Voith CH Series, R Series, S Series, E Series Instruction Manual

High-performance Universal Joint Shafts

including ATEX certification

Series: S, R, CH, E

Instruction manual (Translation) G853 en 07/2013, Version 1

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Publisher

Document number

Date of issue

Copyright

If you have questions regarding the product, please contact us

specifying the serial number and parts list number:

J.M. Voith SE & Co. KG/VTA

Universal Joint Shafts

Alexanderstr. 2

89522 Heidenheim, Germany

Additional contact information:

Telephone +

Fax

E-Mail

Web

49 7321 37-8283

+49 7321 37-7106

UJShafts@Voith.com

www.voith.com

J. M. Voith SE & Co. KG/VTA

Universal Joint Shafts

Alexanderstr. 2

89522 Heidenheim, Germany

E-Mail: UJShafts@Voith.com

G853 en 07/2013 Version 1

July 16, 2013

© 2013, J. M. Voith SE & Co. KG/VTA

This documentation including all of its parts is protected by

copyright. Any use or change outside of the narrow boundaries of

copyright law is not permitted without the agreement of J.M.

Voith SE & Co. KG/VTA and is punishable by law.

This applies especially to copying, translations, microfilming, and

the saving and processing on electronic systems.

2

G853 en 07/2013, Version1

-performance universal joint shaft

J. M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Table of contents

Contents

1 About this instruction manual .....................................................................................7

1.1 Target groups ................................................................................................................ 7

1.2 Product observation ..................................................................................................... 7

1.3 Other applicable documents ....................................................................................... 8

1.4 Additional documents .................................................................................................. 9

1.5 Symbols and markings..................................

.............................................................10

1.6 Warning ........................................................................................................................11

1.6.1 Levels of danger ...........................................................................................................11

1.6.2 Safety symbols ..............................................................................................................12

2 Basic Safety Information ........................................................................................... 13

2.1 Product safety .............................................................................................................13

2.2 Proper use ...................................................................................................................13

2.3 Remaining risks ..........................................................................................................14

2.4 Safety information for the operator ..........................................................................15

2.5 Safety information for the personnel ........................................................................17

2.6 Personal protective equipment .................................................................................21

2.7 Spare parts ..................................................................................................................21

3 High-performance Universal Joint Shafts ..............

................................................. 22

3.1 Structure ......................................................................................................................22

3.2 Application ..................................................................................................................25

3.3 Series ...........................................................................................................................26

3.3.1 Type designations .........................................................................................................26

3.3.2 S Series ........................................................................................................................27

3.3.3 R Series ........................................................................................................................27

3.3.4 CH Series ......................................................................................................................28

3.3.5 E Series ........................................................................................................................28

4 Packaging, transport ................................................................................................. 29

4.1 Packaging ....................................................................................................................29

G853 en 07/2013, Version1

4.2 Unpacking the universal joint shaft and checking the delivery .............................29

4.3 Lifting, transporting, setting down the universal join

-performance universal joint shaft

t shaft ..................................30

3

Table of contents

High

Instruction m

J.M. Voith SE & Co. KG/VTA | Instruction Manual

5 Storage and preservation ......................................................................................... 33

5.1 Storing the universal joint shaft ................................................................................33

5.2 Preserving the universal joint shaft ..........................................................................34

6 Installation .................................................................................................................. 35

6.1 Additional regulations for flange bolted connections ............................................35

6.1.1 Requirements of connecting flange and bolted connections .........................................35

6.1.2 Checking bolted connections and tightened parts .......

.................................................41

6.2 Installing the universal joint shaft .............................................................................42

6.2.1 Removing preservation .................................................................................................44

6.2.2 Transport universal joint shaft to the installation location .............................................44

6.2.3 Cleaning the universal joint shaft and connecting flange .............................................45

6.2.4 Checking, aligning, and fastening connecting flange ...................................................45

6.2.5 Checking the differential angle of the front faces of the connecting flange (with Z

arrangement) ................................................................................................................46

6.2.6 Checking the differential angle of the front faces of the connecting flange (with

W arrangement) ............................................................................................................47

6.2.7 Bolting together the universal joint shaft and the connecting flange ............................47

6.2.8 Final work ......................................................................................................................48

6.3 Additional regulations for Hirth serration ................................................................49

6.4 Additional regulations for use in paper machines ..................................................50

7 Commissioning and operation ................................................................................. 51

7.1 Commissioning the universal joint shaft ...............

..................................................51

7.2 Operating the universal joint shaft ...........................................................................52

8 Eliminating errors ...................................................................................................... 53

9 Maintenance ............................................................................................................... 55

9.1 General notes about the maintenance and inspection of universal joint shafts .56

9.2 Intervals for maintenance and inspections ..............................................................57

9.3 Inspections ..................................................................................................................58

9.3.1 Checking axial clearance of the journal cross set ........................................................58

9.3.2 Checking deflection play of the center part...................................................................59

9.4 Lubrication ..................................................................................................................61

9.4.1 Lubricants .....................................................................................................................61

9.4.2 Lubricating the universal joint shaft .................

.............................................................61

9.5 Main overhaul ..............................................................................................................64

anual (Translation) G853 en 07/2013, Version1

-performance universal joint shaft

4

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Table of contents

9.6 Life span of ATEX universal joint shafts ..................................................................64

10 Removal ...................................................................................................................... 65

11 Repair .......................................................................................................................... 67

12 Disposal ...................................................................................................................... 67

13 Declaration of incorporation ........................

............................................................. 68

14 Declaration of conformity ......................................................................................... 69

15 Index ............................................................................................................................ 70

G853 en 07/2013, Version1

-performance universal joint shaft

5

Table of contents

High

Instruction m

List of figures

Table index

J.M. Voith SE Co. KG/VTA| Instruction Manual

Fig. 3.1: Structure of the universal joint shaft (example of type

RT) ............................................................................ 22

Fig. 3.2: Nameplate of an ATEX-certified universal joint shaft 23

Fig. 3.3: Schematic structure of temperature monitoring ....... 24

Fig. 3.4: Z arrangement .......................................................... 25

Fig. 3.5: W arrangement ......................................................... 25

Fig. 4.1: Attaching the universal joint shaft ............................. 32

Fig. 6.1: Dimensions of the connecting flange and bolted

connections ............................................................... 36

Fig. 6.2: Dimensions of a stud screw ..........................

