Taylor C118, C116, C117 User Manual

ELECTRONIC HORIZONTAL BATCH FREEZER TURBINES ÉLECTRONIQUES HORIZONTALES MANTECADORAS HORIZONTALES ELECTRÓNICAS MANTECATORI ORIZZONTALI ELETTRONICI

MANUAL OF USE AND

MAINTENANCE

MANUEL D’UTILISATION

ET D’ENTRETIEN

MANUAL DE USO Y

MANUTENCION

MANUALE D’USO E

MANUTENZIONE

1 - ENGLISH

IMPORTANT

We recommend to carefully and fully read the present manual before using your TAYLOR COMPANY machine.

In your own interest, pay particular attention to the following warnings:

The non-observance of this warning can jeopardize the user’s health and the correct operation of the machine.

A careful observance of these warnings can lead to a top performance of the machine.

The machine is covered by guarantee according to the conditions reported in the Seller’s

In the following field, please write your machine serial number in capital letters

Serial number

Distributor’s stamp

ENGLISH - 2

Congratulations on purchasing a machine TAYLOR.

The present manual, enclosed to the machine, is integrant and essential part of the machine and shall be delivered to the final user. Before performing any kind of operation, it is recommended to carefully study the reported instructions, as only a careful reading allows you getting the highest performance from your machine. The following pages report all information necessary to correctly install, commission, adjust and service your machine.

TAYLOR COMPANY reserves the right to carry out all changes necessary to improve its product or manual without prior notice and to insert them in the subsequent issues.

INDEX

1. TRANSPORT, HANDLING AND STORAGE………………………………… |

4 |

||

1.1 |

Preliminary Inspection |

………………………………………… |

4 |

1.2 |

Machine unpacking |

………………………………………… |

4 |

1.3 |

Packing dimensions |

………………………………………… |

4 |

2. MARKING AND GRAPHICS |

……………………………………… |

5 |

3. FIELD OF USE |

………………………………………… |

6 |

3.1 Field of use |

………………………………………… |

6 |

3.2 Limits of use |

………………………………………… |

6 |

3.3 Machine outfit |

………………………………………… |

6 |

4. SAFETY DEVICES |

………………………………………… |

7 |

5. OPERATIONS |

………………………………………… |

8 |

5.1 Controls |

………………………………………… |

8 |

5.2 Control panel |

………………………………………… |

9 |

5.3 Ice-cream production |

………………………………………… |

11 |

5.3.1 Automatic cycle |

………………………………………… |

11 |

5.3.1 Semi-Automatic cycle ………………………………… |

12 |

|

5.4 Granita production |

………………………………………… |

13 |

5.4.1 Coffee granita |

………………………………………… |

13 |

5.4.2 Granita siciliana |

………………………………………… |

13 |

6. MAINTENANCE |

………………………………………... |

14 |

6.1 Routine maintenance |

………………………………………… |

14 |

6.1.1 Cleaning and sanitization ………………………………… |

14 |

|

6.1.2 Maintenance of agitator and gaskets ……………………… |

16 |

|

6.1.3 Refrigerating unit |

………………………………………… |

16 |

7. TROUBLE-SHOOTING |

………………………………………… |

17 |

7.1 Alarm management |

………………………………………… |

17 |

7.2 Trouble-shooting |

………………………………………… |

18 |

3 - ENGLISH

1 TRANSPORT, HANDLING AND STORAGE.

1.1 PRELIMINARY INSPECTION

The machine travels at the customer’s risk. In case packing is damaged, immediately inform the carrier.

Immediately inform the carrier also in case of damage to the machine, even if you open the packing a few days after the delivery.

It is always advisable to accept the goods SUBJECT TO INSPECTION.

The equipment shall be assembled with great care: falls and shocks can damage it without showing external damages.

1.2 MACHINE UNPACKING

For a correct machine unpacking, carefully follow the instructions hereunder reported:

•Remove the case upper side and the side walls by means of a nail drawer, pay attention not to disperse the nails and the wood splinters;

•Remove the plastic bag and put it in a safe place;

•Unscrew the machine side panels by means of a cross and/or cut screw-driver;

•Turn out the screws fixing the packing lower side to the machine by means of a 17mm wrench;

•Remove the packing lower part, lift the machine and hook it up to the lifting points specified on the frame with the symbols;

•Reposition the side panels.

The packing shall be stored in a dry place, out of the children’s reach. It can be used again, if correctly preserved, for a possible transfer of the machine.

The storing temperature shall range between 41°F and 131°F (+5°C and +55°C).

Humidity shall range between 30 and 95%.

Packing elements such as plastic bags, nails, expanded polystyrene, cartons, etc. must be left out of the children’s reach.

1.3 PACKING DIMENSIONS

MODEL |

WATER CONDENSER |

AIR CONDENSER |

|||

SIZES (mm) |

WEIGHT (KG) |

SIZES (mm) |

WEIGHT (KG) |

||

|

|||||

C116 |

600x1210x1595 |

410 |

600x1435x1595 |

470 |

|

|

|

|

|

|

|

C117 |

600x960x1595 |

338 |

600x1210x1595 |

378 |

|

|

|

|

|

|

|

C118 |

600x960x1595 |

300 |

600x1090x1595 |

330 |

|

|

|

|

|

|

|

ENGLISH - 4

2. MARKINGS AND GRAPHICS

Never touch the machine with hands and tools during production or maintenance and cleaning operations, without making sure that the machine is in STOP position, the master switch is off and/or the multipolar plug disconnected.

TAYLOR COMPANY declines any liability for accidents deriving from an improper use of the machine due to the non-compliance with the above-mentioned recommendations.

The machine is provided with a plate and some pictograms, which together with the present manual allow using the machine in safer conditions.

