Page 1

Operating and

Service Guide

Keysight

Trueform Series

Waveform

Generator

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Page 2

Page 3

Safety and Regulatory Information

Safety and Regulatory Information

Notices

© Keysight Technologies, Inc. 2013 - 2015

No part of this manual may be reproduced in any form or by any means (including electronic storage and

retrieval or translation into a foreign language) without prior agreement and written consent from

Keysight Technologies, Inc. as governed by United States and international copyright laws.

Manual Information

Part Number: 33500-90901

Manufacturer Address

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Software and Documentation Updates and Licenses

Warranty

The material contained in this document is provided "as is," and is subject to being changed, without

notice, in future editions. Further, to the maximum extent permitted by applicable law, Keysight disclaims

all warranties, either express or implied, with regard to this manual and any information contained herein,

including but not limited to the implied warranties of merchantability and fitness for a particular purpose.

Keysight shall not be liable for errors or for incidental or consequential damagesin connection with the

furnishing, use, or performance of this document or of any information contained herein. Should Keysight

and the user have a separate written agreement with warranty terms covering the material in this

document that conflict with these terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in this document are furnished under a license and may be used

or copied only in accordance with the terms of such license.

Keysight Trueform Series Operating and Service Guide 2

Page 4

Safety and Regulatory Information

Restricted Rights Legend

If software is for use in the performance of a U.S. Government prime contract or subcontract, Software is

delivered and licensed as"Commercial computer software" as defined in DFAR 252.227-7014 (June

1995), or as a "commercial item" as defined in FAR 2.101(a) or as "Restricted computer software" as

defined in FAR 52.227-19 (June 1987) or any equivalent agency regulation or contract clause. Use,

duplication or disclosure of Software is subject to Keysight Technologies’ standard commercial license

terms, and non-DOD Departments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR 52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no

greater than Limited Rights as defined in FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Safety Notices

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that,

if not correctly performed or adhered to, could result in damage to the product or loss of important data.

Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or adhered to, could result in personal injury or death. Do not proceed

beyond a WARNING notice until the indicated conditions are fully understood and met.

Safety Symbols

Alternating current

Frame or chassis terminal (functional ground)

Standby supply. Unit is not completely disconnected from AC mains when switch is

off.

Risk of electric shock

Refer to accompanying documents

3 Keysight Trueform Series Operating and Service Guide

Page 5

Safety and Regulatory Information

Protective Earth ground terminal (safety ground)

The CE mark is a registered trademark of the European Community.

The ETL mark is a registered trademark of Intertek. Applies to 33500 Series instruments

only.

The CSA mark with the 'c' and 'us' subscript indicates the instrument is certified to the

applicable Canadian and United States of America standards respectively. Applies to

33600 Series instruments only.

The C-tick mark is a registered trademark of the Spectrum Management Agency of

Australia. This signifies compliance with the Australian EMC Framework regulations

under the terms of the Radio Communications Act of 1992.

Contains one or more of the 6 hazardous substances above the maximum

concentration value (MCV), 40 Year EPUP.

1SM 1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPR 11, Clause 4).

ICES/NMB001

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

This product complies with the WEEE Directive (2002/96/EC) marking

equipment. The affixed product label indicates that you must not discard

this electrical/electronic product in domestic household waste.

This equipment is Class A suitable for professional use and is for use in

electromagnetic environments outside of the home.

Additional Safety Notices

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings or instructions elsewhere in

this manual violates safety standards of design, manufacture, and intended use of the instrument.

Keysight Technologies assumes no liability of the customer’s failure to comply with the requirements.

Keysight Trueform Series Operating and Service Guide 4

Page 6

Safety and Regulatory Information

General

Do not use this product in any manner not specified by the manufacturer. The protective features of this

product may be impaired if it is used in a manner not specified in the operation instructions.

Before Applying Power

Verify that all safety precautions are taken. Make all connections to the unit before applying power.

Ground the Instrument

This product is provided with protective earth terminals. To minimize shock hazard, the instrument must

be connected to the AC power mains through a grounded power cable, with the ground wire firmly

connected to an electrical ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause a potential shock

hazard that could result in personal injury.

l Do not operate in an explosive atmosphere.

l Do not operate the instrument in the presence of flammable gases or fumes.

l Only qualified, service-trained personnel who are aware of the hazards involved should remove

instrument covers. Always disconnect the power cable and any external circuits before removing the

instrument cover.

Do Not Modify the Instrument

Do not install substitute parts or perform any unauthorized modification to the product. Return the

product to an Keysight Sales and Service Office for service and repair to ensure that safety features are

maintained.

In Case of Damage

Instruments that appear damaged or defective should be made inoperative and secured against

unintended operation until they can be repaired by qualified service personnel.

Unless otherwise noted in the specifications, this instrument or system is intended for indoor use in an

installation category II, pollution degree 2 environment per IEC 61010-1 and 664 respectively. It is

designed to operate at a maximum relative humidity of 5% to 80% at 40 °C or less (non-condensing). This

instrument or system is designed to operate at altitudes up to 3000 meters, and at temperatures between

0 and 55 °C.

5 Keysight Trueform Series Operating and Service Guide

Page 7

Safety and Regulatory Information

Technical Support

If you have questions about your shipment, or if you need information about warranty, service, or

technical support, contact Keysight Technologies.

Declaration of Conformity

Declarations of Conformity for this product and for other Keysight products may be downloaded from the

Keysight Regulatory Web site:

