AH, 295 CCA |

Charging System |

Flywheel Alternator |

Charging Output |

15 Amp DC (Regulated) |

System Polarity |

Negative Ground |

Ignition |

Electronic Capacitive Discharge |

Starter |

12 Volt Electric Ring-Gear Type, Solenoid Shift |

Interlock Switch |

Ignition Lockout by Seat Switch, Transmission Neutral and Blade Clutch |

Circuit Breaker |

Auto Reset (30A) |

|

|

TRANSMISSION |

|

Manufacturer/Model |

Dual Hydrostatic, Eaton Model 7, Each Wheel Independently Driven |

Steering |

Hand Lever Control / Individual Wheel |

Forward Speed Control |

Precision Friction Lock Lever, Cruise Control, with Neutral-Park |

|

Position |

Service Brake |

Dynamic Braking through Hydrostatic Transmission |

Parking Brake |

Mechanical Pin Lock in Transmission Gear |

3

Specifications

MODEL |

MC |

|

TRANSMISSION (continued) |

|

|

Neutral |

Transmission Release by Manual Dump Valve |

|

Final Drive |

Gear Drive Axle |

|

Transmission Fluid |

|

|

Factory Service |

Mobil 1 Synthetic Motor Oil (15W-50) |

|

Alternate Transmission Fluid |

SAE 30W Straight Viscosity Motor Oil |

|

Transmission Fluid Capacity |

1 qt (1 liter) |

|

Transmission Cooling |

Cooling Fan Mounted on Drive Pulley |

|

Ground Travel Speed |

|

|

Forward m.p.h. (km/h) |

0-5 (0-8) |

Infinitely Variable |

Reverse m.p.h. (km/h) |

0-5 (0-8) |

Infinitely Variable |

|

|

|

BLADE DRIVE |

|

|

PTO Shaft |

Quick Disconnect Spline Shaft with Two High-Speed U-Joints |

|

Blade Spindle |

Each Blade (2) Mounts Direct on Peerless Right Angle |

|

|

Gearbox with Tee Gearbox in Center Connected to PTO Shaft |

|

|

(Complete Geared Drive, Peerless Model 1000 Gearboxes) |

|

Blade Drive Clutch and Brake |

Manual Belt Tightener Clutch and Band Brake |

|

|

(Stops Blades within Five (5) Seconds of Disengagement) |

|

Max. Blade Speed |

2900 RPM |

|

[22 in. (56 cm) Blade] @ 3600 |

[16700 FPM (5090 m/min)] |

|

RPM Engine |

|

|

TIRE SIZE |

|

|

Deck Caster Wheel |

8 x 3.00-4 Pneumatic (4-Ply) |

|

36, 42, 48, 56 |

||

52, 62, 74 |

11 x 4.00-5 Pneumatic |

|

Deck Caster Wheel (Optional) |

8 x 3.00-4 Foamed Rubber |

|

36, 42, 48, 56 |

||

Drive |

18 x 8.50-10 (4-Ply Low-Profile) |

|

Drive (Optional Narrow Tire) |

18 x 7.00-8 (4-Ply) |

|

Rear |

13 x 6.50-6 (4-Ply) |

|

|

|

|

TIRE PRESSURE |

|

|

Deck Caster Wheel |

20 PSI (137 kPa) |

|

Drive |

15 PSI (103 kPa) |

|

Rear |

20 PSI (137 kPa) |

|

|

||

|

|

|

DIMENSIONS (Tractor and Mower) |

|

|

Length |

|

|

36 in. (91 cm) GHS Model |

87 in. (221 cm) |

|

42 in. (107 cm) GHS Model |

89 in. (226 cm) |

|

4

Specifications

MODEL |

MC |

|

|

DIMENSIONS (continued) |

|

Width |

|

36 in. (91 cm) SD Model |

41-3/4 in. (106 cm) |

(with Deflector) |

|

42 in. (107 cm) SD Model |

47-3/4 in. (121 cm) |

(with Deflector) |

|

36 in. (91 cm) GHS Model |

37 in. (94 cm) |

