Toro 38451, 38452, 38453, 38454, 38458 Service Manual

...

RESIDENTIAL PRODUCTS

SINGLE STAGE SNOW

ENGINE SERVICE MANUAL

LC168F / LC168FD (163cc)

About this Manual

This service manual was written expressly for Toro service technicians. The Toro Company

has made every effort to make the information in this manual complete and correct. Basic shop

safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the

systems and the related topics covered in this manual. An electronic version of this service

manual is available on the Toro Dealer Portal. We are hopeful that you will find this manual a

valuable addition to your service shop. If you have any questions or comments regarding this

manual, please contact us at the following address:

The Toro Company

Residential and Landscape Contractor Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Chapter 1 – General Service Information

1

Chapter 2 - Engine Service / Maintenance

2

Chapter 3 - Engine Disassembly and Service

3

Chapter 4 - Electrical

4

NOTES:

0

1

Chapter 1 – General Service Information

Safety 2

Service Rules 3

Engine Model / Serial Number Location 3

Engine Fastener Torque Specification 4

General Specifications 5

Engine Specifications 5

Troubleshooting 6

1

Safety

Safety Information

This symbol means WARNING or PERSONAL SAFETY INSTRUCTION – read the instruction because it has

to do with your safety. Failure to comply with the instruction may result in personal injury or even death.

This manual is intended as a service and repair manual only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Toro engine. The Toro operator’s manual contains safety

information and operating tips for safe operating practices.

Avoid Unexpected Engine Start - Turn off engine and disconnect the spark plug before servicing engine.

Avoid Lacerations and Amputations - Stay clear of all moving parts while the engine is running.

Avoid Burns - Do not touch the engine, muffler, or other components which may increase in temperature

during operation, while the unit is running or shortly after it has been running.

Avoid Fires and Explosions - Avoid spilling fuel and never smoke while working with any type of fuel or

lubricant. Wipe up any spilled fuel or oil immediately. Never remove the fuel cap or add fuel when the engine

is running. Always use approved, labeled containers for storing or transporting fuel and lubricants.

Avoid Asphyxiation - Never operate an engine in a confined area without proper ventilation.

Avoid Injury From Batteries - Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes,

and clothing. Battery gases can explode. Keep cigarettes, sparks, and flames away from the battery.

Avoid Injury Due To Inferior Parts - Use only original equipment parts to ensure that important safety

criteria are met.

Avoid Injury To Bystanders - Always clear the area of bystanders before starting or testing power

equipment.

Avoid Injury Due To Projectiles - Always clear the area of sticks, rocks, or any other debris that could be

picked up and thrown by the power equipment.

Avoid Modifications - Never alter or modify any part unless it is a factory approved procedure.

2

1. Only use genuine Toro parts and lubrication products.

2. Always install new gaskets, O-rings and seals when assembling engine.

3. Always torque fasteners to specification and in sequence.

4. Always lubricate friction components with clean engine oil or engine assembly lube

when assembling engine.

