Teledyne 100EU, 100E User Manual

PRINT DATE: 08 April 2009

ADDENDUM TO

MODEL 100E

OPERATORS MANUAL

(P/N 04515)

FOR

MODEL 100EU

TRACE LEVEL SULFUR DIOXIDE

ANALYZER

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

USA

Toll-free Phone: 800-324-5190

Phone: 858-657-9800

Fax: 858-657-9816

Email: Api-sales@teledyne.com

Website: http://www.teledyne-api.com/

© 2007 T-API 08 April 2009

05831 Rev C

DCN 5379

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 TABLE OF CONTENTS

TABLE OF CONTENTS

1. PREFACE ..........................................................................................................................................................................3

1.1 Reference Numbering convention............................................................................................................................. 3

2. SPECIFICATIONS, APPROVALS AND WARRANTY....................................................................................................... 5

2.1 Specifications............................................................................................................................................................5

2.2 EPA Equivalency Designation................................................................................................................................... 6

2.3 CE Mark Compliance ................................................................................................................................................6

2.4 Warranty ...................................................................................................................................................................6

3. GETTING STARTED.......................................................................................................................................................... 7

3.1 Unpacking the M100EU ............................................................................................................................................7

3.2 Internal Layouts ........................................................................................................................................................7

3.3 Functional Check of the M100EU .............................................................................................................................8

3.3.1 Test Functions......................................................................................................................................................8

4. FREQENTLY ASKED QUESTIONS & GLOSSARY........................................................................................................ 11

5. OPTIONAL HARDWARE AND SOFTWARE...................................................................................................................13

6. M100EU OPERATING INSTRUCTIONS..........................................................................................................................15

6.1 Additional Test Parameters.....................................................................................................................................15

6.2 STBL MENU: Setup for the Three Stability Functions.............................................................................................15

7. CALIBRATION PROCEDURES.......................................................................................................................................17

8. EPA PROTOCOL CALIBRATION ................................................................................................................................... 19

9. INSTRUMENT MAINTENANCE....................................................................................................................................... 21

10. THEORY OF OPERATION..........................................................................................................................................23

10.1 Electronic Operation................................................................................................................................................23

10.1.1 Sensor Module ..............................................................................................................................................23

10.1.1.1 Sample Chamber......................................................................................................................................24

11. TROUBLESHOOTING & REPAIR .............................................................................................................................. 27

11.1.1 Fault Diagnosis with Warning Messages....................................................................................................... 27

11.1.2 Fault Diagnosis with Test Functions..............................................................................................................27

11.1.3 Fault Diagnosis with Sync Demod PCA LEDs............................................................................................... 29

11.2 Other Performance Problems .................................................................................................................................29

11.3 Additional Repair Procedures .................................................................................................................................29

11.3.1 UV Lamp Adjustment and/or Replacement ...................................................................................................29

11.3.1.1 Adjusting the UV Lamp (Peaking the Lamp.............................................................................................. 30

11.3.1.2 Replacing the UV Lamp............................................................................................................................32

11.3.2 Replacing the UV filter/lens............................................................................................................................. 33

11.3.3 Replacing the PMT, HVPS or TEC................................................................................................................34

11.3.4 M100EU PMT Hardware Calibration (Factory Cal)........................................................................................ 36

11.4 Technical Assistance ..............................................................................................................................................37

05944 Rev B 1

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

TABLE OF CONTENTS

Addendum to M100E Manual - P/N 04515

LIST OF FIGURES

Figure 3-1: M100EU Internal Layout ................................................................................................................7

Figure 3-2: M100EU Test Functions ................................................................................................................9

Figure 6-1: Accessing the STBL Menu ..........................................................................................................16

Figure 10-2: M100EU Sensor Module Assembly.............................................................................................24

Figure 10-3: M100EU Sample Chamber Exploded View................................................................................25

Figure 11-1: UV Lamp Adjustment...................................................................................................................31

Figure 11-2: Disassembling the Shutter Assembly ..........................................................................................33

Figure 11-3: PMT Assembly - Exploded View..................................................................................................34

LIST OF TABLES

Table 2-1: Model 100EU Basic Unit Specifications.........................................................................................5

Table 3-1: Test Functions Defined..................................................................................................................8

Table 11-1: Test Functions - Possible Causes for Out-Of-Range Values ......................................................27

Table 11-2: Relay PCA Status LED Failure Indications..................................................................................29

USER NOTES:

2 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 PREFACE

1. PREFACE

NOTE

The information contained in this addendum is pertinent to M100EU analyzers running software revision

F.0. Some or all of the information may not be applicable to later revisions of software.

The software revision your analyzer is running is displayed in the upper left-hand corner of the display

any time the instrument is in SETUP mode.

This addendum is based on the Model 100E Operators Manual (P/N 04145). In most ways the M100EU is

identical to the M100E in design and operation, therefore most of the basic set up information, operating

instructions as well as calibration, maintenance, troubleshooting and repair methods are found in that manual.

This addendum documents only those areas where the M100EU is different in design or operating method from

the M100E.

Therefore this addendum includes instructions and information regarding:

Additional Test Functions

Adjusting the PMT HV for “Factory Calibrations”

Differences in theory of operation

1.1 REFERENCE NUMBERING CONVENTION

Unless otherwise specified, chapter, section, figure and table reference numbers referred to within this text are

relative to this document.

EXAMPLE: “Figure 2-1” refers to the figure, within

References to chapters, sections, figures and tables

EXAMPLE: “Figure 6.1 of the M101E Operators Manual (P/N 04145, REV. A)”.

this document, labeled as 2-1.

in the original document will be labeled as such.

USER NOTES

05944 Rev

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

B 3

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

PREFACE

Addendum to M100E Manual - P/N 04515

USER NOTES:

4 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 SPECIFICATIONS, APPROVALS AND WARRANTY

