STA-RITE P4RAA6F-177L, P4R62G3-153, P4RA6G-152L, P4R6F-152L, P4RA6F-151L User Manual

...

DURA-GLAS II

TM

CENTRIFUGAL PUMPS

WITH INTEGRAL TRAP

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

P4R and P4RA Series MODELS

HP

3/4 P4R62D3-150 P4R6D3-150

1 P4R62E3-151 P4R6E-151L P4R6E3-151

1-1/2 P4R62F3-152 P4R6F-152L P4RA6F-151L P4R6F3-152

1-3/4 P4RAA6F-177L

2 P4R62G3-153 P4R6G-153L P4RA6G-152L P4RA6GC-150 P4R6G3-153

2-1/2 P4RAA6G-153L

3 P4R6H3-154

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

North America: 800-752-0183, FAX 800-582-2217

International: 414-728-5551, FAX: 414-728-4461, TELEX: ITT 4970245

Oxnard, CA • Union City, TN • Delavan, WI • Mississauga, Ont.

© 1998, Sta-Rite Industries, Inc. Printed in U.S.A. S272 (Rev. 2/12/98)

This manual should be furnished to

the end user of this pump; its use will

reduce service calls and chance of

injury and will lengthen pump life.

2

‘P4R’ and ‘P4RA’ SERIES II PUMP

WITH TRAP

To avoid unneeded service calls, prevent possible injuries, and get the most

out of your pump, READ THIS MANUAL CAREFULLY!

The Sta-Rite ‘P4R’ and ‘P4RA’ Series II Self-priming Centrifugal pumps:

• Are designed for use with swimming pools or as centrifugal pumps.

• Are excellent performers; durable, reliable.

Table of Contents

Safety Instructions ........................................................................................3

Installation.................................................................................................4-5

Electrical....................................................................................................5-6

Operation..................................................................................................7-8

Storage/Winterizing ......................................................................................8

Pump Service...........................................................................................9-11

Troubleshooting Guide...............................................................................11

Repair Parts List.....................................................................................12-14

Warranty.....................................................................................................15

3

READ AND FOLLOW S AFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your system

or in this manual, look for one of the following signal words and be alert

to the potential for personal injury.

warns about hazards that will cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that can cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that will or can cause minor personal injury

or property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equip-

ment. Keep safety labels in good condition; replace if missing or damaged.

Incorrectly installed or tested equipment may fail, causing

severe injury or property damage.

Read and follow instructions in owner's manual when installing

and operating equipment. Have a trained pool professional per-

form all pressure tests.

1. Do not connect system to a high pressure or city water system.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE SURE all air is out of system

before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-m) torque for testing.

• Water pressure for test must be less than 25 PSI (7.5 kg/cm2).

• Water Temperature for test must be less than 100oF. (38oC).

• Limit test to 24 hours. After test, visually check system to be sure it is ready

for operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For

non-Sta-Rite equipment, consult manufacturer.

IMPOR TA NT

S A FETY

INSTRUCTIONS

Always follow basic safety precautions with this equipment, including the following.

To reduce the risk of

injury, do not permit children to

use this product unless they are

closely supervised at all times.

This pump is for use

with permanently installed pools

and may also be used with hot

tubs and spas if so marked. Do

not use with storable pools. A

permanently installed pool is constructed in or on the ground or in

a building such that it cannot be

readily disassembled for storage.

A storable pool is constructed so

that it may be readily disassembled for storage and reassembled

to its original integrity.

SAVE THESE

INSTRUCTIONS

4

INSTALLATION

Only qualified, licensed personnel should install pump and wiring.

Pump mount must:

Be solid - Level - Rigid - Vibration free. (To reduce vibration and pipe stress,

bolt pump to mount.)

Allow pump suction inlet height to be as close to water level as possible.

Allow use of short, direct suction pipe (To reduce friction losses).

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

NOTICE: Use Teflon tape or Plasto-Joint Stik1for making all threaded connec-

tions to the pump. Do not use pipe dope; pipe dope will cause stress cracking

in the pump.

NOTICE: Pump suction and discharge connections have molded in thread

stops. DO NOT try to screw pipe in beyond these stops.

Teflon Taping Instructions:

Use only new or clean PVC pipe fittings.

Wrap male pipe threads with one to two layers of Teflon tape. Cover entire

threaded portion of pipe.

Do not overtighten or tighten past thread stop in pump port!

If leaks occur, remove pipe, clean off old tape, rewrap with one to two addi-

tional layers of tape and remake the connection.

NOTICE: Support all piping connected with pump!