42 in. (107 cm) GHS Model |

43 in. (109 cm) |

Height |

|

SD Model |

37-1/2 in. (95 cm) |

GHS Model |

49-1/2 in. (112 cm) |

Wheel Base (Tractor) |

42-1/4 in. (107 cm) |

Tread Width (Tractor) |

28-1/4 in. (72 cm) |

Standard Tires |

|

Optional Tires |

29-3/4 in. (76 cm) |

|

|

MOWER DECK |

|

Width of Cut SD/GHS |

36 or 42 in. (91 or 107 cm) |

Cutting Height |

1 to 4 in. (3 to 10 cm) |

Height Adjustment |

7 Positions - 1/2 in. (1 cm) Increment Hitch Pins Installed in |

|

Multi-Position Deck Support |

Blade Size |

|

36 in. (91 cm) SD Model |

20 in. (51 cm) Two (2) Clockwise-Rotating Blades with a 4 in. |

|

(10 cm) Center Overlap |

36 in. (91 cm) GHS Model |

20 in. (51 cm) Two (2) Counter-Rotating Blades with a 4 in. |

|

(10 cm) Center Overlap |

42 in. (107 cm) SD Model |

22 in. (56 cm) Two (2) Clockwise-Rotating Blades with a 2 in. |

|

(5 cm) Center Overlap |

42 in. (107 cm) GHS Model |

22 in. (56 cm) Two (2) Counter-Rotating Blades with a 2 in. |

|

(5 cm) Center Overlap |

Deck Suspension |

Torsion-Flex Frame with Caster Wheels and |

|

Counterweight Springs |

|

|

CURB WEIGHT (Approximate) |

|

SD Tractor Only |

622 lb (282 kg) |

GHS Tractor Only |

753 lb (342 kg) |

SD Tractor and 36 in. SD Deck |

752 lb (341 kg) |

SD Tractor and 42 in. SD Deck |

787 lb (357 kg) |

GHS Tractor and 36 in. GHS Deck |

878 lb (398 kg) |

GHS Tractor and 42 in. GHS Deck |

954 lb (433 kg) |

5

Specifications

MODEL |

MC |

DRIVE BELTS |

|

Engine PTO |

Walker P/N 8230 |

Jackshaft Drive |

Gates 3VX385 (or Walker P/N 6251-1) |

Ground Drive, Micro-V |

Walker P/N 7248 |

Blower (GHS Model) |

Walker P/N 7234-1 |

|

|

GHS SYSTEM (Optional) |

|

Blower |

4-1/2 x 10-1/2 x 1/2 in. (11 x 27 x 1 cm) Three-Blade Paddle Wheel |

|

(Driven by Mower Engine) |

Blower Brake |

Band Brake (Works in Combination with PTO Clutch, Stops |

|

Blower within Five (5) Seconds of PTO Disengagement) |

Max. Blower Speed |

3600 RPM |

Grass Catcher Capacity* |

89 Gallons (335 liters)/9.5 Bushels |

Optional Grass Catcher Capacity |

63 Gallons (238 liters)/6.7 Bushels |

Full Signal |

Oscillating Vane Switch Mounted on Grass Delivery Spout Triggers |

|

Horn Signal |

Powerfil ® |

Oscillating Delivery Spout Driven by 12 Volt Electric Gearmotor |

|

Spreads Material throughout Interior of Catcher @ 25 Cycles/Minute |

|

|

SEAT |

Contour-Molded, with Nylon Backed Vinyl Cover and Integral |

|

Foam Cushion |

|

|

FRAME/BODY CONSTRUCTION |

|

Frame |

All Welded Unitized Steel Chassis |

Body |

14 Gauge Steel |

Deck |

11 Gauge Steel |

GHS Catcher and Chutes |

Molded Cross-Linked Polyethylene (UV Stabilized) |

|

|

*Optional (6.7 Bushel) Grass Catcher subtracts approx. 5 lb (2 kg) and 5 in. (13 cm) in Height

NOTE: The manufacturer reserves the right to make changes in specifications shown herein at any time without notice or obligation.

