Ultimate Products SGX, ER, SC, SA, CW User Manual

...

-INDEX-

A. INSTALLATION INSTRUCTIONS |

2 |

1. TECHNICAL DATA |

2 – 4 |

(a)General Information

(b)ER-Series heating Models (or GX, CW, AL, SC)

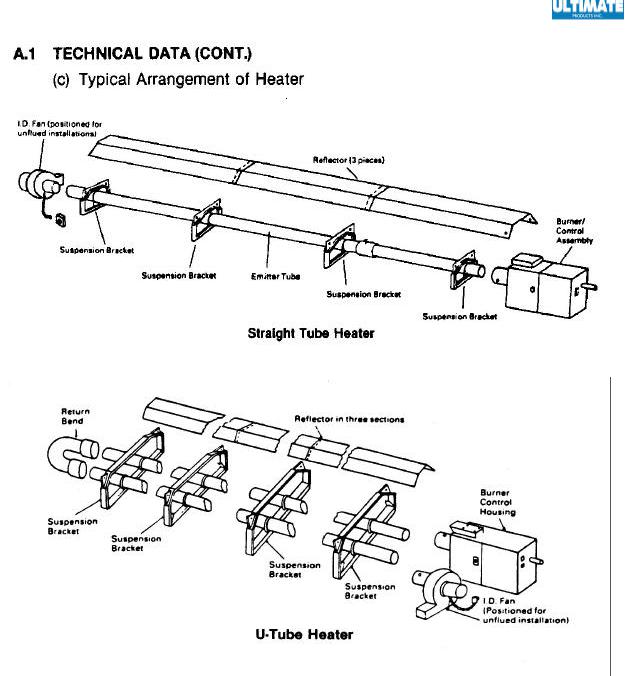

(c)Typical Arrangement of Heater

2. |

PACKAGING AND SHIPPING |

4 – 5 |

3. |

MOUNTING CLEARANCES |

5 – 6 |

4. |

PRE-ASSEMBLY |

6 |

5. INSTALLATION |

7 |

|

6. |

GAS CONNECTION |

8 – 9 |

7. |

ELECTRICAL CONNECTION |

10 – 11 |

8. VENT REQUIREMENT AND DETAILS |

12 – 13 |

|

(a)Unvented units

(b)Vertical Vent

(c)Horizontal Vent

9. FRESH AIR DUCTED INTAKE |

13 |

(a) Vertical Thru Roof |

|

(b) Horizontal Thru Wall |

|

10. INSTALLATION CHECK OUT AND START UP |

14 – 15 |

B. SERVICE AND MAINTENANCE INSTRUCTIONS |

16 – 21 |

1. Servicing Instructions |

|

2. Routing Service |

|

3. Replacement of Components |

|

4. User Instructions |

|

C. Appendix ‘A’ |

22-53 |

D. Appendix ‘B’ |

54-56 |

Note: All reference to standard specifications, codes, regulations, etc., are intended to reflect latest editions included in the ANSI Testing, Construction, Performance and Installation Standards. (ANSI/ NFPA standard 1985)

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 1 - |

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damager, injury, or death. Read the installation, operating, and maintenance instructions thoroughly before installing or servicing this equipment.

A. INSTALLATION INSTRUCTIONS

A.1 TECHNICAL DATA

(a) General Information Model & Heat Input

Information all units:

Gas Supply Connection: ½-inch NPT Male Electrical Supply: 120V, 1 phase, 60Hz

Current Rating: 1.2 AMP MAX (Burner-0.3/Fan – 0.9)

Ignition: Electronic Program Start-up with Spark Ignition

OPTIONS:

1.Modify combustion chamber air intake for fresh air duct.

2.Ultimate Products Black Bulb Thermostat.

3.Control Panel with multi-zone capabilities. (Not A.G.A. Certified)

4.Individual Heater Vent to Exterior.

Notes:

A.Heater is intended for heating non-residential indoor and outdoor spaces and should only be installed where flammable gases or vapors are not generally present.

B.Indoor heaters may be suspended either horizontal or at an angle, or may be wall mounted. Outdoor heaters must be suspended horizontally. SEE SECTION A.3

FOR CLEARANCES.

C.Installation shall conform with local building code requirements and with National Fuel code ANSI-Z223.1.A. (Latest Edition) and section 7.8A-3; Z223.1 (Latest Edition).

D.The unit shall be electrically grounded in accordance with National Electric Code ANSI/NFPA 70-1987.

E.The heater may be installed in aircraft hangars when conformation with ANSI/NFPA 409-1985 for Aircraft Hangars and in automotive garages when conforming with ANSI-NFPA 88A (Latest Edition) for Parking Structures and ANSI/NFPA 88B (Latest Edition) for Repair Garages.

