Page 1

Service

GETtheMANUALS.org

Workshop Manual

Rapid NH 2013 ➤

Rapid NH 2014 ➤

Electrical system

Edition 02.2018

Service Department. Technical Information

Page 2

List of Workshop Manual Repair Groups

GETtheMANUALS.org

Re pa ir G ro up

00 - Technical data

27 - Starter, current supply, CCS

90 - Gauges, instruments

91 - Radio, telephone, navigation

92 - Windscreen wash/wipe system

94 - Lights, bulbs, switches - exterior

96 - Lights, bulbs, switches - interior

97 - Wiring

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

Page 3

Contents

GETtheMANUALS.org

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

Electrical system - Edition 02.2018

00 - Technical data

1 Safety instructions

1.1 Safety precautions when working on vehicles with a start/stop system . . . . . . . . . . . . . . . . 1

1.2 Safety precautions during road tests in which testing and measuring equipment is used . . 1

1.3 Use and safety instructions for gas discharge lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Cable routing and securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Warning instructions and safety precautions when working on the battery . . . . . . . . . . . . 5

3.2 Battery types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

27 - Starter, current supply, CCS

1 Battery

1.1 Assembly overview - battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Summary of components - battery isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Disconnecting and reconnecting battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Checking battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Charging battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6 Removing and installing battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7 Removing and installing earth lead with battery monitoring control unit J367 . . . . . . . . . . 17

1.8 Removing and installing battery isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.9 Battery parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.10 Removing and installing battery tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Jump start point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Summary of components - jump start point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Removing and installing jump start point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Assembly overview: starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Removing and installing starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3 Checking starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4 Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Removing and installing alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 Fixing the B+ wire to the AC generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3 Checking the carbon brushes of the AC generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4 Removing and installing voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.5 Removing and installing V-ribbed belt pulley on alternator . . . . . . . . . . . . . . . . . . . . . . . . 41

5 start-stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1 Safety precautions for vehicles with start-stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3 Fault recognition and fault display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.4 Battery recharging or starting by external source on vehicles with start-stop system . . . . 48

5.5 Replacing the battery on vehicles with “start-stop” system . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6 Voltage stabiliser J532 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.7 Battery monitor control unit J367 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.8 Button for start-stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6 Front Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

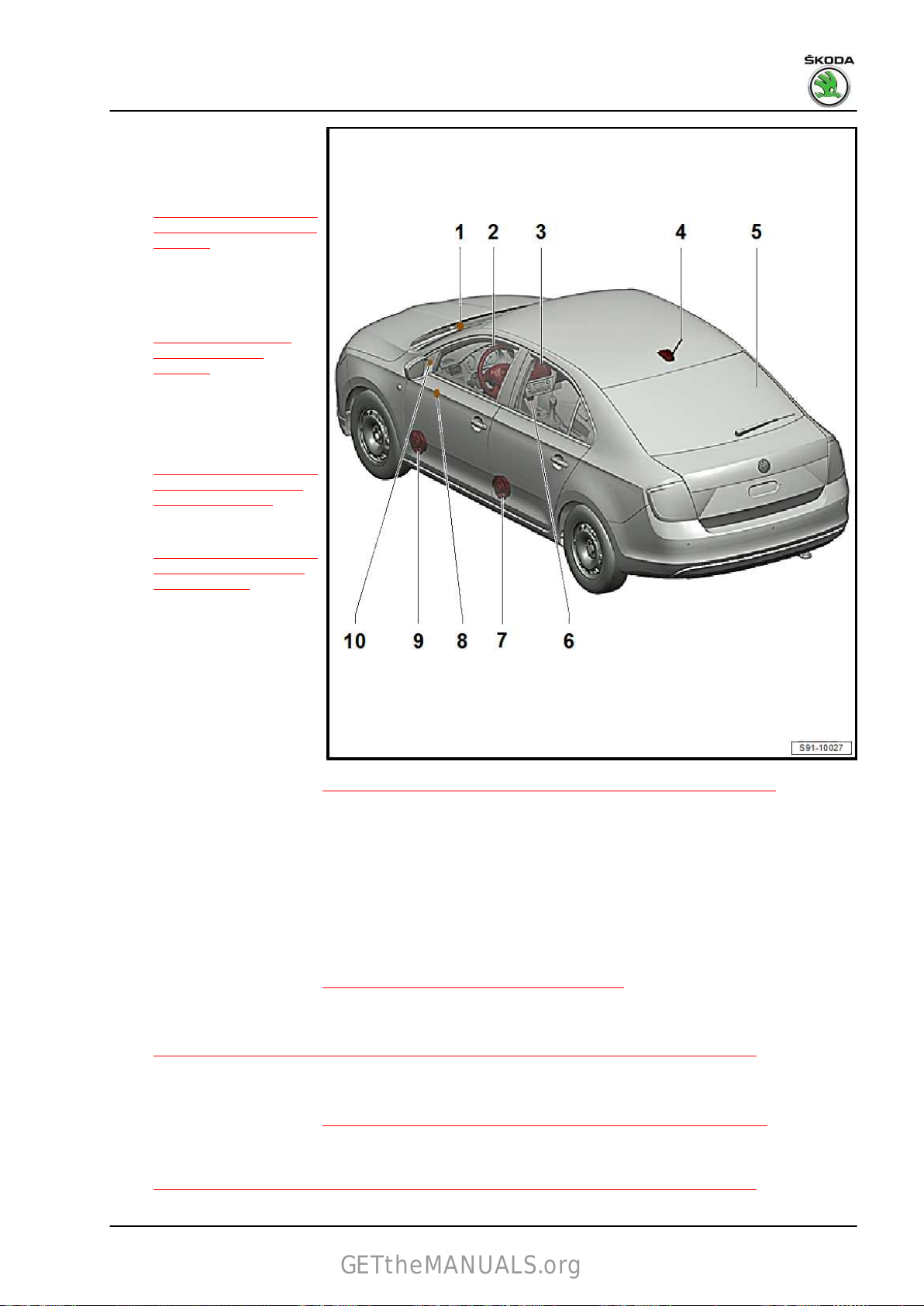

6.1 Installation location overview - Front Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Removing and installing front assistant system control unit . . . . . . . . . . . . . . . . . . . . . . . . 52

6.3 Removing and installing the retaining plate of the front assistant system control unit . . . . 52

6.4 Calibrating the front assistant system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contents i

Page 4

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

90 - Gauges, instruments

1 Dash panel insert

1.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.2 The self-diagnostic function of the dash panel insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.3 Adjust/replace dash panel insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.4 Removing and installing the dash panel insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.5 Contact assignment of plug connection on the dash panel insert . . . . . . . . . . . . . . . . . . . . 57

