Snapper Rear Engine Riders User Manual

DEALER SET-UP INSTRUCTIONS & CHECKLIST For

SNAPPER REAR ENGINE RIDERS

Tools required for set-up are: HAMMER, PLIERS, 7/16” and 1/2” WRENCH or SOCKET.

A package of Battery Acid (Electrolyte), purchased separately, is required for electric start models.

SNAPPER Rear Engine Riding Mowers are shipped with steering components, seat & fuel tank detached. After uncrating, inspect the machine for damage, then proceed as follows to assemble and prepare the unit. Open parts box and hardware bag and identify components shown on pages 5, 6, & 7. NOTE that NOT ALL PARTS in each bag are used on any one rider.

A.STEERING COMPONENTS

1.Steering Shaft

(a)Carefully stand Rider on rear bumper.

(b)Push steering shaft into place (See figure 2).

(c)Remove/discard vinyl cap from steering shaft end.

(d)Tap upper bushing so that it contacts control panel.

(e)Place thrust washer on top of bushing.

(f)Install 3/16” x 1-1/2” cotter-pin from parts bag into steering shaft above thrust washer.

(g)Install bushing cover over cotter-pin, thrust washer and bushing.

(h)Slide foam steering shaft cover over steering shaft. See Figure 1.

FOAM STEERING

SHAFT COVER

THRUST

WASHER

BUSHING COVER (CUP DOWN TO COVER COTTER

PIN) 3/16” X 1-1/2” COTTER PIN

UPPER BUSHING

CONTROL

PANEL

FIGURE 1

2.Installing Tie Rods - Narrow Front Frame (28” & smaller deck)

(a)Install bushings onto tie rods.

(b)Install tie rods into steering shaft. Secure with 3/8” flat washers and 5/32” x 1” cotter-pins. See Figure 2.

STEERING

SHAFT

TIE

ROD

BUSHING

5/32” X 1”

3/8” FLAT

COTTER PIN

WASHER

FIGURE 2

3.Installing Tie Rods - Wide Front Frame (30” & larger deck)

(a)Install tie rods, 5/16” lock washers and 5/16”- 24 hex nuts. Tighten securely. See Figure 3.

STEERING

ARM

TIE ROD

5/16” SPLIT LOCKWASHER

5/16” HEX NUT

FIGURE 3

INSTRUCTION No. 3-5621 (REV. 3, 8/20/99)

4.Installing Steering Wheel

(a)Slide steering wheel on steering shaft. Normally, the offset of the steering wheel should be towards operator’s seat.

NOTE: For more operator room, the steering wheel offset can be turned towards front of the Rear Engine Rider. The “SNAPPER” logo in the center of steering wheel can be snapped out and turned also.

(b) Support steering wheel and drive the 1/4” x 1- 1/2” roll pin into steering wheel and steering shaft. See Figure 4.

SUPPORT STEERING WHEEL

WHILE DRIVING ROLL PIN

STEERING

WHEEL WITH

OFFSET

TOWARDS

OPERATOR’S

SEAT

1/4” X 1-1/2” ROLL PIN

FIGURE 4

B.MOWING DECK

1.Cutting Blade

(a)Check the torque of mowing blade(s) mounting bolt(s). (30 to 40 ft. lbs. recommended for single blade mowers & 40 to 50 ft. lbs. recommended for double blade mowers).

(b)Check blade(s) straightness per operators manual.

C.LUBRICATION

1.Perform normal lubrication of the Rear Engine Rider. Check differential and chain case for proper lubricant levels. See Operator’s manual.

2.After completing lubrication, carefully lower Rear Engine Rider to floor to continue set-up.

D.FUEL SYSTEM

1.Fuel Tank

Place fuel tank in bracket behind seat bracket and push tank down until it snaps into position. See Figure 5.

PUSH

FUEL TANK ORIENTATION

FIGURE 5

2.Fuel Line

Slide fuel line onto fuel tank hose barb and move hose clamp above end of the fuel tank hose barb (approximately 1/8” from end of hose). The fuel filter has been installed by the engine manufacturer. See Figure 6.

FUEL

FUEL LINE

TANK

FUEL

FILTER

HOSE

CLAMPS

FIGURE 6

E.OPERATOR’S SEAT – NON-HINGED MODELS

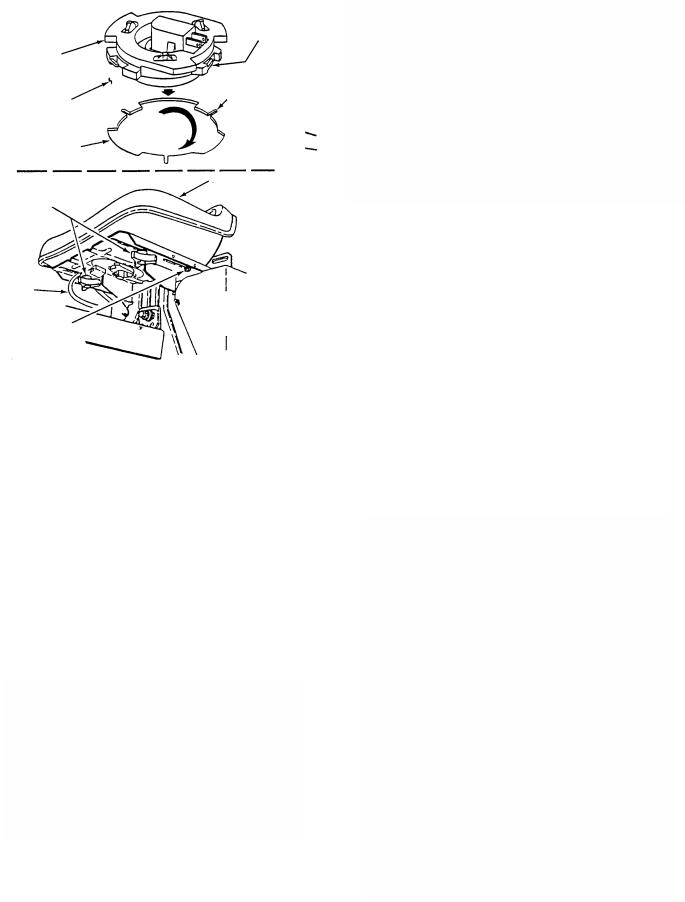

1.Install seat switch into bottom of seat by pushing in and turning clockwise until switch locks into place. See Inset in Figure 7.

2.Lay forward edge of seat onto seat pan with seat switch protruding through opening in pedestal.

3.Connect seat switch wiring harness to male tabs of seat switch (under seat). See Figure 7.

4.Position operator’s seat onto seat bracket.

5.Install two 5/16-18 hex head flange patch lock screws into rear holes of seat.

6.Install two spacers onto the two adjusting knobs.

7.Install adjusting knobs through seat bracket and into the two front holes in operator’s seat.

8.Adjust seat to desired position. Partially tighten rear screws, allowing seat to slide front to back. Tighten adjusting knobs to secure seat in position. See Figure 7.

INSET

SEAT

SWITCH

P.N. 2-9211

BOTTOM OF OPERATOR’S SEAT

SWITCH

MOUNTING

HOLE

ADJUSTING

KNOBS &

SPACERS

SEAT

SWITCH

WIRE

5/16-18 PATCH LOCK SCREW (DO NOT OVERTIGHTEN!)

TAB

LOCKS

TAB LOCK

ENGAGEMENT

SLOTS

INSERT SWITCH &

ROTATE 1/8” OF A

TURN CLOCKWISE

OPERATOR’S

SEAT

FIGURE 7

2

Loading...

Loading...