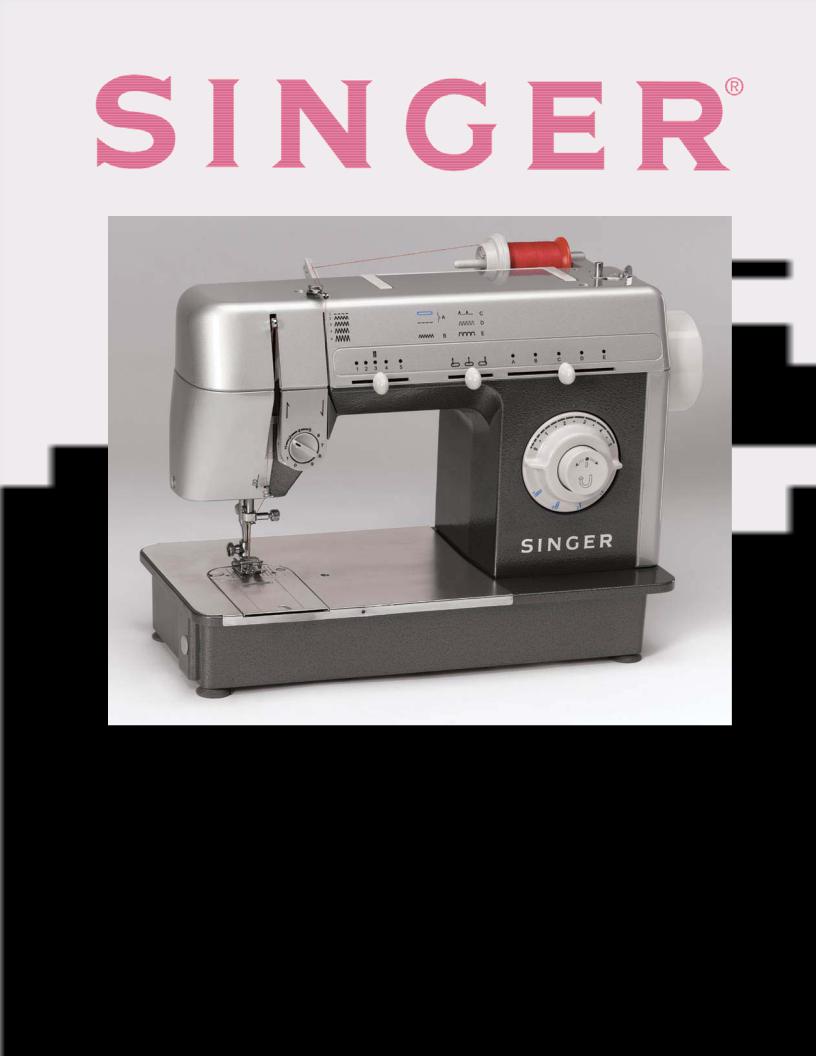

Singer CG-500 User Manual

M O D E L C G - 5 0 0

C O M M E R C I A L G R A D E S E W I N G M A C H I N E

W O R K B O O K

Congratulations on the purchase of your new SINGER®

Congratulations on the purchase of your new SINGER®

Sewing Machine! This commercial grade sewing machine

Sewing Machine! This commercial grade sewing machine

is ideal for all types of sewing, including fashion sewing,

is ideal for all types of sewing, including fashion sewing,

home decorating, quilting and crafts. Your machine is

home decorating, quilting and crafts. Your machine is

designed to deliver the ultimate combination of power,

designed to deliver the ultimate combination of power,

performance and durability.

performance and durability.

This workbook has been created as a tool for learning

This workbook has been created as a tool for learning

various sewing techniques, which you can apply to your

various sewing techniques, which you can apply to your

own projects. We are certain that your creativity will be

inspired, and that you will have many hours of sewing

inspired, and that you will have many hours of sewing

enjoyment with this easy-to-use machine, feature-packed

enjoyment with this easy-to-use machine, feature-packed  machine!

machine!

Enjoy!

Enjoy!

The SINGER® Education Department

The SINGER® Education Department

SINGER® is a registered trademark of the Singer Company Ltd.

© 2004 Singer Sewing Company

© 2004 Singer Sewing Company

All Rights Reserved.