Insure that minimum clearance will be maintained to vehicles parked below the heater.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 2 - |

Pipe Capacities For Propane and Natural Gas

Pipe Capacities For Propane in Thousands of BTUs Per Hour

For pressure drop of 0.5” W.C., based on low-pressure piping based on 6 oz. per sq. in. pressure. Based on one Cubic Foot of Propane = 2500 BTUs.

SIZE |

|

|

|

|

|

LENGTH OF STRAIGHT PIPE IN FEET |

|

|

|

|

|

|||||

PIPE |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INCHES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

30 |

45 |

60 |

75 |

90 |

105 |

120 |

150 |

180 |

210 |

240 |

270 |

300 |

450 |

600 |

½ |

105 |

77.5 |

65 |

55 |

50 |

45 |

40 |

150 |

137.5 |

125 |

115 |

107.5 |

102.5 |

95 |

80 |

67.5 |

¾ |

425 |

300 |

245 |

212.5 |

190 |

172.5 |

160 |

|||||||||

1 |

787.5 |

615 |

505 |

440 |

395 |

362.5 |

330 |

315 |

282.5 |

252.5 |

237.5 |

220 |

205 |

197.5 |

157.5 |

137.5 |

1¼ |

1542.5 |

1070 |

882.5 |

770 |

677.5 |

630 |

582.5 |

542.5 |

487.5 |

440 |

410 |

385 |

362.5 |

347.5 |

282.5 |

237.5 |

1 ½ |

2425 |

1700 |

1402.5 |

1212.5 |

1070 |

977.5 |

912.5 |

857.5 |

772.5 |

700 |

645 |

607.5 |

575 |

542.5 |

440 |

377.5 |

2 |

5040 |

3490 |

2835 |

2520 |

2205 |

2047.5 |

1890 |

1732.5 |

1575 |

1417.5 |

1322.5 |

1245 |

1165 |

1117.5 |

897.5 |

770 |

3 |

13545 |

9607.5 |

7875 |

6772.5 |

5985 |

5512.5 |

5197.5 |

4882.5 |

4252.5 |

3937.5 |

3622.5 |

3387.5 |

3232.5 |

3072.5 |

2520 |

2127.5 |

4 |

28035 |

19687.5 |

16222.5 |

14017.5 |

12600 |

11497.5 |

10710 |

9922.5 |

8820 |

8032.5 |

7560 |

6930 |

6615 |

6300 |

5040 |

4410 |

Pipe Capacities For Natural Gas In Thousands of BTUs Per Hour

For pressure drop of 0.5” W.C. pressure. Based on one Cubic Foot on Natural

Gas = 100 BTUs.

SIZE |

|

|

|

|

|

|

|

LENGTH OF STRAIGHT PIPE IN FEET |

|

|

|

|

|

|

|

|||||||

PIPE |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

125 |

150 |

175 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

1000 |

|

INCHES |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

½ |

170 |

118 |

95 |

80 |

71 |

64 |

60 |

55 |

52 |

49 |

44 |

40 |

37 |

34 |

27 |

23 |

21 |

19 |

|

|

|

|

¾ |

360 |

245 |

198 |

169 |

150 |

135 |

123 |

115 |

108 |

102 |

92 |

83 |

77 |

71 |

57 |

48 |

43 |

39 |

|

|

|

|

1 |

540 |

440 |

325 |

285 |

250 |

225 |

215 |

195 |

185 |

177 |

155 |

140 |

130 |

120 |

100 |

80 |

70 |

65 |

57 |

48 |

40 |

|

1 ¼ |

1125 |

790 |

660 |

570 |

510 |

465 |

440 |

410 |

390 |

375 |

355 |

305 |

280 |

260 |

205 |

180 |

165 |

140 |

125 |

115 |

100 |

|

1 ½ |

1700 |

1200 |

1000 |

865 |

780 |

720 |

670 |

620 |

600 |

570 |

510 |

455 |

430 |

400 |

315 |

265 |

240 |

215 |

195 |

180 |

150 |

|

2 |

3100 |

2225 |

1855 |

1600 |

1450 |

1375 |

1250 |

1175 |

1120 |

1075 |

970 |

880 |

820 |

760 |

610 |

530 |

470 |

420 |

390 |

365 |

320 |

|

2 ½ |

5040 |

3525 |

3000 |

2600 |

2350 |

2175 |

2025 |

1890 |

1810 |

1745 |

1570 |

1420 |

1315 |

1225 |

995 |

845 |

740 |

660 |

620 |

570 |

500 |

|

3 |

9100 |

6500 |

5300 |

4600 |

4435 |

3780 |

3530 |

3290 |

3140 |

3020 |

2905 |

2840 |

2450 |

2140 |

1640 |

1385 |

1210 |

1085 |

930 |

900 |

760 |

|

3 ½ |

|

9500 |

7880 |

6780 |

6140 |

5670 |

5280 |

4940 |

4685 |

4300 |

4000 |

3660 |

3380 |

3185 |

2500 |

2300 |

1890 |

1690 |

1545 |

1445 |

1245 |

|

4 |

|

|

|

9450 |

8500 |

7880 |

7325 |

6870 |

6550 |

6300 |

5600 |

5125 |

4760 |

4400 |

3145 |

3010 |

2870 |

2670 |

2400 |

2100 |

1800 |

|

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 3 - |

A.2 PACKAGING AND SHIPPING INFORMATION

See Appendix ‘A’ for assembly drawings. Materials lists with part numbers and descriptions for each part will accompany each shipment.