............ 41

Fig. 6.3: Universal joint shaft .................................................. 44

Fig. 6.4: Checking the difference in joint angle between the

faces of the connecting flanges ................................ 46

Fig. 6.5: Permissible differential angle (with Z arrangement) . 46

Fig. 6.6: Seals for Hirth serration ............................................ 49

Fig. 6.7: Checking radial offset and flange distance (with use in

paper machines) ....................................................... 50

Fig. 9.1: Checking axial clearance of the journal cross set on

two levels .................................................................. 58

Fig. 9.2: Checking deflection play of the center part .............. 59

Fig. 9.3: Reading off deflection dimension ............................. 60

Fig. 9.4: Lubrication points of the universal joint shaft ........... 62

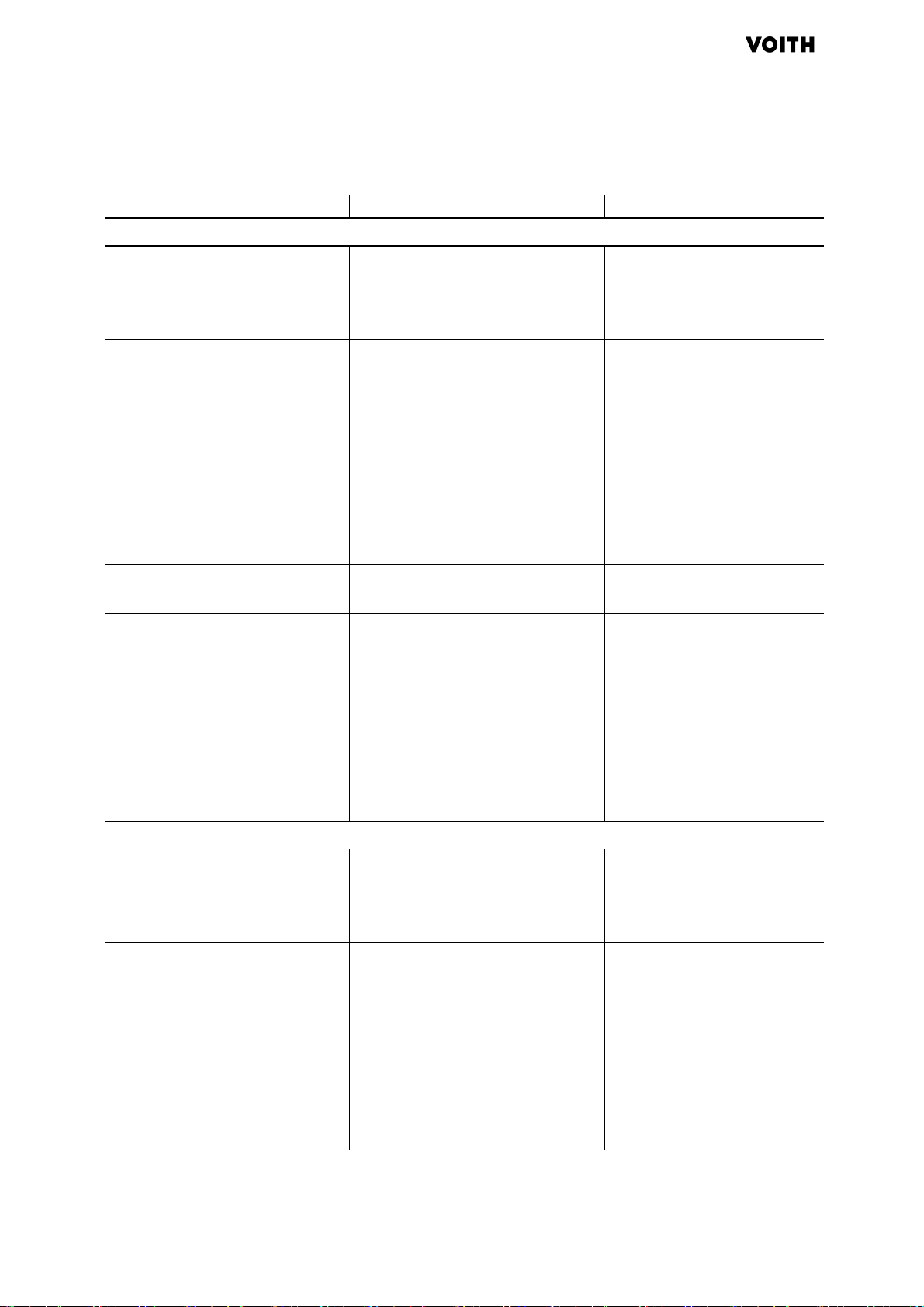

Tab. 1.1: Target groups ............................................................. 7

Tab. 1.2: Other applicable documents ....................................... 9

Tab. 1.3: Symbols and markings ............................................. 10

Tab. 1.4: Meaning of the danger levels ................................... 11

Tab. 1.5: Meaning of the safety symbols .......................