1.6 Warning lights in the dash panel insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.7 Service interval display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2 Cruise control system (CCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

91 - Radio, telephone, navigation

1 Radio - installed up to CW 21.2015

1.1 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1.2 Electronic anti-theft coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1.3 Summary of components - radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1.4 Removing and installing a radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1.5 Plug connections on the radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

1.6 Self-diagnostic function of radio system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

2 Amundsen+ navigation system - installed up to CW 21.2015 . . . . . . . . . . . . . . . . . . . . . . 65

2.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.3 Electronic anti-theft coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.4 Overall view of the navigation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

2.5 Removing and installing the navigation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.6 Plug connections on the navigation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.7 Aerial for GPS signal reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.8 Diagnosis of the navigation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3 Infotainment system - installed as of CW 22.2015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.1 Infotainment system - general notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2 Summary of components - Infotainment system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.3 Installation – Infotainment system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.4 Removing and installing the Infotainment display/control unit . . . . . . . . . . . . . . . . . . . . . . 74

3.5 Remove and install infotainment display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.6 Removing and installing the infotainment control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.7 Electronic anti-theft coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.8 “Basic” (Blues) infotainment - initial setup, self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4 Replacing aerials, aerial modules and aerial cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.1 Summary of components, Rapid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.2 Removing and installing roof aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.3 Removing and installing the GPS aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.4 Removing and installing the GSM aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.5 Rear or side window aerial (Spaceback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.6 Panoramic roof aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.7 Aerial module R254 for rear window aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4.8 Aerial module for rear left side window aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.9 Aerial module for panoramic roof aerial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4.10 Replacing aerial cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5 Telephone system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.1 Mobile phone pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.2 Removing and installing the control unit for the mobile phone operating electronics J412

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.3 Removing and installing the microphone for the telephone R38 . . . . . . . . . . . . . . . . . . . . 93

6 Multi-functional steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

ii Contents

Page 5

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

6.1 Multi-functional steering wheel - general instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.2 Removing and installing switch unit for operating the radio and phone/infotainment . . . . . . 94

6.3 Diagnosis of the multi-functional steering wheel

7 Multimedia socket MEDIA-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.2 Removing and installing the control unit for multimedia system J650 . . . . . . . . . . . . . . . . 96

7.3 Removing and installing connection for external audio sources R199 (AUX-IN, USB) . . . . 97

7.4 Removing and installing the rear USB charging module . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8 Loudspeaker arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.1 Removing and installing front bass speaker and rear full-range speaker . . . . . . . . . . . . . . 99

8.2 Removing and installing the front treble speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9 SmartLink system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.1 SmartLink system - general instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10 SmartGate system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.1 SmartGate system - general notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.2 SmartGate system - check the correct function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.3 Removing and installing the control unit for wireless data transfer J1070 (SmartGate) . . . . 104

10.4 Set the parameters for the WLAN connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.5 Update firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11 Mobile services online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.1 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.2 Installation location overview - mobile online services . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.3 Removing and installing control unit for emergency call module and communication unit J949

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.4 Removing and installing emergency call button E276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11.5 Removing and installing speaker for emergency call module R335 . . . . . . . . . . . . . . . . . . 111

11.6 Replacing battery for control unit for emergency call module and communication unit J949

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11.7 Replacing, adapting and activating control unit for emergency call module and

communication unit J949 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11.8 Checking that the components and communication of the ERA Glonass system are

functioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

92 - Windscreen wash/wipe system

1 Windscreen washer system

1.1 Removing and installing washer fluid reservoir, washer fluid pumps and sensor for washer

fluid level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.2 Removing and installing the spray nozzles for windscreen washer system . . . . . . . . . . . . 117

1.3 Repairing washer fluid lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

2 Windscreen wiper and washer system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2.1 Removing and installing the wiper arms with wiper blades and setting their final setting . . 118

2.2 Removing and installing wiper motor with linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.3 Removing and installing windscreen wiper motor from linkage . . . . . . . . . . . . . . . . . . . . . . 120

2.4 Removing and installing sensor for rain and light detection G397 , vehicles up to CW

21.2015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2.5 Removing and installing sensor for rain and light detection G397 , vehicles from CW

22.2015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.6 Repairing sensor for rain and light detection G397 , vehicles from CW 22.2015 . . . . . . . . 125

3 Rear window wiper and washer system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.1 Removing and installing the wiper arm with wiper blade and setting its final setting . . . . . . 129

3.2 Removing and installing windscreen wiper motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

3.3 Replacing and adjusting the spray nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4 Headlamp cleaning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

4.1 Removing and installing headlight cleaning system pump V11 . . . . . . . . . . . . . . . . . . . . 133

4.2 Removing and installing the lift cylinder for spray nozzles of headlight . . . . . . . . . . . . . . . . 133

4.3 Bleed the headlamp cleaning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Contents iii

Page 6

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

94 - Lights, bulbs, switches - exterior

1 Headlights – halogen headlights

1.1 Summary of components, halogen headlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

1.2 Removing and installing headlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

1.3 Replacing light bulbs in headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1.4 Removing and installing headlight range control motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1.5 Replace headlight fixing brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.6 Removing and installing LED module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.7 Change headlight for right-hand and/or left-hand traffic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1.8 Setting the headlight beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

2 Headlights with Xenon discharge lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

2.1 Summary of components, headlights with Xenon discharge lamps . . . . . . . . . . . . . . . . . . 147

2.2 Removing and installing headlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

2.3 Replacing light bulbs and gas discharge lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

2.4 Replace attachment brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

2.5 Removing and installing headlight range control motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

2.6 Removing and installing the power output module for headlight . . . . . . . . . . . . . . . . . . . . 157

2.7 Removing and installing LED module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

2.8 Change headlight for right-hand and/or left-hand traffic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

2.9 Setting the headlight beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

3 Side turn signal in the wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

3.1 Removing and installing side turn signal in the wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

4 Lights in the exterior mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

4.1 Removing and installing the turn signal light in the exterior mirror . . . . . . . . . . . . . . . . . . . . 161

4.2 Removing and installing signal bulb in exterior mirror L131 / L132 . . . . . . . . . . . . . . . . . . 161

5 Tail lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.1 Removing and installing tail light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.2 Replacing the light bulbs of the tail light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

6 Registration number lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.1 Removing and installing licence plate carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.2 Replacing bulb for the number plate light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

7 Additional brake light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7.1 Removing and installing high level brake light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

