OWNERS/OPERATORS

MANUAL

Model 8042

(S/N 18991 thru 19984

and S/N 0160002332 thru 0160029584)

OH2882

Keep this manual with the vehicle at all times.

Printed in U.S.A. 2/07

8990500 C

WARNING: Improper operation of this vehicle can

cause injury or death. Only trained and authorized operators

should operate this vehicle.

Before starting the engine, do the following:

1. Read this owner/operators manual.

2. Read all the safety decals on the vehicle.

3. Clear the area of other persons.

Learn and practice safe use of vehicle controls in a safe,

clear area before you operate this vehicle on a worksite.

It is your responsibility to observe applicable laws and

regulations and to follow manufacturer's instructions on

vehicle operation and maintenance.

CALIFORNIA

Proposition 65 Warning

Diesel Engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects and other reproductive harm.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

Wash hands after handling

.

Table of Contents

Introduction

The Manual....................................2

Replacement Parts........................2

Reports..........................................2

Safety Practices

Disclaimer......................................3

Hazard Classification System........3

Accident Prevention Tags..............5

New or Additional Operators .........5

Instructional Symbols ....................6

Hazard Symbols ............................7

Avoidance Symbols.......................8

Avoidance Symbols (cont’d)..........9

Personal Considerations .............10

Operational Considerations.........14

Equipment Considerations ..........20

Operation

Operator Controls........................23

Instruments and Indicators..........34

Optional Controls.........................44

Pre-Operation Inspection.............54

Normal Starting............................55

Cold Starting................................56

Jump Starting ..............................57

Refueling .....................................58

Stabil-TRAK System....................60

Operating.....................................63

Using The Capacity Chart ...........72

Fork Ratings ................................81

How To Pick, Carry & Place A

Load..........................................82

Elevating Personnel.....................82

Using Other Attachments ............87

Shut-Off .......................................88

Emergency Operations

Towing A Disabled Vehicle..........89

Emergency Boom Lowering ........91

General Maintenance

General Maintenance................104

Maintenance Schedule And

Checklist.................................105

1. Lubrication Points..............110

2. Air Cleaner And Restriction

Indicator.............................112

3. Engine Cooling System .....116

4. Engine Oil And Filter.........119

5. Engine Fuel System..........123

6. Engine Fan Belt.................128

7. Hydraulic Oil and Filter......129

8. Transmission Oil and

Filter ..................................133

9. Axle Oil..............................136

10. Brake Disk Inspection .......138

11. Wheel End Oil ...................142

12. Wheels and Tires ..............144

13. Batteries............................146

14. Fuse and Relay

Replacement.....................148

15. Boom Chains and Wear

Pads..................................152

Storage and Transport ..............167

Storage......................................167

Transport...................................168

Test Procedures

Stabil-TRAK System Test..........169

Parking Brake/Transmission

De-Clutch Test Procedures....173

Four Wheel Steer Indexing

Procedure...............................175

Specifications

Fluid & Lubrication Capacities...176

Tires ..........................................177

Weights .....................................178

Vehicle Dimensions...................178

Electrical System.......................179

Engine.......................................180

Index.............................................181

Accident Prevention Tags

ã 2003 JLG Industries, Inc.

1

Introduction

Introduction

The Manual

This Owners/Operators Manual provides the information you need to

properly operate and maintain this vehicle.

IMPORTANT! Before

and carefully so you will understand the safety instructions and the

operation of the controls and safety equipment. You must comply with all

Danger, Warning, and Caution notices. They are for your benefit.

All reference to the right side, left side, front, or rear are given from the

operator's seat looking in a forward direction.

JLG Industries, Inc. is hereinafter referred to as JLG.

you operate this vehicle, read this manual completely

Replacement Parts

For easy reference when ordering

replacement parts or making service

inquiries on this vehicle, record its

model and serial number on the back

cover of this manual. The serial

number is stamped into the serial

number plate (1) which is located on

the vehicle’s frame.

IMPORTANT! The replacement of

any part on this vehicle by anything

other than a JLG authorized

replacement part may adversely

affect the performance, durability or

safety of this vehicle and may void the warranty. JLG assumes no liability

for unauthorized replacement parts which adversely affect the performance,

durability or safety of this vehicle.

1

OH0280

Reports

IMPORTANT! A Warranty Registration form must be filled out by the Sky

Trak Distributor, signed by the purchaser, and returned to JLG once the

product is sold and/or put into service. This report activates the warranty

period, assuring that your claims during the warranty period will be

processed promptly. To guarantee full warranty service, make sure your

Sky Trak Distributor has returned the business reply card of this form to

JLG.

2

Model 8042 Rev. 11/03

Safety Practices

Safety Practices

Disclaimer

JLG reserves the right to make changes on and to add improvements upon

its products at any time without public notice or obligation. JLG also

reserves the right to discontinue manufacturing any product at its discretion

at any time.

NOTICE: Under OSHA rules, it is the responsibility of the employer to

provide operator training. Successful completion and certification of Safety

Training for Rough Terrain Forklifts is required. Operator Training Kits are

available by calling Ken Cook Company at (414) 466-6060. An order form

for these kits is available through our website,

http://www.jlg.com.

The information in this manual does not replace any safety rules and laws

used in your area. Before operating this vehicle, learn the rules and laws for

your area. Make sure the vehicle has the correct equipment according to

these rules and laws.

Your safety and the safety of others in the worksite depend significantly

upon your knowlege and understanding of all correct operating practices

and procedures for this vehicle.

WARNING: DO NOT modify or alter (weld, drill, etc.) any

part of this vehicle without consulting JLG. Modifications can

weaken the structure creating a hazard that can cause death or

serious personal injury.

Hazard Classification System

OP0330

This safety alert symbol is used with the following signal words to attract

your attention to messages found within the manual and on hazard decals

located on the vehicle. They are reproduced herein and pertain to proper

operation and procedure messages contained throughout the manual. The

message that follows the symbol contains important information about

Safety. To avoid possible death or serious personal injury, carefully read and

follow the messages! Be sure to fully understand the potential causes of

death or injury.

Model 8042 Rev. 11/03

3

Safety Practices

Signal Word

A signal word is a distinctive word located on hazard decals and used

throughout this manual that alerts the viewer to the existence of and relative

degree of the hazard.

DANGER:

The signal word “DANGER” indicates an imminently hazardous situation

which, if not avoided, will result in death or serious personal injury.

WARNING:

The signal word “WARNING” indicates a potentially hazardous situation

which, if not avoided, could result in death or serious personal injury.

CAUTION:

The signal word “CAUTION” indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

CAUTION:

The signal word “CAUTION”, used without the safety alert symbol, indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

For safe maintenance of the vehicle, read, understand and follow all

DANGER, WARNING and CAUTION information.

4

Model 8042 Rev. 11/03

Safety Practices

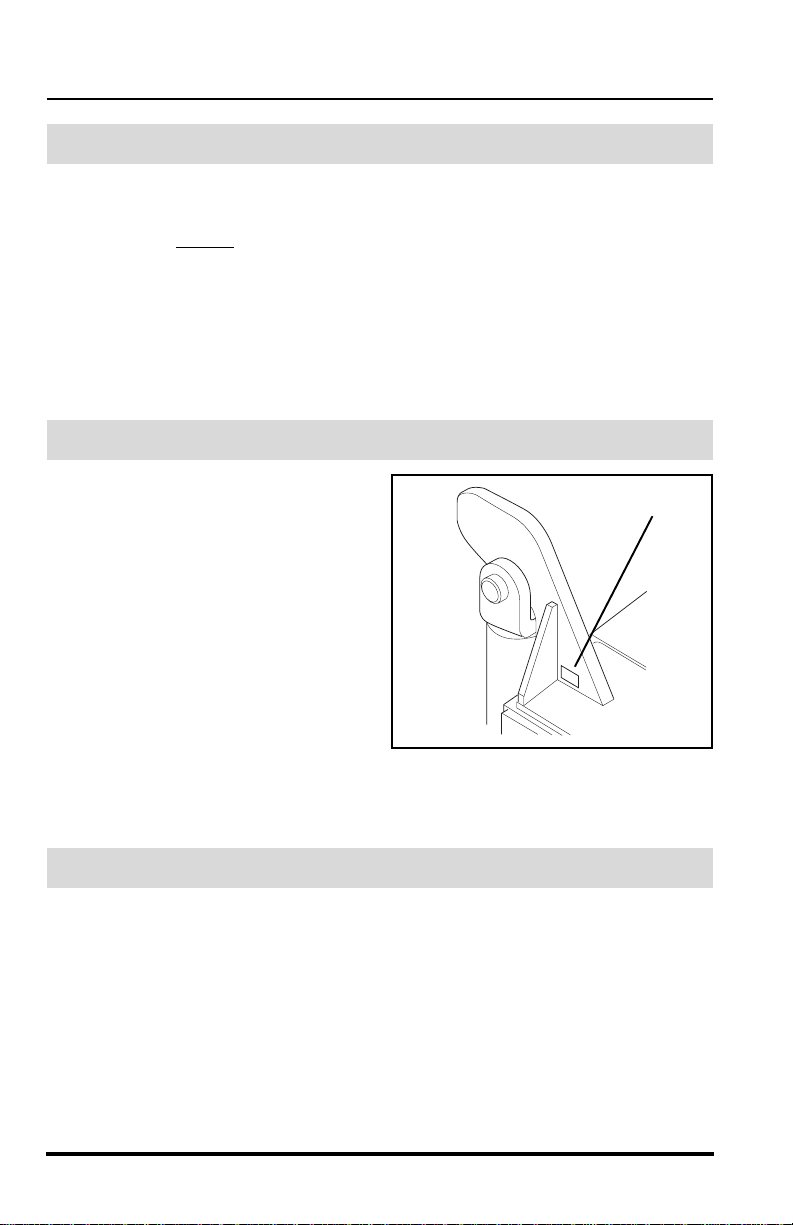

Accident Prevention Tags

Before beginning any maintenance or service, place an Accident Prevention

Tag (1) on both the starter key switch (2) and the steering wheel (3), stating

that the vehicle should not be operated. Actual Accident Prevention Tags,

which can be punched out and used, are included as the last page of this

manual. Retain these Accident Prevention Tags for reuse at a later date.

3

DANGER

DANGER

1

2

OH3350

New or Additional Operators

At the time of original purchase, the purchaser of this vehicle was instructed

by the seller on its proper use. If this vehicle is to be used by an employee or

is loaned or rented to someone other than the purchaser, make certain that

the new operator is trained, in accordance with the OSHA regulations

referenced on page 3, and reads and understands this Operators Manual

before

operating the vehicle.

In addition, make sure that the new operator has completed a walk-around

inspection of the vehicle, is familiar with all decals on the vehicle, and has

demonstrated the correct use of all controls.

Model 8042 Rev. 11/03

5

Safety Practices

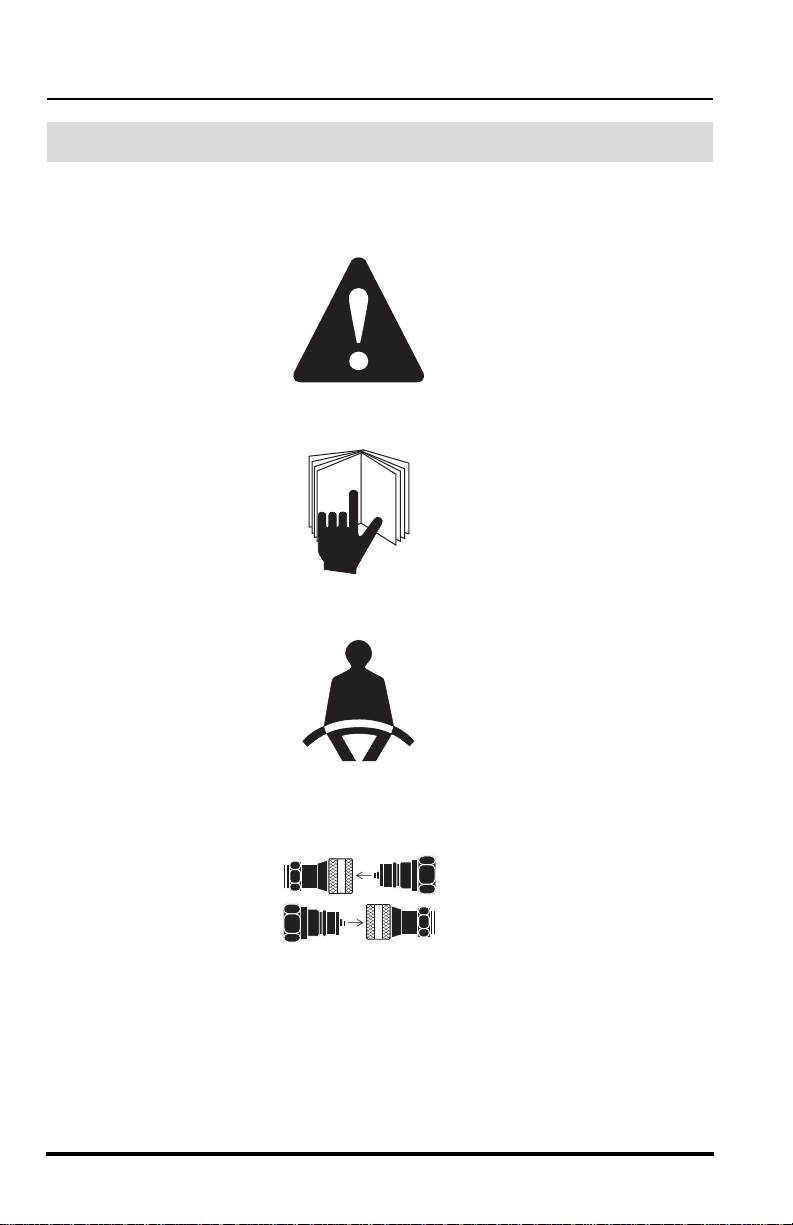

Instructional Symbols

The following symbol definitions will help you understand all hazard

related decals and load charts used on this vehicle.