.......... 12

Tab. 2.1: Personal protective equipment ................................. 21

Tab. 6.1: Dimensions of the connecting flange and bolted

connections (key) ....................................................... 37

Tab. 6.2: Dimensions of the connecting flange and bolted

connections ............................................................... 40

Tab. 6.3: Permissible differential angle (with Z arrangement) . 46

Tab. 6.4: Permissible differential angle (with W arrangement) 47

Tab. 6.5: Permissible radial offset and flange distance (for use

in paper machines) ................................................... 50

Tab. 8.1: Eliminating errors ...................................................... 54

Tab. 9.1: Intervals for maintenance work and inspections ...... 58

Tab. 9.2: Checking axial clearance of the journal cross set .... 59

Tab. 9.3: Permissible deflection ratio....................................... 60

Tab. 9.4: Permissible lubricant quantity for the re-lubrication of

standard center parts. ............................................... 64

anual (Translation) G853 en 07/2013, Version1

-performance universal joint shaft

6

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Target group

Task

About this instruction manual

1 About this instruction manual

Before you use the universal joint shaft, you must read this

instruction manually carefully and understand it.

This instruction manual is part of the product and familiarizes you

with the basic work on the universal joint shaft – from installation to

disposal.

It contains information about the safe and proper use of the

universal joint shaft.

1.1 Target groups

Operator Keep this instruction manual accessible to personnel at all

times.

Make sure that employees read and heed the instruction

manual and the other applicable documents, especially the

basic safety instructions and warnings.

Specialized personnel, service

engineer

1.2 Product observation

Heed additional system-related details and regulations.

Read, heed, and follow this instruction manual and the other

applicable documents, especially the basic safety instructions

and warnings.

Tab. 1.1: Target groups

We are under legal obligation to observe our products, even after

ipment.

sh

Therefore, please inform us about anything that might be of

interest, e.g.:

− Change in operating data

− Experience gained with the universal joint shaft

− Recurring problems

− Damage to the universal joint shaft

− Problems with the instruction manual

G853 en 07/2013, Version1

-performance universal joint shaft

7

About this instruction manual

High

Instruction manual (Translation)

Document

Information

Source

1.3 Other applicable documents

Documents for all designs

J.M. Voith SE & Co. KG/VTA| Instruction Manual

System documentation • System-specific information

about the removal and

installation of the universal joint

shaft.

Dimensional drawing of the

universal joint shaft

• Dimensions of the connection

flange.

• Tightening torques of the

bolted connections of the

flange connections.

• Weight of the universal joint

shaft.

• Shortest and maximum

permissible length of the

universal joint shaft.

Delivery note • Weight of the universal joint

shaft

Repair instructions for the

respective designs and sizes

For the manufacturer's authorized

service personnel:

• Information about repair of the

universal joint shaft

Operator

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

Balancing instruction For the manufacturer's authorized

service personnel:

• Information about the

balancing of the universal joint

shaft

Documents for special designs

Mounting and dismounting

instructions for split flange yokes

For designs with split flange yokes:

• Information about installing and

removing the universal joint

shaft

Mounting and dismounting

instructions for tripod center parts

For designs withtripod center parts:

• Information about installing and

removing the universal joint

shaft

Mounting and dismounting

instructions for spring-mounted

center parts

For designs with spring-mounted

center part:

• Information about installing and

removing the universal joint

shaft

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

G853 en 07/2013, Version1

-performance universal joint shaft

8

J.M. Voith SE & Co. KG | Instruction Manual

High

Instruction manual (Translation)