http://regulations.products.keysight.com/DoC/search.htm

Keysight Trueform Series Operating and Service Guide 6

Page 8

Safety and Regulatory Information

Safety and Regulatory Information 2

Notices 2

Manual Information 2

Manufacturer Address 2

Software and Documentation Updates and Licenses 2

Warranty 2

Technology Licenses 2

Restricted Rights Legend 3

Safety Notices 3

Safety Symbols 3

Additional Safety Notices 4

General 5

Before Applying Power 5

Ground the Instrument 5

Do Not Modify the Instrument 5

In Case of Damage 5

Technical Support

Declaration of Conformity 6

Keysight Trueform Series Waveform Generator Operation and Service Guide 14

Keysight BenchVue Software 15

Use BenchVue to: 15

Save time with: 15

From anywhere: 15

Preliminary Information 16

Operating Information 16

SCPI Programming Reference 16

Service and Repair Information 17

IO Libraries and Instrument Drivers 17

Web Interface 18

Example Programs 18

Contacting Keysight Technologies 19

Models and Options 20

Instrument Models 20

One- and two-channel upgrades for 33500 Series 22

One- and two-channel upgrades for 33600 Series 22

Models and Options

Instrument Models 23

One- and two-channel upgrades for 33500 Series 24

One- and two-channel upgrades for 33600 Series 25

Maximum Waveform Frequencies by Model 25

33500 Series, Lower Frequency Models 25

33500 Series, Higher Frequency Models 25

33600 Series, Lower Frequency Models 26

33600 Series, Higher Frequency Models 26

Operating Information 28

Introduction to Instrument

Instrument at a Glance 28

Front Panel at a Glance 30

Front Panel Display at a Glance 31

Front Panel Number Entry 32

Rear Panel at a Glance

6

22

28

33

7 Keysight Trueform Series Operating and Service Guide

Page 9

Safety and Regulatory Information

Quick Start 34

Prepare Instrument for Use 36

Adjust the Carrying Handle 37

Set Output Frequency 38

Set Output Amplitude 39

Set DC Offset Voltage 41

Set High-Level and Low-Level Values 42

Output a DC Voltage 43

Set Duty Cycle of a Square Wave 44

Configure a Pulse Waveform 45

Select a Stored Arbitrary Waveform 46

Use Built-in Help System 47

Rack Mount the Instrument 49

Front Panel Menu Operation 50

Select Output Termination 50

Reset the Instrument 50

Output a Modulated Waveform 51

Output an FSK Waveform

Output a PWM Waveform 53

Output a Frequency Sweep 55

Output a Burst Waveform 57

Trigger a Sweep or Burst 58

Store or Retrieve the Instrument State 59

Front Panel Menu Reference 61

LAN Configuration Procedure 66

Set Up an Arbitrary Waveform 69

Features and Functions 80

Output Configuration 81

Pulse Waveforms 95

Amplitude Modulation (AM) and Frequency Modulation (FM) 99

Phase Modulation (PM) 106

Frequency-Shift Keying (FSK) Modulation 112

Pulse Width Modulation (PWM) 113

Sum Modulation 119

Frequency Sweep 122

Burst Mode 130

Triggering 137

Dual ChannelOperations

IQ Player (Optional) 145

System-Related Operations 148

Remote Interface Configuration 154

External Timebase Reference 161

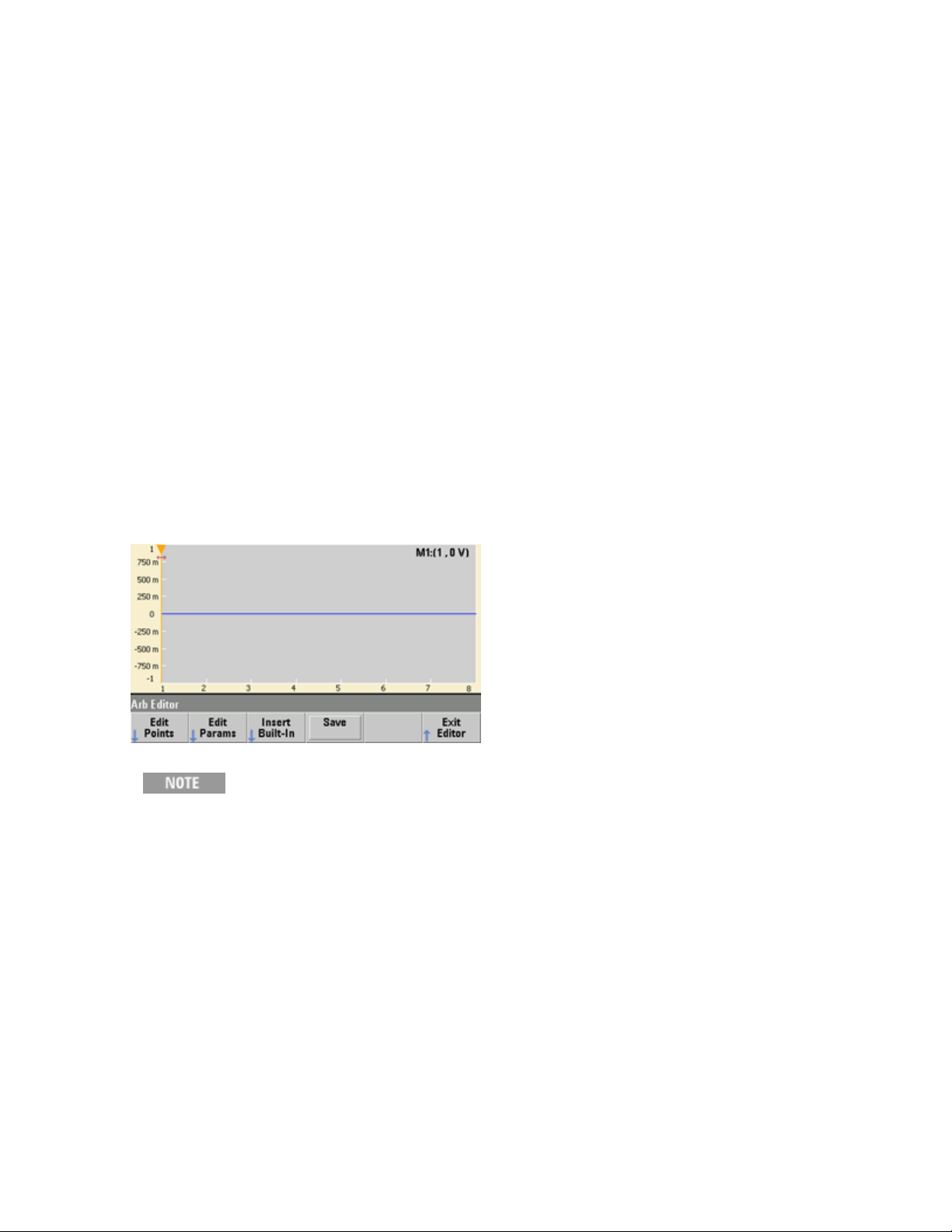

Embedded Waveform Editor 163

Waveform Generation Tutorial 177

Arbitrary Waveforms 178

Quasi-Gaussian Noise 180

PRBS 181

Modulation

Burst 186

Frequency Sweep 187

Attributes of AC Signals 188

Signal Imperfections 190

Ground Loops

52

142

182

191

Keysight Trueform Series Operating and Service Guide 8

Page 10

Safety and Regulatory Information

SCPI Programming Reference 192

Introduction to the SCPI Language 192

Syntax Conventions 192

Command Separators 193

Using the MIN, MAX, and DEF Parameters 193

Querying Parameter Settings 194

SCPI Command Terminators 194

IEEE-488.2 Common Commands 194

SCPI Parameter Types 194

Using Device Clear 196

InternalFunction Waveforms 196

See Also 198

Alphabetical List of SCPI Commands and Queries 198

ABORt 200

AM Subsystem 200

APPLy Subsystem 208

BPSK Subsystem

BURSt Subsystem 225

CALibration Subsystem 230

[SOURce[1|2]:]COMBine:FEED {CH1|CH2|NONE}[SOURce[1|2]:]COMBine:FEED? 236

DATA Subsystem 237

DISPlay Subsystem 246

FM Subsystem 251

FORMat:BORDer {NORMal|SWAPped}FORMat:BORDer? 260

FREQuency Subsystem 260

FSKey Subsystem 265

FUNCtion Subsystem 271

HCOPy Subsystem 295

IEEE-488 Common Commands 296

INITiate Subsystem 308

INPut:ATTenuation[:STATe] {ON|1|OFF|0}INPut:ATTenuation[:STATe]? 310

LIST Subsystem 310

LXI Subsystem 311

MARKer Subsystem 314

MEMory Subsystem 316

MMEMory Subsystem 319

OUTPut Subsystem

PHASe Subsystem 339

PM Subsystem 343

PWM Subsystem 351

RATE Subsystem 359

ROSCillator Subsystem 361

SOURce Subsystem 364

STATus Subsystem Introduction 366

SUM Subsystem Introduction 373

SWEep Subsystem Introduction 379

SYSTem Subsystem

[SOURce[1|2]:]TRACk {ON|OFF|INVerted}TRACk? 402

TRIGger Subsystem Introduction 404

UNIT:ANGLe {DEGree|RADian|SECond|DEFault}UNIT:ANGLe? 408

UNIT:ARBitrary:ANGLe {DEGree|RADian|SECond|SAMPle|DEFault}UNIT:ARBitrary:ANGLe? 410