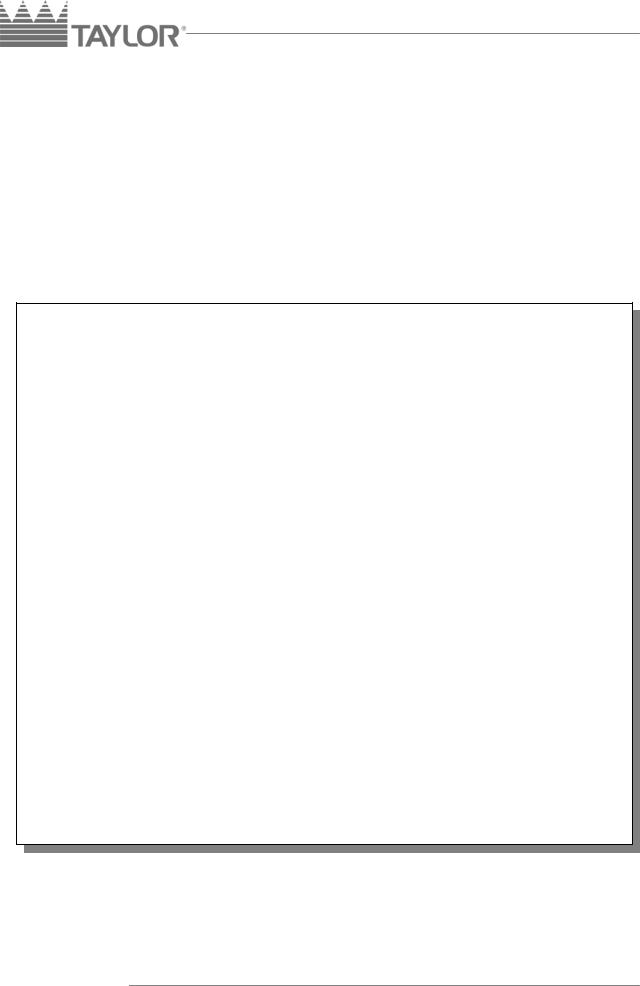

Machine data plate

The adhesive label located on the back of the machine allows identifying the model and reports the following indications:

Manufacturer’s name and address; Machine model and version; Serial number; Rated electrical characteristics; Type and weight of employed Freon; Manufacturing year.

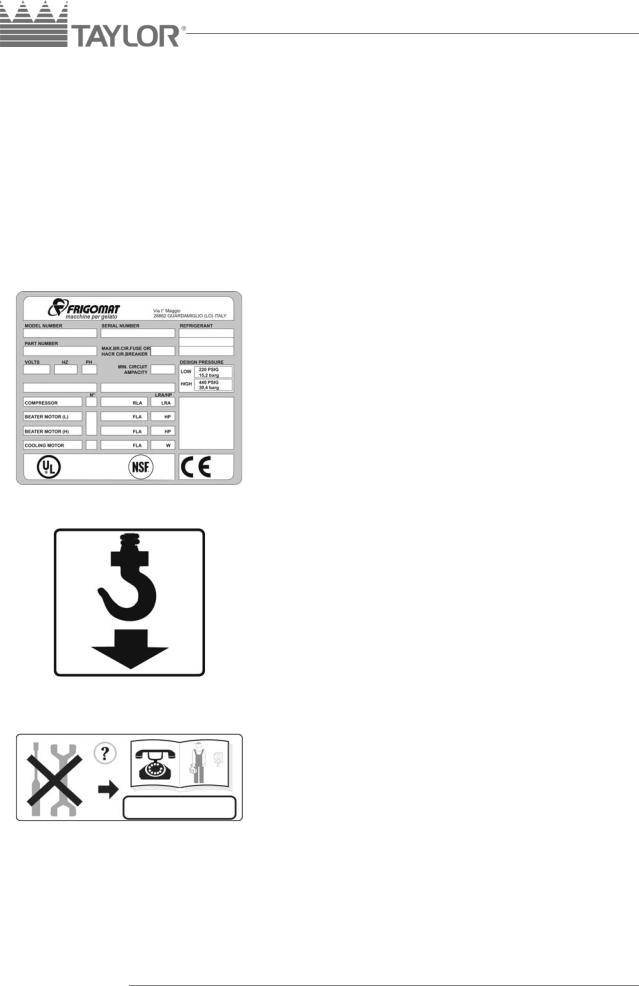

Indication

Points of application of lifting devices.

The following plate is placed on the four sides of the frame lower part and shows the points where lifting hooks shall be positioned in order to perform this operation in safe conditions. By means of a cross screw-driver unscrew the two side panels and then position the lifting devices into the apposite points.

Make sure that they cannot accidentally come out during lifting operations.

Warning!

Maintenance allowed to qualified personnel only.

The following plate placed on the machine back panel forbids extraordinary maintenance operations and/or repairs delegating them to authorized people only, whose address is indicated in the provided space.

5 - ENGLISH

Warning!

Do not touch with hands.

The following plate placed on the back of air-cooled machines shows that cleaning operations on the heat exchanger shall be carried out only by means of a brush or an exhauster.

Warning!

High voltage inside, danger of fulguration.

The following plate is placed on the electric box cover and warns the operator that in no case the cover must be removed avoiding this way the risk of lethal fulguration. Also in this case, maintenance operations on internal components must be performed by authorized personnel only.

3. FIELD OF USE

3.1 FIELD OF USE

TITAN batch freezers are expressly designed and engineered for ice-cream batch freezing cycles and for the production of granita.

3.2 LIMITS OF USE

Never use the machine with variable supply voltage and/or more than +/- 10% of the value showed in the nameplate or when the feeder is damaged;

Do not use the machine for purposes different from the ones indicated in the present manual;

Do not use the machine in explosive environment;

Do not wash the machine with high-pressure jets of water or poisonous substances;

Do not expose the machine to excessive heat or humidity;

Do not use completely unbalanced mixtures and/or quantities not in compliance with the specifications reported on the packing.

3.3 MACHINE OUTFIT

-Cleaning rod

-Gasket extractor

-Manual of use and maintenance

-Certificate of guarantee

-Declaration of conformity

ENGLISH - 6

4. SAFETY DEVICES

Shearing prevention system: realised by means of microswitches and safety circuit; it is activated when the door is opened and/or the grid on the hopper is lifted and it brings the machine to a temporary STOP: EME will appear on the display. Do not use this device to stop the machine during batch freezing cycles, but always use the STOP function instead.

Motor reliability of service: realised by means of temperature relays to protect motors against overloads.

In any case the machine carries out a series of tests during production: Production control system

Carried out by the microprocessor through a current transformer. It controls the agitator motor watt.

Batch freezing safety timer

It operates 35 minutes after the beginning of batch freezing in case the consistency minimum value set up by the manufacturer is not reached. The compressor stops, the agitator runs slowly, the STOP pushbutton is lit up, the production pushbutton and the display blink and an intermittent beep is released. In this case check the presence of troubles in the refrigerant circuit and/or check the proportion of the batch.

Lack of growth in consistency

It operates if the batch stops increasing in consistency due to a wrong proportion of ingredients or due to a non-uniform amalgamation, after the minimum alarm threshold is overcome. The compressor stops, the agitator keeps on running, the PRODUCTION pushbutton blinks and an intermittent beep is released.

Logic unit self-reset in case of lack of power supply

It stops the machine allowing the manual reset of the functions.

Logic unit self-diagnosis (watch-dog)

It controls possible internal troubles and stops the card in case of failure.

