Toshiba EO1-33027E, CB-426-T3-QQ, CB-426-T3 User Manual

TEC Two-Color Printer

CB-426-T3-QQ

Owner’s Manual

Table of Contents

We, TOSHIBATEC Corporation of 570 Ohito Ohito-cho Tagata-Gun Shizuoka-Ken 410-2323 JAPAN, declare in our sole responsibility that this product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This accordance with the instruction manual, may cause harmful interference to radio communications. Operations of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

(for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the user’s authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.”

“Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.” (for CANADA onl y)

CAUTION:

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2.The contents of this manual may be changed without notification.

3.Please refer to your local Authorized Service representative with regard to any queries you may have in this manual.

Trademark:

∙Microsoft, Windows, Windows NT, and the Windows Logo are either registered trademarks or trademarks of Microsoft Corporation in the United States.

∙All other brands and names are the property of their respective owners.

Copyright © 2000

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Safety Precautions

Safety Precautions

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions necessary for safe handling are included in this manual. All warnings and cautions contained in this manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified using the procedures described in this manual, turn off the power, unplug the machine, then contact your authorized TOSHIBA TEC representative for assistance.

Meanings of Symbols

This symbol indicates warning items (including cautions). Specific warning contents are drawn inside the  symbol. (The symbol on the left indicates a general caution.)

symbol. (The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items). Specific prohibited contents are drawn inside or near the  symbol. (The symbol on the left indicates “no disassembling”.)

symbol. (The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed. Specific instructions are drawn inside or near the  symbol.

symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

i

Safety Precautions

WARNING

WARNING

This indicates that there is the risk of death or serious injury if the machines are improperly handled contrary to this indication.

■Do not use voltages other than the voltage (AC) specified on the rating plate, as this may cause fire or electric shock.

Any other than the specified AC voltage is prohibited.

■If the machines share the same outlet with any other electrical appliances which consume large amounts of power, the voltage will fluctuate widely each time these appliances operate. Be sure to provide an exclusive outlet for the machine as this may cause the machines to malfunction.

Prohibited

■Do not insert or drop metal, flammable or other foreign objects into the machines through the ventilation slits, as this may cause fire or electric shock.

Prohibited

■If the machines are dropped or their cabinets damaged, first turn off the power switches and disconnect the power cord plugs from the outlet, and then contact your authorized TOSHIBA TEC representative for assistance. Continued use of the machine in that condition may cause fire or electric shock.

Disconnect the plug.

■Do not plug in or unplug the power cord plug with wet hands as this may cause electric shock.

Prohibited

■Do not place metal objects or water-filled containers such as flower vases, flower pots or mugs, etc. on top of the machines. If metal objects or spilled liquid enter the machines, this may cause fire or electric shock.

Prohibited

ii

Safety Precautions

WARNING (Cont.)

WARNING (Cont.)

■Do not cut, damage or modify the power cords. Also, do not place heavy objects on, pull on, or excessively bend the cords, as this may cause fire or electrical shock.

Prohibited

■Continued use of the machines in an abnormal condition such as when the machines are producing smoke or strange smells may cause fire or electric shock. In these cases, immediately turn off the power switches and disconnect the power cord plugs from the outlet. Then, contact your authorized TOSHIBATEC representative for assistance.

Disconnect the plug.

■If foreign objects (metal fragments, water, liquids) enter the machines, first turn off the power switches and disconnect the power cord plugs from the outlet, and then contact your authorized TOSHIBA TEC representative for assistance. Continued use of the machine in that condition may cause fire or electric shock.

Disconnect the plug.

■Ensure that the equipment is properly grounded. Extension cables should also be grounded. Fire or electric shock could occur on improperly grounded equipment.

Connect a grounding wire.

■When unplugging the power cords, be sure to hold and pull on the plug portion. Pulling on the cord portion may cut or expose the internal wires and cause fire or electric shock.

Disconnect the plug.

■Do not remove covers, repair or modify the machine by yourself. You may be injured by high voltage, very hot parts or sharp edges inside the machine.

No disassembling.

iii

Safety Precautions

CAUTION

CAUTION

Request Regarding

Maintenance

This indicates that there is the risk of personal injury or damage to objects if the machine is improperly handled contrary to this indication.

The following precautions will help to ensure that this machine will continue to function correctly.

∙Try to avoid locations that have the following adverse conditions:

*Temperatures out of the specification

* |

Direct sunlight |

* |

High humidity |

* |

Shared power source |

* |

Excessive vibration |

*Dust/Gas

∙The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic covers.

∙USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

∙DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or gas.

∙Ensure the printer is operated on a level surface.

∙Any data stored in the memory of the printer could be lost during a printer fault.

∙Try to avoid using this equipment on the same power source as high voltage equipment or equipment likely to cause electrical interference.

∙Unplug the machine whenever cleaning or working inside it.

∙Keep the work environment static free.

∙Do not place heavy objects on top of the machines, as these items may become unbalanced and fall causing injury.

∙Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines and may cause fire.

∙Do not lean against the machine. It may fall and cause injury.

∙Care must be taken not to injure yourself with the printer paper cutter.

∙Unplug the machine when it is not used for a long period of time.

∙Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

∙Our preventive maintenance service performs the periodic checks and other work required to maintain the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

∙Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or other parts to deteriorate or cause the paint to peel.

iv

TOC 2

TOC 2

|

|

|

|

Table of Contents |

TableContentsof Contents |

|

|||

1. |

Product Overview ................................................................................................................................................... |

1 |

||

|

1.1 |

Introduction ...................................................................................................................................................... |

1 |

|

|

1.2 |

Features ............................................................................................................................................................ |

1 |

|

|

1.3 |

Unpacking ........................................................................................................................................................ |

1 |

|

|

1.4 |

Accessories and Options ................................................................................................................................. |

2 |

|

|

1.4.1 |

Accessories ............................................................................................................................................. |

2 |

|

|

1.4.2 Cool Release Enhancement Kit ............................................................................................................... |

3 |

||

|

1.4.3 |

Options .................................................................................................................................................... |

3 |

|

|

1.5 |

Appearance ...................................................................................................................................................... |

4 |

|

|

1.5.1 |

Dimensions .............................................................................................................................................. |

4 |

|

|

1.5.2 |

Front View ............................................................................................................................................... |

4 |

|

|

1.5.3 |

Rear View ................................................................................................................................................ |

4 |

|

|

1.5.4 |

Operation Panel ...................................................................................................................................... |

5 |

|

|

1.5.5 |

Interior ..................................................................................................................................................... |

5 |

|

2. |

Printer Installation .................................................................................................................................................. |

6 |

||

|

2.1 |

Installing the Accessories ................................................................................................................................. |

6 |

|

|

2.1.1 |

Fan Filters ................................................................................................................................................ |

6 |

|

|

2.1.2 |

Media Slide ............................................................................................................................................. |

6 |

|

|

2.1.3 |

Supply Shaft Holder ................................................................................................................................ |

6 |

|

|

2.2 |

Connecting the Printer to Your Computer ........................................................................................................ |

7 |

|

|

2.3 |

Connecting the Power Cord ............................................................................................................................. |

8 |

|

|

2.4 |

Turning on/off the Printer .................................................................................................................................. |

9 |

|

|

2.4.1 Turning on the Printer .............................................................................................................................. |

9 |

||

|

2.4.2 Turning off the Printer ............................................................................................................................ |

10 |

||

|

2.5 |

Loading the Media.......................................................................................................................................... |

