Toshiba SL-9000N-FFH-QR, SL-9000-FFH-CA, SL-9000-FFH-QR, EM1-31076EE, SL-9000N-FFH-US User Manual

...

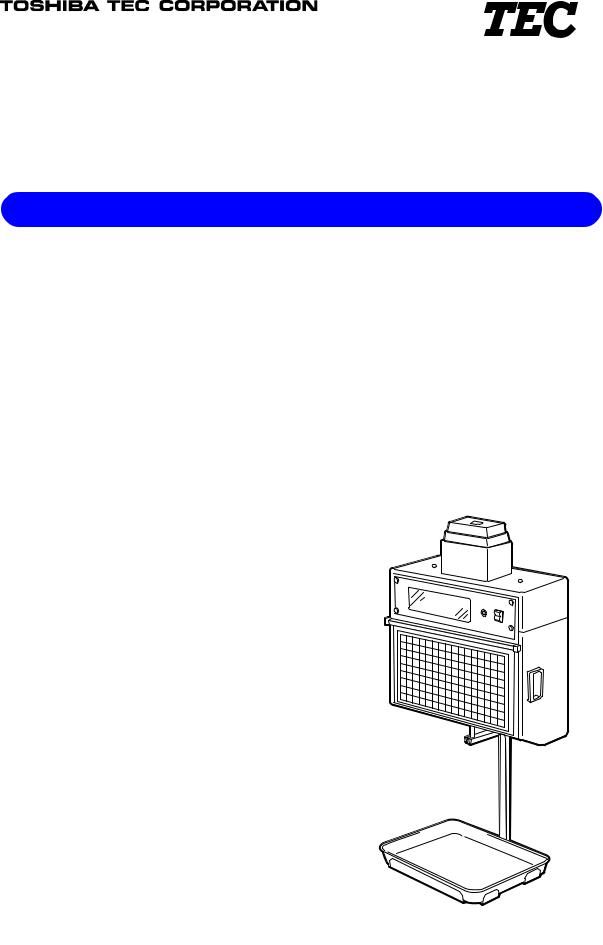

TEC Electronic Computing Scale

SL-9000/9000N-FFH-US/CA/QR

Owner’s Manual

TABLE OF CONTENTS

|

|

|

Page |

|

1. |

INTRODUCTION ..................................................................................................... |

1- |

1 |

|

|

1.1 |

APPLICABLE MODEL ................................................................................... |

1- |

2 |

|

1.2 |

ACCESSORIES............................................................................................. |

1- |

2 |

2. |

SPECIFICATION ..................................................................................................... |

2- |

1 |

|

|

2.1 |

SCALE .......................................................................................................... |

2- |

1 |

|

2.2 |

OPTION ........................................................................................................ |

2- |

2 |

3. |

APPEARANCE........................................................................................................ |

3- |

1 |

|

4. |

DISPLAY................................................................................................................. |

4- |

1 |

|

|

4.1 |

US TYPE....................................................................................................... |

4- |

1 |

|

4.2 |

CA/QR TYPE ................................................................................................ |

4- |

2 |

5. |

KEY LAYOUT ......................................................................................................... |

5- |

1 |

|

|

5.1 |

PROGRAMMING KEYBOARD....................................................................... |

5- |

1 |

|

5.2 |

OPERATION KEYBOARD AND SPEED KEYBOARD.................................... |

5- 3 |

|

6. |

PROCEDURE BEFORE OPERATION..................................................................... |

6- |

1 |

|

7. |

INSTALLATION PROCEDURE ............................................................................... |

7- |

1 |

|

8. |

REMOVAL AND REPLACEMENT OF RECEIPT/LABEL......................................... |

8- |

1 |

|

9. |

OUTLINE OF OPERATION ..................................................................................... |

9- |

1 |

|

10. |

PROGRAMMING PROCEDURES ........................................................................... |

10- 1 |

||

|

10.1 |

PLU DATA EDIT............................................................................................ |

10- 4 |

|

|

10.2 |

PLU DATA SETTING .................................................................................... |

10- 5 |

|

|

10.3 |

INGREDIENT MESSAGE .............................................................................. |

10- 7 |

|

|

10.4 |

NUTRITION SETTING................................................................................... |

10- 8 |

|

|

10.5 |

PLU VERIFYING LABEL ............................................................................... |

10-12 |

|

|

10.6 |

ADDRESS AND COMMERCIAL MESSAGE SETTING .................................. |

10-13 |

|

|

10.7 |

COMBINATION MESSAGE ........................................................................... |

10-14 |

|

|

10.8 |

SPECIAL INFORMATION.............................................................................. |

10-16 |

|

|

10.9 |

GRADE LINE................................................................................................. |

10-16 |

|

|

10.10 |

SPEED KEY SETTING.................................................................................. |

10-17 |

|

|

10.11 |

PRINT FORMAT............................................................................................ |

10-18 |

|

|

10.12 |

DATE/TIME SETTING ................................................................................... |

10-20 |

|

|

10.13 |

CMT/PL-3...................................................................................................... |

10-20 |

|

|

10.14 |

IN-LINE/LOCAL ............................................................................................. |

10-23 |

|

|

10.15 |

LON SYSTEM ............................................................................................... |

10-24 |

|

|

10.16 |

BAR CODE FORMAT .................................................................................... |

10-26 |

|

|

10.17 |

TITLES.......................................................................................................... |

10-28 |

|

|

10.18 |

TRANSFERRING LOGO DATA ..................................................................... |

10-29 |

|

|

10.19 |

IDIOM SETTING............................................................................................ |

10-30 |

|

|

10.20 |

VENDOR SETTING....................................................................................... |

10-31 |

|

|

10.21 |

FREE FORMAT SETTING............................................................................. |

10-32 |

|

|

|

|

Page |

11. |

PROGRAMMED DATA VERIFICATION REPORTS................................................. |

11- 1 |

|

12. |

PASSWORD SECURITY ......................................................................................... |

12- 1 |

|

|

12.1 |

SETTING PASSWORD AND PROTECT MENU............................................. |

12- 1 |

|

12.2 |

CALLING MENU BY ENTERING PASSWORD .............................................. |

12- 3 |

13. |

OPERATING PROCEDURES .................................................................................. |

13- 1 |

|

|

13.1 |

WEIGHING OPERATION............................................................................... |

13- 2 |

|

13.2 |

FIX PRICE OPERATION (FOR US TYPE ONLY) ........................................... |

13- 3 |

|

13.3 |

BY COUNT OPERATION............................................................................... |

13- 4 |

|

13.4 |

PRINT COUNT OPERATION......................................................................... |

13- 6 |

|

13.5 |

ISSUING LABELS WITH NET WEIGHT STATEMENT |

|

|

|

(FOR US TYPE ONLY) .................................................................................. |

13- 9 |

|

13.6 |

TARE/SAVE FUNCTION PROCEDURES ...................................................... |

13-11 |

|

13.7 |

CALLING AND PRINTING GRADE LINES ..................................................... |

13-12 |

|

13.8 |

CALLING AND PRINTING LOGOS ................................................................ |

13-13 |

|

13.9 |

SELECTING PRINT ITEM.............................................................................. |

13-14 |

|

13.10 |

DATE CHANGE............................................................................................. |

13-15 |

|

13.11 |

BATCH PRINT MODE (with 30 Items Run Assignment) ................................. |

13-16 |

|

13.12 |

VISUAL COMMODITY LIBRARY ................................................................... |

13-19 |

|

13.13 |

FLOATING VENDOR..................................................................................... |

13-20 |

14. |

TOTAL OPERATION............................................................................................... |

14- 1 |

|

|

14.1 |

HOURLY TOTAL REPORT............................................................................ |

14- 2 |

|

14.2 |

GRAND TOTAL REPORT.............................................................................. |

14- 2 |

|

14.3 |

PLU TOTAL REPORT ................................................................................... |

14- 2 |

|

14.4 |

VENDOR TOTAL REPORT ........................................................................... |

14- 3 |

15. |

ERROR MESSAGE TABLE..................................................................................... |

15- 1 |

|

16. |

CLEANING THE PRINT HEAD ................................................................................ |

16- 1 |

|

17. |

TROUBLESHOOTING............................................................................................. |

17- 1 |

|

WARNING!

1.The installation should be authorized installing dealer. Please contact your nearest TOSHIBA TEC representative.

2.Installation by anyone except an authorized installing dealer will release the manufacturer from all liabliity for damage or injury to users.

3.Scale is prohibited to be hung from a plaster or wooden board. It has to be installed on structual materials (concrete, steel frame, beam and pillar, etc.)

4.Do not exceed the platter weight of maximum capacity. Or hang any item from the scale which exceed the platter weight.

CAUTION:

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2.The contents of this manual may be changed without notification.

3.Please refer to your local Authorized Service representative with regard to any queries you may have in this manual.

