Vermont Castings 2460 Instruction Manual

Convection

Heater Model

2460, 2461,

2462

7001135 1/07 Rev. 19

Homeowner’s Installation and Operating Manual

DO NOT DISCARD THIS MANUAL: Retain for future use

If this heater is not properly installed, operated, and maintained, a house fire may result.

For safety, follow all installation, operation and maintenance directions. Contact local

building officials about restrictions and installation inspection requirements in your

area.

SAFETY NOTICE

2

Dutchwest

7001135

PLEASE NOTE

Please read this entire manual berfore you install

and use your new room heater. Failure to follow

instructins my result in property damage, bodily

injury or loss of life. Save these instructions for

future use.

The Dutchwest models covered in this Owner’s Guide have been tested and

listed by Inchcape Testing Services / Warnock Hersey of Middleton, Wisconsin. The test standards utilized were ANSI/UL 1482 for the United States and

CAN/CGA - B366.2 for Canada. Dutchwest models are not listed for mobile

home installations.

Patents: U.S. - D288357, 4502395, 4646712;

Canada - 1235969. Other foreign mechanical patents issued.

Accessories

• Bottom Heat Shield

• Clearance-reducing Rear Heat Shields

• Clearance-reducing Heat Shields for single-wall

stove pipe

• 2” legs

• Warming shelves (Small and Large Heaters only)

• Two-speed convection blower

• Automatic thermostat for the blower

Table of Contents

Specifications ............................................................ 3

Installation ..........................................................4

Clearances

.......................................................12

Assembly ..........................................................16

Operation

..........................................................17

Maintenance

.....................................................22

Illustrated Parts List ..........................................30

Proposition 65 Warning: Fuels used in gas, woodburning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

3

Dutchwest

7001135

1. Maximum burn times and heat outputs are based on laboratory testing using full loads of seasoned hardwoods, and may vary in individual use

depending on how the stove is operated, type and moisture content of fuels, and other factors. Maximum burn times are achieved under different

operating conditions than are maximum heat outputs.

2. These values are based on operation in building code-conforming homes under typical Winter climate conditions in the northeastern U.S. If your

home is of nonstandard construction (e.g. unusually well-insulated, not insulated, built underground, or if you live in a more severe or more temperate climate), these figures may not apply. Since so many variables affect performance, consult your Dutchwest Authorized Dealer to determine

realistic expectations for your home.