11 |

|

|

2.5.1 |

Additional Information ........................................................................................................................... |

16 |

|

|

2.6 |

Sensor Adjustments ....................................................................................................................................... |

17 |

|

|

2.6.1 |

Black Mark Sensor ................................................................................................................................ |

17 |

|

|

2.6.2 |

Feed Gap Sensor .................................................................................................................................. |

18 |

|

|

2.6.3 Media Sensor Sensitivity Adjustment ................................................................................................... |

19 |

||

|

2.7 |

Loading the Ribbons (for Hot Release Ribbons) ............................................................................................ |

21 |

|

|

2.7.1 |

Ribbon Positions ................................................................................................................................... |

21 |

|

|

2.7.2 |

Loading Procedure ................................................................................................................................ |

21 |

|

|

2.8 |

Loading the Ribbons (for Cold Release Ribbons) .......................................................................................... |

24 |

|

|

2.8.1 |

Precautions ........................................................................................................................................... |

24 |

|

|

2.8.2 Installing the Ribbon Plate .................................................................................................................... |

25 |

||

|

2.8.3 Installing the SP Ribbon Guides ........................................................................................................... |

26 |

||

|

2.8.4 Installing the Ribbon Tension Sheet ...................................................................................................... |

27 |

||

|

2.8.5 Loading the Cold Release Ribbons ....................................................................................................... |

28 |

||

3. |

Printing |

.................................................................................................................................................................. |

29 |

|

|

3.1 |

Installing the Printer Driver ............................................................................................................................. |

29 |

|

|

3.1.1 ........................................................................................................................... |

System Requirements |

29 |

|

|

3.1.2 ..............................................................................................Installation Procedure (For Windows®98) |

29 |

||

|

3.1.3 ................................................................................................................Uninstalling the Printer Driver |

35 |

||

|

3.2 |

Properties ....................................................................................................................................................... |

37 |

|

|

3.2.1 ................................................................................................................. |

Displaying Printer Properties |

37 |

|

|

3.2.2 ......................................................................................................................... |

Summary of Properties |

38 |

|

|

3.3 |

Page .....................................................................................................................................................Setup |

39 |

|

|

3.3.1 .............................................................................................................................Selecting a label size |

39 |

||

|

3.3.2 ......................................................................................................................Creating a new label size |

40 |

||

|

3.3.3 ............................................................................................................................................. |

Orientation |

41 |

|

|

3.3.4 ....................................................................................................................................... |

Miscellaneous |

42 |

|

|

3.4 |

Graphics ......................................................................................................................................................... |

46 |

|

|

3.4.1 ................................................................................................................................................ |

Dithering |

46 |

|

|

3.4.2 ...................................................................................................................................................... |

Color |

46 |

|

|

3.4.3 ........................................................................................................................................... |

Color Setup |

47 |

|

|

3.4.4 ................................................................................................................................. |

Color Registration |

50 |

|

|

3.5 |

Bar ........................................................................................................................................................Fonts |

52 |

|

|

3.5.1 .................................................................................................................Specifying a New Font Style |

53 |

||

|

3.6 |

Stock .............................................................................................................................................................. |

55 |

|

|

3.6.1 .......................................................................................................................................... |

Print Method |

55 |

|

v

TOC 1

|

|

|

|

Table of Contents |

|

3.6.2 |

Sensor ................................................................................................................................................... |

55 |

|

|

3.6.3 |

Label Gap .............................................................................................................................................. |

55 |

|

|

3.6.4 |

Issue Settings ........................................................................................................................................ |

56 |

|

|

3.6.5 |

Fine Adjustment .................................................................................................................................... |

57 |

|

|

3.7 |

Options ........................................................................................................................................................... |

58 |

|

|

3.7.1 |

Transfer Mode ....................................................................................................................................... |

58 |

|

|

3.7.2 |

Print Density Adjustment ....................................................................................................................... |

58 |

|

|

3.8 |

Testing ............................................................................................................................................................ |

59 |

|

|

3.8.1 |

Testing ................................................................................................................................................... |

59 |

|

|

3.8.2 |

Maintenance .......................................................................................................................................... |

60 |

|

|

3.9 |

Print Test......................................................................................................................................................... |

61 |

|

|

3.9.1 |

Procedures ............................................................................................................................................ |

61 |

|

|

3.10 Printing a Label .............................................................................................................................................. |

62 |

||

4. |

Online Mode .......................................................................................................................................................... |

64 |

||

|

4.1 |

Operation Panel .............................................................................................................................................. |

64 |

|

|

4.2 |

Operation ........................................................................................................................................................ |

65 |

|

|

4.3 |

Reset .............................................................................................................................................................. |

65 |

|

5. |

Maintenance ......................................................................................................................................................... |

66 |

||

|

5.1 |

Cleaning ......................................................................................................................................................... |

66 |

|

|

5.1.1 |

Print Head/Platen .................................................................................................................................. |

66 |

|

|

5.1.2 |

Pinch Roller/Feed Roller/Media Guide .................................................................................................. |

67 |

|

|

5.1.3 |

Fan Filters .............................................................................................................................................. |

67 |

|

|

5.1.4 |

Covers and Panels ................................................................................................................................ |

68 |

|

|

5.1.5 |

Ribbon Modules .................................................................................................................................... |

68 |

|

6. |

Troubleshooting .................................................................................................................................................... |

69 |

||

|

6.1 |

Error Messages .............................................................................................................................................. |

69 |

|

|

6.2 |

Possible Problems .......................................................................................................................................... |

71 |

|

|

6.3 |

Removing Jammed Media ............................................................................................................................. |

72 |

|

|

6.3.1 |

From the Pinch Roller Unit .................................................................................................................... |

72 |

|

|

6.3.2 |

From the Print Head Block .................................................................................................................... |

72 |

|

|

6.4 When the Ribbon is Torn Apart ...................................................................................................................... |

73 |

||

Appendix 1 Specifications ......................................................................................................................................... |

74 |

|||

|

A1.1 Printer ............................................................................................................................................................. |

74 |

||

|

A1.2 Options ........................................................................................................................................................... |

75 |

||

|

A1.3 Media .............................................................................................................................................................. |

75 |

||

|

A1.3.1 |

Media Type ............................................................................................................................................ |

75 |

|

|

A1.3.2 |

Detection Area of the Transmissive Sensor .......................................................................................... |

76 |

|

|

A1.3.3 |

Detection Area of the Reflective Sensor ............................................................................................... |

77 |

|

|

A1.3.4 |

Effective Print Area ................................................................................................................................ |

77 |

|

|

A1.4 Ribbon ............................................................................................................................................................ |

78 |

||

Appendix 2 DIP Switches .......................................................................................................................................... |

79 |

|||

|

A2.1 DIP Switch A .................................................................................................................................................. |

80 |

||

|

A2.2 DIP Switch B .................................................................................................................................................. |

81 |

||

|

A2.3 Ribbon Near End Detection ........................................................................................................................... |

82 |

||

Appendix 3 Quick Reference for Printing ................................................................................................................ |

83 |

|||

Appendix 4 Message and LED .................................................................................................................................. |

86 |

|||

Appendix 5 System Mode.......................................................................................................................................... |

88 |

|||

|

A5.1 Operation Panel .............................................................................................................................................. |

88 |

||

|

A5.2 Overview ......................................................................................................................................................... |

89 |

||

|

A5.3 Self-Diagnostic Test ....................................................................................................................................... |

91 |

||

|

A5.4 Parameter Setting .......................................................................................................................................... |

