Truxta BENDI 300G, BENDI 300D, BENDI 300E, BENDI 450E, BENDI 450G Owner's And Operator's Manual

...

OPERATOR MANUAL & PARTS LIST

MACHINE MODELS

BENDI 300G BENDI 300D BENDI 300E

BENDI 450G BENDI 450D BENDI 450E

SERIAL Numbers After B151040

Page 2

TABLE OF CONTENTS

Declaration of Conformity ...............................................................................3-7

Warning, Symbols & Decals …………………………………………………..………………..8

Machine Specification ………................................................................................9

General Safety / Health & Safety .................................................................10-11

Operating Instructions; - Petrol Diesel ........................................................12-13

(Pre-Start Checks, Start and Stop Procedures)

Service & Maintenance - Petrol & Diesel ....................................................... 14

Service - Pump Control Settings & Adjustment…..……………..……..…..……….. 15

Operating Instructions - Electric …………………………….…….……….....…….…….. 16

Operating Instructions - Battery Charger …………………...…….……..…..……….. 16

Warning, Symbols & Decals ............................................................................ 17

Service & Maintenance - Electric Problem Solving ……………..……..………..18-21

Parts Lists & Assembly

All Machines - Top Frame - Parts List …………………..…....……….….……..…. 22-23

All Machines - Front Chassis - Parts Lists ………………………...………...……...24-25

Petrol & Diesel - Rear Assembly - Parts Lists ………………...….....…...….....26-27

Electric - Rear Assembly - Parts List ………………………..….……..…..….…….28-29

Attachments - Flat Bed - Tow-Ball - Parts List ………………………….……….……...30

Warranty Registration ........................................................................................31

Page 3

We, Tufftruk Ltd, Sheen, nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify

that if the product described within this certificate is bought from an authorised

Tufftruk dealer within the EEC, it conforms to the following EEC directives:

2006/42/CE (This directive replaces directive 98/37/EC), Electromagnetic

Compatibility Directive 2004/108/CE (as amended by 89/336/EEC, 92/31/EEC

& 93/68 EEC).

The Waste Electrical and Electronic Equipment (WEEE) 2002/96/CE, the low

voltage directive 2006/95/CE, BS EN ISO 12100-1:2003 Safety of machinery and

associated harmonised standards, where applicable.

Noise emissions conform to directive 2000/14/EC Annex VI, for machines under

article 12 the notified body is AV Technology Limited, AVTECH House, Birdhall

Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Noise Technical Files are held at the Tufftruk Head Office address stated above.

DECLARATION OF CONFORMITY

Page 4

DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

We

TUFFTRUK Ltd

The Croft, Sheen, Buxton, Derbyshire, SK170EU

Declare that the following equipment conforms to the Directive: 2000/14/EC (as amended) of the European Parliament and of the council on the

approximation of the laws of the Member States relating to the

Noise Emission in

the Environment by Equipment for Use Outdoors.

Equipment Category: Pedestrian Power Barrow

Product Name/Model: TRUXTA

Type/Serial No: B300D & B450D & R300D

The technical documentation is held by: TUFFTRUK Ltd Address above

The conformity assessment procedure followed was in according with annex VI

of the Directive.

Notified Body: AV Technology Ltd SK9 3RW

Measured Sound Power Level: 97 dB (LWA)

Guaranteed Sound Power Level: 100 dB (LWA)

A copy of this certificate has been submitted to the European Commission and to

EU Member State, United Kingdom

Place of Declaration: TUFFTRUK Ltd SK17 0EU

Date: 29/09/2014

Signed by: Ronald Blackhurst

Position in Company:. Managing Director

Name and address of manufacturer or Authorised representative: Tufftruk Ltd SK17 0EU

Page 5

DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

We

TUFFTRUK Ltd

The Croft, Sheen,Buxton,Derbyshire,SK170EU

Declare that the following equipment conforms to the Directive: 2000/14/EC (as

amended) of the European Parliament and of the council on the approximation

of the laws of the Member States relating to the

Noise Emission in the

Environment by Equipment for Use Outdoors.

Equipment Category: Pedestrian Power Barrow

Product Name/Model: TRUXTA

Type/Serial No: B300G & R300G

The technical documentation is held by: TUFFTRUK Ltd Address above

The conformity assessment procedure followed was in according with annex VI

of the Directive.

Notified Body: AV Technology Ltd SK9 3RW

Measured Sound Power Level: 91 dB (LWA)

Guaranteed Sound Power Level: 94 dB (LWA)

A copy of this certificate has been submitted to the European Commission and to

EU Member State, United Kingdom

Place of Declaration: TUFFTRUK Ltd SK17 0EU

Date: 29/09/2014

Signed by: Ronald Blackhurst

Position in Company:. Managing Director

Name and address of manufacturer or Authorised representative: Tufftruk Ltd SK17 0EU

Page 6

DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

We

TUFFTRUK Ltd

The Croft, Sheen, Buxton, Derbyshire, SK170EU

Declare that the following equipment conforms to the Directive: 2000/14/EC (as amended) of the European Parliament and of the council on the

approximation of the laws of the Member States relating to the

Noise Emission in

the Environment by Equipment for Use Outdoors.

Equipment Category: Pedestrian Power Barrow

Product Name/Model: TRUXTA

Type/Serial No: B450G

The technical documentation is held by: TUFFTRUK Ltd Address above

The conformity assessment procedure followed was in according with annex VI

of the Directive.

Notified Body: AV Technology Ltd SK9 3RW

Measured Sound Power Level: 93 dB (LWA)

Guaranteed Sound Power Level: 96 dB (LWA)

A copy of this certificate has been submitted to the European Commission and to

EU Member State, United Kingdom

Place of Declaration: TUFFTRUK Ltd SK17 0EU

Date: 29/09/2014

Signed by: Ronald Blackhurst

Position in Company:. Managing Director

Name and address of manufacturer or Authorised representative: Tufftruk Ltd SK17 0EU

Page 7

DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

We

TUFFTRUK Ltd

The Croft, Sheen, Buxton, Derbyshire, SK170EU

Declare that the following equipment

conforms to the Directive: -

2000/14/EC (as amended)

of the European Parliament and of the council on the approximation of the laws of the Member States

relating to the

Noise Emission in the Environment by Equipment for Use Outdoors.

Equipment Category: Pedestrian Power Barrow

Product Name/Model: TRUXTA

Type/Serial No: B300E / B450E - ELECTRIC OPTIONS

The technical documentation is held by: TUFFTRUK Ltd Address above

The conformity assessment procedure followed was in according with annex VI of the Directive.