4. Under specific conditions used during EPA emissions testing.

5. Based on preliminary results obtained during EPA emissions testing.

Specifications

A

C

B

D

G

F

E

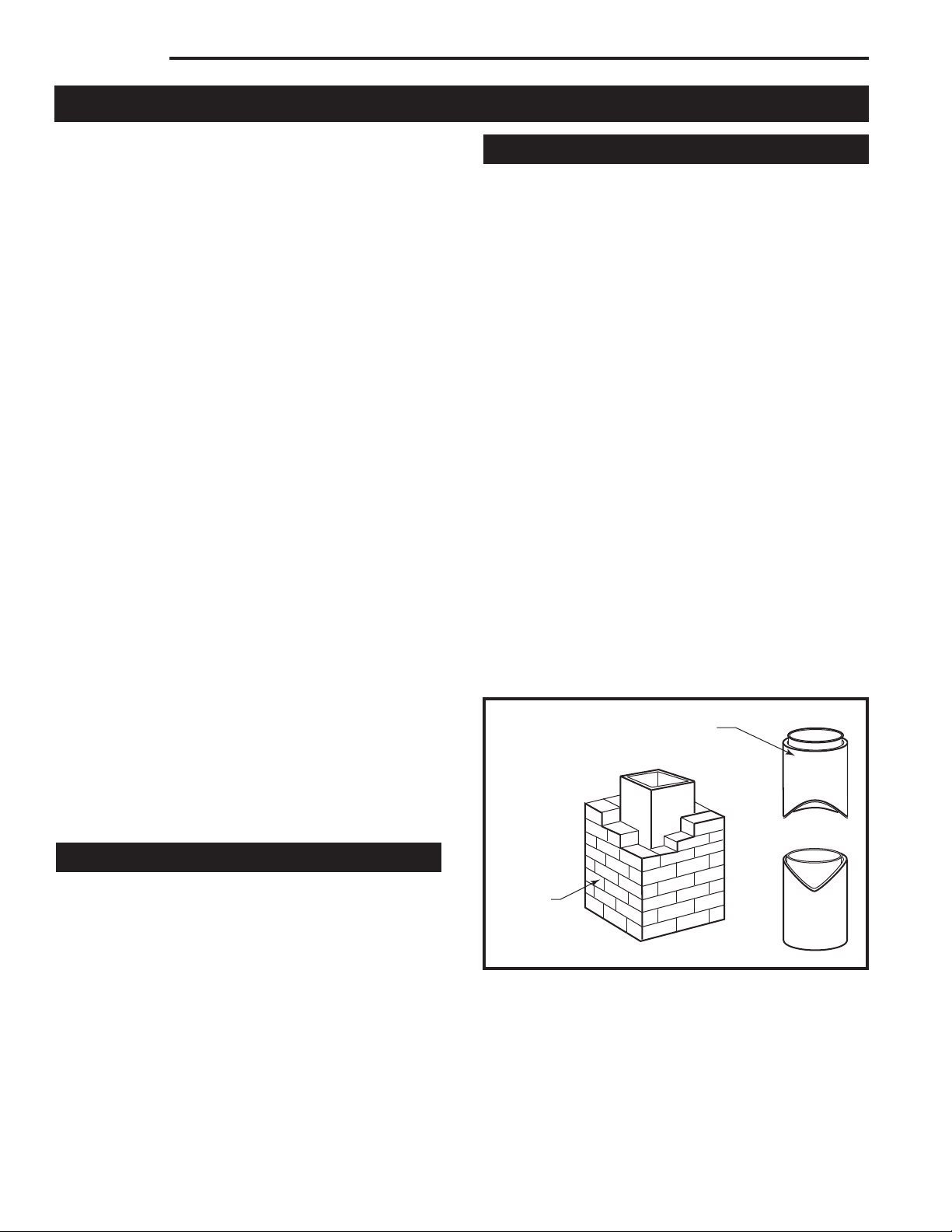

Fig. 1 Dutchwest Convection Heater specifications.

Stove Model Number 2460 2461 2462

A 22” (560 mm) 25³⁄₄” (654 mm) 28¹⁄₄” (717 mm)

B 21” (530 mm) 24¹⁄₂” (620 mm) 27” (690 mm)

C 29³⁄₄” (754 mm) 30” (760 mm) 33” (840 mm)

D 16” (410 mm) 16” (410 mm) 18¹⁄₄” (467 mm)

E 14³⁄₄” (375 mm) 14⁵⁄₈” (380 mm) 17” (430 mm)

F 26³⁄₄” (683 mm) 27” (690 mm) 30¹⁄₈” (763 mm)

G 29³⁄₄” (754 mm) 30” (760 mm) 33” (840 mm)

Log length: 19” (480 mm) 22” (560 mm) 25” (640 mm)

Maximum burn time1: 8 hrs. 9 hrs. 12 hrs.

Average area heated (sq. ft.)2: 700-1,400 (65-130m2) 800-1,600 (75-150m2) 1,200-2,400 (112-224m2)

Range of heat output4: 7,800 - 26,800 Btu/hr. 11,300 - 26,800 Btu/hr. 10,500-27,700 Btu/hr

5

Maximum heat output: 35,000 Btu/hr. 40,000 Btu/hr. 55,000 Btu/hr.

EPA emissions rating4 (g/h, catalytic): 1.1 1.4 1.3

Weight: 380 lbs. (172 kg) 436 lbs. (198 kg) 634 lbs. (288 kg)

Loading: Side or front Side or front Side or front

Flue exit position (reversible): Top or rear Top or rear Top or rear

Air controls: 2 controls 2 controls 2 controls

4

Dutchwest

7001135

Installation

SAFETY NOTICE: IF YOUR DUTCHWEST CONVECTION HEATER IS NOT PROPERLY INSTALLED,

OPERATED AND MAINTAINED, A HOUSE FIRE MAY

RESULT. FOR SAFETY, FOLLOW ALL INSTALLATION, OPERATION AND MAINTENANCE DIRECTIONS. CONTACT LOCAL BUILDING OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION REQUIREMENTS IN YOUR AREA.