Copyright © 2001

by TOSHIBA TEC CORPORATION All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Sizuoka-ken, JAPAN

1.INTRODUCTION

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the TEC SL-9000 electronic computing scale. The TEC SL-9000 is designed to be hung from the ceiling. As you will discover, it has many features and functions designed for user friendliness as well as complete customer satisfaction.

The 256x64 dot fluorescent display provides customers with ample information, the 216 speed keys realize a higher degree of operability, and the 3 inch/sec. print speed ensures fast and clear printing. Password security prevents unauthorized access to the PROG., M.DOWN, REWRAP, REPORT and RESET modes.

The latest high speed in-line system, Local Operation Network (LON), allows easy system configuration and greater throughput.

Various options, including a TMCC Interface, etc., are selectable in accordance with your needs.

We believe that your needs will now be fully satisfied, and you will have total reliability in price calculation. Should you have any questions concerning the scale, please refer to this manual. Be sure to keep this manual for future reference.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operations of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the user’s authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.”

“Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.”

(for CANADA only)

Some procedures described in this manual may be illegal in various state jurisdictions. When there are optional settings to enable various functions or to disable functions. Please ensure that the optional settings for scale operation meet the local requirements of weights and measures. If you are uncertain of specific items, contact the state or county office of weights and measures for clarification.

1-1

1.INTRODUCTION

1.1 APPLICABLE MODEL

1.1 APPLICABLE MODEL

∙ |

SL-9000-15M-FFH-CA |

∙ |

SL-9000-30M-N-FFH-US |

∙ |

SL-9000-15M-FFH-QR |

∙ |

SL-9000-15M-N-FFH-CA |

|

|

∙ |

SL-9000-15M-N-FFH-QR |

The description of the model number is as follows.

S L - 9 0 0 0 - |

3 0 M |

- N - |

F F |

|

H |

- |

U S |

|

Destination Code |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. Capacity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ex.) US, CA, QR, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30M: 30 lbs (decimal pound |

|

|

|

|

|

|

Scale Type |

|

||||||||||||

|

|

|||||||||||||||||||

/multi-interval) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H: Hanging scale |

||

15M: 15 Kg (multi-interval) |

|

|

|

|

Display Type |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FF: Fluorescent full dot display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N: LAN (Option) is available. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Blank: LAN (Option) is not available. |

