Toshiba B-SX8T, B-SX6T User Manual

TOSHIBA Thermal Printer

B-SX6T/SX8T SERIES

System Mode Manual

System Mode Manual

Document No. EO13-33002

Original Mar., 2006

(Revised )

PRINTED IN JAPAN

|

|

|

EO13-33002 |

|

|

|

(Revision Date: Jul. 24, 2008) |

|

|

TABLE OF CONTENTS |

|

|

|

|

Page |

1. INTRODUCTION----------------------------------------------------------------------------------------------------- |

1- 1 |

||

1.1 |

Key Operation Flow ---------------------------------------------------------------------------------------------- |

1- 1 |

|

1.2 |

Operation Panel --------------------------------------------------------------------------------------------------- |

1- 2 |

|

2. SYSTEM MODE ----------------------------------------------------------------------------------------------------- |

2- 1 |

||

2.1 |

Self-diagnostic Test ---------------------------------------------------------------------------------------------- |

2- 3 |

|

2.1.1 |

Printing Mode Selection ----------------------------------------------------------------------------------------- |

2- 4 |

|

2.1.2 |

Dispensing Mode Selection ------------------------------------------------------------------------------------ |

2- 4 |

|

2.1.3 |

Maintenance Counter/Parameter Settings Printing Out ------------------------------------------------- |

2- 5 |

|

2.1.4 |

Self-Diagnostic Test and Result Print Out ----------------------------------------------------------------- |

2-11 |

|

2.1.5 |

Print Head Element Check ------------------------------------------------------------------------------------ |

2-17 |

|

2.2 |

Parameter Setting------------------------------------------------------------------------------------------------ |

2-18 |

|

2.2.1 |

Character Code Selection ------------------------------------------------------------------------------------- |

2-19 |

|

2.2.2 |

Character Zero Selection -------------------------------------------------------------------------------------- |

2-20 |

|

2.2.3 |

Baud Rate Selection -------------------------------------------------------------------------------------------- |

2-20 |

|

2.2.4 |

Data Length Selection ------------------------------------------------------------------------------------------ |

2-21 |

|

2.2.5 |

Stop Bit Length Selection -------------------------------------------------------------------------------------- |

2-21 |

|

2.2.6 |

Parity Selection--------------------------------------------------------------------------------------------------- |

2-22 |

|

2.2.7 |

Flow Control Code Selection---------------------------------------------------------------------------------- |

2-22 |

|

2.2.8 |

LCD Language Selection -------------------------------------------------------------------------------------- |

2-23 |

|

2.2.9 |

Auto Forward Wait Selection---------------------------------------------------------------------------------- |

2-23 |

|

2.2.10 |

Head Up Cut Selection ----------------------------------------------------------------------------------------- |

2-24 |

|

2.2.11 |

Ribbon Save Function Selection ----------------------------------------------------------------------------- |

2-24 |

|

2.2.12 |

Control Code Selection----------------------------------------------------------------------------------------- |

2-25 |

|

2.2.13 |

Ribbon Type Selection ----------------------------------------------------------------------------------------- |

2-26 |

|

2.2.14 |

Strip Wait Status Selection ------------------------------------------------------------------------------------ |

2-26 |

|

2.2.15 |

FEED Key Function Selection -------------------------------------------------------------------------------- |

2-27 |

|

2.2.16 |

KANJI Code Selection ------------------------------------------------------------------------------------------ |

2-27 |

|

2.2.17 |

EURO Code Selection------------------------------------------------------------------------------------------ |

2-27 |

|

2.2.18 |

Auto Print Head Check Selection ---------------------------------------------------------------------------- |

2-28 |

|

2.2.19 |

Centronics Interface ACK/BUSY Timing Selection ------------------------------------------------------ |

2-28 |

|

2.2.20 |

Web Printer Function Selection ------------------------------------------------------------------------------ |

2-29 |

|

2.2.21 |

Media Sensor Selection ---------------------------------------------------------------------------------------- |

2-29 |

|

2.2.22 |

Input Prime Selection ------------------------------------------------------------------------------------------- |

2-30 |

|

2.2.23 |

Expansion I/O Interface Type Selection-------------------------------------------------------------------- |

2-30 |

|

2.2.24 |

Plug & Play Selection------------------------------------------------------------------------------------------- |

2-31 |

|

2.2.25 |

Label End/Ribbon End Selection ---------------------------------------------------------------------------- |

2-31 |

|

2.2.26 |

Pre-Strip Selection----------------------------------------------------------------------------------------------- |

2-33 |

|

2.2.27 |

Reverse Feed Speed Selection ------------------------------------------------------------------------------ |

2-33 |

|

2.2.28 |

Maxi Code Specification Selection -------------------------------------------------------------------------- |

2-33 |

|

2.2.29 |

Strip Motor Torque Selection --------------------------------------------------------------------------------- |

2-34 |

|

2.2.30 |

Stabilizer Function Selection---------------------------------------------------------------------------------- |

2-34 |

|

EO13-33002

(Revision Date: Jul 24, 2008)

|

|

|

Page |

2.3 Printer Parameter Fine Adjustment ----------------------------------------------------------------- |

2-35 |

||

2.3.1 Feed Amount Fine Adjustment ------------------------------------------------------------------------------- |

2-37 |

||

2.3.2 Cut/Strip Position Fine Adjustment -------------------------------------------------------------------------- |

2-38 |

||

2.3.3 Reverse Feed Amount Fine Adjustment ------------------------------------------------------------------- |

2-41 |

||

2.3.4 X Coordinate Fine Adjustment-------------------------------------------------------------------------------- |

2-42 |

||

2.3.5 Print Tone Fine Adjustment (Thermal Transfer/Thermal Direct Print) ------------------------------ |

2-44 |

||

2.3.6 Ribbon Motor Voltage Fine Adjustment (Feed/Take-up Motor) -------------------------------------- |

2-45 |

||

2.3.7 Threshold Manual Fine Adjustment (Black Mark/Feed Gap Sensor) ------------------------------- |

2-46 |

||

2.4 |

Test Print------------------------------------------------------------------------------------------------------------ |

2-47 |

|

2.4.1 Specifying the Print Condition for the Test Print --------------------------------------------------------- |

2-49 |

||

2.4.2 Test Print Pattern Selection ----------------------------------------------------------------------------------- |

2-52 |

||

2.4.3 Slant Line (1 dot)------------------------------------------------------------------------------------------------- |

2-53 |

||

2.4.4 Slant Line (3 dots) ----------------------------------------------------------------------------------------------- |

2-54 |

||

2.4.5 |

Characters--------------------------------------------------------------------------------------------------------- |

2-55 |

|

2.4.6 |

Barcode ------------------------------------------------------------------------------------------------------------ |

2-55 |

|

2.4.7 |

Non-Printing------------------------------------------------------------------------------------------------------- |

2-56 |

|

2.4.8 |

Factory Test------------------------------------------------------------------------------------------------------- |

2-56 |

|

2.4.9 |

Auto Print ---------------------------------------------------------------------------------------------------------- |

2-57 |

|

2.5 |

Sensor Adjustment ---------------------------------------------------------------------------------------------- |

2-58 |

|

2.5.1 |

Sensor Status Display ------------------------------------------------------------------------------------------ |

2-59 |

|

2.5.2 Black Mark Sensor Adjustment------------------------------------------------------------------------------- |

2-59 |

||

2.5.3 Feed Gap Sensor Adjustment -------------------------------------------------------------------------------- |

2-60 |

||

2.5.4 Black Mark Sensor and Feed Gap Sensor Adjustment (Paper End Level)------------------------ |

2-60 |

||

2.6 |

RAM Clear ---------------------------------------------------------------------------------------------------------- |

2-61 |

|

2.6.1 RAM Clear Menu Selection ----------------------------------------------------------------------------------- |

2-62 |

||

2.6.2 |

No RAM Clear ---------------------------------------------------------------------------------------------------- |

2-62 |

|

2.6.3 |

Maintenance Counter Clear ----------------------------------------------------------------------------------- |

2-62 |

|

2.6.4 |

Printer Parameter Clear ---------------------------------------------------------------------------------------- |

2-63 |

|

2.7 |

IP Address Setting----------------------------------------------------------------------------------------------- |

2-66 |

|

2.7.1 Printer IP Address, Gateway IP Address, and Subnet Mask Settings ------------------------------ |

2-67 |

||

2.7.2 |

Socket Port Setting---------------------------------------------------------------------------------------------- |

2-68 |

|

2.7.3 DHCP and DHCP ID Settings -------------------------------------------------------------------------------- |

2-68 |

||

2.7.4 DHCP Host Name Setting ------------------------------------------------------------------------------------- |

2-69 |

||

2.8 |

BASIC Setting ----------------------------------------------------------------------------------------------------- |

2-70 |

|

2.8.1 Basic Specification Selection Mode ------------------------------------------------------------------------- |

2-71 |

||

2.8.2 |

Basic File Browser----------------------------------------------------------------------------------------------- |

2-71 |

|

2.8.3 Basic Trace Selection Mode ---------------------------------------------------------------------------------- |

2-71 |

||

2.8.4 Basic Expansion Mode (Execution of Basic Program)-------------------------------------------------- |

2-72 |

||

2.9 |

RFID Module Setting -------------------------------------------------------------------------------------------- |

