Toshiba EO1-33016E, EO1-33016, B-670 User Manual

TEC Thermal Printer

B-670 SERIES

Owner’s Manual

Table of Contents

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operations of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the user's authority to operate the equipment.

"This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations."

"Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur de Canada."

(for CANADA only)

WARNING!

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

CAUTION:

Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing, etc., be drawn into the moving parts, push the switch in the "OFF" position to stop movement.

As an ENERGY STAR® Partner, TOSHIBA TEC has determined that this product meets the ENERGY STAR® guidelines for energy efficiency.

-- Outline of the International ENERGY STAR® Office Equipment Program --

The International ENERGY STAR® Office Equipment Program is an international program that promotes energy saving through the penetration of energy efficient computers and other office equipment. The program backs the development and dissemination of products with functions that effectively reduce energy consumption. It is an open system in which business proprietors can participate voluntarily. The targeted products are office equipment such as computers, monitors, printers, facsimiles, copiers, scanners, and multifunction devices. Their standards and logos are uniform among participating nations.

ENERGY STAR is a U.S. registered mark.

Copyright © 2002

by TOSHIBA TEC CORPORATION All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Safety Summary

ENGLISH VERSION EO1-33016

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions necessary for safe handling are included in this manual. All warnings and cautions contained in this manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified using the procedures described in this manual, turn off the power, unplug the machine, then contact your authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions). Specific warning contents are drawn inside the  symbol. (The symbol on the left indicates a general caution.)

symbol. (The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items). Specific prohibited contents are drawn inside or near the symbol. (The symbol on the left indicates “no disassembling”.)

symbol. (The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed. Specific instructions are drawn inside or near the symbol.

symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

|

|

This indicates that there is the risk of death or serious injury if the |

||||

WARNING machines are improperly handled contrary to this indication. |

||||||

Any other than the |

|

Do not use voltages other than the |

Prohibited |

|

Do not plug in or unplug the power |

|

specified AC voltage |

|

|

||||

voltage (AC) specified on the rating |

cord plug with wet hands as this may |

|||||

is prohibited. |

|

|||||

|

plate, as this may cause fire or |

|

cause electric shock. |

|||

|

electric shock. |

|

|

|

||

Prohibited |

|

If the machines share the same |

Prohibited |

|

|

Do not place metal objects or |

|

|

|

||||||

|

|

||||||

outlet with any other electrical |

water-filled containers such as flower |

||||||

|

|

||||||

|

appliances which consume large |

|

vases, flower pots or mugs, etc. on |

||||

|

amounts of power, the voltage will |

|

top of the machines. If metal objects |

||||

|

fluctuate widely each time these |

|

or spilled liquid enter the machines, |

||||

|

appliances operate. Be sure to |

|

this may cause fire or electric |

||||

|

provide an exclusive outlet for the |

|

shock. |

||||

|

machine as this may cause the |

|

|

|

|

||

|

machines to malfunction. |

|

|

|

|

||

|

|

|

|

|

|

|

|

Prohibited |

|

Do not insert or drop metal, |

Prohibited |

|

|

Do not scratch, damage or modify |

|

|

|

|

|||||

|

|

|

|||||

flammable or other foreign objects into |

the power cords. Also, do not place |

||||||

|

|

||||||

|

the machines through the ventilation |

|

heavy objects on, pull on, or exces- |

||||

|

slits, as this may cause fire or electric |

|

sively bend the cords, as this may |

||||

|

shock. |

|

cause fire or electrical shock. |

||||

Disconnect |

|

If the machines are dropped or their |

Disconnect |

|

Continued use of the machines in an |

|

|

||||

|

|

||||

the plug. |

cabinets damaged, first turn off the |

the plug. |

abnormal condition such as when the |

||

|

power switches and disconnect the |

|

machines are producing smoke or |

||

|

power cord plugs from the outlet, and |

|

strange smells may cause fire or elec- |

||

|

then contact your authorized |

|

tric shock. In these cases, immedi- |

||

|

|

ately turn off the power switches and |

|||

|

TOSHIBA TEC representative for |

|

|||

|

|

disconnect the power cord plugs from |

|||

|

assistance. Continued use of the |

|

|||

|

|

the outlet. Then, contact your author- |

|||

|

machine in that condition may cause |

|

|||

|

|

ized TOSHIBA TEC representative for |

|||

|

fire or electric shock. |

|

|||

|

|

assistance. |

|||

|

|

|

|

||

(i)