Before you begin the installation, review your plans to

confirm that:

• Your stove and chimney connector will be far enough

from combustible material to meet all clearance requirements.

• The floor protector is large enough and is constructed

properly to meet all requirements.

• You have obtained all necessary permits from local

authorities.

Your local building official is the final authority for approving your installation as safe and for determining

that it meets local and state codes.

Clearance and installation information is printed on the

metal label attached to the rear of the stove. Local authorities generally will accept the label as evidence that,

when the stove is installed according to the information

on the label and in this manual, the installation meets

codes and can be approved.

Codes vary in different areas, however. Before starting

the installation, review your plans with the local building

authority. Your local dealer can provide any additional

information needed.

Important: Failure to follow these installation instructions may result in a dangerous situation, including a

chimney or house fire. Follow all instructions exactly,

and do not allow makeshift compromises to endanger

property and personal safety.

Chimney Types

Your Dutchwest Convection Heater must be connected

to a sound masonry chimney that meets local codes, a

relined masonry chimney that meets local codes, or to

an approved prefabricated metal chimney. Whatever

kind you use, the chimney and chimney connector must

be in good condition and kept clean.

Masonry Chimneys

If you use an existing masonry chimney, it must be

inspected to ensure safe condition before the stove

is installed. Your local professional chimney sweep,

building inspector, or fire department official will be able

either to make the inspection or to direct you to someone who can.

An inspection of the chimney must confirm that it has

a lining. Do not use an unlined chimney. The chimney should also be examined for cracks, loose mortar,

other signs of deterioration, and blockage. Repair any

defects before the chimney is used with your stove.

Unused openings in an existing masonry chimney must

be sealed with masonry to the thickness of the chimney

wall, and the chimney liner should be repaired. Openings sealed with pie plates or wallpaper are a hazard

and should be sealed with mortar or refractory cement.

In the event of a chimney fire, flames and smoke may

be forced out of these unused thimbles.

The chimney should be thoroughly cleaned before use.

A newly-built masonry chimney must conform to the

standards of your local building code or, in the absence

of a local code, to a recognized national code. Masonry

chimneys must be lined, either with code-approved

masonry or pre-cast refractory tiles, stainless steel

pipe, or a code-approved, “poured-in-place” liner. The

chimney’s clean-out door must seal tightly.

Prefabricated Double-Wall

Insulated Chimney

Tile Lined

Masonry

Chimney

ST241

Fig. 2 If in sound condition and approved for use, either a

masonry or a prefabricated chimney may be used.

5

Dutchwest

7001135

Prefabricated Chimneys

A prefabricated metal chimney must be one tested and

listed for use with solid-fuel burning appliances.

A horizontal connector run should be inclined 1/4” per

foot (20 mm per meter) from the stove toward the

chimney. The recommended maximum length of a horizontal run is 3 feet (1m) and the total length of chimney

connector should be no longer than 8 feet (2.5m).

Chimney Height

For proper draft and good performance, the chimney

should extend at least 16’ (5 m) above the flue collar of

the stove.

The chimney must also extend at least 3’ (900 mm)

above the highest point where it passes through a roof,

and at least 2’ (600 mm) higher than any portion of a

building within 10’ (3 m). (Fig. 2)

DO NOT CONNECT THIS UNIT TO A CHIMNEY

FLUE SERVING ANOTHER APPLIANCE.

Chimney Size

The Model 2460 and 2461 heaters should be vented

into a masonry chimney with a square flue with nominal flue size of 8” x 8” (200 x 200 mm), or a round flue

with nominal flue size of 6” (150 mm). The Model 2462

heater should be vented into a masonry chimney with a

nominal flue size of 8” x 8” (200 mm x 200 mm) square,

or 8” (200 mm) round.

Chimney liners larger than 8” x 12” (200 x 300 mm)

may promote rapid cooling of smoke and reduction in

draft, especially if they are located outside the home.

These large chimneys may need to be insulated or

have their flues relined for proper stove performance.

Accessories to help make the connection between

stainless steel chimney liners and the stove are available through your local dealer.