2-73 |

|

2.9.1 |

RFID Read Test-------------------------------------------------------------------------------------------------- |

2-74 |

|

2.9.2 RFID Module Type Selection --------------------------------------------------------------------------------- |

2-75 |

||

2.9.3 RFID Tag Type Selection -------------------------------------------------------------------------------------- |

2-76 |

||

2.9.4 RFID Error Tag Delection-------------------------------------------------------------------------------------- |

2-76 |

||

2.9.5 Maximum Number of RFID Issue Retries------------------------------------------------------------------ |

2-77 |

||

2.9.6 Maximum Number of RFID Read Retries------------------------------------------------------------------ |

2-78 |

||

2.9.7 RFID Read Retry Time-out ------------------------------------------------------------------------------------ |

2-79 |

||

EO13-33002

(Revision Date: Jul 24, 2008)

|

|

Page |

2.9.8 |

Maximum Number of RFID Write Retries ------------------------------------------------------------------ |

2-80 |

2.9.9 |

RFIDWritre Retry Time-out ------------------------------------------------------------------------------------ |

2-81 |

2.9.10 |

RFID Adjustment for Retry ------------------------------------------------------------------------------------ |

2-82 |

2.9.11 |

RFID Wireless Power Level Setting------------------------------------------------------------------------- |

2-83 |

2.9.12 |

RFID AGC Threshold ------------------------------------------------------------------------------------------- |

2-83 |

2.9.13 |

RFID Module Q Value Setting -------------------------------------------------------------------------------- |

2-84 |

2.9.14 |

AGC Threshold for Data Write Setting---------------------------------------------------------------------- |

2-85 |

2.9.15 |

AGC Threshold Lower Limit for Retry Setting ------------------------------------------------------------ |

2-86 |

3. ON LINE MODE ------------------------------------------------------------------------------------------ |

3- 1 |

|

3.1 |

Automatic Threshold Setting --------------------------------------------------------------------------------- |

3- 4 |

3.2 |

Reset Operation --------------------------------------------------------------------------------------------------- |

3- 5 |

3.3 |

Dump Mode --------------------------------------------------------------------------------------------------------- |

3- 6 |

3.4 |

BASIC Expansion Mode ---------------------------------------------------------------------------------------- |

3- 8 |

3.5 |

Automatic Calibration Setting -------------------------------------------------------------------------------- |

3- 9 |

3.6 |

LAN Enable/Disable Setting ---------------------------------------------------------------------------------- |

3-11 |

3.7 |

Real Time Clock (RTC) Setting ------------------------------------------------------------------------------ |

3-12 |

4. PROGRAM DOWN LOAD ----------------------------------------------------------------------------- |

4- 1 |

||

4.1 |

Outline of Features ----------------------------------------------------------------------------------------------- |

4- 1 |

|

4.2 |

Download Program Installation ------------------------------------------------------------------------------ |

4- 1 |

|

4.2.1 |

System Requirements ------------------------------------------------------------------------------------------- |

4- 1 |

|

4.2.2 |

Setup----------------------------------------------------------------------------------------------------------------- |

4- 2 |

|

4.3 |

Firmware Download ---------------------------------------------------------------------------------------------- |

4- 2 |

|

5. RFID ANALYZE TOOL --------------------------------------------------------------------------------- |

5- 1 |

||

5.1 |

System Requirement--------------------------------------------------------------------------------------------- |

5- 1 |

|

5.2 |

Set up ----------------------------------------------------------------------------------------------------------------- |

5- 2 |

|

5.3 |

Application Functions ------------------------------------------------------------------------------------------- |

5- 3 |

|

5.3.1 |

Main Menu---------------------------------------------------------------------------------------------------------- |

5- 3 |

|

5.3.2 |

File Menu ----------------------------------------------------------------------------------------------------------- |

5- 4 |

|

5.3.3 |

Tool Menu ---------------------------------------------------------------------------------------------------------- |

5- 7 |

|

5.3.4 |

Help Menu --------------------------------------------------------------------------------------------------------- |

5-12 |

|

5.4 |

Operating Procedure-------------------------------------------------------------------------------------------- |

5-13 |

|

CAUTION!

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2.The contents of this manual may be changed without notification.

Copyright © 2006

by TOSHIBA TEC CORPORATION All Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

1. INTRODUCTION

EO13-33002

(Revision Date: Jul. 24, 2008)

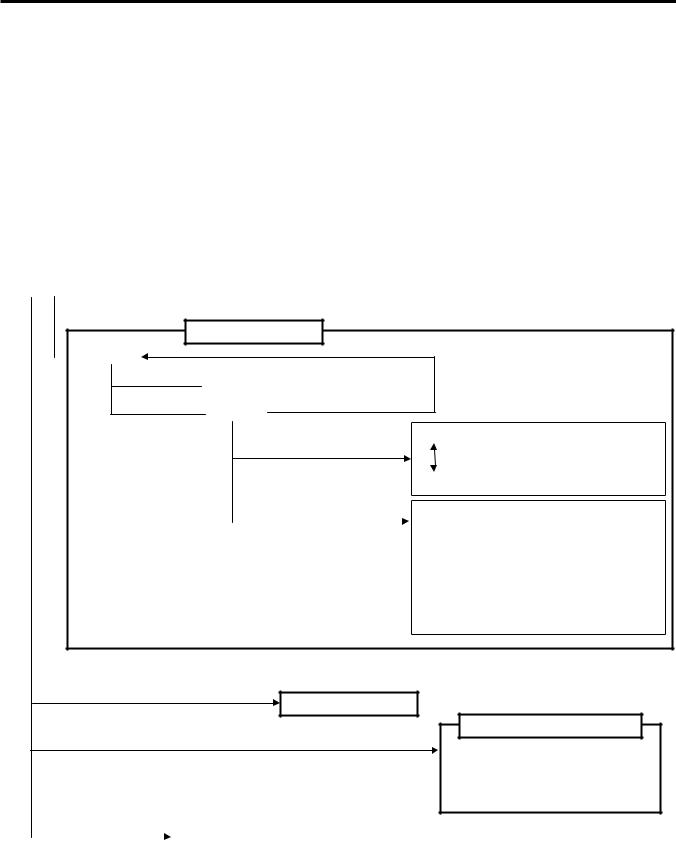

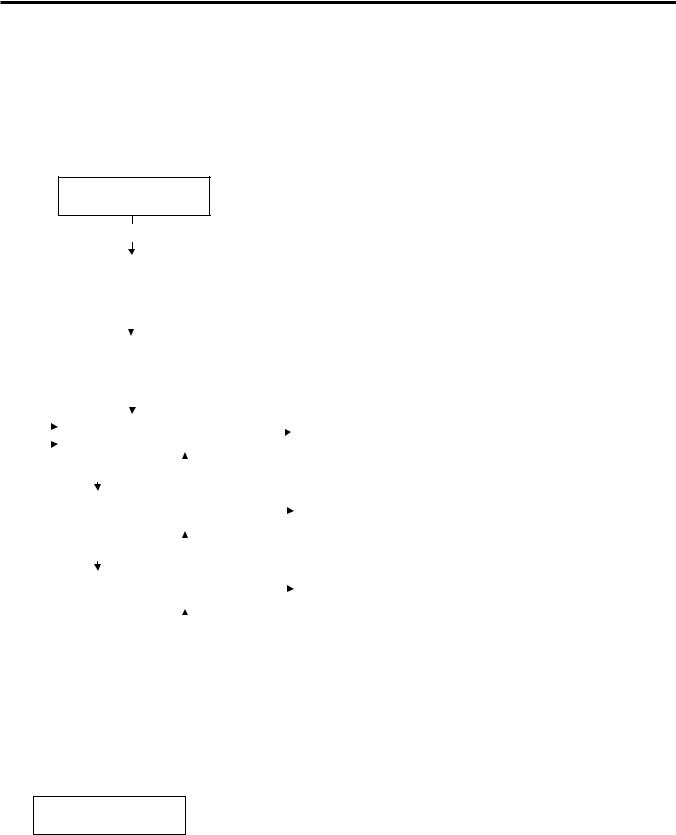

1.1 Key Operation Flow

1. INTRODUCTION

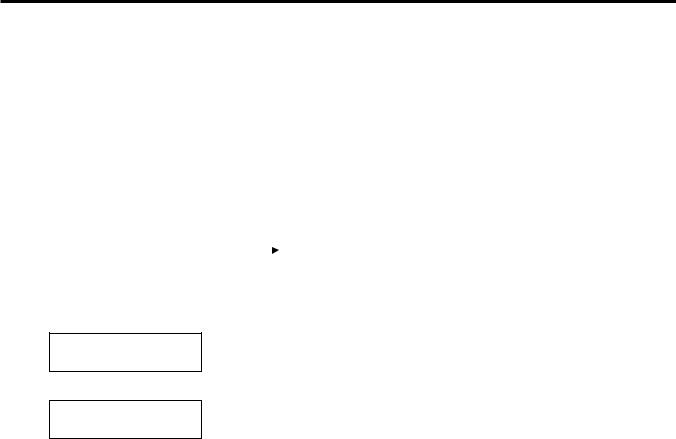

This document describes key operations using the keys and LCD display on the printer that you can operate on a printer alone. Key operations are performed in the following four printer setting modes:

•Online mode where a pause, reset, automatic threshold setting, etc. are performed.

