SPX Cooling Technologies MXF 7400, MXF 4800, MCR3100, MXF 3000 User Manual

/ Marley MARPAK® Modular Biomedia /

The Marley® MARPAK Difference

SPX Cooling Technologies is a world leader in the design, manufacturing and construction of cooling products.

The design and production of modular corrugated PVC media used in Marley cooling products is the same technology and expertise utilized in the development of the MARPAK product line of modular PVC media for biological wastewater treatment.

Since the origin of Marley in 1922, we have maintained a commitment to total quality in engineering, in customer service and in the close teamwork of our employees and representatives around the world. This long term dedication is what makes the Marley MARPAK Difference.

Influent &

Intermediate

Pumping

Secondary

Treatment

Sludge

Treatment

Building

Heating

& Cooling

Relative Energy Consumption

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

10ft. Total Head

10ft. Total Head

30ft. Total Head

100ft. Total Head

Preliminary Treatment

Preliminary Treatment

Primary Treatment

Primary Treatment

Trickling Filter

Trickling Filter

Activated Sludge

Extended Aeration

Incineration

Aerobic Digestion

Thicken & Anaerobic Digestion

Drying Beds

Drying Beds

Haul to Landfill

Aerated Ponds

Chlorination

Chlorination

Northern U.S.

Southern U.S.

Southern U.S.

Source: Water and Sewage Works 3-1

Fixed Film Process

History

For over 100 years the fixed film reactor (trickling filter) has been used in wastewater treatment to reduce the biochemical oxygen demand (BOD) and for nitrification. As the wastewater passes down through the trickling filter, microorganisms on the surface of the media convert the dissolved organic wastes and ammonia nitrogen into stable by-products - carbon dioxide, nitrates, nitrites and biosolids which are removed by clarification.

Advantages

The advantage of the trickling filter process over other methods of treating wastewater include:

1.Lower energy consumption (Fig. 3-1)

2.More resistant to hydraulic and organic shock loads

3.Simple operational procedures

4.Fewer personnel required to operate

5.Reduces sludge bulking problems

Future

With the advent of the highly efficient modular 60° cross flow media (MARPAK MXF Series), the trickling filter is a viable alternative for complete secondary treatment (Figs. 8-1 and 8-2) and nitrification (Fig. 9-1) of municipal wastewater. As energy and labor costs continue to increase, the trickling filter process will become even more cost effective in wastewater treatment.