Safety Summary

ENGLISH VERSION EO1-33016

|

|

Disconnect |

|

If foreign objects (metal fragments, |

Disconnect |

|

|

When unplugging the power cords, |

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

the plug. |

water, liquids) enter the machines, |

the plug. |

be sure to hold and pull on the plug |

|||

|

|

|

first turn off the power switches and |

|

portion. Pulling on the cord portion |

|||

|

|

|

disconnect the power cord plugs from |

|

may cut or expose the internal wires |

|||

|

|

|

the outlet, and then contact your |

|

and cause fire or electric shock. |

|||

|

|

|

authorized TOSHIBA TEC repre- |

|

|

|

|

|

|

|

|

sentative for assistance. Continued |

|

|

|

|

|

|

|

|

use of the machine in that condition |

|

|

|

|

|

|

|

|

may cause fire or electric shock. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connect a |

|

Ensure that the equipment is |

No disassem- |

|

|

Do not remove covers, repair or |

|

|

grounding |

|

|

|

|||

|

|

properly grounded. Extension cables |

bling. |

modify the machine by yourself. You |

||||

|

|

wire. |

||||||

|

|

|||||||

|

|

should also be grounded. Fire or |

|

may be injured by high voltage, very |

||||

|

|

|

|

|||||

|

|

|

|

hot parts or sharp edges inside the |

||||

|

|

|

electric shock could occur on |

|

||||

|

|

|

|

machine. |

||||

|

|

|

improperly grounded equipment. |

|

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

CAUTIONThis indicates that there is the risk of personal Injury or damage to objects if the machines are improperly handled contrary to this indication.

CAUTIONThis indicates that there is the risk of personal Injury or damage to objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

•Try to avoid locations that have the following adverse conditions:

* |

Temperatures out of the specification |

* |

Direct sunlight |

* |

High humidity |

* |

Shared power source |

* |

Excessive vibration |

* |

Dust/Gas |

•The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic covers.

•USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

•DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or gas.

•Ensure the printer is operated on a level surface.

•Any data stored in the memory of the printer could be lost during a printer fault.

•Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains interference.

•Unplug the machine whenever you are working inside it or cleaning it.

•Keep your work environment static free.

•Do not place heavy objects on top of the machines, as these items may become unbalanced and fall causing injury.

•Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines and may cause fire.

•Do not lean against the machine. It may fall on you and could cause injury.

•Care must be taken not to injure yourself with the printer paper cutter.

•Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

•Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines and may cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

•Our preventive maintenance service performs the periodic checks and other work required to maintain the quality and performance of the machines, preventing accidents beforehand. For details, please consult your authorized TOSHIBA TEC representative for assistance.

•Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or other parts to deteriorate or cause the paint to peel.

(ii)