2' MIN.

2' MIN.

3'

MIN.

0 TO 10'

3'

MIN.

0 TO 10'

Reference

Point

AC246

Fig. 3 The 2/3/10 rule for chimneys.

Guidelines for Installing

the Chimney Connector

The chimney connector is the single-wall pipe, or listed

and approved double-wall pipe that connects the stove

to the chimney. The chimney itself is a masonry or

prefabricated structure that encloses the flue. Chimney

connectors are used only to make the connection from

the stove to the chimney.

Do not pass the chimney connector through a combustible wall or ceiling, or through an attic, a closet or any

similar concealed space. If passage through a combustible wall is unavoidable, follow the recommendations in

the following section on Wall Pass-Throughs. Keep the

passage as short and direct as possible, with no more

than two 90 degree turns.

Two Types of Connector

You may use either a single-wall steel connector of the

size and gauge described below, or a listed and approved double-wall connector.

Single-Wall Connector

The single-wall chimney connector should be made of

24 gauge or heavier steel, and must have a minimum

internal diameter of 6” (150 mm) for models 2460 and

2461, or 8” (200 mm) for model 2462.

Install single-wall chimney connector not less than 18”

(450 mm) from the ceiling.

In cathedral ceiling installations, extend the prefabricated chimney downward to within 8 feet (2.5 meters)

of the stove. The entire chimney connector should be

exposed and accessible for inspection and cleaning.

Do not use galvanized chimney connector; it cannot

withstand the high temperatures that can be reached

by smoke and exhaust gases and it may release toxic

fumes under high heat.

Chimney

Elbow

Slip Pipe

Standard Connector

Flue Liner

Flue

Thimble

Flue Collar

Floor Protector

ST418

Fig. 4 Sections of a steel chimney connector of at least 24

gauge thickness are fastened together with screws to

connect the stove to the chimney.

6

Dutchwest

7001135

Double-Wall Connector

Information on assembling and installing double-wall

connectors is provided by the manufacturer of the

double-wall pipe. Follow the manufacturer’s installation

instructions exactly. Most manufacturers of prefabricated double-wall insulated chimneys also offer doublewall connector pipes. Using a chimney and connector

pipe from the same manufacturer helps simplify the

assembly and installation.

NOTE: For installations using double-wall connectors, minimum clearances must conform to listed

clearances in the Stove and Chimney Connector

Clearance Charts on page 12 and 13 of this manual.

Assembling Single-Wall

Chimney Connector

SAFETY NOTE: Always wear gloves and safety

goggles when drilling, cutting or joining sections of

chimney connector.

For double-wall connectors, follow the manufacturer’s

instructions exactly. For single-wall connectors, follow

the instructions below.

1. Insert the crimped end of the first section into the

stove’s flue collar, and keep each crimped end pointing

toward the stove (Fig.5). Using the holes in the flue collar as guides, drill 1/8” (3 mm) holes in the bottom of the

first section of chimney connector and secure it to the

flue collar with three #10 x 1/2” sheet metal screws.

Toward

Stove

Flue Gas

Direction

ST242

Fig. 5 Crimped sections always point toward the stove so

that any liquid condensation will not leak out.

2. Secure each joint between sections of chimney connector, including telescoping joints, with at least three

sheet metal screws.

3. Secure the chimney connector to the chimney. Instructions for various installations follow below.

4. Confirm that the installed stove and chimney con-

nector are correct distances from nearby combustible

material. See the clearance charts on pages 12 and 13.

NOTE: Special slip pipes and thimble sleeves that form

telescoping joints between sections of chimney connector are available to simplify installations. They can

eliminate the need to cut individual connector sections.

Consult your local dealer about these special pieces.

Securing the Connector

to a Prefabricated Chimney

Follow the installation instructions of the chimney

manufacturer exactly as you install the chimney. The

manufacturer of the chimney will supply the accessories to support the chimney, either from the roof of

the house, at the ceiling of the room where the stove is

installed, or from an exterior wall.

Special adaptors are available from your local dealer

to make the connection between the prefabricated

chimney and the chimney connector. (Fig. 6) The top

of such adaptors attach directly to the chimney or to the

chimney’s ceiling support package, while the bottom of

the adaptor is screwed to the chimney connector.