8 Fog lights, fog lights with “Corner” function and daylight driving light . . . . . . . . . . . . . . . . 170

8.1 General description, fault recognition and fault display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

8.2 Removing and installing fog light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

8.3 Adjusting the fog light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8.4 Replacing light bulb for fog light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

9 Entry and start authorisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

9.1 Installation overview - entry and start authorisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

9.2 Install and remove interior aerial 1 for entry and start system R138 . . . . . . . . . . . . . . . . . . 174

9.3 Install and remove aerial in luggage compartment for entry and start system R137 . . . . 175

9.4 Install and remove aerial in rear bumper for entry and start system R136 . . . . . . . . . . . . 175

9.5 Control unit for keyless entry authorisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

9.6 Connection assignment of the connector on the control unit for keyless entry authorisation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

10 Switch unit on the steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

10.1 Summary of components - switch unit on the steering column . . . . . . . . . . . . . . . . . . . . . . 178

10.2 Removing and installing steering column combination switch . . . . . . . . . . . . . . . . . . . . . . 181

10.3 Removing and installing return ring with slip ring from steering column combination switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

10.4 Adjusting centre position for return ring with slip ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

10.5 Removing and installing steering lock housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

10.6 Removing and installing lock cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

iv Contents

Page 7

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

10.7 Removing and installing ignition/starter switch

10.8 Contact assignment on the ignition starter switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

10.9 Removing and installing ignition key anti-removal lock solenoid N376 . . . . . . . . . . . . . . . . 189

11 Parking aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11.1 Assembly overview - parking aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11.2 Removing and installing the parking aid control unit J446 . . . . . . . . . . . . . . . . . . . . . . . . 192

11.3 Removing and installing the rear parking aid warning buzzer H15 . . . . . . . . . . . . . . . . . . 193

11.4 Removing and installing the front parking aid warning buzzer H22 . . . . . . . . . . . . . . . . . . 193

11.5 Removing and installing rear parking aid senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

11.6 Removing and installing front parking aid sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.7 Parking aid sender holder - assignment, fitting location, gluing procedure, drilling of holes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

11.8 Self-diagnosis of the parking aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

12 Rear view camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

12.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

12.2 Summary of components - rear view camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

12.3 Removing and installing handle with rear view camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

12.4 Removing and installing the rear view camera spray nozzle . . . . . . . . . . . . . . . . . . . . . . . . 200

96 - Lights, bulbs, switches - interior

1 Interior lights and warning light for front passenger airbag deactivation

1.1 Removing and installing the front interior light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1.2 Removing and installing the rear interior light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

1.3 Removing and installing the rear interior light on the left and right . . . . . . . . . . . . . . . . . . 203

1.4 Removing and installing glove box light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

1.5 Removing and installing the light for the storage bag in the front door trim . . . . . . . . . . . . 204

1.6 Removing and installing the front footwell light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

1.7 Removing and installing the centre console glove compartment light . . . . . . . . . . . . . . . . 205

1.8 Removing and installing luggage compartment light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

1.9 Removing and installing the warning light for front passenger airbag switch-off function . . 206

2 Switches on the dash panel, in the centre console, in the doors and in the roof cover . . . . 207

2.1 Removing and installing light switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

2.2 Removing and installing the headlight range control adjuster . . . . . . . . . . . . . . . . . . . . . . 207

2.3 Removing and installing the switch for daylight driving light . . . . . . . . . . . . . . . . . . . . . . . . 208

2.4 Removing and installing switches in centre console of the dash panel . . . . . . . . . . . . . . . . 208

2.5 Removing and installing the glove box light switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

2.6 Removing and installing hazard warning lights button . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

2.7 Removing and installing the mirror adjustment switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

2.8 Removing and installing the switch for the power window lifter . . . . . . . . . . . . . . . . . . . . . . 210

2.9 Removing and installing starter button E408 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

2.10 Removing and installing the interior monitoring deactivation button as well as the towing

protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

2.11 Removing an installing the push-button for tyre pressure inspection . . . . . . . . . . . . . . . . . . 212

2.12 Removing and installing the rear seat heating switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

3 Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

3.1 Removing and installing horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

4 Anti-theft warning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.2 Removing and installing the horn H12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

4.3 Removing and installing interior monitoring sensor G273 and vehicle inclination sender G384

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.4 Removing and installing the interior monitoring deactivation button . . . . . . . . . . . . . . . . . . 216

5 12V power sockets, cigarette lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

6 Immobiliser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

6.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

. . . . . . . . . . . . . . 201

Contents v

Page 8

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

6.2 Immobiliser control unit J362 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

6.3 Ignition key

6.4 New identity when changing all the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6.5 System test result (online connection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

97 - Wiring

1 Fuse holder and relay carrier

1.1 Removing and installing fuse holder from dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

1.2 Removing and installing the E-box in engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 222

1.3 Removing and installing relay and fuse holder behind dash panel on the driver's side . . . . 225

1.4 Removing and installing the relay of the relay carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

2 Control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

2.1 Onboard supply control unit J519 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

2.2 Removing and installing data bus diagnostic interface J533 . . . . . . . . . . . . . . . . . . . . . . . . 229

3 Vehicle diagnosis, testing and information systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

4 Wiring harness and plug repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

5 Use contact surface cleaning set VAS 6410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

vi Contents

Page 9

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

00 – Technical data

1 Safety instructions

(SRL001176; Edition 02.2018)

⇒ “1.1 Safety precautions when working on vehicles with a start/

stop system”, page 1

⇒ “1.2 Safety precautions during road tests in which testing and

measuring equipment is used”, page 1

⇒ “1.3 Use and safety instructions for gas discharge lamps”, page

1

1.1 Safety precautions when working on ve‐

hicles with a start/stop system

When working on vehicles with start/stop system, please observe

the following:

Caution

Electrical system - Edition 02.2018

Risk of injury from automatic engine start.

♦ On vehicles with activated start-stop system (recogniza‐

ble by a message in the dash panel insert) there is a risk

that the engine can start automatically.

♦ It is therefore necessary to ensure that the start-stop sys‐

tem is deactivated when carrying out work on the vehicle

(switch ignition off, if required switch ignition on again).

1.2 Safety precautions during road tests in

which

testing and measuring equipment

is used

Note the following if testers and measuring instruments are used

during road tests:

WARNING

There is a risk of accident from insufficient securing of testers

and measuring instruments.

There is a hazard from the release of the passenger airbag in

the event of an accident.

• Drivers operating testing and measuring equipment while

driving can lead to an accident.