92 |

||

|

A5.5 Test Print ....................................................................................................................................................... |

101 |

||

|

A5.6 RAM Clear .................................................................................................................................................... |

104 |

||

|

A5.7 Additional Information .................................................................................................................................. |

106 |

||

|

A5.7.1 |

Self-Diagnostic Test Result Sample and Descriptions ........................................................................ |

106 |

|

|

A5.7.2 |

Maintenance Counter/Parameter Check Print Sample and Descriptions ........................................... |

107 |

|

|

A5.7.3 |

Cut Operation Example ....................................................................................................................... |

108 |

|

|

A5.7.4 |

Pulse Motor Speed ............................................................................................................................. |

108 |

|

|

A5.7.5 |

X-Coordinate Fine Adjustment ............................................................................................................ |

108 |

|

|

A5.7.6 |

Magnified Views of Slant Line Pattern ................................................................................................ |

108 |

|

|

A5.7.7 |

Initial Values after Clearing the Maintenance Counter (MAINTE.CNT.CLEAR) .................................... |

109 |

|

|

A5.7.8 |

Initial Values after Clearing the Parameter (PARAMETER CLEAR) ...................................................... |

110 |

|

|

A5.7.9 |

Initial Values after Clearing the Print Distance (PRINT STEP CLEAR) ................................................. |

111 |

|

Appendix 6 Interface ................................................................................................................................................ |

112 |

|||

vi

Chapter 1 Product Overview

1. Product Overview

1.1Introduction

1.2Features

1.3Unpacking

Thank you for choosing the TOSHIBA TEC CB-426-T3 two-color printer.

This Owner’s Manual describes printer setup and installation procedures, printer properties, settings and adjustments, and maintenance information. Thus it should be read carefully to help gain maximum performance and life from the printer. For further information please refer to this manual and keep it safe for future reference.

The CB-426-T3 two-color printer has the following features:

∙High-speed, quality printing. The printer utilizes Edge Heads that support the high-performance Hot Release Ribbons to produce a maximum print speed of approximately 6 in/s (150 mm/s). In addition, the Cool Release Enhancement Kit is supplied as an accessory, and allows the popular Cold Release Ribbons to be loaded.

∙Fine, sharp color printing. The printer utilizes two high-resolution (305 dpi) print heads, and uses a variety of spot color ribbons for solid printing.

∙A variety of printer fonts and bar code fonts are built into the printer to help create a unique colored label.

∙Cost efficiency. The automatic ribbon saver is standard and allows for conservation of individual ribbons. In addition, the media back feed capability allows you to avoid wasting the media.

Unpack the printer as per the Unpacking Instructions packed with the printer.

Important!

∙Check for damage or scratches on the printer.

However, please note that TOSHIBA TEC shall have no liability of any damage of any kind sustained during transportation of the product.

∙Keep the cartons and pads for future transportation of the printer.

1

Chapter 1 Product Overview

1.4Accessories and Options

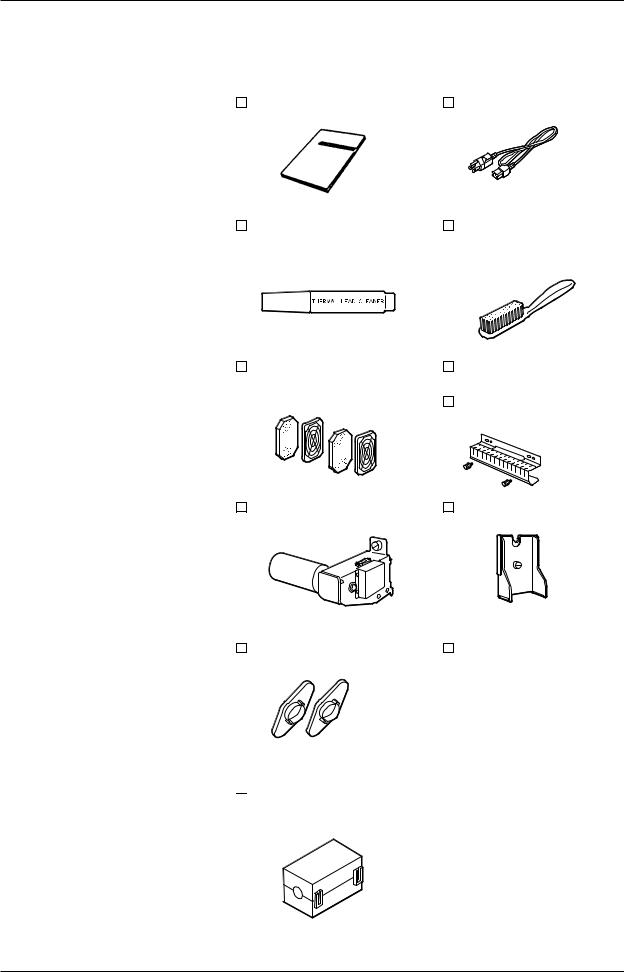

When unpacking the printer, please make sure all accessories are packed with the printer.

1.4.1 |

Accessories |

Owner’s Manual (1 pc.) |

Power Cord (1 pc.) |

|

|

|

(FBC B0030202) |

Thermal Head Cleaner (1 pc.) |

Feed Roller Brush (1 pc.) |

(24089500013) |

(FMQB0047001) |

|

*To be used exclusively for |

|

the Feed Roller |

Fan Filter (2 sets.) |

Media Slide (1 pc.) |

(FMBB0046401) |

(FMCC 0032001) |

|

Black Screw (2 pcs.) |

|

(HAA-0007002) |

Supply Shaft Holder (1 pc.) |

Supply Shaft Holder Stand (1pc.) |

(FMBD 0038901) |

(FMBB0047401) |

Supply Roll Holder (2 pcs.) |

Unpacking Instructions (1 pc.) |

||||||||

(FMHD0007502) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ferrite Core (1 pc.) (HGA-0068001) *Used for RS-232C

Ferrite Core (1 pc.) (HGA-0068001) *Used for RS-232C

2

|

Chapter 1 |

Product Overview |

1.4.2 Cool Release |

Ribbon Plate (2 pcs.) |

Mounting Screw (2 pcs.) |

Enhancement Kit |

(FMCB 0095301) |

(FMDB 0079501) |

D-3x5 Screw (6 pcs.) |

SP Ribbon Guide (A) (1 pc.) |

(X0140305130) |

(FMCB0095601) |

SP Ribbon Guide (B) (1 pc.) |

Ribbon Tension Sheet (2 pcs.) |

(FMCB0095501) |

(FMQC0035901) |

Sheet Fixing Plate (2 pcs.) (FMEB0116901)

Sheet Fixing Plate (2 pcs.) (FMEB0116901)

1.4.3 |

Options |

The following two options are available for the CB-426-T3 two-color |

|

|

printer: |

|

|

∙ The CB-1204-QM Cutter Module, which is used to cut media |

repeatedly.

∙ The CB-1004-QM Ribbon Module, to be used as a spare ribbon module.

Cutter Module |

Ribbon Module |

3

Chapter 1 Product Overview

1.5Appearance

1.5.1Dimensions

Note:

Depth is 34.4 inches (875mm) when the Cutter Module is installed on the printer.