Notified Body: AV Technology Ltd SK9 3RW

Measured Sound Power Level: 69 dB

Guaranteed Sound Power Level: 69 dB

A copy of this certificate has been submitted to the European Commission and to EU Member State, United

Kingdom

Place of Declaration: TUFFTRUK Ltd SK17 0EU

Date: 29/09/2014

Signed by: Ronald Blackhurst

Position in Company:. Managing Director

Name and address of manufacturer or Authorised representative: Tufftruk Ltd SK17 0EU

Page 9

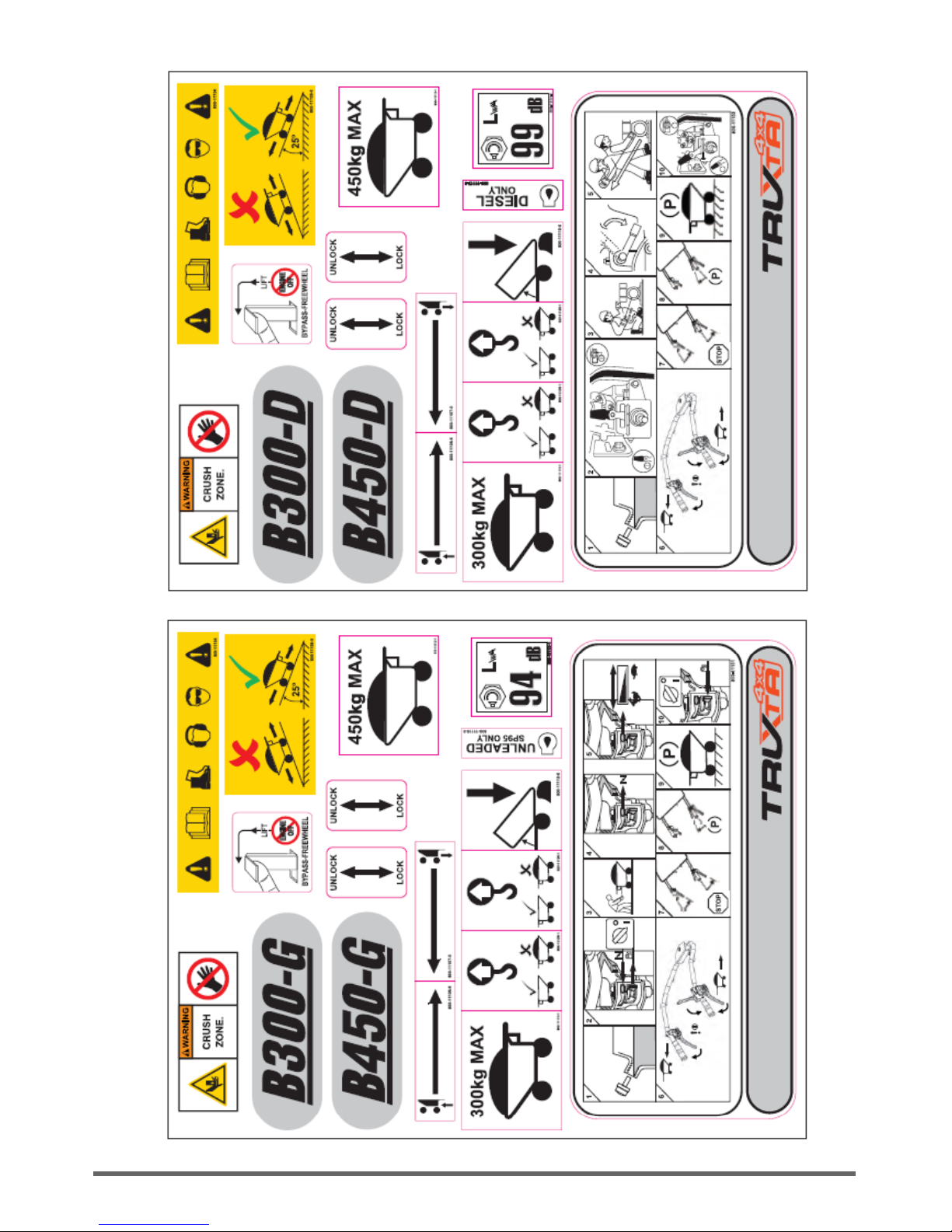

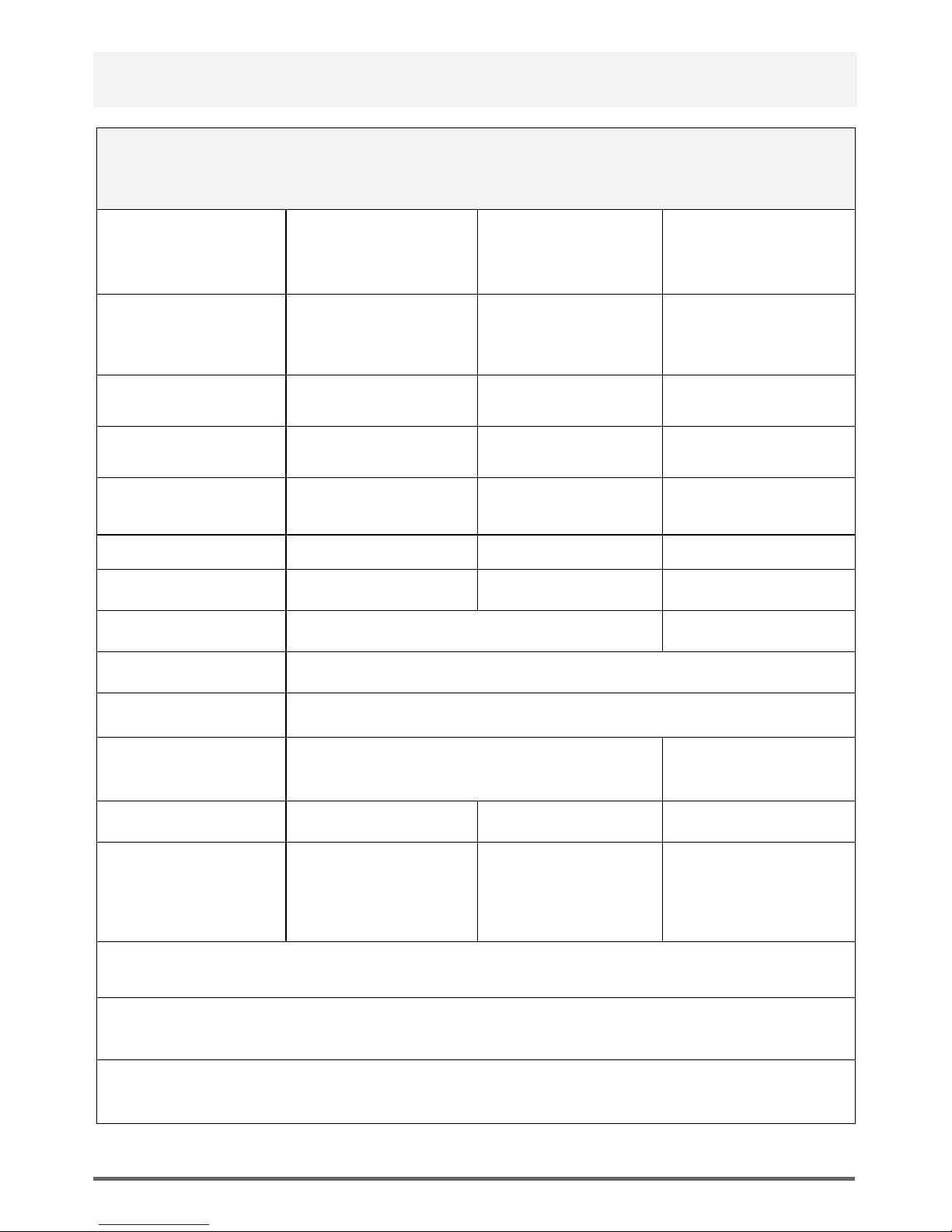

WARNING SYMBOLS & DECALS

TRUXTA BENDI - MACHINE SPECIFICATIONS

Model

Petrol B300G

(Petrol B450G)