6

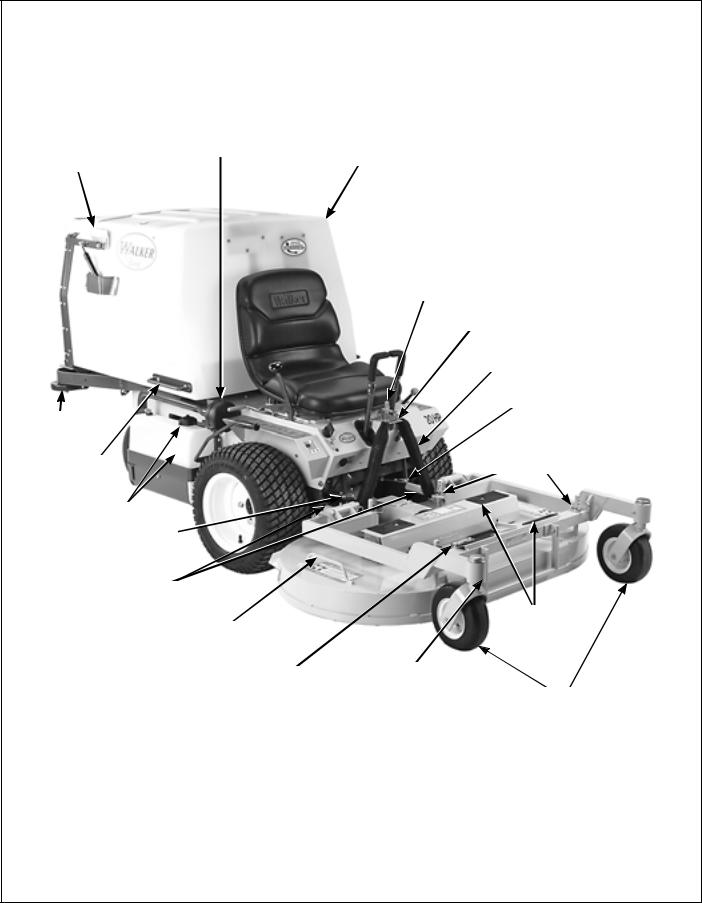

Component Identification

|

|

|

|

|

NOTE: Control Identification |

|

|

|

|

|

shown in Operating |

|

|

|

|

|

Instructions section. |

|

Turbine |

|

Grass Handling System |

|

|

Catcher Door |

Precleaner |

|

|||

|

9.5 Bushel Catcher |

|

|||

Safety Latch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tilt-Up |

|

|

|

|

|

Latch |

|

|

|

|

|

|

Spring Clip |

|

|

|

|

|

Counterweight Spring |

|

|

|

|

|

and Protective Cover |

|

|

|

|

|

Transmission Control Rod |

|

|

|

|

|

Adjustment Nut (LH) |

Anti-Scuff |

|

|

|

|

|

Roller |

|

|

|

|

Deck Support Pins |

|

|

|

|

|

and Height Adjustment |

Catcher Lift / |

|

|

|

|

Hitch Pins |

Dump Handle |

|

|

|

|

|

Fuel Tank and Cap |

|

|

|

|

|

Transmission Control |

|

|

|

|

|

Rod Adjustment Nut |

|

|

|

|

|

(RH) |

|

|

|

|

|

Deck Support Arms |

|

|

|

|

|

|

Deck Lift Handle |

|

|

Footrests |

|

|

|

|

|

||

(Cutting Height Adjustment) |

|

|

|

||

|

|

Tilt-Up Hook |

Tilt-Up |

|

|

|

|

Deck Handle |

|

||

|

|

(Not Visible) |

Deck |

||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Caster Wheels |

|

|

Front View and Right Side View |

|

||

7

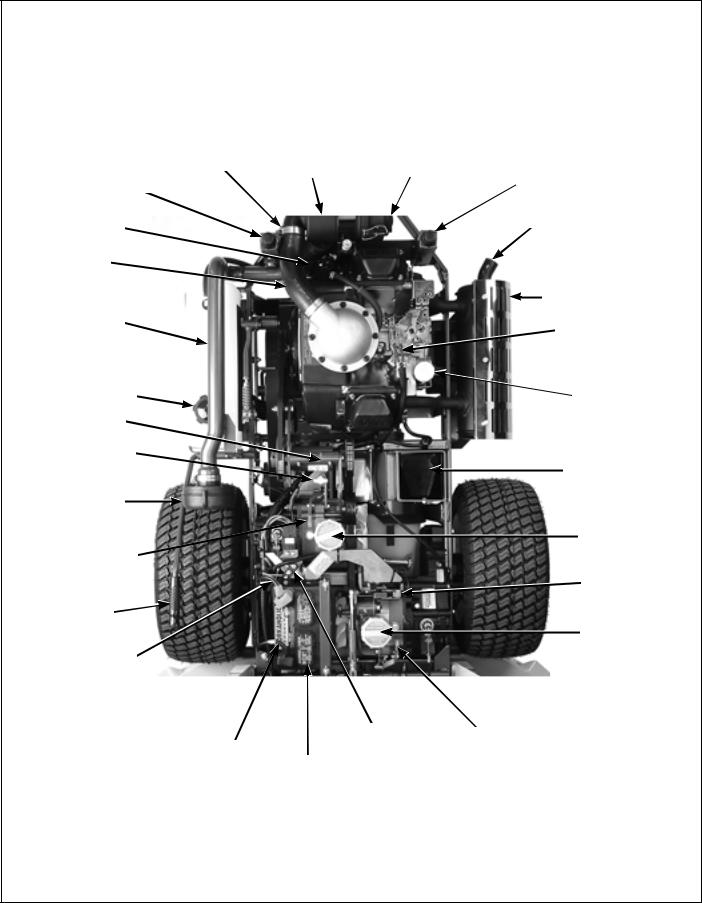

Component Identification

Catcher Door

Gas Spring

Catcher Door

Gas Spring

Protective Cover

Catcher Lift /

Dump Handle

|

|

Muffler |

|

|

|

|

|

|

|

Left Hand |

|

|

|

|

|

Tailpipe |

|||

Drive Wheel |

|

|

||

|

|

|

|

|

|

|

|

|

|

Removable Grass |

|

|

|

|

Catcher Exhaust |

||

Catcher Screen |

|

||

|

Deflector |

||

(Not Visible) |

|

||

|

|

|

|

|

|

|

|

Catcher

Catcher

Door

Catcher

Door Handle Anti-Scuff

Roller

Oil |

|

Oil Drain |

Filter |

|

Plug |

|

|

|

Tailwheel Fork

and Wheel

Rear View and Left Side View

8

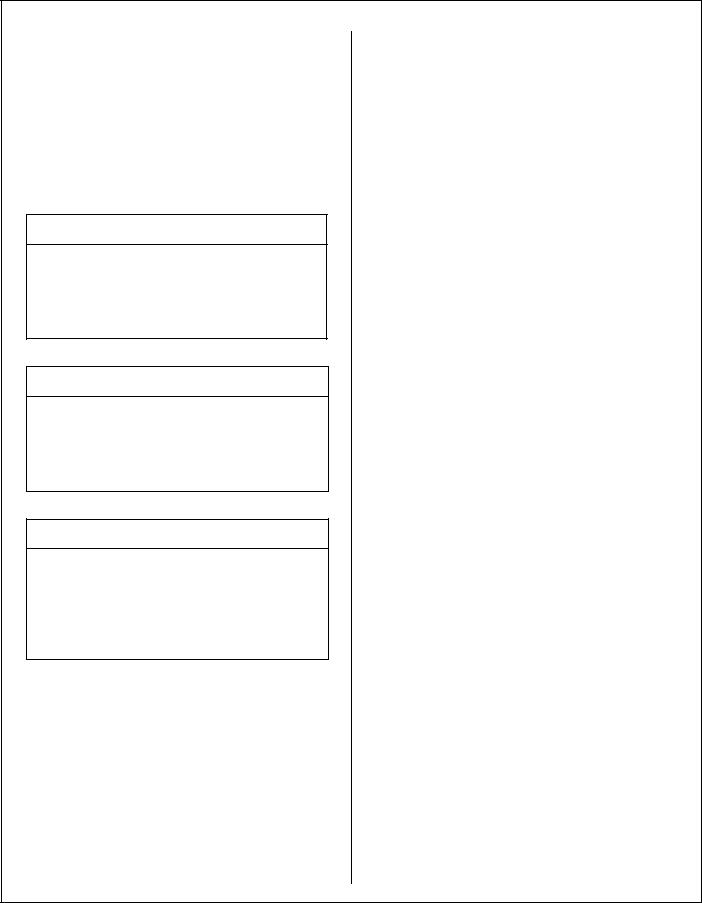

Component Identification

|

Air Restriction |

|

|

|

|

|

Indicator |

Donaldson |

Air Cleaner |

Rubber Bumper |

|

|

(Not Visible) |

||||

Rubber Bumper |

Air Cleaner |

Cover |

|||

(Body Support) |

|

|

|

|

(Body Support) |

|

|

|

|

|

|

Fuel Pump |

|

|

|

|

Muffler |

|

|

|

|

|

|

Air Intake |

|

|

|

|

|

Hose |

|

|

|

|

|

Precleaner |

|

|

|

|

Muffler Heat Shield |

|

|

|

|

Throttle and |

|

Tube |

|

|

|

|

|

|

|

|

|

|

Choke Linkage |

Fuel Tank Cap |

|

|

|

|

Oil Fill/ |

|

|

|

|

Dipstick |

|

|

|

|

|

|

|

Jackshaft |

|

|

|

|

|

PTO Gearbox |

|

|

|

|

|

Dipstick |

|

|

|

|

GHS Blower |

|

|

|

|

|

|

Turbine |

|

|

|

|

|

Precleaner |

|

|

|

|

|

|

|

|

|

|

RH Hydrostatic |

RH Transmission |

|

|

|

|

Transmission |

|

|

|

|

|

|

Lockout Lever |

|

|

|

|

Neutral Safety |