•Download mode where a firmware downloading is performed.

•System mode for service personnel where a self-diagnosis, printer parameter settings, RAM clear, IP address setting etc. are performed.

•System mode for end user where a self-diagnosis, printer parameter settings, fine adjustment, etc., which are same functions as those in System mode for service personnel, are performed.

NOTE: This document uses the B-SX8T for examples of the display.

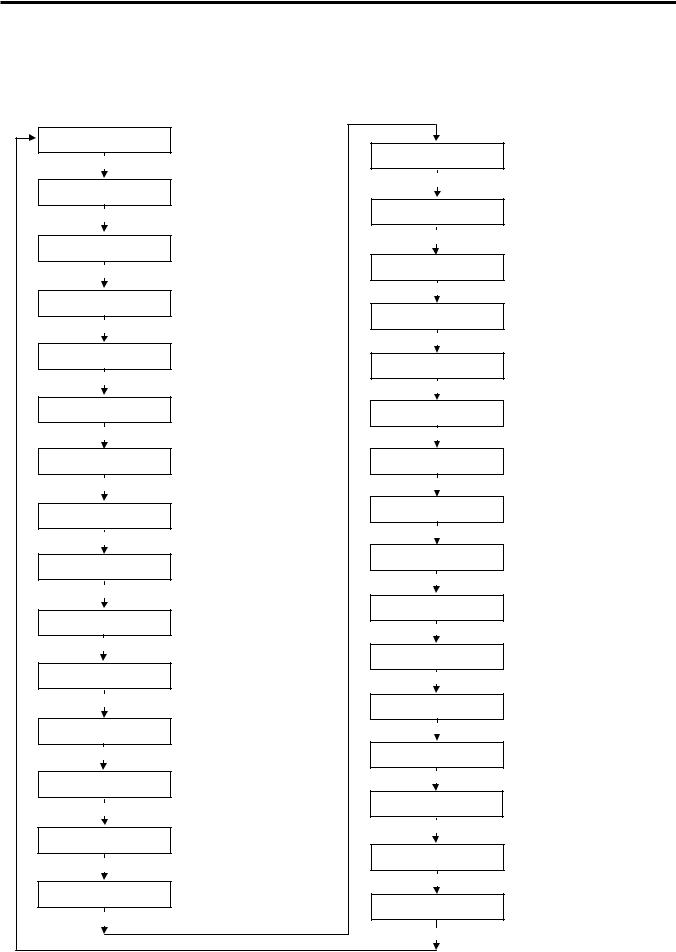

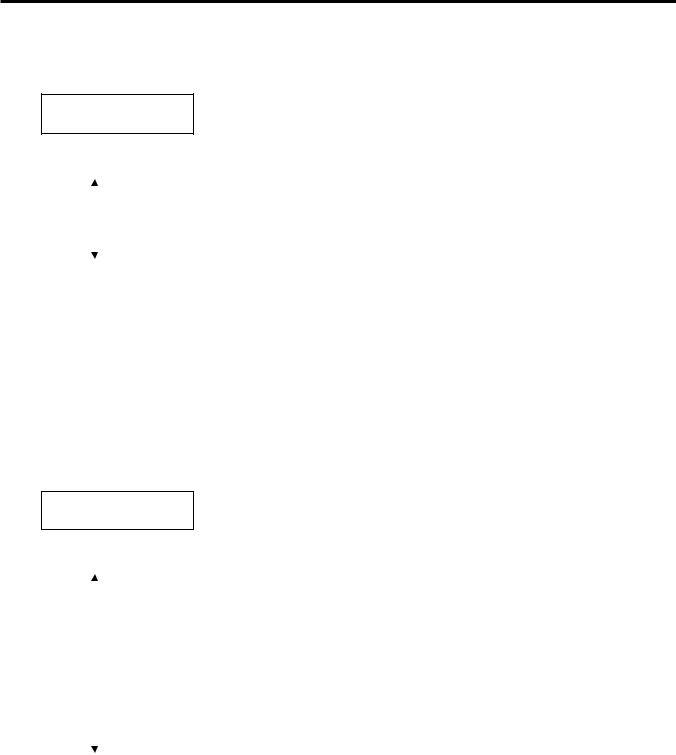

1.1 Key Operation Flow

Power OFF

Turn the power on.

Online mode

Online

Online

[FEED] key

[PAUSE] key

Feeds one label.

Feeds one label.

[RESTART] key

Pause

Pause

Hold down the [PAUSE] key |

Feed gap sensor automatic threshold setting |

for a few seconds. |

[FEED] key or [RESTART] key |

|

Hold down the [RESTART] key |

Black mark sensor threshold setting |

|

|

for a few seconds. |

• Reset |

|

• Parameter Setting |

|

• Fine adjustment |

|

• Dump mode |

|

• Expand mode (Basic expansion mode) |

|

• Automatic calibration mode |

|

• LAN Enable/Disable |

|

• RTC Setting |

While holding down the [FEED],

[RESTART], and [PAUSE] keys, turn the power on.

Download mode

While holding down the [FEED] and [RESTART] keys, turn the power on.

While holding down the |

|

System mode for service personnel |

|

||

|

|

||||

|

|

|

|||

• Self-test |

|||||

[FEED] and [PAUSE] |

|||||

• Parameter setting |

|||||

keys, turn the power on. |

|||||

• Fine adjustment |

|||||

|

|

||||

|

|

• Test print |

|||

|

|

||||

|

|

• Sensor adjustment |

|||

|

|

• RAM clear |

|||

|

|

• IP Address setting |

|||

|

|

• Basic setting |

|||

|

|

• For factory |

|||

|

|

• RFID Module Setting |

|||

|

|

|

|

|

|

System mode for end users

• Self-test

•Parameter setting

•Fine adjustment

•Test print

1- 1

1. INTRODUCTION

EO13-33002

1.2 Operation Panel

1.2 Operation Panel

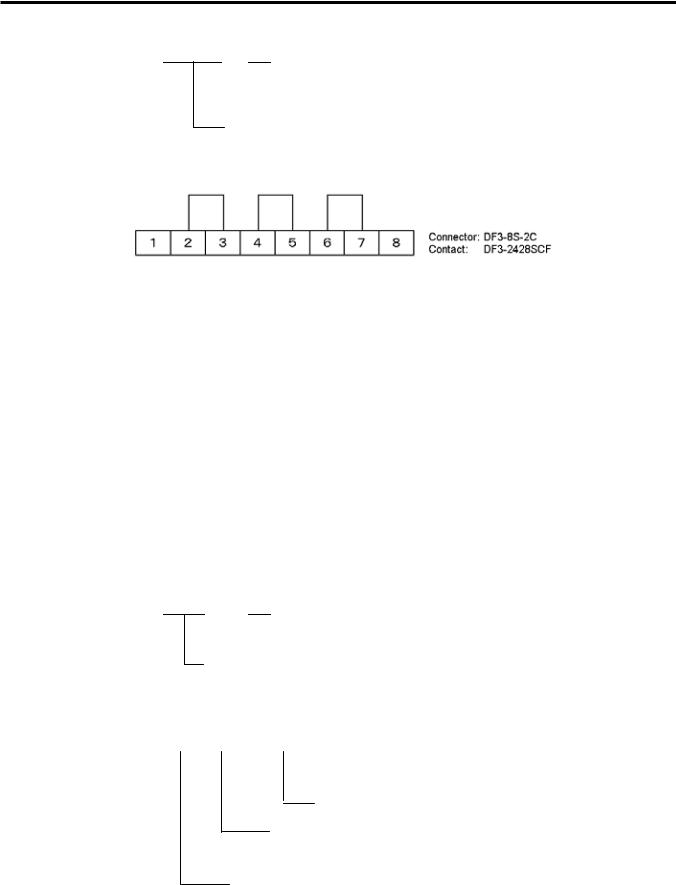

The figure below illustrates the Operation Panel and key functions.

POWER LED (Green)

ERROR LED (Red)

LCD Message

Display

ON LINE LED (Green)

[FEED] key

[RESTART] key

[PAUSE] key

The LCD Message Display is a 16-character x 2-line display, which shows messages in alphanumeric characters and symbols to indicate the printer’s status. .

There are three LEDs on the Operation Panel.

LED |

Illuminates when… |

POWER |

The printer is turned on. |

ON LINE |

The printer is ready to print. |

ERROR |

The printer is in an error state. |

The [FEED], [RESTART] and [PAUSE] keys function as described below.