Diesel B300D

(Diesel B450D)

Electric B300E

(Electric B450E)

Engine/Motor/Power

(kW)/hp

Honda GX 160 3.6 / 4.8

Honda GX200 4.1 / 5.5

Yanmar L48 3.5/ 4.7

Yanmar L48 3.5 / 4.7

DC Brushless

Motor 1000W /24v

Motor 1300W / 24v

Fuel Type

Unleaded Petrol (4 stroke)

Diesel 2 x 12v Batteries

Fuel Capacity

3.1 litres 2.5 litres

Max Payload (kg)

300kg / 7ft³ / 0.2m³

(450kg / 10.6ft³/ 0.3m³)

300kg /7ft³/ 0.2m³

(450kg / 10.6ft³/ 0.3m³)

300kg / 7ft³/ 0.2m³

(450kg / 10.6ft³ / 0.3m³)

Unladen Weight (kg)

170 (180)

201 (219) 224 (255)

Working Gradient

25° 25° 25°

Drive & Controls

Hydrostatic System 24v Motor Gearbox

Brake System

Fail-safe dead-man handle (International patents pending)

Standard Fitment Tyres

Flotation with option for turf tyres

Travel Speed

Fwd/Reverse

0-4 mph forward

0-1.5 mph reverse

0-3.5 mph forward

0-1.5 mph reverse

Noise Level (db.)

< 94 < 100 < 69

Hand Arm

Vibration

3.6 m/s²

4.6 m/s²

3.8 m/s²

3.8 m/s²

2.5 m/s²

2.5 m/s²

All dimensions unless otherwise stated are in mm.

We reserve the right to change specification without prior notice.

A 12 month warranty is applicable on all TRUXTA machines.

Page 10

GENERAL SAFETY

For your own personal protection and for the safety of those around you, please read and

ensure you fully understand the following safety information.

It is the responsibility of the operator to ensure that he/she fully understands how to operate

this equipment safely.

If you are unsure about the safe and correct use of the TRUXTA, consult your supervisor or

TRUXTA

This equipment is heavy and must not be lifted single-handedly, GET HELP and use suitable lifting

equipment.

Cordon off the work area and keep members of the public and unauthorized personnel at a safe distance.

Personal Protective Equipment (PPE) must be worn by the operator when ever this equipment is being used

(see Health & Safety).

Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into

difficulty.

Always switch OFF the engine before transporting, moving it around the site or servicing it.

During use the engine becomes very hot; allow the engine to cool before touching it. Never leave the engine

running and unattended.

Never remove or tamper with any guards fitted, they are there for your protection.

Always check guards for condition and Security, if any is damaged or missing, DO NOT USE THE

TRUXTA until the guard has been replaced or repaired.

Do not operate the machine when you are ill, feeling tired, or when under the influence of alcohol or drugs.

Do not stand the machine on end with the engine running.

Do not use the TRUXTA to transport people.

Do not release the brake suddenly when travelling forward at speed with a heavy load as the machine may

topple forward.

(Brake off). Close the throttle if necessary so that engine braking controls the speed.

Always ensure that when moving downwards on a hill, the machine is travelling in reverse.

Before refuelling, switch off the engine and allow it to cool.

When refuelling, DO NOT smoke or allow naked flames in the area.

Spilt fuel must be made safe immediately, by using sand. If fuel is spilt on your clothes, change them.

VIBRATION

Some vibration from the operation is transmitted through the handle to the operator’s hands. DO NOT

exceed the maximum usage times. (See Technical Data section)

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust

Mask and Steel Toe capped.

Footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any

jewellery which may catch in the equipment’s moving parts.

Petrol And Diesel Machines.

Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel splashes

immediately. If you get fuel in your eyes,

Irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

Do not operate the TRUXTA indoors or in a confined space, make sure the work area is adequately

ventilated.

Electric

Do not attempt to charge the electric machine if cable or connectors are damaged

Do not connect or disconnect the machine with wet hands immediately replace damaged charging parts

HEALTH AND SAFETY

Safe Disposal.

Instructions for the protection of the environment.

The machine contains valuable materials.

Take the discarded apparatus and accessories to the relevant recycling facilities.

ENVIRONMENT

Page 11

Page 12

OPERATING THE TRUXTA BENDI

1. Start the engine by putting the throttle to the run position and turning the ignition on.

(use choke if cold)

2. Grip the dead man lever and hold it down.

3. Use the forward and reverse levers to control direction of travel and speed.

Never press both levers at once or whilst the dead man is released as this will cause unnecessary

EMPTYING THE SKIP

1. Stop the machine by releasing the Drive Lever followed by releasing the dead man Brake Lever.

2. Once the machine has become stationary, pull the Skip Release Lever and the Skip will tip forwards

disposing of its contents.

3. When the Skip is empty, push back to its original position. The Skip will lock into place

PRE START UP INSPECTION

The following pre-start-up inspection must be performed before the start of each work session or after every

four hours of use, whichever is first.

Please refer to the service section for detailed guidance.

If any fault is discovered, the TRUXTA must not be used until the fault is rectified.

1. Thoroughly inspect the TRUXTA for signs of damage.

2. Check components are present and secure.

3. Check fluid lines, hoses filler openings, drain plugs and any other areas for signs of leakage.

Fix any leaks before operating.

4. Check the engine oil and fuel levels and top up as necessary.

5. Check the tyre pressures and top up as necessary.

6. Check for fuel and oil leaks.

Electric models

1. Check mains lead is stored correctly and is secured to the machine.

2. Check mains lead is not damaged in any way and replace as necessary.

OPERATING INSTRUCTIONS - PETROL AND DIESEL

Page 13

OPERATING THE PETROL TRUXTA B300G / B450G

Start the engine by putting the throttle to the run position and turning the ignition on.

(use choke if cold)

Grip the dead man lever and hold it down.

Use the forward and reverse levers to control direction of travel and speed. (Never press both

levers at once or whilst the dead man is released as this will cause unnecessary damage to the

machine.

Release the dead man to stop.

PETROL AND DIESEL - OPERATING INSTRUCTIONS

OPERATING THE L48 ELECTRIC START DIESEL TRUXTA B300D / B450D

Start the engine by turning the ignition key on. Move throttle to desired speed

Grip the dead man lever and hold it down.

Use the forward and reverse levers to control direction of travel and speed.

Never press both levers at once or whilst the dead man is released as this will cause

unnecessary damage to the machine.

TRANSMISSION BY-PASS FREEWHEEL FACILITY

This allows the Truxta to be moved without the engine running.

In the event of engine or drive belt failure it is possible to manually move the Truxta by lifting the by-pass

lever and locating to the left, then depress the yellow Deadman brake lever and the Truxta will now freewheel.