|

|

|

|

|

|

PTO |

|

|

|

|

Switch |

|

|

|

|

|

|

Clutch Lever |

|

|

|

|

LH Hydrostatic |

|

|

|

|

|

Transmission |

Positive (+) |

|

|

|

|

|

Battery Cable |

|

|

|

|

|

|

|

|

30 Amp |

LH Transmission |

|

|

Negative (-) |

Circuit Breaker |

Lockout Lever |

||

|

Battery Cable |

Battery |

|

|

|

|

Top View (Engine Compartment) |

|

|||

9

Safety Instructions

Pay particular attention to any information labeled

DANGER, WARNING, CAUTION, IMPORTANT, and NOTE in this manual.

When you see the Safety Alert Symbol (  ), read, understand, and follow the instructions. Failure to comply with safety instructions may result in personal injury.

), read, understand, and follow the instructions. Failure to comply with safety instructions may result in personal injury.

The seriousness or degree of importance of each type of information is defined as follows:

DANGER

DANGER

An IMMEDIATE hazard that WILL result in severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

WARNING

WARNING

A POTENTIAL hazard that COULD result in severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

CAUTION

CAUTION

Possible hazards or unsafe practices that MAY result in MODERATE personal injury or property damage, or machine damage, if warning is ignored and proper safety precautions are not taken.

IMPORTANT: Identifies mechanical information demanding special attention, since it deals with the possibility of damaging a part or parts of the machine.

NOTE: Identifies information worthy of special attention.

Walker Manufacturing cannot predict every potentially dangerous situation. Therefore, items labeled as such in this manual do not cover all conceivable situations. Any person using procedures, tools, or control techniques not recommended by Walker Manufacturing must take full responsibility for safety.

The Walker Rider Lawnmower has been designed with many safety features to protect the operator from personal harm or injury. However, it is necessary for the operator to use safe operating procedures at all times. Failure to follow safety instructions contained in this manual may result in personal injury or damage to equipment or property.

If you have any questions concerning setup, operation, maintenance, or safety, please contact your authorized Walker Mower Dealer or call Walker Manufacturing Company at (970) 221-5614.

BEFORE OPERATING

1.Read and understand the contents of this Owner's Manual before starting and operating the machine. Become thoroughly familiar with all machine controls and how to stop the machine and disengage the controls quickly. Replacement Owner's Manuals are available by sending the Model and Serial Number to:

Walker Manufacturing Company

5925 East Harmony Road

Fort Collins, CO 80528

2.Never allow children to operate rider mower.