About this instruction manual

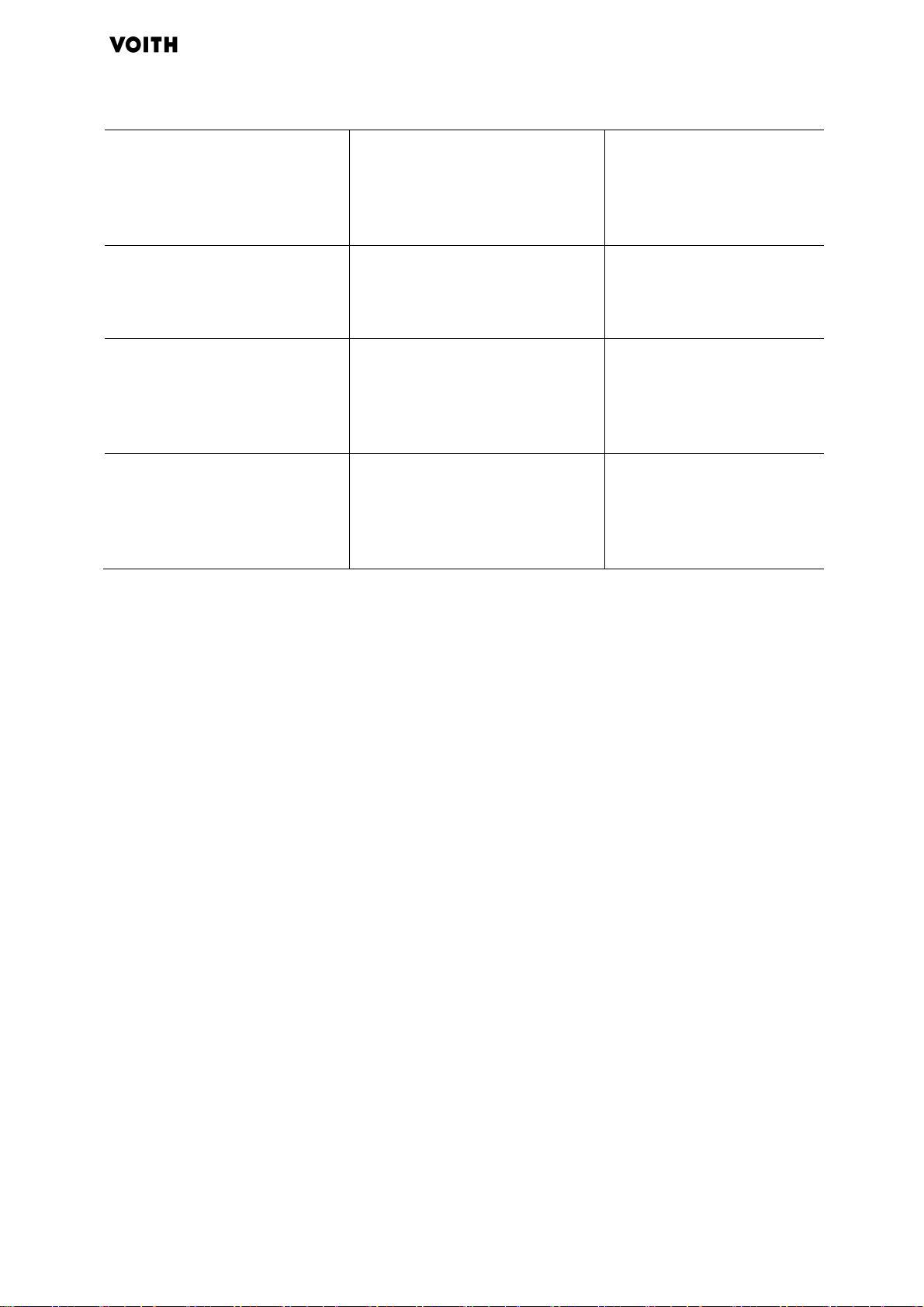

Mounting and dismounting

instructions for hydraulicallymovable center parts

Mounting and dismounting

instructions for deflection brakes

Mounting and dismounting

instructions for shaft angle

limiters

Mounting and dismounting

instructions for quick-release

couplings

For designs with hydraulic center

part:

• Information about installing and

removing the universal joint

shaft

For designs with deflection brake:

• Information about installing and

removing the universal joint

shaft

For designs with shaft angle

limitation:

• Information about installing and

removing the universal joint

shaft

For designs with quick-release

coupling:

• Information about installing and

removing the universal joint

shaft

Tab. 1.2: Other applicable documents

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

J.M. Voith SE & Co. KG/VTA

1.4 Additional documents

For additional information about the universal joint shafts, please

see the following documents:

• High-performance universal joint shafts catalogue

• General delivery conditions

• Hirth serrations

Order from: UJShafts@Voith.com

G853 en 07/2013, Version1

-performance universal joint shaft

9

About this instruction manual

High

Instruction manual (Translation)

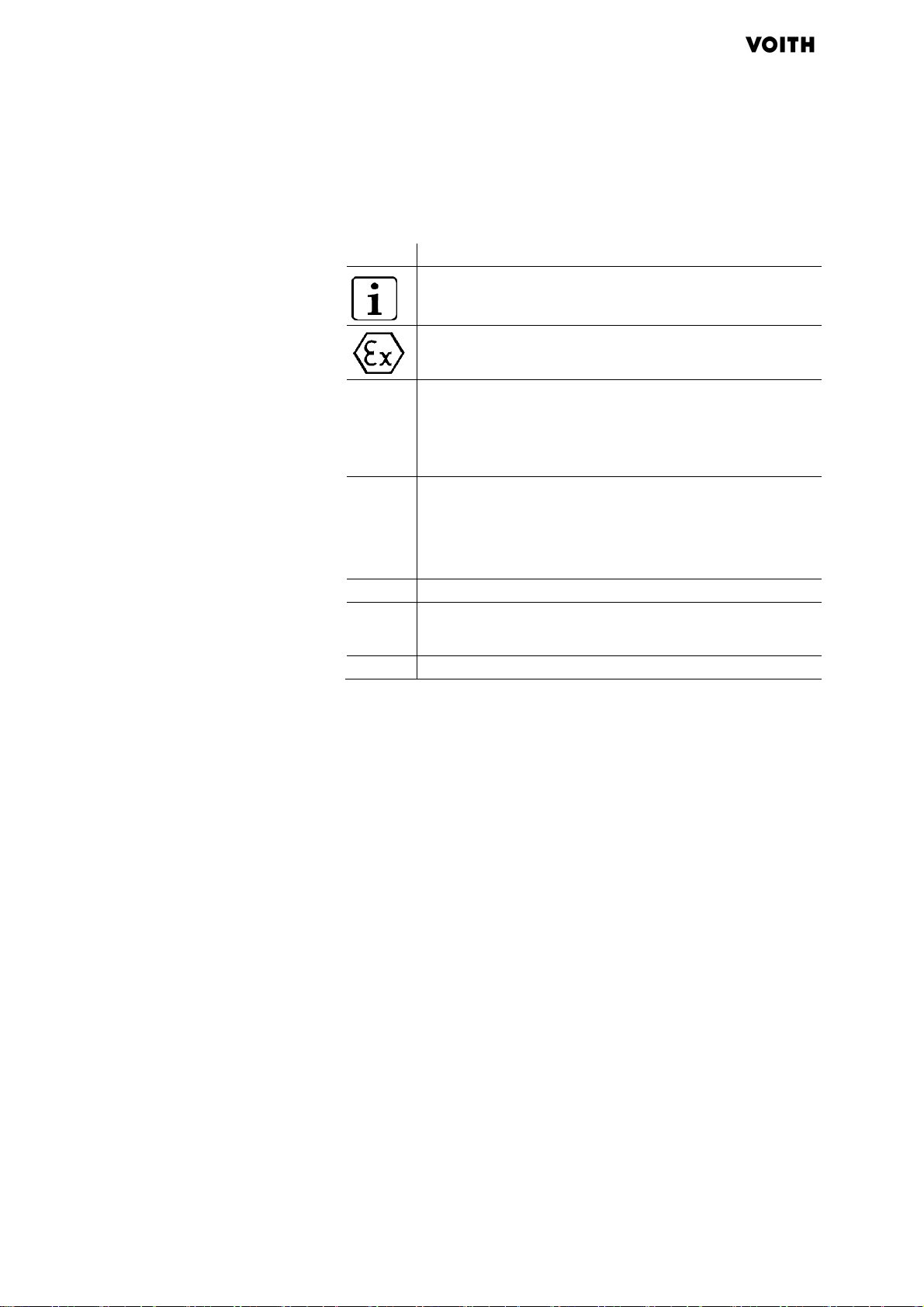

Symbol

Meani

ng

1.5 Symbols and markings

Symbols and markings are used in this instruction manual in order

to allow you quick access to information.