7 - ENGLISH

5. OPERATION

5.1 CONTROLS

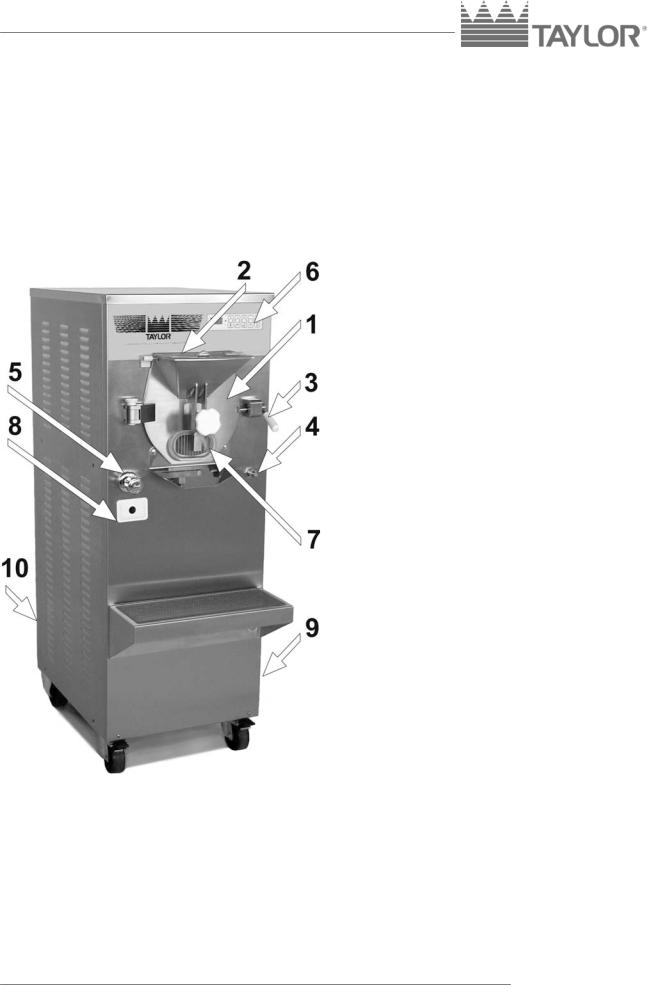

1. Door

It hermetically seals the cylinder during the working cycles. It can be easily removed for cleaning purpose.

2. Safety grid - hopper cover

It allows the operator to charge the product under safe conditions. The cover prevents the batch to get in contact with dust.

3. Door locking handle

It hermetically seals the door, when the lever is turned downward. To open the door, make sure that all product has been delivered and that the machine is in STOP position, then turn the lever upward to unlock the door and turn it to the left.

4. Water shower system

It is equipped with a flexible pipe and it is used by the operator to wash the cylinder and the agitator. Do not aim the water jet at the machine panels.

5. |

Water cock |

|

|

It run and stops the water from the |

|

|

shower. |

|

6. |

Pushbutton panel |

|

|

It allows selecting the working |

|

|

programs. |

|

7. |

Delivery door |

|

|

It is used to deliver ice-cream and to |

|

|

let water |

off while cleaning the |

|

cylinder. To unlock it loosen the knob |

|

|

and push it upward. |

|

8. |

Drip drawer |

|

|

It allows collecting possible liquid |

|

|

leakage from the cylinder stuffing box. |

|

9. Electric box

10.Water/power supply inlet

ENGLISH - 8

5.2 CONTROL PANEL

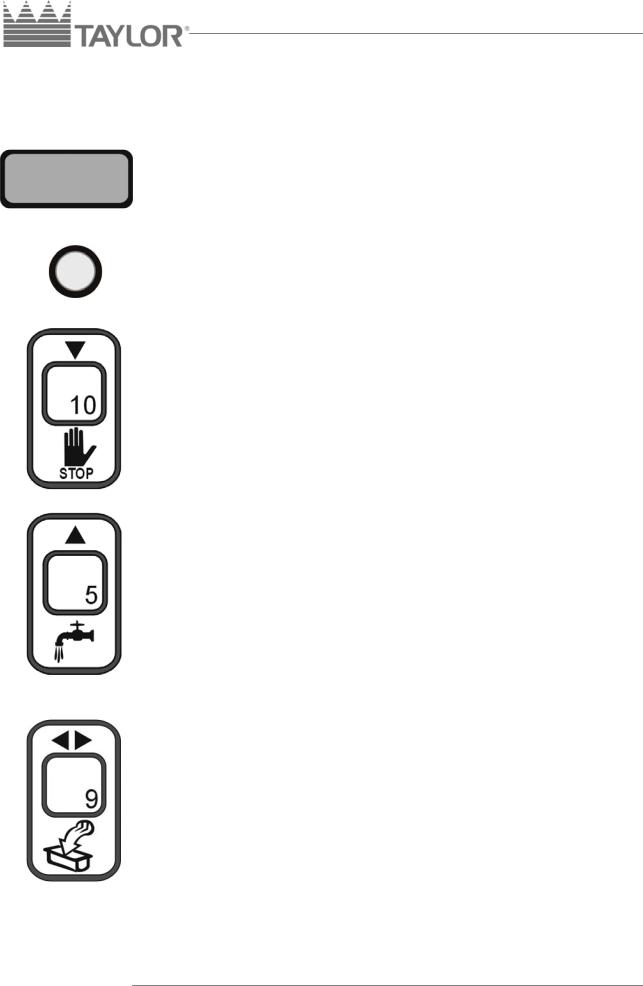

Alphanumeric display

After switching the machine on, an abbreviation made up by one letter and two numbers appears on the display: for example the abbreviation M 1.3 indicates the type of programme M = BATCH FREEZER (MANTECATORE) and 1.3 = SOFTWARE VERSION

NUMBER.

SET signal

This led lights up when a granita production programme is selected.

STOP/DECREASE VALUE pushbutton (↓)

This pushbutton has 2 functions:

1.Whatever machine working cycle is in progress, press STOP to cancel any function in progress. Whether in automatic or is semiautomatic cycle, never stop the machine when the ice-cream is about to reach its maximum consistency; always remember this if you want to extend the life of the driving belt and of the agitator motor.

2.During SEMI-AUTOMATIC cycles, press STOP to decrease the selected value.

CLEANING/INCREASE VALUE pushbutton (↑)

This pushbutton has 2 functions:

1.When the machine is in STOP function mode, press CLEANING to start the agitator motor at reduced speed.

2.By pressing CLEANING during any other machine working cycle, the agitator motor keeps running at reduced speed and the compressor stops.

3.When the machine is in SEMI-AUTOMATIC function mode, press CLEANING to increase the selected value.