1

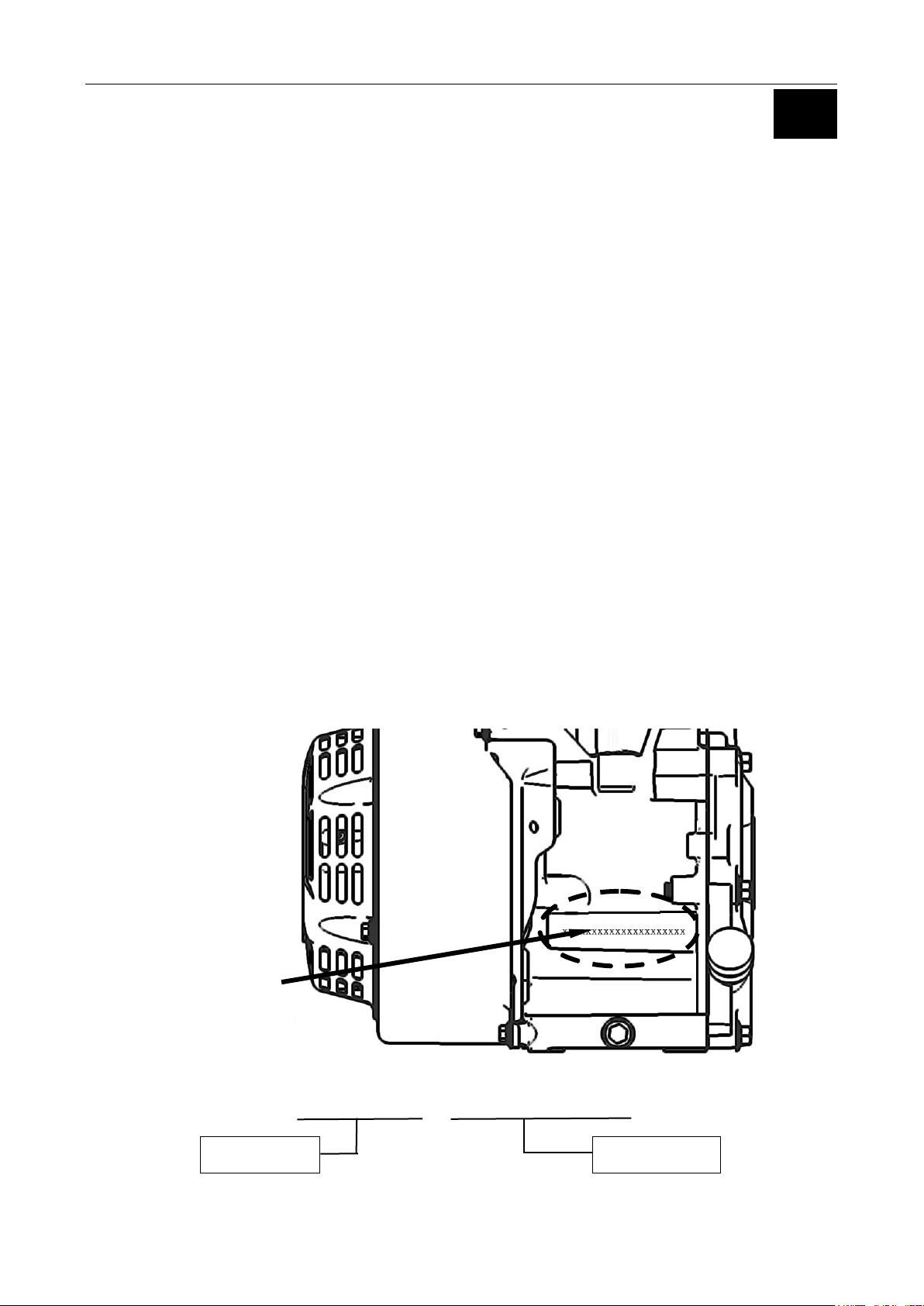

Engine Model and

Serial Numbers

Engine Model

Serial Number

Service Rules

Engine Model / Serial Number Location

2010-2011 - The engine model and serial number are stamped into the crankcase near the electric starter

mounting position on the side of the engine towards the front of machine (shown below).

2012 - The engine model and serial number are stamped into the crankcase near the rear of the machine.