2. SPECIFICATIONS, APPROVALS AND WARRANTY

2.1 SPECIFICATIONS

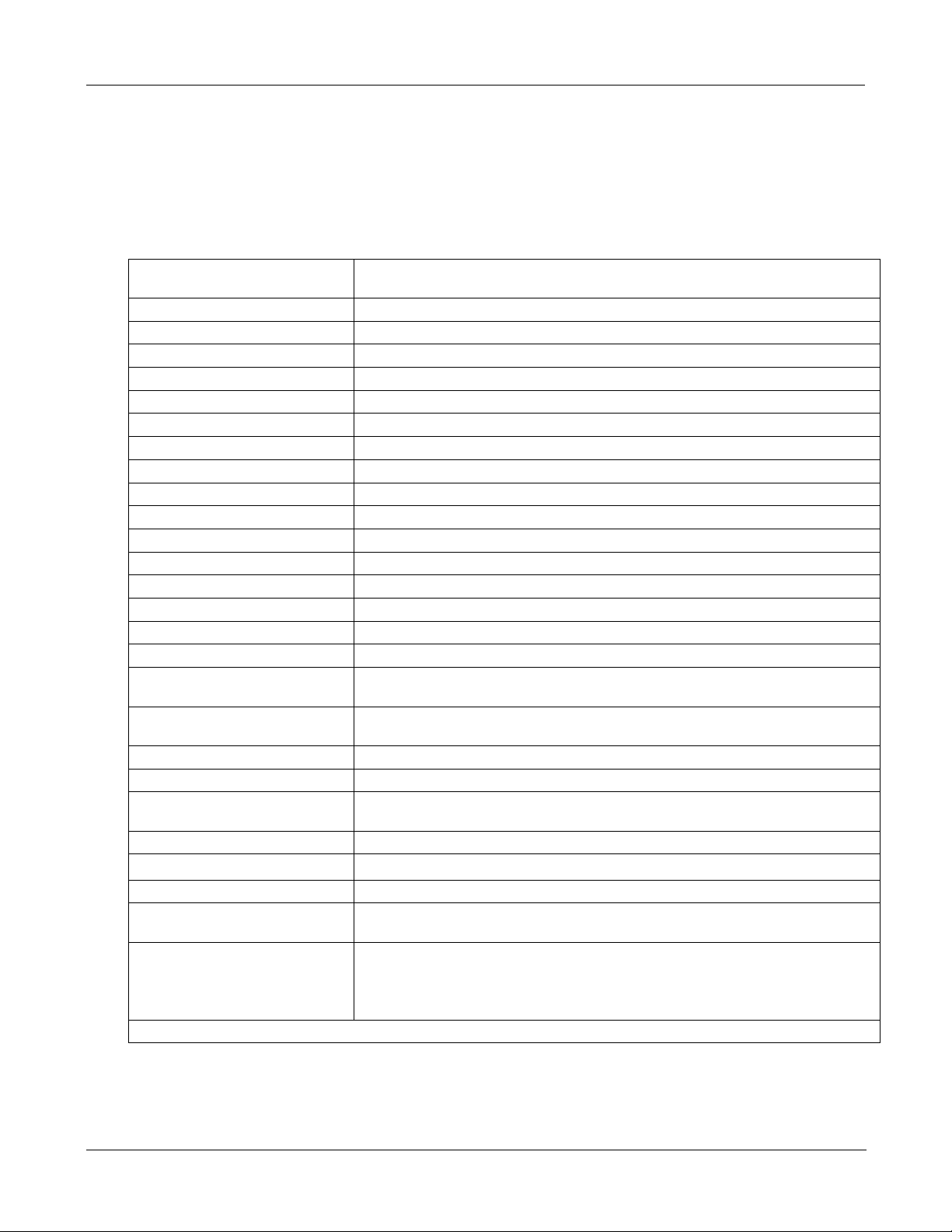

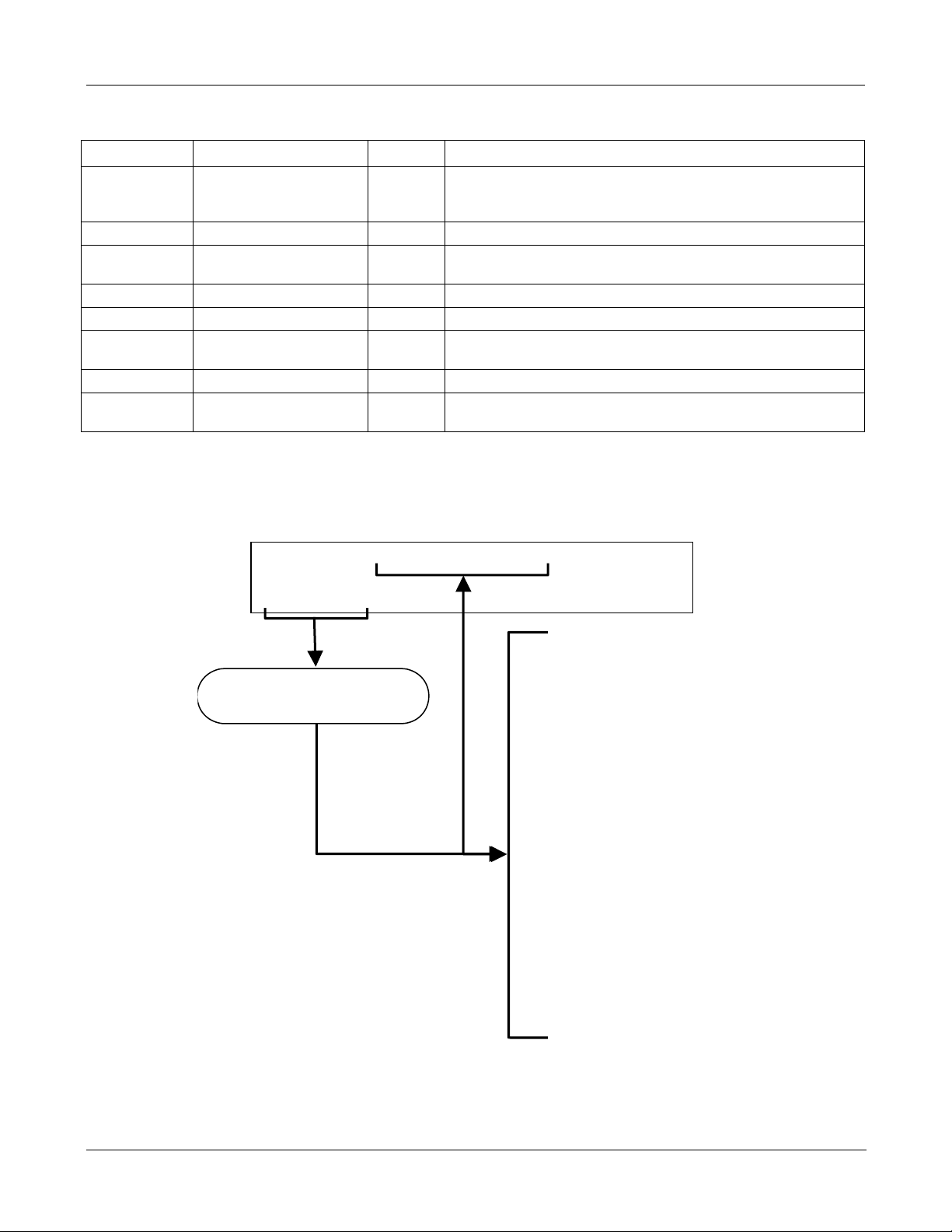

Table 2-1: Model 100EU Basic Unit Specifications

Min/Max Range

(Physical Analog Output)

Measurement Units ppb, ppm, µg/m3, mg/m3 (user selectable)

Zero Noise2 25 ppt RMS (50 ppt RMS with 360 nM filter installed)

Span Noise2 0.5% of reading RMS, above 5 ppb

Lower Detectable Limit3 50 ppt RMS

Zero Drift (24 hours) <200 ppt (<400 ppt with 360 nM filter installed)

Zero Drift (7 days) <200 ppt (<400 ppt with 360 nM filter installed)

Span Drift (7 Days) <0.5% FS

Linearity 1% of full scale

Precision 0.5% of reading

Temperature Coefficient < 0.1% per oC

Lag Time1 30 sec

Rise/Fall Time1 95% in <140 sec

Sample Flow Rate 650cc/min. ±10%

Temperature Range 5-40oC

Humidity Range 0 - 95% RH, non-condensing

Dimensions H x W x D 7" x 17" x 23.5" (178 mm x 432 mm x 597 mm)

Weight, Analyzer

(Basic Configuration)

AC Power Rating

Environmental Installation category (over-voltage category) II; Pollution degree 2

Analog Outputs Three (3) Outputs

Analog Output Ranges

Analog Output Resolution 1 part in 4096 of selected full-scale voltage

Status Outputs 8 Status outputs from opto-isolators

Control Inputs 6 Control Inputs, 3 defined, 3 spare

Serial I/O

Certifications

1-As defined by the USEPA; 2 – 25 samples taken, 10 sec. interval; 3 – Twice zero noise

In 1ppb increments from 50ppb to 20 000ppb, dual ranges or auto ranging

45 lbs (20.5 kg) w/internal pump

100 V, 50/60 Hz (3.25A); 115 V, 60 Hz (3.0 A);

220 – 240 V, 5

100 mV, 1 V, 5 V, 10 V, 2-20 or 4-20 mA isol

All Ranges with 5% Under/Over Range

One (1) RS-232; One (1) RS-485 (2 connecters in parallel)

Baud Ra

EN61326 (1997 w/A1: 98) Class A, FCC Part 15 Subpart B Section 15.107 Class

A, ICES-003 Class A (ANSI C63.4 19

Class A.