DELIVERY/CONFIRM VALUE pushbutton (↔)

This pushbutton has 2 functions:

1.When the machine is in STOP function mode, press DELIVERY to start the agitator motor at reduced speed and after a few seconds the motor will reach high speed automatically. By pressing DELIVERY during any other machine working cycle, the agitator motor increases its speed within a few seconds from low speed to high speed, and the compressor is disabled.

2.When the machine is in SEMI-AUTOMATIC function mode, press DELIVERY to confirm the selected value.

9 - ENGLISH

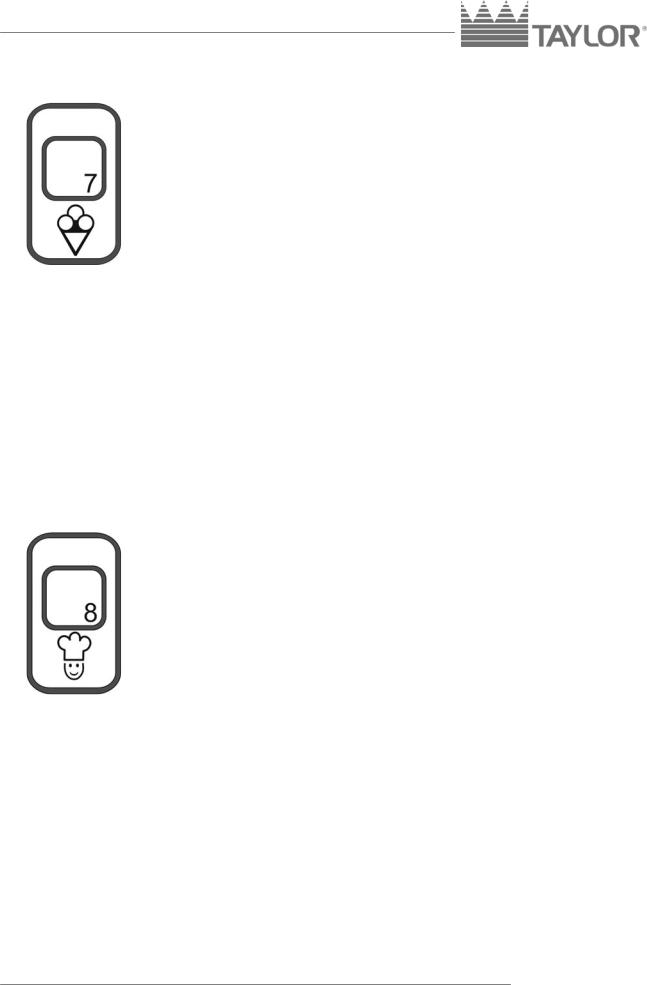

AUTOMATIC PRODUCTION pushbutton

In the AUTOMATIC PRODUCTION function, the machine operates a batch freezing cycle until the consistency value of 240 is reached or until the ice-cream stops increasing its consistency within the sampling interval, which has been set in the electronic card (see

Chapter 6.2.2.1).

Once the cycle has been completed, the machine will switch automatically to the preservation function. Let the compressor run two or three cycles to increase the product maximum consistency even further and to obtain consequently a drier and more compact ice-cream.

Press the pushbutton pictured on the left to switch to the

AUTOMATIC PRODUCTION mode: the agitator motor will start at reduced speed and after a few seconds the compressor motor, the motor ventilating fans (only for machines with air condensating system) and the electronic module for consistency control start up too; the electronic module allows reaching the ideal level of batch freezing, independently of the kind of mixture used, on condition that it is within the minimum and maximum quantities allowed for the machine capacity.

The following safety devices are all enabled: door safety catch, batch freezing safety timer, control for lack of growth in consistency and the emergency signals.

SEMI-AUTOMATIC PRODUCTION pushbutton

In the SEMI-AUTOMATIC PRODUCTION function, the operator can set a value for the maximum consistency. This is especially useful for special batch freezing or when the operator is not fully satisfied with the results obtained with the AUTOMATIC cycle.

Press the SEMI-AUTOMATIC pushbutton to switch to the SEMIAUTOMATIC mode and set the required consistency value (see Chapter 5.3.2); confirm the set value and the agitator motor starts at reduced speed and after a few seconds the compressor motor, the motor ventilating fans (only machines with air condensating system) and the electronic module for consistency control start up too.

The following safety devices are all enabled: door safety catch, batch freezing safety timer, control for lack of growth in consistency and the emergency signals.

ENGLISH - 10

5.3 ICE-CREAM PRODUCTION

After the machine has been installed according to the instructions reported in chapter 3 and carefully cleaned and sanitized according to the instructions reported in chapter 6, proceed as follows to start up the ice-cream production:

-Check that the master switch is closed, the STOP pushbutton is lighted up and the water supply cock is open.

-Lift the hopper cover and pour the mixture into the cylinder. Observe the suggested minimum and maximum quantities per cycle according to the following table:

MODEL |

MINIMUM |

MAXIMUM |

C116 |

4.2 quart (4 liter) |

15.8 quart (15 liter) |

C117 |

2.1 quart (2 liter) |

10.5 quart (10 liter) |

C118 |

1.05 quart (1 liter) |

6.3 quart (6 liter) |

The non-observance of the minimum and maximum batch values can cause the malfunction of the machine and, sometimes, serious damages.

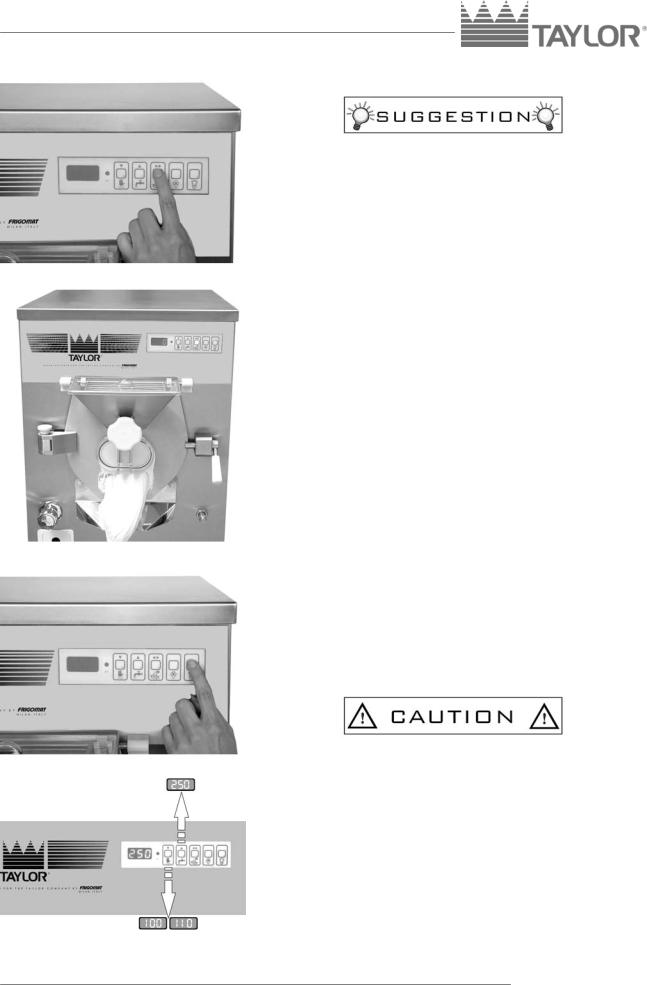

5.3.1 AUTOMATIC CYCLE

-Place the cover back on the hopper to prevent dust and other impurities from getting in contact with the mixture.