Heaters include: Burner/Control Radiant Tubes Reflectors Brackets Vacuum Fan

U-Bend (U-Tube Units only)

Wiring Junction Boxes (Straight Tube Units Only)

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 4 - |

A.2 PACKAGING AND SHIPPING INFORMATION (CONT.)

Options: Fresh air Intake (Mounted to Burner/Control)

Fan Vent AdaptersVertical and Horizontal

Thermostat

Flexible Gas Connector

Ball Valve

Vent Hoods

Hanging Assembly (chain, etc.)

Shipping packages for individual projects will be boxed and crated as outlined on the specific bill of lading.

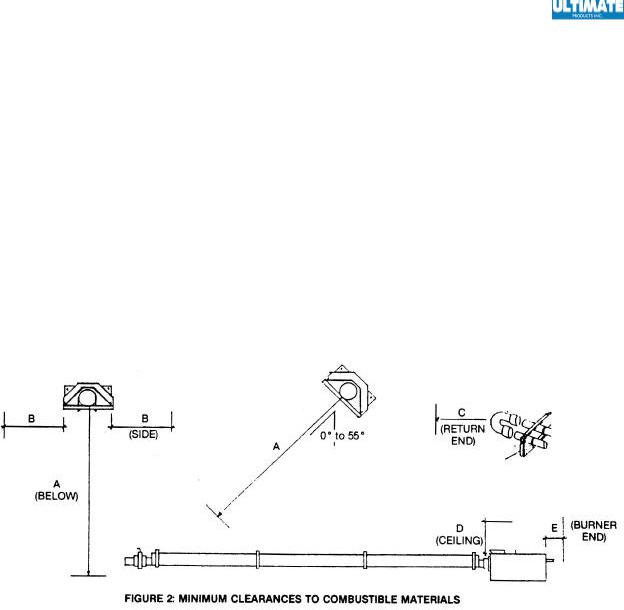

A.3 MOUNTING CLEARANCES

The heater should be positioned so that clearances from combustible materials will meet or exceed those shown in the following table. Also, ensure that there is at least 6” clearance on all sides of burner for service access and for free flow of combustion air. When heater is angle mounted, the burner/control assembly must remain horizontal.

Minimum Clearances To Combustibles In Inches

Model |

Input – BTU / HR |

A |

B |

D |

E |

GH / ER / AL / SC 12 |

40,000 |

43 |

20 |

4 |

6 |

GH / ER / AL / SC 15 |

50,000 |

66 |

20 |

* |

6 |

GH / ER / AL / SC 18 |

60,000 |

66 |

20 |

* |

6 |

GH / ER / AL / SC 22 |

75,000 |

66 |

20 |

* |

6 |

GH / ER / AL / SC 29 |

100,000 |

72 |

30 |

12 |

6 |

GH / ER / AL / SC 38 |

130,000 |

72 |

30 |

12 |

6 |

GH / ER / AL / SC 44 |

150,000 |

93 |

36 |

12 |

6 |

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 5 - |

A.3 MOUNTING CLEARANCES (CONT.)

|

MOUNTING HEIGHT ABOVE FLOOR |

||

Mounting |

40,000 – 75,000 B.T.U |

100,000 – 130,000 B. T. U. |

150,000 B. T. U |

Position |

|

|

|

Horizontal |

|

|

|

Recommended |

14 ft |

16ft |

18ft |

Minimum |

12ft |

14ft |

16ft |

Inclined |

|

|

|

Recommended |

11ft |

13ft |

15ft |

Minimum |

10ft |

12ft |

14ft |

Ensure that there is adequate provision in the building for combustion and ventilating air supply. Installation must meet minimum requirements of applicable codes.

When installed in public garages and airplane hangars ensure that minimum clearances specified in ANSI/NFPA 88A or B, ANSI/NFPA 409, respectively, are met; and in no case less than those in the preceding tables.

A.4 PRE-ASSEMBLY

Each heating unit is assembled as follows:

Note that the emitter tube consists of more than one tube. The tube to be connected to the burner box is the thinner stainless steel or aluminized steel tube. Other tubes may be mild (thicker tubes), stainless or aluminized steel. Connections between tubes is by a coupling with three bolts. The coupling has an inner compression sleeve that holds the pipe securely when the nuts are turned tight.