• Increased risk of accident due to unsecured test and

measuring devices.

Always secure the testing and measuring equipment with a belt

on

the rear seat and have a second person operate them there.

1.3 Use and safety instructions for gas dis‐

charge lamps

All other notes and comments to this chapter can be found in the

Workshop Manual “Electrical System- General Notes” ⇒ Electri‐

cal System- General Notes; Rep. gr. 94 Chapter “94”. If a note

1. Safety instructions 1

Page 10

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

cannot be accessed, open the Workshop Manual “Electrical Sys‐

tem - General Notes” manually in “ELSA”.

2 Rep. gr.00 - Technical data

Page 11

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

2 Repair instructions

⇒ “2.1 Contact corrosion”, page 3

⇒ “2.2 Cable routing and securing”, page 3

2.1 Contact corrosion

The use of unsuitable connection elements (screws, nuts, wash‐

ers, etc.) causes contact corrosion.

This is why only connection elements with a special surface coat‐

ings are fitted.

Therefore, the rubber or plastic parts and the adhesives are made

from electrically non-conductive materials.

In case of doubt regarding the re-use of certain parts, the use of

new parts is recommended.

WARNING

♦ It is recommended to use only original connection material

as well as spare parts which are tested and compatible

with aluminium, see ⇒ Electronic Catalogue of Original

Parts “ETKA” .

♦ It is recommended to use only Škoda accessories.

♦ Any damage resulting from contact corrosion is not cov‐

ered by the terms of the warranty.

Electrical system - Edition 02.2018

2.2 Cable routing and securing

Caution

Risk of damage to cables, risk of fire and failure of onboard

electrical system!

♦ To rule out mix ups and ensure the original fitting position,

mark

the lines before disassembly. This includes lines for

fuel, hydraulics, underpressure, activated charcoal filter,

or electric cables. Make photos or sketches where nec‐

essary.

♦ To prevent damage to lines, sufficient clearance from all

moving or hot components must be ensured in the engine

compartment due to its cramped construction.

♦ All plug connections must be locked using catches, if nec‐

essary with special securing clips, to prevent them dis‐

connecting unintentionally. When connecting, the catches

must engage audibly; for plug connections with catch, lock

the plug connection by pushing in the catch. If necessary,

check it is locked correctly by pulling gently on the plug

connection.

Example of a connector catch with special securing clip -1-.

Primary voltage supply in the relay and fuse carrier under the

dash panel:

2. Repair instructions 3

Page 12

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

Note

After inserting the plug up to the stop -2- to terminal 30+ on the

relay and fuse carrier -3-, secure the plug connection by pushing

the securing clip -1- in -direction of arrow- up to the stop!

4 Rep. gr.00 - Technical data

Page 13

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

3 Battery

⇒ “3.1 Warning instructions and safety precautions when working

on the battery”, page 5

⇒ “3.2 Battery types”, page 5

3.1 Warning instructions and safety precau‐

tions when working on the battery

All the notes and comments for this chapter can be found in the

Workshop

27 . If a note cannot be accessed, open the Workshop Manual

“Electrical System - General Notes” manually in “ELSA”, Section

“27”.

3.2 Battery types

When working on the battery wear proper protection and ob‐

serve safety precautions (see “Electrical System - General

notes” ⇒ Electrical System - General notes; Rep. gr. 27 Sec‐

tion “27”). If a note cannot be accessed, open the Workshop

Manual “Electrical System - General Notes” manually in “EL‐

SA”.

Manual ⇒ Electrical System - General notes; Rep. gr.

WARNING

Electrical system - Edition 02.2018

Batteries with a magic eye and plugs covered in adhesive tape

are

factory-installed in all vehicles (except vehicles with start-stop

system).

In vehicles with start/stop system, (depending on types of engines

see ⇒ Electronic Catalogue of Original Parts“ETKA” ), a fleece

battery (AGM) or a battery with magic eye with EFB technology

(Enhanced Flooded Battery) is installed.

Description of the function, test and maintenance of the previous

batteries see “Electrical System – General notes” ⇒ Electrical

System – General notes; Rep. gr. 27 . If a note cannot be ac‐

cessed, open the Workshop Manual “Electrical System - General

Notes” manually in “ELSA”.

3. Battery 5

Page 14

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

27 – Starter, current supply, CCS

1 Battery

⇒ “1.1 Assembly overview - battery”, page 6

⇒ “1.2 Summary of components - battery isolation”, page 10

⇒ “1.3 Disconnecting and reconnecting battery”, page 10

⇒ “1.4 Checking battery”, page 13

⇒ “1.5 Charging battery”, page 13

⇒ “1.6 Removing and installing battery”, page 13

⇒ “1.7 Removing and installing earth lead with battery monitoring

control unit J367 ”, page 17

⇒ “1.8 Removing and installing battery isolation”, page 18

⇒ “1.9 Battery parameterisation”, page 19

⇒ “1.10 Removing and installing battery tray ”, page 19

WARNING

When working on the battery wear proper protection and ob‐

serve safety precautions (see ⇒ Electrical System - General

notes; Rep. gr. 27 ). If a note cannot be accessed, open the

Workshop Manual “Electrical System - General Notes” man‐

ually in “ELSA”, Chapter “27”.

1.1 Assembly overview - battery

⇒ “1.1.1 Summary of components - battery in engine compart‐

ment”, page 6

⇒ “1.1.2 Summary of components - battery in luggage compart‐

ment”, page 8

1.1.1 Summary of components - battery in engine compartment

6 Rep. gr.27 - Starter, current supply, CCS

Page 15

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

1 - Collar

2 - Nut

❑

6 Nm

3 - Battery-cable terminal

❑ Earth cable

❑ Disconnecting and con‐

necting the battery

⇒ “1.3 Disconnecting

and reconnecting bat‐

tery”, page 10

4 - Cap

5 - Earth cable

❑ Removing

⇒ “1.7.1 Removing and

installing earth lead with

battery monitoring con‐

trol unit J367 - battery in

engine compartment”,

page 17

On vehicles with start-stop

system:

❑

with battery monitoring

control unit - J367-

❑ Battery parameterisa‐

tion

⇒ “1.9 Battery parame‐

terisation”, page 19

6 - Electrical plug connection

On vehicles with start-stop

system:

❑

Battery monitor control

unit - J367-

❑ Follow the steps for dis‐

connecting and connecting the battery

7 - Nut

❑

15 Nm

8 - Battery

❑ Removing and installing

❑

Disconnecting and reconnecting

❑

Check

❑

Charge

9 - Screw

❑

15 Nm

10 - Battery carrier

❑ Removing and installing

⇒ “1.10.1 Removing and installing the battery tray in the engine compartment”, page 19