|||

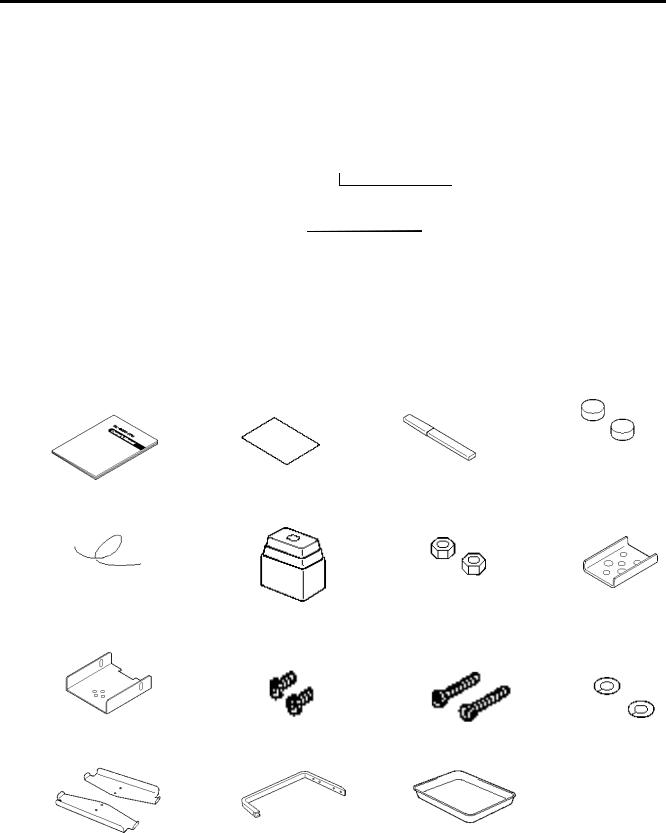

1.2 ACCESSORIES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Owner’s Manual |

|

Quality control |

|

Print Head Cleaner |

Sealing Lead |

|||||||||||||||

(EM1-31076) |

|

report (US type only) |

(24089500013) |

|

||||||||||||||||

Stranded Wire |

Rubber Pipe Cover |

Nut (N-6) |

Pipe Spacer |

Hanging Support (R) |

Cap Screw |

Cap Screw |

Spring Washer |

|

(M-6x12) |

(M-6x60) |

(SW-6) |

Platter Mount Plate |

Platter Arm |

Platter |

NOTE : Check that there are no missing or incorrect parts in the accessories

1- 2

2.SPECIFICATION

2.1 SCALE

2. SPECIFICATION

2.1 SCALE

Item |

US |

CA |

|

|

QR |

|

|

|

|

|

|

Maximum Capacity |

30 lb |

15 Kg (30 lb) |

|

||

Minimum Scale Division |

0.005 lb (0 to 15 lb.) |

0.002 Kg (0 to 6 Kg) |

|

||

|

|

0.005 Kg (6 to 15 Kg) |

|

||

|

0.01 lb (15 to 30 lb.) |

0.005 lb (0 to 15 lb) |

|

||

|

|

0.01 lb (15 to 30 lb) |

|

||

Display Range |

0 to 30.05 lb |

0 to 15.025 Kg (0 to 30.05 lb) |

|||

Maximum Tare |

2.000 lb |

1.000 Kg (2.205 lb) |

|

||

|

|

|

|

|

|

Unit Price Presettable |

$ 0.01 to 99.99 |

$ 0.01 to 99.99 |

|

0 to 99999 |

|

Minimum Price Display |

$ 0.01 |

$ 0.01 |

|

|

1 |

Power Requirement |

AC 120 V ±10%, 60 Hz (US/CA type) |

|

|||

|

AC 220 V ±10%, 50/60 Hz (QR type) |

|

|||

Power Consumption |

US/CA: 85 W, 1.4 A (Standby: 30 W, 0.5 A) |

|

|||

|

QR: 80 W, 0.66 A (Standby: 32 W, 0.26 A) |

|

|||

Temperature Limits |

32°F to 104°F (0 to 40 ) |

|

|||

Relative Humidity |

35 % to 85 % (No condensation) |

|

|||

Message Display |

256 x 64 dots Fluorescent display |

|

|||

Weight |

5 digits (US/CA type), 5 digits (QR type) |

|

|||

Unit Price |

4 digits (US/CA type), 5 digits (QR type) |

|

|||

Total Price |

5 digits (US/CA type), 6 digits (QR type) |

|

|||

Display Mode |

Dual sides |

|

|

|

|

Capacity of PLU Memory |

SL-9000: 560 PLUs (Standard), 240 PLUs when LOGO is available. |

||||

|

3120 PLUs max. (Option) |

|

|||

|

SL-9000N: 3600 PLUs max. (Standard) |

|

|||

Print Head |

Thermal Print Head (2 inch wide) |

|

|||

Media Issue Method |

On-demand/Batch |

|

|

|

|

Dot Density |

193 dots/inch (7.6 dots/mm) |

|

|||

Print Speed |

3 inch/sec. (76.2 mm/sec.) |

|

|||

Available Media Width |

1.89 inch (48 mm), 2.24 inch (57 mm) |

|

|||

Recommended Media |

|

|

|

|

|

Thermal Label |

VHTS, VLTS (OSP)/Outer diameter: φ150 mm (Max.) |

||||

Variable Length Label |

VHTS, VLTS (OSP)/Outer diameter: φ150 mm (Max.) |

||||

Thermal Receipt |

120 FC (RICOH)/Outer diameter: φ90 mm (Max.) |

|

|||

Interface |

CMT/PL-3 interface (Program Loader) |

|

|||

|

LON interface (RS-485) |

|

|

|

|

|

TMCC interface (Option) |

|

|

|

|

|

LAN Interface (10 Base T, SL-9000N Option) |

|

|||

Dimensions (approx.) |

|

|

|

|

|

Without a platter |

15.6 inch (width) x 7.1 inch (depth) x 19.3 inch (height) |

||||

|

395 mm (width) x 181 mm (depth) x 490 mm (height) |

|

|||

With a platter |

15.6 inch (width) x 10.8 inch (depth) x 32.7 inch (height) |

||||

|

395 mm (width) x 274 mm (depth) x 830 mm (height) |

|

|||

Weight |

37.5 lb (17 Kg) |

|

|

|

|

2- 1

2.SPECIFICATION

2.2 OPTION

2.2 |

OPTION |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Option Name |

Model No. |

Description |

Source |

|||

|

or Part No. |

||||||

|

|

|

|

|

|

||

|

|

LON Connector |

Part No. |

A modular connector used to connect scales |

See |

||

|

|

TM8P-88P |

EAJ-0028001 |

to each other in a LON configuration. |

Note 2 |

||

|

|

LON Terminal |

Part No. |

A modular resistor attached to the scales |

See |

||

|

|

EAJ-0029001 |

connected at both ends of the LON |

Note 2 |

|||

|

|

Resistor 285D-8P |

|||||

LON |

|

|

configuration. |

|

|

||

|

|

|

|

|

|||

|

|

LON Cable |

Part No. |

An 8-pin telephone cable used with the LON |

See |

||

|

|

10319100003 |

connectors attached |

to both ends of the |

Note 2 |

||

|

|

S-STLAN-2P |

|||||

|

|

|

cable. This cable connects scales to each |

|

|||

|

|

(200 m/roll) |

|

|

|||

|

|

|

other in a LON configuration. |

|

|||

|

|

|

|

|

|||

|

|

|

OP-9000-IOB |

An I/O board equipped with the TMCC |

See |

||

|

|

I/O PC Board |

|

interface. It is used to construct a TMCC |

Note 1 |

||

TMCC |

|

|

system. |

|

|

||

|

|

TMCC Cable kit |

OP-9000-IOCN- |

A cable kit for the TMCC interface. |

See |

||

|

|

TMCC |

|

|

Note 1 |

||

|

|

|

|

|

|||

|

|

|

OP-9000- |

This board is used to expand the PLU |

See |

||

MEMO PC Board |

PIGGYBACK |

memory to 4MB by installing the memory |

Note 1 |

||||

(SL-9000 only) |

OP-9000- |

module. |

|

|

|||

|

|

|

PIGGYBACK-S/F |

|

|

|

|

|

|

|

OP-9000-RAM- |

DIP type PS-RAM to be installed on the |

See |

||

|

|

|

512KB |

MEMO PC board (OP-9000-PIGGYBACK) for |

Note 1 |

||

|

|

|

|

memory expansion. |

When expanding the |

and 3 |

|

Memory Module |

|

memory, install the two modules as one set. |

|

||||

OP-9000-SRAM- |

DIP type S-RAM to be installed on the MEMO |

|

|||||

|

|

|

|

||||

|

|

|

512KB |

PC board (OP-9000-PIGGYBACK-S/F) for |

|

||

|

|

|

|

memory expansion. When expanding the |

|

||

|

|

|

|

memory, install the two modules as one set. |

|

||

|

|

|

---------- |

Please locally purchase a power cord of |

See |

||

Power Cord |

|

proper length for the installation location. |

Note 1 |

||||

|

Power cord shall be a standardized article of |

|

|||||

|

|

|

|

|

|||

|

|

|

|

each destination. |

|

|

|

10 Base T (LAN) Interface |

OP-9000N-LAN |

This board enables the SL-9000N to be used |

See |

||||

Board |

(SL-9000N only) |

|

in a LAN network. |

|

Note 1 |

||

LAN Cable Kit (SL-9000N |

OP-9000N-LAN- |

This kit is required when installing the OP- |

See |

||||

FFH |

9000N-LAN (LAN Interface Board) on the SL- |

Note 1 |

|||||

only) |

|

|

|||||

|

|

|

9000N-FFH. |

|

|

||

|

|

|

|

|

|

||

NOTES:

1.Contact TOSHIBA TEC H.Q. or your nearest TOSHIBA TEC representative.

2.Order from TOSHIBA TEC Parts Center or purchase locally.

3.When purchasing memory modules locally, select one having the following specifications.

■ Maker: HITACHI Pseudo Static RAM (OP-9000-RAM-512KB) HITACHI Static RAM (OP-9000-SRAM-512KB)

■ Type: HM658512ALP-8V 80 ns, 600 mil 32-pin Plastic DIP (DP-32) (OP-9000-RAM-512KB) HM628512ALP-770ns, 600mil 32-pin Plastic DIP (DP-32) (OP-9000-SRAM-512KB)

4. The MEMO PC Board (with Flash ROM) is installed in the SL-9000N model as standard.

2- 2

3.APPEARANCE

3. APPEARANCE

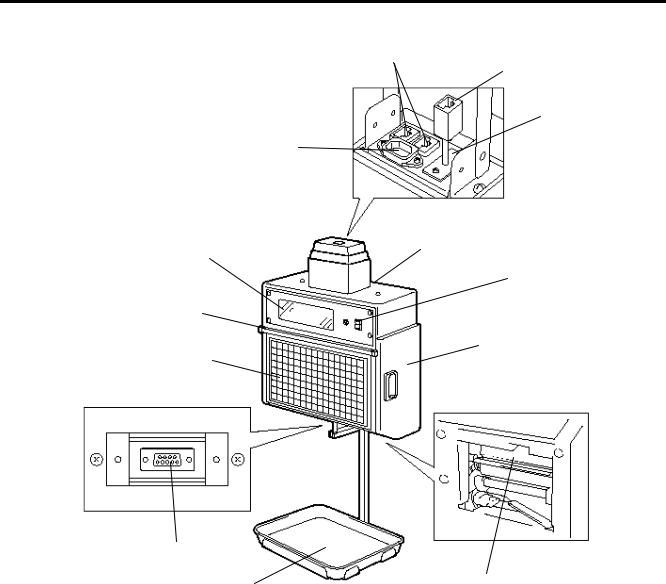

3. APPEARANCE |

LON Interface |

LAN Interface |

|

||

|

(SL-9000N option) |

|

|

|

TMCC Interface (Option)

Power Inlet

Front Display |

Rear Display |

Main Power

Keyboard Frame |

|

Printer Cover |

|

||

Operation/Speed/ |

|

|

|

||

|

|

|

Programming |

|

|

Keyboard |

|

|

CMT/PL-3 Interface

Print Head

Platter

NOTE: To set the speed/operation key sheet, open the keyboard frame and insert the two tabs of the key sheet into the two slots of the keyboard frame bottom.

3- 1

4.DISPLAY

4.1 US TYPE

4. DISPLAY

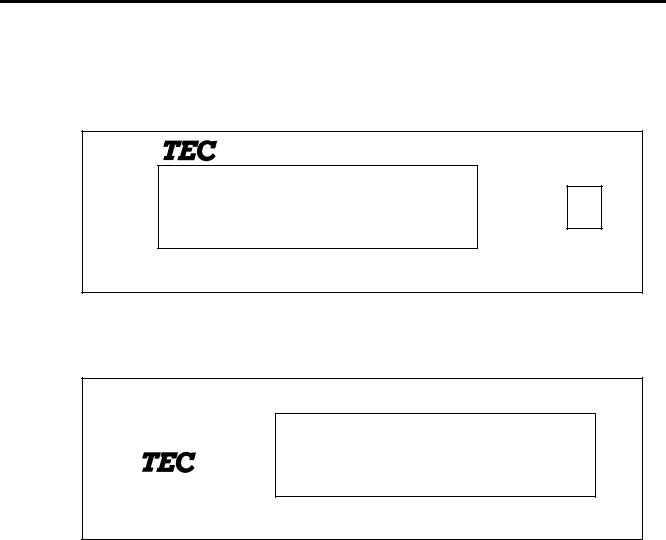

4.1 US TYPE

nFront Display Panel

SL-9000N

x

o

CAPACITY |

WEIGHT |

e=d |

SCROLLING MESSAGE INDICATES |

|

0 15 lb |

0.005 lb |

|

|

15 30 lb |

0.01 lb |

SCALE AT ZERO |

nRear Display Panel

SL-9000N

CAPACITY |

WEIGHT |

e=d |

SCROLLING MESSAGE INDICATES |

|

0 15 lb |

0.005 lb |

|

|

15 30 lb |

0.01 lb |

SCALE AT ZERO |

4- 1

4.DISPLAY

4.2 CA/QP TYPE

4.2 CA/QR TYPE

nFront Display Panel

SL-9000N

|

|

|

|

|

|

|

|

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

|

|

|

|

|

|

CAPACITY |

|

|

|

|

|

|

|

|

WEIGHT |

e=d |

WEIGHT |

e=d |

|

|

|

|

|

|

|

|||||||

|

0 6 kg |

0.002 kg |

0 15 lbs |

0.005 lbs |

|

|||

CAPACITÉ |

6 15 kg |

0.005 kg |

15 30 lbs |

0.01 lbs |

|

|||

nRear Display Panel

SL-9000N

CAPACITY

CAPACITÉ

WEIGHT |

e=d |

WEIGHT |

e=d |

0 6 kg |

0.002 kg |

0 15 lbs |

0.005 lbs |

6 15 kg |

0.005 kg |

15 30 lbs |

0.01 lbs |

NOTE: For the SL-9000 model, the model name on the display panel is “SL-9000”.