-Press the AUTOMATIC PRODUCTION pushbutton to start batch freezing.

-The consistency value is visualised on the display during the whole batch freezing cycle.

-After a few minutes and after the ideal consistency level in relation to the type and quantity of mixture used has been reached, the compressor stops, the PRODUCTION pushbutton blinks an intermittent beep is released to warn the operator that the ice-cream can be drawn out. If this is not possible, the agitator keeps on rotating until the consistency level falls by a predetermined percentage value (called consistency HYSTERESIS set up by the manufacturer and programmable) and the icecream PRESERVATION phase begins, which can be stopped at any time with the delivery of the ice-cream.

11 - ENGLISH

To obtain a thicker ice-cream, it is advisable to let the compressor run one or two cycles.

-To deliver the ice-cream, loosen the knob on the door and push it upward so as to open the delivery hole completely; then press the

DELIVERY pushbutton to bring the machine from low speed to high speed and to guarantee a fast ice-cream delivery from the freezing cylinder.

-Once the ice-cream delivery has been completed, press the STOP pushbutton, close the door again and the machine is ready for another batch freezing.

5.3.2 SEMI – AUTOMATIC CYCLE

-With the machine in STOP mode, press the SEMI-AUTOMATIC pushbutton: the display, which visualises the last consistency value that had been set manually, and the STOP-

CLEANING-DELIVERY pushbuttons will light up.

The mchine is now ready to be programmed with a new ice-cream consistency value.

-Press STOP (↓) and CLEANING (↑) pushbuttons to decrease or increase the consistency value visualised on the display (within a range between

100-110 and 250). After setting the required value, press the DELIVERY pushbutton (↔) to store the new programme; the SEMIAUTOMATIC pushbutton light up and the STOP-

CLEANING-DELIVERY pushbuttons turn off. The batch freezing cycle starts.

The maximum programmable consistency value is 250, but such value cannot be reached with all mixtures.

-Wait for a few minutes and when the machine has completed the batch freezing cycle, deliver the ice-cream as described in paragraph 5.3.1.

ENGLISH - 12

5.4 GRANITA PRODUCTION

5.4.1 “COFFEÈ” GRANITA (crushed-ice drink)

In this production cycle it is possible to set and programme the processing time and not the consistency value as for the ice-cream automatic and semi-automatic production cycles.

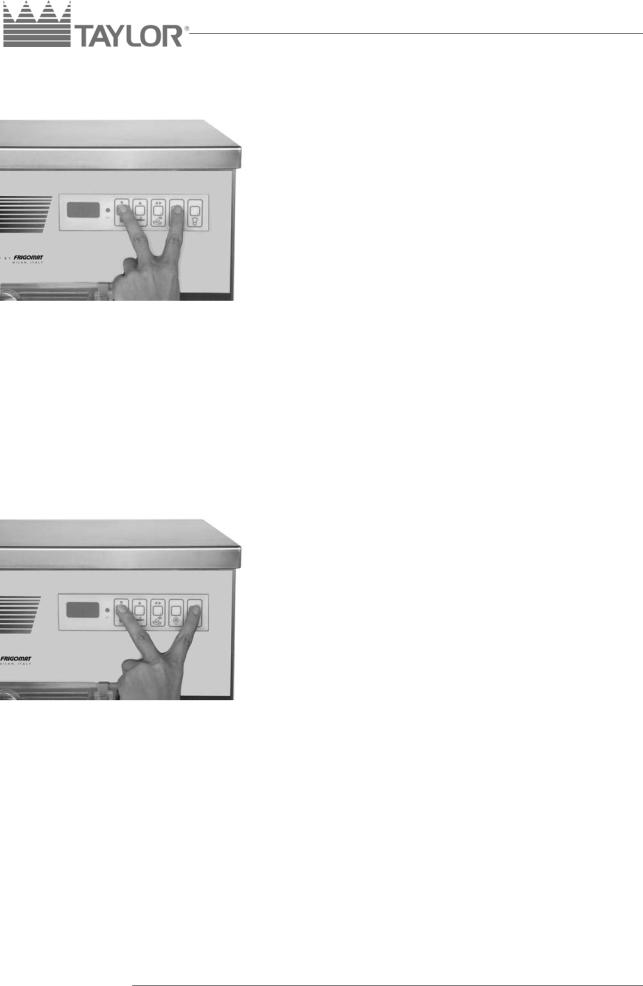

- To switch to the GRANITA CAFFE’ function mode, press the STOP and PRODUCTION pushbuttons simultaneously. The SET led lights up to signal that the GRANITA mode is now active and the display visualises the last time value (expressed in minutes) which has been set manually.

-Press STOP (↓) and CLEANING (↑) pushbuttons to decrease or increase the processing time for the production of granita. Once the required value has been set, press DELIVERY (↔) to confirm the programme and start the cycle.

The maximum programmable time is 10 minutes.

-During this cycle the compressor keeps on working without interruptions, while the agitator stops for 10 seconds and runs for half a second alternately. After the programmed time has elapsed, the PRODUCTION pushbutton blinks and an intermittent beep is released.

-Press the STOP pushbutton and deliver the product.

5.4.2GRANITA “SICILIANA” (Sicilian-style

crushed-ice drink)

In this production cycle it is possible to set and programme the consistency values, exactly as the icecream semi-automatic production cycle.

-To switch to the GRANITA SICILIANA function mode, press the STOP and SEMI-AUTOMATIC pushbuttons simultaneously. The SET led lights up to signal that the GRANITA mode is now active and the display visualises the last consistency value which has been set manually.

-Press STOP (↓) and CLEANING (↑) pushbuttons to

decrease or increase the required consistency value (within a range between 120 and 180). After setting the required value, press the DELIVERY pushbutton (↔) to confirm the programme and start the cycle.

The recommended value ranges between 140 and 160.