Support the assembled radiant tube with screws facing upwards, on blocks, etc. at least 6” above floor level, preferably under the position of installation. Ensure that the tube is clear internally.

Slip the suspension brackets onto the tube assembly and attach by means of “U” bolts and nuts. Note that there are two types of brackets; type C and type B. Type C attaches reflectors together. Bracket C & B are placed on the assembled radiant tube in position shown on the assembly drawing in APPENDIX “A”. Tighten nuts to secure brackets to the tubes at spacing indicated with all brackets oriented in the same level position.

NOTE: CLOSE ALL S-HOOKS TO INSURE THAT THE CHAINS DO NOT COME OFF OF THE HOOK.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 6 - |

A.5 INSTALLATION

Heater units: At this point raise the tube assembly into position and suspend from previously fixed chains (9 gauge min. galvanized welded link construction), or attach to wall mounting brackets. Wall mounting brackets must support heater at an angle of inclination of 45° ±10°. Longer tube assembly may be raised in more than one sub-assembly with final tube connection made in the air.

It is recommended that the heater be suspended to slope slightly downward from the burner approximately 1 inch in 20 feet, but not more than 2 -inches total.

Remove the protective plastic film from the reflector surface. Note that each section of reflector has two holes punched at one end. This end is firmly fixed by bolting to the lugs provided on the reflector bracket type C. The other end of each reflector section is free floating in suspension bracket type B thereby allowing for thermal expansion.

Position reflector sections so that ends with holes lap at type C brackets and secure with nuts, bolts, and large washers provided in the burner box crate. Reflector should be allowed free movement through brackets type B. Note: Reflectors may be installed before tube is raised to position at installer’s option.

Slide burner/control assembly onto the burner end of the radiant tube ensuring it is fully engaged and upright, (i.e. with air inlet cover plate facing upwards) and secure with locking screws provided.

Slide the fan assembly on the opposite end of radiant tube, ensuring that it is fully engaged with fan outlet facing horizontally for outdoor installations and for indoor installations either unvented or with horizontal thru wall venting. Fan outlet should face upward for vertical venting thru the roof.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 7 - |

A.6 GAS CONNECTION

The gas connection on the heater is ½” NPT external thread.

SERVICE REQUIREMENTS |

NAT. GAS |

L.P. GAS |

|

|

|

Max. inlet gas supply pressure (in.w.c.) |

10.0 |

14.0 |

Min. inlet gas supply pressure (in.w.c.) |

6.5 |

11.0 |

|

|

|

Injector sizes and manifold pressure for the burner are shown in the attached table for all heater units.

The gas supply piping and connections must be installed so that the minimum pressure stated is achieved.

A gas shut-off valve and union should be fitted in the gas supply line close to the heater, and a 1/8 inch N.P.T. plugged tapping, accessible for test gauge connection, provided immediately upstream of the appliance gas inlet.

It is essential to provide some flexibility in the final gas connection preferably by use of an approved armored flexible connector or stainless steel expansion loop. (See Appendix ‘A’)

