Volvo L150F, L180F, L220F Service Manual

VOLVO CONSTRUCTION EQUIPMENT

RECYCLING MANUAL

L150F, L180F, L220F

MORE CARE. BUILT IN.

Foreword

1

Foreword

Foreword

Caring for the environment is one of Volvo’s core values, along with quality and safety.

This brochure is for all those who work with dismantling and scrapping of a complete machine, both service workshops as well as dismantling companies and recycling companies. It can also be used for service work during the machine’s lifetime, as a guide for handling used products that are replaced during repairs and service.

The purpose is to facilitate correct handling of hazardous waste or other equipment and components that may cause personal injury and environmental damage. It also serves as a material map to see which materials are included in the product.

The brochure does not include any instructions for recycling technicians since these will change with time, and an instruction from today may prove to be completely different in the future. There is also national legislation and a variety of local regulations that differ significantly.

The information in the brochure is developed for Volvo L150F, L180F, and

L220F, and shall not be used in any way for other products.

Information and data included in the brochure are valid at the time of publication. We reserve the right to change specifications and equipment without prior notice.

This recycling manual is for a so-called ’basic machine’. When the machine is purchased, a variety of optional equipment may be selected and all of these are not included or described in this manual.

Overall perspective

Volvo Construction Equipment’s overall perspective on how environmental aspects shall be fulfilled means that the company’s products are regarded in a much greater context:

•Society works for common environmental legislation and facilitates good work planning and provides systems for recycling.

•Volvo and its sub-suppliers replace materials that have negative impact on man and the environment, and improve use of products and manufacturing methods.

•Dealers make sure that the customers get the right machines that are exactly adapted to their applications.

•Operators and owners handle the machines correctly with regards to use, service, and maintenance.

•Recycling is performed in a manner that is safe to both man and the environment. Scrapping and dismantling take place in a way that enables maximized reuse or recycling of the machine.

Safety

2

Safety

Safety

Volvo Construction Equipment AB assumes that work with our machines follows the safety and work instructions included in the Service manual and Operator’s manual for the model in question.

Dismantling and recycling of machines shall be performed by personnel with sufficient knowledge, and in a professional manner in order to avoid personal injury and environmental damage.

If in effect, national legislation governing dismantling of machines is the primary legislation to be followed. This Recycling manual is only a supplement to the valid Service manual and Operator’s manual for Volvo L150F, L180F, and L220F.

Recycling Work

3

Recycling Work

Work and recycling

A Volvo wheel loader consists of metals to approx. 80%. In general, metals are suitable for recycling. However, in certain cases the components’ design and installation may make recycling impossible, both practically and economically, despite the included materials themselves being recyclable.

The recycling process has 5 readily identifiable steps, where one should strive to get the biggest fractions of the machine’s material as high up as possible on the recycling steps.

Recycling steps

Strive to get as much material as possible, as high as possible, on the steps.

Source: Thomas Magnusson IVF

Main work process when dismantling Volvo wheel loaders

This work process should be followed for dismantling work to proceed in an optimal way:

1Identify the machine by reading signs and plates as well as the instructions in the manual.

2Check governing regulations/legislation for recycling and producer responsibility. Also check if there are special safety aspects for dismantling.

3Decontaminate the machine from fluids and specially marked components that have to be removed and sorted out for special handling.

4 Dismantle the machine in a safe and environmentally correct manner.

5 Sort the dismantled parts and components in fractions for recycling.

Sorting

4

Sorting

Sorting

There is a number of thought fractions in which to sort the material, examples of these are found below. Handling of these fractions is governed by national legislation and local regulations, which shall be followed.

•Materials and components that can be reused as components in old and/or new machines. These may be in need of repairs or upgrades in order to meet quality requirements. For example, this may be engine, axles, transmission, and hydraulic cylinders.

•Materials that can be material-recycled with or without loss of quality. Examples of material recycling without loss of quality are metals and certain plastics. Loss of quality refers to, e.g., plastics that only can be given a dark colour when material-recycled.

•Materials for energy extraction are, among others, unsorted plastics and oils.

•Materials that have to be deposited mainly come from fragmentation and unsorted materials.

Producer responsibility

A number of the machine’s components are governed by the principle of producer responsibility, which means that they shall be taken care of according to special instructions. These instructions may vary from one country to another. If you do not know what this includes or are unsure about applicable governing regulations, contact your Volvo dealer or Volvo directly.