XXX-XXXX XXXXXXXXXXX

3

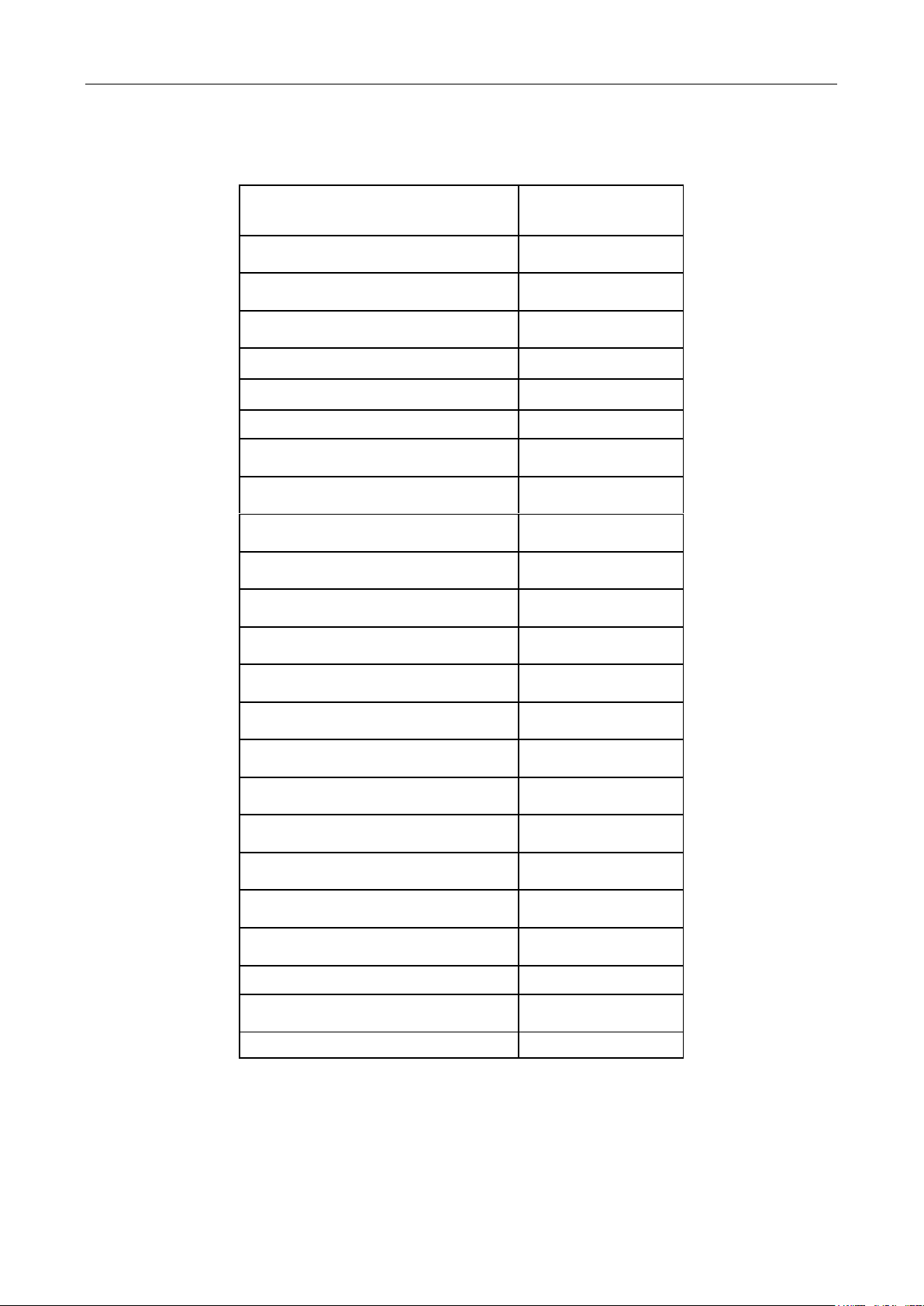

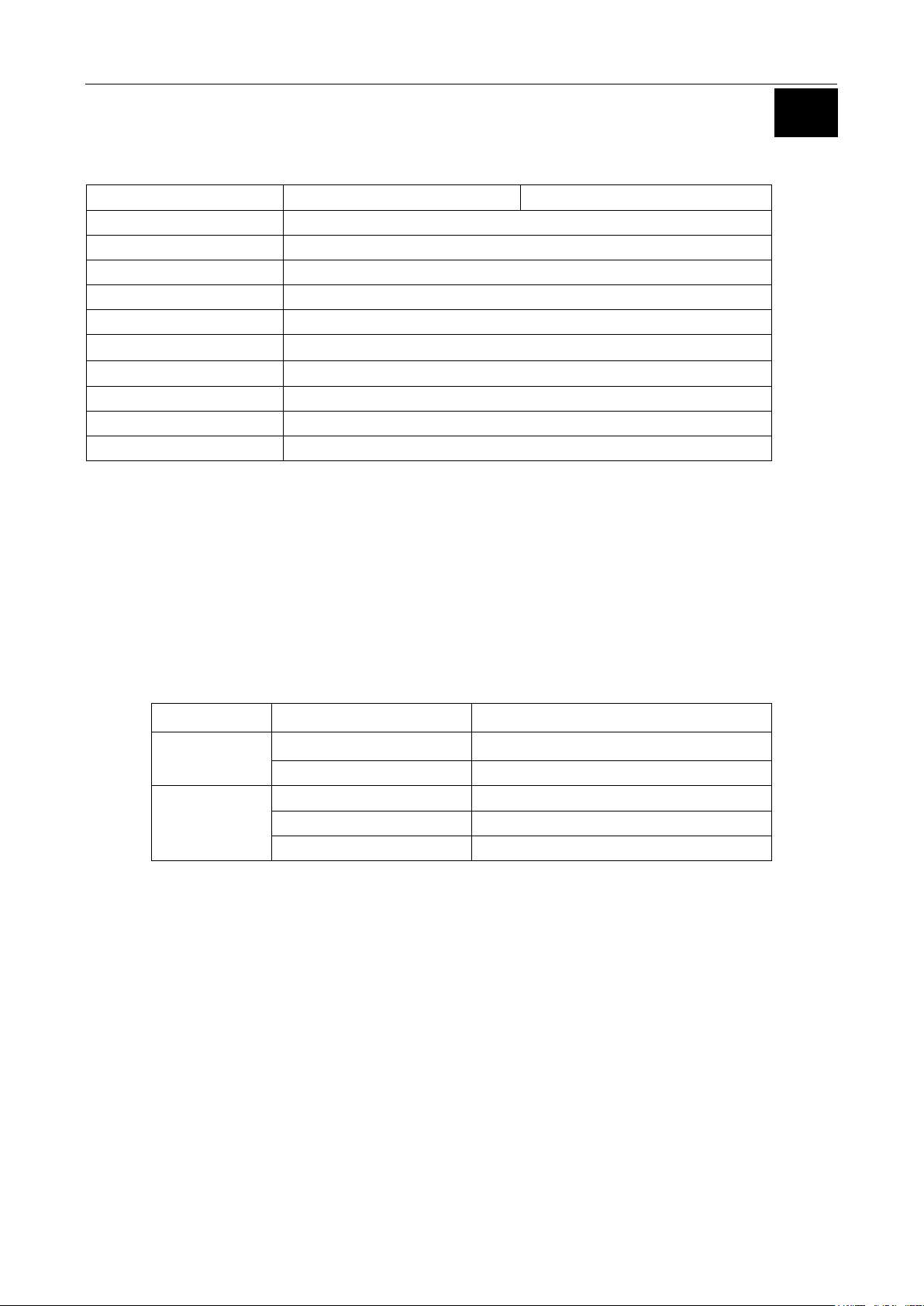

Item

Torque

Specification

Oil Drain Plug

17 ft-lbs (23 Nm)

Connecting Rod Bolts

8.5 ft-lbs (12 Nm)

Crankcase & Cover Bolts

17.5 ft-lbs (24 Nm)

Valve Lash Lock Nut

11 ft-lbs (15 Nm)

Rocker Arm Studs

22 ft-lbs (30 Nm)

Spark Plug

22 ft-lbs (30 Nm)

Valve Cover Bolts

7 ft-lbs (10 Nm)

Starter Bolts

7 ft-lbs (10 Nm)

Recoil Mounting Bolts

7 ft-lbs (10 Nm)

Cylinder Head Bolt

25 ft-lbs (34 Nm)

Heater Box Nuts

7 ft-lbs (10 Nm)

Flywheel Nut

62.5 ft-lbs (85 Nm)

Ignition Coil Bolts

7 ft-lbs (10 Nm)

Throttle Control Bolts

7 ft-lbs (10 Nm)

Governor Arm Nut

7 ft-lbs (10 Nm)

Muffler / Exhaust to Cylinder Nuts

22 ft-lbs (30 Nm)

Muffler Mounting Plate Bolts

7 ft-lbs (10 Nm)

Standard Torque Values

M5 Bolt / Nut

4.5 ft-lbs (6 Nm)

M6 Bolt / Nut

7.5 ft-lbs (10 Nm)

M8 Bolt / Nut

19 ft-lbs (26 Nm)

M10 Bolt / Nut

28 ft-lbs (38 Nm)

M12 Bolt / Nut

41 ft-lbs (55 Nm)

Engine Fastener Torque Specifications

4

MODEL

LC168F-1 (Recoil Start)

LC168FD-1 (Electric Start)

Engine Type

OHV Single Cylinder, Four Stroke, Forced Air Cooling

Displacement (cc)

163

Bore x Stroke (mm)

68 x 45

Compression Ratio

8.5:1

Engine Operating RPM

3550 - 3850 RPM

Oil Capacity

20 oz. (0.6 l)

Fuel Type

Unleaded Gasoline, 87 Octane