J.M. Voith SE & Co. KG /VTA| Instruction Manual

Note about the effective use of the universal joint shaft

and this instruction manual

Note for ATEX certified universal joint shafts

1.

Action with several steps, whose sequence is relevant

2.

3.

Action with one step

–or–

Action with several steps, whose sequence is not

relevant

Prerequisite

•

List (first level)

−

List (second level)

Cross-reference to additional information

Tab. 1.3: Symbols and markings

G853 en 07/2013, Version1

-performance universal joint shaft

10

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

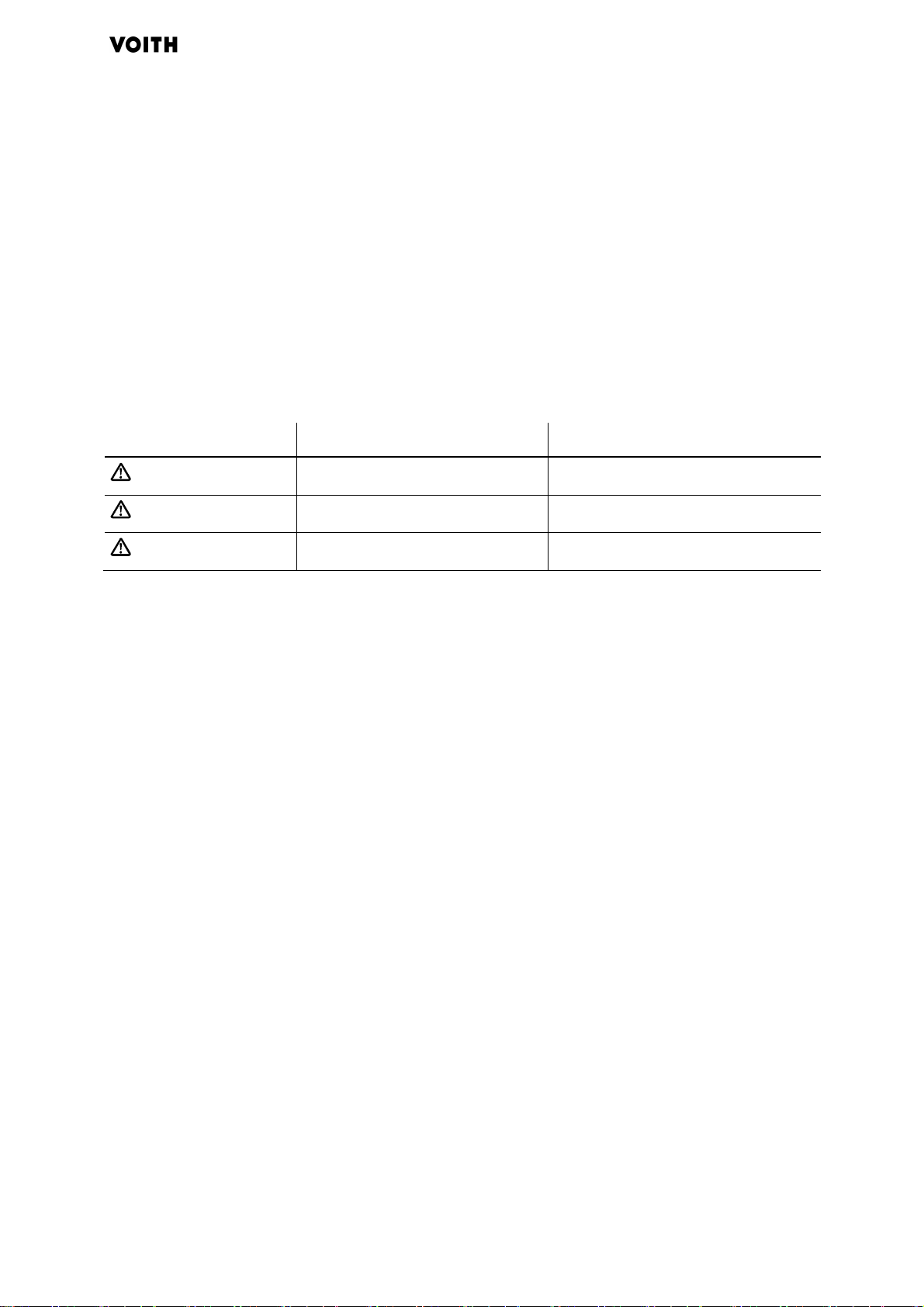

Level of danger

Likelihood of occurrence

Consequences if not heeded

DANGER

WARNING

CAUTION

1.6 Warning

For your safety, warnings are used in this instruction manual. The

warnings are next to the appropriate action instruction.

Depending on the likelihood of occurrence and consequences if

the instructions are not heeded, various danger levels are used.

The warnings are indicated with safety symbols, which depict the

type of danger visually.