OP0330

Safety Alert Symbol

OH2100

Read Operator’s Manual

OH2090

Fasten Seat Belt

OH3100

This Symbol Signifies That

Specific Attachments Must

Only Be Used On Vehicles

Equipped With Auxiliary

Hydraulics.

Always Connect Couplers.

6

Model 8042 Rev. 11/03

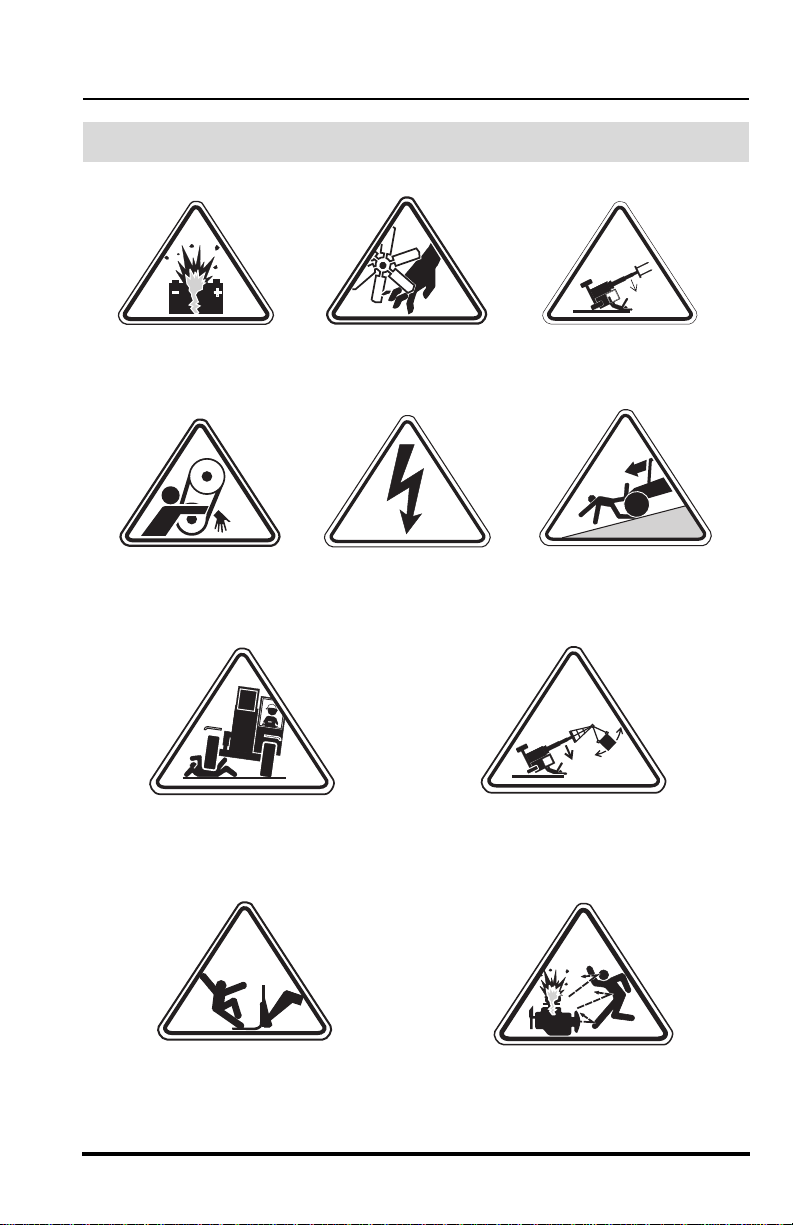

Hazard Symbols

Safety Practices

OH2110

-

Lead Acid Batteries

Generate Explosive

Gases

OH2300

Rotating Belts Can Cut

Or Entangle

OH2120

Rotating Fan Blades

Can Cut

OH2150

Electrocution Can

Cause Death Or

Serious Injury

OH3160

OH2130

Vehicle Tipover Can

Crush

OH2140

Vehicle Roll Away Can

Cause Death Or Serious

Injury

OH3110

AVOID CRUSHING, Falling Off

Vehicle Can Cause Death Or

Serious Injury

FALLING OFF ATTACHMENT Can

Result In Death Or Serious Injury

Model 8042 Rev. 11/03

OH2161

Swinging Loads Can Cause

Vehicle Tipover Which Can Result

In Death Or Serious Injury

OU1450

ENGINE EXPLOSION

Can Result In Death Or

Serious Injury

7

Safety Practices

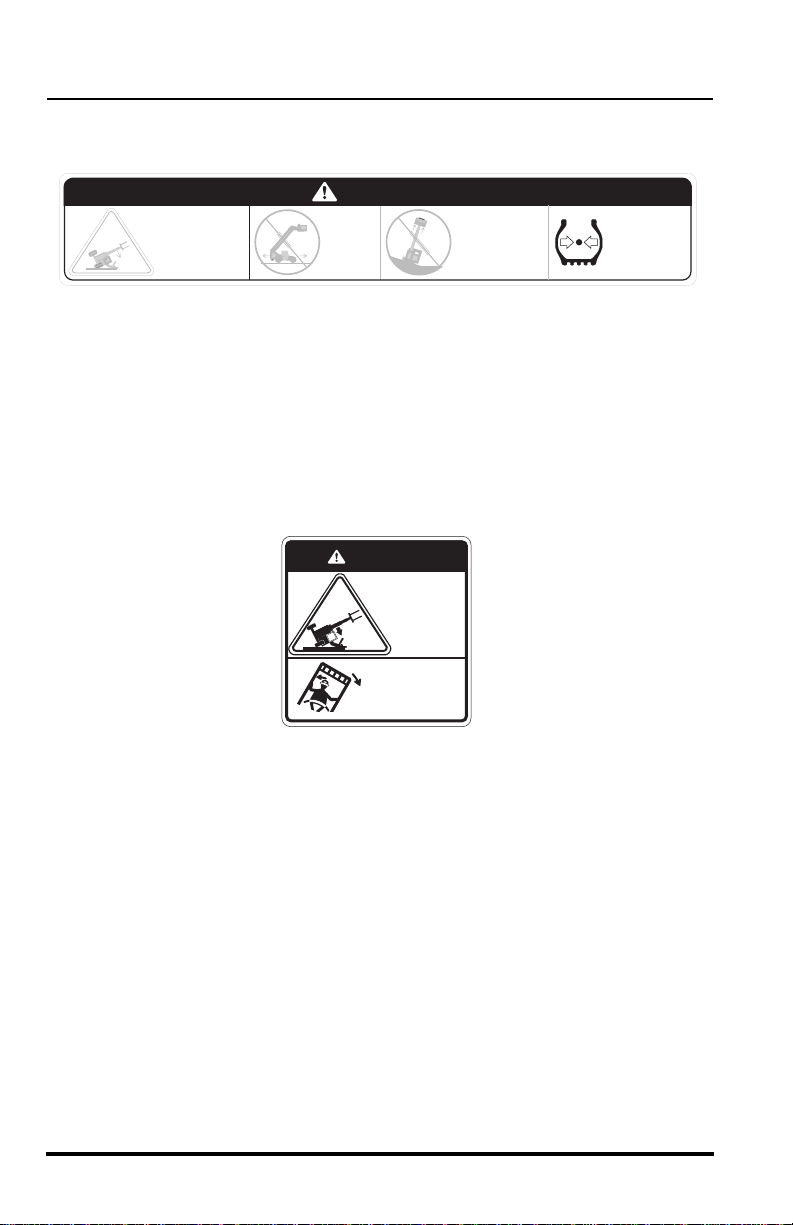

Avoidance Symbols

OH2320 OH2330

Keep Lit Cigarettes

Away

OH2310 OH2270

Keep Away From

Rotating Fan Blades

OH2280

Do Not Raise Boom

While On A Slope

Keep Flames and

Ignition Sources Away

OU1520

Stop Operation At

This Point

OU1510

Prohibition

Symbol. DO NOT

Operate

Do Not Travel With

Boom Raised

OH2290

Maintain Proper Air

Pressure In Tire

To Avoid Vehicle Tipover

ALWAYS:

•Travel Slowly

• Rig Properly

• Use Two Tethers

OH3120

8

Model 8042 Rev. 11/03

Safety Practices

Avoidance Symbols (cont’d)

OH2260 OH2250

Engage Parking Brake

Do Not Travel With

Personnel In Work

Platform

OU1460

DO NOT Use Ether Or

Other High Energy

Starting Aids.

Engine Equipped With

Grid Heating System.

Keep Clear Of Power

Lines

OH2240 OH2230

Carry No Riders

OH2170

Use Only Compliant Work

Platforms To Raise Or Lower

Personnel

DO NOT JUMP

• Brace Yourself and Stay

With Vehicle

• Keep Seat Belt Fastened

• Hold On Firmly

• Lean Away From The Point

OH2220

Of Impact

Model 8042 Rev. 11/03

9

Safety Practices

Personal Considerations

1. Seat Belt

Always fasten the seat belt before starting the engine.

2. Clothing and Safety Gear

DO NOT wear loose clothing or jewelry that can get caught on controls

or moving parts. Wear protective clothing and personal safety gear

issued or called for by job conditions.

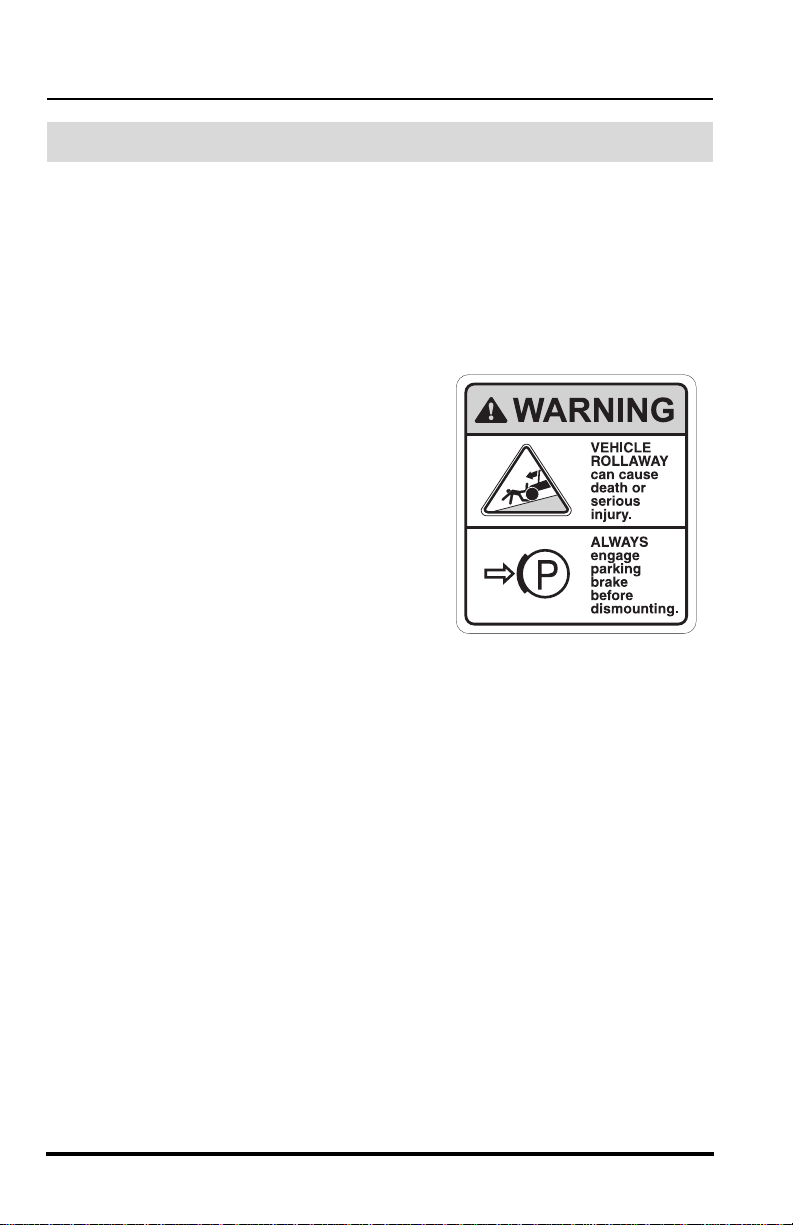

3. Dismounting

DO NOT get off the vehicle until you:

• level the vehicle,

• ground the carriage,

• place the travel select lever in

(N) NEUTRAL,

• place the neutral lock lever in (N)

NEUTRAL LOCK,

• engage the parking brake

switch,

• turn the engine OFF, if appropriate,

• unbuckle the seat belt,

• exit the vehicle using the hand holds.

4. Chemical Hazards

A. Exhaust Fumes

Fumes from the engine exhaust can cause death or serious

personal injury. DO NOT operate vehicle in an enclosed area

without a ventilation system capable of routing the hazardous

fumes outdoors.

B. Explosive Fuel

Engine fuel is flammable and can cause a fire and/or an explosion.

Avoid danger by keeping sparks, open flames and smoking

materials away from the vehicle and from fuel during refueling or

when servicing the fuel system. Know where fire extinguishers are

kept on the worksite and how to use them.