11 - Screw

❑

20 Nm

12 - Retaining clip

13 - Water drain hose

❑ not fitted to all battery trays

❑ When installing, guide the hose without kinking it

and installing

⇒ “1.3 Disconnecting and reconnecting battery”, page 10

⇒ “1.6 Removing and installing battery”, page 13

⇒ “1.3 Disconnecting and reconnecting battery”, page 10

⇒ “1.4 Checking battery”, page 13

⇒ “1.5 Charging battery”, page 13

1. Battery 7

Page 16

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

14 - Nut

❑

15 Nm

15 - Battery-cable terminal

❑ for plus terminal

❑ Disconnecting and connecting the battery

16 - Plus terminal

⇒ “1.3 Disconnecting and reconnecting battery”, page 10

1.1.2 Summary of components - battery in luggage compartment

1 - Retaining clip

2 - Bolts

❑

4 pieces

❑ 18 Nm

3 - Cover

❑ for negative pole

4 - Protective collar

5 - Fuse holder A - SA-

❑ Disconnecting and re‐

connecting

⇒ “1.3 Disconnecting

and reconnecting bat‐

tery”, page 10

❑

with battery isolation

❑ Removing and installing

battery isolation

⇒ “1.8 Removing and in‐

stalling battery isola‐

tion”, page 18

6 - Screw

7 - Nut

❑

6 Nm

8 - Earth cable

❑ with battery monitoring

control unit - J367-

❑ Disconnecting and re‐

connecting

⇒ “1.3 Disconnecting

and reconnecting bat‐

tery”, page 10

❑ Removing

⇒ “1.7.2 Removing and

installing earth lead with battery monitoring control unit J367 - battery in luggage compartment”,

page 17

9 - Screw

10 - Nut

❑

20 Nm

11 - Hose

❑ for central degassing

12 - Washer

❑ of the hose for central degassing

and installing

8 Rep. gr.27 - Starter, current supply, CCS

Page 17

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

13 - Adjustment link

14 - Battery carrier

❑

glued into the spare wheel well

❑ Removing and installing

⇒ “1.10.2 Removing and installing the battery tray in the luggage compartment”, page 20

15 - Screw

❑

18 Nm

16 - Bolts

❑ 3 pieces

❑ 18 Nm

17 - Battery carrier

❑ glued into the spare wheel well

18 - Battery - A19 - Nut

❑ 6 Nm

20 - Cover

❑ for positive pole

1. Battery 9

Page 18

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

1.2 Summary of components - battery isolation

1 - Fuse holder A - SA2 - Battery isolation

3 - Nut

❑

10 Nm

4 - Connector

1.3 Disconnecting

⇒ “1.3.1 Disconnect battery”, page 10

⇒ “1.3.2 Reconnecting battery”, page 11

1.3.1 Disconnect battery

WARNING

Observe the battery handling instructions as well as the warn‐

ing instructions and safety precautions for lead acid batteries

⇒ “3.1 Warning instructions and safety precautions when work‐

ing on the battery”, page 5 .

– Switch off all electrical components and take out the ignition

key.

Battery in engine compartment:

10 Rep. gr.27 - Starter, current supply, CCS

and reconnecting battery

Page 19

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Loosen

ative terminal of the battery.

nut -2- and disconnect pole terminal -4- from the neg‐

Note

If both terminals are disconnected, only then disconnect pole ter‐

minal (-) from battery earth.

Battery in luggage compartment:

– Raise the luggage compartment floor and attach it to the body.

– Open the cover -3- above the negative terminal of the battery.

– Loosen nut -1- and disconnect pole terminal -2- from the neg‐

ative terminal of the battery.

1.3.2 Reconnecting battery

WARNING

Please observe the following additional instructions after work‐

ing on the airbag system or on the belt tighteners or the safety

belts:

♦ Switch on the ignition before connecting the battery.

♦ Nobody should be in the vehicle when the battery is being

connected.

1. Battery 11

Page 20

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

Note

♦

Neither grease nor oil the battery terminals.

♦

The battery pole terminals must only be fitted by hand without

using any force in order to avoid damaging the battery hous‐

ing.

♦

Install the battery pole terminals in such a way that the battery

pole with the terminal is on the same level or protrudes.

♦

If both terminals are disconnected, only then disconnect the

battery positive pole terminal (+).

♦

After connecting the battery and switching on the ignition, the

warning light for the stability program TCS/ESP and the warn‐

ing light for the power-assisted steering remain lit. The warning

lights go out automatically after driving a few metres forward.

Thereby the steering angle sender - G85- is activated again.

Vehicles with battery monitoring control unit - J367- (with startstop system)

– Disconnect the plug -3- from the control unit -2- before con‐

necting to the battery.

– Fit pole terminal (-) with control unit onto the “-” pol of the bat‐

tery and tighten the fixing nut -1-.

– Fit the plug -3- again onto the control unit.

Vehicles without battery monitoring control unit - J367-

pole terminal of the earth line onto the battery negative ter‐

– Fit

minal and tighten the nut -arrow-.

Continued for all vehicles:

When the battery is reconnected, perform the following opera‐

tions depending on the vehicle equipment:

♦ Set clock.

♦ Check the power windows ⇒ Maintenance ; Booklet Rapid .

♦ Code radio/navigation with anti-theft coding (not valid for radio

systems/navigation systems mounted at factory, see

⇒ “1.2 Electronic anti-theft coding”, page 60 ).

♦ Connect the ⇒ Vehicle diagnostic tester, query the event mem‐

ory and delete any event memory entries.

Tightening torques

All types of pole terminals 6 Nm

12 Rep. gr.27 - Starter, current supply, CCS

Page 21

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

1.4 Checking battery

All the notes and comments for this chapter can be found in the

Workshop

27 . If a note cannot be accessed, open the Workshop Manual

“Electrical System - General Notes” manually in “ELSA”, Section

“27”.

Manual ⇒ Electrical System - General notes; Rep. gr.

1.5 Charging battery

All the notes and comments for this chapter can be found in the

Workshop Manual ⇒ Electrical System - General notes; Rep. gr.

27 . If a note cannot be accessed, open the Workshop Manual

“Electrical System - General Notes” manually in “ELSA”, Section

“27”.