VOLTage Subsystem Introduction

219

331

381

410

9 Keysight Trueform Series Operating and Service Guide

Page 11

Safety and Regulatory Information

Programming Examples 419

Configure a Sine Wave 419

Configure a Square Wave 420

Configure a Ramp Wave 421

Configure a Pulse Wave 422

Create a List of Frequencies 423

Configure an arbitrary waveform 423

Keysight Trueform Series Command Quick Reference 425

Factory Reset State 442

SCPI Error Messages 448

Service and Repair - Introduction 464

Types of Service Available 464

Extended Service Contracts 464

Obtaining Repair Service (Worldwide) 464

Repackaging for Shipment 465

Cleaning 465

Electrostatic Discharge (ESD) Precautions

Introduction to Calibration - 33500 Series 465

Keysight Technologies Calibration Services 466

Calibration Table of Contents 466

Calibration Overview - 33500 Series 467

Calibration Security - 33500 Series 470

Verification - 33500 Series 472

Performance Verification Tests - 33500 Series 472

Internal Timebase Verification - 33500 Series 473

AC Amplitude (high-impedance) Verification - 33500 Series 474

DC Offset Voltage Verification - 33500 Series 475

-8 dB Range Flatness Verification - 33500 Series 475

-24 dB Range Flatness Verification - 33500 Series 477

General Calibration/Adjustment Procedure - 33500 Series 479

Aborting a Calibration in Progress - 33500 Series 480

Sequence of Adjustments - 33500 Series 480

Self-Test - 33500 Series 480

Frequency (Internal Timebase) Adjustment - 33500 Series 481

Internal ADC Adjustment - 33500 Series 482

Self Calibration Adjustment - 33500 Series 483

Output Impedance Adjustment - 33500 Series

AC Amplitude (high-impedance) Adjustment - 33500 Series 484

-24 dB Range Flatness Adjustment - 33500 Series 486

-8 dB Range Flatness Adjustment - 33500 Series 487

Channel 2 Adjustments - 33500 Series 489

Calibration Errors - 33500 Series 495

Introduction to Calibration - 33600 Series 496

Keysight Technologies Calibration Services 497

Calibration Table of Contents 497

Calibration Overview - 33600 Series 498

Calibration Security - 33600 Series

Verification - 33600 Series 503

Performance Verification Tests - 33600 Series 503

Internal Timebase Verification - 33600 Series 504

AC Amplitude (high-impedance) Verification - 33600 Series 505

DC Offset Voltage Verification - 33600 Series

465

483

501

506

Keysight Trueform Series Operating and Service Guide 10

Page 12

Safety and Regulatory Information

1 Vpp Range Flatness Verification - 33600 Series 507

4 Vpp Range Flatness Verification - 33600 Series 510

8 Vpp Range Flatness Verification - 33600 Series 514

General Calibration/Adjustment Procedure - 33600 Series 519

Aborting a Calibration in Progress - 33600 Series 519

Sequence of Adjustments - 33600 Series 520

Self-Test - 33600 Series 520

Frequency (Internal Timebase) Adjustment - 33600 Series 520

Internal ADC Adjustment - 33600 Series 521

Self Calibration Adjustment - 33600 Series 522

Output Impedance Adjustment - 33600 Series 523

AC Amplitude (high-impedance) Adjustment - 33600 Series 524

1 Vpp Flatness Adjustment - 33600 Series 526

4 Vpp Flatness Adjustment - 33600 Series 529

8 Vpp Flatness Adjustment - 33600 Series 531

Channel 2 Adjustments - 33600 Series 532

Calibration Errors - 33600 Series 543

Block Diagram - 33500 Series

Block Diagram - 33500 Series 547

Block Diagram - 33600 Series 547

Block Diagram - 33600 Series 550

Power Supplies - 33500 Series 550

Power Supplies - 33600 Series 551

Troubleshooting - 33500 Series 551

Unit is Inoperative 551

Unit Fails Self-Test 552

Power Supplies 552

Self-Test Errors 605 - 609 553

10 MHz Out 555

Troubleshooting - 33600 Series 555

Unit is Inoperative 556

Unit Fails Self-Test 556

Power Supplies 556

Self-Test Errors 607 through 611 558

10 MHz Out 560

Self-TestProcedures 560

Power-On Self-Test 560

FullSelf-Test

To Run Self-Test 561

Self-Test Error Numbers and Messages (33500 Series) 561

Self-Test Error Numbers and Messages (33600 Series) 564

Replaceable Parts 568

Disassembly - 33500 Series 569

Tools Required 569

General Disassembly Procedure 570

Main Component Disassembly 571

Front Panel Disassembly 574

Disassembly - 33600 Series

Tools Required 575

General Disassembly Procedure 575

Main Component Disassembly 576

To remove the main board 577

Battery Replacement

545

561

575

578

11 Keysight Trueform Series Operating and Service Guide

Page 13

Safety and Regulatory Information

Tools Required 579

Procedure 580

Installing the Optional GPIB Interface 581

Tools Required 581

Installation Procedure 581

Retain GPIB Cover Plate 581

Index 584

Keysight Trueform Series Operating and Service Guide 12

Page 14

Safety and Regulatory Information

13 Keysight Trueform Series Operating and Service Guide

Page 15

Keysight Trueform Series Waveform Generator Operation and Service Guide

Keysight Trueform Series Waveform Generator Operation and

Service Guide

This document includes user, service, and programming information for the Keysight Trueform Series

waveform generators.

Keysight Trueform Series Operating and Service Guide 14

Page 16

Keysight Trueform Series Waveform Generator Operation and Service Guide

Keysight BenchVue Software

Keysight

The

Trueform Series waveform generators work with BenchVue software, which provides

easy multi-instrument control.

Use BenchVue to:

l View and control all of your bench instruments from a single screen

l Save/recall the state of your entire bench

l Acquire data and screenshots from multiple instruments

Save time with:

l Time aligned multi-instrument export to Excel, Word, MATLAB

l Export of waveform generator data to Word

l Drag and drop waveforms between your waveform generator and oscilloscope

l Integrated library capability for downloading instrument documentation, software drivers, firmware

updates, FAQs, videos, and more

From anywhere:

l Mobile companion apps to monitor and control your bench

15 Keysight Trueform Series Operating and Service Guide

Page 17

Keysight Trueform Series Waveform Generator Operation and Service Guide

Preliminary Information

Safety and Regulatory Information

Models and Options

Maximum Waveform Frequencies by Model

Operating Information

Introduction to Instrument

Quick Start

Front Panel Menu Operation

Front Panel Menu Reference

LAN Configuration Procedure

Set Up Arbitrary Waveform

Features and Functions

Waveform Generation Tutorial

SCPI Programming Reference

Introduction to SCPI Language

Internal Function Waveforms

Alphabetical List of SCPI Commands and Queries

Programming Examples

Command Quick Reference

Factory Reset State

SCPI Error Messages

Keysight Trueform Series Operating and Service Guide 16

Page 18

Keysight Trueform Series Waveform Generator Operation and Service Guide

Service and Repair Information

Service and Repair Introduction

Calibration and Adjustment: 33500 Series

Calibration and Adjustment: 33600 Series

Block Diagram - 33500 Series

Block Diagram - 33600 Series

Power Supplies - 33500 Series

Power Supplies - 33600 Series

Troubleshooting - 33500 Series

Troubleshooting - 33600 Series

Self-Test Procedures

Replaceable Parts

Disassembly - 33500 Series

Disassembly - 33600 Series

Battery Replacement

Installing the Optional GPIB Interface

IO Libraries and Instrument Drivers

The Keysight IO Libraries Suite software, including installation instructions, is on the Keysight IO

Libraries Suite CD provided with your instrument.

17 Keysight Trueform Series Operating and Service Guide

Page 19

Keysight Trueform Series Waveform Generator Operation and Service Guide

Web Interface

The instrument includes a built-in Web Interface. You can use this interface over LAN for remote

instrument access and control via a Java™-enabled Web browser, such as Microsoft Internet Explorer.

To use the Web Interface:

1.

Establish a LAN connection from your PC to the instrument.

2.

Open your PC's Web browser.

3.

Launch the instrument's Web Interfaceby entering the instrument's IP address or fully-qualified

hostname in the browser address field.

4.

Follow the instructions in the Web Interface's on-line help.

Keysight Trueform Series Operating and Service Guide 18

Page 20

Keysight Trueform Series Waveform Generator Operation and Service Guide

19 Keysight Trueform Series Operating and Service Guide

Page 21

Models and Options

Models and Options

This section describes the models and options in the Trueform Series of instruments. For information on

loading licensesfor options via the front panel, see License Installation. For information on loading

licensesvia SCPI, see the SYSTem:LICense commands.

Instrument Models

Instrument models with numbers of the form 335XXA or 335XXB are referred to as the 33500 Series, and

instrument models with numbers of the form 336XXA are referred to as the 33600 Series. Collectively, the

33500 Series and 33600 Series instruments comprise the Trueform Series of waveform generators. Unless

specified otherwise, all manual topics apply to all instruments in the Trueform Series.

To determine the model number of your instrument, read the label on the instrument's front panel. You

can also either execute the *IDN? query over the remote interface or press[System] >Help > About on

the front panel.

The Trueform Series model numbers and option numbers are shown and described in the table below.