IEC 61010-1:90 + A1:92 + A2:95,

0/60 Hz (2.5 A)

ated current loop.

te : 300 – 115200: Optional Ethernet Interface

92) & AS/NZS 3548 (w/A1 & A2; 97)

05944 Rev

B 5

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

SPECIFICATIONS, APPROVALS AND WARRANTY

Addendum to M100E Manual - P/N 04515

2.2 EPA EQUIVALENCY DESIGNATION

At this time the M100EU has not been certified by the EPA as an equivalent method at the time of this writing

however it is anticipated that the M100EU will qualify as Reference Method Number EQSA-0495-100 per 40

CFR Part 53 in the near future. Please see section 2.2 of the M100E manual, P/N 04515 for details.

2.3 CE MARK COMPLIANCE

See Section 2.3 of the M100E Manual - P/N 04515

2.4 WARRANTY

See Section 2.4 of the M100E Manual - P/N 04515

User Notes:

6 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 GETTING STARTED

3. GETTING STARTED

3.1 UNPACKING THE M100EU

Unpack the M100EU as per the directions in Section 3.1 of the M100E Manual - P/N 04515, with the following

change. There are two redheaded shipping screws that hold down the PMT/Sensor assembly and must be

removed prior to operation. They are located along the base of the PMT housing adjacent to the chassis.