1.6 Removing and installing battery

⇒ “1.6.1 Removing and installing the battery in the engine com‐

partment”, page 13

⇒ “1.6.2 Removing and installing the battery in the luggage com‐

partment”, page 15

1.6.1 Removing and installing the battery in the engine compartment

Electrical system - Edition 02.2018

WARNING

Observe the battery handling instructions as well as the warn‐

ing instructions and safety precautions for lead acid batteries

⇒ “3.1 Warning instructions and safety precautions when work‐

ing on the battery”, page 5 .

Removing

– Disconnect the battery earth strap -4-

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

– Fold open the cover -3- and slacken the nut of the positive

terminal -2-.

– Slightly press down the catches one after the other using a

screwdriver,

of arrow -A- and fold the fuse box with the positive terminal

-1- to the side in direction of arrow -B-.

then release by tilting the screwdriver in direction

1. Battery 13

Page 22

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Unscrew bolt -1-.

– Remove mounting bracket -2-.

– Take battery -3- out of battery tray -4-.

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– Insert battery in such a way that the rear battery foot strip

catches below the pegs of the battery tray -arrows-

.

14 Rep. gr.27 - Starter, current supply, CCS

Page 23

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– The

– For batteries with hose for the central degassing, make sure

– For batteries without hose for the central degassing, make

– Check that the battery is sitting firmly after installation.

battery is properly installed when the middle recess of the

front battery foot strip is aligned at the bottom with the bore in

the battery tray -arrows-.

that the hose is not disconnected. Only then can the battery

degasify.

sure that the opening on the battery lid is not clogged.

Caution

There are certain dangers if the battery is incorrectly mounted

or mounted loosely:

♦ Shortened service life due to damage from vibration (dan‐

ger of explosion)

♦ Damage to the grid plates of the battery.

♦ Damage to battery housing by securing bracket (possibil‐

ity of acid leaking, with high consequential costs)

♦ Poor crash safety

– Lay

Tightening torques

the positive cable between the battery tray and the battery.

Battery-earth strap to battery terminal

Positive cable to battery terminal 6 Nm

Additional cable to battery positive termi‐

nal

Nuts for attaching the fuses and the con‐

nection cables in the fuse box

Mounting bracket for battery 20 Nm

6 Nm

6 Nm

6 Nm

1.6.2 Removing and installing the battery in the luggage compartment

WARNING

Observe the battery handling instructions as well as the warn‐

ing instructions and safety precautions for lead acid batteries

⇒ “3.1 Warning instructions and safety precautions when work‐

ing on the battery”, page 5 .

Removing

– Switch off the ignition and all electrical consumers!

– Raise the luggage compartment floor and attach it to the body.

– Remove boxes with tool kit and vehicle equipment.

1. Battery 15

Page 24

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Unscrew the screws -arrows- and remove the retaining clip

-1-.

– Detach and remove cover -7- for battery negative terminal

-arrows-.

– Loosen

ative terminal of the battery.

– Remove the positive terminal cover -1-.

– Loosen nut -4- and disconnect pole terminal -3- with fuse hold‐

er from the battery positive terminal.

– Disconnect hose -6- for central degassing.

– Unscrew screw -8- and remove securing bracket -9-.

– If present, remove battery's protective cover.

– Remove battery from the luggage compartment.

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– For batteries with hose for the central degassing, make sure

that the hose is not disconnected. Only then can the battery

degasify.

– Check that the battery is sitting firmly after installation.

nut -2- and disconnect pole terminal -5- from the neg‐

Caution

There are certain dangers if the battery is incorrectly mounted

or mounted loosely:

♦ Shortened service life due to damage from vibration (dan‐

ger of explosion)

♦ Damage to the grid plates of the battery.

♦ Damage to battery housing by securing bracket (possibil‐

ity of acid leaking, with high consequential costs)

♦ Poor crash safety

16 Rep. gr.27 - Starter, current supply, CCS

Page 25

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

1.7 Removing and installing earth lead with battery monitoring control unit - J367-

⇒ “1.7.1 Removing and installing earth lead with battery monitor‐

ing control unit J367 - battery in engine compartment”,

page 17

⇒ “1.7.2 Removing and installing earth lead with battery monitor‐

ing control unit J367 - battery in luggage compartment”,

page 17

1.7.1 Removing and installing earth lead with

battery monitoring control unit - J367- battery in engine compartment

Removing

– Switch off all electrical components and take out the ignition

key.

– Undo nuts -1- and remove the pole terminal with the control

unit -3- from the battery-cable terminal.

– Disconnect connector -2-.

Electrical system - Edition 02.2018

– Unscrew

tery monitoring control unit - J367- .

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– Follow the work procedure when connecting the battery

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

– Adapt the battery monitoring control unit - J367-

⇒ “1.9 Battery parameterisation”, page 19 .

Tightening torques

♦ ⇒ “1.1.1 Summary of components - battery in engine com‐

partment”, page 6

the nuts -2- and remove the earth cable -1- with bat‐

1.7.2 Removing and installing earth lead with

battery monitoring control unit - J367- battery in luggage compartment

Removing

Note

Cable straps should be fastened again in the same place when

installing.

– Switch off all electrical components and take out the ignition

key.

1. Battery 17

Page 26

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Raise

– Remove boxes with tool kit and vehicle equipment.

– Open the cover -3- above the negative terminal of the battery.

– Loosen nut and disconnect pole terminal -6- from the negative

– Separate electrical plug connection -7-.

– Cut cable straps -1-.

– Install earth lead -arrow-.

– Unscrew the nuts -5- and remove the earth cable -4- with bat‐

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– Connecting battery

Tightening torques

♦ ⇒ “1.1.2 Summary of components - battery in luggage com‐

the luggage compartment floor and attach it to the body.

terminal of the battery.

tery monitoring control unit - J367- .

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

partment”, page 8

1.8 Removing and installing battery isola‐

tion

WARNING

Observe the battery handling instructions as well as the warn‐

ing instructions and safety precautions for lead acid batteries

⇒ “3.1 Warning instructions and safety precautions when work‐

ing on the battery”, page 5 .

Removing

– Switch off all electrical components and take out the ignition

key.

– Raise

– Remove boxes with tool kit and vehicle equipment.

– Disconnect battery

– Disconnect plug connection -2-.

– Remove nuts -1- and remove battery isolation-4- from fuse

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– Connecting battery

Tightening torques

♦ ⇒ “1.1.2 Summary of components - battery in luggage com‐

the luggage compartment floor and attach it to the body.

⇒ “1.3 Disconnecting and reconnecting battery”, page 10

holder A - SA- ..

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

partment”, page 8

♦ ⇒ “1.2 Summary of components - battery isolation”, page 10

18 Rep. gr.27 - Starter, current supply, CCS

Page 27

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

1.9 Battery parameterisation

It is performed on vehicles with a start-stop system when replac‐

ing the battery with a new one of another type or with higher

capacity.