Model Description Options

33521A 30 MHz

One channel

Arbitrary waveforms

NISPOM Security

1 MSa Memory per channel

33522A 30 MHz

Two channels

Arbitrary waveforms

NISPOM Security

1 MSa memory per channel

33509B 20 MHz

One channel

No arbitrary waveforms

33510B 20 MHz

Two channels

No arbitrary waveforms

33511B 20 MHz

One channel

Arbitrary waveforms

33512B 20 MHz

Two channels

Arbitrary waveforms

002 - 16MSa Arb Memory

004 - GPIBInterface

010 - High-stability OCXO Timebase

002 - 16MSa Arb Memory

004 - GPIBInterface

010 - High-stability OCXO Timebase

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

33519B 30 MHz

One channel

No arbitrary waveforms

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

Keysight Trueform Series Operating and Service Guide 20

Page 22

Models and Options

Model Description Options

33520B 30 MHz

Two channels

No arbitrary waveforms

33521B 30 MHz

One channel

Arbitrary waveforms

33522B 30 MHz

Two channels

Arbitrary waveforms

33611A 80 MHz

One channel

Arbitrary waveforms

33612A 80 MHz

Two channels

Arbitrary waveforms

33621A 120 MHz

One channel

Arbitrary waveforms

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

GPB - GPIB interface module – factory installed

33622A 120 MHz

Two channels

Arbitrary waveforms

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

GPB - GPIB interface module – factory installed

21 Keysight Trueform Series Operating and Service Guide

Page 23

One- and two-channel upgrades for 33500 Series

Model Description

335BW1U Increase bandwidth to 30 MHz for one-channel models

335BW2U Increase bandwidth to 30 MHz for two-channel models

335ARB1U Add arbitrary waveforms to one-channel models

335ARB2U Add arbitrary waveforms to two-channel models

335MEM1U 16 MSa per channel memory for one-channel models

335MEM2U 16 MSa per channel memory for two-channel models

33500U-OCX Add high-stability OCXO timebase

335SECU Add NISPOMand File security

335IQPU Add IQ Baseband signal player

Models and Options

33522B-DST Enable all software options for demonstration

One- and two-channel upgrades for 33600 Series

Model Description

336BW1U Increase bandwidth to 120 MHz for one-channel models

336BW2U Increase bandwidth to 120 MHz for two-channel models

336MEM1U 64 MSa per channel memory for one-channel models

336MEM2U 64 MSa per channel memory for two-channel models

33600U-OCX Add high-stability OCXO timebase

336SECU Add NISPOMand File security

336IQPU Add IQ Baseband signal player

33622A-DST Enable all software options for demonstration

3446GPBU GPIB user installable interface module

Models and Options

This section describes the models and options in the Trueform Series of instruments. For information on

loading licensesfor options via the front panel, see License Installation. For information on loading

licensesvia SCPI, see the SYSTem:LICense commands.

Keysight Trueform Series Operating and Service Guide 22

Page 24

Models and Options

Instrument Models

Instrument models with numbers of the form 335XXA or 335XXB are referred to as the 33500 Series, and

instrument models with numbers of the form 336XXA are referred to as the 33600 Series. Collectively, the

33500 Series and 33600 Series instruments comprise the Trueform Series of waveform generators. Unless

specified otherwise, all manual topics apply to all instruments in the Trueform Series.

To determine the model number of your instrument, read the label on the instrument's front panel. You

can also either execute the *IDN? query over the remote interface or press[System] >Help > About on

the front panel.

The Trueform Series model numbers and option numbers are shown and described in the table below.

Model Description Options

33521A 30 MHz

One channel

Arbitrary waveforms

NISPOM Security

1 MSa Memory per channel

33522A 30 MHz

Two channels

Arbitrary waveforms

NISPOM Security

1 MSa memory per channel

33509B 20 MHz

One channel

No arbitrary waveforms

33510B 20 MHz

Two channels

No arbitrary waveforms

33511B 20 MHz

One channel

Arbitrary waveforms

33512B 20 MHz

Two channels

Arbitrary waveforms

002 - 16MSa Arb Memory

004 - GPIBInterface

010 - High-stability OCXO Timebase

002 - 16MSa Arb Memory

004 - GPIBInterface

010 - High-stability OCXO Timebase

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

33519B 30 MHz

One channel

No arbitrary waveforms

33520B 30 MHz

Two channels

No arbitrary waveforms

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

23 Keysight Trueform Series Operating and Service Guide

Page 25

Model Description Options

Models and Options

33521B 30 MHz

One channel

Arbitrary waveforms

33522B 30 MHz

Two channels

Arbitrary waveforms

33611A 80 MHz

One channel

Arbitrary waveforms

33612A 80 MHz

Two channels

Arbitrary waveforms

33621A 120 MHz

One channel

Arbitrary waveforms

33622A 120 MHz

Two channels

Arbitrary waveforms

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 16 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

GPB - GPIB interface module – factory installed

MEM - 64 MSa Memory per channel

OCX - Add High-stability OCXO Timebase

SEC - Enable NISPOM & File Security

IQP - Add IQ Baseband signal player

GPB - GPIB interface module – factory installed

One- and two-channel upgrades for 33500 Series

Model Description

335BW1U Increase bandwidth to 30 MHz for one-channel models

335BW2U Increase bandwidth to 30 MHz for two-channel models

335ARB1U Add arbitrary waveforms to one-channel models

335ARB2U Add arbitrary waveforms to two-channel models

335MEM1U 16 MSa per channel memory for one-channel models

335MEM2U 16 MSa per channel memory for two-channel models

33500U-OCX Add high-stability OCXO timebase

335SECU Add NISPOMand File security

335IQPU Add IQ Baseband signal player

33522B-DST Enable all software options for demonstration

Keysight Trueform Series Operating and Service Guide 24

Page 26

Models and Options

One- and two-channel upgrades for 33600 Series

Model Description

336BW1U Increase bandwidth to 120 MHz for one-channel models

336BW2U Increase bandwidth to 120 MHz for two-channel models

336MEM1U 64 MSa per channel memory for one-channel models

336MEM2U 64 MSa per channel memory for two-channel models

33600U-OCX Add high-stability OCXO timebase

336SECU Add NISPOMand File security

336IQPU Add IQ Baseband signal player

33622A-DST Enable all software options for demonstration

3446GPBU GPIB user installable interface module

Maximum Waveform Frequencies by Model

33500 Series, Lower Frequency Models

33509B 33510B 33511B 33512B

Waveform Maximum Frequency

Sine 20 MHz

Square/Pulse 20 MHz

Noise 20 MHz

Ramp/Triangle 200 kHz

PRBS 50 Mbps

Arbitrary 160 MSa/s

33500 Series, Higher Frequency Models

33521A 33522A 33519B 33520B 33521B 33522B or other 33500 Series models with option 335BW1U

or 335BW2U.

Waveform Maximum Frequency

Sine 30 MHz

25 Keysight Trueform Series Operating and Service Guide

Page 27

Waveform Maximum Frequency

Square/Pulse 30 MHz

Noise 30 MHz

Ramp/Triangle 200 kHz

PRBS 50 Mbps

Arbitrary 250 MSa/s

33600 Series, Lower Frequency Models

33611A 33612A

Waveform Maximum Frequency

Sine 60 MHz up to 10 Vpp

80 MHz up to 8 Vpp

Models and Options

Square/Pulse 50 MHz up to 10 Vpp

Noise 60 MHz up to 10 Vpp

80 MHz up to 8 Vpp

Ramp/Triangle 800 kHz

PRBS 100 Mbps

Arbitrary 660 MSa/s

33600 Series, Higher Frequency Models

33621A 33622A or other 33600 Series models with option 336BW1U or 336BW2U.

Waveform Maximum Frequency

Sine 60 MHz up to 10 Vpp

80 MHz up to 8 Vpp

120 MHz up to 4 Vpp

Square/Pulse 50 MHz up to 10 Vpp

100 MHz up to 4 Vpp

Noise 60 MHz up to 10 Vpp

80 MHz up to 8 Vpp

120 MHz up to 4 Vpp

Ramp/Triangle 800 kHz

PRBS 100 Mbps up to 10 Vpp

200 Mbps up to 4 Vpp

Arbitrary 1 GSa/s

Keysight Trueform Series Operating and Service Guide 26

Page 28

Models and Options

27 Keysight Trueform Series Operating and Service Guide

Page 29

Operating Information

Operating Information

Introduction to Instrument

Quick Start

Front Panel Menu Operation

Front Panel Menu Reference

LAN Configuration Procedure

Set Up Arbitrary Waveform

Features and Functions

Waveform Generation Tutorial

Introduction to Instrument

The Keysight Technologies Trueform Series is a series of synthesized waveform generators with built-in

arbitrary waveform and pulse capabilities.

Instrument at a Glance

Front Panel at a Glance

Front Panel Display at a Glance

Front Panel Number Entry

Rear Panel at a Glance

Instrument at a Glance

The instrument's combination of bench-top and system features makes it a versatile solution now and in

the future.