ENGLISH VERSION EO1-33016

TABLE OF CONTENTS

|

|

|

Page |

1. |

INTRODUCTION .............................................................................................. |

E1- 1 |

|

|

1.1 |

APPLICABLE MODEL .............................................................................. |

E1- 1 |

|

1.2 |

ACCESSORIES ........................................................................................ |

E1- 1 |

2. |

SPECIFICATIONS ............................................................................................ |

E2- 1 |

|

|

2.1 |

PRINTER .................................................................................................. |

E2- 1 |

|

2.2 |

OPTIONS .................................................................................................. |

E2- 2 |

|

2.3 |

MEDIA ....................................................................................................... |

E2- 3 |

|

2.4 |

RIBBON .................................................................................................... |

E2- 3 |

3. |

OVERVIEW ...................................................................................................... |

E3- 1 |

|

|

3.1 |

FRONT/REAR VIEW ................................................................................. |

E3- 1 |

|

3.2 |

OPERATION PANEL ................................................................................ |

E3- 1 |

4. |

DIP SWITCH FUNCTIONS ............................................................................... |

E4- 1 |

|

5. |

SET UP PROCEDURE ..................................................................................... |

E5- 1 |

|

|

5.1 |

REQUIREMENTS FOR OPERATION ...................................................... |

E5- 1 |

|

5.2 |

SETTING UP THE PRINTER .................................................................... |

E5- 1 |

6. |

INSTALLING THE PRINTER ............................................................................ |

E6- 1 |

|

|

6.1 |

CONNECTING THE POWER CORD AND CABLES ................................ |

E6- 1 |

|

6.2 |

HOLDER STAND INSTALLATION ........................................................... |

E6- 1 |

7. |

LOADING THE RIBBON ................................................................................... |

E7- 1 |

|

8. |

LOADING THE MEDIA ..................................................................................... |

E8- 1 |

|

9. |

INSERTING THE OPTIONAL FLASH MEMORY CARD .................................. |

E9- 1 |

|

10. INSERTING THE OPTIONAL PCMCIA CARD ............................................... |

E10- 1 |

||

11. CARE/HANDLING OF THE MEDIA AND RIBBON ........................................ |

E11- 1 |

||

12. GENERAL MAINTENANCE ........................................................................... |

E12- 1 |

||

|

12.1 CLEANING .............................................................................................. |

E12- 1 |

|

|

12.2 UNDER THE MEDIA GUIDES ................................................................ |

E12- 3 |

|

|

12.3 COVERS AND PANELS ......................................................................... |

E12- 3 |

|

|

12.4 REMOVING JAMMED MEDIA ................................................................ |

E12- 4 |

|

|

12.5 THRESHOLD SETTING ......................................................................... |

E12- 6 |

|

13. TROUBLESHOOTING ................................................................................... |

E13- 1 |

||

CAUTION:

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2.The contents of this manual may be changed without notification.

3.Please refer to your local Authorized Service representative with regard to any queries you may have in this manual.

WARNING!

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

CAUTION:

Do not touch moving parts. To reduce the risk that fingers, jewelry, clothing. etc., be drawn into the moving parts, push the switch in the "OFF" position to stop movement.

1. |

INTRODUCTION |

ENGLISH VERSION EO1-33016 1.1 APPLICABLE MODEL

1. INTRODUCTION

Thank you for choosing the TEC B-670 Series thermal/transfer printer. This new generation high performance/quality printer is equipped with the latest hardware including the newly developed high density (12 dot/mm, 305 dot/inch) edge print head. This will allow very clear print at a maximum speed of 203.2 mm/sec. (8 inch/sec.). Other standard features include an external media supply. Optional features include a strip mechanism and Cutter mechanism. This manual contains general set-up and maintenance information and should be read carefully to help gain maximum performance and life from your printer. For most queries please refer to this manual and keep it safe for future reference.