After a new start battery is installed and the battery has been par‐

ameterised, the technical data of the new battery are sent to the

battery monitoring control unit - J367- .

– ⇒ Vehicle diagnostic tester connect and select the operating

mode “Targeted fault-finding”.

– Select the “Selected Functions/Components” and subse‐

quently the following menu points using the button “Skip”:

Version 1 (older model years):

♦ Body

♦ Electrical system

♦ Diagnostic capable systems

♦ Checking battery

♦ Battery monitoring function

♦ Adaption battery parameterisation

Version 2 (recent model years):

Body

Electrical system

Systems capable of diagnostics

0019 - Data bus diagnostic interface - J5330019 - Data bus diagnostic interface - J533- function

19 - Adapt battery

Electrical system - Edition 02.2018

1.10 Removing and installing battery tray

⇒ “1.10.1 Removing and installing the battery tray in the engine

compartment”, page 19

⇒ “1.10.2 Removing and installing the battery tray in the luggage

compartment”, page 20

1.10.1 Removing and installing the battery tray

in the engine compartment

Removing

– Remove the battery

⇒ “1.6 Removing and installing battery”, page 13 .

– Vehicles

er -1-, if present, by releasing -arrows- from the battery tray

-2-.

– Vehicles with the automatic gearbox control unit fitted to the

battery tray - remove automatic gearbox control unit ⇒ Gear‐

box; Rep. gr. 37 .

with start-stop system - slacken and remove the cov‐

1. Battery 19

Page 28

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Unscrew screws -4- -3- and nuts -1-.

– Swivel air filter housing -2- slightly, raise battery tray -5- and

detach

together with water drain hose.

Installing

Installation is carried out in the reverse order.

Tightening torques

water drain hose (if present), if necessary remove tray

Nut, Pos. -1Screw, Pos. -3- 10 Nm

Screw, Pos. -4- 16 Nm

16 Nm

1.10.2 Removing and installing the battery tray

in the luggage compartment

Special tools and workshop equipment required

♦ Separating device for glued windows - V.A.G 1474 A- or sep‐

arating device for glued windows - VAS 6452-

♦ Cutting tool - V.A.G 1351-

♦ Hand pressure gun - V.A.G 1628-

20 Rep. gr.27 - Starter, current supply, CCS

Page 29

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

♦ Cartridge heater - V.A.G 1939-

Removing

– Remove the battery

⇒ “1.6.2 Removing and installing the battery in the luggage

compartment”, page 15 .

– Pull the cutting thread through the adhesive sealant to the in‐

side using a tool from the window adhesive set.

– Secure the end of the cutting thread with the pull handle -

V.A.G 1351/1- to prevent it being pulled out.

– Similarly

adhesive sealant to the inside, at the edge of the battery tray.

– Attach the mounts to the ends of the cutting thread.

– Press the cutting thread against the battery tray with the

wedge while cutting free to ensure clearance to the spare

wheel well.

– Cut out the battery tray in stages in this way.

Installing

Installation is performed in the reverse order, pay attention to the

following points:

guide the other end of the cutting thread through the

Electrical system - Edition 02.2018

WARNING

Do not prime the adhesive surface and do not treat with clean‐

ing solution. Keep the adhesive surfaces free of dirt or grease.

The activator must not come into contact with paintwork, oth‐

erwise there will be paint damage.

Do not prime the adhesive surface you have just cut with acti‐

vator or treat it with cleaning solution.

1. Battery 21

Page 30

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Cut

The remaining material serves as holding primer for the newly

applied adhesive sealing material. Keep the adhesive surfaces

free of dirt or grease.

– Glue on the battery tray with window pane adhesive ⇒ Elec‐

– Install the battery

back the remaining material on the spare wheel well using

the U-shaped cutting knife, but do not remove completely.

Note

WARNING

Exception: if the bonding is carried out later than one day after

cutting back the adhesive bead, the remaining material must

be activated with the activator.

The activator is applied evenly in one go with the applicator.

Activator must not come into contact with the paint, as this will

damage the paint.

Drying time: approx. 10 min.

tronic Catalogue of Original Parts“ETKA”

⇒ “1.6.2 Removing and installing the battery in the luggage

compartment”, page 15 .

22 Rep. gr.27 - Starter, current supply, CCS

Page 31

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

2 Jump start point

⇒ “2.1 Summary of components - jump start point”, page 23

⇒ “2.2 Removing and installing jump start point”, page 23

2.1 Summary of components - jump start point

1 - Support

❑ for jump start point and

air filter housing

❑ Removing and installing

⇒ “2.2 Removing and in‐

stalling jump start point”,

page 23

2 - Nut

❑ 2 pieces

❑ 20 Nm

3 - Plus terminal

4 - Nut

❑ 20 Nm

5 - Cap

6 - Connecting bar

❑ for positive cables

7 - Nut

❑ 10 Nm

8 - Plus terminal

❑ to E-box

9 - Screw

❑ 10 Nm

10 - E box

11 - Side panel

12 - Earth tap

❑ 20 Nm

13 - Cover

for positive tap

14 - Positive tap

❑ 20 Nm

15 - Plus terminal

❑ To starter

16 - Screw

❑ 20 Nm

Volkswagen Technical Site:

http://vwts.ru http://vwts.info

2.2 Removing and installing jump start point

Removing

– Disconnect battery

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

2. Jump start point 23

Page 32

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Remove the air filter housing ⇒ Body Work; Rep. gr. 24 .

– Release catches -arrows- and remove cover -1-.

– Unscrew and detach positive tap -6-.

– Disconnect electrical cable -7- and move clear.

– Release cap -2-.

– Unscrew nuts -1- and -5-.

– Disconnect electrical cables -3- and -4- and move clear.

– Unscrew nuts -2-.

– Unscrew bolt -3-.

– Raise mount -1- and disconnect plug connections.

– Move clear the wiring harness and take out mount -1-.