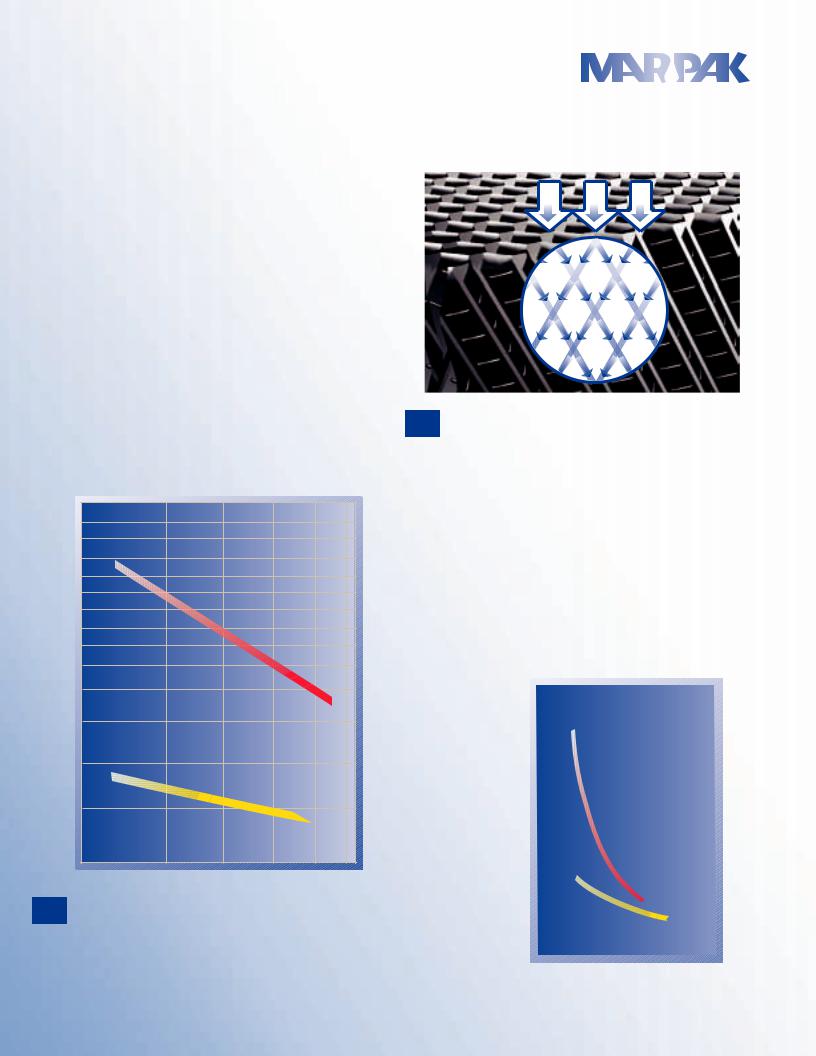

Modular Biological Treatment Media

MARPAK is a modular PVC corrugated media specifically designed for biological treatment applications. MARPAK media is manufactured from rigid PVC sheets that are UV protected and resistant to rot, fungi, bacteria, acids

and alkalies commonly found in wastewater. MARPAK modules are manufactured in various sheet thicknesses to meet specific structural requirements. MARPAK includes a full range of modular PVC media geometries for wastewater treatment including - complete secondary treatment (Figs. 8-1 and 8-2), nitrification (Fig. 9-1), denitrification, industrial roughing filters and anaerobic treatment.

Flow Configuration

of MARPAK MXF Series Media

4-1

Retention Time Versus Flow

At A Media Depth Of 10ft.

|

|

Flow m3/m2/h |

|

|

|

|

|

|

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

|

15 |

|

|

|

|

|

|

14 |

|

|

|

|

|

|

13 |

|

|

|

|

|

|

12 |

|

|

|

|

|

|

11 |

|

|

|

|

|

|

10 |

|

|

|

|

|

|

9 |

|

|

60° Cross Flow |

|

|

|

8 |

|

|

|

||

|

|

|

Modular Media |

|

||

|

7 |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

5 |

|

|

|

|

|

In Minutes |

4 |

|

|

|

|

|

3 |

|

|

|

|

|

|

2 |

|

Vertical Flow |

|

|

||

Time |

|

Modular Media |

|

|

||

|

|

|

|

|

|

|

Retention |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0.4 |

0.8 |

1.2 |

1.6 |

2.0 |

2.4 |

4-2 |

Flow GPM/ft2 |

|

|

|

||

|

|

|

|

|

||

Source: “Plastic-Packed Trickling Filters” by E. Sarner

Faster Installation

Extensive testing has proven that taller modules produce the same water distribution as alternating 1'-0 modules. This means 4 ft, 6 ft, or even 8 ft modules can be used to reduce installation time and minimize the number of clog-prone module interfaces.

Retention Time Versus Flow

At A Media Depth Of 10ft.

Flow m3/m2/h

|

1.2 |

2.4 |

3.6 |

|

|

20 |

|

60° Cross Flow |

|

|

|

|

||

|

|

|

Modular Media |

|

|

16 |

|

Random Media |

|

|

|

|||

|

|

|||

MinutesIn |

12 |

|

|

|

8 |

|

|

|

|

|

|

|

|

|

Time |

4 |

|

|

|

0 |

|

|

|

|

Retention |

|

|

|

|

|

2 |

|

|

|

0 0.5 1.0 1.5

Flow GPM/ft2

4-3 |

Source: “Evaluation of Plastic Media In Trickling Filters”, |

|

by T. Richards and D. Reinhart |

|

Loading...

Loading...