These adaptors are designed so the top end will fit

outside the inner wall of the chimney, and the bottom

end will fit inside the first section of chimney connector.

Any soot or creosote falling from the inner walls of the

chimney will stay inside the chimney connector.

Prefab (Insulated)

Chimney

Ceiling Support

Package

Prefab Chimney

Adapter

Chimney Connector

(Stovepipe)

ST419

Fig. 6 Joining the chimney connector to a prefabricated

chimney.

7

Dutchwest

7001135

Securing the Connector

to a Masonry Chimney

The Dutchwest Convection heaters may be connected

to either a freestanding masonry chimney or a masonry

fireplace chimney.

Freestanding Installations

If the chimney connector must pass through a combustible wall to reach the chimney, follow the recommendations in the wall pass-through section that follows.

The opening through the chimney wall to the flue

(the “breech”) must be lined with either a ceramic or

metal cylinder, called the “thimble”, which is securely

cemented in place. (Fig. 7) Most chimney breeches

incorporate thimbles, but check to be sure the fit is snug

and the joint between thimble and chimney wall firmly

cemented.

A special piece called the “thimble sleeve,” slightly

smaller in diameter than the standard connector and

most thimbles, will ease the removal of the chimney

connector system for inspection and cleaning. Thimble

sleeves should be available from your local dealer.

To install a thimble sleeve, slide it into the breech until

it is flush with the inner flue wall. Don’t extend it into

the actual flue passage, as that could interfere with the

draft.

The thimble sleeve should protrude 1-2” (25-50 mm)

into the room. Use furnace cement and thin gasketing

to seal the sleeve in place in the thimble. Secure the

chimney connector to the outer end of the sleeve with

sheet metal screws.

Fireplace Installations -

Above the Fireplace

In this installation, the chimney connector rises from

the stove, turns ninety degrees, and goes back into the

fireplace chimney. The liner of the fireplace chimney

should extend at least to the point at which the chimney

connector enters the chimney. Follow all the guidelines

for installing a chimney connector into a freestanding

masonry chimney, and pay special attention to these

additional points:

• Check the stove and chimney connector clearances

to combustible mantel or trim materials. Use the

necessary combination of mantel, trim, and connector heat shields to provide the required clearances.

(Fig. 8)

• Double-check connector clearance from the ceiling.

• The fireplace damper must be closed and sealed

to prevent room air from being drawn up the flue,

reducing the draft. However, it must be possible to

re-open the damper to inspect or clean the chimney.

Flue Liner

Extend Chimney Connector to the First

Tile of

the Flue Liner

Observe

Miniumum Clearances

Damper

Plate is

Remvoed

or Locked

in Open

Position

Close Of

f

the Damper

Opening with

Sheet Metal

and Sealant

ST245a

Fig. 9 The connector passes through the fireplace to enter

flue. Special Fireplace Adapter Kits to simplify fireplace installations are available from your local dealer.

Masonry Wall

Ceramic Flue Liner

Chimney Connector Shield

Block-Of

f Plate

Chimney Connector

ST244a

Fig. 8 The connector enters flue above the fireplace. If the

clearance between the chimney connector and either the

mantel and/or the ceiling is inadequate, special protective

shields will be required.

Thimble

Sleeve

Elbow

Flue

Keep

Sleeve

End Flush

with Flue

Tile

Thimble

Flue Liner

Chimney

Connector

ST243

Fig. 7 The thimble, made of either ceramic or metal, must be

cemented in place securely.

8

Dutchwest

7001135

Fireplace Installations -

Through the Fireplace

The Convection heaters may be installed either without

legs* as a fireplace insert, or with standard legs attached - depending on the safety regulations that apply

to your situation, the height of the fireplace opening and

your own preference. For either situation, the chimney

connector/positive connection kit extends back from the

stove, enters the fireplace cavity, and turns upward. It

then passes through the fireplace damper opening and

smoke chamber and connects to the chimney flue.

In such installations, a “positive connection” must be

made to the chimney flue with a special kit available

from your local dealer. Also, special clearance and floor

protection provisions must be observed. These provisions are discussed in the Clearance and Floor Protection sections respectively.