Ignition System

T.C.I Transistorized Magneto

Lubrication System

Splash

Cylinder

Aluminum with Cast Iron Bore

Spark Plug

Gap

0.0275 - 0.0314” (0.7-0.8 mm)

Valve

Clearance

Intake Cold

0.0059” (0.15 mm)

Exhaust Cold

0.0078” (0.20 mm)

Ignition Coil

Resistance (primary)

1-1.6Ω

Resistance (secondary)

15.5K Ω ±15%

Gap to Flywheel

0.011- 0.019” (.3-.5 mm)

1

General Specifications

Engine Specifications

NOTE: The only internal parts available for this engine are gaskets and seals.

5

Troubleshooting

Hard Starting / Poor Running

- Incorrect Fuel (Level, Age, Octane, Ethanol Content)

- Fuel System Contamination and / or debris in Carburetor

- Incorrect Oil Level

- Spark Plug (Incorrect Gap, Fouled, Loose or Faulty)

- Air Intake System Leaks

- Ignition Coil to Flywheel Gap Incorrect

- Weak / No Spark

- Choke / Linkage

- Operating RPM Incorrect

- Governor Adjustment Incorrect

- Engine Valve Clearance out of Specification

- Low Compression or Excessive Leakdown

Overheating

- Incorrect Oil Level

- Cylinder Head Gasket Leak

- Debris Build-Up Restricting Air Flow

6

2

Chapter 2 - Engine Service / Maintenance

Engine Oil Change Procedure 8

Spark Plug Service 9

Valve Clearance Inspection and Adjustment 10

Engine Governor – Zero Point Setting 11

Engine RPM Adjustment 11

Fuel Filter Replacement 12

7

Loading...

Loading...