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 8 - |

Model Designation |

|

Air Inlets |

|

Natural Gas |

Liquid Petroleum |

|||||

|

(Inches/ Millimeters) |

Orifice |

Orifice |

|||||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

Input |

Model Tube |

Tube Dia. |

Burner Intake |

Fan Inlet |

Injector |

Manifold |

Injector |

Manifold |

|

|

KW |

Diameter |

Pressure |

Diameter |

Pressure |

|||||

|

Configuration |

(In) |

(in. / M.M.) |

(in. / M.M.) |

||||||

|

BTU/HR |

(inches ) |

(in.W.C.) |

(inches) |

(in./mm) |

|||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

GH/ER/AL/SC |

12/40,000 |

S-20 |

3" |

1.125"/29mm |

1.312"/33mm |

0.130" |

1.9 |

0.080" |

6.7 |

|

|

|

S-25 |

3" |

1.125"/29mm |

1.438" /37mm |

0.130" |

1.9 |

0.080" |

6.7 |

|

|

|

S-30 |

3" |

1.125"/29mm |

1.438" /37mm |

0.130" |

1.9 |

0.080" |

6.7 |

|

|

|

U-20 |

3" |

1.125"/29mm |

1.187/30mm |

0.130" |

1.9 |

0.080" |

6.7 |

|

|

|

U-30 |

3" |

1.125"/29mm |

1.187/30mm |

0.130" |

1.9 |

0.080" |

6.7 |

|

|

|

|

|

|

|

|

|

|

|

|

GH/ER/AL/SC |

15/150000 |

S-20 |

3" |

1.312"/33MM |

1.438"/37 MM |

0.130" |

3 |

0.080" |

6.7 |

|

|

|

S-25 |

3" |

1.125"/29 MM |

1.438"/37 MM |

0.130" |

3 |

0.080" |

6.7 |

|

|

|

S-30 |

3" |

1.125"/29 MM |

1.438"/37 MM |

0.130" |

3 |

0.080" |

6.7 |

|

|

|

U-20 |

3" |

1.312"/33MM |

1.438"/37 MM |

0.130" |

3 |

0.080" |

6.7 |

|

|

|

U-30 |

3" |

1.312"/33MM |

1.312"/33 MM |

0.130" |

3 |

0.080" |

6.7 |

|

|

|

|

|

|

|

|

|

|

|

|

GH/ER/AL/SC |

18/60,000 |

S-20 |

3" |

1.750"/44 MM |

2.00"/50 MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-25 |

3" |

1.312"/33 MM |

1.438"/37 MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-30 |

3" |

1.312"/ 33 MM |

1.438"/37 MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-40 |

3" |

1.312" /33 MM |

1.438"/37 MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-20 |

3" |

1.312" /33 MM |

1.750"/44MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-30 |

3" |

1.312" /33 MM |

1.438"/37 MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

S-40 |

3" |

1.312" /33 MM |

1.312"/33MM |

0.161" |

2.4 |

0.098" |

6.7 |

|

|

|

|

|

|

|

|

|

|

|

|

GH/ER/AL/SC |

22/75,000 |

S-20 |

3" |

1.750"/44 MM |

2.625"/67 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

S-25 |

3" |

1.750"/44 MM |

2.00"/50 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

S-30 |

3" |

1.750"/44 MM |

2.00/50 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

S-40 |

3" |

1.750"/44 MM |

1.75"/44MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

U-20 |

3" |

1.750"/44 MM |

2.625"/67 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

U-30 |

3" |

1.750"/44 MM |

2.00/50 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

U-40 |

3" |

1.750"/44 MM |

2.00/50 MM |

0.161" |

3.8 |

0.098" |

10.5 |

|

|

|

|

|

|

|

|

|

|

|

|

GH/ER/l/SC |

29/100,000 |

S-40 |

4" |

2.312"/59 MM |

2.00"/50 MM |

0.182" |

4.9 |

1.20" |

10 |

|

|

|

S-50 |

4" |

2.312"/59 MM |

2.00"/50 MM |

0.182" |

4.9 |

1.20" |

10 |

|

|

|

S-60 |

4" |

2.312"/59 MM |

2.00"/50 MM |

0.182" |

4.9 |

1.20" |

10 |

|

|

|

U-35 |

4" |

2.312"/59 MM |

2.00"/50 MM |

0.182" |

4.9 |

1.20" |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

GH/ER/AL/SC |

38/130,000 |

S-40 |

4" |

2.312"/59 MM |

2.625"/67MM |

0.206" |

4.9 |

0.136" |

10 |

|

|

|

S-50 |

4" |

2.312"/59 MM |

2.625"/67MM |

0.206" |

4.9 |

0.136" |

10 |

|

|

|

S-60 |

4" |

2.312"/59 MM |

2.625"/67MM |

0.206" |

4.9 |

0.136" |

10 |

|

|

|

U-35 |

4" |

2.312"/59 MM |

2.625"/67MM |

0.206" |

4.9 |

0.136" |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

SC/ER/GX |

44/150,000 |

S-40 |

4" |

2.312"/59 MM |

4.00"/100MM |

0.228" |

4.6 |

0.149" |

10 |

|

S-50 |

4" |

2.312"/59 MM |

4.00"/100MM |

0.228 |

4.6 |

0.149" |

10 |

|||

|

|

|||||||||

|

|

S-60 |

4" |

2.312"/59 MM |

4.00"/100MM |

0.228 |

4.6 |

0.149" |

10 |

|

|

|

U-35 |

4" |

2.312"/59 MM |

4.00"/100MM |

0.228 |

4.6 |

0.149" |

10 |

|

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com |

- 9 - |

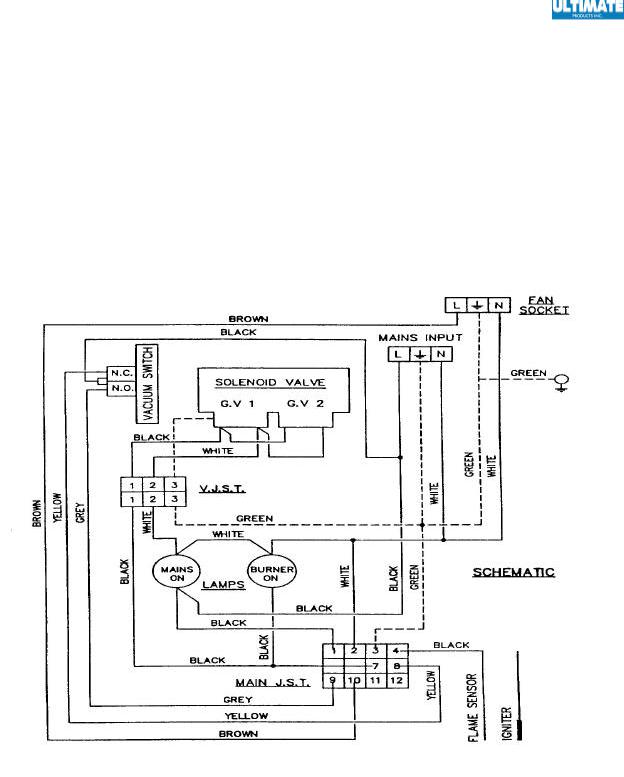

A.7 ELECTRICAL CONNECTION

(a)Burner/Control Internal Wiring

IMPORTANT: All electrical work should be done by a qualified electrician in accordance with the National Electrical Code ANSI/NFPA 70.

Supply: 120 V, 60 Hz, single phase Current Rating: 0.3 amp max