1.6.1 Levels of danger

Imminent danger Death, severe bodily harm

Possible imminent danger Death, severe bodily harm

About this instruction manual

Possible imminent danger Slight bodily harm

Tab. 1.4: Meaning of the danger levels

G853 en 07/2013, Version1

-performance universal joint shaft

11

About this instruction manual

High

Instruction manual (Translation)

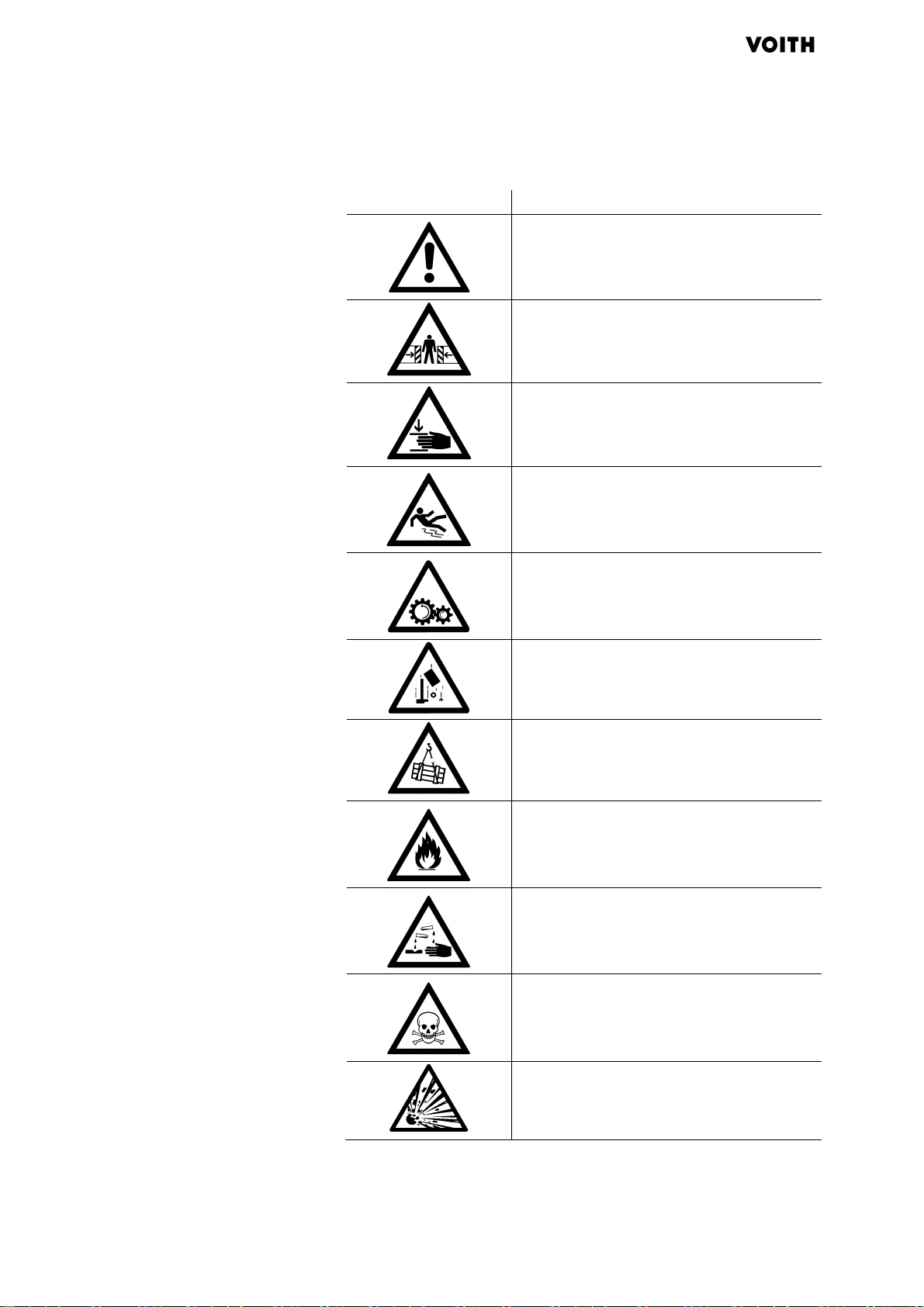

Safety symbols

Warning about

1.6.2 Safety symbols

J.M. Voith SE & Co. KG/VTA | Instruction Manual

General dangers

The type of danger is described in more

detail in the warning.

ushing

Cr

Hand injuries

Slipping

Rotating parts

Falling parts

Suspended loads

Flammable materials

Acidic materials

Poisonous materials

12

nger of explosion

Da

Tab. 1.5: Meaning of the safety symbols

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Foreseeable misuse

2 Basic Safety Information

Please heed the following safety information before engaging

in any activities.

2.1 Product safety

The universal joint shaft has been developed and built according to

he state of technology as well as the applicable safety regulations

t

at the time it was put on the market.

Nevertheless, its use can result in danger to life and limb of the

user or damage to the universal joint shaft itself and other property.

Only install the universal joint shaft if it is in proper condition

and only for the designated use, in a safety-conscious

manner that complies with the instruction manual.

Basic Safety Information

2.2 Proper use

Immediately correct (or have corrected) any defects that

adversely affect safety.

Universal joint shafts transmit torques between defined drive and

machine components. Therefore, the universal joint shaft is

intended for installation in the specific machine/system for which it

was selected.

Any other use, especially installation in other machines, is not

proper and forbidden.

Voith universal joint shafts are not approved for use in the food

industry.

In liquid media, universal joint shafts may only be used with written

permission of the manufacturer.

The universal joint shaft type we make and size can only be

regarded as recommendations.

Any improper use or activities on the universal joint shafts not

described in this instruction manual are impermissible misuse

outside of the legal liability limits of the manufacturer.

G853 en 07/2013, Version1

-performance universal joint shaft

Heed the following measures to avoid misuse:

nly operate the universal joint shaft within the specified

O

speed and torque range.

13

Basic Safety Information

High

Instruction manual (Translation)

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Universal joint shafts are resiliently-flexible bodies that are

designed for bending vibrations and bending-critical speeds.

Therefore, for safety reasons, the maximum operating speed

must be significantly below the critical-bending speed 1st and

2nd order (see universal joint catalog G830).

For sufficient balance and security for the universal joint

shaft, it must be ensured that the operating speed does not

exceed the maximum permissible value depending on the

shaft angle (see universal joint catalog G830) and that the

driving and driven system parts are aligned with one another

(plan and concentric run-out see page 40)

Do not exceed permissible shaft angles of the universal joint

shaft.