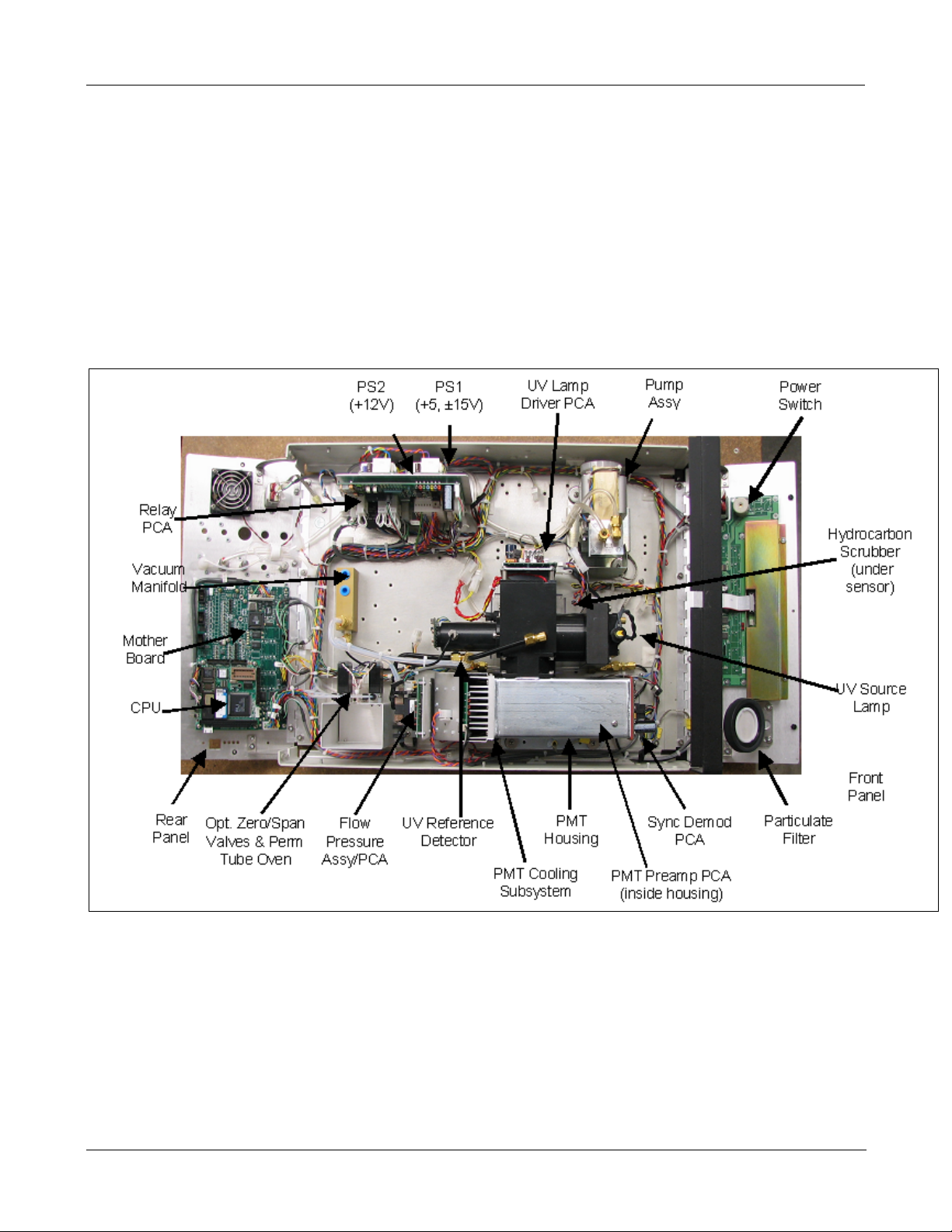

3.2 INTERNAL LAYOUTS

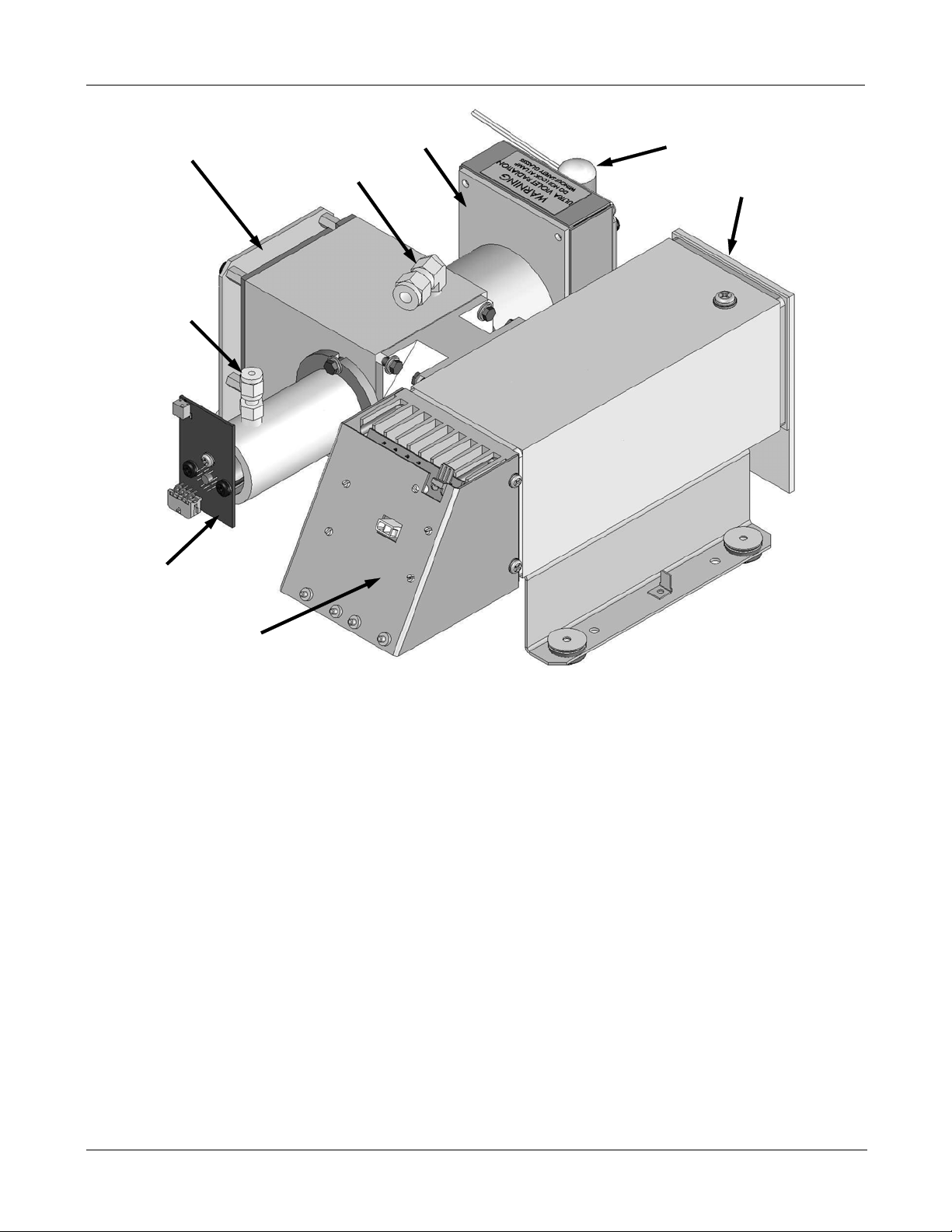

Figures 3-1 replaces Figure 3-9 in the M100E manual. The primary difference between the M100EU and M100E

layouts is the differences in the PMT Housing, the location of the PMT preamp PCA and the addition of a Sync

Demodulator PCA.

Figure 3-1: M100EU Internal Layout

05944 Rev

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

B 7

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

GETTING STARTE

Addendum to M100E Manual - P/N 04515

D

3.3 FUNCTIONAL CHECK OF THE M100EU

To perform an initial functional check of the M100EU follow the steps contained in Section 3.2.4 of the M100E

Manual - P/N 04145, but use the Test functions described in below.

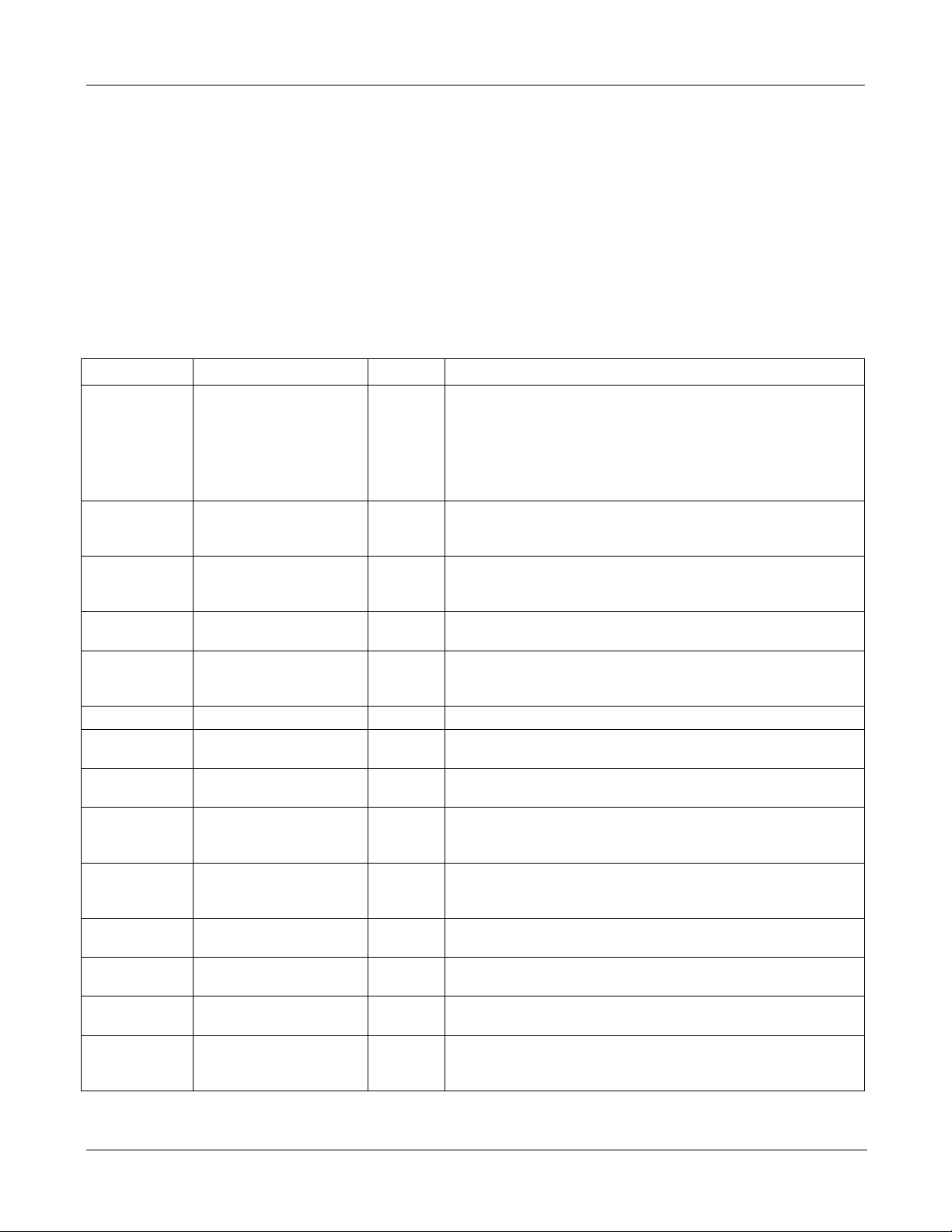

3.3.1 TEST FUNCTIONS

Table 3-1 supersedes the figure in Step 2 of Section 3.2.4 and Figure 6-2 of the M100E Manual - P/N 04145.

Table 11-1 supersedes Table 6-2. The only differences between the M100E an

the addition of STABIL2 and UV STAB.

Table 3-1: Test Functions Defined

DISPLAY PARAMETER UNITS DESCRIPTION

The Full Scale limit at which the repo

ANALOG OUTPUTS is currently set.

THIS IS NOT the Physical Range of the instrument. See Section

6.7 of M100E manual for more information.

If DUAL or AUTO Range modes have been selected, two

RANGE functio

Standard deviation of SO

are recorded every ten seconds. The calculation uses the last

25 data points.

Standard deviation of SO

Data points are recorded every 120 seconds. The calculation

uses the last 25 data points.

The current pressure of the sample

chamber, measured between the SO

The flow rate of the sample gas through the sample chamber.

Th

is value is not measured but calculated from the sample

pressure.

he output voltage of the PMT after normalization for offset and

T

temperature/pressure compensation (if activated).

Standard deviation of UV reference detector output. Data points

are recorded

25 data points.

The current output of the UV referenc

reading stored in the CPU’s memory from the last time a UV

Lamp calibration was performed.

The offset due to stray light recorded by the CPU during the last

zero-point cal

The PMT output reading recorded the la

lamp shutter was closed.

The UV reference detector output readin

the UV source lamp shutter was closed.

The sensitivity of the instrument as calculate

calibration activity.

calibration point of the analyzer.

s will appear, one for each range.

n

every ten seconds. The calculation uses the last

ibration performed.