Convenient bench-top features

l 16 standard waveforms

l Built-in 16-bit (33500 Series) or 14-bit (33600 Series) arbitrary waveform capability

l Precise pulse waveform capabilities with adjustable edge time

l LCD display with numeric and graphical views

l Easy-to-use knob and numeric keypad

l Instrument state storage with user-defined names

l Portable, ruggedized case with non-skid feet

l Isolated outputs to break ground loops

Keysight Trueform Series Operating and Service Guide 28

Page 30

Operating Information

Flexible system features

l Downloadable waveform memory of 1MSa (33500 Series) or 4 MSa (33600 Series). This can be

upgraded to 16 MSa (33500 Series) or 64 MSa (33600 Series).

l USB, GPIB, and LAN remote interfaces (GPIB is optional on some models; see Models and Options for

details.)

l LXI Class C Compliant

l SCPI (Standard Commands for Programmable Instruments) compatibility

29 Keysight Trueform Series Operating and Service Guide

Page 31

Front Panel at a Glance

The BNC connectors, both the shell and center pin, on the front panel of the instrument are

isolated up to ±42 Vpk from chassis. The shells of these BNC connectors are connected to

each other, and internal circuitry will attempt to keep the isolated voltage to within ±42 Vpk

to chassis. Exceeding the isolation voltage beyond ±42 Vpk from chassis may destroy the

instrument and cause a hazard that could result in personal injury or death.

Operating Information

Item Description

1 USB Port

2 On/Off Standby Switch

3 Display

4 Menu Softkeys

5 Fixed Function Buttons

(column of seven keys)

6 Manual Trigger Button

7 Sync Connector

8 Numeric Keypad

9 Channel 1 and Channel 2

(depending on model)

10 Knob and cursor arrows

Pressand hold any front panel key or softkey to get context-sensitive help.

Keysight Trueform Series Operating and Service Guide 30

Page 32

Operating Information

Front Panel Display at a Glance

Item Description

1 Channel 1 information

2 Channel 2 information (depends on model)

3 Waveform parameters

4 Waveform display

5 Sweep, modulation, or burst parameters

6 Softkey labels

31 Keysight Trueform Series Operating and Service Guide

Page 33

Operating Information

Front Panel Number Entry

You can enter numbers from the front panel in two ways:

l Use the knob and cursor keys to modify the number. Rotate the knob to change a digit (clockwise

increases). The arrows below the knob move the cursor.

l Use the keypad to enter numbers and the softkeys to select units. The [+/-] key changes the number's

sign.

Keysight Trueform Series Operating and Service Guide 32

Page 34

Operating Information

Rear Panel at a Glance

The rear panels on the 33500 Series and 33600 Series instruments have similar features, but their

locations vary, as shown below.

33500 Series

33600 Series

Item Description

1 External 10 MHz Reference Input

2 Internal 10 MHz Reference Output

3 GPIB Connector

4 Chassis Ground

5 Instrument Cable Lock

6 AC Power

33 Keysight Trueform Series Operating and Service Guide

Page 35

Item Description

7 External Modulation Input

8 External Trig/Gate/FSK/Burst (Input and Output)

9 USB Interface Connector

10 Local Area Network (LAN) Connector

The external 10 MHz reference input BNC connector, both the shell and center pin, on the

rear panel of the instrument is isolated up to ±42 Vpk from chassis. The shell of this BNC

connector is isolated from the rest of the instrument. Internal circuitry will attempt to keep

the isolated voltage to within ±42 Vpk to chassis. Attempts to float this input beyond ±42 Vpk

from chassis may destroy the instrument and cause a hazard that could result in personal

injury or death.

The external modulation input BNC connector, both the shell and center pin, on the rear panel

of the instrument is isolated up to ±42 Vpk from chassis. The shell of this BNC connector is

connected to the shells of the front panel BNC connectors. Internal circuitry will attempt to

keep the isolated voltage to within ±42 Vpk to chassis. Attempts to float the outputs beyond

±42 Vpk from chassis may destroy the instrument and cause a hazard that could result in

personal injury or death.

Operating Information

This is a Protection Class 1 equipment (chassis must be connected to a protective earth ground).

The mains plug shall only be inserted in an outlet provided with a Protective Earth Terminal.

Quick Start

This section describes basic procedures to help you get started quickly with the instrument.

l Prepare Instrument for Use

l Adjust the Carrying Handle

l Set Output Frequency

l Set Output Amplitude

l Set DC Offset Voltage

l Set High-Level and Low-Level Values

l Output a DC Voltage

l Set Duty Cycle of a Square Wave

l Configure a Pulse Waveform

l Select a Stored Arbitrary Waveform

Keysight Trueform Series Operating and Service Guide 34

Page 36

Operating Information

l Use Built-in Help System

l Rack Mount the Instrument

35 Keysight Trueform Series Operating and Service Guide

Page 37

Operating Information

Prepare Instrument for Use

Verify that you received the following items. If anything is missing, please contact your nearest Keysight

sales office or Keysight authorized reseller.

l Power cord (for country of destination)

l Certificate of Calibration

l

Keysight Trueform Series Product Reference CD (product software, programming

examples, and manuals)

l

Keysight IO Libraries Suite CD

l USB 2.0 cable

Note: All product documentation is on the Keysight Trueform Series Product Reference

CD.

The instrument may be used with mains power of either 100-240 V, 50/60 Hz or 100-120 V, 400 Hz. The

maximum power usage is 150 VA. Ensure that you are using the correctly rated mains cord based on the

instrument’s rating and your country's electrical codes. Connect the power cord and LAN, GPIB, or USB

cable as desired. Turn the instrument on by pressing the power switch in the lower left corner of front

panel. The instrument runs a power-on self test and then displays a message about how to obtain help,

along with the current IP address. It also displays the GPIB address if the GPIB option is installed and

enabled.

PowerSwitch:

The instrument's default function isa 1 kHz, 100 mVpp sine wave (into a 50 Ω termination). At power-on,

the channel output connectors are disabled. To enable output on a channel connector, press the key

above the channel connector and then press the Output Off / On softkey.

If the instrument does not turn on, verify that the power cord is firmly connected. Also make sure that the

instrument is connected to an energized power source. If the LED below the power switch is off, there is no

AC power connected. If the LED is amber, the instrument is in standby mode with AC power connected,

and if it is green, the instrument is on.

If the power-on self test fails, the display shows ERR in the upper right corner. It also prominently displays

"Check for error messages in the error queue."

See SCPI Error Messages for information on error codes. See Service and Repair - Introduction for

instructions on returning the instrument for service.

To turn off the instrument, hold the power switch down for about 500 ms. This prevents you from turning

the instrument off by accidentally brushing the power switch.

Keysight Trueform Series Operating and Service Guide 36

Page 38

Operating Information

Adjust the Carrying Handle

Grasp the sides of the handle, pull outward, and rotate the handle.

37 Keysight Trueform Series Operating and Service Guide

Page 39

Operating Information

Set Output Frequency

The default frequency is 1 kHz. You can change the frequency, and you can specify frequency in units of

period instead of Hz.

To change frequency with the knob:

To change frequency with the numeric keypad:

Finish by selecting frequency units:

To change the units to period instead of frequency:

Keysight Trueform Series Operating and Service Guide 38

Page 40

Operating Information

Set Output Amplitude

The instrument's default function isa 1 kHz, 100 mVpp sine wave (into a 50 Ω termination).

The following steps change the amplitude to 50 mVpp.

1. Press [Units] > Amp/Offs or High/Low to make sure that you are in Amp/Offs.

The displayed amplitude is either the power-on value or the amplitude previously selected. When you

change functions, the same amplitude is used if it isvalid for the newfunction. To choose whether you

want to specify voltage as amplitude and offset or high and low values, press [Units] and then the

second softkey. In this case, we will highlight Amp/Offs.

2. Enter the magnitude of the desired amplitude.

Press[Parameters] > Amplitude. Using the numeric keypad, enter the number 50.

39 Keysight Trueform Series Operating and Service Guide

Page 41

Operating Information

3. Select the desired units.

Pressthe softkey that corresponds to the desired units. When you select the units, the instrument

outputs the waveform with the displayed amplitude (if the output is enabled). For this example, press

mVpp.

You can also enter the desired value using the knob and arrows. If you do so, you do not need to use a

units softkey. You can easily convert unit types. Simply press [Units] > Ampl As and select the

desired units.

Keysight Trueform Series Operating and Service Guide 40

Page 42

Operating Information

Set DC Offset Voltage

At power-on, the DC offset is 0 V. The following steps change the offset to –1.5 VDC.

1. Press [Parameters] > Offset.

The displayed offset voltage is either the power-on value or the offset previously selected. When you

change functions, the same offset is used if the present value is valid for the new function.