Wall Pass-Throughs

Whenever possible, design your installation so the connector does not pass through a combustible wall. If you

must use a wall pass-through in your installation, check

with your building inspector before you begin and construct it in accordance with local building codes. Also

check with the chimney connector manufacturer for any

specific requirements.

Accessories are available for use as wall passthroughs. If using one of these, make sure it has been

tested and listed for use as a wall pass-through.

All combustible material in the wall is cut away a sufficient distance from the single-wall connector to provide

the required 12” (305 mm) clearance for the connector.

Any material used to close up the opening must be noncombustible.

The following wall pass-through methods may be approved in your area:

• Use a section of listed factory-built chimney with a

nine-inch clearance to combustibles.

• Place a chimney connector pipe inside a ventilated

thimble, which is then separated from combustibles

by six inches (152 mm) of fiberglass insulating material.

• If the stove is installed without legs, we recommend

the use of noncombustible tiles or pavers as shims

to allow air flow into the convection air inlets under

the stove. Make sure not to block air slots instove

bottom with shims or remove fan cover.

• Place a chimney connector pipe inside a section of

listed solid-insulated, factory-built chimney, with an

inside diameter 2 inches (51 mm) larger than the

chimney connector and having 1 inch (25.4 mm) or

more of insulation and maintaining a minimum 2 inch

air space between the outer wall of the chimney and

combustibles.

In Canada: The Canadian Standards Association has

established different guidelines. Figure 11 shows one

method, in which all combustible material in the wall is

cut away to provide the required 18” (450 mm) clearance for the connector. The resulting space must

remain empty.

DO NOT CONNECT THE HEATER TO ANY AIR

DISTRIBUTION DUCT OR SYSTEM.

18”

(450mm)

Empty Space

All Around

the Chimney

Connector

Sheet Metal

Cover

(One side

only)

ST421

Fig. 11 Hollow wall pass-through.

Chimney Connector

12”

(305mm)

12”

(305mm)

ST420

Fig. 10 Wall pass-through enclosed with noncombustible

materials.

9

Dutchwest

7001135

A flush-mounted sheet metal cover may be used on one

side only. If covers must be used on both sides, each

cover must be mounted on non-combustible spacers

at least 1” (25 mm) clear of the wall. Your Dutchwest

dealer or your local building inspector can provide details of other approved methods of passing a chimney

connector through a combustible wall. In Canada, this

type of installation must conform to CAN/CSA-B365,

Installation Code for Solid Fuel Burning Appliances and

Equipment.

NOTE: Do not vent your Dutchwest stove into a factorybuilt (zero-clearance) fireplace. These appliances and

their chimneys are specifically designed as a unit for

use as fireplaces. It may void the listing or be hazardous to adapt them for any other use.

Floor Protection

A tremendous amount of heat radiates from the bottom

plate of your Dutchwest stove. The floor area directly

under and around the stove will require protection from

radiant heat as well as from stray sparks or embers that

may escape the firebox.

Heat protection is provided through the use of a CFM

Corporation Bottom Heat Shield. Spark and ember

protection must be provided by a floor protector constructed with noncombustible material as specified.

Most installations will require that the bottom heat

shield be attached. Only when the stove is placed on a

completely noncombustible surface such as unpainted

concrete over earth may it be used without the heat

shield.

Even when the bottom heat shield is installed, you must

provide special protection to the floor beneath. For

installation with the heat shield attached, use a noncombustible floor protector such as 1/4” non-asbestos

mineral board or equivalent, or 24 gauge sheet metal.

The floor protector may be covered with a decorative

noncombustible material if desired. Do not obstruct the

space under the heater.

Protection requirements vary somewhat between the

United States and Canada as follows:

U.S. Installations: The floor protector is required under

the stove and must extend at least 16 inches from the

front and left (loading door) side of the stove, and at

least 6 inches from the right side and rear. (Fig. 12)

Refer to Figure 12 for minimum noncombustible floor

protection dimensions for each stove model.