4- 2

5.KEY LAYOUT

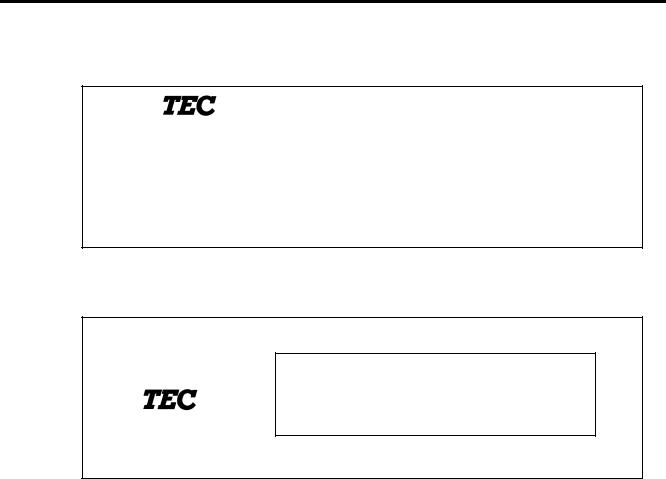

5.1 PROGRAMMING KEYBOARD

5. KEY LAYOUT

5.1 PROGRAMMING KEYBOARD

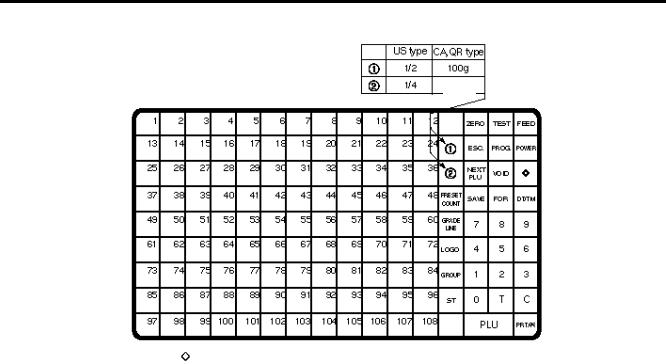

NOTE: Blank keys have no function.

■ Programming Keyboard Function

Name of Key |

Function |

||||

|

|

|

|

|

|

|

|

|

|

|

1. Clears numeric data just entered. |

|

CLEAR |

|

|||

|

|

2. Releases the scale from the error mode. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Selects the upper case or lower case. |

|

SHIFT |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calls the PLU # which follows the PLU # currently called. |

|

SET |

|

|||

|

|

|

|||

|

NEXT |

|

Sets the media transparency on the sensor. |

||

|

|

|

|

|

|

|

|

|

|

|

Calls the PLU # registered right after currently called PLU #. |

|

NEXT |

|

|||

|

|

|

|||

|

PLU |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Sets “AUTO CODE”. |

|

AUTO |

|

|||

|

CODE |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Changes the PLU # currently called. |

|

CHANGE |

|

|||

|

|

|

|||

|

PLU |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Deletes PLU. |

|

DELETE |

|

|||

|

PLU |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Prints data set in the currently called PLU. |

|

TEST |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inputs data to the SL-9000 system during programming. |

|

ENTER |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displays the preceding PLU data. (only when changing the unit price) |

|

VOID |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

RPT/ |

|

|

|

Inputs data to the SL-9000 system during programming. (only when changing the unit |

|

* |

|

|

||

|

|

|

price) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Returns to the main menu. |

|

ESC. |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

5- 1

5.KEY LAYOUT

5.1 PROGRAMMING KEYBOARD

Name of Key |

|

Function |

||

|

|

|

|

|

|

|

|

1. |

Displays the preceding PLU data. |

|

|

|

||

|

|

|

2. Used to set an auto code. |

|

|

|

|

3. |

Calls the preceding label format # when setting the print position. |

|

|

|

||

|

|

|

|

|

|

|

|

Moves the cursor to left. |

|

|

← |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Moves the cursor to right. |

|

|

→ |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Deletes a character selected by the cursor when setting the commodity name or |

|

DELETE |

|

||

|

|

|

message. |

|

|

(A) |

|

|

|

|

1/2 |

|

2. |

Sets a unit price per 1/2 lb. |

|

|

|

|

|

|

|

|

1. |

Inserts a space at the cursor position when setting the commodity name or |

|

INSERT |

|

|

message. |

|

1 |

|

2. |

Sets a unit price per lb/100g/Kg. |

|

|

|

||

|

|

|

|

|

|

|

Deletes all characters on the current setting line when setting the commodity name or |

||

|

DELETE |

|

||

|

(B) |

|

message. |

|

|

|

|

1. |

Displays the next line when setting the ingredient and message. |

|

RETURN |

|

||

|

|

2. |

Sets a unit price per 1/4 lb. |

|

|

1/4 |

|

||

|

|

Inserts a blank space in descriptors. |

||

|

↑ |

|

||

|

SPACE |

|

|

|

|

|

|

Stores “ingredient data” in the temporary memory. |

|

|

SEND |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Calls “ingredient data” from the temporary memory. |

|

|

RECEIVE |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Sets the preceding item when setting PLU and nutrition information. |

|

|

↑ |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Sets the following item when setting PLU and nutrition information. |

|

|

↓ |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Returns to the programming menu. |

|

|

PROG. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Changes the programming menu page. |

|

|

|

2. |

Selects capitals or small letters. |

|

|

|

||

|

|

3. |

Sorts the file when setting PLU data, ingredient data and nutrition data. |

|

|

|

|

||

|

|

|

4. |

Sets a block PLU # using the confirmation label procedure. |

|

|

|

||

|

|

|

5. |

Selects the scrolling message or fixed message. |

|

|

|

6. |

Changes the speed key page and sets a department #. |

|

|

|

7. |

Selects the adjusting item of print format in rotation. |

|

|

|

8. |

Toggles between In-line and Local or in-line and off-line of LON system. |

|

|

|

|

|

Other Keys |

The other keys are used to set the character. |

|||

|

|

|

|

|

5- 2

5.KEY LAYOUT

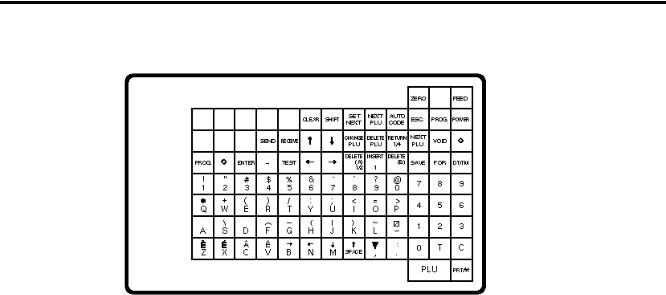

5.2 OPERATION KEYBOARD AND SPEED KEYBORAD

5.2 OPERATION KEYBOARD AND SPEED KEYBOARD

LB/kg

(4)

(3)

NOTES: 1. Pressing the |

|

key enables another 108 PLUs assignment. |

|

|

|

2.When the initial setting #8-7 is set to 1 (SL-9000) or #28-4 is set to 1 (SL-9000N), the (3) key will function as a Tare% key instead of a speed key.

3.When the initial setting #12-8 is set to 1, the (4) key will function as an AUTO/MANUAL key instead of a speed key.

■Operation Keyboard Function

|

Name of Key |

Function |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enters PLU #, unit price and tare. |

|

0 |

|

to |

|

9 |

|

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Clears numeric entries. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

2. Releases the scale from error mode. |

|

|

|

|

|

|

|

|

|

|

3. Releases the scale from SAVE mode. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Subtracts tare. |

|

|

|

|

T |

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calls a PLU or clears displayed PLU. |

|

|

|

PLU |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Prints the customer label. |

|

|

|

PRT/* |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Saves tare and unit price after taking off the commodity from a platter. |

|

|

|

SAVE |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sets the number of articles in “BY COUNT” mode. |

|

|

|

FOR |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displays the date. |

|

|

|

DT/TM |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Selects the item for change Print/OFF. |

|

|

|

NEXT |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

PLU |

|

|

|

|

||

5- 3

5.KEY LAYOUT

|

|

|

|

|

|

|

|

|

|

|

5.2 OPERATION KEYBOARD AND SPEED KEYBORAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

■ Operation Keyboard Function |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name of Key |

Function |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Corrects data just after the registration. |

|

|

|

|

|

VOID |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Selects the speed key page. |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