10

OH1650

Model 8042 Rev. 11/03

Safety Practices

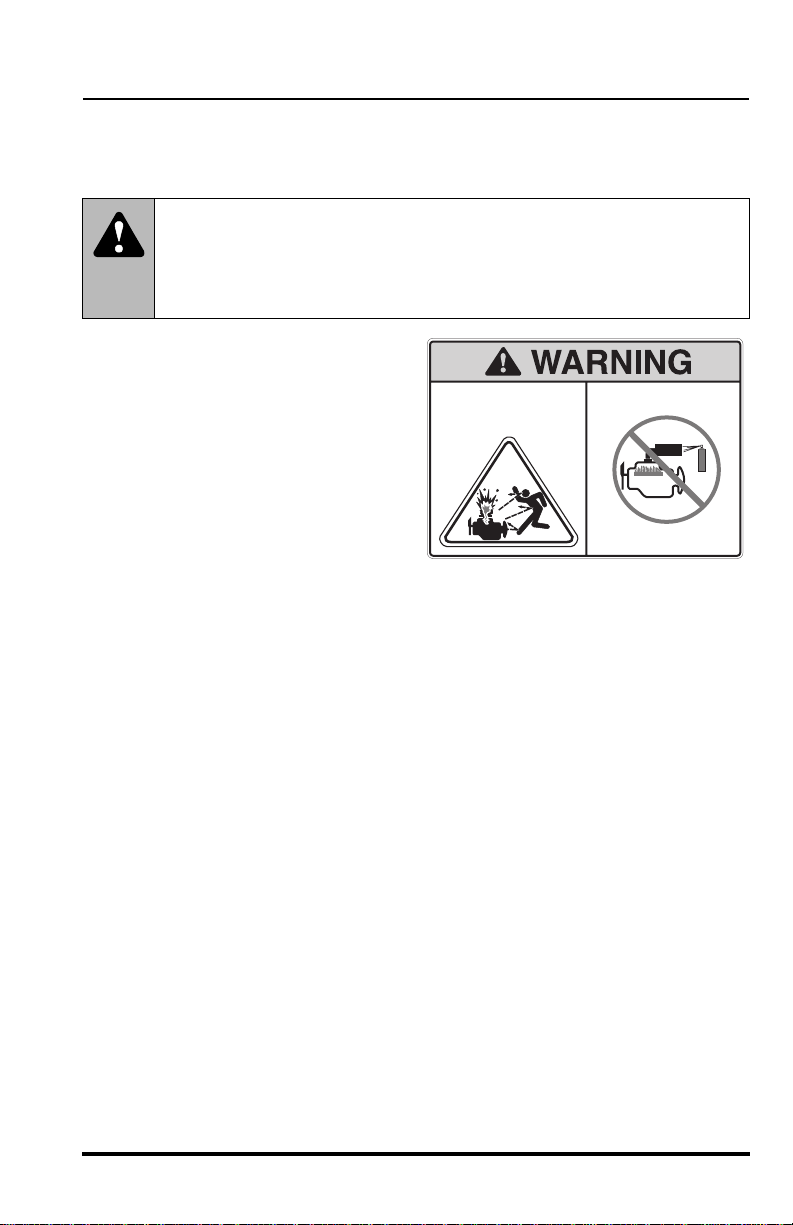

C. Ether or High Energy Starting Aids

The engine utilizes a grid heating system inside the induction

manifold for cold starting conditions.

WARNING: This diesel engine uses a grid heating system

inside the induction manifold. DO NOT use ether or any high

energy fuels to assist starting. An explosion may cause death or

serious personal injury or engine damage.

DO NOT use ether or any

other high energy starting

aids during cold starting. An

engine explosion can result

in death or serious personal

injury.

D. Hydraulic Fluid

DO NOT attempt to repair or tighten any hydraulic hoses or fittings

while the engine is running or when the hydraulic system is under

pressure. Fluid in the hydraulic system is under enough pressure

that it can penetrate the skin causing death or serious personal

injuries.

ENGINE EXPLOSION can

result in death or serious

personal injury.

DO NOT use Ether or other

high energy starting aids.

Engine equipped with

grid heating system.

4110460

OU1470

HOT HYDRAULIC FLUID WILL CAUSE SEVERE BURNS. Wait

for fluid to cool down before disconnecting lines.

DO NOT use your hand to check for leaks. Use a piece of

cardboard or paper to search for leaks. Wear gloves to protect

hands from spraying fluid.

Hydraulic fluid can cause permanent eye injury. Wear appropriate

eye protection and stop engine. Relieve pressure before

disconnecting lines by moving all joysticks back and forth through

all functions.

If anyone is injured by or if any hydraulic fluid is injected into the

skin, obtain medical attention immediately or gangrene may result.

Model 8042 Rev. 11/03

11

Safety Practices

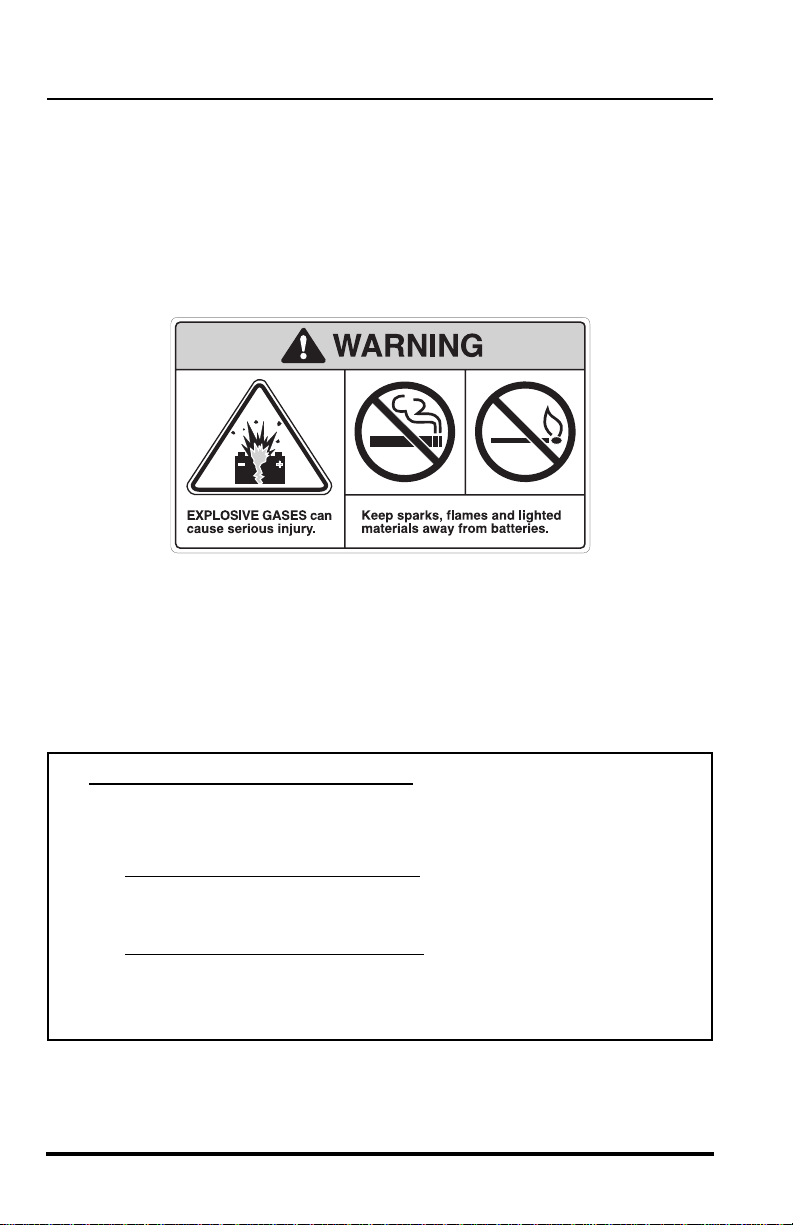

E. Batteries

The following WARNING is intended to supplement and does not

replace the warnings and information provided on the battery by the

battery manufacturer.

When jump starting the vehicle, carefully follow instructions found

under “Jump Starting” on page 57.

-

Keep sparks, flames and lit smoking materials away from the

battery at all times. Lead acid batteries generate explosive gases.

Severe chemical burns can result from improper handling of battery

electrolyte. Wear safety glasses and proper protective gear when

handling batteries to prevent electrolyte from coming in contact with

eyes, skin or clothing.

OS0621

Battery Electrolyte First Aid:

• External Contact — Flush with water.

• Eyes — Flush with water for at least 15 minutes and

get medical attention immediately

• Internal Contact — Drink large quantities of water. Follow

with Milk of Magnesia, beaten egg or vegetable oil.

Get medical attention immediately

IMPORTANT! In case of internal contact, DO NOT give fluids that

would induce vomiting!

12

.

.

Model 8042 Rev. 11/03

Safety Practices

5. Moving Parts Hazard

DO NOT place limbs near moving parts. Severing of any body part can

result.

Turn OFF engine and wait until fan and belts stop moving before

servicing.

MOVING PARTS can cut.

Keep clear of fan and belts

while engine is running.

MOVING PARTS can entangle.

OT0810

6. Lowering Boom or Falling Load Hazard

DO NOT get under a raised boom unless it is blocked up safely. Always

empty the attachment of any load and block the boom up before doing

any servicing that would require the boom to be raised.

NEVER allow anyone to walk or stand under the boom. A lowering

boom or falling load can result in death or serious personal injury.

Model 8042 Rev. 11/03

13

Safety Practices

Operational Considerations

1. Preparation and Prevention

Know the location and function of all vehicle controls.

Make sure all persons are away from the vehicle and that the travel

select lever is in the (N) NEUTRAL position with the parking brake

switch engaged before starting the engine.

Holes, obstructions, debris and other worksite hazards can cause death

or serious personal injury. Always walk around and look for these and

other hazards before operating the vehicle in a new worksite.

Prevent accidents when you move the vehicle around the worksite.

Know the rules for movement of people and vehicles on the worksite.

Have a person act as a lookout for you. Follow the instructions of

signals and signs.

DO NOT operate the vehicle unless all hazard and instructional decals

are in place and readable. (Replace all missing, illegible, or damaged

decals.)

2. Clearances

Look out for and avoid other personnel, machinery and vehicles in the

area. Use a spotter if you do not have a clear view of conditions that

affect clearances. Travel with the boom fully retracted and lowered as

far as possible while still maintaining enough ground clearance for

conditions.

Always check boom clearances carefully before driving underneath

door openings, bridges, etc.

Always check for power lines when raising the boom. Beware of

overhead wires. Contact with electrical power lines can result in

electrocution. See “Electrocution Hazards” on page 15.

3. Visual Obstruction

Dust, smoke, fog, etc. can decrease vision and cause an accident.

Always stop or slow the vehicle until the obstruction clears and the

worksite is visible again. Have a lookout person assist you.

Where the load will obstruct the operator’s vision, it is recommended

that the vehicle be operated in REVERSE, looking backwards in the

direction of travel. Travel at a slower speed and get someone to direct

you.

14

Model 8042 Rev. 11/03

Safety Practices

4. Underground Hazards

Know the location of all underground hazards before operating this

vehicle in a new area or worksite. Electrical cables, gas and water

pipes, sewer, or other underground objects can cause death or serious

personal injury. Contact your local underground utility service or diggers

hotline to mark all underground hazards.

5. Electrocution Hazards

NEVER operate this vehicle in an area where overhead power lines,

overhead or underground cables, or other power sources may exist

without first requesting that the appropriate power or utility company deenergize the lines, or take other suitable precautions.

OS0063

Model 8042 Rev. 11/03

15

Safety Practices

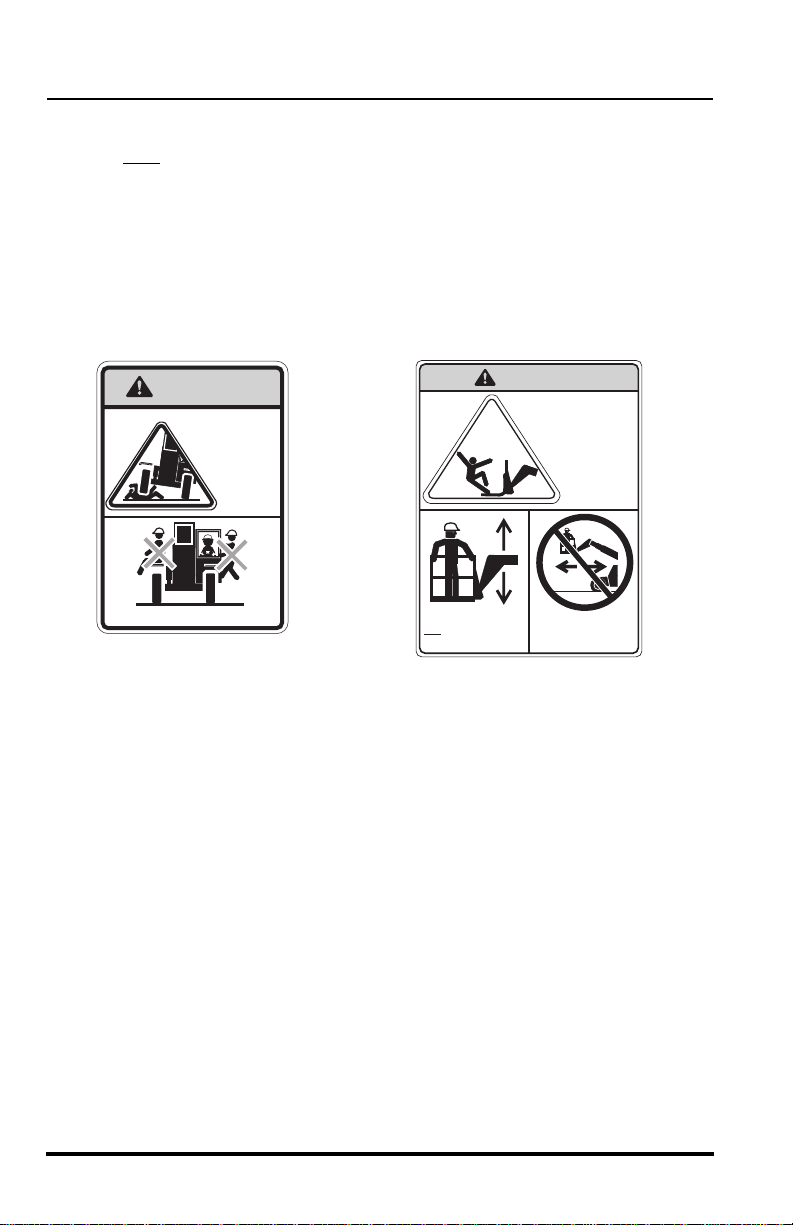

6. Elevating Personnel

Use only a compliant work platform meeting the ASME B56.6 standards

for lifting and lowering personnel. NEVER transport personnel in a work

platform for even the shortest distance.