2. Enter the desired offset.

In this case we will use the numeric keypad to enter –1.5.

3. Select the desired units.

Pressthe softkey for the desired units. When you select the units, the instrument outputs the

waveform with the displayed offset (if the output is enabled). For this example, press V. The voltage

will be set asshown below.

You can also enter the desired value using the knob and arrows.

41 Keysight Trueform Series Operating and Service Guide

Page 43

Operating Information

Set High-Level and Low-Level Values

You can specify a signal by setting its amplitude and DC offset, described above. You can also specify the

signal as high (maximum) and low (minimum) values. This is typically convenient for digital applications. In

the following example, we will set the high level to 1.0 V and the low level to 0.0 V.

1. Press [Units] > Ampl/Offs to toggle to High/Low as shown below.

2. Press the [Parameters] > High Level. Using the numeric keypad or knob and arrows, select a value of

1.0 V. (If you are using the keypad, you will need to select the V unit softkey to enter the value.)

3. Press the Low Level softkey and set the value.

Again, use the numeric keypad or the knob to enter a value of 0.0 V.

These settings (high-level = 1.0 V and low-level = 0.0 V) are equivalent to setting an amplitude of 1.0 Vpp

and an offset of 500 mV.

Keysight Trueform Series Operating and Service Guide 42

Page 44

Operating Information

Output a DC Voltage

You can output a constant DC voltage, from -5 V to +5 V into 50 Ω, or -10 V to +10 V into a high

impedance load.

1. Press [Waveforms] > More > DC.

The Offset value becomes selected.

2. Enter the desired voltage offset.

Enter 1.0 with the numeric keypad or knob, and press the V softkey if you used the keypad.

43 Keysight Trueform Series Operating and Service Guide

Page 45

Operating Information

Set Duty Cycle of a Square Wave

The power-on default for square wave duty cycle is 50%. The duty cycle is limited by the minimum pulse

width specification of 16 ns on the 33500 Series, or 5 ns up to 4 Vpp and 8 ns up to 10 Vpp on the 33600

Series. The following procedure changes the duty cycle to 75%.

1. Select the square wave function.

Press[Waveforms] > Square.

2. Press the Duty Cycle softkey.

The displayed duty cycle is either the power-on value or the percentage previously selected. The duty

cycle represents the amount of time per cycle that the square wave is at a high level.

3. Enter the desired duty cycle.

Using the numeric keypad or the knob and arrows, select a duty cycle value of 75. If you are using the

numeric keypad, press Percent to finish the entry. The instrument adjusts the duty cycle immediately

and outputs a square wave with the specified value (if the output is enabled).

Keysight Trueform Series Operating and Service Guide 44

Page 46

Operating Information

Configure a Pulse Waveform

You can configure the instrument to output a pulse waveform with variable pulse width and edge time.

The following steps configure a 500 ms periodic pulse waveform with a pulse width of 10 ms and edge

times of 50 ns.

1. Select the pulse function.

Press[Waveforms] > Pulse to select the pulse function.

2. Set the pulse period.

Pressthe [Units] key and then pressFrequency/Period to choose Period. Then press [Parameters]

>Period. Set the period to 500 ms.

3. Set the pulse width.

Press[Parameters] >Pulse Width. Then set the pulse width to 10 ms. The pulse width represents the

time from the 50% threshold of the rising edge to the 50% threshold of the next falling edge.

4. Set the edge time for both edges.

Pressthe Edge Times softkey and then set the edge time for both the leading and trailing edges to 50

ns. The edge time represents the time from the 10% threshold to the 90% threshold of each edge.

45 Keysight Trueform Series Operating and Service Guide

Page 47

Operating Information

Select a Stored Arbitrary Waveform

There are nine built-in arbitrary waveforms stored in non-volatile memory. They are Cardiac, D-Lorentz,

Exponential Fall, Exponential Rise, Gaussian, Haversine, Lorentz, Negative Ramp, and Sinc.

This procedure selects the built-in "exponential fall" waveform from the front panel. For information on

creating a custom arbitrary waveform, refer to Set Up Arbitrary Waveform.

1. Press [Waveforms] >Arb > Arbs.

2. Choose Select Arb and use the knob to select Exp_Fall. Press Select.

Keysight Trueform Series Operating and Service Guide 46

Page 48

Operating Information

Use Built-in Help System

The built-in help system provides context-sensitive help on any front panel key or menu softkey. A list of

help topics is also available to assist you with several front panel operations.

View the help information for a function key

Pressand hold any softkey or front panel key, such as [Waveforms]. If the message contains more

information than will fit on the display, press the down arrow softkey or use the knob to view the remaining

information.

PressDone to exit Help.

View the list of help topics.

Press[System] > Help to view the list of available help topics. To scroll through the list, press the up and

down arrow softkeys or use the knob. Select the topic Get HELP on any key and then press Select. Note

that the topics may vary from the list shown below, depending on model and firmware version.

PressDone to exit Help.

47 Keysight Trueform Series Operating and Service Guide

Page 49

Operating Information

View the help information for displayed messages.

Whenever a limit is exceeded or any other invalid configuration is found, the instrument displays a

message. The built-in help system provides additional information on the most recent message. Press

[System] > Help. Then select the topic View the last message displayed, and press Select.

PressDone to exit Help.

Local Language Help

All messages, context-sensitive help, and help topics are available in English, Chinese,

French, German, Japanese, Korean, and Russian. Softkey labels and status line

messages are not translated. To select the language, press [System] > System Setup

> User Settings >HelpLang. Then select the desired language.

Keysight Trueform Series Operating and Service Guide 48

Page 50

Operating Information

Rack Mount the Instrument

You can mount the instrument in a standard 19-inch rack cabinet using one of two optional kits, each of

which includes instructions and mounting hardware. Any Keysight System II instrument of the same size

can be rack-mounted beside the instrument.

Remove the carrying handle, and the front and rear rubber bumpers, before rackmounting the instrument.

To remove the handle, rotate it to vertical and pull the ends outward.

To remove the rubber bumper, stretch a corner and then slide it off.

Front Rear (bottom view)

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-8769 and flange kit 5063-

9212. Be sure to use the support rails in the rack cabinet.

To prevent overheating, do not block airflow to or from the instrument. Air enters at the

rear of the instrument and exits at both sides and the bottom. Ensure that at least one

side is unblocked to allow the ventilation air to exhaust freely. Do not block the fan on

the instrument rear panel.

The 33600 Series instrument's fan speed runs at a constant speed up to an ambient

temperature of 28 °C and increases when the ambient temperature goes above 28 °C.

The 33600 Series instruments monitor critical internal temperatures and will shut down

if limits are exceeded. Failure of ventilation could result in shutdown.

49 Keysight Trueform Series Operating and Service Guide

Page 51

Operating Information

Front Panel Menu Operation

This section introduces front panel keys and menus. See Features and Functions, Front Panel Menu

Reference, LAN Configuration Procedure, and Set Up an Arbitrary Waveform for additional front panel

operation information.

l Select Output Termination

l Reset the Instrument

l Output a Modulated Waveform

l Output an FSK Waveform

l Output a PWM Waveform

l Output a Frequency Sweep

l Output a Burst Waveform

l Trigger a Sweep or Burst

l Store or Retrieve the Instrument State

Select Output Termination

The instrument has a fixed series output impedance of 50 Ω to the front panel channel connectors. If the

actual load impedance differs from the value specified, the displayed amplitude and offset levels will be

incorrect. The load impedance setting is simply a convenience to ensure that the displayed voltage

matches the expected load.

1.

Pressa channel output key to open the channel configuration screen. Note that the current output

termination values (both 50 Ω in thiscase) appear on the tabs at the top of the screen.

2. Begin specifying the output termination by pressing Output Load.

3.

Select the desired output termination either by using the knob or numeric keypad to select the desired

load impedance or by pressing Set to 50 Ω or Set to High Z.

Reset the Instrument

To reset the instrument to its factory default state, press [System] > Set to Defaults >Yes.

Keysight Trueform Series Operating and Service Guide 50

Page 52

Operating Information

Output a Modulated Waveform

A modulated waveform consists of a carrier waveform and a modulating waveform. In AM (amplitude

modulation), the carrier amplitude is varied by the modulating waveform. For this example, you will

output an AM waveform with 80% modulation depth. The carrier will be a 5 kHz sine wave and the

modulating waveform will be a 200 Hz sine wave.