Adhere to the lengths and temperatures specified for the

selection of the universal joint shaft.

For universal joint shafts with length compensation, make

sure that the maximum permissible movement path is not

exceeded.

2.3 Remaining risks

A local heating of the universal joint shaft, e.g. due to the

burning off of old color remnants is not permissible in order to

change the run-out properties.

Protect components coated with Rilsan against too-high

temperatures, chemical solvents, steam, and mechanical

damage.

Attaching parts to the universal joint shaft by welding or other

connection types is not permissible.

Adhere to the manufacturer's specifications with respect to

operation, maintenance, and repairs.

Have work on universal joint shafts done by the manufacturer

or by service technicians authorized by the manufacturer.

Do not make any unauthorized modifications or changes.

In areas subject to explosion (atmosphere), only use ATEXcertified universal joint shafts. Here, heed certification ( Chapter

3.1, page 22).

Before beginning construction and planning, the remaining risks of the

niversal joint shaft were analyzed and evaluated.

u

G853 en 07/2013, Version1

Remaining risks that could not be avoided during the entire life cycle

of the universal joint shafts are:

-performance universal joint shaft

14

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Safety

-

conscious working

• Risk of death and injury due to

− Misuse

− Improper handling

− Improper transport

− Missing protection systems

− Defective or damaged mechanical parts

• Environmental hazard, e.g. due to

− Improper handling of preserving agents and lubricants

• Property damage to the universal joint shaft due to

− Improper handling

− Hazardous environmental influences, application

− Operating specifications not adhered to

− Unsuitable operating materials (e.g. bearing grease)

• Property damage to other assets due to improper handling

Basic Safety Information

conditions

• Performance or functional limitations due to

− Improper handling

− Improper maintenance or repair

− Subsequent damage due to overload

Avoid existing remaining risks with the practical imp

heeding of the following specifications:

• Basic safety instructions and warnings in this instruction manual

• Work instructions from the operator

• Technical data for the system ( system documentation)

2.4 Safety information for the operator

The operator must take appropriate safety precautions in

order to prevent the endangering of people and materials due

to rotating universal joint shafts and their parts.

For the operation of the universal joint shaft within a machine,

the EU machine directive must be heeded.

Ensure adherence and monitoring:

lementation and

G853 en 07/2013, Version1

-performance universal joint shaft

− Of proper use

− Of laws and regulations for accident prevention and

environmental protection

− Of safety regulations for the handling of hazardous

materials

− Of applicable standards and guidelines for the country of

operation

15

Basic Safety Information

High

Instruction manual (Translation)

Organizational measures

Selection and qualification of

J.M. Voith SE & Co. KG/VTA | Instruction Manual

Make protective equipment available ( Chapter 2.6, page

21).

For telescopic lengths without profile guard: provide guard in

the system.

Keep this instruction manual and all applicable documents

accessible to personnel at all times.

Specify responsibilities of the personnel clearly and monitor

adherence.

staff

All activities on the universal joint shaft may only

be performed by

authorized personnel.

Ensure that the staff members

− are at least 18 years old.

− have read and understood the "Basic safety information"

chapter.

− can apply and implement the contents of the "Basic safety

instructions" chapter.

− have the bodily and mental abilities to perform their

responsibilities, tasks, and activities on the universal joint

shaft.

− are trained according to their responsibilities, tasks, and

activities on the universal joint shaft.

− have understood and can practically implement the

technical documentation with respect to their

responsibilities, tasks, and activities on the universal joint

shaft.

− is familiar with and can apply the components of the

system and their function.

16

− is familiar according to his responsibilities with the

instructions for cleaning, preserving, lubricating, and using

hazardous materials and taking first aid measures in case

of accidents.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Warranty

Safety

-

conscious wo

rking

The warranty is voided in case of any change to the universal

joint shaft without our written permission.

During the warranty, obtain the manufacturer's permission

before making repairs to the universal joint shaft.

Only use original parts or parts approved by the

manufacturer.

2.5 Safety information for the personnel

The consumption of alcohol, drugs, medications or other mind-

ltering substances is forbidden.

a

Protect universal joint shaft against unauthorized operation.

Adhere to applicable accident prevention regulations.

If necessary or required by regulations, wear personal

protective equipment ( Chapter 2.6, page 21).

Basic Safety Information

Keep unauthorized personnel out of the danger area of the

universal joint shaft.

Keep safety and notice signs on the universal joint shaft in

easily-legible condition, e.g. lubrication points.

Follow the supervisor or safety officer's safety and work

instructions.

Only linger in the workplaces provided in the danger area

( system documentation).

Do not make any constructional changes to the universal joint

haft.

s

Handle hazardous materials according to the safety data

sheets. Heed safety measures and wear personal protective

equipment.

G853 en 07/2013, Version1

-performance universal joint shaft

17

Basic Safety Information

High

Instruction manual (Translation)

Lifting, transport, setting down

Pr

eservation

installation

J.M. Voith SE & Co. KG /VTA| Instruction Manual

Depending on the design, universal joint shafts can weigh up to 80

tons.

Heed weight ( Delivery note/Dimensional drawing of the

universal joint shaft).

Only lift and transport universal joint shafts with sufficiently-

dimensioned transport equipment ( Fig. 4.1, page 32).

Heed common attachment regulations.

Do not load profile guard.

Heed the center of gravity (hoist axis).

Only store universal joint shafts

− on floors with sufficient load capacity

− on suitable bases

Secure universal joint shaft against rolling away.

Only transport universal joint shaft in areas not subject to explosion

(atmosphere).

Unsecured universal joints can tip during lifting, tr

ansport, setting

down.

Secure universal joints against tipping, e.g. with a suitable

rope or wedge.

Never reach between the universal joint, even if there is a

deflection guard present.

For telescopic lengths: an unsecured telescoping part

can be

pulled apart when lifting, transporting or setting down.