The By-pass lever is located next to the oil reservoir under the steering column.

THE BY-PASS LEVER MUST NOT BE LIFTED WITH THE ENGINE RUNNING.

SERVICE & MAINTENANCE - PETROL & DIESEL

Page 14

Hydrostatic Oil

Top up if oil is below minimum level when machine is cold. If there are any signs of leakage, stop using the machine

and contact your local dealer or Tufftruk ltd.

Machine Cleaning

Clean the machine after it has been used to prevent the collection of hardened debris. Hardened debris is very

difficult to remove. To clean it use an old brush or hand brush with water. Never pressure wash or hose down the

engine or electric motor housing. Clean only with a cloth or compressed air.

Air Filter - If it is dirty, proceed as follows:-

Foam Element - Wash the element in a solution of washing-up liquid and water. Allow the element to dry, then soak

in clean engine oil and squeeze out the excess oil. If the engine smokes during start-up then too much oil has been

left on the foam.

Paper Element - Tap the element on a hard surface or blow from inside using compressed air to remove any excess

dust within the filter. Replace every 200 hours or if it is extremely dirty.

Transmission Drive Chains

Clean and lubricate the 3 transmission drive chains once a year.

Every 20

hours

Every 50

hours

Every 200

hours

ROUTINE MAINTENANCE

ENGINE OIL

CHANGE

AIR FILTER

CHECK CONDITION

CLEAN / REPLACE

SPARK PLUG CHANGE

SPARK PLUG AND OIL DATA

Engine Oil

Type

Quantity

(gals)

Fuel Type

Capacity

(gals)

Spark

Plug

Electrode Gap

(mm)

Hydrostatic

Transmission Oil

PETROL

HONDA

S.A.E

10W30

0.17 UNLEADED 0.53 BPR5ES 0.07-0.8 20W50

YANMAR DIE-

SEL l48

SAE

5W-30

0.18 DIESEL 0.55 N/A N/A 20W50

POWER CIRCUIT—Diesel Electric Start

Page 15

SERVICE & MAINTENANCE - PETROL & DIESEL

PUMP CONTROL SETTINGS & ADJUSTMENT

FORWARD CONTROL CABLE

REARWARD CONTROL CABLE

DIRECTION SAFETY PIN

(SHOWN IN LOCKED POSITION)

CABLE ADJUSTMENT NUTS

PUMP NEUTRAL SETTING

SCREW

DEPRESS DEADMAN LEVER

TO DISENGAGE PIN

PUMP DIRECTION BRACKET

1: Adjust Deadman lever cable tension if required, see engage angle. Adjust cable adjustment nuts. With Deadman

lever in fully pressed position ensure the direction safety pin is clear of control plate (see above)

2: Adjust forward/reverse direction levers cable tension if

required, ensure 3mm - 5mm gap when fully pressed.

Adjust cable adjustment nuts.

3: Ensure that with forward lever fully pressed the pump

direction bracket turns

15 degree forward direction 75 rpm @ wheels

4: Ensure that with rearward lever fully pressed the pump

direction bracket turns

5 degree rearward direction 30 rpm @ wheels

PUMP NEUTRAL SETTING

1: Adjust pump neutral setting if required if machine creeps

forwards/backwards when in neutral,

disconnect forward and rearward control cables

fully press Deadman lever to disengage the direction safety

pin

loosen pump neutral setting screw

adjust angle of pump control bracket by rotating forward/

backward until no creep

re tighten pump neutral setting screw when wheel rotation is

0 rpm

CABLE

ADJUSTMENT

NUTS

DEADMAN LEVER

ENGAGE ANGLE

10-

20 degree

DEADMAN LEVER

FULLY PRESSED

POSITION

DIRECTION LEVERS

GAP TO HANDLE 5MM

WHEN FULLY

PRESSED

CHARGING THE ELECTRIC TRUXTA

TRUXTA has a built-in 24v charger

Turn off ignition switch.

Push in the large red button.

Connect the cable provided to a mains supply 110-230 v. Charger is dual voltage.

Check batteries are charging by observing small window on left hand side of battery box.

The CHARGING light is normally ORANGE which changes to GREEN when the battery is fully charged.

The charger is a Smart Charger, it can be left connected to the batteries after full charge (green light) without

harming batteries. The charger uses minimum power in this stand-by mode (after battery is fully charged),

maintains the batteries at full charge and extends battery life.

MACHINE CLEANING

Clean the machine after it has been used to prevent the collection of hardened debris. Hardened debris is very

difficult to remove. To clean it use an old brush or hand brush with water. Never pressure wash or hose down the

electric motor housing. Clean only with a cloth or compressed air.

TRANSMISSION DRIVE CHAINS

Clean and lubricate the 3 transmission drive chains once a year.

OPERATING INSTRUCTIONS & CHARGING - ELECTRIC TRUXTA

OPERATING THE TRUXTA

Pull out large red button. (DEADMAN KILL SWITCH)

Turn ignition key on.

Depress dead man lever (yellow) on right hand controls.

To Move Forward — squeeze right hand lever to move forward.

To Reverse — squeeze and hold left hand lever, then squeeze the right hand

lever to move the machine in reverse.

STOPPING THE TRUXTA

Release the right hand lever to stop the machine

Release the dead man yellow lever to engage the parking brake

In emergencies hit the large red button (DEADMAN KILL SWITCH)

When machine is not in use, always push in the large red button.

PARKING BRAKE

The Parking Brake operates automatically when the dead man lever (yellow)

is in the upright position.

The brake is on until the dead-man (yellow) lever is compressed to release it.

MOVING the TRUXTA with NO POWER

For manual brake release when the machine has no power

Push brake release lever forward and hold

Page 16

ELECTRIC TRUXTA - WARNING SYMBOLS & DECALS

Page 17

Page 18

ELECTRIC TRUXTA - WIRING DIAGRAM - DIAGNOSTICS & TROUBLESHOOTING

ELECTRIC TRUXTA - DIAGNOSTICS & TROUBLESHOOTING

TRUXTA Electric Service Diagnostics

The 1229 controller detects a wide variety of faults or error conditions.

Diagnostic information can be obtained through the 3100R fuel gauge display where an error code in the

format “Err ##”; the codes are listed in Table 4.

The troubleshooting chart (Table 5) describes the faults and their possible causes; the faults are listed in

alphabetical order.

Whenever a fault is encountered and no wiring or vehicle fault can be found, shut off KSI and turn it back

on to see if the fault clears. If it does not, shut off KSI and remove the 35-pin connector. Check the

connector for corrosion or damage, clean it if necessary, and re-insert it.