FEED |

Feeds or ejects one media. |

|

Adjusts media to a proper position if the media is not properly positioned by feeding |

|

one or two blank media before printing. |

|

Prints data in the image buffer on one media according to the system mode setting. |

|

In system mode, this key is used to select various parameters or to set a fine |

|

adjustment value in the negative direction (-). |

RESTART |

Resumes printing when the printer is in a pause state or an error state. |

|

Restores the same state as when the power is turned off and on again. |

|

In system mode, this key is used to select various parameters or to set a fine |

|

adjustment value in the positive direction (+). |

|

|

PAUSE |

Stops printing temporarily. |

|

Programs threshold values. |

|

In system mode, this key is used as an enter key. |

1- 2

2. SYSTEM MODE

2. SYSTEM MODE

EO13-33002

2. SYSTEM MODE

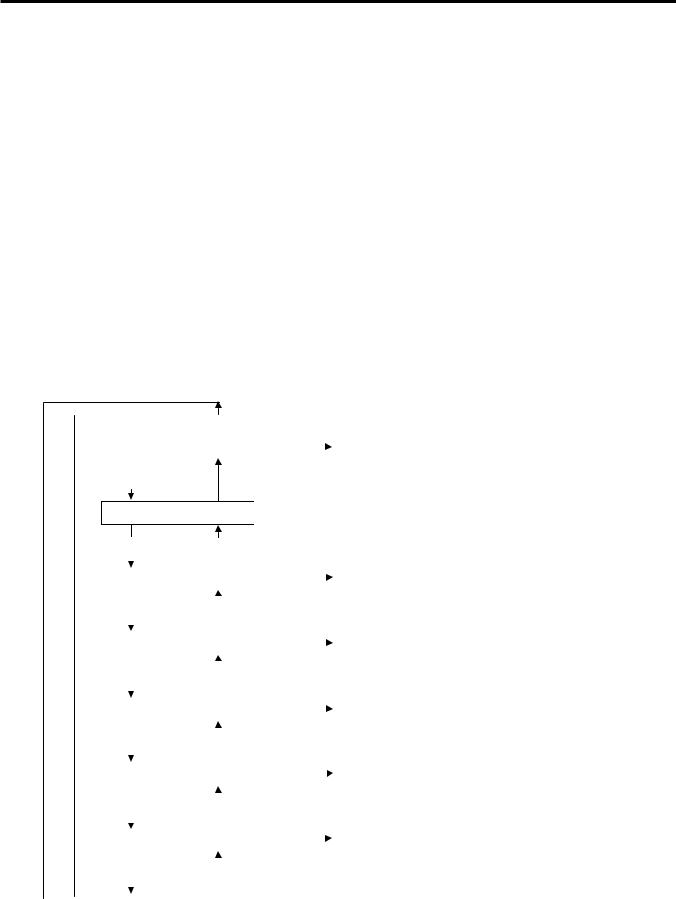

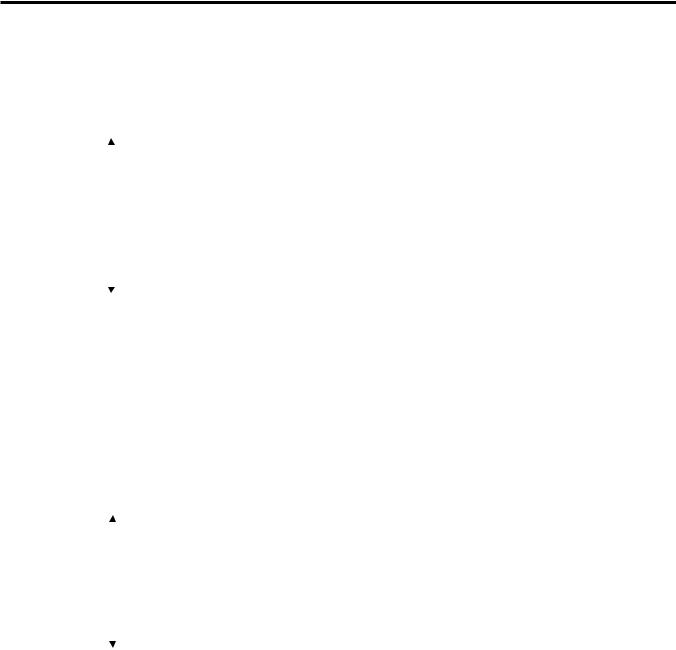

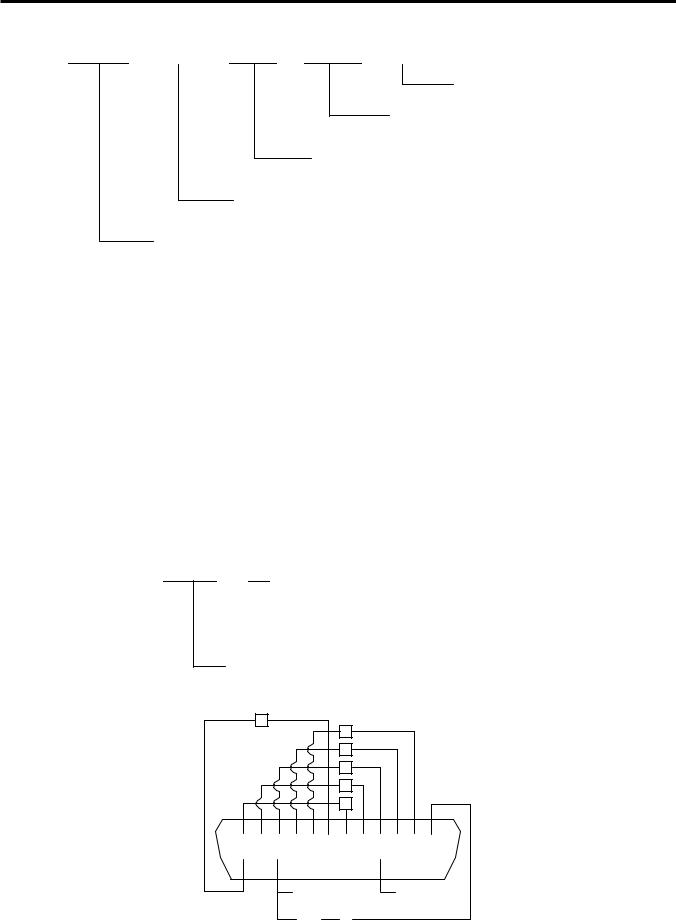

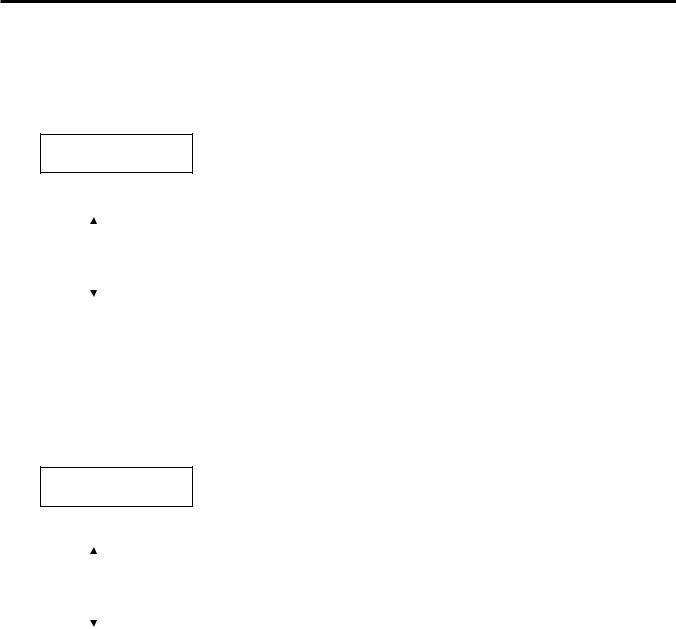

System mode consists of ten main menus: Self-diagnostic test, Parameter setting, Printer parameter fine adjustment, Test print, Sensor adjustment, RAM clear, IP address setting, Basic setting, and Factory mode.

Each menu is used for the following purposes:

•To check and print the system status, the Maintenance Counter, and the Print Head Element.

•To set the parameters for the communication with the host computer, and the printer functions such as the language for LCD message, Feed key function, etc.

•To make fine adjustment related to the media issue.

•To perform a test print for checking print quality.

•To check the status of the sensors and to set the threshold of the media sensor for pre-printed media.

•To perform a Maintenance Counter clear and Parameter clear.

•To set the IP address

•To set the Basic setting

•To perform the factory mode

To enter System mode, turn on the printer while pressing the [FEED] and [PAUSE] keys at the same time. Hold both keys until “<1>DIAG. Vx.x” message appears on the display.

|

|

|

|

[RESTART] |

|

|

|

This is the start of the Self-Diagnostic Test |

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

|

[PAUSE] |

|

|||||

|

|

|

menu. → Section 2.1 |

||||||

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

||

<2>PARAMETER SET  [PAUSE]

[PAUSE]

[FEED] [RESTART]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<3>ADJUST SET |

|

|

[PAUSE] |

|

|

|||||||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[RESTART] |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<4>TEST PRINT |

|

|

[PAUSE] |

|

|

|||||||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[RESTART] |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<5>SENSOR ADJ. |

|

|

[PAUSE] |

|

|

|||||||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

[RESTART] |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<6>RAM CLEAR |

|

|

|

[PAUSE] |

|

|

||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[RESTART] |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<7>IP ADDRESS |

|

[PAUSE] |

|

|

|

|||||||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[RESTART] |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This is the start of the Parameter Setting menu. → Section 2.2

This is the start of the Printer Parameter Fine Adjustment menu. → Section 2.3

This is the start of the Test Print menu.

→ Section 2.4

This is the start of the Sensor Adjustment menu. → Section 2.5

This is the start of the RAM Clear menu.

→ Section 2.6

This is the start of the IP Address Setting menu. → Section 2.7

Continued on the next page.

2- 1

2. SYSTEM MODE

EO13-33002 (Revision Date: Jul. 24, 2008)

2. SYSTEM MODE

Continued from the previous page.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<8>BASIC |

|

|

|

[PAUSE] |

|

|

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

[RESTART] |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<9>FOR FACTORY |

|

|

[PAUSE] |

|

|

|||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

[RESTART] |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<10>RFID |

|

|

|

|

[PAUSE] |

|

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This is the start of the Basic Setting menu.