Death or serious personal injury can occur if these rules are not

obeyed. Riders can fall and be crushed or run over. Avoid accidents.

For other specific precautions, see “Elevating Personnel” on page 82.

WARNING

CRUSHING,

falling off

vehicle can

cause death

or serious

Allow no riders

AVOID

injury

OH3180

WARNING

FALLING OFF ATTACHMENT,

Lift or lower personnel

only in a compliant

work platform.

can result in death or

serious injury.

DO NOT TRAVEL

with personnel in

a work platform.

4110389

OU0620

16

Model 8042 Rev. 11/03

Safety Practices

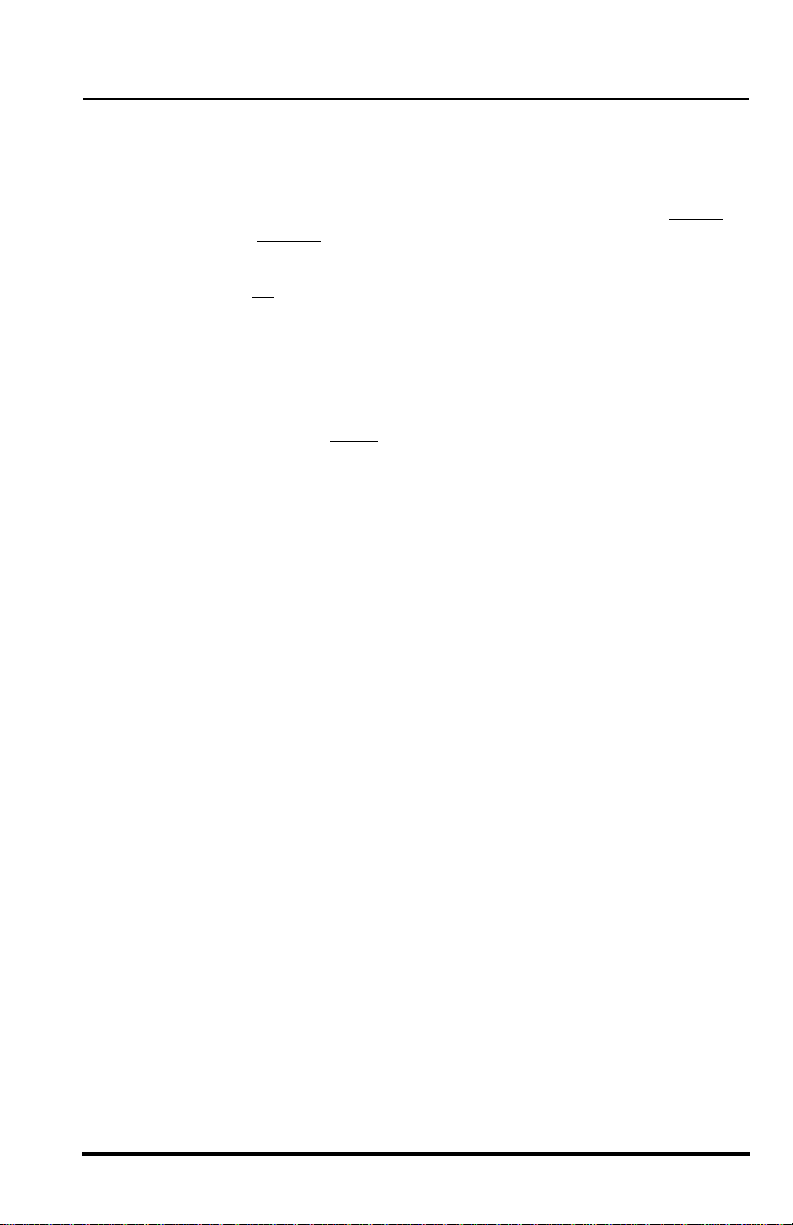

7. Tip Over Hazard

DANGER

VEHICLE

TIPOVER

can result

in death or

serious injury.

DO NOT

travel

with the

boom

raised.

DO NOT raise

boom while

on a slope

unless load

is level.

Traveling with the boom raised is dangerous and can cause tipover.

Keep the boom as low as possible. Travel with extreme caution

the slowest

possible speed.

Keep the vehicle under control at all times. When negotiating turns,

slow down and turn the steering wheel in a smooth sweeping motion.

Avoid jerky turns, starts or stops. Reduce vehicle speed on rough

ground and slopes.

DO NOT exceed the rated lift capacity of the vehicle as structural

damage and unstable conditions will result.

To ensure that the vehicle is positioned in the most stable condition

before operating an attachment, use the frame sway control (frame tilt)

to level the vehicle. The vehicle is level when the frame level indicator

gauge reaches (0°) zero degrees.

MAINTAIN

proper tire

pressure at

all times.

and at

OS0086

If the vehicle cannot be leveled using the frame sway control, reposition

the vehicle.

Frame swaying left or right with the boom raised above horizontal is

dangerous. Always use the frame sway control to level the vehicle

before

raising the boom above horizontal, with or without a load. If the

vehicle cannot be leveled using frame sway control, reposition the

vehicle.

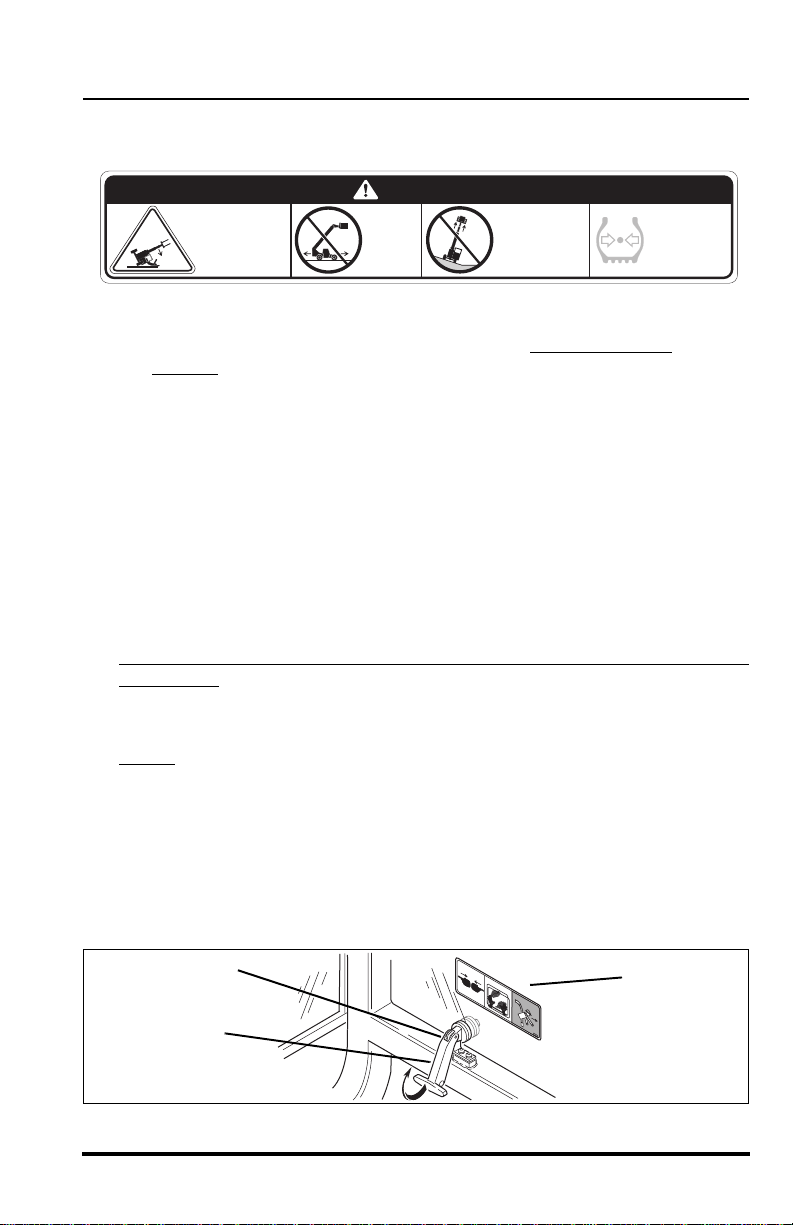

8. Emergency Exit Rear Window

The rear window (1) in the enclosed cab can be used as an emergency

exit by removing the latch pin (2) located on the window latch (3). The

window is then free to swing open.

2

3

Model 8042 Rev. 11/03

1.

2.

3.

4

109

7

91

1

OH1730

17

Safety Practices

9. Tire Pressure

DANGER

VEHICLE

TIPOVER

can result

in death or

serious injury.

DO NOT

travel

with the

boom

raised.

MAINTAIN proper tire pressures at all times. An underpressurized

tire(s) adversely affects vehicle stability. If proper tire pressures are not

maintained, this vehicle can tip over.

To ensure proper vehicle stability, check all four tire pressures before

operating the vehicle.

10.Do Not Jump

DANGER

AVOID CRUSHING

if vehicle tips.

Jumping can

result in death

or serious

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

injury.

DO NOT raise

boom while

on a slope

unless load

is level.

OH3190

MAINTAIN

proper tire

pressure at

all times.

OS0085

If a vehicle ever becomes unstable and starts to tip over:

• BRACE YOURSELF and STAY WITH THE VEHICLE,

• KEEP YOUR SEAT BELT FASTENED,

• HOLD ON FIRMLY and

• LEAN AWAY FROM THE POINT OF IMPACT.

Indecision and trying to escape from a tipping vehicle can result in

death or serious personal injury.

18

Model 8042 Rev. 11/03

Safety Practices

11.Slopes

DO NOT park the vehicle on an incline and leave it unattended.

• Driving across a slope is dangerous, as unexpected changes in

the slope can cause tipover. Ascend or descend slopes slowly

and with caution

• Ascend or descend slopes with the heavy end of the vehicle

pointing up

NOTE: The rear of the vehicle is normally considered the heavy end unless

the carriage is fully loaded. In this case the front of the vehicle is now the

heavy end.

• Unloaded vehicles should be operated on all slopes with the

carriage pointing down

• On all slopes, the load must be tilted back and raised only as far

as necessary to clear the ground.

• When operating on a downhill slope, reduce travel speed and

downshift to a low gear to permit compression braking by the

engine and aid the application of the service brakes.

.

the slope.

the slope.

12.Falling Load Hazard

DO NOT exceed the total rated load capacity of the specific type fork

being used. Each fork is stamped with a maximum load capacity. If the

capacity is exceeded, forks may break. See “Fork Ratings” on page 81.

DO NOT downshift at a high ground speed. Sudden slowing can cause

the load to drop off the forks.

13.Ventilation

Sparks from the electrical system and the engine exhaust can cause an

explosion. DO NOT operate this vehicle in an area with flammable dust

or vapors unless good ventilation has removed the hazard.

Carbon monoxide fumes from the engine exhaust can cause suffocation

in an enclosed area. Good ventilation is very important when operating

this vehicle.

Model 8042 Rev. 11/03

19

Safety Practices

Equipment Considerations

WARNING: DO NOT modify or alter (weld, drill, etc.) any

part of this vehicle without first consulting JLG. Modifications can

weaken the structure creating a hazard that can cause death or

serious personal injury.

DO NOT by-pass or disconnect any electrical or hydraulic circuits.

Consult the JLG Service Department or your local Sky Trak Distributor

if any circuit is malfunctioning.

DO check for frayed or cut seat belt webbing, damaged buckles or loose

mounting brackets. Replace immediately if required.

ALWAYS wear a seat belt when operating the vehicle.

DO check tire pressure on all four tires. Add air if required.

DO check the condition of all four rims. Check for bent flanges and/or

bead mounting areas.

DO check the parking brake/transmission de-clutch operation. Refer to

the test procedures on page 173. Repair immediately if required.

DO keep all non-skid surfaces clean and free of debris. Replace if worn,

damaged or missing.

DO check the condition of decals. Replace decals if missing, damaged

or illegible. The following pages show the proper location of the decals.