Page 19

DIAGNOSTICS & TROUBLESHOOTING - TRUXTA ELECTRIC

Page 20

ELECTRIC TRUXTA - DIAGNOSTICS & TROUBLESHOOTING

Page 21

TOP FRAME - PARTS LIST

Page 22

ITEM NO. PART NUMBER DESCRIPTION QTY NOTES

1 101-00400-N TOP FRAME WA 1

2 101-00800-H REAR STEERING PIVOT WA 1

3 101-01000-I HANDLE AND PIVOT WA 1

4 101-00901-C ROD STEERING 1

5 3-5026-0 ROD END M10 RH 2

6 8-10003-1 NUT M10 BZP 1

7 8-10005-0 NUT M10 THIN LH 1

8 101-99914-F PRESSING TIP HANDLE 1

9 102-99939-2 SPACER TIP LEVER 1

10 101-99945-F ENGINE COVER 1

11 53-0160-0 BEARING BALL 42x25x9 2

12 72-0200-0 MOULDING TIP HANDLE 1

13 75-01500-3 CABLE ASSY FWD 2

14 75-01700-0 CABLE ASSY DEADMAN 1

15 75-00900-A CABLE SKIP RELEASE (B) 1

16 75-01900-0 CABLE ASSY FWD ELECTRIC 1 ELECTRIC OPTION

17 75-02000-0 CABLE ASSY DEADMAN ELECTRIC 1 ELECTRIC OPTION

18 75-02100-0 CABLE ASSY REV ELECTRIC 1 ELECTRIC OPTION

19 74-1022-0 HANDLE GRIP 2

20 7-10130-0 COACHBOLT M10 X 30 1

21 2-1100 DAMPER ASSEMBLY 1

22 74-1023-0 HINGE 50x50x6 2

23 4-1005-1 WASHER FLAT M10 FORM A BZP 5

24 8-10006-0 NUT M10 NYLOC 4

25 7-6056-A M6 X 15 BUTTON HD CAP 4

26 4-6001-1 WASHER M6 FORM A BZP 8

27 7-6007-0 SCREW - 6 X 15 CSK SCREW BZP 4

28 4-6018-0 WASHER M6 X 20 X1.2 BZP 4

29 8-6007-0 NUT M6 NYLOC 8

30 4-8006 WASHER M8 FORM A BZP 2

31 8-8008-0 NUT M8 NYLOC BZP 2

32 9-10012-0 BOLT M10 X 60 BZP 1

33 7-10005-0 SCREW SET M10 X 25 BZP 1

34 7-8080-0 BOLT M8 X 20 HEX BZP 6

TOP FRAME - STEERING ASSEMBLY

Page 23

800-18003-0

25/04/16

Page 24

FRONT CHASSIS - PARTS LIST

ITEM

NO.