In Canada: a noncombustible floor protector is required

under the heater also. The floor protector must extend

18 inches (457mm) from the front and left (loading

door) side of the stove, and at least 8 inches (203mm)

from the right side and rear. (Fig. 12)

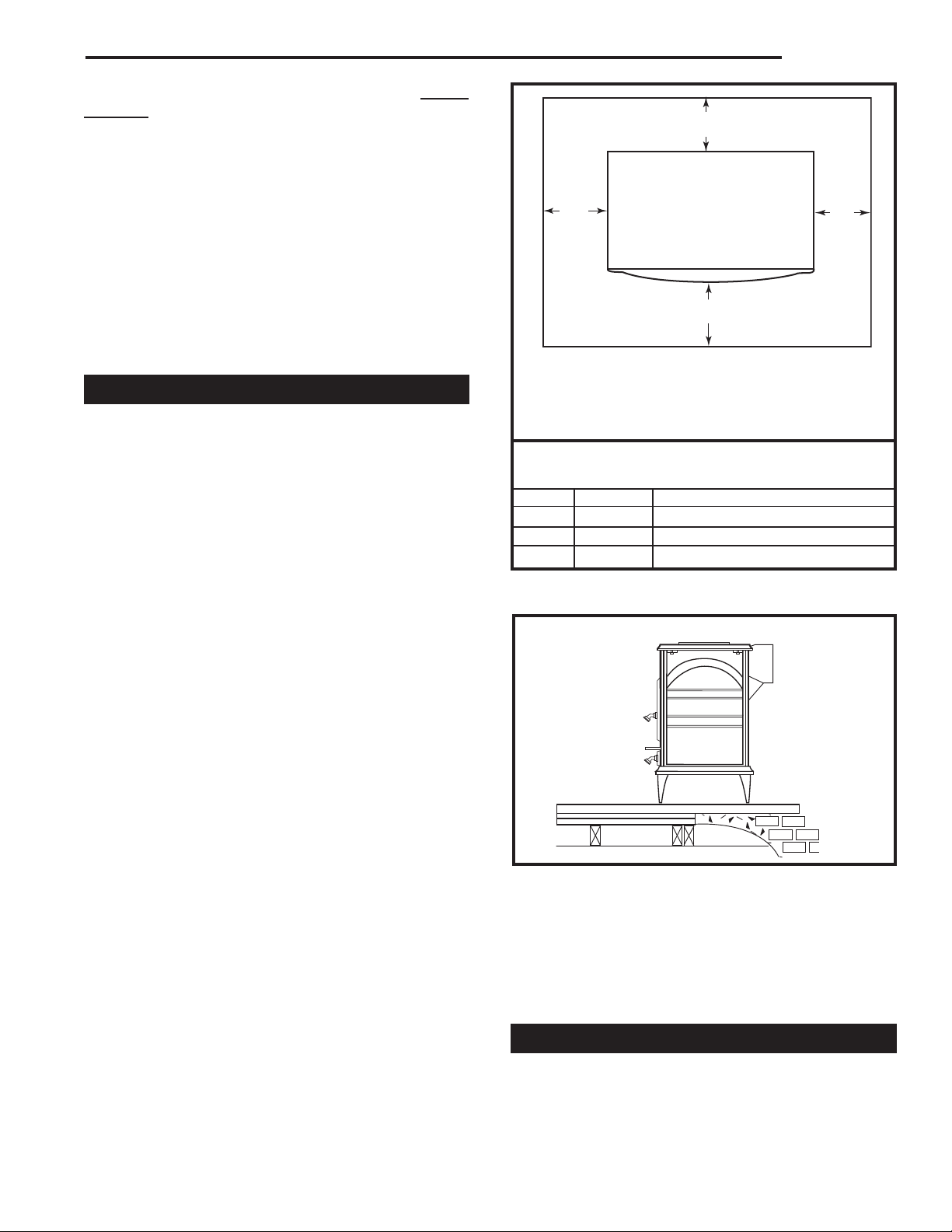

ST422

Fig. 12 Be sure to follow exactly the floor protection requirements on all four sides of the stove.

Minimum Dimensions for Noncombustible Floor

Protectors (Depth x Width):

Model U.S. Canada

2460 38” x 44” 42” x 48” (1067mm x 1219mm)

2461 38” x 48” 42” x 52” (1067mm x 1320mm)

2462 42” x 52” 46” x 56” (1168mm x 1422mm)

B

B

A

A

U.S. Canada

A. 16” 18” (457 mm)

B. 6” 8” (203 mm)

A

ST423

Fig. 13 Combustible supporting timbers (A) may lie beneath

fireplace hearths; such situations require additional floor

protection.