20

Model 8042 Rev. 11/03

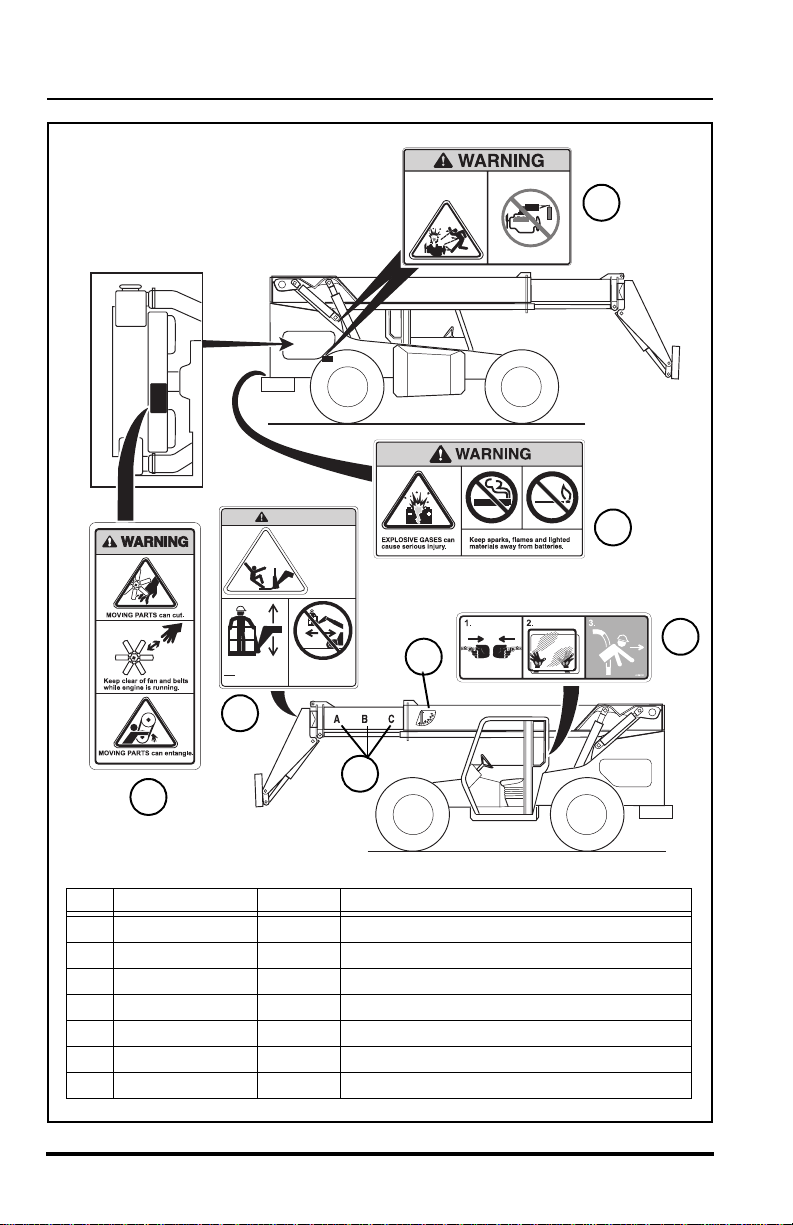

Safety Practices

3

7

2

WARNING

AVOID

CRUSHING,

falling off

vehicle can

cause death

or serious

injury

1. Read operator's manual

before operating.

2. Fasten seat belt.

3. Allow no riders.

4. Use a compliant

work platform to lift

or lower personnel.

4

1

Allow no riders

Item Part Number Quantity Decal Description

1

2 4110188 1 Vehicle Rollaway Warning

3 4108991 1 Electrocution Danger

4 7301676 1 Load Chart Booklet

5 4110137 1 Tipover danger

6 4110187 1 Do Not Jump Danger

7 4110188 1 Safety Instructions

4110188 1 No Riders Warning

5

6

DANGER

AVOID CRUSHING

if vehicle tips.

Jumping can

result in death

or serious

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

OH17431

injury.

Model 8042 Rev. 11/03

21

Safety Practices

Lift or lower personnel

only in a compliant

work platform.

3

WARNING

FALLING OFF ATTACHMENT,

can result in death or

serious injury.

DO NOT TRAVEL

with personnel in

a work platform.

ENGINE EXPLOSION can

result in death or serious

personal injury.

DO NOT use Ether or other

high energy starting aids.

7

Engine equipped with

grid heating system.

4110460

2

6

5

4110389

4

1

Item Part Number Quantity Decal Description

1

2 4110172 1 Explosive Gases Warning

3 4110389 1 Carrying Personnel Warning

4 4107442 1 Boom Extend Letters

5 4105262 1 Boom Angle Indicator

6 4109791 1 Emergency Exit (Enclosed Cab Only)

7 4110460 2 Ether Starting Warning

22

4110184 2 Moving Parts Warning

Model 8042 Rev. 11/03

OH2894

Operation

Operation

Operator Controls

Accelerator Pedal

Pressing down the accelerator pedal (8) increases engine and hydraulic

speed of the vehicle. The pedal is spring-loaded to return to idle speed.

NOTE: The accelerator pedal is also used to activate the Cummins ECM

Diagnostic system. With the ignition switch in the RUN position, depress

and release the pedal three times to activate the system.

Service Brake Pedal

Pressing down the brake pedal (9) decreases the speed of the vehicle by

applying the service brakes located in the axles. In the event of engine

power loss, the service brake pedal can also be used for braking. It also

activates and locks the rear axle to frame lock system when boom angles

are greater than 40°, as long as the pedal is depressed.

Steering Wheel

Turning the steering wheel (10) to the left or right steers the vehicle in the

corresponding direction. Any one of the steering modes are selectable.

Refer to “Steering Select Switch” on page 25.

Horn Button

Pressing the button (11) sounds the horn.

11

9

Model 8042 Rev. 11/03

10

8

MA8560

23

Operation

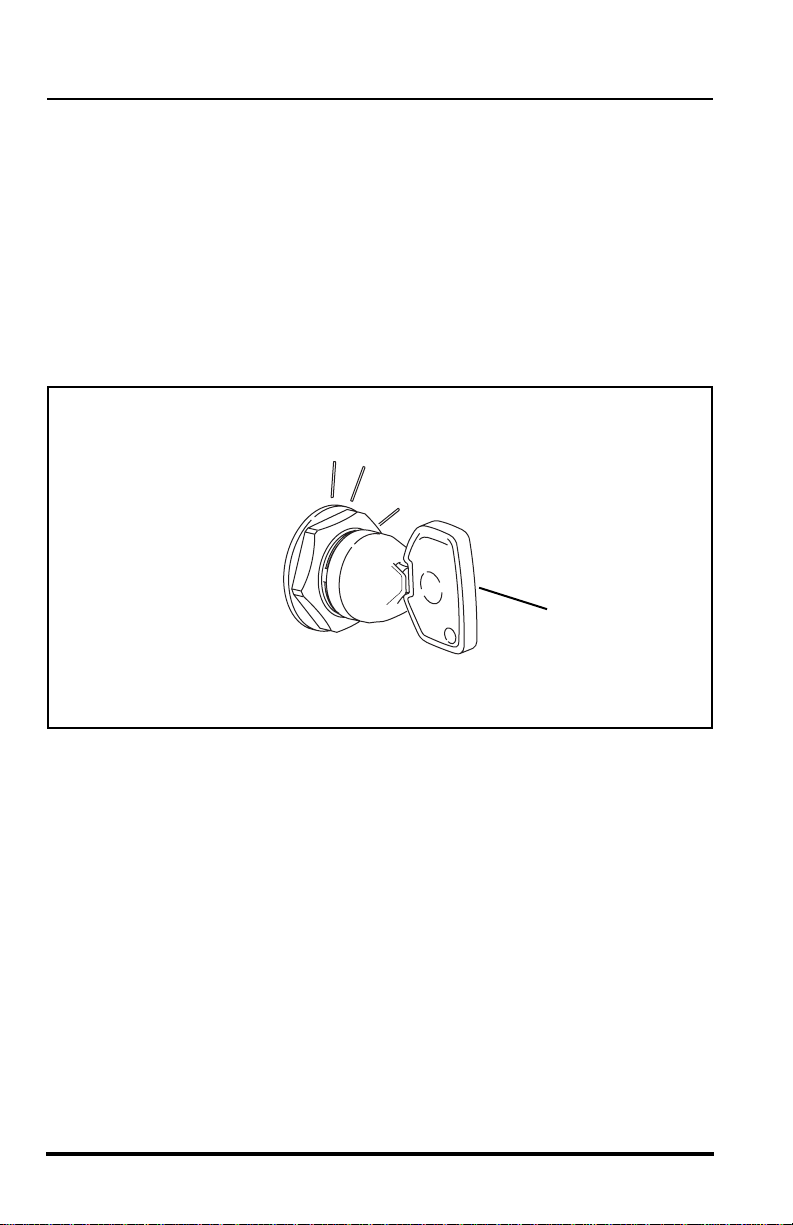

Ignition Switch

Using the ignition switch key (1), the switch may be turned clockwise from

the OFF (2) position to the RUN (3) and START (4) positions. The START

position is spring-loaded to return to the RUN position and must be

manually held in place for starting.

OFF position (2) — The entire electrical system is shut down.

RUN position (3) — All controls and indicators are operable.

START position (4) — Engages starter motor to crank the engine when the

parking brake switch is engaged and the transmission is in NEUTRAL.

2

3

4

1

24

OT0680

Model 8042 Rev. 11/03

Operation

Steering Select Switch

This vehicle has one steering select switch (5) with three positions. The

switch is located in the lower switch bank (6) on right side dash panel.

Refer to “Steering Modes” on page 65 for detailed information.

6

Model 8042 Rev. 11/03

5

OH3240

25

Operation

Park Brake Switch

The Parking Brake Switch (1) has two positions:

ENGAGED............ toggle switch downward

P

OS0121

P

DISENGAGED........... toggle switch upward

OS1323

The Parking Brake Switch (1) must be ENGAGED to permit engine starting.

A red LED, on the parking brake switch, and a light in the instrument cluster

will indicate the brake is ENGAGED.

The parking brake may be used to stop in an EMERGENCY situation.

However, use caution because the stop will be abrupt and the operator and

the load may be jolted forward unexpectedly.

With boom angles greater than 40°, this switch activates the locked mode of

the Stabil-TRAK system.

1

26

OH3240

Model 8042 Rev. 11/03

Operation

N D

Neutral Lock Lever

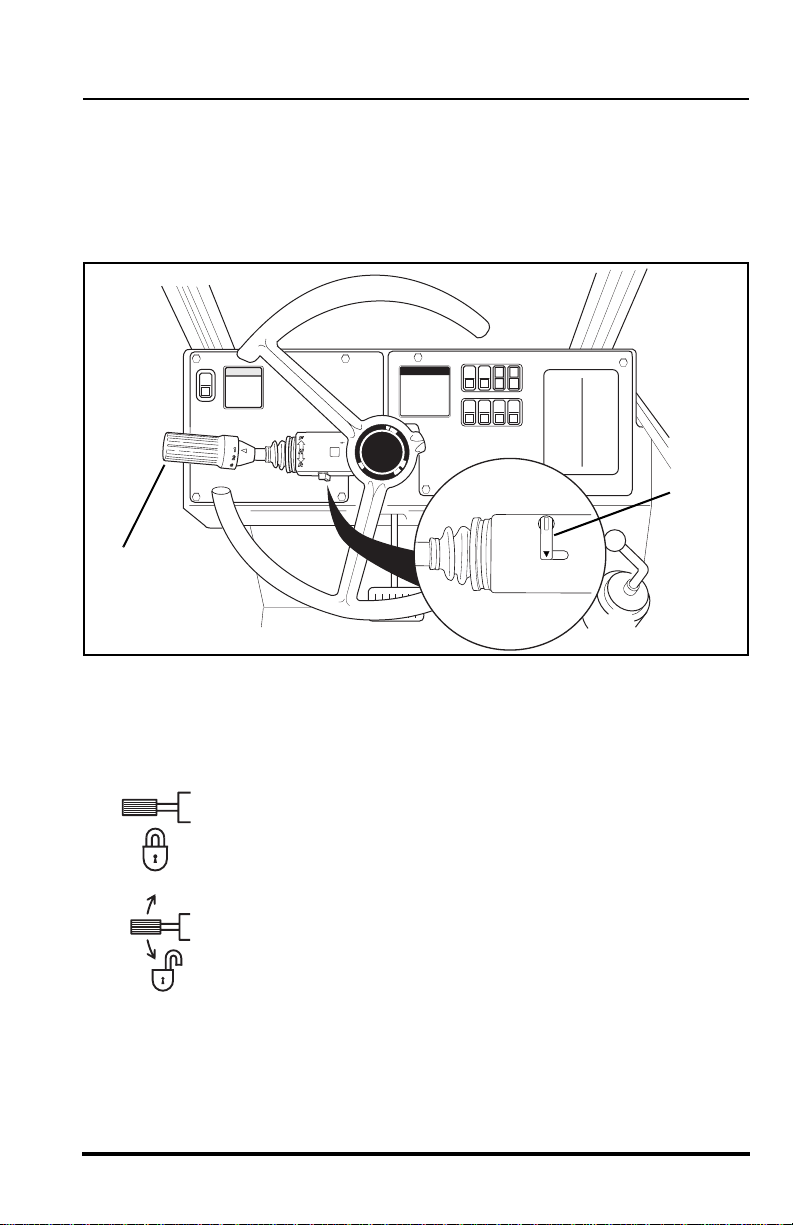

The Travel Select Lever (2) is equipped with a neutral lock. The Neutral Lock

Lever (3) locks the Travel Select Lever in NEUTRAL or unlocks the Travel

Select Lever so that it can be moved into the FORWARD or REVERSE drive

position.

3

2

OH3250

To lock the Travel Select Lever (2) in the NEUTRAL position, place the lever

in the NEUTRAL position and move the Neutral Lock Lever (3) to the (N)

NEUTRAL LOCK position.

To unlock, move the Neutral Lock Lever to the (D) DRIVE position.