PART NUMBER DESCRIPTION QTY NOTES ITEM NO. PART NUMBER DESCRIPTION QTY NOTES

1 101-03300-I CHASSIS FRONT WA 1 40 53-0130-0 BEARING BALL 26x10x8 2

2 101-99908-B PRESSING MIDDLE COVER 1 41 53-0170-0 BEARING BALL 25x47x12 1

3 101-04100-D GIMBLE WA KEYED 1 42 21-2100-0 CHAIN 5/8" 67R FRONT 1

4 101-04000-C CENTRE STEERING PIVOT WA KEYED 1 43 2-1001-2 TENSIONER ASSEMBLY 2

5 101-00500-G ` 1

SERIAL NO UPTO

B151049

44 4-9021-0 WASHER 3/4" ID X 38 x 2.0 2

6 101-00100-K GIMBLE WA 3/4" 1

SERIAL NO UPTO

B151049

45 7-10050-0 WHEEL STUD 3/8"X24UNF 8

7 3-0093-0 PIN SPIROL 8 X 50 LONG 2

SERIAL NO UPTO

B151049

46 4-9031-0 WASHER 50X8.5X1.5 BZP 6

8 4-8006 WASHER M8 FORM A BZP 14 47 21-1500-0 COG 13T 66.32PCD 1

9 7-8061-1 SCREW SET M8 X 70mm (PLAIN) 1 48 7-6031-0 SCREW GRUB M6 X 12 2

10 4-8003 WASHER M8 SPRING BZP 2 49 21-1200-0 KEY 3/16"SQ X 40mm 3

11 102-99921-9 PRESSING BE ARING FRONT 1 50 8-3800-0 WHEEL NUT - 3/8" UNF 8

12 101-99961-B COVER BEARING FRONT 1 51 8-6011-0 RIVNUT M6 HEXAGON 8

13 102-99948-C PRESSING FRONT COVER 1 52 8-8011-0 RIVNUT M8 HEXAGON 4

14 101-99943-B SPACER BEARING COVER 1 53 102-99940-3 BOSS TENSIONER SUPPORT 2

15 101-99942-B PLATE BEARING COVER 1 54 104-99913-2 BOSS TENSIONER SPACER 1

16 21-1600-0 KEY 6X6X25 1 55 3-1050-0 CLIP-E (TO SUIT DIA 12 SHAFT) 2

17 70-5011-1 NUT 25mm BULK HD 1 56 7-10003-0 SCREW SET M10 X 35 BZP 2

18 70-5030-0 CABLE GLAND 1 57 7-8088-0 BOLT M8 X 60 HEX BZP 1

19 72-1000-0 BLANKING PLUG 25MM 1 58 8-10006-0 NUT M10 NYLOC 4 DIESEL OPTION

20 101-01200-E SKIP CATCH BRACKET WA 1 59 8-10003-1 NUT M10 BZP 2

21 101-02100-4 FRAME SKIP CARRIER W.A 1 60 4-1204-1 WASHER M12 FORM A BZP 2

22 101-02901-E PLATE SKIP CATCH 1 61 9-8067-0 BOLT M8 X 25 COACH 2

23 101-99929-3 PRESSING TIP RETAINER 2 62 8-8008-0 NUT M8 NYLOC BZP 6

24 2-1012-0 SPRING INNER 1 63 7-8080-0 BOLT M8 X 20 HEX BZP 24

25 2-1013-0 SPRING OUTER 1 64 7-8037

DIFF BOLT 5/16" UNC X 4" FLANGED

HEAD

4

26 3-0091 PIN LATCH PIVOT 1 65 8-8024-0 NUT 5/16" UNC NYLOC BZP 6

27 2-1007-1 SPRING EXT (RETAINER CATCH) 2 66 7-6060-0 SCREW M6 X 14 SER HD BZP 8

28 100-00500-7 SKIP 300 W.A. 1 BENDI 300 67 7-8007-0 BOLT M8 X 35 BZP 1

29 100-01100-D SKIP 450 W.A. 1 BENDI 450 68 101-99957-A PRESSING BATTERY CARRIER 1 DIESEL OPTION

30 6-1200-0 DIFFERENTIAL AXLE FRONT - 100-248EP-18024 1 69 101-99958-B BRACKET BATTERY CLAMP 1 DIESEL OPTION

31 102-03100-4 HUB W.A. 2 70 70-2900-1 BATTERY 12V 101E 1 DIESEL OPTION

32 104-99925-0 GEAR 22T PCD111.55 1 71 9-10033-0 M10 X 220 COACHBOLT 2 DIESEL OPTION

33 104-99926-0 COG 8T 41.48PCD 2 72 4-1004-0 WASHER M10 FORM C BZP 2 DIESEL OPTION

34 60-6509RHF-0 WHEEL ASSY 16X6.5X8 RHS FLOAT 1 73 70-0138-0 FUSE INLINE 70A FLAT DIA6 1 DIESEL OPTION

35 60-6509LHF-0 WHEEL ASSY 16X6.50X8 LHS FLOAT 1 74 70-0130-0 FUSE HOLDER INLINE 1 DIESEL OPTION

36 72-0400-0 MOULDING HUB COVER 2 75 70-0144-0

POWER CABLE +VE 1200MM 6/6

DIESEL

1 DIESEL OPTION

37 3-1061-0 CLIP E- 3/4" SHAFT 2 76 70-0145-0

POWER CABLE -VE 1200MM 6/6

DIESEL

1 DIESEL OPTION

38 53-0110-1 BEARING BALL 25 bore mounted 2 77 70-0146-0

POWER CABLE +VE 300MM 6/6

DIESEL

1 DIESEL OPTION

39 53-0120-0 BEARING BALL 19.05 bore mounted 5

Page 25

FRONT CHASSIS - ASSEMBLY

800-18002-0

19/04/16

Page 26

REAR ASSEMBLY PARTS LIST - ALL ENGINES

ITEM NO. PART NUMBER DESCRI PTION QTY NOTES ITEM NO. PART NO DESCRIPTION QTY. NOTES

1 101-03200-J REAR CHASSIS WA 1 57 101-99926-0 PRESSING FOOT BRKT HONDA 1 PETROL OPTION

2 101-04400-A REAR CHASSIS WA 1 SERIAL B151040 - B151049 58 101-99927-0 PRESSING DRAIN BRKT HONDA 1 PETROL OPTION

3 53-0120-0 BE ARING BALL 19.05 bore mounted 5 SERIAL B151040 - B151049 59 21-3040-0 PULLEY SPA100-01 TPL1610 0.75 1 PETROL OPTION

4 2-1009-0 TENSIONER SE11 1 SERIAL B151040 - B151049 60 20-1600-1 HONDA GX160 1 PETROL OPTION

5 101-99956-D PRESSING ENGINE DECK 1 61 20-2000-0 ENGINE HONDA GX200 UT2 QX4 1 450 SKIP OPTION

6 101-99960-B COVER BEARING REAR 1 62 21-0500-0 A V MOUNT 30x15xM8 4 PETROL OPTION

7 101-99943-B SPACER BEARING COVER 1 63 21-0800-0 KEY 3/16"SQ X 2" X 30MM LG 1 PETROL OPTION

8 101-99942-B PLATE BEARING COVER 1 64 20-4801-0 Diesel Engine L48N 1 DIESEL OPTION