The names of the parts or units introduced in this section are used in the following chapters.

|

13.7(350) |

|

|

|

|

|

|

|

20.4(520) |

|

|

|

|

11.0(280) |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15.1

(385)

Dimensions in inches + (mm)

1.5.2Front View

Top Cover

Message Display (LCD)

Supply Roll Holder

Supply Shaft Holder

Operation Panel |

Supply Shaft Holder Stand |

|

|

|

Media Outlet |

1.5.3Rear View

|

Serial Interface Connector |

Media Sensor Adjuster |

(RS-232C) |

Air Vents

(Cooling Fans)

Expansion I/O

Interface Connector

Media Inlet

Parallel Interface

Connector

(Centronics)

Supply Shaft Holder Slots |

Power Switch |

|

AC Power Inlet |

||

|

||

|

Harness |

4

Chapter 1 Product Overview

1.5.4Operation Panel

Message Display (LCD)

ON LINE LED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

(Green) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ERROR LED |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

POWER LED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Green) |

||||||

|

(Red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

POWER |

ON LINE |

ERROR |

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

FEED |

Key |

|

|

FEED |

RESTART |

PAUSE |

|

|

|

PAUSE |

Key |

||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

RESTART |

|

|

|

|

|

||||||||||||

Please see Appendix 3 for further information about the Operation

Panel.

1.5.5Interior

Top Cover

Pinch Roller Unit

Head Lever

Pinch Roller Lever

Ribbon Module

Media Pressure Plate

5

Chapter 2 Printer Installation

2. Printer Installation

2.1Installing the Accessories

2.1.1Fan Filters

Note:

Please clean the Filter Pads periodically. See Section 5.1.3.

2.1.2Media Slide

Notes:

∙Either a roll of labels or tags can be loaded in the printer.

∙In this Owner's Manual, labels and tags are generically called "media".

∙TOSHIBA TEC recommends that labels are rolled outside, and the tags are rolled inside. The media loading procedure depends on which type of media is going to be loaded. See Section 2.5 for more detail.

This chapter describes in detail how to set up the printer to get ready for printing.

First install the accessories on the printer.

1Unpack the Fan Filters.

2Mount the Fan Filters over the Air Vents.

Filter Pad

Filter Retainer

Air Vents

(Cooling Fans)

Attach the Media Slide with the two supplied black screws.

When loading a roll of labels, fit the Media Slide on the screw holes above the Media Inlet.

or

When loading a roll of tags, fit the Media Slide on the screw holes below the Media Inlet.

Media Slide (for labels)

Media Slide (for tags)

Media Slide (for tags)

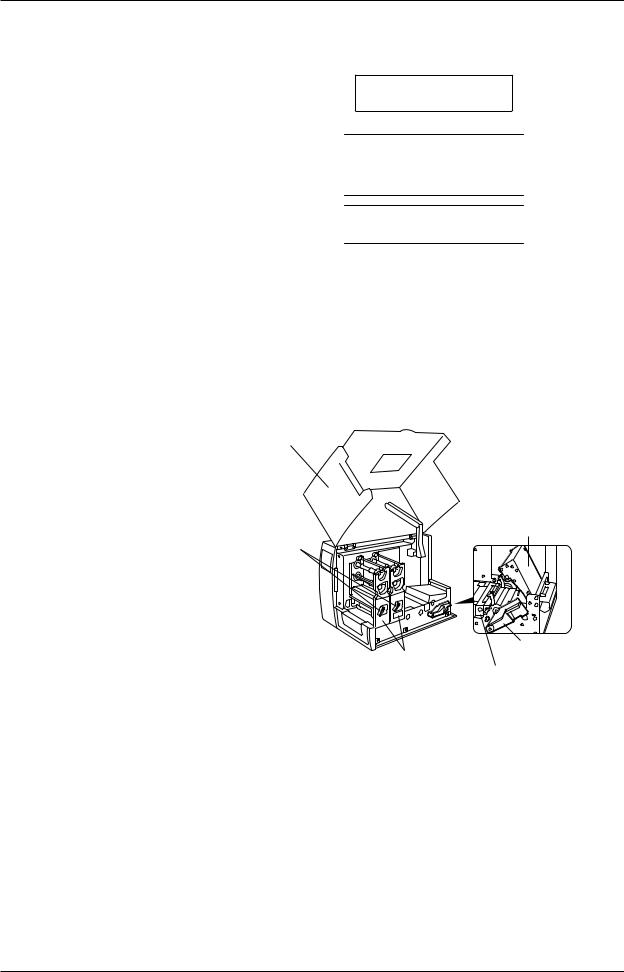

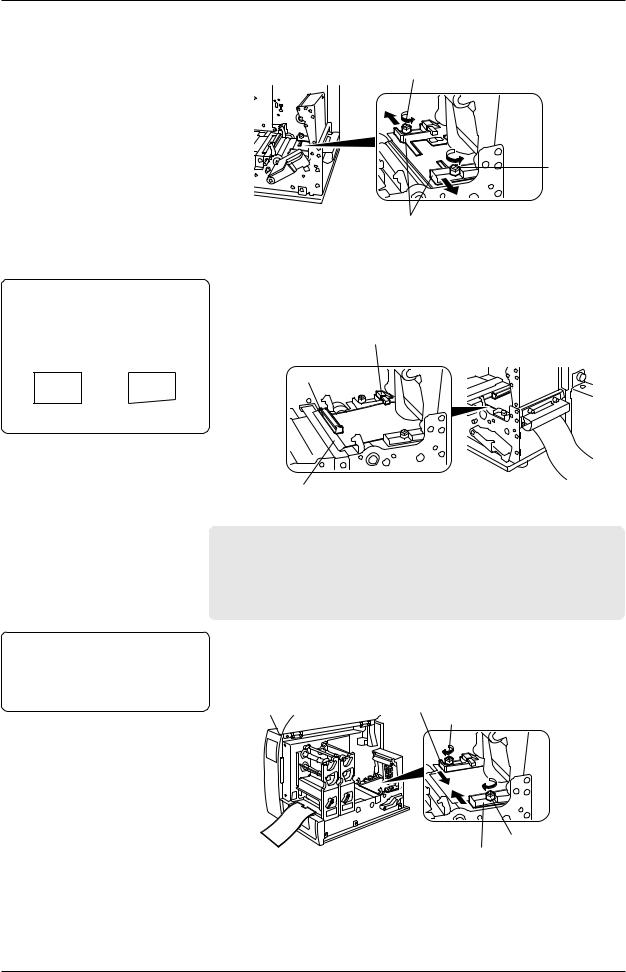

2.1.3 |

Supply Shaft Holder |

1 |

Connect the Supply Shaft Holder Harness to the harness attached |

|

|

|

on the rear of the printer. |

|

|

2 |

First hook the lower parts of the Supply Shaft Holder into the |

|

|

|

lower two Supply Shaft Holder Slots on the rear of the printer. |

|

|

|

Then fix the Supply Shaft Holder in place by tightening the screw. |

To remove the Supply Shaft Holder from the printer, just reverse the installation procedure.

Supply Shaft

Screw |

Holder Slots |

|

|

|

Harness |

Supply Shaft Holder

Supply Shaft Holder Harness

6

Chapter 2 Printer Installation

2.2Connecting the Printer to Your Computer

Note:

The interface cable is not included in the accessories.

The printer can be connected to any computer, since it supports both serial and parallel interface cables. Before connecting the printer, please make sure which interface cable will be used.

1Be sure that both printer and computer are turned off. (o) indicates OFF.

Power Switch

2Connect the interface cable to the interface connector on the printer. As illustrated below, connect the interface cable to either of the interface connectors, depending on which interface cable will be used.