Due to the side loading door, floor protector requirements call for more protection on the left side than on

the right. If you wish a more balanced look, increase

the other side of the hearth as well. Do not reduce

side protection under any circumstances.

Fireplace Installations

You may install your Dutchwest Convection Heater in

an existing fireplace as a fireplace insert with no legs,*

or with the standard legs attached.

10

Dutchwest

7001135

To install the heater without legs as a fireplace insert,

the floor must be completely noncombustible, such as

an unpainted concrete floor over earth.

Many fireplaces do not satisfy the “completely noncombustible” requirement because the brick or concrete hearth in front of the fireplace opening usually is

supported by heavy wooden framing as in Figure 13.

Because heat passes readily through brick or concrete,

it can easily pass through to the wood. As a result,

such fireplace hearths are considered a combustible

floor. You may not install a heater on a combustible

hearth without legs. Standard leg installations must

include the bottom heat shield. The floor protector

must also meet standard requirements for freestanding

installations.

Floor Protection for Fireplace

Installations with Standard Legs

Fireplace installations with the standard legs and the

bottom heat shield must have a floor protector of the

same construction as that specified for freestanding installations: 1/4” non-asbestos mineral board or equivalent, or 24 gauge sheet metal (that may be covered with

a decorative noncombustible material if you desire).

The floor protector must extend at least 16” (406 mm)

[18” / 457 mm in Canada] from the front of the stove

and from the left (loading door) side, and at least 6”

(152 mm) from the right side and rear. It must also

provide protection beneath any horizontal runs of the

chimney connector, including 2” to either side.

Many raised hearths will extend less than the required

distance from the front of the heater when it is installed.

In such cases, sufficient floor protection, as described

above, must be added to extend the hearth 16” (406

mm) [18” (457 mm) in Canada].

Hearth rugs do not satisfy the requirements for floor

protection.

Fireplace insert installations also have specific clearance requirements to the side walls, side decorative

trim, and fireplace mantel. This information is found in

“Fireplace Installation Clearances” in this section.

REMINDER- FIREPLACE INSERT INSTALLATIONS

WITHOUT LEGS ARE PERMISSIBLE ONLY IF THE

HEARTH IS COMPLETELY NONCOMBUSTIBLE,

SUCH AS UNPAINTED CONCRETE OVER EARTH.

Keep the Stove a Safe Distance

From Surrounding Materials

Both a stove and its chimney connector radiate heat

in all directions when operating. A safe installation requires that adequate clearance be maintained between

the stove and nearby combustible materials to ensure

that such materials do not overheat.

Clearance is the distance between either your stove or

chimney connector, and nearby walls, floors, the ceiling,

and any other fixed combustible surface. Keep furnishings and other combustible materials away from the

stove as well. In general, a distance of 48” (1220 mm)

must be maintained between the stove and moveable

combustible items such as drying clothes, furniture,

newspapers, firewood, etc. Keeping those clearance

areas empty assures that nearby surfaces and objects

will not overheat.

Safe Ways To Reduce Clearances

Your stove has specific clearance requirements that

have been established through careful research and

testing to UL and ULC standards.

Clearance requirements have been established to meet

every installation possibility, and they involve the combination of basic variables:

• When the stove has no listed heat shield

• When the stove has a listed heat shield

• When the wall has no heat shield

• When the wall has a heat shield

• When the stove has a double-wall chimney con-

nector.

• When the stove has a single-wall connector

wit heat shields, or without heat shields.

In general, the greatest clearance is required when you

locate a stove with no heat shield near a wall with no

heat shield. The least clearance is required when both

the stove and the wall have heat shields. Reducing a

stove clearance may require a listed heat shield on the

chimney connector as well, or a double-wall connector.

Clearances may be reduced only by means approved

by the regulatory authority and in accordance with the

clearances listed in this manual. The charts and sample

installations that follow list all the clearances required

for the various installation configurations of Dutchwest

Convection Heaters.

Loading...

Loading...