1

Lake Chemical Co., Chicago, Illinois

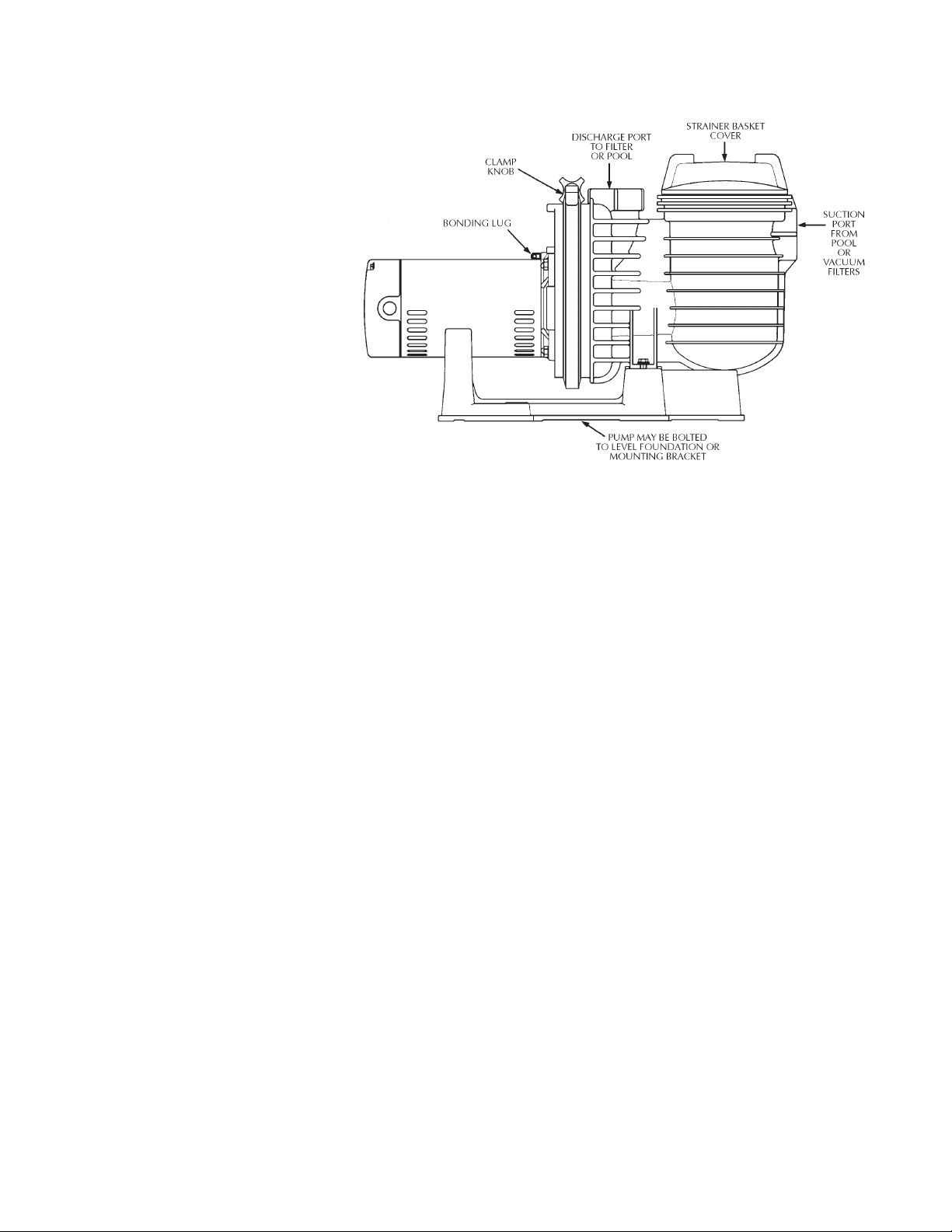

Figure 1

5

Piping:

Use at least 2" IPS PVC (51mm) pipe. Increase size if a long run is needed.

To avoid strains on the pump, support both suction and discharge pipes inde-

pendently. Place these supports near the pump.

To avoid a strain left by a gap at the last connection, start all piping at the

pump and run pipe away from the pump.

Never use a suction pipe smaller than pump suction connection.

To avoid airlocking, slope suction pipe slightly upward toward the pump.

NOTICE: To prevent flooding when removing pump for service, all flooded

suction systems must have gate valves in suction and discharge pipes.

Fittings:

Fittings restrict flow; for best efficiency use fewest possible fittings.

Avoid fittings which could cause an air trap.

Pool fittings must conform to International Association of Plumbing and

Mechanical Officials (IAPMO) standards.

Use only non-entrapping suction fitting or double suction.

TABLE I - RECOMMENDED FUSING AND WIRING DATA

Serv. to Motor - Dist. in Ft. (M)

Motor Branch Fuse Max Load Voltage/ 0-100' 101-200' 201-300'

HP Rating Amps* Amps Hz/Phase (0-30 M) (30-60 M) (60-90 M)

P4R Models:

1 30 19.2 115/60/1 10(5.5) 8(8.4) 6(13)

1 15 9.6 230/60/1 14(2) 14(2) 12(3)

1-1/2 15 12.0 230/60/1 14(2) 14(2) 12(3)

2 15 11.2 230/60/1 14(2) 14(2) 12(3)

P4RA Models:

1-1/2 30 19.2 115/60/1 10(5.5) 8(8.4) 6(13)

1-1/2 15 9.6 230/60/1 14(2) 14(2) 12(3)

1-3/4 15 12.0 230/60/1 14(2) 14(2) 12(3)

2 15 12.0 230/60/1 14(2) 14(2) 12(3)

2-1/2 15 11.2 230/60/1 14(2) 14(2) 12(3)

P4R62 Models:

3/4 15 3.8 200/60/3 14(2) 14(2) 14(2)

1 15 5.6 200/60/3 14(2) 14(2) 14(2)

1-1/2 15 6.6 200/60/3 14(2) 14(2) 14(2)

2 15 9.8 200/60/3 14(2) 14(2) 14(2)

P4R6 3-Phase Models:

3/4 15/15 3.6/1.8 230/460/60/3 14(2) 14(2) 14(2)

1 15/15 4.7/2.35 230/460/60/3 14(2) 14(2) 14(2)

1-1/2 15/15 5.8/2.9 230/460/60/3 14(2) 14(2) 14(2)

2 15/15 7.0/3.5 230/460/60/3 14(2) 14(2) 14(2)

2-1/2 15/15 9.7/4.9 230/460/60/3 14(2) 14(2) 12(3)/14(2)

3 15/15 11.5/5.8 230/460/60/3 14(2) 14(2) 12(3)/14(2)

* Time delay fuses are recommended instead of standard fuses in any motor circuit.

Wire

Size

AWG

(mm2)

}

Wire

Size

AWG

(mm2)

}

Wire

Size

AWG

(mm2)

}

Wire

Size

AWG

(mm2)

}

Loading...

Loading...