1.1APPLICABLE MODEL

∙B-672-QQ

Model name description

B - 6 7 2 - Q Q

Destination Code

Destination Code

QQ : North America bloc

Thermal direct/Thermal transfer

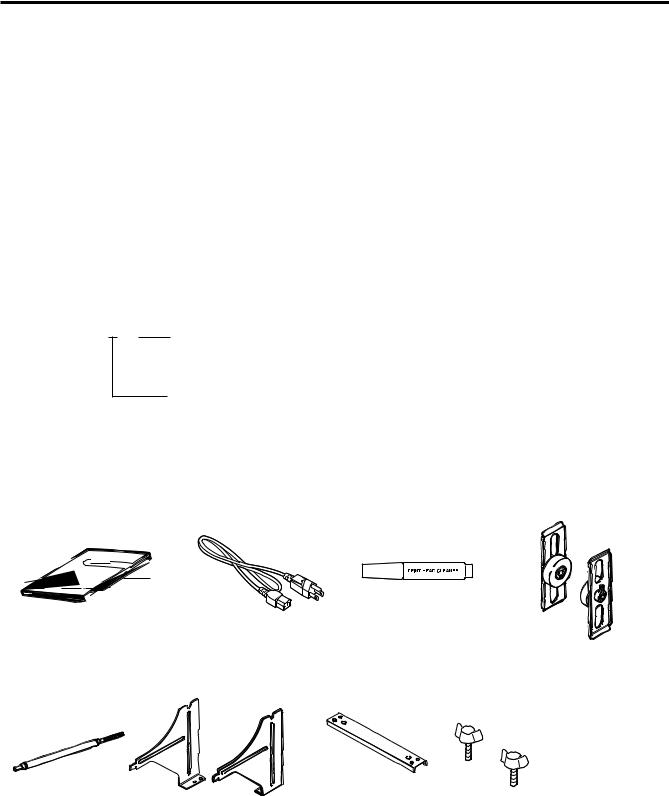

1.2 ACCESSORIES

Owner's Manual |

Power Cord |

Print Head Cleaner |

Media Holder |

(EM1-33039) |

|

(24089500013) |

|

Holder Shaft |

Left/Right Side Holder |

Holder Base

Thumbscrew

(M-4x6)

Quality control report

E1-1

2. SPECIFICATIONS

ENGLISH VERSION EO1-33016

2.1 PRINTER

2. SPECIFICATIONS

2.1 PRINTER

Model |

B-672-QQ |

|

Item |

||

|

||

Supply voltage |

Universal (automatic switching) |

|

|

85-138 V, 50/60 Hz |

|

|

187-276 V, 50/60 Hz |

|

|

Be sure to use a power cord which meets the standard. |

|

Power consumption |

3.5 A, 260 W maximum (standby: 360 mA, 20 W maximum) |

|

Operating temperature |

5˚C ~ 40˚C |

|

range |

|

|

Relative humidity |

25% ~ 85%RH (no condensation) |

|

Print head |

Thermal print head 12 dots per mm (305 dots per inch) |

|

Printing methods |

Thermal direct or Thermal transfer |

|

Print speeds |

76.2 mm/sec. (3 inch/sec.), 101.6 mm/sec. (4 inch/sec.), |

|

|

203.2 mm/sec. (8 inch/sec.) When the media width is 160mm or less. |

|

Maximum print width |

170.6 mm (6.72 inches) |

|

Dispensing modes |

Batch (Continuous), Strip (On-demand) and Cut modes |

|

|

(Both cut and strip modes are available only when their respective modules |

|

|

are fitted.) |

|

Message display |

20 characters x 1 line |

|

Dimensions |

437 mm (width) x 282 mm (depth) x 395 mm (height) |

|

Weight |

25 kg (without media and ribbon) |

|

Available bar-code types |

JAN8, JAN13, EAN8, EAN8 + 2 digits, EAN8 + 5 digits |

|

|

EAN13, EAN13 + 2digits, EAN13 + 5 digits |

|

|

UPC-E, UPC-E + 2 digits, UPC-E + 5 digits |

|

|

UPC-A, UPC-A + 2 digits, UPC-A + 5 digits |

|

|

MSI, ITF, NW-7, CODE39, CODE93, CODE128 |

|

|

EAN128, Industrial 2 to 5 |

|

Two-dimensional code |

Data Matrix, PDF417, |

|

Fonts |

Times Roman (6 sizes), Helvetica (6 sizes), Presentation (1 size), |

|

|

Letter Gothic (1 size), Prestige Elite (2 sizes), Courier (2 sizes), |

|

|

OCR (2 types), Writable characters (40 types), Outline font (1 type) |

|

Rotations |

0˚, 90˚, 180˚, 270˚ |

|

Standard interfaces |

Serial interface (RS-232C) |

|

|

Parallel interface (Centronics) |

|

|

Expansion I/O interface |

|

|

Flash memory card interface |

|

|

|

Data MatrixTM is a trademark of International Data Matrix, Inc. PDF417 is a trademark of Symbol Technologies, Inc.