Serial Interface |

Serial Interface |

|

Connector |

||

Cable |

||

|

||

Parallel Interface |

Parallel Interface |

|

Connector |

||

Cable |

||

|

Note:

Please refer to the user's manual of the computer.

3Secure the cable with the clamps or screws.

4When using the serial interface cable, attach the supplied ferrite core to the cable.

5Connect the interface cable to the interface connector on the computer.

|

Screws |

Ferrite Core |

|

(For Serial Interface |

|

Cable) |

Clamps |

|

7

Chapter 2 Printer Installation

2.3Connecting the Power Cord

CAUTION!

∙Please turn off the printer before connecting the power cord, as this may cause an electric shock or damage to the printer.

∙Please use the supplied power cord only. Use of other cords may cause an electric shock or a fire.

1Be sure that both printer and computer are switched OFF. (o) indicates OFF.

Power Switch

2Connect the supplied power cord to the AC Power Inlet of the printer.

AC Power Inlet

3 Plug the power cord in an outlet.

8

Chapter 2 Printer Installation

2.4Turning on/off the Printer

2.4.1Turning on the Printer

Note:

Just in case the printer is not turned on, or any error message appears, please see Chapter 6.

When turned on, the printer checks the print head and memory. When turned off, the printer will lose data in non-volatile memory.

CAUTION!

Use the power switch to turn on/off the printer. Unplugging the power cord for turning on/off the printer may cause a fire, an electric shock, or damage to the printer.

Important!

When the printer is connected to the computer,

∙Turn ON the printer before turning on the computer.

∙Turn OFF the computer before turning off the printer.

1 Turn on the printer. ( ) indicates ON.

Power Switch

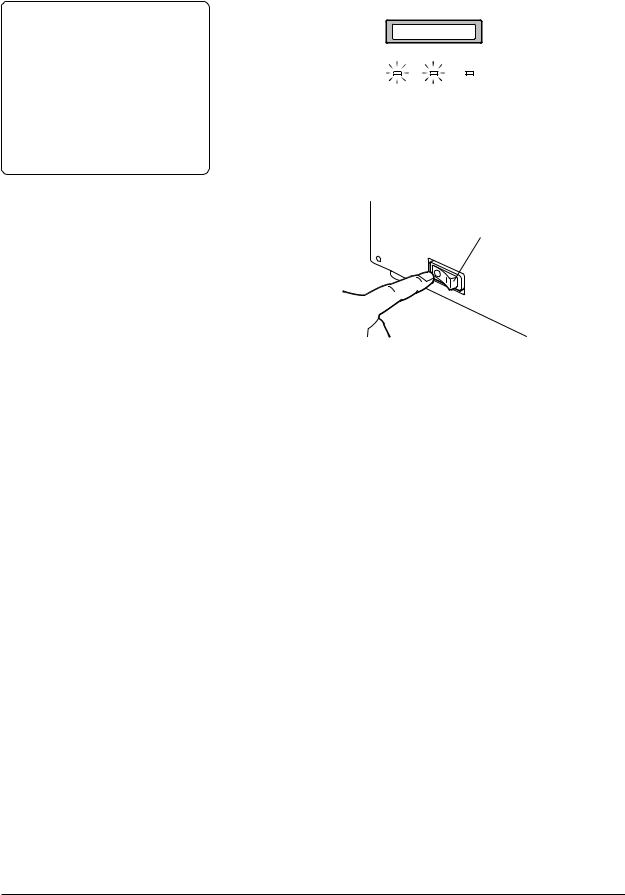

2The “ON LINE” message appears on the Message Display. The POWER LED illuminates green. Then the ON LINE LED also illuminates green.

ON LINE

POWER ON LINE ERROR

FEED RESTART PAUSE

9

|

|

Chapter 2 |

|

Printer Installation |

||||||

2.4.2 Turning off the |

1 When turning off the printer, make sure of the following: |

|||||||||

|

Printer |

∙ The “ON LINE” message is shown on the Message Display. |

||||||||

|

|

∙ Both POWER and ON LINE LED’s are illuminated. |

||||||||

|

CAUTION! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

∙ Do not turn off the printer |

|

|

ON LINE |

|

|

||||

|

while a label is being issued, |

|

|

|

|

|

|

|

|

|

|

as this may cause a paper jam |

|

|

|

|

|

|

|

|

|

|

or damage to the printer. |

|

POWER |

ON LINE |

ERROR |

|

||||

|

∙ Do not turn off the printer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

when the ON LINE LED is |

|

FEED |

RESTART |

PAUSE |

|

||||

|

blinking, as this may cause |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

damage to the computer |

|

|

|

|

|

|

|

|

|

|

connected to the printer. |

2 Turn off the power switch. |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Power Switch |

|

10

Chapter 2 Printer Installation

2.5Loading the Media

Labels or tags can be loaded in the printer. The media loading procedure depends on which media is going to be used.

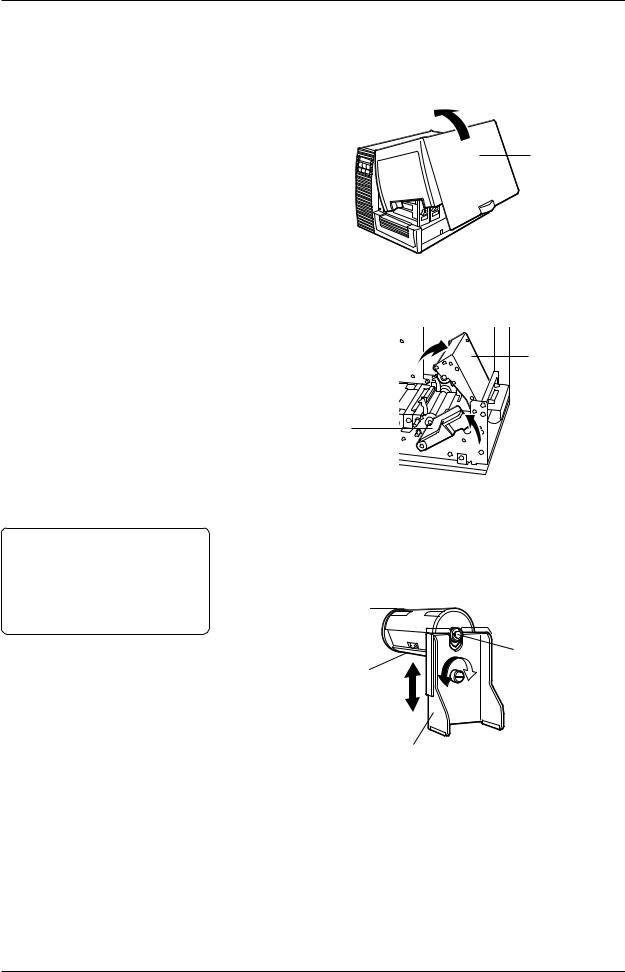

1 Open the Top Cover.

Top Cover

Note:

The Supply Shaft cannot be kept level because of its weight, as the printer becomes older. So before loading the media, adjust the Supply Shaft so that it can be kept level.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

Pinch Roller Unit

Pinch Roller Lever

(To ROLLER RELEASE)

3Loosen the screw on the Supply Shaft Holder Stand.

4Fit the Supply Shaft Holder Stand to the Supply Shaft, as illustrated below. The Supply Shaft Holder Stand moves up or down so that the Supply Shaft is kept level.

Supply Shaft

Screw

Screw

Supply Shaft Holder Stand

5Remove the Supply Shaft Holder Stand from the Supply Shaft, when adjustment to its height is complete.