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 10 -

A. 7 ELECTRICAL CONNECTION (CONT.)

The electrical supply to the heater is by three wires: live, neutral and ground connections. It is recommended that the supply cable be in metallic conduit to the 3/4'” hole provided.

Power is ONLY supplied to the terminal in the back of burner as shown below:

Power is supplied to fan through the knock out on the side of the burner housing.

Fan leads should be connected to the burner leads using the wire nuts provided. Connect yellow/green wire from fan, to green wire of the burner, connect either black wire from the fan, one to the white and one to the black/brown of burner. Insure that conduit clamp is firmly tightened.

It is recommended that the electrical circuit controlling the heater or group of heaters include thermostats, a time switch and if required manual control switches. All such controls and switch gear must be rated to handle the total inductive load of the circuit they control. For large installations, the use of relays or contractors should be considered.

Control panels are available from the manufacturer incorporating multiple Black Bulb Thermostats controlling up to 10 heaters per thermostat for zone control of the heated area. Typical External Wiring is shown in diagram. (Control panels are not A.G.A. design certified.)

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 11 -

A.8 VENT REQUIREMENTS AND DETAILS

(1)UNVENTED UNITS: Heaters may be installed without a flue providing the governing building codes are met and that consideration is properly given to possibilities of condensation on cold surfaces.

Installation shall meet the following requirements when unvented:

(A)Internal volume of the heated room must be greater than 214 cu. ft. per 100 BTU/HR of heaters installed.

(B)Natural or mechanical means shall be provided to supply and exhaust at least 4 CFM per 1,000 BTU per hour input of installed heaters.

(C)Combustion gases shall not impinge on combustible materials with a temperature in excess of 150° F.

(D)The blower discharge must be horizontal.

(2)VERTICAL VENTING: The heater may be installed with a vertical flue. A down vent elbow must be fitted to the induced draft fan exhaust outlet, which should be rotated to a vertical position.

A vent elbow designed to accept a 6 -inch nominal sheet metal flue pipe is available as an optional extra.

All flue piping should be adequately supported from the building structure and terminated with an approved terminal. The maximum flue length is 30 ft. with a maximum of two bends. All connections should be properly sealed. Generally, terminal may be located horizontally a dimension equal to its vertical dimension.

(3)HORIZONTAL VENTING: Individual units may be vented horizontally through side walls. Venting must be installed in accordance with ANSI Z2223.1 (NFPA-54) and local codes.

Maximum length of vent is 25 ft. with 2-90 degree long radius elbows.

Runs of 12 ft. or shorter can use 4-inch diameter flue with Ultimate Products part number V0200.

Runs over 12 ft. should use 6-inch dia. flue pipe. Any portion of flue that passes through a combustible wall must be insulated or use an approved insulating thimble.

Recommended parts are Ultimate Products’ (Part # V-0200) for 4-inch flue and (Part # V-0800) for 6-inch flue. Standard vent terminals must extend at least 6-inches from the wall and at least 24-inches from any combustible overhang. Protect the building material from degradation by flue gases.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 12 -

A. 8 VENT REQUIREMENTS AND DETAILS (CONT.)

Flue joints should be sealed using RTV high temperature sealant and secured using at least three (3) sheet metal screws. Should condensation occur flue should be shortened or insulated.

The terminal must exit the building at least 7 ft. above any area accessible to the public.

The terminal must be at least 3ft. away from any air intake to the building.

If the heater is equipped with ducted combustion air, the terminal must be at least 3 ft. away from the air inlet and located higher than the inlet.

The vent terminal must be protected from blockage by snow.

A.9 FRESH AIR DUCTED INTAKE

Whenever the heater is installed in locations where air born dust or other polluted atmosphere is present; a fresh air supply should be ducted to the burner.

A heater modified for fresh air intake should be specified when ordering. This model is modified with a 4 -inch diameter duct connection at the burner.