The slope parameter is used to set the span

RANGE

STABIL

STABIL2

PRES

SAMP FL

PMT

NORM PMT

UV LAMP

UV STAB

LAMP RATIO

STR. LGT

DRK PMT

DRK LMP

SLOPE

(table continued)

RANGE

- -

RANGE1

RANGE2

STABILITY ppb

STABILITY ppb

SAMPLE PRESSURE in-Hg-A

SAMPLE FLOW

PMT Signal mV The raw output voltage of the PMT.

NORMALIZED PMT

Source UV Lamp

Intensity

Stability of UV Lamp

Intensity

UV Source lamp ratio %

Stray Light ppb

Dark PMT mV

Dark UV Source Lamp mV

measurement Slope -

SO

2

Signal

PPB,

PPM,

UGM &

MGM

cm³/min

(cc/m)

mV

mV The output voltage of the UV reference detector.

mV

d M100EU’s test functions are

rting range of the analyzer’s

Concentration readings. Data points

2

Concentration readings, per EPA.

2

gas as it enters the sample

and Auto-Zero valves.

2

e detec

tor divided by the

st time the UV source

g recorded the last time

d during the last

8 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

1

g

Addendum to M100E Manual - P/N 04515 GETTING STARTED

Table 3-1: Test Functions Defined

DISPLAY PARAMETER UNITS DESCRIPTION

lated during the last

analyzer case.

OFFSET

HVPS

RCELL TEMP

BOX TEMP

PMT TEMP

IZS TEMP

2

TEST

TIME

The overall offset of the instrument as calcu

measurement Offset -

SO

2

HVPS V The PMT high voltage power supply.

SAMPLE CHAMBER

P

TEM

BOX TEMPERATURE °C The ambient temperature of the inside of the

PMT TEMPERATURE °C The current temperature of the PMT.

1

IZS TEMPERATURE

TEST SIGNAL

CLOCK TIME

1

2

°C The current temperature of the sample chamber.

°C

mV Signal of a user-defined test function on output channel A4.

hh:mm:s

s

calibration activity. The offset parameter is used to set the zero

point of the analyzer response.

The current temperature of the internal zero/span option. Only

appears when IZS option is enabled

The current day time for iDAS records and calibration events.