-During this cycle the compressor and the agitator keep on working without interruptions. Once the programmed consistency value has been reached, the SEMIAUTOMATIC pushbutton blinks and an intermittent beep is released.

-Press the STOP pushbutton and deliver the product.

13 - ENGLISH

6. MAINTENANCE

6.1 ROUTINE MAINTENANCE

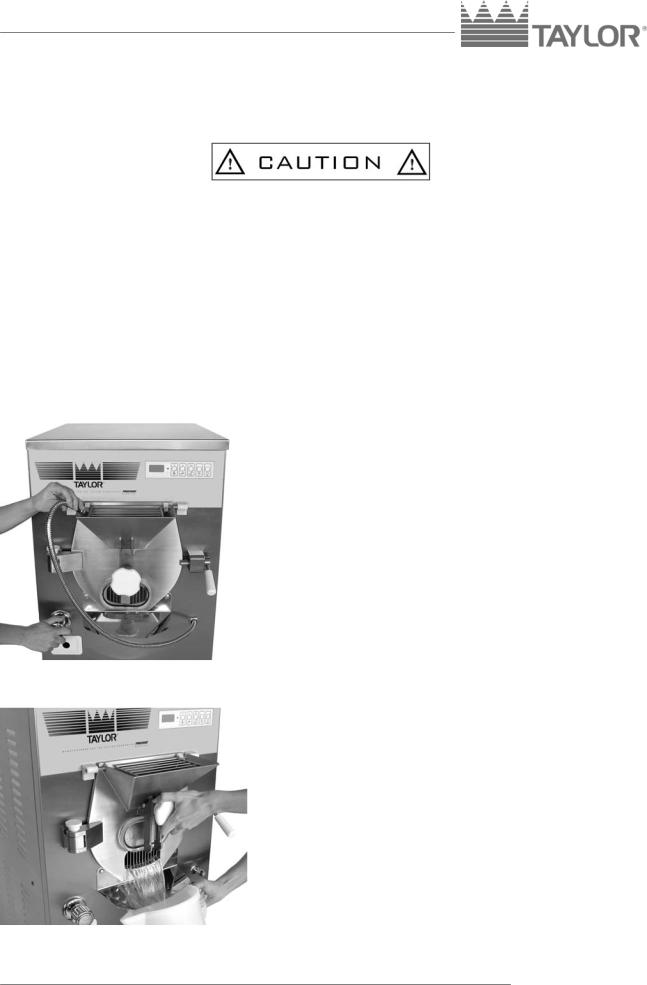

During production, cleaning and maintenance operations, never touch the machine with hands or tools without making sure that the machine has been disconnected from mains.

In case of troubles, make sure that they are not caused by a lack of servicing. On the contrary, ask for the intervention of a FRIGOMAT customer service. In case it is necessary to replace a piece, always ask a distributor or an authorized retailer for ORIGINAL spare parts.

It is advisable to make the machine be checked by a Customer Service every 6/8 months.

6.1.1 CLEANING AND SANITIZATION

Bacteria and moulds easily proliferate due to the presence of fats in cream, that is why it is necessary to carefully wash and clean all parts in contact with the product, such as the cylinder, the agitator and the door.

Rustless materials and/or made of plastic for food industry used for our machines, in conformity with the most severe international standards, make washing operations easier, however they cannot prevent mould proliferation, etc. caused by insufficient cleaning.

TAYLOR COMPANY recommends cleaning the tank and the parts in contact with the product after the employment and in any case in compliance with the sanitary standards in force in the country of installation. To thoroughly clean your batch freezer, proceed as follows:

1.Pour approximately 15.8 quart (15 litres) of clean cold water into the cylinder for model C116, 10.5 quart (10 litres) for model C117, 6.3 quart (6 litres) for model C118.

2.Press the CLEANINING pushbutton and let the machine run for a few minutes. Press STOP and let the washing water off. Repeat the operation until the water coming out of the cylinder is clean.

3.Pour approximately 15.8 quart (15 litres) of detergent solution/sanitiser into the cylinder for model C116, 10.5 quart (10 liters) for model C117 and 6.3 quart (6 liters) for model C118.

4.Press the CLEANINING pushbutton and let the machine run for a few minutes. Press and let all the solution off.

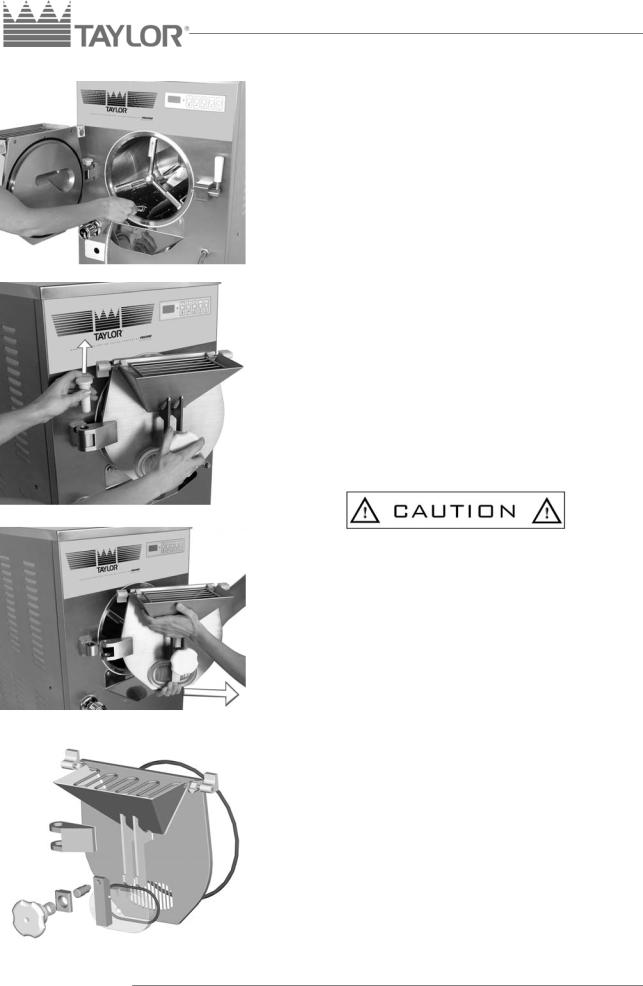

5.To disassemble the door, pull up the lever, make the door rotate to the left and, whilst holding it with one hand, remove the hinged knob with the other

ENGLISH - 14

hand. The door is now ready for being disassembled.

6. Dismantle the door into pieces:

•Unscrew the handle adjusting knob.

•Remove the guide and the spring.

•Remove the delivery door.

•Remove the O-rings.

7.Pull the agitator and the stuffing box out: remove the scraping pads and wash them thoroughly. Use the cleaning rod to clean the pads seats on the agitator.