Installing

Installation is performed in the reverse order, pay attention to the

following points:

– Connecting battery

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

Tightening torques

♦ ⇒ “2.1 Summary of components - jump start point”, page 23

24 Rep. gr.27 - Starter, current supply, CCS

Page 33

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

3 Starter

⇒ “3.1 Assembly overview: starter”, page 25

⇒ “3.2 Removing and installing starter”, page 29

⇒ “3.3 Checking starter”, page 36

3.1 Assembly overview: starter

⇒ “3.1.1 Assembly overview - starter, vehicles with 5-speed man‐

ual gearbox MQ200-5F”, page 25

⇒ “3.1.2 Assembly overview - starter, vehicles with 5-speed man‐

ual gearbox MQ250-5F”, page 26

⇒ “3.1.3 Assembly overview - starter, vehicles with 6-speed man‐

ual gearbox 02U (MQ200-6F)”, page 27

⇒ “3.1.4 Starter, vehicles with 7-speed automatic gearbox 0CW

(DQ200-7F)”, page 28

3.1.1 Assembly overview - starter, vehicles with 5-speed manual gearbox MQ200-5F

1 - Starter

❑ Removing

⇒ “3.2.1 Removing and

installing the starter, ve‐

hicles with 5-speed

manual gearbox

(MQ200-5F)”,

page 29

❑

Check

⇒ “3.3 Checking start‐

er”, page 36

2 - Line 30/B+

3 - Nut

❑

20 Nm

4 - Screw

❑ 2 pieces

❑ 80 Nm

5 - Protective cap

6 - Fixing nut for line holder

❑ 20 Nm

and installing

3. Starter 25

Page 34

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

3.1.2 Assembly overview - starter, vehicles with 5-speed manual gearbox MQ250-5F

1 - Starter

❑ Removing

⇒ “3.2.2 Removing and

installing the starter, ve‐

hicles with 5-speed

manual gearbox

(MQ250-5F)”,

page 31

❑

Check

⇒ “3.3 Checking start‐

er”, page 36

2 - Screw

❑

2 pieces

❑ 80 Nm

3 - Earth cable

❑ Depends on equipment

4 - Nut

❑ Depends on equipment

❑ 20 Nm

5 - Connector

6 - Nut

❑ 2 pieces

❑ 20 Nm

7 - Cap

8 - Line 30/B+

9 - Nut

❑ Depends on equipment

❑ 20 Nm

10 - Earth cable

❑ Depends on equipment

11 - bracket for wire harness

and installing

26 Rep. gr.27 - Starter, current supply, CCS

Page 35

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

3.1.3 Assembly overview - starter, vehicles with 6-speed manual gearbox 02U (MQ200-6F)

1 - Starter

❑ Removing

⇒ “3.2.3 Removing and

installing the starter, ve‐

hicles with 6-speed

manual gearbox

(MQ200-6F)”,

page 33

❑

Check

⇒ “3.3 Checking start‐

er”, page 36

2 - Screw

❑

2 pieces

❑ 80 Nm

3 - Connector

4 - Line 30/B+

5 - Nut

❑ 20 Nm

6 - Cap

7 - bracket for wire harness

8 - Nut

❑ 20 Nm

and installing

3. Starter 27

Page 36

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

3.1.4 Starter, vehicles with 7-speed automatic gearbox 0CW (DQ200-7F)

1 - Starter

❑ Removing

⇒ “3.2.4 Removing and

installing the starter - ve‐

hicles with automatic

gearbox”, page 35

❑

Check

⇒ “3.3 Checking start‐

er”, page 36

2 - Screw

❑

80 Nm

3 - Earth cable

❑ Depends on equipment

4 - Nut

❑ Depends on equipment

❑ 20 Nm

5 - Connector

6 - Nut

❑ 20 Nm

7 - Cap

8 - Line 30/B+

9 - Screw

❑ 80 Nm

and installing

28 Rep. gr.27 - Starter, current supply, CCS

Page 37

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

3.2 Removing and installing starter

⇒ “3.2.1 Removing and installing the starter, vehicles with 5speed manual gearbox (MQ200-5F)”, page 29

⇒ “3.2.2 Removing and installing the starter, vehicles with 5speed manual gearbox (MQ250-5F)”, page 31

⇒ “3.2.3 Removing and installing the starter, vehicles with 6speed manual gearbox (MQ200-6F)”, page 33

⇒ “3.2.4 Removing and installing the starter - vehicles with auto‐

matic gearbox”, page 35

3.2.1 Removing and installing the starter, ve‐

hicles with 5-speed manual gearbox

(MQ200-5F)

Note

♦

Due to the higher requirements on the starter when the start/

stop system is activated, e.g. in urban traffic/driving, its life has

been increased and the ring gear reinforced.

♦

When carrying out repairs, pay attention to the correct desig‐

nation of the spare parts (see ⇒ Electronic Catalogue of

Original Parts “ETKA” ). Components adapted to start/stop

system are not identified separately and are not or barely dif‐

ferent from normal components in their appearance.

Electrical system - Edition 02.2018

Removing

– Disconnect battery earth strap

⇒ “1.3 Disconnecting and reconnecting battery”, page 10 .

– Engage 5th gear.

1.2 l and 1.6 MPI engine

– Remove hose -2-.

– Remove screw -1- and release retaining lugs -arrows-.

1.2 TSI engine

– Remove air exhaust -1- and hose -2-.

Continue for all engines

3. Starter 29

Page 38

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Electrical system - Edition 02.2018

– Unlock and pull off connector -1-.

– Pull

– Unscrew the plug -arrow-.

– Remove noise insulation ⇒ Engine; Rep. gr. 66 .

off the plastic cap -2-, unscrew nuts, and remove line from

terminal 30.

– Unscrew the nut -arrow- and remove the bracket for the ca‐

bles.

30 Rep. gr.27 - Starter, current supply, CCS

Page 39

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

– Unscrew screw -arrow- and take out the starter by moving it

downwards.

Installing

Installation is performed in the reverse order, pay attention to the

following points:

Note

Always use a new self-locking nut to attach the earth strap and

the positive cable (see ⇒ Electronic Catalogue of Original

Parts“ETKA” ).

Caution

In an incorrect cable/cable attachment to terminal B+ can

cause cable damage, a short-circuit and a vehicle fire.

The cable to terminal B+ must be laid and attached so that it

does not come into contact with rotating or moving parts of the

assembly (e.g. with the shift mechanism, with rotating parts of

the assembly etc.)!

Electrical system - Edition 02.2018

Tightening torques

♦ ⇒ “3.1.1 Assembly overview - starter, vehicles with 5-speed

manual gearbox MQ200-5F”, page 25

3.2.2 Removing and installing the starter, ve‐

hicles with 5-speed manual gearbox

(MQ250-5F)

Note

♦

Due to the higher requirements on the starter when the start/

stop system is activated, e.g. in urban traffic/driving, its life has

been increased and the ring gear reinforced.

♦

When carrying out repairs, pay attention to the correct desig‐

nation of the spare parts (see ⇒ Electronic Catalogue of

Original Parts “ETKA” ). Components adapted to start/stop

system are not identified separately and are not or barely dif‐