1. Select the function, frequency, and carrier amplitude.

Press[Waveforms] >Sine. Press the Frequency, Amplitude, and Offset softkeys to configure the

carrier waveform. For this example, select a 5 kHz sine wave with an amplitude of 5 Vpp, with 0 V

offset.

Note that you may specify amplitude in Vpp, Vrms or dBm.

2. Select AM.

Press[Modulate] and then select AM using the Type softkey. Then press the Modulate softkey to

turn modulation on. Notice that the [Modulate] key is illuminated, and the status message "AM

Modulated by Sine" appears at the top left of the display.

3. Set the modulation depth.

Pressthe AM Depth softkey and then set the value to 80% using the numeric keypad or the knob and

arrows.

4. Select the modulating waveform shape.

PressShape to select the modulating waveform's shape. For this example, select a sine wave.

5. Press AM Freq. On the 33500 Series, you will first have to press the More softkey to get to the correct

menu. Set the value to 200 Hz using the numeric keypad or the knob and arrows. Press Hz to finish

entering the number if you are using the numeric keypad.

51 Keysight Trueform Series Operating and Service Guide

Page 53

Operating Information

Output an FSK Waveform

You can configure the instrument to "shift" its output frequency between two preset values (called the

"carrier frequency" and the "hop frequency") using FSK modulation. The rate at which the output shifts

between these two frequencies isdetermined by the internal rate generator or the signal level on the rearpanel Ext Trig connector. For this example, you will set the "carrier" frequency to 5 kHz and the "hop"

frequency to 500 Hz, with an FSK rate of 100Hz.

1. Select the function, frequency, and carrier amplitude.

Press[Waveforms] >Sine. Press the Frequency, Amplitude, and Offset softkeys to configure the

carrier waveform. For this example, select a 5 kHz sine wave with an amplitude of 5 Vpp, with 0 V

offset.

2. Select FSK.

Press[Modulate] and then select FSK using the Type softkey. Then press the Modulate softkey to

turn modulation on. Notice the status message "FSK Modulated" at the top left of the display.

3. Set the "hop" frequency.

Pressthe Hop Freq softkey and then set the value to 500 Hz using the numeric keypad or the knob

and arrows. If you use the numeric keypad, be sure to finish the entry by pressing Hz.

4. Set the FSK "shift" rate.

Pressthe FSK Rate softkey and then set the value to 100 Hz using the numeric keypad or the knob

and arrows.

At this point, the instrument outputs an FSK waveform if the channel output is enabled.

Keysight Trueform Series Operating and Service Guide 52

Page 54

Operating Information

Output a PWM Waveform

You can configure the instrument to output a pulse width modulated (PWM) waveform. PWM is only

available for the Pulse waveform, and the pulse width varies according to the modulating signal. The

amount by which the pulse width varies is called the width deviation, and it can be specified as a

percentage of the waveform period (that is, duty cycle) or in units of time. For example, if you specify a

pulse with 20% duty cycle and then enable PWM with a 5% deviation, the duty cycle variesfrom 15% to

25% under control of the modulating signal.

To change from pulse width to pulse duty cycle, press [Units].

For this example, you will specify a pulse width and pulse width deviation for a 1 kHz pulse waveform with

a 5-Hz sine wave modulating waveform.

1. Select the carrier waveform parameters.

Press[Waveforms] > Pulse. Use the Frequency, Amplitude, Offset, Pulse Width and Edge Times

softkeys to configure the carrier waveform. For this example, select a 1 kHz pulse waveform with an

amplitude of 1 Vpp, zero offset, a pulse width of 100 µs, and an edge time of 50 ns (both leading and

trailing).

2. Select PWM.

Press[Modulate] > Type > PWM. Then press the first softkey (Modulate) to turn modulation on.

Notice the status message "PWM Modulated by Sine" in the upper-left corner of the display.

53 Keysight Trueform Series Operating and Service Guide

Page 55

Operating Information

3. Set the width deviation.

Pressthe Width Dev softkey and set the value to 20 µs using the numeric keypad or the knob and

arrows.

4. Set the modulating frequency.

Pressthe PWM Freq softkey and then set the value to 5 Hz using the numeric keypad or the knob and

arrows.

5. Select the modulating waveform shape.

PressShape to select the modulating waveform's shape. For this example, select a sine wave.

To view the actual PWM waveform, you would need to output it to an oscilloscope. If you do this, you will

see how the pulse width varies, in this case, from 80 to 120 µs. At a modulation frequency of 5 Hz, the

deviation is easily visible.

Keysight Trueform Series Operating and Service Guide 54

Page 56

Operating Information

Output a Frequency Sweep

In the frequency sweep mode, the instrument moves from the start frequency to the stop frequency at a

sweep rate, which you specify. You can sweep up or down in frequency, and with either linear or

logarithmic spacing, or using a list of frequencies. For this example, you will output a swept sine wave from

50 Hz to 5 kHz.

1. Select the function and amplitude for the sweep.

For sweeps, you can select sine, square, ramp, pulse, triangle, PRBS waveforms, or arbitrary

waveforms (noise and DC are not allowed). For this example, select a sine wave with an amplitude of 5

Vpp.

2. Select the sweep mode.

Press[Sweep] and verify that the linear sweep mode iscurrently selected on the second softkey. Press

the Sweep softkey to turn sweep on. Notice the Linear Sweep status message at the top of the tab

for the current channel. The button isalso illuminated.

55 Keysight Trueform Series Operating and Service Guide

Page 57

Operating Information

3. Set the start frequency.

PressStart Freq and then set the value to 50 Hz using the numeric keypad or the knob and arrows.

4. Set the stop frequency.

PressStop Freq and set the value to 5 kHz using the numeric keypad or the knob and arrows.

At this point, the instrument outputs a continuous sweep from 50 Hz to 5 kHz if output is enabled.

You can also set the sweep frequency boundaries of the sweep using a center frequency and frequency

span. These parameters are similar to the start frequency and stop frequency (above) and they provide

added flexibility. To achieve the same results, set the center frequency to 2.525 kHz and the frequency

span to 4.950 kHz.

To generate a frequency sweep, press [Trigger] twice. The first press puts the trigger in manual mode, and

the second one sends a trigger. For more information, seeTrigger Sweep or Burst.

Keysight Trueform Series Operating and Service Guide 56

Page 58

Operating Information

Output a Burst Waveform

You can configure the instrument to output a waveform with for a specified number of cycles, called a

burst. You can control the amount of time that elapses between bursts with the internal timer or the signal

level on the rear-panel Ext Trig connector. For this example, you will output a three-cycle sine wave with

a 20 ms burst period.

1. Select the function and amplitude for the burst.

For burst waveforms, you can select sine, square, ramp, pulse, arbitrary waveforms, triangle, or PRBS.

Noise is allowed only in the "gated" burst mode and DC is not allowed. For this example, select a sine

wave with an amplitude of 5 Vpp.

2. Select the burst mode.

Press[Burst] > Burst Off/On. Notice that a status message N Cycle Burst, Trig Imm is shown in the

tab of the current channel.

57 Keysight Trueform Series Operating and Service Guide

Page 59

Operating Information

3. Set the burst count.

Press# of Cycles and set the count to "3" using the numeric keypad or knob. Press Enter to finish

data entry if you are using the numeric keypad.

4. Set the burst period.

PressBurst Period and set the period to 20 ms using the numeric keypad or the knob and arrows. The

burst period sets the time from the start of one burst to the start of the next burst. At this point, the

instrument outputs a continuous three-cycle burst at 20 ms intervals.

You can generate a single burst (with the specified count) by pressing the [Trigger] key. For more

information, see Trigger Sweep or Burst.

You can also use the external gate signal to create gated bursts, where a burst is produced while a gate

signal is present on the input.

Trigger a Sweep or Burst

You can select one of four different types of triggers from the front panel for sweeps and bursts:

l Immediate or "automatic" (default): instrument outputs continuously when sweep or burst mode is

selected.

l

External: triggering controlled by rear panel Ext Trig connector.

l

Manual: initiates one sweep or burst each time you press[Trigger]. Continue pressing [Trigger] to retrigger instrument.

l Timer: issues one or more triggers a fixed time amount apart.

If sweep or burst is on, pressing [Trigger] displays the trigger menu. An illuminated [Trigger] key (solid or

blinking) indicates that one or both channels are awaiting a manual trigger. Solid illumination occurs when

the trigger menu isselected, and flashing illumination occurs when the trigger menu is not selected. The

[Trigger] key is disabled when the instrument is in remote.