Identifying

5

Identifying

Identifying the machines

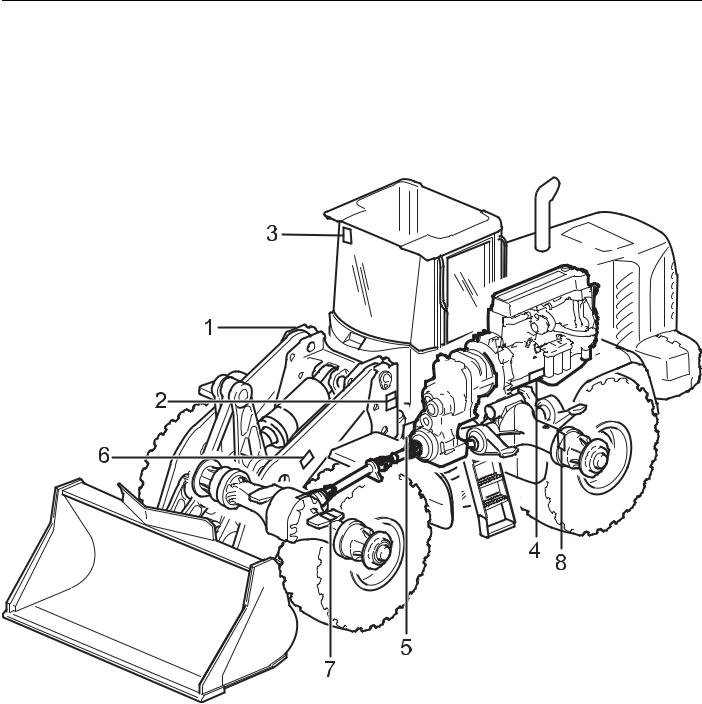

This manual is only valid for the stated models; Volvo L150F, L180F, and L220F, see illustration below for identification marking. The machines have been manufactured in Sweden by Volvo Construction Equipment AB from the year 2007. The primary colour is yellow.

1 Machine PIN, Product Identification Number (stamped on right side).

2Product plate including, among other things, machine type and PIN. Additional plate with, among other things, CE-marking (only for country of origin within the EU), as well as an emission plate. A total of three plates.

3 Plate identifying that ROPS-test has been performed and approved.

4 CIN-plate (Component Identification Number) for engine.

5 CIN-plate for transmission

6 CIN-plate for boom

7 CIN-plate for front axle

8 CIN-plate for rear axle

Materials - Identifying

6

Materials - Identifying

A marking system is used where all plastic parts are marked with a material code, making the materials easy to identify. Many materials can be granulated and reused, while other plastics are used for energy extraction by incineration. Certain plastics must be taken care of in a special way or destroyed, through some form of pre-treatment.

Volvo standards applicable to these machines are:

•Std 103-0002 Material identification and marking of components made of plastic or elastic material

•Std 5052,41 Material identification and marking of plastic parts

•Std 5052,411 Symbols and abbreviations

•Std 5052,412 Symbols for plastic containers

The following few examples show what the marking may look like:

>ABS< |

Part consisting of one material, in this case ABS-plastic. |

|

|

>ABS+PC< |

Part consisting of a mix of two materials. |

|

|

>PVC,PUR,ABS< |

Part consisting of 3 materials where PVD is the visible (coating) and PUR with inclusion of ABS. ABS is biggest by weight (under- |

|

lined). |

|

|

>PP – MD30< |

Part containing reinforcing or filler material with 30 percent by weight. |

|

|

|

For more complicated mixtures, see Std 103-0002. |

|

Contact your Volvo dealer or Volvo directly to obtain these standards. |

Decontamination |

|

Draining fluids |

7 |

Decontamination

Draining fluids

It is important that fluids are handled in a safe and correct manner, with regards to national legislation as well as local regulations.

Follow instructions in the Service manual and Operator’s manual for draining fluids in axles, tanks, and other containers and/or reservoirs.

The following table is intended to serve as a checklist.

|

Total volume in litres |

|

||

|

Machine type |

|

|

|

|

|

|

|

|

Position |

L150F |

|

L180F |

L220F |

|

|

|

|

|

Engine, including filters |

49 |

|

49 |

49 |

|

|

|

|

|

Transmission and torque converter, including filters |

50 |

|

50 |

48 |

|

|

|

|

|

Front axle, including hub reduction |

49 |

|

49 |

82 |

|

|

|

|

|

Rear axle, including hub reduction |

59 |

|

59 |

76 |

|

|

|

|

|

Rear axle cradle |

- |

|

- |

3 |

|

|

|

|

|

Hydraulic system |

261 |

|

265 |

330 |

|

|

|

|

|

Hydraulic oil tank |

156 |

|

156 |

226 |

|

|

|

|

|

Fuel tank |

335 |

|

335 |

335 |

|

|

|

|

|

Cooling system |

60 |

|

60 |

60 |

|

|

|

|

|

Oil bath pre-cleaner |

9,1 |

|

9,1 |

9,1 |

|

|

|

|

|

Refrigerant (R134a) |

2,1 kg |

|

2,1 kg |

2,1 kg |

|

|

|

|

|

Washer fluid reservoir |

5 |

|

5 |

5 |

|

|

|

|

|

Filter

There is a wide range of filters on the machine that, when dismantled, contain impurities and the medium which they filter. Note that there are special regulations for handling of filters.

Filter table. This table is intended to serve as a checklist.

Number |

Position |

Medium |

Quanti- |

Comments |

|

|

|

ty |

|

|

|

|

|

|

1 |

Transmission |

Transmission oil |

1 |

|

|

|

|

|

|

2 |

Engine |

Oil |

3 |

|

|

|

|

|

|

3 |

Engine |

Coolant |

1 |

|

|

|

|

|

|

4 |

Hydraulic tank |

Hydraulic fluid |

1 |

|

|

|

|

|

|

5 |

Rear axle |

Oil |

1 |

In comb. with axle oil cooling |

|

|

|

|

|

6 |

Front axle |

Oil |

1 |

In comb. with axle oil cooling |

|

|

|

|

|

7 |

Air cleaner |

Air |

2 |

Paper + filter |

|

|

|

|

|

8 |

Cab |

Air |

2 |

Paper filter |

|

|

|

|

|

9 |

Engine compart- |

Diesel |

2 |

|

|

ment |

|

|

|

|

|

|

|

|

- |

Breathing |

Air / oil mist |

5 |

Axles, transmission, hydraulic tank, and fuel tank |

|

|

|

|

|

Loading...

Loading...