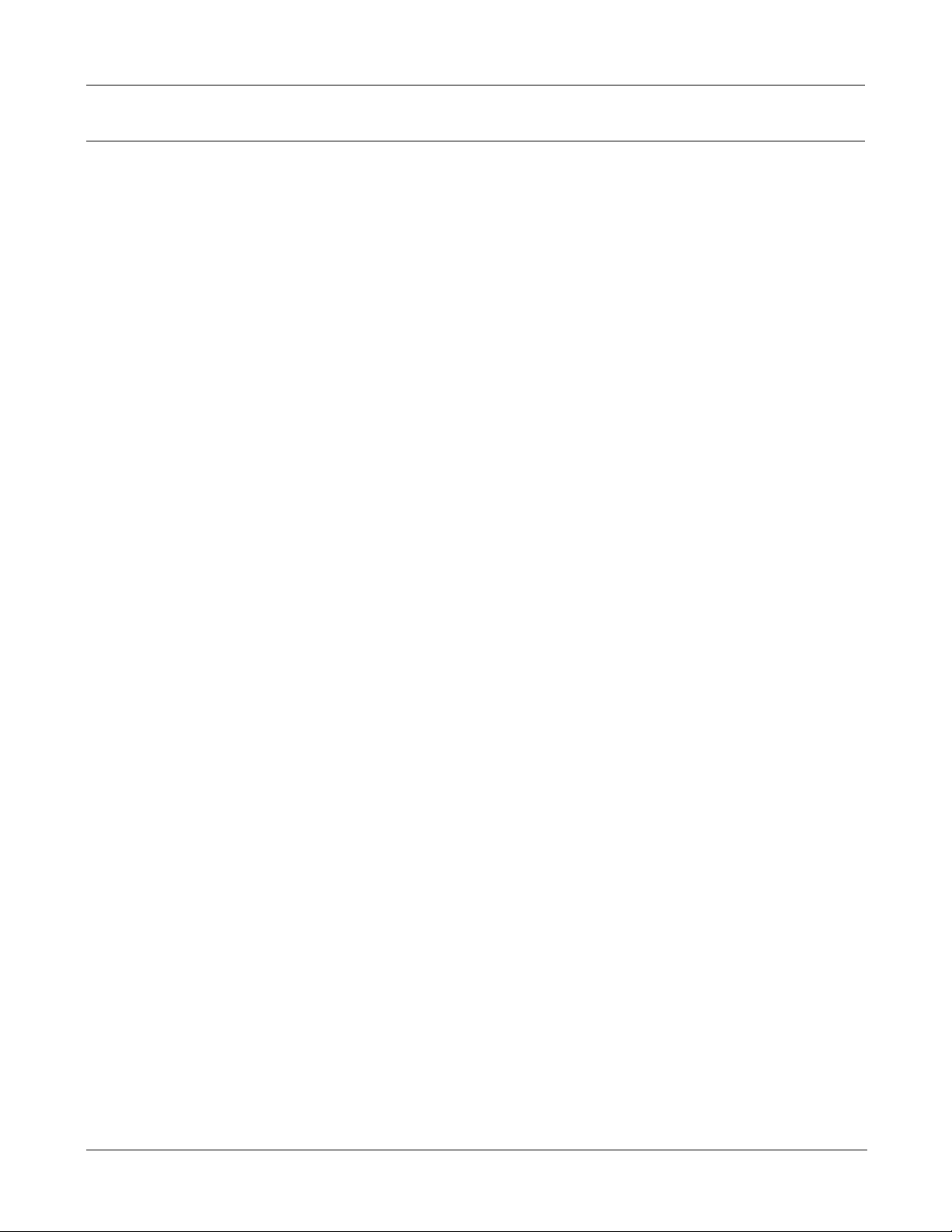

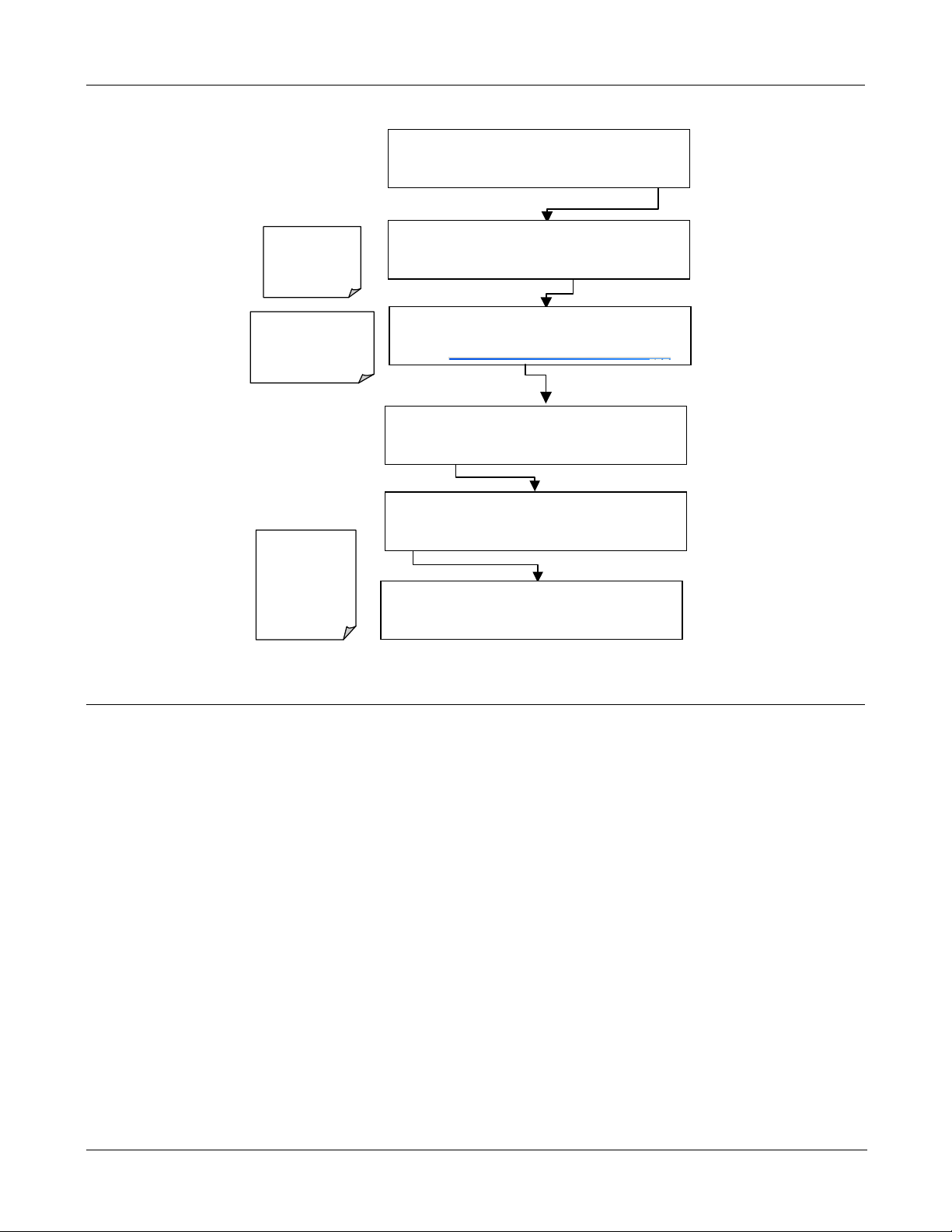

To view the TEST Functions press the following Key sequence:

SAMPLE

RANGE = 500.0 PPB

< TST TST >

CAL SETUP

Toggle <TST TST> keys to

scroll throu

Only appears if IZS option is

installed.

2

Only appears if analog output

h list of functions

A3 is actively reporting a test

function

SO2 =XXX.X

RANGE

STABIL

STABIL2

PRES

SAMP FL

PMT

NORM PMT

UV LAMP

UV STAB

LAMP RATIO

STR. LGT

DARK PMT

DARK LAMP

SLOPE

OFFSET

HVPS

RCELL TEMP

BOX TEMP

PMT TEMP

IZS TEMP

TEST

TIME

1

2

Refer to

Section

6.2.1 for

definitions

of these

test

functions.

Figure 3-2: M100EU Test Functions

05944 Rev

B 9

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

GETTING STARTED

Addendum to M100E Manual - P/N 04515

USER NOTES:

10 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 FREQENTLY ASKED QUESTIONS & GLOSSARY

4. FREQENTLY ASKED QUESTIONS & GLOSSARY

Please refer to Section 4 of the M100E manual, PN 04515 for information.

05944 Rev

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

B 11

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

FREQUENT

LY ASKED QUESTIONS & GLOSSARY

Addendum to M100E Manual - P/N 04515

USER NOTES:

12 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 OPTIONAL HARDWARE AND SOFTWARE

5. OPTIONAL HARDWARE AND SOFTWARE

Please refer to Section 5 of the M100E manual, PN 04515 for information.

05944 Rev

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

B 13

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

OPTIONAL

HARDWARE AND SOFTWARE

Addendum to M100E Manual - P/N 04515

USER NOTES:

14 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04515 M100EU OPERATING INSTRUCTIONS

6. M100EU OPERATING INSTRUCTIONS

NOTE

For the most part the operation instruction for the M100EU are the same as those described in Chapter 6

of the M100E Manual - P/N 04515 with the exception that there are additional test parameters and setup

procedures.

6.1 ADDITIONAL TEST PARAMETERS

Please see Section 3.3 above for details on the additional test parameters.