9 101-99917-F PRESSING REAR COVER 1 65 101-99921-1 PRESSI NG YANMAR FOOT BRKT 2 DIESEL OPTION

10 72-1000-0 BLANKING PLUG 25MM 1 66 101-99933-B PRESSING ENG. MOUNTING L48 (B) 1 DIESEL OPTION

11 101-99951-C COVER REAR UNIT 1 67 101-99936-A PRESSING L48 CORNER MOUNT 1

12 70-5010-0 FITTING DIA 25MM BULK HD 1 68 21-0510-0 A V MOUNT 40x30xM8 2

13 70-5002-0 BULK HD CLAMP NUT 1 69 21-0530-0 A V MOUNT 50x20xM10 2 DI ESEL OPTION

14 6-2000-0 TRANSMISSION UNIT 1 70 4-8006 WASHER M8 FORM A BZP 45

15 101-03600-F BR ACKET BASE WA 1 71 8-8008-0 NUT M8 NYLOC BZP 24

16 101-99947-F BRACKET LEVER DIRECTION 1 72 21-1000-0 KEY 3/16" X 23MM LONG 1 DIESEL OPTION

17 101-99949-E BRACKET CORNER UPPER 1 73 7-8011-0 BOLT M8 X 20 HEX BZP 3

18 101-99948-E PLATE BRAKE LOCK 1 74 21-3070-0 PULLEY SPA71/01 HT6 WITH TPL1210 0.75 1 B450D OPTION

19 9-10034-0 SHOULDER BOLT M10 X 16 1 75 21-3060-0 PULLEY SPA80/01 HT6 WITH TPL1210 0.75 1 DIESEL OPTION

20 101-99953-C BRACKET EXP TANK 1 76 21-3050-0 BELT - A18 1 DIESEL OPTION

21 101-99962-A BRACKET DAMPENER 1 77 7-8004-0 SCREW SET M8 X 12 HTS BZP 6

22 101-99952-C PLATE PUMP OVERRIDE 1 78 4-8003 WASHER M8 SPRI NG BZP 8

23 6-2001-0 EXPANSION TANK 71328 1 79 4-1003-0 WASHER - M10 SPRING BZP 2

24 2-1300-0 DAMPENER STRUT 1 80 4-1007-A WASHER FLAT M10 FORM A BZP 4

25 8-19001-0 UNF 3/4" NUT 1 81 8-10006-0 NUT M10 NYLOC 6

26 6-0001-0 ADAPTOR ST 7/16" UNC-1/4" BSP SS 1 82 7-10004-1 SCREW SET M10 X 20 BZP 2

27 6-0002-0 ELBOW 90DEG F-M 1/4" BSP - 1/4" BSPT SS 1 83 21-1800-0 KEY 8x7X40 LG ROUND END 1

28 6-0003-0 HOSE PINCH CLIP 17/20 2 84 7-8010-0 SCREW CAP M8X25MM SCKT HD BZP 4

29 6-0004-0 PIPE 3/4" REINFORCED CLEAR 1 85 21-1700-0 KEY 5x5x20 LG ROUND END 1

30 2-1010-0 SPRING EXT 1 86 7-8007-0 BOLT M8 X 35 BZP 8

31 2-1011-0 SPRING EXT 12.7X1.63X50.8 ENTEX 2128 1 87 72-1300-0 BOOT RA 16ID 8ID 2

32 6-1300-0 DIFFERENTIAL AXLE REAR 1 88 8-6011-0 RIVNUT M6 HEXAGON 6

33 101-99954-B PLATE BEARING REAR 1 89 8-8011-0 RIVNUT M8 HEXAGON 25

34 102-03100-5 HUB W.A. 2 90 800-11120-0 DECAL SHEET PETROL 1

35 53-0110-1 BE ARING BALL 25 bore mounted 3 91 9-8020-0 BOLT M8 X 60 BZP 2

36 60-6509RHF-0 WHEEL ASSY 16X6.5X8 RHS FLOAT 1 92 9-8022-0 BOLT M8 X 70 BZP 3

37 60-6509LHF-0 WHEEL ASSY 16X6.50X8 LHS FLOAT 1 93 7-8080-0 BOLT M8 X 20 HEX BZP 43

38 72-0400-0 MOULDING HUB COVER 2 94 4-6001-1 WASHER M6 FORM A BZP 4

39 3-1061-0 CLIP E- 3/4" SHAFT 2 95 7-6037-0 1/4 UNF BY 5/8 LG SET SCREW 2

40 8-3800-0 WHEEL NUT - 3/8" UNF 8 96 8-6007-0 NUT M6 NYLOC 2

41 21-1200-0 KEY 3/16"SQ X 40mm 2 97 7-6060-0 SCREW M6 X 14 SER HD BZP 10

42 104-99926-0 COG 8T 41.48PCD 3 98 7-8012-0 BOLT M8 X 25 BZP 4

43 101-03700-E SHAFT OUPTU DRIVE WA 1 99 7-4014-0 SCREW M4 X 20 HEX HD SET 1

44 104-99925-0 GEAR 22T PCD111.55 1 100 4-4001 WASHER M4 FORM A BZP 2

45 102-99940-3 BOSS TENSIONER SUPPORT 1 101 8-4005-0 M4 NYLOCK BZP 1

46 53-0130-0 BE ARING BALL 26x10x8 3 102 4-1004-0 WASHER M10 FORM C BZP 1

47 53-0170-0 BEARING BALL 25x47x12 1 103 4-9021-0 WASHER 3/4" ID X 38 x 2.0 2

48 21-1500-0 COG 13T 66.32PCD 1 104 8-8024-0 NUT 5/16" UNC NYLOC BZP 4

49 21-1600-0 KEY 6X6X25 1 105 7-10050-0 WHEEL STUD 3/8"X24UNF 8

50 7-6031-0 SCREW GRUB M6 X 12 2 106 7-8037 DIFF BOLT 5/16" UNC X 4" FLANGED HEAD 4

51 21-2080-0 CHAIN REAR 5/8" SHORT 1 107 7-10003-0 SCREW SET M10 X 35 BZP 3

52 21-2090-0 CHAIN REAR LONG 5/8" 1 108 8-10003-1 NUT M10 BZP 3

53 21-0650-E ASSEMBLY DRIVE JOINT 1 109 4-5002-0 WASHER M5 FORM A BZP 2

54 2-1001-2 TENSIONER ASSEMBLY 3 110 8-5003-1 NUT NYLOC M5 2

55 4-9031-0 WASHER 50X8.5X1.5 BZP 6 111 9-8067-0 BOLT M8 X 25 COACH 2

56

21-3030-0 BELT - A22 1 PETROL OPTION 112 4-8004-1 WASHER M8 X 30 X 3 1

Page 27

REAR ASSEMBLY - ALL ENGINE MODELS

800-18000-0

19/04/16

Page 28

ELECTRIC REAR ASSEMBLY - PARTS LIST

ITEM NO. PART NUMBER DESCRIPTION QTY NOTES

1 101-03200-J REAR CHASSIS WA 1

2 101-99960-B COVER BEARING REAR 1

3 101-99943-B SPACER BEARING COVER 1

4 101-99942-B PLATE BEARING COVER 1

5 70-5010-0 FITTING DIA 25MM BULK HD 1

6 70-5002-0 BULK HD CLAMP NUT 1

7 6-1300-0 DIFFERENTIAL AXLE REAR 1

8 102-03100-5 HUB W.A. 2

9 53-0120-0 BEARING BALL 19.05 bore mounted 4 SERIAL B161056-B161064

10 53-0110-1 BEARING BALL 25 bore mounted 3

11 60-6509RHF-0 WHEEL ASSY 16X6.5X8 RHS FLOAT 1

12 60-6509LHF-0 WHEEL ASSY 16X6.50X8 LHS FLOAT 1

13 72-0400-0 MOULDING HUB COVER 2

14 3-1061-0 CLIP E- 3/4" SHAFT 2

15 8-3800-0 WHEEL NUT - 3/8" UNF 8

16 21-1200-0 KEY 3/16"SQ X 40mm 2

17 104-99926-0 COG 8T 41.48PCD 3

18 104-99925-0 GEAR 22T PCD111.55 1

19 53-0130-0 BEARING BALL 26x10x8 3

20 53-0170-0 BEARING BALL 25x47x12 1

21 21-1500-0 COG 13T 66.32PCD 1

22 21-1600-0 KEY 6X6X25 1

23 7-6031-0 SCREW GRUB M6 X 12 2

24 21-0650-E ASSEMBLY DRIVE JOINT 1

25 2-1001-2 TENSIONER ASSEMBLY 3

26 4-9031-0 WASHER 50X8.5X1.5 BZP 6

27 7-6060-0 SCREW M6 X 14 SER HD BZP 18

28 4-6001-1 WASHER M6 FORM A BZP 2

29 8-6007-0 NUT M6 NYLOC 4

30 102-99940-3 BOSS TENSIONER SUPPORT 2

31 7-8012-0 BOLT M8 X 25 BZP 5

32 4-8003 WASHER M8 SPRING BZP 4

33 4-8006 WASHER M8 FORM A BZP 18

34 101-99964-A TOP COVER BATTERY BOX 1

35 101-99965-A PRESSING ELECTRIC CENTRE COVER 1

36 101-03800-D BATTERY BOX W.A. 1

37 101-99946-D BATTERY CLAMP 1

38 70-3000-0 Battery 24-AGM 2

39 70-3100-0 Battery 27AGM 2

40 70-0128-0 CURTIS SOL 24V CO 1

41 70-0129-0 CURTIS DC MOTOR CONTROLLER 1

42 70-0130-0 FUSE HOLDER INLINE 1

43 101-99966-B BRAKE PIVOT BRACKET 1

44 70-0134-0 BATTERY CHARGER 1

45 70-0137-0 240V 16A SKT INLET IN0021 1

46 101-99973-C BEARING REAR BRACKET 1

47 70-0800-0 MOTOR 1000W 1 SERIAL B161056-B161064

48 6-1500-0 GEARBOX 30:1 30MM BORE 71B14 1 SERIAL B161056-B161064

49 101-03500-B BRACKET ELECTRIC GEARBOX 1 SERIAL B161056-B161064

50 101-04200-B OUTPUT SH AFT ELETRIC 1 SERIAL B161056-B161064

51 101-99968-A BR ACKET AXLE BEARING ELECTRIC 1 SERIAL B161056-B161064

52 101-99963-B PRESSING REAR COVER ELECTRIC 1