8.Wash all components with a detergent/sanitiser solution. Let them dry in the open air.

9.Accurately sanitise the cooling cylinder.

10.Remove the drip drawer from the front panel and thoroughly wash it. If the drip drawer contains some mxture, the agitator stuffing box is leaking and shall be replaced.

11.Lubricate the OR rings and the stuffing box. Once a week, it is advisable to rotate the agitator stuffing box so that the rubber elasticity can be recovered.

-To preserve plastic components and gaskets, never use solvents and/or diluents during washing.

-Sanitizing chemicals shall be used according to laws in force and with the utmost caution.

-After any sanitizing operation, it is indispensable not to touch the sterilized parts either with hands or with towels, sponges or other.

-Avoid making the agitator run empty, as the machine can be damaged.

15 - ENGLISH

6.1.2 MAINTENANCE OF AGITATOR AND GASKETS

The agitator blades are equipped with scraping pads made of atoxic plastic materials suitable for food industry. These components are subject to wear according to the characteristics of the employed mixture: with high sugar content and low fat percentage a remarkable wear of pads can be the detected.

When the clearance between the pads and the cylinder is excessive, the agitator is no more able to perfectly scrap the cooling cylinder walls resulting in

an extention of batch freezing times. To restore the machine performance, it is sufficient to replace the scraping pads.

6.1.3 REFRIGERATING UNIT

In case of machine provided with air condenser, it is necessary to periodically clean the condenser fins from the dirtiness sucked in by the fan motor, which can obstruct it and considerably reduce its efficiency.

To clean the condenser, make use of a brush or an exhauster.

ENGLISH - 16

7 TROUBLE-SHOOTING

7.1 ALARMS MANAGEMENT

The “OMEGA” electronic card is a powerful control logic unit which signals possible machine troubles by means of alphanumeric messages visualised on the display; the technician shall understand them to quickly find the reason of this trouble.

MESSAGE |

DESCRIPTION |

REMEDIES |

|

EME |

The door is open or the safety grid on the hopper is not |

Make sure that the door |

|

is closed and the safety |

|||

completely lowered. |

|||

EMERGENCY |

An intermittent beep is released. |

grid on the hopper is |

|

lowered. |

|||

|

|

||

|

|

|

|

TER |

When a motor thermal cutout is triggered, it is followed by |

After checking the |

|

MOTOR |

the blinking of the led TER and by the release of an |

machine, press STOP to |

|

restore correct |

|||

THERMAL |

intermittent beep. |

||

functioning. |

|||

CUTOUT ALARM |

|

||

|

|

||

EPO |

When the machine is started up, the microprocessor checks |

|

|

the data stored in the EPROM memory: if this data are not |

Send for a technician. |

||

STORED DATA |

correct EPO will appear on the display, followed by the |

||

|

|||

ALARM |

release of an intermittent beep. |

|

|

|

|

|

|

EPI |

If, during normal functioning, the memory is not |

|

|

acknowledged, EPI will appear on the display, followed by |

Send for a technician. |

||

MEMORY ALARM |

the release of an intermittent beep. |

|

|

|

|

|

|

LI |

If, during normal functioning, the voltage is too low, LI will |

Check mains voltage |

|

POWER SUPPLY |

appear on the display, followed by the release of an |

and machine power |

|

intermittent beep. |

supply. |

||

ALARM |

|||

|

|

||

|

|

|

|

OUT |

If, during normal functioning, the output control module is |

Send for a technician. |

|

USCITE MODULE |

faulty or if it is not acknowledged, OUT will appear on the |

||

display, followed by the release of an intermittent beep. |

|

||

ALARM |

|

||

|

|

||

|

|

|

|

TA |

If, during normal functioning, an anomaly of the current |

|

|

transformer occurs, TA will appear on the display, followed |

Send for a technician. |

||

TA ALARM |

by the release of an intermittent beep. |

|

|

|

|

|

|

UTA |

If, during normal functioning, an anomaly of the |

|

|

TA MICRO- |

microprocessor controlling the consistency calibration |

Send for a technician. |

|

occurs, UTA will appear on the display, followed by the |

|||

PROCESSOR |

|

||

release of an intermittent beep. |

|

||

ALARM |

|

||

|

|

17 - ENGLISH

7.2 TROUBLE-SHOOTING

TROUBLE |

POSSIBLE CAUSES |

REMEDIES |

|

The machine does not start (STOP |

Electric trouble. |

Send for a technician. |

|

pushbutton ON without active |

|

|

|

Incorrect power supply. |

Check phases. |

||

alarms) |

|||

|

|

|

|

The machine does not start |

Master switch open. |

Turn the the switch off. |

|

|

|

||

(pushbuttonSTOP off) |

Burnt fuses. |

Check and replace. |

|

|

|||

|

|

|

|

|

|

Check for the presence of water in |

|

|

Machine with water condensating |

the water system to which the |

|

Since the first phases of the batch |

system: lack of condensing water. |

machine is connected. Check the |

|

freezing cycle, the compressor |

|

cocks. |

|

works intermittently |

Machine with air condensating |

Clean the condenser by means of |

|

|

system: dirty air condenser or |

a brush and check that the fan |

|

|

broken down fan. |

motor correctly works. |

|

|

|

Check condensating. |

|

The machine interrupts the batch |

Alarm: safety timer: the maximum |

|

|

Make sure that the room |

|||

freezing cycle after 16’ and |

time set for batch freezing has |

temperature is not too high. |

|

switches to STOP mode |

been exceeded. |

Make sure that you have used a |

|

|

|

correct amount of mixture and that |

|

|

|

it is properly balanced. |

|

The machine interrupts the batch |

Alarm: lack of growth in |

Make sure that you have used a |

|

freezing cycle after 16’ and |

|||

consistency: the consistency has |

|||

switches to STOP mode, an |

correct amount of mixture and that |

||

not grown within the sampling |

|||

intermittent beep is released and |

it is properly balanced. |

||

interval (Step 7 OMEGA) |

|||

the agitator keeps working. |

|

||

|

|

||

|

Worn out agitator scraping pads. |

Check and replace if required |

|

|

|

|

|

|

Trouble in freezing system. |

Send for a technician. |

|

|

|

|

|

|

Unbalanced mixture or wrong |

Make sure that you have used a |

|

|

correct amount of mixture and that |

||

The machine works regularly but |

amount of mixture. |

||

it is properly balanced. |

|||

the ice-cream is too soft. |

|

||

Insufficient condensating. |

Check condensating and make |

||

|

|||

|

sure that the room temperature is |

||

|

|

not too high. |

|

|

In semi-automatic cycle: the |

Programme a higher consistency |

|

|

programmed consistency value is |

||

|

value. |

||

|

too low. |

||

|

|

||

During batch freezing the machine |

The belts slip. |

Check the belt tension and in case |

|

is noisy and the agitator stops. |

of necessity replace all the belts. |

||

|

|||

During the delivery of ice-cream, |

The product is too hard. |

Make sure that you have pressed |

|

the machine is noisy. |

the “DELIVERY”pushbutton. |

||

|

|||

Traces of liquid ice-cream in the |

Worn-out agitator stuffing box. |

Check and/or replace. |

|

drip drawer. |

|||

|

|

ENGLISH - 18

1 - FRANÇAIS

IMPORTANT

Nous vous recommandons de lire attentivement et entièrement ce manuel avant d’utiliser votre machine TAYLOR COMPANY.