A fresh air duct of 4-inch diameter should be installed from the fresh air to the air intake connection on the burner housing. A flexible jointing piece should be installed at the burner connection with hose clamps to facilitate the disconnection when servicing the burner assembly.

The maximum recommended length of fresh air duct is 25 feet and the maximum number of bends is two (2). The minimum length is 18 inches. The location of the fresh air duct inlet must be where it will receive dust free clean air. An Ultimate Products inlet cap with bird screen must be fitted at the inlet of the duct. If the duct inlet is located above the roof the underside of the inlet terminal

must be at least 2 ft. above roof level and at least 10 inches above any projection on the roof within 7 ft. of the inlet.

See Appendix ‘A’ for typical installation drawing and Ultimate Products part numbers. Intake pipe, fittings, and sealant are not furnished by Manufacturer.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 13 -

A.10 INSTALLATION CHECK OUT AND START UP

Inspect installation and ensure that it has been carried out in accordance with these instructions. Ensure that electrical and gas supplies are isolated.

The gas supply should be purged and tested for soundness in accordance with Local and National Safety codes.

Open isolating gas valve and test gas connections for soundness using soap solution.

Remove burner cover plate by unscrewing 6 screws. Take care not to damage the sealing gasket. Inspect the burner and electrode assemblies ensuring these are securely fixed and all electrical connections securely made. Replace the burner cover plate ensuring that the sealing gasket is correctly positioned and the six screws are fully tightened. The heater will not operate until this plate is refitted.

Remove the control housing cover plate by unscrewing the five securing screws.

Ensure all internal components are securely fixed and all connections securely made. Open the manual gas valve.

Switch on the electrical supply to the heater and observe the correct start up sequence. Ensure that the settings of any time switch and thermostat are such that the heating system will be required to operate.

The fan will start to run and “Power On” lamp will illuminate. Safe-start checks are carried out automatically.

After the fan has run up to full speed and a satisfactory vacuum condition has been established, ignition sequence will commence. The spark ignition will be energized producing a spark at the ignition electrode. The gas valve will at the same time be energized.

If the ignition is successful the flame sensing probe and the ignition spark is switched off. The ‘burner on” lamp indicates that the gas solenoid valve is energized.

If ignition is unsuccessful the gas valve will close and the spark ignition deenergized after approximately 6 seconds. For approximately 10 to 20 seconds the fan will purge the system then re-ignition will be attempted. After three (3) attempts at ignition the control unit will “lock-out” - the “power on” lamp will remain illuminated and the fan will continue to run. To reset after “lock-out” switch off the power supply to the system and wait 5 minutes. Then turn the power on.

If repeated “locked-out” occurs investigate the cause.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 14 -

A.10 INSTALLATION CHECK OUT AND START UP (CONT.)

To shut down the heater, switch off the power supply to the system. Automatic control of the heater or a series of heaters may be achieved by incorporating thermostats, time switches, manual over-ride switches etc. in the electrical supply to the heater(s). It is essential to allow a delay of 15 seconds after switching off the system before attempting to restart.

If at a ny time after completion of the start up sequence, loss of flame should occur, the control unit will attempt to reignite. If this is unsuccessful lock out will occur.

Set burner gas pressure as follows. Switch off the power supply to the heating system. Connect a ‘U’ tube manometer to the pressure test nipple provided on the combination gas control valve. Remove the cover from the pressure regulator revealing the adjustable screw. Start the heater and using a suitable screwdriver adjust the pressure regulator, turning the screw clockwise to increase the pressure or counter clockwise to decrease the pressure. Set the pressure to appropriate in w.c. from the table of dimensions for correct heater description. Switch off the power supply to the heating system. Disconnect ‘U’ tube manometer and securely replace screw in pressure test nipple. Replace cover screw on pressure regulator.

Check the operation of the flame safeguard equipment as follows: With the heater running normally, switch off the gas supply at the shut off valve. The heater should attempt to relight and if the gas valve has been left off “lockout” should occur indicated by the “Power On” light only being illuminated and fan running.

Check the operation of the vacuum proving switch as follo ws. With the heater running normally, pull off the silicone rubber tube connecting the vacuum switch to the combustion chamber. Within one second, the burner should shut off. Then replace the tube securely and observe that the heater proceeds to ignite in the normal way.

Replace the controls cover securing the five fixing screws.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 15 -

B. SERVICE AND MAINTENANCE

INSTRUCTIONS

B.1 SERVICING INSTRUCTIONS

Under normal working conditions, it is recommended that the Ultimate Products Heater should be serviced annually. In exceptionally dirty or dusty conditions such as may occur in a foundry, more frequent servicing may be desirable. Servicing work should be carried out by a qualified gas service engineer.

IMPORTANT:

1.Never rest anything, especially ladders, against the heater.