→ Section 2.8

This is the start of the Factory Mode menu.

This is the RFID Module Setting menu.

→ Section 2.9

NOTES: 1. System Mode menu can be selected with the [RESTART] or [FEED] key.

2.Pressing the [PAUSE] key allows you to enter the sub menus of each System Mode menu. Flowcharts of each menu’s sub menus are provided on the following pages.

3.“x.x” of “DIAG. Vx.x” indicates firmware version and revision.

2- 2

2. SYSTEM MODE

EO13-33002

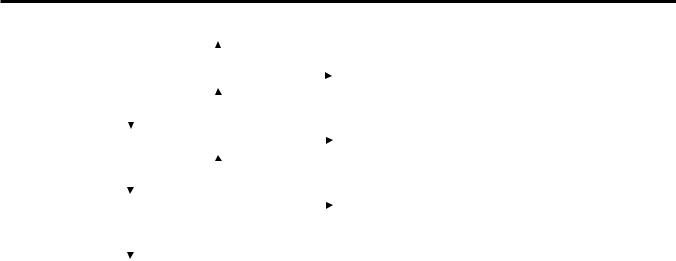

2.1 Self-diagnostic Test

2.1 Self-diagnostic Test

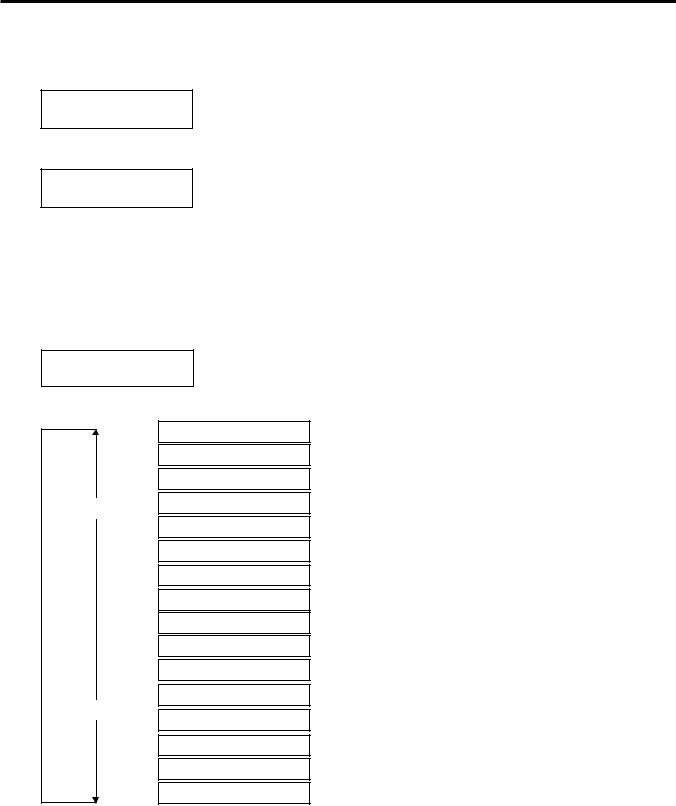

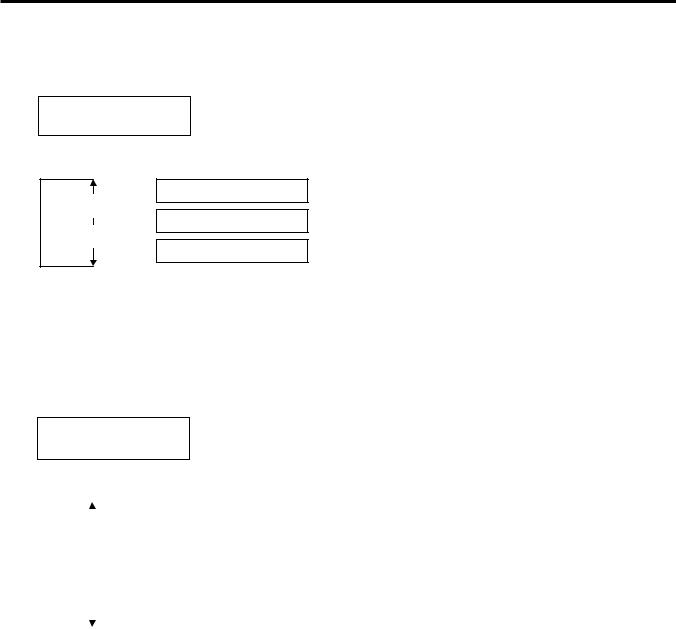

Outline of Self-diagnostic Test

In the Self-diagnostic test mode, the printer automatically checks and prints out the printer system information such as the sensor status or interface, and the maintenance counter. Also it performs a print head broken element check.

The Self-diagnostic test contains the following sub menus:

<1>DIAG. Vx.x

[PAUSE]

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

|

|

Selection of the printing mode. |

||||||||||

|

|

|

|

PRT TYPE TRANSFR |

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[PAUSE] |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

|

|

Selection of the dispensing mode. |

||||||||||

|

|

|

|

TYPE[S] NO CUT |

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[PAUSE] |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

[PAUSE] |

|

|

|

|

Prints out the Maintenance Counter /Parameter Settings. |

||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

MAINTENANCE CONT. |

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

[RESTART] |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

|

|

Performs a Self-Diagnostic Test, and prints out the result. |

||||||||||

|

|

|

|

|

|

[PAUSE] |

|

|

||||||||||||||||

|

|

|

|

AUTO DIAGNOSTIC |

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

[RESTART] |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

|

|

Checks to see if there is any problem with the print head. |

||||||||||

|

|

|

|

|

[PAUSE] |

|

|

|

||||||||||||||||

|

|

|

|

HEAD CHECK |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[RESTART] |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: Use the [FEED] or [RESTART] key to select a desired option.

How to Enter Self-diagnostic Test Mode

Turn on the printer while pressing the [FEED] and [PAUSE] keys at the same time. Hold both keys until the “<1>DIAG. Vx.x” message appears in the display.

<1>DIAG. Vx.x

2- 3

2. SYSTEM MODE

EO13-33002

2.1 Self-diagnostic Test

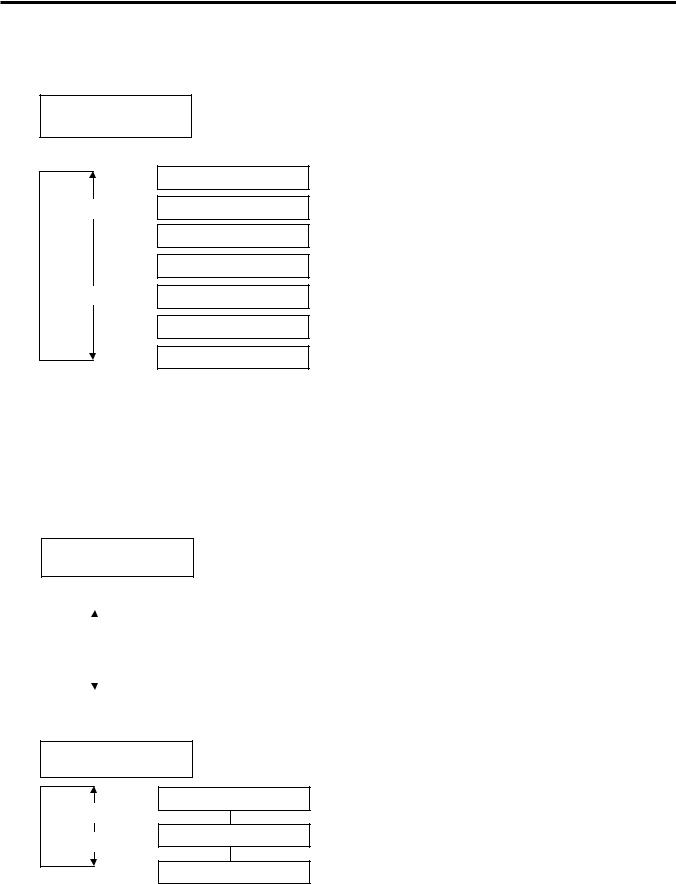

2.1.1 Printing Mode Selection

While “PRT TYPE TRANSFR” is displayed on the LCD, press the [PAUSE] key. The type of printing mode can be selected:

“TRANSFR” (Thermal transfer) or “DIRECT” (Thermal direct).

After selecting the printing mode to be used, press the [PAUSE] key.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

Thermal transfer: When transparent ribbon is used. |

|

|

|

|

|

|

PRT TYPE TRANSFR |

|

|

[RESTART] |

|

|

||||

|

|

|

|

||||

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

Thermal transfer: When non-transparent ribbon is used. |

|

|

|

|

|

|

PRT TYPE NO TRAN |

|

|

|

[FEED] |

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

<1>DIAG. Vx.x |

Thermal direct: When thermal paper is used. |

|

|

|

|

|

|

PRT TYPE DIRECT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: When using the ribbon, be sure to select “Thermal Transfer”. When using the thermal media, be sure to select the “Thermal Direct”.