N = NEUTRAL LOCK ...................all the way LEFT

OT0570

D = DRIVE................................... all the way RIGHT

OT0580

Model 8042 Rev. 11/03

27

Operation

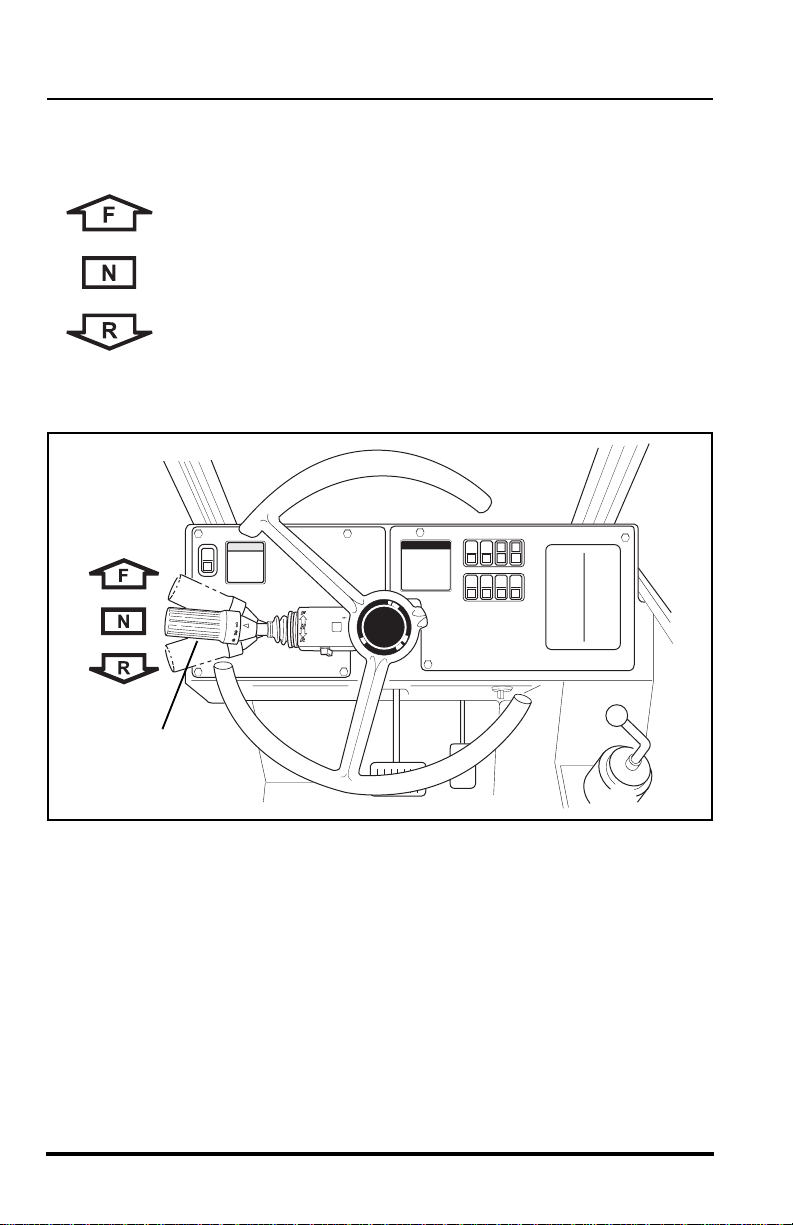

Travel Select Lever

The Travel Select Lever (1) has three positions to select direction of travel:

F = FORWARD (2)..........all the way FORWARD

N = NEUTRAL (3)...........CENTER position

R = REVERSE (4) .......... all the way REARWARD

OS0340

2

3

4

1

OH3260

To change travel selections, move the lever FORWARD or REARWARD to

the desired selection.

When the Travel Select Lever is shifted to REVERSE, the back-up alarm will

automatically sound.

NOTE: The Travel Select Lever must be in the (N) NEUTRAL position to

permit engine starting and when boom angles are greater than 40°, shifting

into NEUTRAL activates the locked mode of the Stabil-TRAK system.

28

Model 8042 Rev. 11/03

Operation

Gear Select Lever

The Gear Select Lever (5) has a twist grip handle with four positions.

Vehicles have four forward gears and three reverse gears.

5

OH3270

Use first gear for highest torque and pulling power. Use higher gears for

higher ground speed. The recommendations listed in the table that follows

are guidelines only. Always use good judgement when traveling with a load.

Recommended Gear/Speed for Various Load/Travel Conditions

Load Size Surface Gear Speed

No Load Smooth 4th* 0 to 20 mph (0 to 32 km/h)

Improved 3rd 0 to 14 mph (0 to 23 km/h)

Rough 2nd 0 to 6 mph (0 to 9,7 km/h)

Load Smooth 3rd 0 to 14 mph (0 to 23 km/h)

up to 4,500 lbs Improved 2nd 0 to 6 mph (0 to 9,7 km/h)

(up to 2.041 kg)

Load Smooth 3rd 0 to 14 mph (0 to 23 km/h)

4,500 to 8,000 lbs Improved 2nd 0 to 6 mph (0 to 9,7 km/h)

(2.041 to 3.629 kg)

Rough 2nd 0 to 6 mph (0 to 9,7 km/h)

Rough 1st 0 to 3.5 mph (0 to 5,6 km/h)

*NEVER travel in 4th gear when carrying a load.

Model 8042 Rev. 11/03

29

Operation

Boom Control Lever

The boom control lever (1) is a joystick with variable motion from the center

to control the boom functions:

Boom Lift .............................move lever backward

Boom Lower ........................move lever forward

Boom Extend....................... move lever to the right

OH0170

Boom Retract ...................... move lever to the left

Two boom functions can be accomplished at the same time by moving the

lever into the proper quadrant. For example: moving the lever forward and to

the left will lower and retract the boom simultaneously.

The speed of the function depends directly upon the amount of lever travel

in the corresponding direction. Increasing the engine speed will also

increase the function speed.

1

30

OH2900

Model 8042 Rev. 11/03

Operation

Attachment Tilt and Frame Sway Control Lever

The attachment tilt and frame sway control is a joystick (2) with four

perpendicular motions from the center to control two attachment tilt

functions and two frame sway functions:

Frame Sway Left ................. move lever to the left

Frame Sway Right............... move lever to the right

Attachment Tilt Down...........move lever forward

OH0410

Attachment Tilt Up ...............move lever backward

The attachment is self leveling and will retain any set angle throughout

boom lifting, lowering, retracting or extending operations.

2

OH2900

Model 8042 Rev. 11/03

31

Operation

Seat Belt

WARNING: Death or serious personal injury may result

from failure to wear the seat belt installed on this vehicle. The seat

belt is a critical component of the Operator’s protective Structure,

and is provided for the operator’s protection in case of vehicle

upset. The seat belt MUST be worn whenever this vehicle is operated.

IMPORTANT! Inspect the seat belt every time it is used, looking for cut or

worn webbing, or any defect in the latch assembly. If any wear or damage is

noted, DO NOT operate the vehicle until the seat belt is replaced.

Before the engine is started, adjust the seat as required for position and

comfort. Then adjust the seat belt as follows:

1. Grasp both free ends of the belt and make certain that the belt webbing is not twisted or entangled in any portion of the seat assembly.

2. With your back straight in the seat, couple the retractable end or the

male end of the belt into the receptacle (buckle) end of the belt.

3. With the belt buckle as low on your body as possible, pull the

retractable end of the belt or the free end of the belt away from the

buckle until it is tight across the lap.

STANDARD 2 INCH WIDE

SEAT BELT

1

4. To release the belt latch, depress the red button (1) or lift the black

cover (2) of the buckle (dependant on belt style installed), and pull

the free end (3) from the buckle.

An optional 3 inch wide seat belt is available for those locations that require

a 3 inch seat belt.

3

32

OPTIONAL 3 INCH WIDE

SEAT BELT

2

Model 8042 Rev. 11/03

3

OL0430

Operator’s Seat Adjustment

The operator’s seat can be adjusted three ways:

A. Fore and Aft Adjustment

Pull the handle (4) outward to adjust the seats forward and

backward. Release the handle to lock the seat in the desired

position.

B. Suspension Adjustment

Turn the knob (5) on the front of the seat (6) to adjust the

suspension to correspond with the operator’s weight. Turn

clockwise to increase stiffness. Turn counter-clockwise to reduce

the stiffness.

C. Backrest Angle Adjustment

The angle of the seat backrest can be adjusted to suit the operator.

Move the lever (7) located on the left side of the seat backrest (8) to

adjust the angle.

Operation

8

6

5

4

Model 8042 Rev. 11/03

7

OH1820

33

Operation

Instruments and Indicators

Hourmeter

OS0260

The hourmeter (1) records engine operating hours and has a total readout

of 9,999.99 hours. It is located at the lower portion of the instrument cluster

(2) on the right side console.

Fuel Gauge

OH2470

The fuel gauge (3) indicates the quantity of fuel in the fuel tank. The gauge

is located in the center of the instrument cluster (2) on the right side

console. Capacity of the fuel tank is 37 gallons (140 liters) total capacity

with a usable capacity of 35.6 gallons (135 liters).

3

34

P

2

0000 00

1

Model 8042 Rev. 11/03

OH1810

Operation

Instrument Cluster Light Test

Test the bulbs in the instrument cluster before starting the engine.

Turn the ignition switch to the RUN position, ALL nine lights in the

instrument cluster will come ON for a few seconds and then go out. Replace

any bulbs that DO NOT come ON during this test. These lights will warn the

operator if an abnormal condition should arise during operation and will also

inform the operator when the Stabil-TRAK system is active, road lights are

on high beam or the turn signals are activated.

(4)

(5) (6)

(7) (8)

(9) (10)

(11) (12)

Position of corresponding lights:

• Alternator Charging Light (4)

• Park Brake Light (5)

• Engine Oil Pressure Light (6)

• Engine Coolant Temperature Light (7)

• Hydraulic Tank Temperature Light (8)

• Transmission Temperature Light (9)

• High Beam Light (10)

• Stabil-TRAK Light (11)

• Turn Signal Light (12)

P

0000 00

OH1810

Model 8042 Rev. 11/03

35

Operation

Function Indicator Lights

A. Stabil-TRAK Indicator Light

OH2500

The Stabil-TRAK light (1) will come ON when the system has been

activated. The rear axle will lock when one or more of the following

conditions exist with the boom above a 40° angle.

• Parking Brake Switch engaged

• Travel select lever in (N) NEUTRAL

• Service brake pedal depressed and held

With the boom above a 40° angle and traveling in a forward or reverse

drive gear, the Stabil-TRAK Light (1) will go OFF. In this condition the

rear axle is unlocked and is allowed to pivot, but will respond slowly

changes in terrain.

ALWAYS be sure the Stabil-TRAK system is functioning properly when

operating vehicle. Refer to “Understanding the Stabil-TRAK System”

later in this manual for a detailed explanation of this system.

DANGER: Vehicle tipover can result in death or serious

injury. Traveling with the boom raised is dangerous and can cause

vehicle tipover. Keep the load as low as possible. Travel with

extreme caution

and at the slowest possible speed.

to

36

P

0000 00

1

OH1810

Model 8042 Rev. 11/03

B. Park Brake Light

Operation

P

OH2480

The park brake light (2) illuminates any time the park brake is applied

and the ignition switch is in the RUN position.

C. High Beam Light

(used with optional road

light package only)

The high beam light (3) illuminates when the road option headlights are

on full (high) beam and will turn OFF when the headlights are switched

to low beam.

OH2490

D. Turn Signal Light

(used with optional road

light package only)

The turn signal light (4) will

illuminate and flash when the road option turn signals are activated in

either direction or when the road option hazard lights are activated.

2

P

OH2510

Model 8042 Rev. 11/03

0000 00

3

4

OH1810

37

Operation

Warning Indicator Lights

There are five additional indicator lights in the instrument cluster that will

illuminate during critical circumstances. All five warning indicator lights

demand immediate attention and vehicle servicing. In many cases, the

vehicle should be shut down AS SOON AS PRACTICAL

mechanical failure.

The five warning indicator lights are:

A. Engine Coolant Temperature Warning Indicator Light

OH2520

The engine coolant temperature warning light (1) illuminates when

the engine coolant temperature is too high; above 210° F (99° C).

SHUT THE VEHICLE DOWN AS SOON AS PRACTICAL.

B. Transmission Temperature Warning Indicator Light

OH2530

to prevent serious

The transmission temperature warning light (2) illuminates when

the transmission oil temperature is too high; above 250° F (121° C).

Stop and idle the vehicle in NEUTRAL, allowing time for cooling. If

the light does not go out after two minutes, shut the vehicle down.

C. Hydraulic Oil Temperature Warning Indicator Light

OH2540

The hydraulic oil temperature warning light (3) illuminates when the

hydraulic oil temperature is too high; above 195° F (91° C). Stop

and idle the engine, allowing time for cooling. If the light does not go

out after five minutes, shut the vehicle down.

38

Model 8042 Rev. 11/03

Operation

5

4

1

P

3

2

0000 00

D. Engine Oil Pressure Warning Indicator Light

OH2550

The engine oil pressure warning indicator light (4) will come ON

during engine start-up and go OUT once the engine has started.

This is normal. If the light comes ON while the engine is running,

this indicates that the engine oil pressure is too low.

SHUT THE VEHICLE DOWN AS SOON AS PRACTICAL.

E. Alternator Charging Warning Indicator Light

OH2560

The alternator charging warning light (5) illuminates when the

charging system is not working properly. Service the engine

alternator.

OH1810

Model 8042 Rev. 11/03

39

Operation

Function Indicator Lights

There are two additional indicator lights located on the right side of the front

dash:

A. Engine Air-Intake Heater Indicator

OU0040

The engine air-intake heater indicator light (1) located in the upper

switch bank on the right side of the front dash. This light illuminates,

with the ignition switch in the RUN position, any time the ambient

temperature drops below 40° F (4° C). The engine grid heater then

becomes active and the engine should not be cranked until the light

goes OFF. Once the light goes OFF it indicates that the grid heater

is at the proper temperature and the engine is ready to start.

NOTE: This indicator light may come ON when the engine is running to indicate that the post heat function is active. This is a normal condition when

ambient temperatures are below 40° F (4° C).

3

40

1

Model 8042 Rev. 11/03

2

4

OH3280

B. Engine Function Indicator Lights

The engine function indicator lights (2) are located in the upper

switch bank on the right side of the front dash. The light indicates

any faults that arise in the engine during operation. The light

contains a RED light (3) and a AMBER light (4).