11

Chapter 2 Printer Installation

2.5Loading the Media (Cont.)

CAUTION!

Do not push into the Supply Roll Holder (inside) with the claw locked in the notches, as this may cause damage to the claw or notches.

See Section 2.5.1 for more detail.

Note:

The media is rolled either outside or inside, depending on the type of media that is loaded. Whichever media is used, load it with print side facing up. See Appendix 1 for more detail.

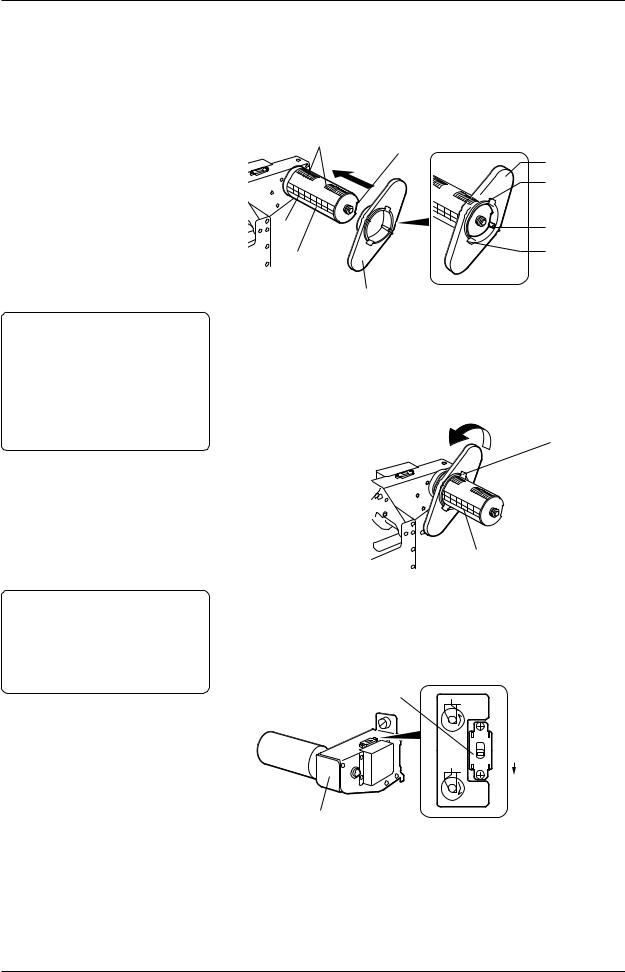

6Turn the Supply Shaft so that the notches face upward, and the marks face the Media Inlet.

7To attach the Supply Roll Holder (inside), fit the tooth of the Supply Roll Holder to the groove of the Supply Roll Shaft. Turn the Supply Roll Holder clockwise to the end.

Notches Groove

Supply Roll Holder

Claw

Marks |

Tooth |

Supply Shaft |

Claw |

|

Supply Roll Holder

8Push the Supply Roll Holder (inside) to the end of the Supply Shaft. Then turn the Supply Roll Holder counterclockwise so that the claw is locked into the notch. When inserting the Supply Roll Holder into the Supply Shaft, more pressure should be applied when passing over the roller on the way to the end of the Supply Shaft.

Claw

Notches

Notches

Marks

9Switch the Back Tension Selector, depending on whether the media is rolled outside or inside. Switch the Selector to A for the media rolled outside. Switch it to B for the media rolled inside, as indicated by the arrows.

Back Tension Selector

A

Media rolled outside

Media rolled outside

Media rolled inside

B

Supply Shaft Holder

10 Measure width of the media that will be loaded.

12

Chapter 2 Printer Installation

2.5Loading the Media (Cont.)

Note:

When inserting a roll of labels or tags, push on the media core only. Otherwise, core material drags against the Supply Shaft causing telescoping of the media supply roll.

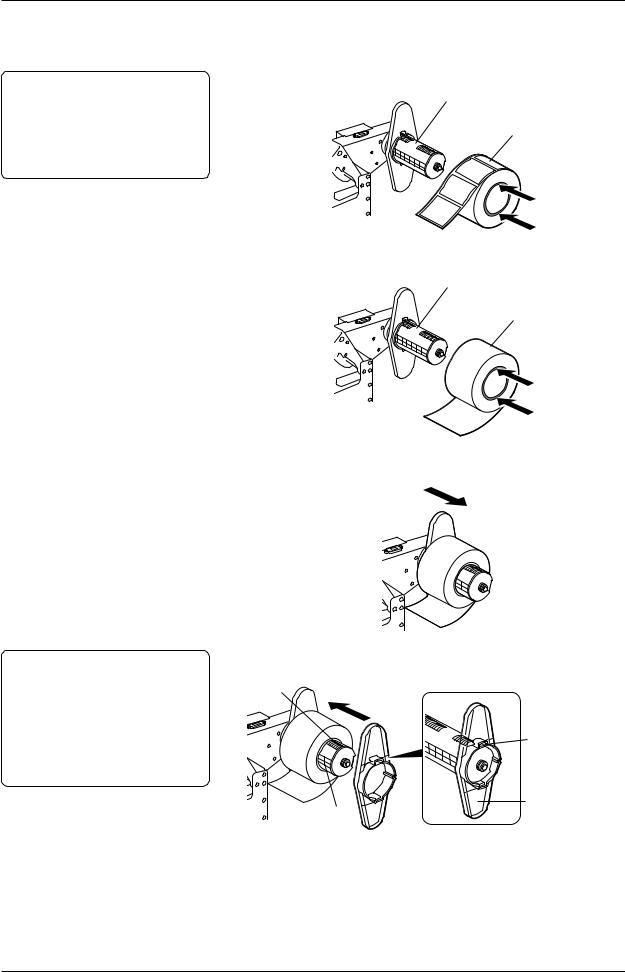

11Based on width of the media measured in Step 10, push the media into the Supply Roll Holder (inside), and place it with reference to the marks on the Supply Shaft.

∙ Loading a roll of labels

Supply Shaft

Labels

∙ Loading a roll of tags

Supply Shaft

Tags

CAUTION!

To remove the Supply Roll Holder (outside), turn it to disengage the claw from the notches. Otherwise, the claw or the notches may be damaged. See Section 2.5.1 for more detail.

12 Slide the Supply Roll Holder (inside) to the loaded media.

Supply Roll Holder

Supply Roll Holder

13 Slide the Supply Roll Holder (outside) to the loaded media.

Notches

|

Claw |

Supply Shaft |

Supply Roll Holder |

(Outside) |

13

Chapter 2 Printer Installation

2.5Loading the Media (Cont.)