2. Selects the function for change Print/OFF. |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Returns to the main menu. |

|

|

|

|

|

ESC. |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Accesses print item, auto message timer, print format and issue mode selection |

|

|

|

|

|

PROG. |

|

|

|

|||||

|

|

|

|

|

|

mode. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turns the display on/off when the scale power is on. |

|

|

|

|

|

POWER |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changes between 1/2 lb and 1/4 lb (US type only). |

|

|

|

|

1/2 |

|

|

1/4 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changes the unit of measure to 100 g (CA/QR type only). |

|

|

|

|

|

100g |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changes the unit of measure between lb and kg (CA/QR type only). |

|

|

|

|

|

LB/kg |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sets the number of labels to print. |

|

|

|

|

|

PRESET |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

COUNT |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Prints a grade line. |

|

|

|

|

|

GRADE |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

LINE |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calls the logo. |

|

|

|

|

|

LOGO |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No function. |

|

|

|

|

|

GROUP |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

# |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

No function. |

|

|

|

|

|

|

ST |

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This key is used for item or subtotal discount by entering a percentage. |

|

|

|

|

|

|

% |

|

|

|

|

|||

|

|

|

|

|

|

|

|

(Optional key by initial setting) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Feeds the label. |

|

|

|

|

|

FEED |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Issues a test label. |

|

|

|

|

|

TEST |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjusts the zero point. |

|

|

|

|

|

ZERO |

|

|

|

|||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUTO/ |

|

Changes the label issue mode between Automatic issue and manual issue. |

|

|||||

|

|

|

|

MANUAL |

|

(Optional key by initial setting) |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calls the PLU frequently used. |

|

|

|

1 |

to |

108 |

|

|

||||||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

5- 4

6.PROCEDURE BEFORE OPERATION

6. PROCEDURE BEFORE OPERATION

6. PROCEDURE BEFORE OPERATION

1.Ask an authorized installing dealer for the scale installation. Please contact your nearest TOSHIBA TEC representative.

2.Hang the platter arm from the scale. (See page 7-1.)

3.Load the label or receipt.

4.Set the following programming menus:

Menu Page |

ITEM No. |

Programming Name |

2 |

0 |

PRINT FORMAT |

2 |

1 |

DATE/TIME SETTING |

1 |

1 |

PLU DATA SETTING |

If necessary, set the following program menu:

Menu Page |

ITEM No. |

Programming Name |

1 |

2 |

INGREDIENT MESSAGE |

1 |

3 |

NUTRITION SETTING |

1 |

5 |

ADDRESS AND COMMECIAL MESSAGE SETTING |

1 |

7 |

SPECIAL INFORMATION |

1 |

8 |

GRADE LINE |

1 |

9 |

SPEED KEY SET |

5.Call a PLU which contains the unit price used in weighing mode, then place a weight on the platter and check a correct price is displayed.

6.Label issued is ready.

NOTE: For details of the programming menus, refer to Section 10.

6- 1

7.INSTALLATION PROCEDURE

7. INSTALLATION PROCEDURE

7. INSTALLATION PROCEDURE

■Scale installation on the wall or ceiling

The installation should be an authorized installing dealer. Please contect your nearest TOSHIBA TEC representative.

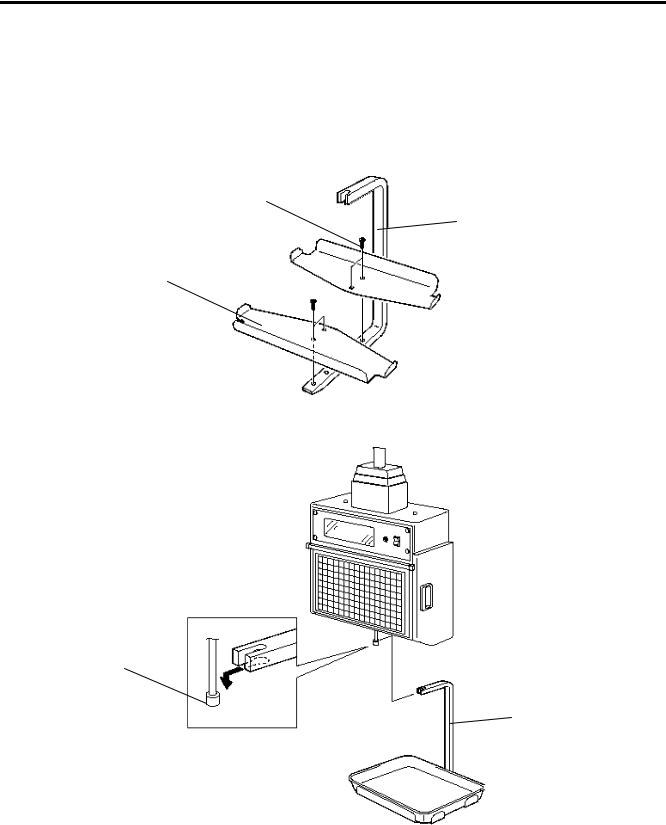

■Platter

1.Attach the two platter mount plates to the platter arm with the four D-4x8 screws.

Screw

Platter Arm

Platter Mount Plate

2. Fit the notch of the platter arm on the joint nut of the scale.

Joint nut

Platter Arm

7- 1

8.REMOVAL AND REPLACEMENT OF RECEIPT/LABEL

8. REMOVAL AND REPLACEMENT OF RECEIPT/LABEL

8. REMOVAL AND REPLACEMENT OF RECEIPT/LABEL

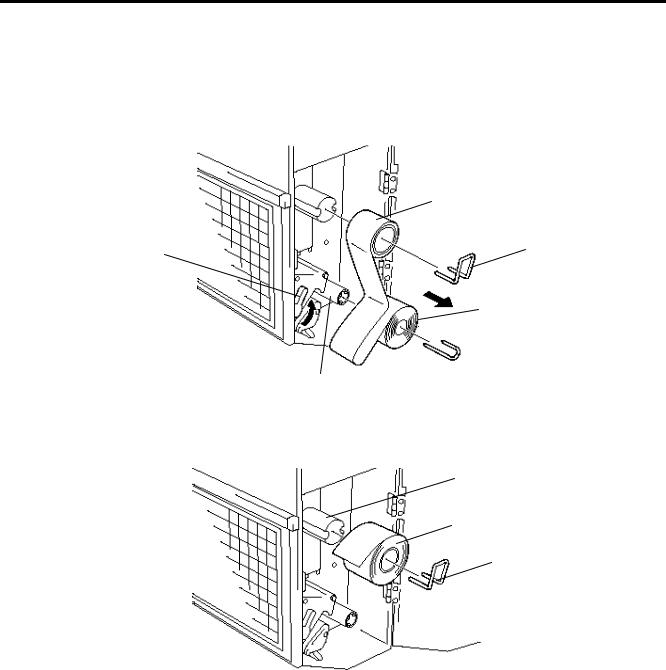

1.Open the printer cover and turn the head-up lever to the anticlockwise.

2.Pull out the roll stopper and backing paper stopper, then remove the receipt/label core with the backing paper. You can loosen the backing paper by turning the paper winding shaft anticlockwise.

|

Receipt/Label Core |

Head-up Lever |

Roll Stopper |

|

Backing Paper (Labels only)

Backing Paper Stopper

Backing Paper Stopper

Paper Winding Shaft

3. Put a new receipt/label roll over the media shaft and fix it with the roll stopper. Media Shaft

Receipt/Label

Roll Stopper

8- 1

8.REMOVAL AND REPLACEMENT OF RECEIPT/LABEL

8. REMOVAL AND REPLACEMENT OF RECEIPT/LABEL

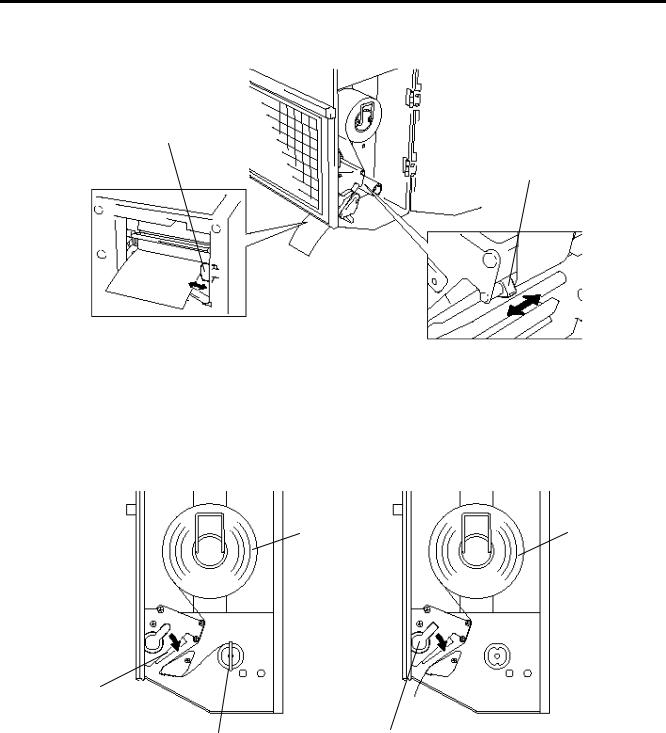

4.Insert the tip of the receipt/label into the print head.