Do not allow adults to operate without proper instruction.

3.Clear the area to be mowed of any foreign objects which may be picked up and thrown by cutter blades. Pick up all sticks, stones, wire, and any other debris.

4.Keep everyone, especially children and pets, a safe distance away from the area being mowed.

Do not mow with bystanders in the area.

5.Do not operate the machine barefoot or wearing sandals, sneakers, tennis shoes, or similar lightweight footwear. Wear substantial protective footwear.

10

Safety Instructions

6.Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this machine while wearing shorts; always wear adequate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable and required by some local ordinances and insurance regulations.

7.Prolonged exposure to loud noise can cause impairment or loss of hearing. Operator hearing protection is recommended; particularly for continuous operation of the GHS Model due to blower noise level. Wear a suitable hearing protective device, such as earmuffs or earplugs.

8.Keep all protective shields and safety devices in place. If a protective shield, safety device, or decal is damaged, unusable, or missing, repair or replace it before operating the machine.

9.Be sure interlock switches are functioning correctly, so the engine cannot be started unless the Forward Speed Control lever is in the NEUTRAL-PARK position, and the PTO clutch is in the DISENGAGED position. Also, the engine should stop if the operator lifts off the seat with the PTO clutch in the ENGAGED position.

10.Handle gasoline with care. Gasoline is highly flammable and its vapors are explosive:

a.Use an approved fuel container.

b.Never add fuel to a running engine or hot engine (allow hot engine to cool several minutes).

c.Keep matches, cigarettes, cigars, pipes, open flames, or sparks away from the fuel tank and fuel container.

d.Always fill the fuel tank outdoors using care. Fill to about one inch from the top of the tank. Use a funnel or spout to prevent spilling.

e.Replace the machine fuel cap and container cap securely and clean up any spilled fuel before starting the engine.

11.Never attempt to make any adjustments while the engine is running, except where specifically instructed to do so.

12.The electrical system battery contains sulfuric acid. Avoid any contact with skin, eyes, and clothing. Keep the battery and acid out of reach of children.

OPERATING

1.Operate the mower only in daylight or in good artificial light with good visibility of the area being mowed.

2.Sit on the seat when starting the engine and operating the machine. Keep feet on the deck footrests at all times when the tractor is moving and/or mower blades are operating.

3.For a beginning operator, learn to steer (maneuver) the tractor with a slow engine speed before attempting any mowing operation.

Be aware that, with the front mounted mower configuration, the back of the tractor swings to the outside during turns.

4.Remember, for an emergency stop, the forward motion of the tractor can always be stopped by pulling the Forward Speed Control (FSC) into the NEUTRAL-PARK position.

5.In case either of the transmission drive belts break during operation, and if the machine is on a slope, the machine will freewheel down the slope. To maintain control, immediately (1) Release the steering levers and simultaneously

(2) Move the FSC to the NEUTRAL-PARK position. When the machine is stopped or moving slowly, engage the parking brake.

NOTE: This is exactly the same procedure used to normally stop and park the machine.

6.Disengage the blade clutch and put the FSC in the NEUTRAL-PARK position before starting the engine (an ignition interlock switch normally prevents starting of the machine if these controls are in the OPERATING position).

7.Do not run the engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and can be deadly.

8.Do not carry passengers - maximum seating capacity is one (1) person.

11

Safety Instructions

9.Watch for holes, rocks, and roots in the terrain and for other hidden hazards. When mowing tall grass, mow higher than desired to expose any hidden obstacles. Then, clean the area and mow to the desired height.

10.Avoid sudden starts or stops. Before backing the machine up, look to the rear to be sure no one is behind the machine. Watch carefully for traffic when crossing or working near roadways.

11.Disengage the blade drive when transporting the machine across drives, sidewalks, etc. Never raise the mower deck while blades are rotating.

12.The maximum recommended side slope operating angle is 20 degrees or 33% grade.

When operating the machine on a slope, reduce speed and use caution to start, stop, and maneuver. To prevent tipping or loss of control of the machine, avoid sharp turns or sudden changes in direction.

13.Never adjust cutting height with the engine running. Before adjusting cutting height or servicing, disengage the blade clutch (PTO), stop the engine, and remove the ignition key. Wait for all movement to stop before getting off the seat.

NOTE: A blade/blower brake should normally stop drive line rotation within five (5) seconds of disengaging the PTO clutch.

14.For side discharge mower decks, do not operate with the grass deflector chute removed.

Keep the deflector in the lowest possible position.

15.For tractors equipped with tilt-up deck, observe the following recommendations:

a.Do not move tractor with deck in tilt-up position.

b.Never tilt body forward with deck in tilt-up position.

16.For GHS equipped models, do not operate the machine with the grass catcher in the DUMP position or with the back door OPEN. Dangerous projectiles may be thrown out of the discharge chute or the back of the grass catcher.

17.For GHS equipped models, use care when closing the grass catcher door. Keep fingers and hands away from the hinge and pinch points when the door is being closed. Also, keep fingers and hands clear of the door frame. The door is held closed with springs and the door may slam shut with considerable force.