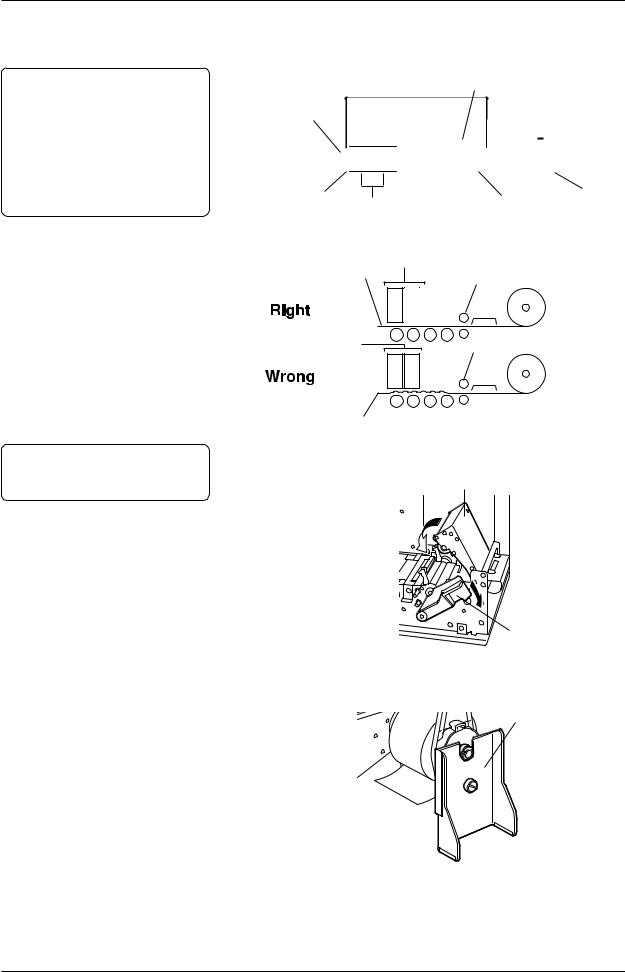

Note:

Make sure that the leading edge of media is cut straight before inserting the media into the printer, as this may cause a media jam.

Right Wrong

CAUTION!

Do not over tighten the two screws, as this may cause damage to the Media Guides.

14Loosen the two screws. Slide the Media Guides in the direction of the arrows below until they stop (completely open).

Screw

Screw

Media Guides

15Unroll about 1.5 to 2 inches (40 to 50cm) of the media.

16Insert the media into the Media Inlet. Make sure that the media passes under the Media End Sensor, the media sensor and the Media Pressure Plate.

Media End Sensor

Media Sensor

Media Pressure Plate

Important!

∙According to the media is loaded, adjust the position of the media sensor. See Section 2.6 for more detail.

∙Whenever the type of media is changed, adjust sensitivity of the media sensor. See Section 2.7 for more detail.

17Slide the Media Guides in the direction of the arrows below until both guides come in contact with the media (media should be in center of media path). Hand tighten the two screws.

Media Guide

Screw

Screw

Media Guide

14

Chapter 2 Printer Installation

2.5Loading the Media (Cont.)

Notes:

∙Pass the media straight from the Supply Holder Unit to the Media Outlet to avoid skewing.

∙Use the marks at the Media Slide and the Media Outlet so that the media can be centered.

∙Be sure to take up any slack in the media.

18Feed the media to the Media Outlet manually until its leading edge comes out of the Media Outlet.

(Top View of the Printer)

Media Guide

Media

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supply Roll |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Media Outlet Print Head Blocks |

Media Inlet |

||||||||||||||

Holder |

|||||||||||||||

(Side View of the Printer)

Print Head Blocks

Media

Pinch Roller

Note:

Push down the Pinch Roller Unit gently on the “PUSH HERE” label.

Print Head Blocks |

Pinch Roller |

Media

19 Push down the Pinch Roller Unit until it is hooked. Then push down the Pinch Roller Lever to the ROLLER LOCK position.

[PUSH HERE]

Pinch Roller Lever

(To ROLLER LOCK)

20Reinstall the Supply Shaft Holder Stand to the Supply Shaft Holder, whose level is adjusted in Steps 3 to 5.

Supply Shaft Holder Stand

15

Chapter 2 Printer Installation

2.5Loading the Media (Cont.)

Note:

When loading labels, make a straight cut in the gap area between labels.

21Close the Top Cover gently. Make sure that the POWER LED and ON LINE LED are illuminated, and that the “ON LINE” message is shown. Press the FEED key on the Operation Panel to feed the media about 1 inch (20 to 30cm). Check that the media is fed successfully.

Label

Cut here.

Label

Right Wrong

2.5.1 |

Additional |

This section contains more information concerning the care that should |

|

Information |

be taken when loading the media. |

|

|

∙ The figure below indicates the direction the Supply Roll Holder |

|

|

(inside) can be moved with the claws of the Supply Roll Holder |

|

|

locked into the notches. |

|

Wrong |

Supply Roll Holder |

Right |

(Inside) |

Notches |

|

∙The figure below indicates the direction the Supply Roll Holder (outside) can be moved with the claws of the Supply Roll Holder locked into the notches.

Right

Wrong

Supply Roll Holder

(Outside)

Notches

16

Chapter 2 Printer Installation

2.6Sensor Adjustments

2.6.1Black Mark Sensor

Note:

“1” marked on the sensor indicates the Black Mark Sensor position.

This section describes in detail how to adjust the media sensor positions and their sensitivity.

Whenever the type of media is changed, a positional adjustment of the media sensor is needed. The media sensors are designed to keep positional alignment of the image on each label or tag when issued.

Important!

NEVER skip the media sensor positional adjustment.

The printer has two types of media sensors: Black Mark Sensor and Feed Gap Sensor.

The Black Mark Sensor (reflective sensor) is used to detect black marks on the back of the media by the reflection of light. On the other hand, the Feed Gap Sensor (transmissive sensor) is used to detect gaps by the transmission of light.

Which media sensor to adjust depends on the type of media loaded.

When the media with black marks on the BACK is loaded, adjust the Black Mark Sensor (reflective sensor) position as follows:

1Open the Top Cover.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

3Align the Media Guides to the width of the media.

4Fold the media so that a black mark faces upward.

5Insert the media into the Media Inlet.

6Turn the Media Guide Knob, and move the media sensor so that it is positioned at the center of the black mark.

|

Media Sensor |

Black Mark detected here |

|

|

Sensor |

|

|

Media |

|

Media Guide Knob |

Black Mark |

Note: |

7 The Black Mark Sensor Position Adjustment has been completed. |

|

SeeA1.3.3 for black mark specifications.

17

Chapter 2 Printer Installation

2.6.2Feed Gap Sensor

Note:

“2” marked on the sensor indicates the Feed Gap Sensor position.

When the media with gaps or rectangular holes is loaded, adjust the Feed Gap Sensor (transmissive sensor) position as follows:

1Open the Top Cover.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

3Align the Media Guides to width of the media.

4Insert the media into the Media Inlet.

∙If the media with gaps is loaded, go to Step 5.

∙If the media with rectangular holes is loaded, go to Step 6.

5Turn the Media Guide Knob, and move the media sensor so that the gap between labels will pass under the sensor.

Media Sensor

Gap detected here

Sensor |

Label |

Gap

Media Guide Knob |

Backing Paper |

6Turn the Media Guide Knob, and move the media sensor so that it is positioned at the center of the rectangular hole.

Media Sensor |

Hole detected here |

Sensor

Hole

Media

Media Guide Knob

Note: |

7 The Feed Gap Sensor Position Adjustment has been completed. |

SeeA1.3.2 for gap or hole specifications. |

|

18

|

Chapter 2 |

Printer Installation |

2.6.3 Media Sensor |

Whenever the type of media is changed, adjust the media sensor |

|

Sensitivity |

sensitivity. |

|

Adjustment |

Please note that the adjustment procedures are slightly different, |

|

|

depending on which type of media loaded. |

|

Media Sensor Adjustor

Feed Gap Sensor Lamp

Black Mark Sensor Lamp

Green

Red

Black Mark Sensor

Adjusting Knob

Feed Gap Sensor Adjusting Knob

Note:

As soon as the upper two lamps illuminate green, stop turning the knob.