If the RED light (3) comes ON during operation, STOP

IMMEDIATELY and diagnose the fault by activating the ECM

diagnostic system. Activate the system with the accelerator pedal.

Activate the system and read the code as indicated by the RED

light. Contact your local Cummins dealer for an explanation of these

codes or refer to the Cummins Engine Owners Manual or call the

Cummins Customer Assistance Center at 1-800-343-7357.

If the AMBER light (4) comes ON during operation, the engine

diagnostic system has detected a fault within the engine. Stop the

engine and diagnose the fault by activating the ECM diagnostic

system.

Activate the system and read the code as indicated by the light.

Contact your local Cummins dealer for an explanation of these

codes or refer to the Cummins Engine Owners Manual or call the

Cummins Customer Assistance Center at 1-800-343-7357.

Cummins ECM Diagnostic System Activation

Operation

43

OH3290

the engine

With the engine OFF, turn the ignition switch to the RUN position.

DO NOT start the engine.

Completely depress and release the accelerator pedal three times.

This will activate the system, both the AMBER light and RED light

will come ON momentarily and then both will begin to flash the

code. If the system has been activated with the accelerator pedal

and no faults are present, both the AMBER light and the RED light

will come ON and stay ON.

ECM Light Code Identification

The AMBER light will flash one time to identify the start of the code

followed by a one or two second pause. Then the RED light will

flash the code sequence, pausing for one or two seconds between

numbers. The AMBER light will flash once after the RED light has

flashed the code to signify the end of that fault code.

Model 8042 Rev. 11/03

41

Operation

Frame Level Indicator

The indicator (1) is mounted on the top inside of the Operator's Protective

Structure (cab). This is a bubble type indicator which allows the operator to

tell if the vehicle has been positioned in a level condition. Always frame

sway the vehicle either right or left until the indicator reads zero degrees

(0°). If zero cannot be achieved, then reposition the vehicle until it is level

before placing the load.

NOTE: Maximum frame sway is 10° in either direction.

1

OS0232

Boom Angle Indicator

The boom angle indicator is a plumb arrow (2) with angular graduations (3)

from minus 10° to plus 80°. It is located on the left side of the boom and is

visible from the operator’s position. Use this indicator to determine the

boom angle when reading the capacity chart (see “Using The Capacity

Chart”).

42

4105262

2

3

OH0302

Model 8042 Rev. 11/03

Operation

Rear View Mirrors

Two rear view mirrors are provided to aid the operator's rear vision. A

rectangular flat lens mirror (4) is mounted on the upper left of the cab. A

convex lens mirror (5) is mounted on the right side of the frame. Both

mirrors are adjustable to obtain the best rear view by the operator.

5

4

OH1830

Model 8042 Rev. 11/03

43

Operation

Optional Controls

Auxiliary Attachment Control Lever

The auxiliary attachment control lever (1) controls the functions of an

optional attachment that is mounted to the vehicle and requires a hydraulic

supply for operation. Some of the optional attachments that require auxiliary

hydraulics are: Side Tilt Carriage, Swing Carriage, Auger, and 3 Foot Truss

Boom w/Winch.

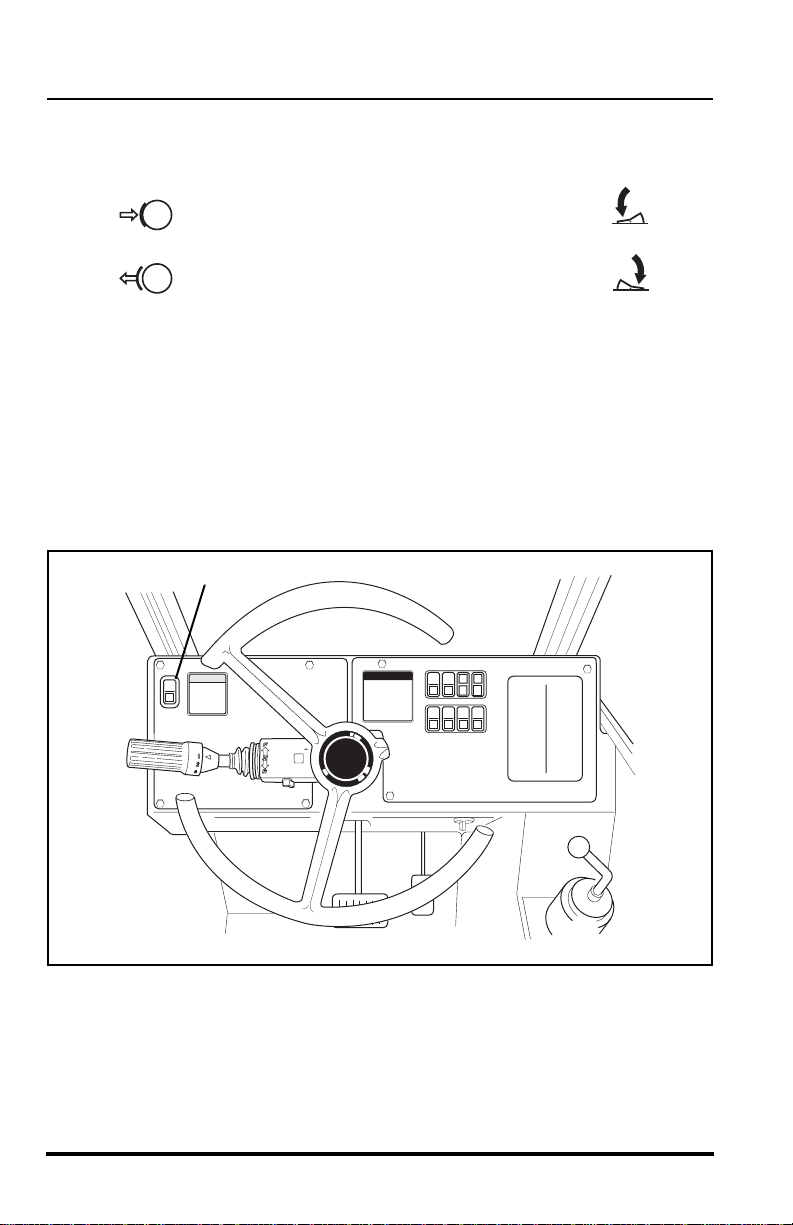

When the control lever is moved to the right

it will provide

hydraulic system pressure through the female disconnect

coupling for the auxiliary attachment. Hydraulic fluid will return

OH0431

to the tank through the male disconnect coupling.

When the control lever is moved to the left it will provide

hydraulic system pressure to the male disconnect coupling for

the auxiliary attachment. Hydraulic fluid will return to the tank

OH0451

through the female disconnect coupling.

The control lever will provide the following typical functions for each specific

attachment if they are connected properly. Operation will be reversed if

incorrectly connected. We recommend reversing the disconnect couplings

on the hoses that are supplied with the attachment if operation is reversed.

Side Tilt Carriage Operation:

• Control Lever right ..................... tilt right

• Control Lever left ....................... tilt left

Swing Carriage Operation:

• Control Lever right ..................... swing right

• Control Lever left ....................... swing left

Auger Operation:

• Control Lever right ..................... auger dig

• Control Lever left ....................... auger retract

3 Foot Truss Boom w/Winch Operation:

• Control Lever right ..................... cable extends

• Control Lever left ....................... cable retracts

44

1

OH2910

Model 8042 Rev. 11/03

Operation

Worklight Switch (Front, Rear & Boom Worklights)

OH2570

This three position rocker switch (2) controls the front, rear and boom

worklights. The switch is located in the upper switch bank on the right side

dash panel. These lights will only operate when the ignition switch is in the

RUN position.

• Push the top of the switch in to turn all the

worklights OFF.

• To turn the front and boom worklight ON,

position the rocker switch to the center

position.

OH2591

OH2601

• Push the bottom of the switch in to turn all the

worklights ON.

2

OH2611

OH3300

Model 8042 Rev. 11/03

45

Operation

Beacon Light Switch

OH2580

This rocker switch (1) turns the beacon light ON and OFF. The switch is

located in the lower switch bank on the right side dash panel. This light will

only operate when the ignition switch is in the RUN position.

• Push the bottom of the switch in to turn the

beacon light ON.

• Push the top of the switch in to turn the

beacon light OFF.

1

OH2611

OH2591

46

OH3310

Model 8042 Rev. 11/03

Operation

Worklight Switch (with Optional Road Lights)

OH2620

This rocker switch (2) activates the worklight system. The switch is located

in the upper switch bank on the right side dash panel. This system will only

operate when the ignition switch is in the RUN position. See “Parking Lights,

Headlights & High/Low Beam Switch” on page 49 for operation of the road

lights.

• Push the top of the switch IN to

DEACTIVATE the entire the worklight

system.

• To ACTIVATE the boom worklight

position the rocker switch to the center

position.

OH2591

OH2601

• Push the bottom of the switch IN to

ACTIVATE the boom worklight and

rear worklights.

OH2611

2

OH3320

Model 8042 Rev. 11/03

47

Operation

Emergency Flashers

OS1920

This switch (1) is located in the upper switch bank on the right side dash

panel.

• To ACTIVATE the emergency flashers, push

the bottom of the switch IN.

• To DEACTIVATE the emergency flashers

push the top of the switch IN.

1

OH2611

OH2591

48

OH3320

Model 8042 Rev. 11/03

Operation

Turn Signals

OH2510

The directional signals are ACTIVATED from the lever (2) on the right side

of the steering wheel and will only operate when the ignition switch is in the

RUN position.

To activate the left turn signal (3), raise the lever. To activate the right turn

signal (4), lower the lever. To deactivate either directional signal, the lever

must be manually returned to the center position. The lever will not cancel

automatically after a turn.

Parking Lights, Headlights & High/Low Beam Switch

With the ignition switch in the RUN position use the turn signal switch to

control the high/low beam headlights, turn on the parking lights and the

headlights. Turn the twist grip end of the turn signal switch counterclockwise to the first position (5) to turn the parking lights ON. Turn the twist

grip to the second position (6) to turn the headlights and parking lights ON.

Turn the twist grip clockwise to the OFF position (7) to turn all the lights

OFF. Pull the turn signal switch toward you to switch from low beam to high

beam. When the high beam is ON the high beam indicator light will

illuminate.

Model 8042 Rev. 11/03

3

4

2

7

5

6

OH3330

49

Operation

Windshield Wiper Control

OS1930

This three position rocker switch (1) controls the speed of the windshield

wiper. This switch is located in the lower switch bank on the right side dash

panel.

• To STOP the windshield wiper, push

the top of the switch IN.

• To OPERATE the windshield wiper at

LOW speed, position the switch in the

CENTER POSITION.

• To OPERATE the windshield wiper at

HIGH speed, push the bottom of the

switch IN.

OH2591

OH2601

OH2611

50

1

2

3

Model 8042 Rev. 11/03

OH3310

Operation

Skylight Wiper Control

OH1900

This rocker switch (2) turns the skylight wiper ON and OFF. This switch is

located in the lower switch bank on the right side dash panel.

• Push the bottom of the switch IN to turn the

skylight wiper ON.

OH2611

• Push the top of the switch IN to turn the

skylight wiper OFF.

OH2591

Windshield & Skylight Washer Control

OS1940

This rocker switch (3) is spring loaded to return to the OFF position when

released. This switch is located in the lower switch bank on on the right side

dash panel.

• Pressing down on the bottom of the switch

will dispense washer fluid to the windshield

and skylight wiper at the same time. The

switch must be held in place to activate the

washer control.

• Release the switch to deactivate the washer

control.

OH1910

OH2611

OH2591

Model 8042 Rev. 11/03

51

Operation

Cab Heater & Fan Control

OS1950

The cab heater controls (1) are located directly below the switch banks on

the right side dash panel. The control panel consists of: a variable speed

fan control knob (2) and a temperature control knob (3).

Control of air flow to the windshield is made by opening, closing or

redirecting the air vent louver on the front dash. The cab is heated by the

heater unit positioned under the operators seat.

To heat the cab:

OS1950

• Turn temperature control knob (3) to far right position

(RED = HOT),

• Direct desired air flow by adjusting vent louvers,

• Turn fan control (2) to “3” (4) to assure rapid warm-up.

To defrost the cab:

52

OA1390

• Turn temperature control knob (3) to the far right position

(RED = HOT),

• Direct desired air flow by adjusting vent louver,

• Turn fan control (2) to “3” (4) to assure rapid defrost.

2

4

3

1

Model 8042 Rev. 11/03

OH3340

Operation

Rear Window Latch

The rear window (5) can be partially opened and secured in place with the

rear window latch (6). To open the window, grab the latch handle and pull up

and then push the window outward. To close and secure the window, pull

the latch handle forward and down.

NOTE: In an emergency situation, the operator can exit through the rear

window opening by removing the latch pin (7) on the window latch. The window is then free to swing open.

1.

7

2.

3.

6

5

4

1

09

7

91

OH1730

Door Latches

(not pictured)

There are two door latches. The outside latch is a key lockable pull-to-

release type. The inside latch is also a pull-to-release latch.

Door Window Latch

(not pictured)

The door window can be swung open by releasing the window from inside

the cab. Swing the window all the way open and lock in place on the outside

of the cab. To release the window from the open position, push up the

release on the lower side of the outside hold or release using the release on

the side wall of the cab below the left side window.

Model 8042 Rev. 11/03

53

Operation

Pre-Operation Inspection

1. Check safety belt for damage. Check for frayed or cut seat belt webbing, damaged buckles or loose mounting brackets. Make any necessary repairs before operating the vehicle.

2. Check all four tires and rims for damage. Check for proper tire pressure, add air if required. Observe the condition of each tire looking

specifically for punctures, cracks, cuts, gouges, bulges or any other

damage. Check the condition of each rim for bent flanges or any

other damage. Make any necessary repairs before operating the

vehicle.