2.1.2 Dispensing Mode Selection

When “TYPE[S] NO CUT” is displayed, press the [PAUSE] key. The type of dispensing mode can be selected:

“[S] NO CUT” (Batch issue) or “[C] WITH CUT” (Cut issue)

After selecting the dispensing mode to be used, press the [PAUSE] key.

|

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

TYPE[S] NO CUT |

|

[RESTART] |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

TYPE[C] WITH CUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[FEED] |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[S] NO CUT (Batch issue): To issue media in batch mode.

[C] WITH CUT (Cut issue): When an optional cutter module is installed.

NOTE: When using the cutter module, be sure to select “[C] WITH CUT”. When the cutter module is not installed, be sure to select “[S] NO CUT”.

2- 4

2. SYSTEM MODE

EO13-33002

2.1 Self-diagnostic Test

2.1.3 Maintenance Counter/Parameter Settings Print Out

When “MAINTENANCE CONT” is displayed, the printer is ready to print out the Maintenance Counter/Parameter Settings. Press the [PAUSE] key to start.

|

<1>DIAG. Vx.x |

|

|

|

|

|

|

|

<1>DIAG. Vx.x |

|

|

|

<1>DIAG. Vx.x |

||

|

|

|

|

[PAUSE] |

|

|

|

|

|

|

|||||

|

MAINTENANCE CONT |

|

|

|

|

CHECKING & PRINT |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

(1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Print Sample |

|

TOTAL FEED |

|

|

1.1km |

[QM] |

|

||||||||

|

|

(2) |

|

FEED |

|

|

1.1km |

|

|

|

|

|

|||

|

|

(3) |

|

|

|

0.5km |

|

|

|

|

|

||||

|

|

(4) |

|

CUT |

|

|

96 |

|

|

|

|

|

|||

|

|

(5) |

|

HEAD U/D |

|

|

12320 |

|

|

|

|

|

|||

|

|

(6) |

|

RIBBON |

|

|

3h |

|

|

|

|

|

|||

|

|

(7) |

|

SOLENOID |

|

|

2h |

|

|

|

|

|

|||

|

|

(8) |

|

232C ERR |

|

|

255 |

|

|

|

|

|

|||

|

|

(9) |

|

SYSTEM ERR |

|

|

0 |

|

|

|

|

|

|||

|

|

(10) |

|

POWER FAIL |

|

|

0 |

|

|

|

|

|

|||

|

|

(11) |

|

[PC] |

|

|

[KEY] |

|

|

|

|

|

|||

|

|

|

FEED |

+2.0mm |

FEED |

|

+0.0mm |

|

|||||||

|

|

(12) |

|

CUT |

+0.0mm |

CUT |

|

+1.0mm |

|

||||||

|

|

(13) |

|

BACK |

+0.0mm |

BACK |

|

+0.0mm |

|

||||||

|

|

(14) |

|

TONE(T) |

+0 step |

TONE(T) |

|

+0 step |

|

||||||

|

|

(15) |

|

TONE (D) |

+0 step |

TONE(D) |

|

+0 step |

|

||||||

|

|

(16) |

|

RBN(FW) |

-10 |

RBN (FW) |

-8 |

|

|

|

|||||

|

|

(17) |

|

RBN (BK) |

+0 |

RBN (BK) |

+0 |

|

|

|

|||||

|

|

(18) |

|

X ADJ. |

+0.0mm |

|

|

|

|

|

|

||||

|

|

(19) |

|

THRESHOLD (R) |

1.0V |

|

|

|

|

|

|||||

|

|

(20) |

|

THRESHOLD (T) |

1.4V |

|

|

|

|

|

|||||

|

|

(21) |

|

FONT |

|

|

[PC-850] [0] |

|

|

|

|

|

|||

|

|

(22) |

|

SPEED |

|

|

[9600] |

|

|

|

|

|

|||

|

|

(23) |

|

DATA LENG. |

|

|

[8] |

|

|

|

|

|

|||

|

|

(24) |

|

STOP BIT |

|

|

[1] |

|

|

|

|

|

|||

|

|

(25) |

|

PARITY |

|

|

[EVEN] |

|

|

|

|

|

|||

|

|

(26) |

|

CONTROL |

|

|

[XON+READY AUTO] |

|

|||||||

|

|

(27) |

|

MESSAGE |

|

|

[ENGLISH] |

|

|

|

|

|

|||

|

|

(28) |

|

FORWARD WAIT |

[ON] +0.0mm |

|

|

|

|

|

|||||

|

|

(29) |

|

HEAD UP CUT |

|

|

[ON] |

|

|

|

|

|

|||

|

|

(30) |

|

RIBBON SAVE |

|

|

[ON:LABEL] |

|

|

|

|

|

|||

|

|

(31) |

|

CODE |

|

|

[AUTO] |

|

|

|

|

|

|||

|

|

(32) |

|

RIBBON |

|

|

[TRANS] |

|

|

|

|

|

|||

|

|

(33) |

|

PEEL OFF STATUS |

[ON] |

|

|

|

|

|

|||||

|

|

(34) |

|

FEED KEY |

|

|

[FEED] |

|

|

|

|

|

|||

|

|

(35) |

|

KANJI |

|

|

[TYPE1] |

|

|

|

|

|

|||

|

|

(36) |

|

EURO CODE |

|

|

[B0] |

|

|

|

|

|

|||

|

|

(37) |

|

AUTO HD CHK |

|

|

[OFF] |

|

|

|

|

|

|||

|

|

(38) |

|

ACK/BUSY |

|

|

[TYPE1] |

|

|

|

|

|

|||

|

|

(39) |

|

WEB PRINTER |

|

|

[OFF] |

|

|

|

|

|

|||

|

|

(40) |

|

SENSOR POSITION |

[CENTER] |

|

|

|

|

|

|||||

|

|

(41) |

|

INPUT PRIME |

|

|

[ON] |

|

|

|

|

|

|||

|

|

(42) |

|

EX. I/O MODE |

|

|

[TYPE1] |

|

|

|

|

|

|||

|

|

(43) |

|

PLUG & PLAY |

|

|

[OFF] |

|

|

|

|

|

|||

|

|

(44) |

|

LBL/RBN END |

|

|

[TYPE1] |

|

|

|

|

|

|||

|

|

(45) |

|

PRE PEEL OFF |

[ON] +0.0mm |

|

|

|

|

|

|||||

|

|

(46) |

|

BACK SPEED |

|

|

[STD] |

|

|

|

|

|

|||

|

|

(47) |

|

MAXI CODE SPEC. |

[TYPE1] |

|

|

|

|

|

|||||

|

|

(48) |

|

PEEL OFF TRQ |

[R3] |

|

|

|

|

|

|||||

|

|

|

|

------------------------------------------------------------------------------ |

|

||||||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|||||||||||

2- 5

2. SYSTEM MODE

EO13-33002

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

(49) |

------------------------------------------------------------------------------- |

|||

STABILIZER |

[ON] |

|

||

(50) |

AUTO CALIB. |

[OFF] |

|

|

(51) |

LAN |

[ON SNMP ON] |

|

|

(52) |

PRTR IP ADDRESS |

[192.168.010.020] |

|

|

(53) |

GATE IP ADDRESS |

[000.000.000.000] |

|

|

(54) |

SUBNET MASK |

[255.255.255.000] |

|

|

(55) |

MAC ADDRESS |

[00-80-91-34-00-CC] |

||

(56) |

TTF AREA |

[1280KB] |

|

|

(57) |

EXT CHR AREA |

[ 256KB] |

|

|

(58) |

BASIC AREA |

[ 128KB] |

|

|

(59) |

PC SAVE AREA |

[ 128KB] |

|

|

(60) |

SOCKET PORT |

[OFF][08000] |

|

|

(61) |

BASIC |

[OFF] |

|

|

(62) |

BASIC TRACE |

[OFF] |

|

|

(63) |

DHCP |

[OFF] |

|

|

(64) |

DHCP ID |

[FFFFFFFFFFFFFFFFFFFF] |

||

(65) |

|

[FFFFFFFFFFFF] |

|

|

DHCP HOST NAME |

[ |

|

] |

|

(66) |

RTC BATT. CHK |

[ON] |

|

|

(67) |

RTC RENEWAL |

[PAGE] |

|

|

(68) |

RFID MODULE |

[U2] |

|

|

(69) |

RFID TAG TYPE |

[NONE |

] |

|

(70) |

RFID ERR CHECK |

[OFF] |

|

|

(71) |

RFID RETRY |

[ |

3] |

|

(72) |

RFID RD CYCLE |

[ |

5] [2.0sec] |

|

(73) |

RFID WT CYCLE |

[ |

5] [2.0sec] |

|

(74) |

RFID ADJ RETRY |

[+00mm] |

|

|

(75) |

RFID POWER LEV |

[ 18] |

|

|

(76) |

RFID AGC THR. |

[0] |

|

|

(77) |

RFID Q VAL |

[0] |

|

|

(78) |

RFID WT AGC |

[ |

0] |

|

(79) |

RFID WT AGC MIN |

[ |

0] |

|

(80) |

RFID WT OK TAGS |

|

0 |

|

(81) |

RFID VOID PRINT TAGS |

|

0 |

|

|

|

|

|

|

NOTE: Print conditions:

Print speed: 4”/sec., Sensor: No sensor, Printing mode: Thermal transfer/Direct thermal(*1), Media length: 240 mm, Issue mode: Batch printing

(*1) Depends on the printing mode setting.