Black Mark Sensor Sensitivity Adjustment

1Open the Top Cover.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

3Insert the media with black marks into the Media Inlet so that the Black Mark Sensor can detect the WHITE part of the media.

4Lock the Pinch Roller Unit.

5Turn on the printer.

6Turn the Black Mark Sensor Adjusting Knob to the left most position.

7Keep turning the knob clockwise slowly. When the upper two Black Mark Sensor Lamps illuminate green, the adjustment is complete.

19

|

|

Chapter 2 |

Printer Installation |

2.6.3 Media Sensor |

Feed Gap Sensor Sensitivity Adjustment |

||

Sensitivity |

(for Label with Gaps) |

|

|

Adjustment (Cont.) |

|

|

|

|

1 |

Open the Top Cover. |

|

|

2 |

Lift the Pinch Roller Lever to the ROLLER RELEASE position |

|

|

|

to open the Pinch Roller Unit. |

|

|

3 |

Insert the label with gaps into the Media Inlet so that the Feed |

|

|

|

Gap Sensor can detect the LABEL part. |

|

|

4 |

Lock the Pinch Roller Unit. |

|

|

5 |

Turn on the printer. |

|

|

6 |

Turn the Feed Gap Sensor Adjusting Knob to the left most position. |

|

Note:

As soon as the upper two lamps illuminate green, stop turning the knob.

7Keep turning the knob clockwise slowly. When the upper two Feed Gap Sensor Lamps illuminate green, the adjustment is complete.

Feed Gap Sensor Sensitivity Adjustment

(for Media with Rectangular Holes)

1Open the Top Cover.

2Lift the Pinch Roller Lever to the ROLLER RELEASE position to open the Pinch Roller Unit.

3Insert the media with rectangular holes into the Media Inlet so that the Feed Gap Sensor can detect the PAPER part.

4Lock the Pinch Roller Unit.

5Turn on the printer.

6Turn the Feed Gap Sensor Adjusting Knob to the left most position.

Note:

As soon as the upper two lamps illuminate green, stop turning the knob.

7Keep turning the knob clockwise slowly. When the upper two Feed Gap Sensor Lamps illuminate green, the adjustment is complete.

20

Chapter 2 Printer Installation

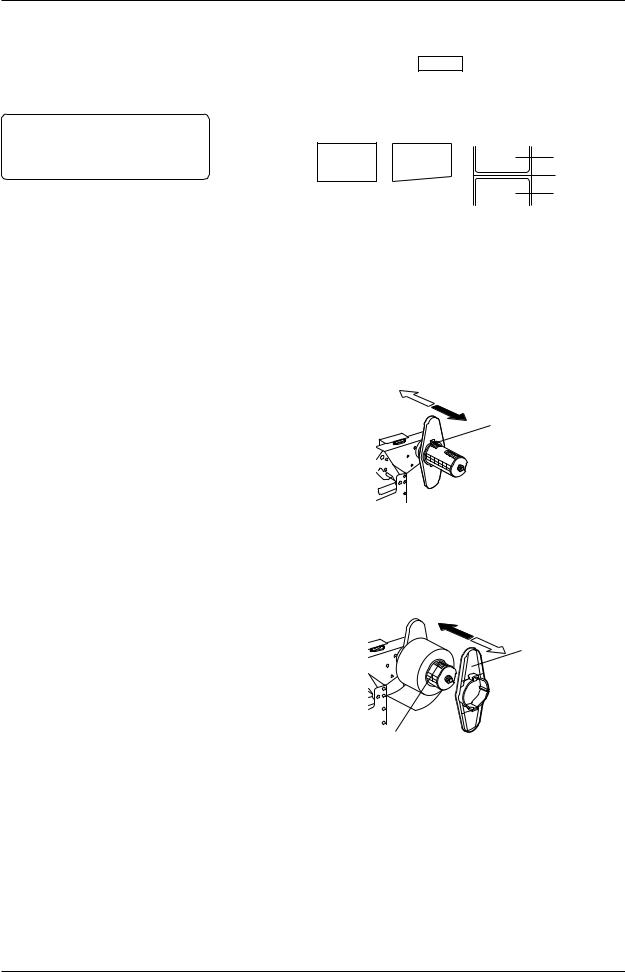

2.7Loading the Ribbons

(for Hot Release

Ribbons)

Note:

Media Width does not include width of the backing paper.

2.7.1Ribbon Positions

Important!:

When loading the ribbons, please do not forget to specify the ribbon colors in the printer properties. See Section 3.4.3 for more detail.

2.7.2Loading Procedure

Notes:

∙Turn the Head Lever to the OPEN position completely, or the Ribbon Module cannot be removed.

∙Do not bend, drop, or give any shock to the Ribbon Module. Distortion of the Ribbon Module may cause poor print.

This section describes in detail how to load the ribbons in the printer. Please use the ribbon width corresponding to the media width from the table shown below.

Ribbon Width |

Media Width |

|

|

2.7 (68) |

2 to 2.6 (50 to 65) |

3.5 (88) |

2.6 to 3.4 (65 to 85) |

4.3 (109) |

3.4 to 4.4 (85 to 110) |

Dimensions in inches + (mm)

There are two types of ribbons: high-performance Hot Release Ribbons that provide fast, quality print, and the popular Cold Release Ribbons. This section focuses on how to load the Hot Release Ribbons.

See Section 2.8 for loading procedures of the Cold Release Ribbons. Also refer to the table in Section 3.8.2 for specific information about each ribbon type. If the ribbon type to be used cannot be found in the table, contact an authorized sales representative.

Please load the ribbons, as illustrated below.

Head 2 (Front) |

Head 1 (Back) |

1Open the Top Cover.

2Turn the Head Lever to the OPEN position. Pull out each Ribbon Module in the direction of the arrow, and remove it from the printer.

Head Lever

LOCK HEAD

OPEN

Ribbon Module

3Remove the two Ribbon Shafts from the Ribbon Module. Remove the Ribbon Stopper from each Ribbon Shaft.

Ribbon Shaft

Ribbon Stoppers

21

|

|

Chapter 2 |

Printer Installation |

2.7.2 |

Loading |

4 Insert the Ribbon Shaft into the Ribbon Winding Core. Fit the |

|

|

Procedure (Cont.) |

protrusion of the Ribbon Shaft into the notch of the Ribbon |

|

|

|

Winding Core. Insert the other Ribbon Shaft into the Ribbon Feed |

|

|

|

Core in the same manner. |

|

|

|

Ribbon Winding Core |

|

|

|

Protrusion |

Ribbon Feed Core |

|

|

|

|

|

|

Notch |

|

Ribbon Shaft

CAUTION!

Push in the Ribbon Stoppers gently. Otherwise, damage may occur.

Note:

Please make sure that the Ribbon Stoppers are completely inserted into the Ribbon Winding Core and Ribbon Feed Core respectively.

5 Attach the Ribbon Stoppers gently to each Ribbon Shaft.

Ribbon Feed Core

Ribbon Shaft

Ribbon Winding Core

Ribbon Shaft |

Ribbon Stoppers |

6 Unroll about 1 inch (30cm) of the ribbon. Place the Ribbon Module on the ribbon.

Ribbon Module

Ribbon Feed Core

Ribbon Winding Core |

Ribbon |

|

7Insert the Ribbon Feed Core, and then the Ribbon Winding Core on the Ribbon Module, as illustrated below.

Ribbon Feed Core

CAUTION!

Loading the ribbon upside down may cause damage to the print head, as well as print failure.

Ribbon Winding Core

22

Loading...

Loading...