Pressing [Trigger] when it is solidly illuminated causes a manual trigger. Pressing [Trigger] when it is

flashing selects the trigger menu; a second press causes a manual trigger.

Keysight Trueform Series Operating and Service Guide 58

Page 60

Operating Information

Store or Retrieve the Instrument State

You can store instrument states in any number of state files, (extension .sta). You can do this for backup

purposes, or you can save your state to a USB drive and load it on another instrument to have instruments

with matching configurations. A stored state contains the selected function, frequency, amplitude, DC

offset, duty cycle, symmetry, and any modulation or burst parameters in use. The instrument does not

store volatile arbitrary waveforms.

1.

Select the desired storage location.

59 Keysight Trueform Series Operating and Service Guide

Page 61

Operating Information

2. Press Name and specify the name for the selected location.

33500 Series

To add characters, press the right-cursor key until the cursor isto the right of the existing name and

then turn the knob. To delete a character, rotate the knob until you get to the blank character before

the capital A. To delete all characters from the cursor position to the end of the line, press [+/-]. You

can enter numbers directly from the numeric keypad.

33600 Series

Use the front panel right and left arrows (under the knob) to select the characters to edit. You can go

past the final character to add a newcharacter to the end. Then use the knob to select the desired

character and use the arrows to move to the next character to edit.

You can delete one or more characters with the Delete Char and Clear Entry softkeys.

PressDone when you have finished entering the name.

3.

Store the instrument state.

Keysight Trueform Series Operating and Service Guide 60

Page 62

Operating Information

To restore (retrieve) a stored state:

Front Panel Menu Reference

This chapter begins with an overview of the front panel menus. The remainder of this chapter contains

examples of using the front panel menus.

Selects waveform

l Sine

l Square

l Ramp

l Pulse

l Arbitrary

l Triangle

l Noise

l PRBS

l DC

Configures waveform-specific parameters

l Period/Frequency

l Amplitude or High and Low Voltage

l Offset

l Phase

61 Keysight Trueform Series Operating and Service Guide

Page 63

l Duty Cycle

l Symmetry

l Pulse Width

l Edge Times

l Arbitrary Waveform

l Sample Rate

l Filter

l Arb Phase

l Bandwidth

l PRBSData

l Bit Rate

Operating Information

Specifies unit and parameter preferences

l Arb Rate: Sa/s, Freq or Period

l Voltage as Amplitude/Offset or High/Low

l Voltage units as Vpp, Vrms, or dBm

l Pulse Width or Duty Cycle

l Burst Phase as Degrees, Radians, or Seconds

l Arb Phase as Degrees, Radians, Seconds, or Samples

l Frequency sweep as Center/Span or Start/Stop

Configures modulation parameters

l Modulation on or off

l Modulation type: AM, FM, PM, PWM, BPSK, FSK, or Sum

l Modulation source

l Modulation parameters (vary by modulation type)

Keysight Trueform Series Operating and Service Guide 62

Page 64

Operating Information

Configures frequency sweep parameters

l Sweep on or off

l Sweep type: Linear, logarithmic or frequency list

l Sweep time

l Start/stop frequencies or center/span frequencies

l Dwell, hold, and return times

Configures burst parameters

l Burst on or off

l Burst mode: triggered (N Cycle) or externally-gated

l Cycles per burst (1 to 100,000,000 or infinite)

l Starting phase angle of burst (-360° to +360°)

l Burst period

Stores and recalls instrument states

l Store instrument states in non-volatile memory.

l Assign custom names to storage locations.

l Recall stored instrument states.

l Delete stored instrument states.

l Select the instrument’s power-on configuration (last power-down or factory default).

63 Keysight Trueform Series Operating and Service Guide

Page 65

Configures instrument I/O interfaces

l Turn LAN on and off

l Configure LAN (IP address and network configuration)

l Reset the LAN

l Specify USB settings

l Select GPIB address

Operating Information

Performs system administration tasks

l Perform self-test

l Calibrate instrument

l Clear instrument memory (NISPOM secure)

l Install licensed features

l Update firmware

Keysight Trueform Series Operating and Service Guide 64

Page 66

Operating Information

Configures system-related parameters

l Set screen layout

l Select local language for front panel messages and help text

l Select how periods and commas are used in numbers on display

l Turn display on and off

l Enable or disable error beeper

l Enable disable keypad click

l Enable or disable screen saver

l Adjust display brightness

l Set date and time

l Manage files and folders (copy, rename, delete, screen capture, and so on)

l Configure 10 MHz reference oscillator

Shows list of Help topics

l View last message displayed

l View remote command error queue

l Get help on any key

l Learn how to obtain technical support

l View "about" data - serial number, IP address, firmware version, and so on

65 Keysight Trueform Series Operating and Service Guide

Page 67

Enables and configures channels

l Turn channel on and off

l Specify which channel is the focus of the menus

l Select output termination (1 Ω to 10 kΩ, or Infinite)

l Enable / disable amplitude autoranging

l Select waveform polarity (normal or inverted)

l Specify voltage limits

l Specify whether output is normal or gated

l Configure dual channel operation (coupling, tracking, and combine)

Operating Information

Configures trigger settings and sync output signal

l Perform a manual trigger, when illuminated

l Specify the trigger source for sweep, burst or arbitrary waveform advance

l Specify the trigger voltage level, count, and delay

l Specify the slope (rising or falling edge) for an external trigger source

l Specify the slope (rising or falling edge) of the trigger output signal

l Enable / disable the signal output from the "Sync" connector

l Specify the Sync source, polarity, mode, marker point, and so on

LAN Configuration Procedure

There are several parameters that you might need to set to establish network communication using the

LAN interface. Primarily, you will need to establish an IP address. You might need to contact your network

administrator for help in establishing communication with the LAN interface.

1. Select the "I/O" menu.

Press[System] > I/O Config.

Keysight Trueform Series Operating and Service Guide 66

Page 68

Operating Information

2. Select the LAN Settings menu.

Pressthe LAN Settings softkey.

You can select Modify Settings to change the LAN settings, or you can turn LAN Services on and off

or restore the LAN settings to default values.

This screen reflects the 33500 Series display. The 33600 Series also includes a LAN

Status indicator in the upper right corner to indicate whether the LAN connection is good

or faulty.

3. Press Modify Settings.

To access most items on this screen, use the first softkey to switch from DHCP to Manual. With DHCP

on, an IP address will automatically be set by DHCP (Dynamic Host Configuration Protocol) when you

connect the instrument to the network, provided the DHCP server is found and is able to do so. DHCP

also automatically deals with the subnet mask and gateway address, if required. This is typically the

easiest way to establish LAN communication for your instrument. All you need to do is leave DHCP on.

Contact your LAN administrator for details.

67 Keysight Trueform Series Operating and Service Guide

Page 69

Operating Information

4. Establish an "IP Setup."

If you are not using DHCP (if the first softkey is set to Manual), you must establish an IP setup,

including an IP address, and possibly a subnet mask and gateway address. The IP Address and

Subnet Mask buttons are on the main screen, and you pressMore to configure the Gateway.

Contact your network administrator for the IP address, subnet mask, and gateway to use. All IP

addresses take the dot-notation form "nnn.nnn.nnn.nnn" where "nnn" in each case is a byte value in

the range 0 through 255. You can enter a new IP address using the numeric keypad (not the knob).

Just type in the numbers and the period delimitersusing the keypad. Use the left cursor key as a

backspace key. Do not enter leading zeros.

5. Configure the "DNSSetup" (optional)

DNS (Domain Name Service)is an Internet service that translates domain names into IP addresses. Ask

your network administrator whether DNS is in use, and if it is, for the host name, domain name, and

DNS server address to use.

a. Set the "hostname." Press Host Name and enter the hostname. A hostname is the host portion of

the domain name, which is translated into an IP address. The hostname isentered as a string using

the knob and cursor keys to select and change characters. The hostname may include letters,

numbers, and dashes ("-"). You can use the keypad for the numeric characters only.

b. Set the "DNS Server" addresses. From the LAN configuration screen, press More to go to the

second of three sets of softkeys.

Enter the Primary DNS and Second DNS. See your network administrator for details.

Keysight Trueform Series Operating and Service Guide 68

Page 70

Operating Information

More about IP Addresses and Dot Notation