18.In case of a clogged or plugged mower deck or GHS catching system:

a.Disengage the blade clutch (PTO) and turn the engine off before leaving the seat.

b.LOOK to make sure blade drive shaft and blower drive pulley movement has stopped before trying to unclog the system.

c.Disconnect the spark plug wires.

d.Never place hands under the deck or in the GHS blower - use a stick or similar tool to remove clogged material.

19.If the cutting blades strike a solid object or the machine begins to vibrate abnormally, immediately disengage the blade clutch (PTO), stop the engine, and wait for all moving parts to stop. To prevent accidental starting, disconnect the spark plug wires. Thoroughly inspect the mower and repair any damage before restarting the engine and operating the mower. Make sure

cutter blades are in good condition and blade nuts are torqued to 60 ft-lb (81.3 N·m).

20.Do not touch the engine or muffler while the engine is running or immediately after stopping the engine. These areas may be hot enough to cause serious burns.

21.When leaving the machine unattended, disengage the blade clutch (PTO), stop the engine, and remove the key.

MAINTENANCE

1.To prevent accidental starting of the engine when servicing or adjusting the machine, remove the key from the ignition switch and disconnect the spark plug wires.

12

Safety Instructions

2.To reduce fire hazards, keep the engine free of grass, leaves, excessive grease, and dirt.

3.Keep all nuts, bolts, and screws tight to ensure the machine is in a safe, working condition. Check the blade mounting nuts frequently, making sure they are tight.

4.Perform only maintenance instructions described in this manual. Unauthorized maintenance operations or machine modifications may result in unsafe operating conditions.

5.If the engine must be running to perform a maintenance adjustment, keep hands, feet, and clothing away from moving parts. Do not wear jewelry or loose clothing.

6.Always use the proper engine service manual when working on the engine. Unauthorized maintenance operations or modifications to the engine may result in unsafe operating conditions.

7.Altering the equipment or engine in any manner which adversely affects its operation, performance, durability, or use will VOID the warranty and may cause hazardous conditions.

8.Never attempt to disconnect any safety devices or defeat the purpose of these safety devices.

9.Do not change the engine governor settings or overspeed the engine. The governor has been factory-set for maximum-safe engine operating speed.

10.Use genuine factory replacement parts.

Substitute parts may result in product malfunction and possible injury to the operator and/or others.

11.Use care when charging the battery or performing maintenance on the battery and electrical system:

a.Make sure the battery charger is unplugged before connecting or disconnecting cables to the battery.

b.Charge the battery in a well-ventilated space, so gases produced while charging can dissipate. Make sure the battery vents in the caps are open.

c.Keep sparks, flames, and smoking materials away from the battery at all times. To avoid sparks, use care when removing battery cables from posts.

d.Disconnect both battery cables before unplugging any wiring connectors or making repairs on the electrical system.

IMPORTANT: Keep all applicable manuals immediately accessible to anyone who may operate or service this machine.