E2-1

2. SPECIFICATIONS

ENGLISH VERSION EO1-33016

2.2 OPTION

2.2 OPTION

Option Name |

|

Type |

Description |

|

|

|

|

|

|

Cutter module |

B-4208-QM |

A stop and cut swing cutter |

||

|

|

|

|

|

High speed PC |

B-4800-PC-QM |

This interface kit allows extremely high speed information |

||

interface kit |

|

|

|

transfer between the printer and PC. |

|

|

|

|

|

Strip module |

B-4908-H-QM |

This module strips the label from the backing paper with the |

||

|

|

|

|

take-up block and strip block. |

|

|

|

|

|

D-RAM PC Board |

FMBC0067801 |

A 2MB RAM upgrade which enhances the image handling |

||

|

|

|

|

capability of the printer. |

|

|

|

|

|

Flash memory |

|

|

|

A flash ROM card (1MB and 4MB) for storing logos, writable |

card |

|

|

|

characters and formats. |

|

|

|

|

|

E2-2

2. SPECIFICATIONS

ENGLISH VERSION EO1-33016

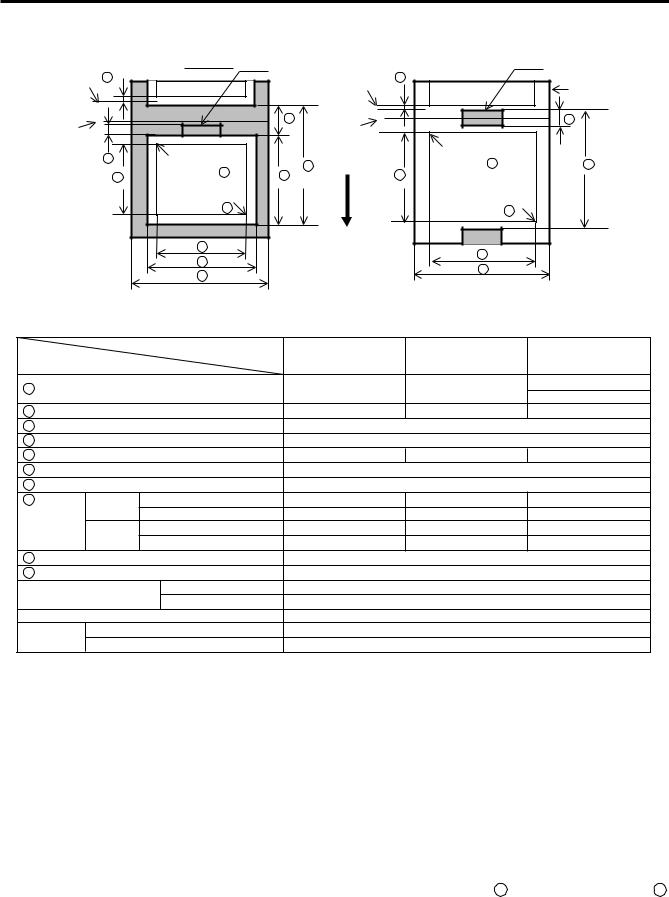

2.3 MEDIA

2.3 |

MEDIA |

|

|

|

Refer to the following |

|

|

|

|

|

|

|

|

|

|

NOTE 2. |

|

|

|

|

|

|

|

Label |

Black Mark |

Tag paper |

Black Mark |

||

|

Stop |

I |

|

|

|

(on reverse side) |

I |

|

(on reverse side) |

|

|

|

|

Stop |

|

Tag paper |

|||

|

|

|

|

|

|

|

|||

|

position |

|

|

|

|

|

|

||

|

|

|

|

|

|

position |

|

|

|

|

|

|

|

|

|

E |

|

|

F |

|

Cut |

|

|

|

|

Cut |

|

|

|

|

position |

|

|

|

|

position |

Reference |

|

|

|

|

J |

|

Reference |

|

|

|

|

|

|

|

|

|

A |

coordinate |

1 |

A |

||

|

|

|

|

1 |

|||||

|

|

|

H |

coordinate |

B |

H |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Reference |

|

|

Reference |

|

|

|

|

|

|

coordinate |

2 |

|

coordinate |

2 |

|

|

|

|

|

G |

|

Feed direction |

G |

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

C |

|

Fig. 2-1 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

[Unit: mm] |

|

|

|

|

Label dispensing mode |

Batch mode |

Strip mode |

Cut mode |

|||

Item |

|

|

|||||||

|

|

|

|

|

|

|

|||

A : |

Span of one label/tag |

10.00 ~ 999.0 |

25.4 |

~ 999.0 |

Label: 38 ~ 999.0 |

||||

Tag: 25.4 ~ 999.0 |

|||||||||

|

|

|

|

|

|

|

|||

B : |

Label length |

|

7.5 ~ 996.5 |

22.9 |

~ 996.5 |

25.0 |

~ 993.0 |

||

C : Width including backing paper |

|

84.0 ~ 175.0 (See NOTE 3.) |

|

||||||

D : |

Label width |

|

|

81.0 |

~ 172.0 |

|

|

||

E : Gap length |

|

2.5 ~ 20.0 |