Nous vous conseillons vivement de faire particulièrement attention aux avertissements suivants :

Si vous ne respectez pas cet avertissement-ci, vous courez des risques pour votre santé et/ou pour le bon fonctionnement de la machine.

Vous pourrez obtenir de votre machine un maximum de prestations uniquement si vous respectez attentivement ces conseils.

La machine est sous garantie aux conditions illustrées par le vendeur.

Veuillez bien indiquer dans le champ ci-dessous le numéro d’immatriculation de votre machine

Numéro d’immatriculation

Cachet du concessionnaire

FRANÇAIS - 2

Nous vous félicitons pour avoir choisi une machine TAYLOR.

Le présent manuel, fourni avec la machine, doit être considéré comme partie intégrante et essentielle de celle-ci et il devra être remis à l’utilisateur final. Avant d’effectuer toute opération, nous vous recommandons d’étudier attentivement les instructions qu’il contient : seule une lecture attentive vous permettra d’obtenir de votre machine un maximum de prestations. Dans les pages qui suivent figurent toutes les indications permettant d’effectuer correctement les opérations d’installation, de fonctionnement, de réglage et d’entretien courant. TAYLOR COMPANY se réserve le droit d’apporter toutes les modifications qu’elle jugera nécessaires à l’amélioration de son produit ou de son manuel technique, en insérant les variantes dans les éditions successives.

TABLE DES MATIERES

1. TRANSPORT, MANUTENTION ET STOCKAGE |

…………. |

4 |

||

1.1 |

Inspection préliminaire |

………………………………………… |

4 |

|

1.2 |

Déballage de la machine |

………………………………………… |

4 |

|

1.3 |

Dimensions emballage |

………………………………………… |

4 |

|

2. MARQUAGE ET SIGNES GRAPHIQUES …………………………………… |

5 |

|

3 UTILISATIONS |

………………………………………… |

6 |

3.1 Utilisations |

………………………………………… |

6 |

3.2 Limites d’utilisation |

………………………………………… |

6 |

3.3 Equipement machine |

………………………………………… |

6 |

4. DISPOSITIFS DE SECURITE |

………………………………………… |

7 |

5. FONCTIONNEMENT |

………………………………………… |

8 |

5.1 Commandes |

………………………………………… |

8 |

5.2 Tableau de commandes |

………………………………………… |

9 |

5.3 Production de glace |

………………………………………… |

11 |

5.3.1 Cycle automatique |

………………………………………… |

11 |

5.3.1 cycle semi-automatique ………………………………… |

12 |

|

5.4 Production de granite |

………………………………………… |

13 |

5.4.1 Granite Cafe |

………………………………………… |

13 |

5.4.2 Granite Sicilien |

………………………………………… |

13 |

6. ENTRETIEN |

………………………………………... |

14 |

6.1 Entretien ordinaire |

………………………………………… |

14 |

6.1.1 Nettoyage et assainissement………………………………… |

14 |

|

6.1.2 Entretien de l’agitateur et garnitures ………………… |

16 |

|

6.1.3 Installation frigorifique ………………………………………… |

16 |

|

7. . INSTRUCTIONS POUR L’IDENTIFICATION DES PANNES………………… 17 |

||

7.1 Gestion des alarmes |

………………………………………… |

17 |

7.2 Recherche des pannes |

………………………………………… |

18 |

3 - FRANÇAIS

1 TRANSPORT, MANUTENTION ET STOCKAGE.

1.1 INSPECTION PRELIMINAIRE

La machine voyage aux risques et périls de l’acquéreur; si vous remarquez que l’emballage est abîmé, émettez immédiatement une réserve auprès du transporteur.

Si vous remarquez que la machine est abîmée, émettez également une réserve auprès du transporteur tout de suite après le déballage, même s’il est effectué quelques jours après la livraison. Il est toujours préférable d’accepter la marchandise SOUS RESERVE DE VERIFICATION.

L’appareil doit être déplacé avec soin; les chutes et les chocs peuvent l’abîmer même sans qu’il y ait de dommages apparents.

1.2 DEBALLAGE DE LA MACHINE

Pour déballer correctement la machine, suivre attentivement les indications suivantes :

•Enlever la partie supérieure de la caisse et ensuite les parties latérales à l’aide d’un arrache-clous. Ne pas laisser traîner les clous ni les éventuels bouts de bois;

•Enlever la protection plastique et bien la ranger;

•Dévisser les panneaux latéraux de la machine à l’aide d’un tournevis cruciforme et/ou normal;

•Dévisser les vis qui fixent la partie inférieure de l’emballage à l’aide d’une clé 17 mm;

•Enlever la partie inférieure de l’emballage en soulevant la machine par les points de levage sur le châssis caractérisés par le symbole;

•Remettre les panneaux latéraux.

L’emballage doit être conservé dans un endroit sec et hors de portée des enfants. Il pourra

être réutilisé, s’il est correctement conservé, pour un éventuel déplacement successif.

La température de stockage doit être comprise entre 41°F et 131°F (+5°C et +55 °C). Le taux d’humidité doit être compris entre 30 et 95%.

Conserver hors de portée des enfants les emballages et les éléments qui les composent tels que les sachets plastiques, les clous, le polystirène expansé, les cartons etc.

1.3 DIMENSIONS DE L’EMBALLAGE

MODELE |

CONDENSATION EAU |

CONDENSATION AIRE |

||

DIMENSIONS |

POIDS (KG) |

DIMENSIONS |

POIDS (KG) |

|

|

(mm) |

(mm) |

||

|

|

|

||

C116 |

600x1210x1595 |

410 |

600x1435x1595 |

470 |

|

|

|

|

|

C117 |

600x960x1595 |

338 |

600x1210x1595 |

378 |

|

|

|

|

|

C118 |

600x960x1595 |

300 |

600x1090x1595 |

330 |

|

|

|

|

|

FRANÇAIS - 4

Loading...

Loading...