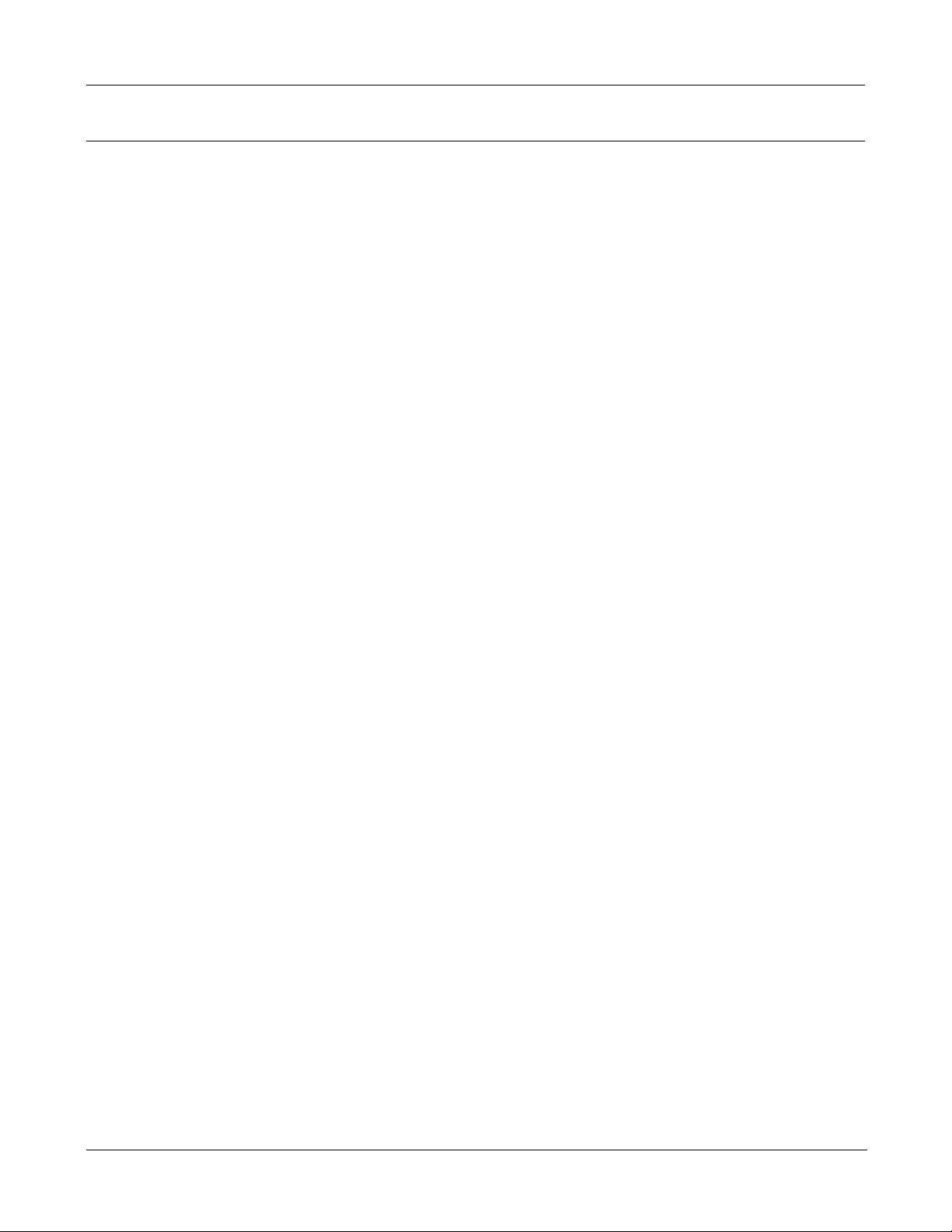

6.2 STBL MENU: SETUP FOR THE THREE STABILITY FUNCTIONS

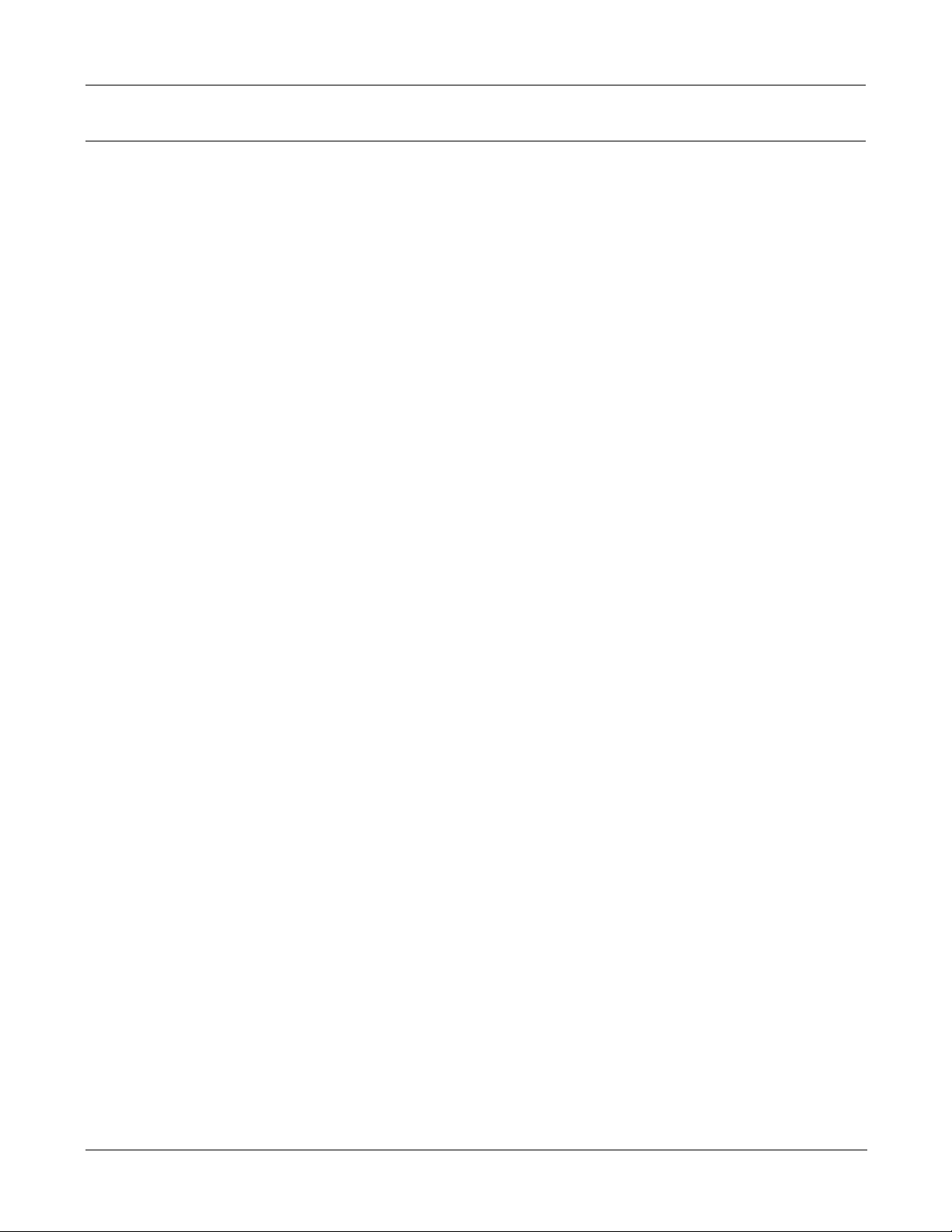

There is an additional submenu on the Secondary Setup Menu in the M100EU’s software. The STBL menu, see

Figure 6-1 allows the user to modify the settings for the three stabili

Functions on the front panel and are available via the serial data port and that can be logged with the iDAS.

Test Function STABIL, CONC1 in the menus below, is equivalent to the standard M100E STABIL function and is

useful when conducting calibrations and other operations in which the operator has limited time to view the

display. CONC2, which is the same as the STABIL2 test function has been configured so that it calculates

stability in the same way as required by the EPA. STABIL2 is useful when comparing instruments against the

EPA standard but is very slow and difficult to use for calibration or other activities where the operator must wait

for analyzer to settle to the desired value. UVLAMP is the same as UV STAB on the front panel is a diagnostic

that can be used to understand the stability of the UV lamp.

ty calculations that are displayed as Test

05944 Rev

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

B 15

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

M100EU OPERATING INSTRUCTIONS

Addendum to M100E Manual - P/N 04515

EXIT returns

to the main

SAMPLE

display

returns

EXIT

to the PRIMARY

SETUP MENU

CONC2 is

setup for

STABIL2 test

function,

UVLAMP for

UV STAB test

function

SAMPLE RANGE = 500.000 PPB SO2 =XXX.X

< TST TST > CAL SETUP

SETUP X.X

CFG DAS RNGE PASS CLK

SETUP X.X

COMM VARS

SETUP X.X

NEXT EDIT PRNT EXIT

SETUP X.X

PREV NEXT EDIT PRNT EXIT

SETUP X.X

PREV EDIT PRNT EXIT

PRIMARY SETUP MENU

EXIT

MORE

SECONDAR Y S E TU P MENU

STBL

DIAG

CONC1, 10SEC, 25 SAMPLES

CONC2, 120SEC, 25 SAMPLES

UVLAMP, 10SEC, 25 SAMPLES

User Notes:

Figure 6-1: Accessing the STBL Menu

16 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04145 CALIBRATION PROCEDURES

7. CALIBRATION PROCEDURES

Calibration of the M100EU should be performed according to the procedures described in Chapters 7 & 8 of the

M100E Manual - P/N 04145. However, delivering span and zero gases for the lower ranges that the M100EU is

designed for can be difficult. For best results when calibrating the M100EU, wait one hour for the instrument to

stabilize when delivering zero and span gases before pressing the zero and span buttons. Attention must be

paid to the quality of the gasses, the level of contaminants in the gases as well as the history and conditioning of

the gas delivery components. Only Teflon or glass should be used for any “wetted” surfaces that the calibration

gasses contact. All delivery system components should be conditioned by running span gas for a minimum of

four hours before conducting actual span calibrations.

05944 Rev B 17

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

CALIB

RATION PROCEDURES

Addendum to M100E Manual - P/N 04515

USER NOTES:

18 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04145 EPA PROTOCOL CALIBRATION

8. EPA PROTOCOL CALIBRATION

The M100EU is designated as an equivalent method for measuring SO2 under certification EQSA-0495-100.

Calibration of the M100EU is done so in a manner that is consistent with EPA requirements. For calibration in

this manner please refer to section 8 of the M100E manual.

05944 Rev B 19

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

EPA PROTOC

OL CALIBRATION

Addendum to M100E Manual - P/N 04515

USER NOTES:

20 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04145 INSTRUMENT MAINTENANCE

9. INSTRUMENT MAINTENANCE

Instrument maintenance is almost identical to that in the M100E. The M100EU uses a 1 micron sample filter, instead of the 5

micron sample filter used in the M100E. Replacement part numbers are shown below.