2.5 |

~ 20.0 |

6.0 |

~ 20.0 |

|||

F : Black mark length (Tag paper) |

|

2.5 |

~ 10.0 |

|

|

||||

G : |

Effective print width |

|

10.0 |

~ 170.6 |

|

|

|||

H : |

|

Label |

Standard |

5.5 ~ 298.6 |

20.9 |

~ 298.6 |

23.0 |

~ 298.6 |

|

Effective |

Max. memory |

5.5 ~ 981.3 |

20.9 |

~ 981.3 |

23.0 |

~ 981.3 |

|||

|

|||||||||

print length |

Tag |

Standard |

8.0 ~ 298.6 |

23.4 |

~ 298.6 |

23.4 |

~ 298.6 |

||

|

|

Max. memory |

8.0 ~ 981.3 |

23.4 |

~ 981.3 |

23.4 |

~ 981.3 |

||

|

|

|

|||||||

I : Print speed up/slow down area |

|

|

1.0 |

|

|

||||

J : Black mark length (Label) |

Refer to the following NOTE 2. |

|

|||||||

Maximum effective |

Standard |

|

149.3 |

|

|

||||

length for on the fly issue Max. memory |

|

490.6 |

|

|

|||||

Outer roll diameter |

|

|

Ø200 Max. |

|

|

||||

Thickness |

Label |

|

|

0.13 ~ 0.17 |

|

|

|||

Tag |

|

|

0.10 ~ 0.17 |

|

|

||||

NOTES:

1.The media specification other than above are unchanged.

2.When marking black marks on label rolls, the following requirements must be satisfied. When the gap length is less than 4 mm:

The black mark length should be longer than the gap length. When the gap length is 4 mm or more:

The black mark should not overlap the gap for more than 4 mm and the following label.

3.When the print speed is 8"/sec., the width including backing paper will be 84 to 150 mm. When the optional cutter module or strip module is used, the width including backing paper will be 101.6 to 175 mm.

4.If the label used is smaller than specified, the print head life may be shortened.

5.When issuing thermal labels at 8"/sec., the print stop position should be set to a minimum of 1 mm inside the label.

2.4 RIBBON

Type |

Spool type |

|

|

Width |

115 mm ~ 185 mm |

|

(See NOTE 5.) |

|

|

Length |

300 m |

|

|

Outer diameter |

Ø72 mm (max.) |

NOTES:

1.“On the fly issue” means that the printer can draw and print without stopping between labels.

2.To ensure print quality and print head life use only TOSHIBA TEC specified media and ribbons.

3.When using the cutter ensure that label length B plus inter label gap length E exceeds 35 mm. (i.e. label pitch should be greater than 35 mm.)

4.To avoid ribbon wrinkles use the ribbon which is wider than media by 5mm or more. However, too much difference in width between the two may cause wrinkles.

5.When the print speed is 8"/sec., the width will be 115 to 160 mm.