13

Safety Instructions

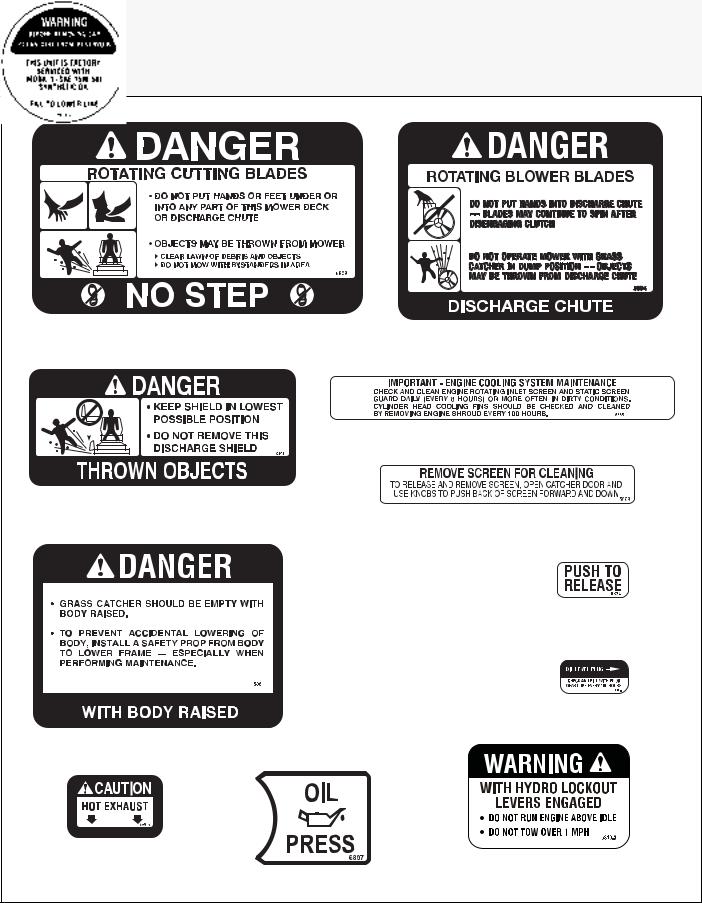

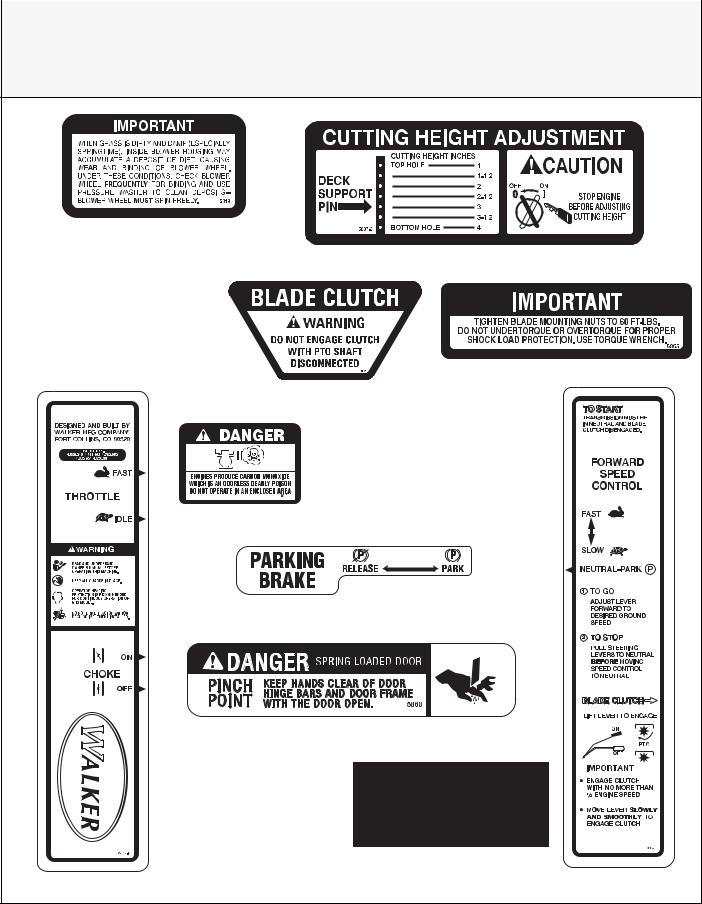

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine;

if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The Decal Part Number is listed below and in the Parts Manual.

Each End of Mower Deck (5808)

SD Deck Discharge Shield (5848)

Underside of Body (5861)

Adjacent to Blower Discharge Chute through Body (5804)

Engine Shroud (5855)

Rear of Grass Catcher Exhaust Screen (5869)

Catcher Safety Latch,

RH Side (5874)

Hydrostat Oil |

Gear Axle (5810-1) |

Reservoir (5810-2) |

|

LH Side of Body, |

|

Bridge Assembly and |

|

Above Muffler (5805) |

|

||

Lower Front Body (6807) |

LH Gear Axle (5810-3) |

||

|

14

Safety Instructions

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine;

if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The Decal Part Number is listed below and in the Parts Manual.

Top of Blower Housing (5819)

Deck Gearbox Cover (5807-3)

Jackshaft Support Adjacent

to Dipstick (7827)

Deck Carrier Frame (5865)

Right Side of Body (5806)

On Engine (6810) |

Deck Carrier Frame (8647) |

|

|

Right Side, Below Operator Seat (7809) |

|

Catcher Door Hinge Bar, LH and RH Sides (5868)

Deck Carrier Frame (8653)

|

Rear Bumper (5815) |

Fender, LH Side (5802-2) |

Fender, RH Side (7802) |

|

15

Assembly Instructions

SETUP INSTRUCTIONS

Walker Mowers are shipped partially assembled. After uncrating the tractor and mower deck, initial setup is required.

NOTE: During the process of unpacking, any damaged or missing parts should be noted and reported to the delivering carrier immediately (put in writing within 15 days). The carrier will provide directions for proceeding with a claim to receive compensation for damage.

Tire Installation (Tractor)

•Install the drive tires using the eight (8) lug bolts that are supplied with the owner's packet of materials. Drive tires are 18 x 8.50-10, 4-ply; rear tire is 13 x 6.50-6, 4-ply.

•Check and adjust the inflation of the tires. The tire inflation recommendations are:

Drive = 15 PSI (103 kPa)

Rear = 20 PSI (137 kPa)

Battery Service

Tilt mower body up (lift on rear of body) for battery access. Check the battery for electrolyte level and charge. The electrolyte level should be at the bottom of the vent wells [1/4 to 1/2 in. (6 to 13 mm) above plates]. If the specific gravity is less than 1.225, the battery needs charging. If the battery has been shipped dry, or is wet but needs service, refer to the following instructions.

IMPORTANT: Make sure battery is securely mounted in the frame. A loose battery may cause damage to the case resulting in acid leakage and severe damage to the machine. A hazard may be created by damage to critical working parts and safety systems.

Wet Battery Service

If the battery has been shipped wet, but the electrolyte level is low or the battery needs to be charged then:

1.Fill each battery cell with drinking water to the bottom of the vent wells.

2.Charge battery. Refer to Battery Charging in this section.

Dry Battery Service

DANGER

DANGER

Activating a battery can be dangerous. The battery should be taken to a reliable service station, battery store, or power equipment dealer where a trained technician can activate the battery safely. DO NOT attempt to activate the battery unless you are experienced in battery service work. The following activation and charging instructions are provided for use by a trained battery technician.