3. Check and add engine oil if required. This procedure is explained in

greater detail on page 119.

4. Check and add transmission oil if required. This procedure is

explained in greater detail on page 133.

5. Check the cooling system overflow bottle for coolant. Add coolant if

required. This procedure is explained in greater detail on page 116.

Remove any debris blocking the radiator cooling fins.

6. Check the hydraulic oil level sight glass and add hydraulic oil if

required. This procedure is explained in greater detail on page 130.

7. Walk around the vehicle and check for oil leakage as well as damaged or missing parts. Make any necessary repairs before operating the vehicle.

54

Model 8042 Rev. 11/03

Operation

Normal Starting

1. Enter the cab using the hand holds and adjust the seat for comfortable operation.

2. Adjust the mirrors to obtain the best rear view from the operator’s position.

WARNING: DO NOT start the engine unless you are in the

seat with the seat belt fastened around you. Death or serious personal injury could result if the belt is not securely fastened.

3. Fasten the seat belt.

4. Make sure the parking brake switch is ENGAGED.

5. Place the travel select lever in (N) NEUTRAL and move the neutral

lock lever to NEUTRAL LOCK position.

6. Turn the ignition switch to the START position (fully clockwise) to

crank the engine. Release the key when the engine starts. If the

engine fails to start on the first try, wait until the engine and starter

come to a complete stop before cranking the engine again.

IMPORTANT! DO NOT crank the starting motor continuously for more than

30 seconds. Stop cranking the starter and allow the starter to cool for 2

minutes before engaging the starter again.

7. After the engine starts, run engine at partial throttle for 30 to 60 seconds before operating the vehicle. Return to idle before engaging

the travel or range select lever.

8. Move the Neutral Lock Lever to the (D) DRIVE position before you start operating.

9. Disengage the parking brake switch before you start operating.

Model 8042 Rev. 11/03

55

Operation

Cold Starting

The engine is equipped with a 120 volt 750 watt block heater. Block heaters

are recommended when temperatures drop below 10° F (-12° C).

(Temperature ranges will vary when using different oil weights. Consult the

engine manufacturer’s manual for other variables.)

WARNING: This diesel engine uses a grid heating system

inside the induction manifold. DO NOT use ether or any high

energy fuels to assist starting. An explosion may cause death or

serious personal injury or engine damage.

The engine is equipped with a grid heater inside the induction manifold. If

the temperature drops below 40° F (4° C) the air-intake heater system will

be activated when the ignition switch is turned to the RUN position. When

the system is active the air-intake heater light (see page 40) will illuminate

on the front dash. DO NOT turn the ignition switch to START until the airintake heater light goes OFF.

At temperatures below -10° F (-12° C), operate the engine at moderate

speeds for 5 minutes before full loads are applied.

1. Enter the cab using the hand holds and adjust the seat for comfortable operation.

2. Adjust the mirrors to obtain the best rear view from the operator’s position.

WARNING: DO NOT start the engine unless you are in the

seat with the seat belt fastened around you. Death or serious personal injury could result if the belt is not securely fastened.

3. Fasten the seat belt.

4. Make sure the parking brake switch is ENGAGED.

5. Place the travel select lever in (N) NEUTRAL and move the neutral

lock lever to NEUTRAL LOCK position.

6. Turn the ignition switch to the START position to crank the starter.

IMPORTANT! DO NOT crank the starting motor continuously for more than

30 seconds. Stop cranking the starter and allow the starter to cool for 2

minutes before engaging the starter again.

7. As the engine starts, release the ignition switch to the RUN position. Depress the accelerator pedal enough to provide a smooth

idle speed.

56

Model 8042 Rev. 11/03

Operation

8. The engine oil pressure warning indicator light should go OFF

within five seconds after starting. If the light remains ON, turn the

ignition switch OFF immediately and check the oil level or change

to a lighter weight oil. Consult the engine manufacturer’s manual for

alternative oils for cold weather operation.

Jump Starting

Jump starting at the batteries or battery replacement is required when the

batteries are discharged to the point where the batteries will not crank the

starter.

WARNING: NEVER jump start the vehicle directly to the

starter solenoid. Death or serious personal injury could result from

the vehicle lurching forward or backward and running over the person attempting to jump start the vehicle directly to the starter.

WARNING: To avoid death or serious personal injury when

jump starting with another vehicle, be certain that the two vehicles

are not touching. Never jump start a frozen battery as it will

explode. Keep sparks, flames and lighted smoking materials away

from the battery. Lead acid batteries generate explosive gases

when charging. Wear safety glasses when working near batteries.

The booster battery must be a 12 volt type. The vehicle used for jump

starting must have a negative ground electrical system. To jump start the

vehicle, proceed as follows:

1. Connect the positive (+) jumper cable to the positive (+) post of the discharged battery.

2. Connect the other end of the positive (+) jumper cable to the positive (+) post of the booster battery.

3. Connect one end of the negative (-) jumper cable to the negative (-) post of the booster battery.

4. Make the final cable connection to the furthest point from the batteries.

5. Follow the steps in “Normal Starting” on page 55.

6. Remove the jumper cables in the reverse order of their connection

(i.e. negative cable ground connection first, etc.).

Model 8042 Rev. 11/03

57

Operation

Refueling

Make sure the vehicle is level to assure an accurate fuel level reading. The

fuel tank is capable of holding 37 gallons (140 liters) of diesel fuel. The

usable capacity of the fuel tank is 35.6 gallons (135 liters).

Fuel Types

OH0480

Use ASTM #2 diesel fuel with a minimum Cetane rating of 40. #2 diesel fuel

gives the best fuel economy and performance under most operating

conditions. Fuels with Cetane ratings higher than 40 may be needed in

higher altitudes or extremely low ambient temperatures to prevent misfiring

and excessive smoke.

• When operating at temperatures above 32° F (0° C), use

standard #2 diesel fuel.

• When operating at temperatures below 32° F (0° C), use a blend

of #1 & #2 diesel fuels, most commonly known as “winterized” #2

diesel.

WARNING: Engine fuel is flammable and can cause a fire

or an explosion. Keep sparks and open flames away from the

vehicle and DO NOT use smoking materials while refueling.

58

Model 8042 Rev. 11/03

Fuel Cap

Unlock the fuel cap (1) through the fuel cap access hole (2).

Slowly remove the fuel cap from the fuel fill neck.

Fill fuel tank.

Operation

2

1

OH1920

Reassemble the fuel cap onto the fill neck and turn to lock in place. Line up

the locking tabs to reassemble a lock if desired.

Model 8042 Rev. 11/03

59

Operation

Stabil-TRAK System

Understanding the Stabil-TRAK System

OS1970

The following describes the three basic modes of the patented Stabil-TRAK

system. The vehicle may operate in any one of these three modes.

Free Pivot Mode

With the boom below 40° (1), the Stabil-TRAK system is in the free pivot

mode (2) and the rear axle is allowed to pivot freely. The frame sway will

function normally. The Stabil-TRAK light will be OFF (3).

1

2

3

OH0703

60

Model 8042 Rev. 11/03

Operation

Locked Mode

With the boom above 40° (4) and by activating one or more of the functions

(as follows), the Stabil-TRAK system is in the LOCKED MODE (5). The rear

axle is locked so it is rigid with the frame. The Stabil-TRAK light will be ON

(6).

• Engaging the parking brake switch

• Placing the travel select lever in (N) NEUTRAL

• Depressing and holding the service brake pedal

The frame sway will function slower than normal in this mode.

5

4

6

OH0713

Model 8042 Rev. 11/03

61

Operation

Slow Pivot Mode

With the boom above 40° (1), the Stabil-TRAK System is now in the SLOW

PIVOT MODE (2). In this mode the rear axle is UNLOCKED and is allowed

to pivot but will respond SLOWLY

light will be OFF (3).

The frame sway will function normally in this mode.

To check that the Stabil-TRAK System is functioning properly, refer to the

test procedure on page 169 for the proper system function.

to changes in terrain. The Stabil-TRAK

2

1

3

OH0724

62

Model 8042 Rev. 11/03

Operation

Operating

Starting Travel

1. Enter the operator cab, fasten the seat belt, start the engine, apply

the service brake pedal and disengage the parking brake switch.

2. Rotate the twist grip of the range select lever (4) to 1st gear.

3. Move the travel select lever (5) to (F) FORWARD to travel in a forward direction or to (R) REVERSE to travel backward.

4. Slowly remove your foot from the service brake pedal and press the

accelerator pedal to start travel.

IMPORTANT! Check for warning lights frequently during operation. Any

abnormal indication should be corrected as soon as practical.

Changing Travel Direction

1. Stop the vehicle by applying the service brakes.

2. Grasp the travel select lever, pull it toward the steering wheel, then

move the lever up or down in the opposite direction;

(R) REVERSE or (F) FORWARD.

4

5

Model 8042 Rev. 11/03

OH3270

OH3260

63

Operation

Shifting Gears

1. Rotate the twist grip of the gear select lever to the next desired

gear. The transmission has four forward gears and three reverse

gears.

2. Use first gear for highest torque and pulling power. Use higher

gears for higher ground speed. The recommendations listed in the

table that follows are guidelines only. Always use good judgement

when traveling with a load.

Recommended Gear/Speed for Various Load/Travel Conditions

Load Size Surface Gear Speed

No Load Smooth 4th* 0 to 20 mph (0 to 32 km/h)

Improved 3rd 0 to 14 mph (0 to 23 km/h)

Rough 2nd 0 to 6 mph (0 to 9,7 km/h)

Load Smooth 3rd 0 to 14 mph (0 to 23 km/h)

up to 4,500 lbs Improved 2nd 0 to 6 mph (0 to 9,7 km/h)

(up to 2.041 kg)

Load Smooth 3rd 0 to 14 mph (0 to 23 km/h)

4,500 to 8,000 lbs Improved 2nd 0 to 6 mph (0 to 9,7 km/h)

(2.041 to 3.629 kg)

Rough 2nd 0 to 6 mph (0 to 9,7 km/h)

Rough 1st 0 to 3.5 mph (0 to 5,6 km/h)

*NEVER travel in 4th gear when carrying a load.

NOTE: Shifting to the next higher gear may be done while the vehicle is in motion.

IMPORTANT! When downshifting, allow the engine speed to slow down

before shifting to the next lower gear.

Stopping Travel

1. Apply the service brake pedal and downshift the vehicle to a lower

gear if necessary to slow the vehicle until it comes to a complete

stop.

2. Move the travel select lever to (N) NEUTRAL and engage the parking brake switch. For longer stops, place the neutral lock lever to

NEUTRAL LOCK position and engage the parking brake switch.

64

Model 8042 Rev. 11/03

Operation

Steering Modes

IMPORTANT! DO NOT change steering modes unless you are at a

complete stop and all four tires are in the “straight-ahead” position.

The three steering modes are:

• Four Wheel Steering (1)

• Front Wheel Steering (2)

• Crab Steering (3)

The steering modes can be changed using a single rocker switch (4)

located in the lower switch bank on the right side dash panel.

4

Model 8042 Rev. 11/03

3

2

1

OH3360

65

Operation

Four Wheel Steer Indexing

If the vehicle does not drive “straight,” the steering could be ”out of phase.”

Perform the “Four Wheel Steer Indexing Procedure” on page 175 to

synchronize the front and rear steering.

1. Four Wheel Steering

WARNING: NEVER use the Four Wheel Steering Mode

when traveling at high speed. Rapid turning in this mode can

cause tipover. Use only the Front Wheel Steering Mode at higher

speeds and slow the vehicle when turning.

The front wheels will steer in the direction that the steering wheel is turned;

the rear wheels will steer in the opposite direction. This steering mode

allows an extremely short turning radius and enables the rear wheels to

follow the tracking of the front wheels which can be an advantage in mud

and sand conditions.

66

OH1660

Model 8042 Rev. 11/03

Operation

2. Front Wheel Steering

The front wheels will steer in the direction that the steering wheel is turned.

The rear wheels will remain in a fixed forward position. This steering mode

should be used when loading or unloading the vehicle from a trailer and for

on-highway travel at higher speeds.

OH1670

Model 8042 Rev. 11/03

67

Operation

3. Crab Steering

WARNING: NEVER use the Crab Steering Mode when

traveling at high speed. Rapid turning in this mode can cause

tipover. Use only the Front Wheel Steering Mode at higher speeds

and slow the vehicle when turning.

All wheels will steer in the same direction that the steering wheel is turned.

This steering mode allows the operator to move the vehicle “sideways”

toward the landing point of a load. This is especially useful on a congested

worksite in order to line up at the exact spot in front of the loading location.

OH1680

68

Model 8042 Rev. 11/03

4. Maximum Fork Sweep

CAUTION: Allow for adequate clearance between the

attachment and other objects when turning.

The attachment extends beyond

operator must be aware of the maximum sweep (2) of the attachment when turning in order to avoid hitting personnel and other

objects in the area.

Operation

the end of the vehicle (1). The

1

2

OH1690

Leveling Frame

When placing a load while on a slope, use the frame sway control to keep

the vehicle level. The operator should observe the frame level indicator to

assure that the vehicle is level at all times.

DANGER: Use of the frame sway control with the boom

raised above horizontal can cause tipover resulting in death or

serious personal injury. Always use the frame sway control to level

the vehicle before

cannot be leveled using the frame sway control, reposition the

vehicle.

Model 8042 Rev. 11/03

raising the boom above horizontal. If the vehicle

69

Operation

Quick Attach

This vehicle is equipped with a quick attach system for easy attachment

changing.

Attachment Removal

Be sure you are performing this procedure on level ground.

1. Place the travel select lever in (N) NEUTRAL, come to a complete