E2-3

3. OVERVIEW

ENGLISH VERSION EO1-33016

3.1 FRONT/REAR VIEW

3. OVERVIEW

3.1 FRONT/REAR VIEW

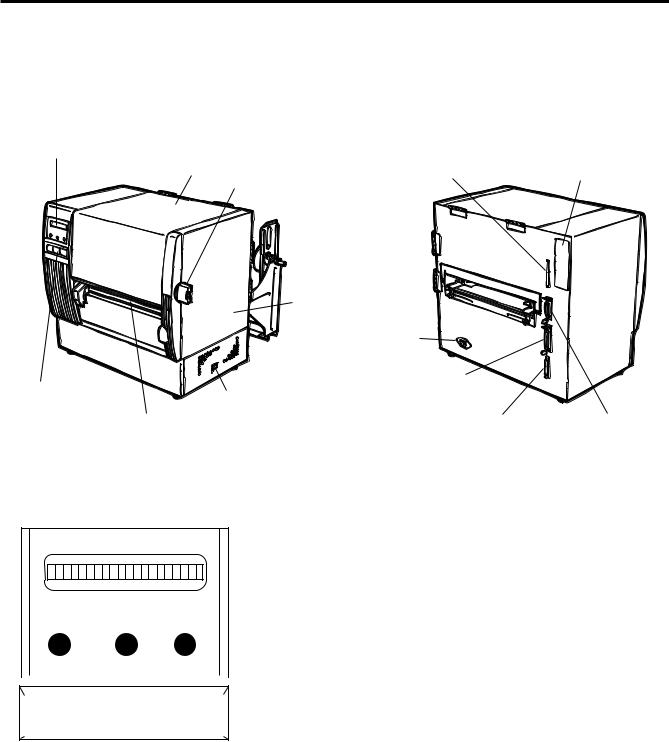

Front View |

Rear View |

Message Display (LCD)

Top Cover |

Memory Card Slot |

|

Head Lever |

|

|

Right Side Cover |

|

|

|

|

|

AC Power Inlet |

|

|

|

|

Parallel I/F Connector |

|

Operation Panel |

Power Switch |

(Centronics) |

|

|

|

0: |

OFF |

|

Serial Interface |

Media Outlet |

1: |

ON |

|

|

|

Connector |

|||

|

|

|

Fig. 3-1 |

|

|

|

|

(RS-232C) |

|

Outlet for the high speed PC interface cable (Option)

Expansion I/O

Interface Connector

3.2 OPERATION PANEL

MESSAGE DISPLAY (LCD)

Displays messages in the language selected by DIP switch. When power is turned on and it is ready to print, “ON LINE” is displayed.

|

|

|

|

|

POWER LED (Green) |

|

|

POWER |

ON LINE |

ERROR |

Lights when the power is turned on. |

||

|

|

|

||||

|

|

|

|

|

ON-LINE LED (Green) |

|

|

|

|

|

|

1) |

Flashes when communicating with a host computer. |

|

|

|

|

|

2) |

On while printing. |

|

|

|

|

|

ERROR LED (Red) |

|

|

|

|

|

|

||

|

|

|

|

|

Lights when a communication error occurs, when the media/ribbon |

|

|

|

|

|

|

||

|

FEED |

RESTART |

PAUSE |

|

ends or the printer does not operate correctly. |

|

|

|

|

|

|

|

|

FEED Key

Feeds paper.

Fig. 3-2 |

RESTART Key |

|

|

|

Resets the printer when paused or when an error occurs. |

|

Used to set the threshold. (Refer to page 11-6) |

|

PAUSE Key |

|

Pauses printing. |

|

Message display shows “PAUSE” and an unprinted count. |

|

Used to set the threshold. (Refer to page 11-6) |

E3-1

4. DIP SWITCH FUNCTIONS

ENGLISH VERSION EO1-33016

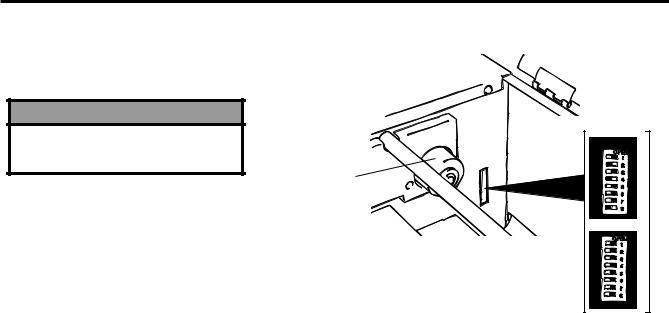

4. DIP SWITCH FUNCTIONS

4. DIP SWITCH FUNCTIONS

The DIP switches are located to the right of the Guide Wheel.