5.Align the two media guides with the right edge of the receipt/label.

Media Guide

Media Guide

6.Thread the receipt/label as shown below.

NOTE: Labels and receipts should be left-aligned as viewed from the front of the machine, and always threaded in parallel with the media shaft and the print head. Failure to do this may cause a paper jam or a skew feed.

7.Turn the head-up lever to the arrow indicating direction to set the print head in position.

(Label threading method) |

(Receipt threading method) |

Label |

Receipt |

Head-up Lever

Winding Roll

Winding Roll

Print Head

Backing Paper Stopper |

Head-up Lever |

8.Close the printer cover.

9.Finally press the Feed key to confirm that the labels/receipts are loaded correctly.

8- 2

9.OUTLINE OF OPERATION

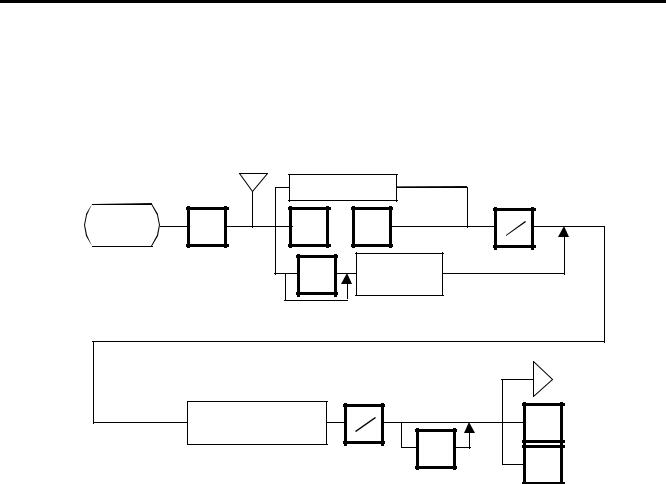

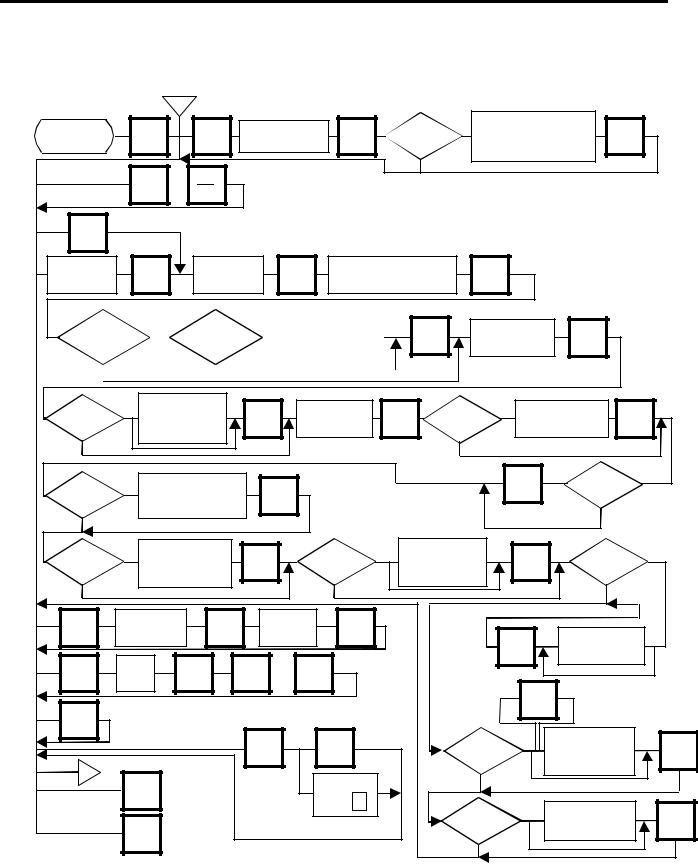

9. OUTLINE OF OPERATION

9. OUTLINE OF OPERATION

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Main Power |

|

|

|

|

|

|

Main Menu |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Switch ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Menu#1 |

|

|

|

Select the |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

Display OFF |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Menu # |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Other than Menu #1. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Press the |

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

POWER |

key |

|

|

|

|

|

|

Password |

Unnecessary |

|||||

|

Press the |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

POWER |

key |

|

|

|

|

|

|

|

|

Necessary |

|

|

|

|

|

|

|||

Scanning Display |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

||||||||||||||||

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Password Input

REG |

MARK DOWN |

REPORT |

SECURITY |

|

Menu |

|

Menu |

Menu |

Menu |

REWRAP |

PROG |

|

RESET |

|

|

Menu |

Menu |

|

Menu |

|

Press |

|

POWER Key |

Display OFF |

No Press

|

|

|

|

Press |

|

|

|

|

|

||

ESC. |

|

Key |

|

|

|

|

|||||

|

|

|

|||

No Press

Return to each mode

NOTES:

1.You can register a password to avoid unauthorized access to each menu except for REG. menu.

2. To avoid unneeded use of the display, press the POWER key to turn the display off while being unused. Pressing the POWER key again allows you to enter REG mode without scanning.

3. Refer to respective sections for explanation of each menu enclosed by a thick rectangle.

9- 1

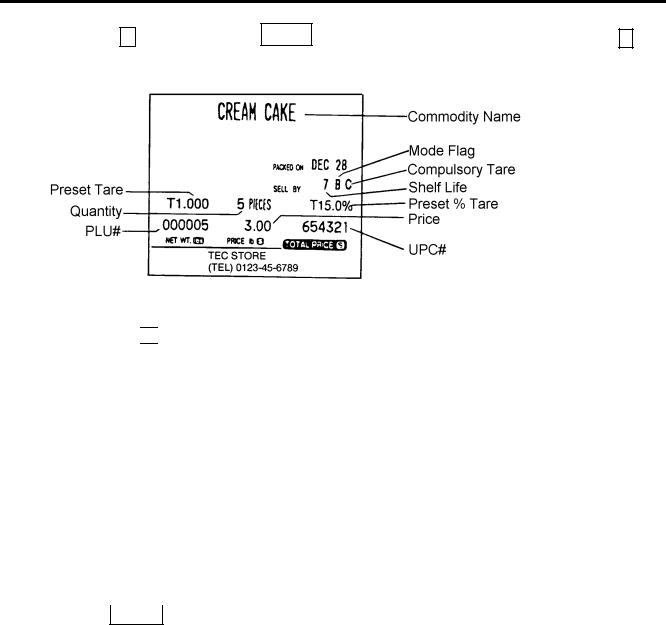

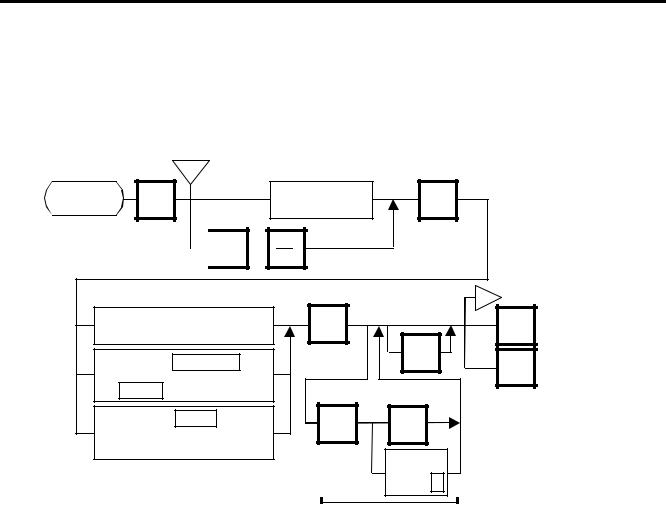

10. PROGRAMMING PROCEDURES

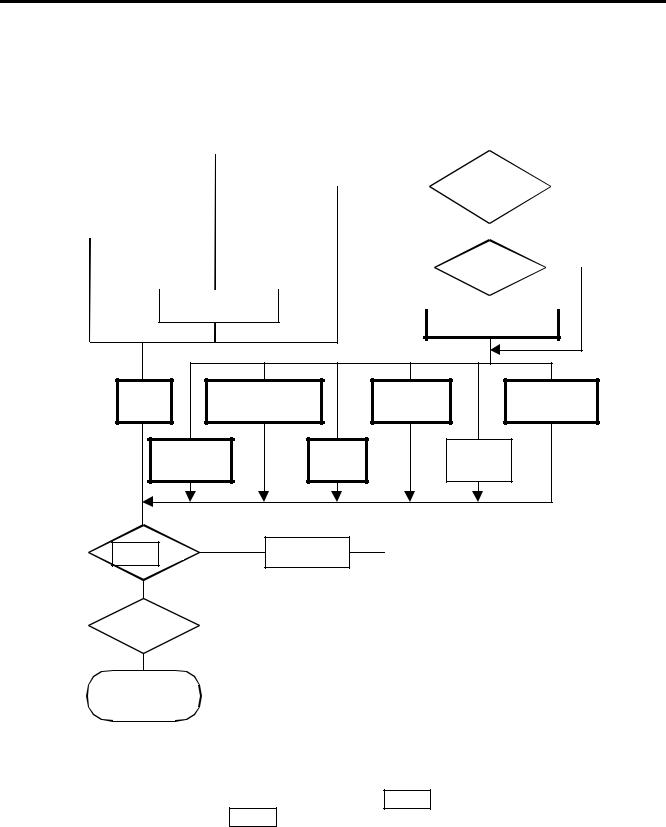

■ How to access to Programming Menu

10.PROGRAMMING PROCEDURES

■How to access to Programming Menu

|

|

Select the |

|

Enter a |

|

programming |

|

unnecessary |

|||

menu page. |

|||

menu number |

|||

|

|

ESC. |

0 |

neccesary |

Enter the |

|

|

Password |

Password |

|

|||

|

Select an item No. (See next page.)