DANGER

DANGER

Battery electrolyte is a poisonous and corrosive sulfuric acid solution.

•Avoid spillage and contact with skin, eyes, and clothing - causes severe burns.

•To prevent accidents, wear safety goggles and rubber gloves when working with electrolyte.

•Neutralize acid spills with baking soda and water solution.

To fill (activate) battery with electrolyte (if battery has been shipped dry):

1.Remove the battery hold down bar, disconnect the battery cables and lift the battery out of the tray.

IMPORTANT: Battery must be removed from the mower before filling with electrolyte.

IMPORTANT: Obtain and use only battery grade sulfuric acid electrolyte with a 1.265 specific gravity to activate the battery. DO NOT use water or any other liquid during initial activation.

2.Remove the filler caps and carefully fill each cell until the electrolyte is just above the plates.

16

Assembly Instructions

3.After the battery is filled with electrolyte, replace the filler caps and charge the battery. Refer to

Battery Charging.

Battery Charging

DANGER

BATTERIES PRODUCE EXPLOSIVE GASES

•Charge the battery in a well-ventilated area, so that gases produced while charging can dissipate.

•Keep sparks, flames, and smoking materials away from the battery at all times.

•Make sure the battery cap vents are open after the battery is filled with acid (check manifold vent on each cap).

•Make sure the battery charger is unplugged before connecting or disconnecting cables to the battery.

1.Charge the battery at 15 amps for 10 minutes. DO NOT exceed 20 amps maximum recommended charging rate. Charge until specific gravity is at least 1.250. Total charging time should not exceed one (1) hour.

2.After charging the battery, adjust the electrolyte level to the bottom of the vent wells [1/4 to 1/2 in. (6 to 13 mm) above the plates].

IMPORTANT: DO NOT overfill the battery. Electrolyte will overflow through the vented caps onto parts of the machine and WILL result in severe corrosion.

3.Install battery.

Battery Installation

IMPORTANT: Make sure battery is securely mounted in the frame. A loose battery may cause damage to the case resulting in acid leakage and severe damage to the machine. A hazard may be created by damage to critical working parts and safety systems.

Install the battery in the mower as shown in Battery Installation photo. Connect the positive and negative cables to the proper battery terminal (red cable and boot connects to the Positive (+) terminal).

Slide the rubber boot up and over the battery post, making sure it covers the post completely to prevent an electrical short.

WARNING

WARNING

Make sure the battery cap vents are open. Improper venting of the battery COULD cause a battery explosion.

Battery Clamp

Secured by

Wing Nut(s)

(+) Battery Cable

Connection

Battery Installation

Mower Deck Assembly

Deck Caster Wheels Installation

1.Remove the bolt, nut, axle spacer tube, and spacer washers from each deck caster wheel fork.

NOTE: Spacer washers are used only when the optional semi-pneumatic deck wheels (8.25 x 2.75) are installed.

2.Fit the axle spacer tube through the wheel hub, position the spacer washer on each side of the hub (if used), and fit the assembly into the wheel fork.

3.Insert the 3/8-16 x 4-1/2 in. bolt through the wheel fork with the bolt head to the outside and install the 3/8-16 in. Keps nut.

4.Tighten the bolt and nut until the axle spacer tube bottoms against the inside of the wheel fork (will not turn) while the wheel and spacer washers (if used) spin freely without binding.

17

Assembly Instructions

Grease Fitting

Locations

Spacer Washer

Axle Spacer Tube

Deck Caster Wheel Installation

5.Grease the caster wheel bearings and caster pivot bearings - one grease fitting for each wheel and each pivot.

Deck Discharge Chute Installation

(GHS Rear Discharge Models Only)

Mount the discharge chute hinge on top of the deck discharge opening using the 1/4-20 x 1/2 in. socket button head bolt and 1/4-20 ESNA nut. Position the bolt with the head inside of the chute and the nut on the outside.

Carrier Frame

Tube Sockets

|

|

Attach |

|

|

Chute |

Attach Guard |

Nut on Top

Discharge Chute and PTO Shaft Guard Installation on Rear Discharge Deck

Deck Discharge Shield Installation

(Side Discharge Models Only)

Attach the deck side discharge shield by positioning the shield hinge lug in front of the deck mount and fastening with two 3/8-16 x 1-1/4 in. bolts, 3/8-16 ESNA nuts, and 3/8 in. wave spring washers. The wave washers fit between the two hinging surfaces. Tighten the nuts until the shield moves freely but is not loose.

WARNING

WARNING

DO NOT operate the machine without the grass deflector shield attached and in the lowest possible position.

Attach Shield

Discharge Shield Installation

on Side Discharge Deck

PTO Shaft Guard Installation

Position the shaft guard as shown and mount with two 1/4-20 x 1/2 in. bolts.

Tilt-Up Roller Wheel Installation

Mount the two (2) tilt-up roller wheels on the brackets on the rear skirt of the deck housing using the P/N 8490 axle bolt, 3/8 in. wave spring washer and 3/8-16 in. Whiz locknut. Tighten the axle bolt until the wheel rolls freely, but is not loose.

18

Loading...

Loading...