WARNING!

Turn the POWER OFF before switching the functions.

Guide Wheel

(1) |

DIP SW 2 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

ON/OFF |

|

FUNCTION |

|||||

|

|

1 |

1 |

2 |

|

|

|

|

|

|

|

|

OFF |

OFF |

2400 BPS |

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

ON |

OFF |

4800 BPS |

|

|

Transmission speed |

||

|

|

2 |

OFF |

ON |

9600 BPS |

|

|

|

|

|

|

|

|

ON |

ON |

19200 BPS |

|

|

|

|

|

|

|

3 |

OFF |

1 bit |

|

|

|

Stop bit length |

||

|

|

ON |

2 bits |

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

4 |

OFF |

7 bits |

|

|

|

Data length |

||

|

|

ON |

8 bits |

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

5 |

OFF |

Without |

|

|

Parity check |

|||

|

|

ON |

With |

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

6 |

OFF |

EVEN |

|

|

|

Parity check (effective when DIP |

||

|

|

ON |

ODD |

|

|

|

SW #5 is set to ON.) |

|||

|

|

|

|

|

|

|||||

|

|

|

7 |

8 |

|

|

|

|

|

|

|

|

|

OFF |

OFF |

XON/XOFF (No XON is output at the power on time.) |

|

|

|||

|

|

7 |

|

|

|

(No XOFF is output at the power off time.) |

|

|

||

|

|

|

|

|

READY/BUSY (DTA) |

|

|

|

|

|

|

|

|

|

|

(No XON is output at the power on time.) |

|

|

|

|

|

|

|

|

ON |

OFF |

(No XOFF is output at the power off time.) |

|

|

|||

|

|

|

READY/BUSY (RTS) |

|

|

Data protocol |

||||

|

|

|

|

|

(No XON is output at the power on time.) |

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

(No OFF is output at the power off time.) |

|

|

|

|

|

|

|

|

|

|

XON/XOFF+READY/BUSY |

|

|

|

|

|

|

|

8 |

OFF |

ON |

(XON is output at the power on time.) |

|

|

|

|

|

|

|

|

|

(XOFF is output at the power off time.) |

|

|

|

|

||

|

|

|

ON |

ON |

XON/XOFF (XON is output at the power on time.) |

|

|

|||

|

|

|

|

(XOFF is output at the power off time.) |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

(2) |

DIP SW 1 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

ON/OFF |

|

|

FUNCTION |

|

||

|

|

1 |

|

OFF |

|

Must be set to OFF |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

2 |

3 |

4 |

|

|

|

|

|

|

|

|

OFF |

OFF |

OFF |

English |

|

|

|

|

|

|

|

ON |

OFF |

OFF |

German |

|

|

|

|

|

|

|

OFF |

ON |

OFF |

French |

|

Language to display LCD error |

|

|

|

|

3 |

ON |

ON |

OFF |

Dutch |

|

|

||

|

|

|

message |

|

||||||

|

|

|

OFF |

OFF |

ON |

Spanish |

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

ON |

OFF |

ON |

Japanese |

|

|

|

|

|

|

4 |

OFF |

ON |

ON |

Italian |

|

|

|

|

|

|

ON |

ON |

ON |

Not used |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

5 |

|

OFF |

|

Without |

|

Auto media feed after a cut issue |

|

|

|

|

|

ON |

|

With |

|

(See page 8-4) |

|

||

|

|

|

|

|

|

|

||||

|

|

6 |

|

OFF |

|

Must be set to OFF |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

OFF |

|

Fixed type |

|

Media sensor selection |

|

|

|

|

|

ON |

|

Movable type |

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

8 |

|

OFF |

|

Must be set to OFF |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTES: The Shaded settings are the factory default settings. "OFF" means "OPEN".

2

DIPSW 1

Fig. 4-1

E4-1

Loading...

Loading...