Secure telescoping part against being pulled apart, e.g. with

a suitable rope.

Cleansers and anti-corrosion agents are usually flammable in their

liquid form.

Ensure sufficient ventilation.

Prevent direct bodily contact and inhalation.

Heed the manufacturer's safety data sheets.

18

Heed additional regulations for flange bolted connections

( Chapter 6.1, page 35).

Heed safety instructions for lifting, transport, setting down.

Secure drive against starting up.

G853 en 07/2013, Version1

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Commissioning and operation

Keep personnel who are not participating away, e.g. using

supervisory personnel, enclosures, fences.

Only install universal joint shaft in areas not subject to explosion

(atmosphere).

For specially-designed universal joint shafts, improper installation

and removal can cause severe injuries or even death.

Heed and if necessary order additional documentation

( Chapter 1.3, page 8).

Only put a completely functional and safe universal joint

shaft/system into operation.

Before commissioning, remove deflection and transport

braces.

Before commissioning, check tightening torques and null

markings.

Basic Safety Information

Only operate universal joint shaft with appropriate guards

( system documentation).

For telescopic lengths: protect gearing of the telescopic parts

against dirt and foreign bodies.

In case of changed operating state and faults, take the

universal joint shaft out of commission immediately. Report

changed operating states and faults to the responsible

office/person immediately.

Do not perform cleaning work when operation is ongoing.

If it is not possible to prevent people from lingering in the

danger radius of the universal joint shaft while it is in

operation, special safety measures must be taken in case of

a universal joint shaft break.

If there can be blockages or collisions with resulting personal

injury as a result of a universal joint break in the case of

mobile drives, appropriate arresting devices must be

provided for the universal joint shafts.

In case of ATEX-certified universal joint shafts, it must be ensured

that

G853 en 07/2013, Version1

-performance universal joint shaft

The surface temperature in the field of joint bearings not

exceed 140°C.

Voith recommends at both joints, to attach a temperature

monitoring in the field of the joint bearings.

19

Basic Safety Information

High

Instruction manual (Translation)

Maintenance work and

Repair

Decommissioning

Removal

Disposal

J.M. Voith SE & Co. KG/VTA | Instruction Manual

inspections

The operator's service personnel may only perform the maintenance

work and inspections described in this instruction manual. Other

maintenance work (especially overhauls) may only be performed by

the manufacturer's service personnel or personnel authorized by the

manufacturer.

Observe specified intervals ( Chapter 9.2, page 57).

Do not perform any maintenance work or inspections during

ongoing operation.

Before maintenance and inspection work, secure the drive

against starting up.

Do not remove any safety equipment as long as the universal

joint shaft/system is not standing still and secured against

starting up again.

When the universal joint shaft is standing still, do not load it

with high lifting or attachment forces and do not place any

objects on the universal joint shaft or hang or attach anything

to it.

Before reattaching the universal joint shaft/system, reattach

all safety equipment.

The universal joint shaft must be checked regularly for

changed running noises and vibrations.

Repairs may only be made by the manufacturer's servic

e

personnel or personnel authorized by the manufacturer.

Only make repairs after consultation with the manufacturer.

Do not make any repairs when operation is ongoing.

Only repair universal joint shaft in areas not subject to explosion

(atmosphere).

See system documentation

See repair instructions/system documentation

ly remove universal joint shaft in areas not subject to explosion

On

(atmosphere).

Dispose of packaging material according to the applicable

regulations in the place of use.

Dispose of operating and hazardous materials separately

according to the locally-applicable regulations. Heed the

manufacturer's safety data sheets.

G853 en 07/2013, Version1

20

-performance universal joint shaft

J.M. Voith SE & Co. KG/VTA | Instruction Manual

High

Instruction manual (Translation)

Activity

Protective equipment

2.6 Personal protective equipment

Heed additional notices in the system documentation.

Heed additional operator-side regulations.

In order to prevent injuries, wear personal protective

equipment according to the following table:

Re-installation • Safety helmet

Basic Safety Information

• Safety shoes with slip-proof, oil-resistant

soles

• Protective gloves

• Fall protection

• Safety glasses

Commissioning

and operation

• Closely-fitting clothing

• Ear protection

• Safety shoes with slip-proof, oil-resistant

soles

• Safety glasses

Transport • Safety helmet

• Safety shoes with slip-proof, oil-resistant

soles

• Safety glasses

Preservation • Safety glasses

• Protective gloves

Maintenance • Safety helmet

• Protective gloves

• Safety shoes with slip-proof, oil-resistant

soles

• Fall protection

• Safety glasses

Tab. 2.1: Personal protective equipment

2.7 Spare parts

G853 en 07/2013, Version1

-performance universal joint shaft

Spare parts must meet the technical specifications of the

manufacturer. Same is guaranteed if original parts are used, as

these are subject to a regular quality control. Spare parts from

other suppliers may, in some cases, change the characteristics of

the machine and result in substantial defects, for which Voith

cannot assume any responsibility.

21

High-performance Universal Joint Shafts

High

Instruction manual (Translation)

Link head

Journal cross set

Flange yoke

Telescopic length with

J.M. Voith SE & Co. KG/VTA | Instruction Manual

3 High-performance Universal Joint Shafts

3.1 Structure

standard center part

Fig. 3.1: Structure of the universal joint shaft (example of type RT)

The link head consists of:

• an integral flange yoke

–or–

a semi-integral flange yoke

A journal cross set constits of:

• a journal cross

• four bearing units

The flange yokes depend on the universal joint shaft type

( Chapter 3.3, page 26).

Depending on the size, the telescopic length is eithe

r equipped

with an involute profile or a diameter-centered SAE profile with

length compensation.

The involute profile can optionally be provided with a lowmaintenance Rilsan® plastic coating.

G853 en 07/2013, Version1

22

-performance universal joint shaft

Loading...

Loading...