2- 6

2. SYSTEM MODE

EO13-33002

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

• Descriptions of the Maintenance Counter

# |

Item |

Count Condition |

Range |

(1) |

Total media distance |

Counts when the feed motor is driven to feed, print or issue media. |

0.0 to 3200.0 km |

|

covered |

(Counted also during a reverse feed.) See NOTE 2. |

|

(2) |

Media distance |

Destination printed on the same line indicates one selected for a |

0.0 to 3200.0 km |

|

covered |

parameter clear. |

|

(3) |

Print distance |

Counts while printing. (Reverse feed is not counted.) See NOTE 3. |

0.0 to 200.0 km |

(4) |

Cut count |

Counts every cut. See NOTE 4. |

0 to 1000000 times |

(5) |

Head up and down |

Counts every head up and down cycle by means of the solenoid which |

0 to 2000000 times |

|

cycle count |

is used for the ribbon save function. See NOTE 4. |

|

(6) |

Ribbon motor driving |

Counts when the ribbon motor is driven to feed, print or issue media. |

0 to 2000 hours |

|

time |

(The driving time is also counted during a reverse feed.) See NOTE 5. |

|

(7) |

Solenoid drive time for |

Counts when the ribbon save function is activated. See NOTE 5. |

0 to 1000 hours |

|

head up |

|

|

(8) |

RS-232C hardware |

Counts when a parity, overrun or framing error occurs. See NOTE 6. |

0 to 255 times |

|

error count |

|

|

(9) |

System error count |

Counts when a system error occurs. |

0 to 15 times |

(10) |

Momentary power |

Counts when a momentary power interruption occurs. |

0 to 15 times |

|

failure count |

|

|

(80) |

Number of successful |

Counts when an RFID write has succeeded. |

0 to 9999999 times |

|

RFID write |

|

|

(81) |

Number of failure in |

Counts when an RFID write has failed. |

0 to 9999999 times |

|

RFID write |

|

|

NOTES:

1.Item from (2) through (10) are initialized to “0” after RAM clear.

2.If the media distance covered is 50.0 cm or less, it is rounded down and no data is added to the memory at power off.

3.If the print distance is 5.5 m or less, it is rounded down and no data is added to the memory at power off.

4.If the count is 31 or less, it is rounded down and no data is added to the memory at power off.

5.If the driving time is 27 sec. or less, it is rounded down and no data is added to the memory at power off.

6.When a sent command results in an error, the same number as the data capacity of the command is counted by byte.

2- 7

2. SYSTEM MODE

EO13-33002

(Revision Date: Mar. 26, 2009)