2.Turn off gas and electrical supplies before servicing or repair work is started.

3.Unless otherwise instructed, reassemble parts in reverse order to the following instructions.

B.2 ROUTINE SERVICE

A.FAN – Inspect the main fan propeller and remove any dust brushing with a soft brush. Similarly remove any dust from the finger guard covering the secondary (cooling) impeller and the mesh aperture in the motor cover. Ensure that the impeller turns

freely and that there is not excessive play in the bearings.

B.EMITTER TUBE – Brush away any dust on the exterior of the emitter tube.

Inspect the emitter tube internally by removing the burner control box as directed in “D” below. If there is any appreciable build up of dust or deposits, the tube should be cleaned internally. The emitter tube may be cleaned by use of an industrial vacuum cleaner with a long extension tube, which is passed down the emitter tube.

Replace the burner/control assemblies engaging them fully on their tubes and secure by tightening the screws ensuring that they are squarely positioned (i.e. with the air inlet cover plate facing upwards).

C. REFLECTOR – The condition of the reflector should be noted and any necessary cleaning performed. The reflectors can be simply removed for cleaning by removing the reflector clamp screws securing them to the suspension brackets and sliding them out of the suspension brackets. The reflector can be cleaned with a soft cloth and detergent in water.

A mild non-abrasive metal polish may be used in cases of extreme discoloration.

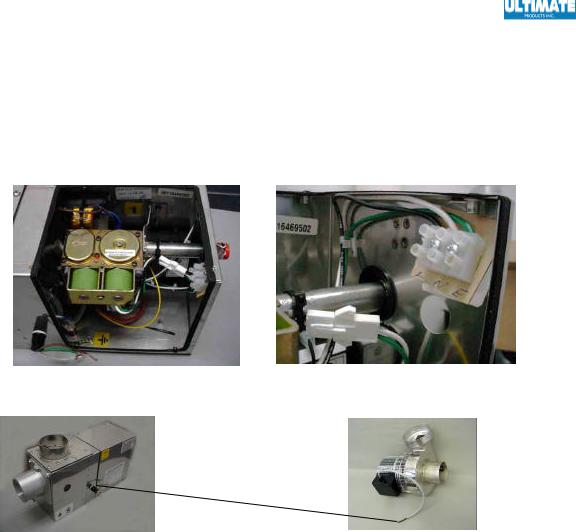

D. REMOVAL OF BURNER/CONTROL ASSEMBLY – Remove the burner/ control assembly by disconnecting the gas and electrical supply (and fresh air inlet duct if fitted). Slacken the burner fixing screws and draw the assembly off the emitter tube.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 16 -

E. BURNER NER/ELECTRODE ASSEMBLY – Inspect the burner/electrode assembly by removing the six screws securing the combustion chamber cover plate to top of control box, taking care not to damage the sealing gasket. Remove the burner head by unscrewing it from the injector taking care not to drop it on the leads of the ignition electrodes. Replace the electrode assembly if it is not in good condition. The assembly is removed by removing the screws which attach it to the bracket on the front wall of the combustion chamber. The assembly is then lifted out of the combustion chamber and the cable disconnected. If the electrode assembly is in good order check the spark electrode gap, this should be .125 inches ±.030 inches. Adjust the gap if necessary by bending the ground rod. Ensure the electrical connections are secure.

Inspect the injector a nd clean as necessary using a soft bristle brush. To remove or replace the injector, with the burner head removed, unscrew the injector from its carrier using a wrench, on the hexagon portion of its body. When replacing the injector ensure that it is fully tightened in its carrier. (TIGHTEN SNUG -- DO NOT

OVERTIGHTEN)

Replace the burner head. Replace the combustion chamber top cover, renewing the rubber sealing gasket if this is not in good condition.

Inspect the burner fresh air inlet duct if fitted and ensure that it is free of any blockage or obstruction. Inspect the air inlet terminal and ensure this is not liable to obstruction.

Recheck the heater by following the procedure for check out and start up, taking care to check that the burner gas pressure is correctly set, and that the vacuum switch and flame safeguard equipment function correctly.

F. AUXILIARY CONTROLS – Check that auxiliary controls such as room thermostats, time switches, etc. function correctly and are set to operate at the desired temperatures. Ensure that the user is aware of the functions of the auxiliary controls and their correct settings. For most efficient operation of the heating system the time switch, if fitted, should be set to switch on normally between ¼ hour and 1 hour before commencement of occupancy of the building depending on local conditions. The correct setting of the room thermostat can only be determined by experience in cold weather when it should be set to shut off the heaters when a comfortable level of warmth has been achieved. This setting will normally be several degrees below that which would be required with a convective heating system.

2319 Laurelbrook Street, Raleigh, NC 27604 · (800) 542-7221 · FAX (919) 834-4526 · www.ultimate-products.com - 17 -

Loading...

Loading...