Part Number Description

009690200 AKIT, TFE FLTR ELEMENT, 47MM, 1UM (100)

05920 UV Zinc LAMP, M100EU

For all other maintenance questions, please refer to section 9 in the M100E manual.

05944 Rev B 21

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

INSTRU

MENT MAINTENANCE

Addendum to M100E Manual - P/N 04515

USER NOTES:

22 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

M100EU – OPERATIONS MANUAL TELEDYNE INSTRUMENTS

Addendum to M100E Manual - P/N 04145 THEORY OF OPERATION

10. THEORY OF OPERATION

The M100EU is a modified M100E. The primary differences are the way in which the PMT and UV reference

signals are acquired and processed. The M100EU has no shutter but rather employs synchronous

demodulation to capture the dark and light PMT and UV reference signals several times per second. A printed

circuit board, the Sync Demodulator, attached to the end of the PMT housing, on the sensor assembly, includes

circuitry that digitizes the PMT and UV reference signals and synchronizes the operation of the UV source with

these measurements. This method of signal processing minimizes the error that changing offsets could make in

an instrument that is designed to operate near its detection limit.

10.1 ELECTRONIC OPERATION

The following information is in addition to that contained in Section 10.2 of the M100E Manual - P/N 04145.

10.1.1 SENSOR MODULE

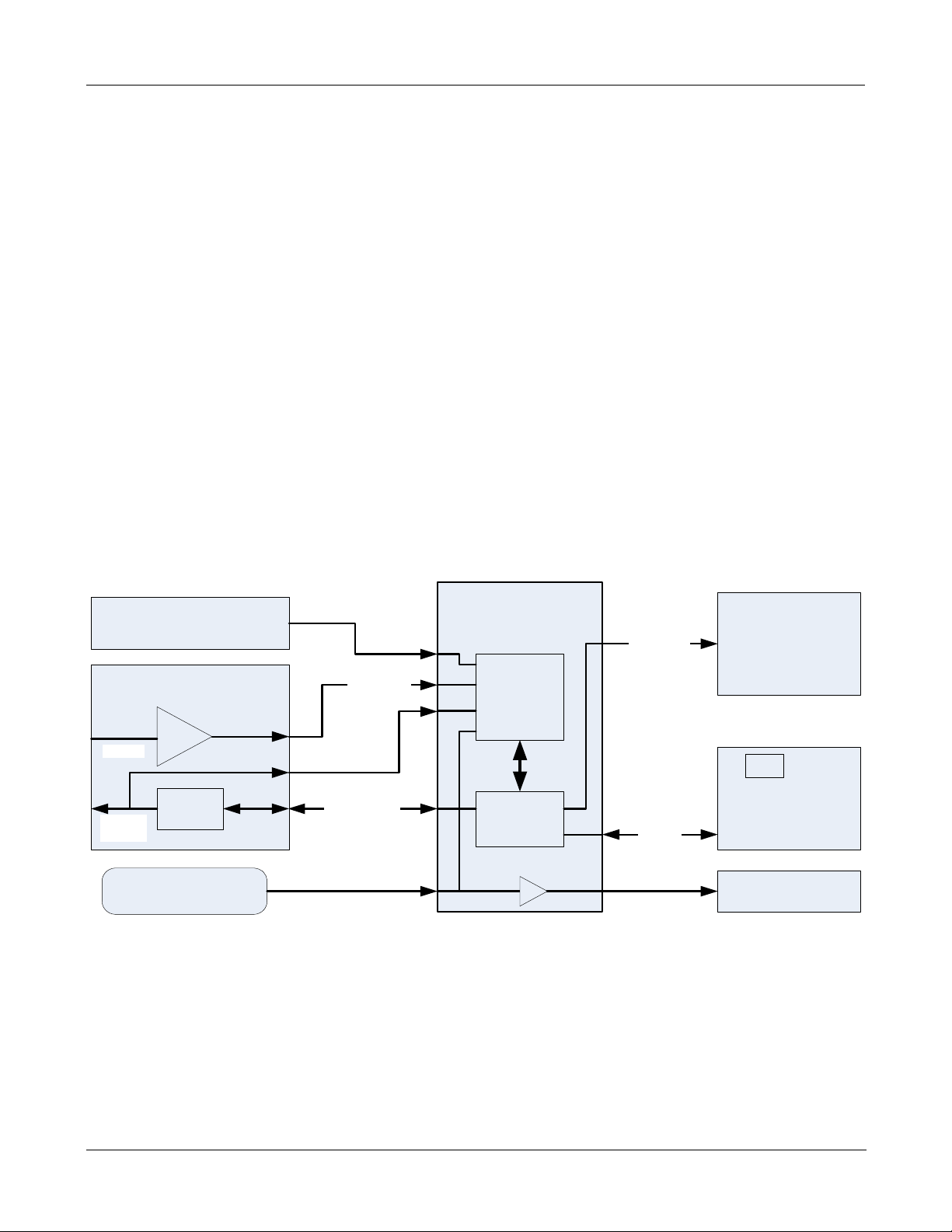

At the heart of the M100EU’s signal processing, illustrated in Figure 10-1 below, is the Synchronous

Demodulator PCA. The PCA is attached to the end of the PMT housing and serves to seal the end of the PMT

housing. The sync demodulator controls the operation of the UV Lamp driver, digitizes the analog output

signals from the PMT UV reference detector and PMT temperature sensor, controls the PMT cooler (TEC),

controls the PMT HV via a local I2C bus, and communicates with the analyzer’s CPU over the master I2C bus.

Digitized and processed data from the UV reference and PMT are passed to the analyzer’s CPU over the master

I2C bus and data for control of the PMT HV control DAC is passed from the CPU to the DAC on the PMT

preamp via the microcontroller on the Sync Demod board.

UV REF PCA

(End of Sensor Module)

PMT PREAMP PCA

(Inside PMT Housing)

PMT IN

8 bit DAC

PMT HV

Control

PMT Temp Sensor

(Inside PMT Housing)

I2C

SYNC DEMOD PCA

(End of PMT Housing)

UV REF

`

PMT Signal

PMT HV

Monitor

Local I2C Bus

A/D

Converter

Micro

Controller

Figure 10-1: Sensor Block Diagram

Lamp Sync

Master

I2C Bus

UV LAMP DRIVER

PCA

(Side of Sensor Assy)

CPU

MOTHERBOARD

(Rear Panel)

PMT Cooler

(End of PMT Housing)

05944 Rev B 23

DCN 5063 PRINTED DOCUMENTS ARE UNCONTROLLED

TELEDYNE INSTRUMENTS M100EU – OPERATIONS MANUAL

THEORY OF OPERATION

Reaction Cell

Sample Gas Inlet

Addendum to M100E Manual - P/N 04515

Lamp Shutter Housing

Sample Gas Outlet

UV LAMP

PMT PREAMP PCA

SAMPLE

CHAMBER

PMT HOUSING

Reference Detector

PMT Cooling System

Figure 10-2: M100EU Sensor Module Assembly

These compo

nents are divided into two significant subassemblies. The sample chamber and the PMT

assembly.

Figure 10-3 shows an exploded view of the sample chamber assembly

Figure 11-3 shows an exploded view of the PMT Assembly

10.1.1.1 Sample Chamber

The main electronic components of the sample chamber are the reference detector(see Section 10.2.2 of the

M100E Manual - P/N 04145); the UV Lamp (see Section 10.2.1 of the M100E Manual - P/N 04145) and its

electronically operated shutter (see Section 9.2.1 of this addendum); and the sample chamber heating circuit,

24 05944 Rev B

PRINTED DOCUMENTS ARE UNCONTROLLED DCN 5063

Loading...

Loading...