2.1 Self-diagnostic Test

• Descriptions of the Parameters

Item |

# |

Description |

Specification |

|

FEED |

(11) |

Print start position fine adjustment (PC), (KEY) |

-50.0 mm to +50.0 mm |

|

CUT |

(12) |

Cut/strip position fine adjustment (PC), (KEY) |

-50.0 mm to +50.0 mm |

|

BACK |

(13) |

Reverse feed amount fine adjustment (PC), (KEY) |

-9.9 mm to +9.9 mm |

|

TONE(T) |

(14) |

Print tone fine adjustment (Thermal transfer), (PC), (KEY) |

-10 step to +10 step |

|

TONE(D) |

(15) |

Print tone fine adjustment (Thermal direct), (PC), (KEY) |

-10 step to +10 step |

|

RBN(FW) |

(16) |

Ribbon take-up motor driving voltage fine adjustment |

-15 step to +0 step |

|

|

|

(PC), (KEY) |

|

|

RBN(BK) |

(17) |

Ribbon feed motor driving voltage fine adjustment (PC), |

-15 step to +10 step |

|

|

|

(KEY) |

|

|

X ADJ. |

(18) |

X coordinate fine adjustment |

-99.9 mm to +99.9 mm |

|

THRESHOLD<R> |

(19) |

Threshold manual fine adjustment for the black mark |

0.0V to 4.0V |

|

|

|

sensor |

|

|

THRESHOLD<T> |

(20) |

Threshold manual fine adjustment for the feed gap sensor |

0.0V to 4.0V |

|

FONT |

(21) |

Character code |

PC-850 PC-851 PC-1252 LATIN9 PC-852 |

|

|

|

|

PC-855 PC-1253 Arabic PC-857 PC-1250 |

|

|

|

|

PC-1254 PC-8 PC-1251 PC-1257 PC-866 |

|

|

|

|

UTF-8 |

|

|

|

Character “0” |

0: without slash |

|

|

|

|

0: with slash |

|

SPEED |

(22) |

Baud rate |

2400: 2400 bps |

19200: 19200 bps |

|

|

|

4800: 4800 bps |

38400: 38400 bps |

|

|

|

9600: 9600 bps |

115200: 115200 bps |

DATA LENG. |

(23) |

Data length |

7: 7 bits |

|

|

|

|

8: 8 bits |

|

STOP BIT |

(24) |

Stop bit length selection |

1: 1 bit |

|

|

|

|

2: 2 bits |

|

PARITY |

(25) |

Parity |

NON: None |

|

|

|

|

ODD: ODD |

|

|

|

|

EVEN: EVEN |

|

CONTROL |

(26) |

Flow control code |

XON/XOFF: XON/XOFF |

|

|

|

|

READY/BUSY: READY/BUSY (DTR) |

|

|

|

|

XON+READ AUTO: |

|

|

|

|

XON/XOFF+READY/BUSY (DTR) |

|

|

|

|

XON/XOFF AUTO: XON/XOFF |

|

|

|

|

READY/BUSY RTS: RTS |

|

MESSAGE |

(27) |

Language selection for LCD message |

ENGLISH: English |

|

|

|

|

GERMAN: German |

|

|

|

|

FRENCH: French |

|

|

|

|

DUTCH: Dutch |

|

|

|

|

SPANISH: Spanish |

|

|

|

|

JAPANESE: Japanese |

|

|

|

|

ITALIAN: Italian |

|

FORWARD WAIT |

(28) |

Auto forward wait |

ON: Available |

|

|

|

|

OFF: Unavailable |

|

|

|

|

NOTE: The stop position fine adjustment |

|

|

|

|

value is also printed out. |

|

HEAD UP CUT |

(29) |

Head up cut in cut issue mode |

ON: Activated |

|

|

|

|

OFF: Not activated |

|

RIBBON SAVE |

(30) |

Ribbon saving function |

ON(TAG): Activated |

|

|

|

|

(When the head lever is set to |

|

|

|

|

the tag position.) |

|

|

|

|

ON(LBL): Activated |

|

|

|

|

(When the head lever is set to |

|

|

|

|

the label position.) |

|

|

|

|

OFF: Not activated |

|

CODE |

(31) |

Control code selection |

AUTO: Automatic selection |

|

|

|

|

ESC LF NUL: ESC LF NUL mode |

|

|

|

|

{ | }: Mainframe mode |

|

|

|

|

xx xx xx: Optional code |

|

|

|

|

(The values are given in HEX.) |

|

2- 8

2. SYSTEM MODE |

|

|

|

|

|

EO13-33002 |

||

|

|

|

|

|

|

|

(Revision Date: Mar. 26, 2009) |

|

|

|

|

|

|

|

|

2.1 Self-diagnostic Test |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

# |

|

Description |

|

Specification |

|

|

|

RIBBON |

(32) |

Ribbon type selection |

TRANS: Transparent ribbon |

|

|||

|

|

|

|

|

|

NON TRANS: Non transparent ribbon |

|

|

|

PEEL OFF STATUS |

(33) |

Strip wait status selection |

ON: Available |

|

|||

|

|

|

|

|

|

OFF: Unavailable |

|

|

|

FEED KEY |

(34) |

Feed key function |

FEED: Feeds one label |

|

|||

|

|

|

|

|

|

PRINT: Prints image buffer on one label |

|

|

|

KANJI |

(35) |

Kanji code type (Not supported by QM model) |

TYPE 1: Windows code |

|

|||

|

|

|

|

|

|

TYPE 2: Original code |

|

|

|

EURO CODE |

(36) |

Euro font code |

20H to FFH |

|

|||

|

AUTO HD CHK |

(37) |

Auto print head broken element check |

ON: Available |

|

|||

|

|

|

|

|

|

OFF: Unavailable |

|

|

|

ACK/BUSY |

(38) |

Centronics interface ACK/BUSY timing setting |

TYPE1: A rise of ACK signal and a release |

|

|||

|

|

|

|

|

|

|

of BUSY occur at the same time. |

|

|

|

|

|

|

|

TYPE2: A fall of ACK signal and a release |

|

|

|

|

|

|

|

|

|

of BUSY occur at the same time. |

|

|

WEB PRINTER |

(39) |

Web printer function |

ON: Available |

|

|||

|

|

|

|

|

|

OFF: Unavailable |

|

|

|

SENS POSI |

(40) |

Media sensor |

CENTER: Fixed sensor |

|

|||

|

|

|

|

|

|

EDGE: Movable sensor |

|

|

|

INPUT PRIME |

(41) |

Input prime selection |

ON: Available |

|

|||

|

|

|

(Reset operation when |

INIT |

signal is ON) |

OFF: Unavailable |

|

|

|

EX. I/O MODE |

(42) |

Expansion I/O interface operating mode |

TYPE1: Standard mode |

|

|||

|

|

|

|

|

|

TYPE2: Inline mode |

|

|

|

PLUG&PLAY |

(43) |

Plug & Play setting |

ON: Available |

|

|||

|

|

|

|

|

|

OFF: Unavailable |

|

|

|

LBL/RBN END |

(44) |

Print processing setting at the label/ribbon error detection |

TYP1: |

Printing is paused in the middle of |

|

||

|

|

|

|

|

|

|

printing. |

|

|

|

|

|

|

|

TYP2: |

Printing is paused after the label is |

|

|

|

|

|

|

|

|

issued. |

|

|

PRE PEEL OFF |

(45) |

Pre-Strip setting |

OFF: Unavailable |

|

|||

|

BACK SPEED |

(46) |

Reverse Feed Speed setting |

STD: 3”/second |

|

|||

|

|

|

|

|

|

LOW: 2”/second |

|

|

|

MAXI CODE SPEC. |

(47) |

MAXI code specification selection |

TYPE1: |

Compatible with the current |

|

||

|

|

|

|

|

|

|

version |

|

|

|

|

|

|

|

TYPE2: |

Special specification |

|

|

PEEL OFF TRQ |

(48) |

Strip motor torque |

R0: Standard |

|

|||

|

STABILIZER |

(49) |

Stabilizer function |

ON: Stabilizer function is used. |

|

|||

|

|

|

|

|

|

OFF: Stabilizer function is not used. |

|

|

|

AUTO CALB. |

(50) |

Automatic calibration |

OFF: Disabled |

|

|||

|

|

|

|

|

|

ON TRANS: Enabled with the transmissive |

|

|

|

|

|

|

|

|

|

sensor |

|

|

|

|

|

|

|

ON REFLECT: Enabled with the reflective |

|

|

|

|

|

|

|

|

|

sensor |

|

|

LAN |

(51) |

Enabling or disabling the LAN |

ON SNMP ON: LAN Enabled |

|

|||

|

|

|

|

|

|

|

SNMP Enabled |

|

|

|

|

|

|

|

ON SNMP OFF: LAN Enabled |

|

|

|

|

|

|

|

|

|

SNMP Disabled |

|

|

|

|

|

|

|

OFF: |

LAN Disabled |

|

|

PRTR IP ADDRESS |

(52) |

Printer IP address |

***.***.***.*** |

|

|||

|

GATE IP ADDRESS |

(53) |

Gateway IP address |

***.***.***.*** |

|

|||

|

SUBNET MASK |

(54) |

Subnet mask |

***.***.***.*** |

|

|||

|

MAC ADDRESS |

(55) |

MAC (Media Access Control) address for LAN controller |

¶¶-¶¶-¶¶-¶¶-¶¶-¶¶ |

|

|||

|

|

|

on the MAIN PC Board |

|

|

|

||

|

TTF AREA |

(56) |

True type font registration area size |

0 KB to 3072 KB (unit of 128 KB) |

|

|||

|

EXT CHR AREA |

(57) |

External character registration area size |

0 KB to 3072 KB (unit of 128 KB) |

|

|||

|

BASIC AREA |

(58) |

BASIC file store area size |

0 KB to 1792 KB (unit of 128 KB) |

|

|||

|

PC SAVE |

(59) |

PC saving area size |

0 KB to 3072 KB (unit of 128 KB) |

|

|||

|

SOCKET PORT |

(60) |

Socket port number |

ON: Available |

|

|||

|

|

|

|

|

|

OFF: Unavailable |

|

|

|

|

|

|

|

|

Port No. 0 to 65535 |

|

|

2- 9

2. SYSTEM MODE |

|

|

EO13-33002 |

||

|

|

|

|

(Revision Date: Mar. 26, 2009) |

|

|

|

|

|

2.1 Self-diagnostic Test |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

# |

Description |

Specification |

|

|

BASIC |

(61) |

BASIC interpreter setting |

ON: Available |

|

|

|

|

|

OFF: Unavailable |

|

|

BASIC TRACE |

(62) |

BASIC interpreter trace setting |

ON: Available |

|

|

|

|

|

OFF: Unavailable |

|

|

DHCP |

(63) |

DHCP function setting |

ON: Available |

|

|

|

|

|

OFF: Unavailable |

|

|

DHCP ID |

(64) |

DHCP ID setting |

Max. 16 characters |

|

|

DHCP HOST NAME |

(65) |

DHCP host name |

Max. 16 characters |

|

|

RTC BATT. CHK |

(66) |

RTC Low Battery Check setting |

ON: Available |

|

|

|

|

|

OFF: Unavailable |

|

|

RTC RENEWAL |

(67) |

RTC data renewal timing |

BATCH: per batch |

|

|

|

|

|

PAGE: per page |

|

|

RFID MODULE |

(68) |

RFID module type |

NONE: No RFID kit is installed. |

|

|

|

|

|

U2: U2 B-SX708-RFID-U2-EU-R, |

|

|

|

|

|

B-SX708-RFID-U2-CN-R |

|

|

RFID TAG TYPE |

(69) |

RFID tag type |

NONE: 11 |

|

|

|

|

|

EPC C1 Gen2: 24 |

|

|

RFID ERR CHECK |

(70) |

RFID error tag detection |

ON: An error tag detection is performed. |

|

|

|

|

|

OFF: An error tag detection is not |

|

|

|

|

|

performed. |

|

|

RFID RETRY |

(71) |

Maximum number of RFID issue retries |

0 to 255 |

|

|

RFID RD CYCLE |

(72) |

Maximum number of RFID read retries |

0 to 255 |

|

|

|

|

RFID read retry time-out |

0 sec. to 9.9 sec. |

|

|

RFID WT CYCLE |

(73) |

Maximum number of RFID write retries |

0 to 255 |

|

|

|

|

RFID write retry time-out |

0 sec. to 9.9 sec. |

|

|

RFID ADJ RETRY |

(74) |

RFID adjustment for retry |

-99 mm to +99 mm |

|

|

RFID POWER LEV |

(75) |

RFID wireless power level setting |

9 to 18 |

|

|

RFID AGC THR. |

(76) |

RFID AGC Threshold Setting |

0 to 15 |

|

|

RFID Q VAL |

(77) |

RFID Q VAL (Q value) |

0 to 5 |

|

|

RFID WT AGC |

(78) |

RFID WT AGC (AGC threshold for data write) |

0 to 15 |

|

|

RFID WT AGC MIN |

(79) |

RFID WT MIN AGC (AGC threshold lower limit for retry) |

0 to 15 |

|

2- 10

2. SYSTEM MODE

EO13-33002

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

2.1.4 Self-Diagnostic Test and Result Print Out

When the Maintenance Counter/Parameter Settings is printed, the message returns to “<1>DIAG. Vx.x”. Press the [PAUSE] key twice.

The Self-Diagnostic Test is ready. Press the [PAUSE] key to start.

<1>DIAG. Vx.x AUTO DIAGNOSTIC

The printer starts a self-diagnosis, and prints out the result. During printing, the message below appears on the display.

<1>DIAG. Vx.x CHECKING & PRINT

After printing is completed, the display returns to “<1>DIAG. Vx.x”.

NOTE: If an error occurs, an error message appears, the printer stops printing. After clearing the error, press the [PAUSE] key to return the display to “<1>DIAG.Vx.x”. The printer does not restart printing automatically.

• Print Sample |

(1) |

PROGRAM |

B-SX8T |

|

|

|

MAIN |

15OCT2005 V1.0A: 1A00 |

|

|

|

BOOT |

20SEP2005 V1.0: 8500 |

|

|

(2) |

FONT |

AD00 |

|

|

(3) |

KANJI |

GOTHIC :9F00 |

|

|

|

|

MINCHO :7400 |

|

|

(4) |

EEPROM |

OK |

|

|

(5) |

SDRAM |

16MB |

|

|

(6) |

SENSOR1 |

00000000, 00000111 |

|

|

(7) |

SENSOR2 |

[H]23°C |

[A]22°C |

|

|

|

[R]4.2V |

[T]2.5V |

|

(8) |

PE LV. |

[R]1.2V |

[T]4.3V |

|

(9) |

M THRE. |

[R]5.0V |

[T]5.0V |

|

|

|

[RANK]1 305DPI |

|

|

(10) |

EXP.I/O |

NG |

|

|

(11) |

EX.232C |

NG |

|

|

(12) |

SIO |

NG NG |

|

|

(13) |

STRIP |

NG |

|

|

(14) |

RFID |

OK #00RV972 (EU0) |

|

|

|

|

|

|

NOTES: 1. Print conditions: Print speed: 4”/sec., Sensor: No sensor, Printing method: Thermal transfer/Direct thermal(*1), Media length: 87 mm, Issue mode: Batch printing

(*1) Depends on the printing mode setting.

2.Software version No., Part No. of ROM and checksum vary according to the software version of PROGRAM ROM.

3.The last two digits of the checksum are usually “00”.

4.When Kanji ROM is not installed, the checksum becomes “0000”.

5.The symbol “°” of “°C” may not be printed depending on the type of character code.

2-11

2. SYSTEM MODE

EO13-33002

2.1 Self-diagnostic Test

• Descriptions

(1) Program ROM Check (Model Name, Date, Version, Part number, Checksum)

PROGRAM B-SX8T

Program area

Model name

Main area |

|

MAIN 15OCT2002 |