53 70-01200-0 MOTOR 1300W 1

54 6-2200-0 GEARBOX 1300W 1

55 21-1800-0 KEY 8x7X40 LG ROUND END 1

56 7-8010-0 SCREW CAP M8X25MM SCKT HD BZP 4

57 21-1700-0 KEY 5x5x20 LG ROUND END 1

58 6-2100-0 GEARBOX TKM48B 71B5 1

59 70-01000-0 MOTOR 1000W 1

60 7-8007-0 BOLT M8 X 35 BZP 4

61 8-8008-0 NUT M8 NYLOC BZP 9

62 101-04300-A OUTPUT SHAFT ELETRIC 1

63 101-99967-A BRACKET CABLE WRAP 1

64 72-1600-0 GROMMET 20MM 1

65 21-2200-0 CHAIN ELECTRIC 1ST 1

66 21-2400-0 CHAIN 2 5/8" 1

67 101-99969-A BRAKE DISENGAGE LEVER 1

68 9-10033-0 M10 X 220 COACHBOLT 2

69 70-0136-0 IGNITION SWITCH 1

70 70-0127-0 CURTIS ED125 1

71 70-0135-0 FUSE HOLDER SCI R3-14 250V 10A 1

72 70-0142-0 FUSE 10A ROUND 1

73 70-0133-0 CURTIS 906R24HGAAO 1

74 101-99972-B BASE BRACKET GEARBOX 1

75 101-99971-C CABLE CLAMP BRACKET 1

76 70-0131-0 FUSE INLINE 125A FLAT DIA6 1

77 70-0121-0 POWER CABLE -VE 400MM 8/8 1

78 70-0122-0 POWER CABLE +VE 650MM 8/6 1

79 70-0123-0 POWER CABLE +VE 400MM 8/6 1

80 70-0124-0 POWER CABLE -VE 600MM 8/6 1

81 70-0125-0 POWER CABLE +VE 125MM 8/6 1

82 70-0126-0 POWER CABLE +VE 850MM 8/6 1

83 70-0132-0 FUSE INLINE 100A FLAT DIA6 1

84 72-1100-0 PVC CAP RED DIA10 X 25 LONG 1

85 70-0139-0 POWER CABLE UK PLUG 1

86 72-1300-0 BOOT RA 16ID 8ID 2

87 101-99970-C BRACKET POTENTIOMETER 1

88 101-99975-A CLAMP LEVER POTENTIOMETER 1

89 101-03900-D MOTOR COVER WA 1

90 70-6000-0 CABLE HARNESS 1

91 8-8011-0 RIVNUT M8 HEXAGON 10

92 8-6011-0 RIVNUT M6 HEXAGON 12

93 800-11122-0 DECAL SHEET ELECTRIC 1

94 4-9021-0 WASHER 3/4" ID X 38 x 2.0 2

95 8-8024-0 NUT 5/16" UNC NYLOC BZP 4

96 7-10050-0 WHEEL STUD 3/8"X24UNF 8

97 7-8080-0 BOLT M8 X 20 HEX BZP 28

98 7-8037 DIFF BOLT 5/16" UNC X 4" FLANGED HEAD 4

99 7-10003-0 SCREW SET M10 X 35 BZP 3

100 8-10003-1 NUT M10 BZP 2

101 8-10006-0 NUT M10 NYLOC 5

102 4-5002-0 WASHER M5 FORM A BZP 1

103 8-5003-1 NUT NYLOC M5 2

104 9-8067-0 BOLT M8 X 25 COACH 2

105 4-1004-0 WASHER M10 FORM C BZP 2

106 4-8004-1 WASHER M8 X 30 X 3 1

107 7-10100-0 BOLT M10 X 30 HEX BZP 4

108 72-1400-0 SPACER F/R SW 1

109 70-0140-0 POTENTIOMETER CURTIS CM4475 1

110 70-0141-0 MICROSWITCH ROLLER 1

111 72-1500-0 SPACER THIN F/R SW 1

112 2-1010-0 SPRING EXT 1

113 2-1014-0 SPRING EXT 1

114 7-6037-0 1/4 UNF BY 5/8 LG SET SCREW 3

115 8-6001-0 NUT M6 BZP 3

116 7-5025-0 M5 X 25 BZP 1

117 7-3013-0 M5 X 20 SCREW HEX HD BZP 2

Page 29

ELECTRIC REAR ASSEMBLY

800-18001-0

19/04/16

TRUXTA ATTACHMENTS: FLAT BED & TOW BALL - PARTS LIST

TOW BALL ATTACHMENT FOR TRUXTA

ITEM NO. PART NUMBER DESCRIPTION QTY.

1 73-1500-B HANDLE TOW ATTACHMENT 1

2 73-1400-A TOW BALL C/W CLEVIS PIN 1

3 73-1300-C BODY TOW ATTACHMENT 1

4 74-1022-0 HANDLE GRIP 1

FLAT BED ATTACHMENT FOR TRUXTA

ITEM NO. PART NUMBER DESCRIPTION QTY NOTES

1 73-0100-H FLAT BED W.A. 1

2 73-0111-C FLAT BED BASE 1

3 73-0112-B FLAT BED REAR 1

4 73-0900-G FLATBED REAR WA 1

5 8-10006-0 NUT M10 NYLOC 20

6 4-1005-1 WASHER FLAT M10 FORM A BZP 20

7 7-10041-0 COUNTERSUNK M10 X 40 BZP 10

8 7-10004-1 SCREW SET M10 X 20 BZP 6

9 OPTT13-DIO-0 LOAD STOPS FLATBED ATT 1 LOAD STOPS OPTION

10 7-10005-0 SCREW SET M10 X 25 BZP 4

11 73-0120-A FLAT BED REAR 450 1 450 OPTION

12 73-0119-A FLAT BED BASE 450 1 450 OPTION

Page 30

Page 31

Your new TRUXTA is warranted to the original purchaser for a period of one-year (12 months) from the original date

of purchase.

The TRUXTA warranty is against defects in design, materials and workmanship.

The following are not covered under the TRUXTA warranty:

1. Damage caused by abuse, misuse, dropping or other similar damage caused by or as a result of failure to follow

assembly, operation or user maintenance instructions.

2. Alterations, additions or repairs carried out by persons other than Tufftruk or their recognised agents.

3. Transportation or shipment costs to and from TRUXTA or their recognised agents, for repair or assessment against

a warranty claim, on any machine.

4. Materials and /or labour costs to renew repair or replace components due to fair wear and tear the following

components are not covered by warranty.

· Drive belt · Engine air filter · Engine spark plug

TRUXTA and/or their recognised agents, directors, employees or insurers will not be held liable for consequential or

other damages, losses or expenses in connection with or by reason of or the inability to use the machine for any

purpose

Warranty Claims

All warranty claims should firstly be directed to the point of purchase: your TRUXTA reseller / distributor

Keep a record of the warranty form for your records

For warranty claims: Tel 01666 500123 or Email; truxtasales@tufftruk.co.uk

Any warranty issues please do contact your place of purchase.

To Register your Warranty please complete the warranty form and post to

TRUXTA SALES

Unit 1 Hampton Street Ind Est.

Hampton Street

Tetbury, Glos

GL8 8LD

Tel 01666 500123

truxtasales@tufftruk.co.uk

Alternatively scan / photocopy and Email the completed warranty form to truxtasales@tufftruk.co.uk

Also for your records , please complete this warranty registration in operator manual.

DATE OF PURCHASE

……………………………………………………………………...……………………………..

PLACE OF PURCHASE/ COMPANY

…………………………………………………………………….………………………………..

CUSTOMER NAME

……………………………………………………………….……………………………………..

ADDRESS

………………………………..…………..…………….………………………………………..

MACHINE MODEL NO

…………………………………..……………………...………………………………………..

SERIAL NO OF MACHINE

……………………………………………………………………………..……………………..

WARRANTY REGISTRATION FORM

UK & EIRE

TRUXTA SALES

UNIT 1

HAMPTON STREET IND EST

HAMPTON STREET

TETBURY

GLOUCESTERSHIRE

GL8 8LD

Tel 01666 500123

truxtasales@tufftruk.co.uk

Op Manual 06/06/2016

Your local TRUXTA Dealer

EUROPE / ROW

TRUXTA

TUFFTRUK LTD

THE CROFT

SHEEN

BUXTON

DERBYSHIRE

SK17 0EU

Tel 00 44 01298 84687

office@tufftruk.co.uk

Loading...

Loading...