0 |

|

9 |

Programming |

Programming |

PROG. |

|

starts |

completes |

||

|

NOTES:

1.When the selected menu ( 0 ) is protected from an access, refer to Section 12.2 and enter the password.

2.In Section 10.1, 10.2 and 10.3, items which have been sold on that day cannot be called before resetting (refer to Section 14) unless Initial Set #1-4 is set to 1.

<Menu> PROG.1

0. |

PLU DATA EDIT |

5. |

MESSAGE |

1. |

PLU DATA |

6. |

MSG. COMBINATION |

2. |

INGREDIENT |

7. |

SPECIAL INFO |

3. |

NUTRITION |

8. |

GRADE LINE |

4. |

CONFIRMATION LABEL |

9. |

SPEED KEY SET |

|

|

|

|

|

|

|

|

<Menu> PROG.2 |

|

|

|

0. |

PRT LOCATION |

5. |

INITIAL SET |

1. |

DATE TIME |

6. |

BAR CODE FORMAT |

2. |

CMT |

7. |

TITLE |

3. |

ON-LINE/LOCAL |

8. |

LOGO |

4. |

LON SYSTEM |

9. |

IDIOM |

|

|

|

|

<Menu> PROG.3

0.VENDOR

1.FREE FORMAT

2.LAN SYSTEM (SL-9000N only)

10- 1

10. PROGRAMMING PROCEDURES

■ Title and Contents of Programming Menu

■ Title and Contents of Programming Menu

Table 1.

NO. |

TITLE |

MENU |

ITEM |

CONTENTS |

Page |

|

|

PAGE |

NO. |

|

|

|

|

|

|

|

|

1 |

PLU DATA EDIT |

1 |

0 |

CHANGE UNIT PRICE |

10-4 |

|

|

|

|

|

|

2 |

PLU DATA |

1 |

1 |

PROGRAM/CHANGE/DELETE PLU |

10-5 |

|

|

|

|

|

|

3 |

INGREDIENT MESSAGE |

1 |

2 |

PROGRAM/CHANGE INGREDIENT |

10-7 |

|

|

|

|

|

|

4 |

NUTRITION SETTING |

1 |

3 |

PROGRAM/CHANGE NUTRITION FACTS TABLE |

10-8 |

|

|

|

|

|

|

5 |

CONFIRMATION LABEL |

1 |

4 |

VERIFY THE PROGRAMMING DATA OF PLU |

10-12 |

|

|

|

|

|

|

6 |

ADDRESS OR MESSAGE SETTING |

1 |

5 |

PROGRAM MESSAGE/ADDRESS |

10-13 |

|

|

|

|

|

|

7 |

COMBINATION MESSAGE |

1 |

6 |

PROGRAM MESSAGE ON DISPLAY AND TIME |

10-14 |

|

|

|

|

|

|

8 |

SPECIAL INFO. |

1 |

7 |

PROGRAM SPECIAL INFORMATION |

10-16 |

|

|

|

|

|

|

9 |

GRADE LINE |

1 |

8 |

PROGRAM GRADE LINE |

10-16 |

|

|

|

|

|

|

10 |

SPEED KEY SETTING |

1 |

9 |

ASSIGN COMMON PLU TO SPECIFIC SPEED KEY |

10-17 |

|

|

|

|

|

|

11 |

PRT LOCATION |

2 |

0 |

SELECT LABEL FORMAT AND ADJUST |

10-18 |

|

|

|

|

|

|

12 |

DATE/TIME SETTING |

2 |

1 |

PROGRAM DATE/TIME/MACHINE #/STORE CODE |

10-20 |

|

|

|

|

|

|

13 |

CMT/PL-3 |

2 |

2 |

BACK-UP/LOAD DATA OF PLU/ING/NUTRI./SPEED |

10-20 |

|

|

|

|

KEY |

|

|

|

|

|

|

|

14 |

IN-LINE/LOCAL |

2 |

3 |

SET PARAMETERS FOR TMCC |

10-23 |

|

|

|

|

|

|

15 |

LON SYSTEM |

2 |

4 |

SET PARAMETERS FOR LON |

10-24 |

|

|

|

|

|

|

16 |

INITIAL SET |

2 |

5 |

SET INITIAL PARAMETERS |

---- |

|

|

|

|

|

|

17 |

BAR CODE FORMAT |

2 |

6 |

PROGRAM BARCODE FORMAT |

10-26 |

|

|

|

|

|

|

18 |

TITLE |

2 |

7 |

PROGRAM/CHANGE TITLE ON DISPLAY/PRINT |

10-28 |

|

|

|

|

|

|

19 |

LOGO |

2 |

8 |

SEND/RECEIVE LOGO DATA |

10-29 |

|

|

|

|

|

|

20 |

IDIOM |

2 |

9 |

PROGRAM IDIOM |

10-30 |

|

|

|

|

|

|

21 |

VENDOR |

3 |

0 |

VENDOR NAME |

10-30 |

|

|

|

|

|

|

22 |

FREE FORMAT |

3 |

1 |

PROGRAM FREE FORMAT |

10-31 |

|

|

|

|

|

|

23 |

LAN SYSTEM (SL-9000N only) |

3 |

2 |

PROGRAMS PARAMETERS FOR LAN |

---- |

|

|

|

|

|

|

NOTE: Menu No. 16 and 23 are program for use of dealers. Contact your nearest TOSHIBA TEC representative if you desire to use them. When you enter one of these menus by mistake, press [ESC.] key to return to Main Menu.

10- 2

10. PROGRAMMING PROCEDURES

■ How to enter characters

■ How to enter characters

Use the following procedure to enter a commodity name, address and ingredient message.

Example) 1st line: |

TEC STORE |

2nd line: |

(TEL) 0123-45-6789 |

T E C

SPACE |

S |

T |

O |

R |

E |

RETURN |

1/4 |

1 st line content

SHIFT |

( |

|

|

|

|

DELETE |

SHIFT |

T |

E |

E |

(A) |

|

|

|

|

1/2 |

L |

6 |

7 |

8 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 nd line content |

||||||||||

NOTES: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

1. |

|

← |

and |

→ |

keys are the cursor keys. |

||||||||||||||||||||

2. |

|

To |

insert |

a space, move the cursor to the next character to the space to be inserted, and |

|||||||||||||||||||||

|

|

press |

INSERT |

|

key. |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

3. |

To delete a line, press |

DELETE (B) |

key. |

||||||||||||||||||||||

4. |

To move |

the cursor to |

the preceding |

line when entering a commodity name, press |

|

|

|

|

|||||||||||||||||

|

|

|

|

||||||||||||||||||||||

|

|

key, or |

↑ |

|

key. |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. |

Pressing the |

|

|

|

key toggles between the capital and small letter. |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENTER |

|

↓ |

|

|

|

|

|

6. |

When entering a commodity name, press or |

|

key instead of the |

key to |

|||||||||||||||||||||

|

|

RETURN 1/4 |

return. |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

7. |

Pressing the |

CHANGE PLU |

key toggles the type font between normal and boldface. |

||||||||||||||||||||||

8. |

To call a preset ingredient message idiom, follow the procedure below: |

||||||||||||||||||||||||

|

|

|

|

PLU |

|

|

|

|

|

|

|

|

RETURN |

|

|||||||||||

|

|

|

|

|

|

|

|

Enter the idiom #. |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

NEXT |

|

|

|

|

|

1/4 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9. To skip a line when entering an ingredient message, follow the procedure below:

SET |

|

Enter the line #. |

|

RETURN |

NEXT |

|

|

|

1/4 |

|

|

|

||

|

|

|

|

|

10- 3

10. PROGRAMMING PROCEDURES

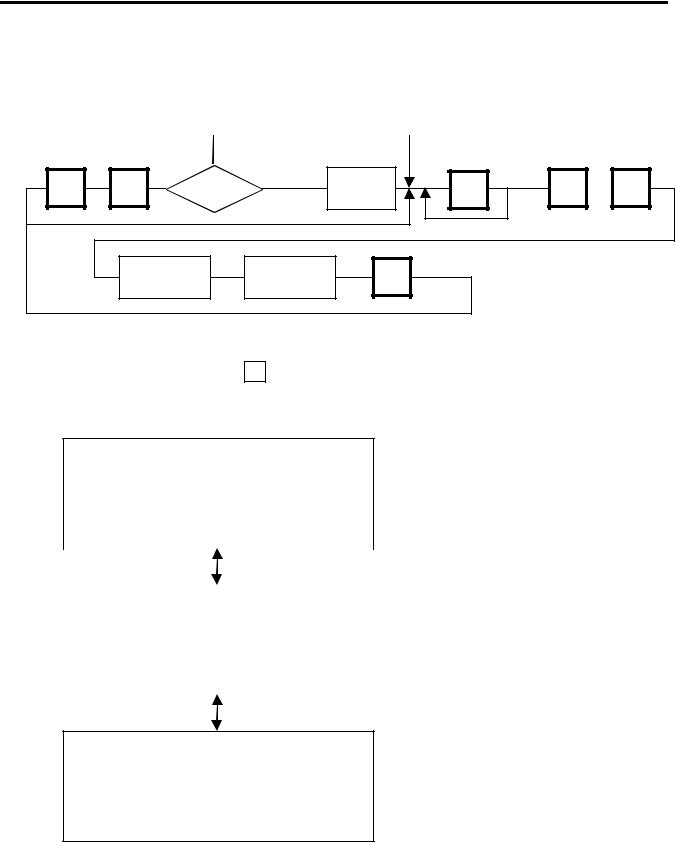

10.1 PLU DATA EDIT

10.1PLU DATA EDIT

Menu Page: 1

Item No.: 0

In this procedure, use operation keys (except when calling a PLU by using a speed key). The unit price stored in a PLU can be changed with this menu.

<MENU> |

0 |

|

Page 1 |

||

|

a |

Enter the PLU # |

|

||

|

|

|||

|

NEXT |

or |

VOID |

PRT |

|

PLU |

* |

||

|

|

|

||

|

|

|

Enter the |

|

|

|

Speed key # |

|

|

|

|

|

|

|

|

Speed key |

|

|

|

|

Page 1ÖPage 2 |

|

||

Change the unit price (max. 4 digit)

PRT |

* |

TEST |

a |

|

|

PROG. |

<MENU> |

|

Page 1 |

||

|

||

ESC. |

Main |

|

<MENU> |

||

|

NOTES:

1.An attempt to call a PLU # that has not been stored in the PLU file results in an error.

2.Under this Menu (Menu No. 0), “open-price” PLU’s price cannot be changed.

10- 4

10. PROGRAMMING PROCEDURES

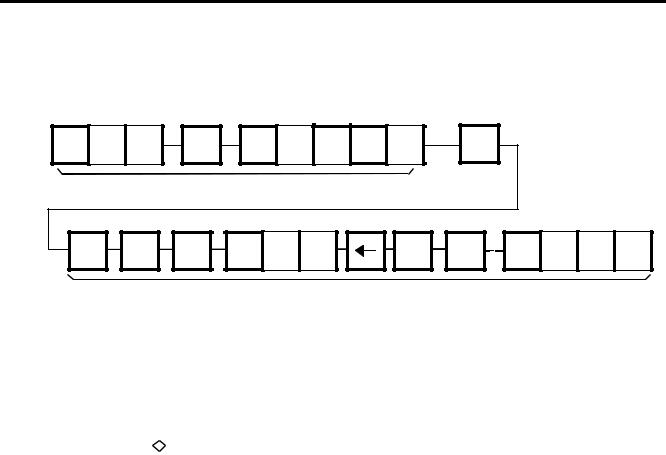

10.2 PLU DATA SETTING

10.2 PLU DATA SETTING

Menu Page: 1

Item No.: 1

Setting or changing the contents of PLU (PLU#, UPC#, Commodity Name, etc).

|

b |

|

|

|

|

|

|

|

<MENU> |

1 |

AUTO |

Set auto code |

|

Is status |

1 |

Set tare limit. |

|

|

|

Max. 2 lb (US) |

|

|||||

Page 1 |

CODE |

for the UPC# |

ENTER |

of initial set |

|

ENTER |

||

|

|

#8-2? |

|

Max. 1Kg/2.205 lb (CA/QR) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

NEXT or |

|

|

|

|

|

|

|

|

PLU |

|

|

|

|

|

|

|

SET |

NEXT |

Enter PLU# |

ENTER |

Enter UPC# |

ENTER |

Enter commodity name. |

ENTER |

|

(max. 6 dig.) |

(Max. 6 dig.) |

(max. 32 chars.×4 lines) |

||||

|

|

|

||||

|

|

BY COUNT |

|

|

|

Is status |

1 |

|

|

|

|

|

|

|

|

|

In what mode |

|

Enter quantity for that |

|

|||||

|

|

|

|

||||||

of initial set |

|

|

is PLU used? |

|

price. (Max. 2 dig.) |

|

|||

|

|

|

|

||||||

#1-6? |

|

WEIGH |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

0 |

|

|

or FIX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENTER |

Enter unit price. |

|

|

(max. 4 dig.) |

ENTER |

||

|

Is status |

1 |

Enter flag of |

|

of initial set |

|

unit price. |

ENTER |

#26-4? |

|

(Refer to NOTE4) |

|

|

|

|

|

0 |

|

|

|

Enter shelf life. (Max. 3 dig.)

|

Is status |

1 |

Enter PERIOD OF |

|

ENTER |

of initial set |

|

RELISH (Max. 3 dig.) |

ENTER |

|

#7-8? |

|

|

|

|

|

|

|

|

|

0 |

|

|

|

Is status |

1 |

Enter tare. |

|

of initial set |

|

Max. 2lb (US) |

ENTER |

#23-1? |

|

Max. 1 kg/2.205 lb (CA/QR) |

|

0 |

|

|

|

à |

2 |

Is status |

|

|

of initial set |

||

|

|

#8-1? |

|

Select |

|

0 or 1 |

|

compulsory tare |

|||

|

|||

Is status |

1 |

Selection Mode Flag |

|

|

|

Is status |

1 |

Safe Handing |

|

Status |

1 |

||

of initial set |

0: Weight |

|

|

ENTER |

of initial set |

Instruction |

ENTER |

of initial set |

|||||

1: By Count |

|

|

0: Non Print |

||||||||||

#1-5? |

|

|

|

|

|

#10-5? |

|

|

#8-7/28-4? |

||||

0 |

|

2: Fix Price |

|

|

|

|

0 |

|

1: Print |

|

0 |

See |

|

|

|

|

|

|

|

|

|

|

|

NOTE7. |

|||

CHANGE |

Enter current |

|

|

|

Enter new |

|

|

|

|

|

|||

PLU |

|

PLU# |

|

ENTER |

|

PLU# |

ENTER |

|

|

Set tare % |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENTER |

(Max. 99.9%) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DELETE |

Enter |

ENTER |

|

|

Y |

or |

N |

|

|

|

|

|

|

PLU |

PLU# |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

The setting label is issued. |

|

|

|

|

|

|

à |

(Price↔%) |

|

|||

TEST |

|

|

|

(Sorting) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

à |

|

|

Is status |

2 |

Enter discount price |

|

|

|

|

|

|

|

|

Y |

|

or rate. |

|

|||

|

|

|

|

|

|

|

|

of initial set |

|

ENTER |

|||

|

|

|

|

|

|

|

|

|

(Price: Max. 5 digit |

||||

|

|

|

|

|

|

|

|

|

|

#12-4? |

|

Rate: Max. 3 digit) |

|

b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<MENU> |

|

|

|

|

|

0 or 1 |

|

|

|

||

|

|

|

|

|

|

Any key |

|

|

|

||||

|

PROG. |

|

|

|

|

|

|

|

|||||

|

Page 1 |

|

|

|

except |

Y |

|

|

|

|

|||

|

|

|

|

|

|

|

1 |

Enter LOGO #. |

|

||||

|

|

|

|

|

|

|

|

Is status |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

(Not Sorting) |

of initial set |

|

(#0 - 26) |

ENTER |

|

|

|

|

Main |

|

|

|

|

|

or (#0 - 99)* |

||||

|

ESC. |

|

|

|

|

|

|

#9-4? |

|

|

|||

|

<MENU> |

The memory file is sorted when a |

|

|

|

|

|||||||

|

|

|

0 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

memory full error occurs. |

|

*: Selectable by the initial setting #10-7. |

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

(SL-9000N only) |

|

||