Part # 640 5052550GK

Part # 640 5052550GK

Straight Stitching |

1 |

Straight Stitch for Topstitching |

2 |

Create Quilted Fabric |

3 |

Speed Basting |

4 |

Making Piping |

5 |

Attaching Purchased Piping |

6 |

Centered Zippers |

7 |

Satin Stitch Applique |

9 |

Lace Insertion |

11 |

Button Sewing |

13 |

Four-Step Buttonholes |

15 |

Free-Motion Monogramming |

17 |

Free-Motion Embroidery |

19 |

Blindstitch Hem |

2 |

Stretch Blindstitch Hem |

23 |

Attaching Beaded Trims |

25 |

Mending with Multi-Stitch Zigzag |

26 |

Crazy Quilting |

27 |

Seam Allowence with Stretch Blindstitch |

28 |

Attaching Elastic |

29 |

Sewing with a Wing Needle |

30 |

Twin Needle Sewing |

31 |

Applying Ribbon with a Twin Needle |

32 |

Sewing on Leather |

33 |

Narrow Hem |

34 |

Gathering with the Cording Foot |

35 |

Applying Trims, Cords & Braids |

36 |

Shirring with the Gathering Foot |

37 |

Using the Even Feed Foot to Sew Multiple Fabric Layers |

39 |

Using the Even Feed Foot to Sew Plaid Fabrics |

40 |

Using the Even Feed Foot to Sew Pile Fabrics |

41 |

Sewing with the Side Cutter |

42 |

Sewing with the Ruffler |

44 |

Heavy Duty Commercial Grade

|

CG-500 |

Up to 1100 Stitches-Per- |

Machine sews faster than a standard sewing machine. |

Minute Sewing Speed |

|

|

|

Electronic Foot Control |

Guarantees consistent speed with no jump starts. |

|

Includes a regulating dial that allows for slower speeds, |

|

regardless of the pressure applied. |

60% Stronger Motor |

The motor is stronger than a standard sewing machine |

|

motor, which means it can sew heavyweight fabrics with |

|

ease. |

Steel Plate on Machine |

Sewing pins won’t damage the steel surface of the |

Bed |

machine free arm. This feature is particularly beneficial |

|

for quilting. |

|

|

Duratec™ Frame |

A SINGER® Exclusive. This provides rigid support and |

|

helps prevent rusting. |

|

|

Double Insulated |

Double insulation protects against electric shock by |

|

creating a non-conducting barrier between the operator |

|

and the electrical components inside. |

|

|

Finger Guard |

Provides additional protection to keep fingers from |

|

getting too close to the needle area. This is especially |

|

helpful and desirable for high speed sewing. |

|

|

Utility Stitches |

A variety of stitches for fashion sewing, home dec and |

|

quilting. |

|

|

6mm Stitch Width |

Stitches can be set for a maximum width of 6mm. |

|

|

Automatic Built-In |

Buttonhole sewing is a 4-step simple process that |

Four Step Buttonhole |

provides reliable results. |

|

|

Balance Adjustment Dial |

Guarantees control for even stitching of buttonholes, as |

|

well as stretch and decorative stitches, regardless of |

|

fabric type. |

|

|

Infinitely Variable Stitch |

Settings for length and width can be adjusted as |

Length and Width |

desired, to suit any project. |

Adjustment |

|

|

|

Multiple Needle Positions |

Needle position can be changed for individual projects, |

|

such as inserting zippers or cording and topstitching. |

Horizontal Thread |

The thread feeds into the threading path in a |

Delivery |

horizontal direction, which keeps the thread from |

|

getting too much twist. |

|

|

Touch-N-Wind™ |

Needle bar easily disengages for winding the bobbin. |

Declutch Bobbin Winder |

|

Automatic Tension |

This system ensures stable stitch quality, whatever |

|

type of fabric is being used. |

Jam-Resistant Bobbin System |

This is a system in which the bobbin case actually |

|

floats above the hook, precluding thread jams. The |

|

machine will not jam, even when sewing on sheer |

|

fabric or no fabric at all! |

Top-Loading Drop-In Bobbin |

The bobbin conveniently inserts-no bobbin cases to |

|

remove or adjust. It is easy to monitor the thread |

|

supply. |

|

|

Extra-High Presser Foot Lifter |

There are 2 heights to the presser foot lifter. The |

|

second height offers ¼” more clearance, which is |

|

needed when placing multiple layers of bulky fabric |

|

under the presser foot. |

Thread Cutter |

Located for precise thread cutting, eliminating the |

|

extra step of cutting thread with scissors. |

|

|

Automatic Pressure System |

This feature automatically adjusts the pressure for |

|

sewing on fabrics from the lightest weight tricots to |

|

the heaviest denim, to maximize feed accuracy. |

|

|

Twin Needle Capable |

Stitches can be adjusted for twin needle |

|

sewing by just moving a lever. |

Suction Cup Machine Base |

Holds the machine securely to the table, even when |

|

sewing at maximum speed. |

Accessories |

Special Purpose Presser Foot |

|

Buttonhole Presser Foot |

|

Blindstitch Hem Presser Foot |

|

Zipper Foot |

|

General Purpose Foot |

|

Feed Dog Cover |

|

Finger Guard |

|

Needle Pack |

|

Bobbins |

|

|

Self-Lubricating |

Because the machine is permanently lubricated, |

|

there is no need to oil the machine, and no oil gets on |

|

fabric. |

25 Year Limited Commercial, |

Peace of mind knowing the machine has a 25 year |

School and Home Warranty |

limited warranty. |

Portable |

Machine has a built-in carry handle, making it |

|

easy to transport the machine. |

|

|

Cabinet Mountable |

Machine can be mounted into a cabinet. |

|

|

SINGER® is a registered trademark of the Singer Company Ltd.

© 2004 Singer Sewing Company.

© 2004 Singer Sewing Company.

All Rights Reserved.

All Rights Reserved.

Straight Stitching

Straight Stitching

The Straight Stitch is generally used to join seams or do topstitching. It is the

The Straight Stitch is generally used to join seams or do topstitching. It is the

most basic of the stitches and is the most commonly used. For a longer stitch

most basic of the stitches and is the most commonly used. For a longer stitch  or for thicker fabrics, lengthen the Stitch Length.

or for thicker fabrics, lengthen the Stitch Length.

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

3-4 |

Presser Foot: |

General Purpose Foot |

Needle Position: |

Center |

Materials:

Materials:

(2) 4” x 4” pieces of cotton, right sides together

(2) 4” x 4” pieces of cotton, right sides together

Procedure:

Procedure:

Place fabrics under the foot, matching the raw edges with the ⅝” seam guide.

Sew the length of the fabric.

Use the Reverse Button to reinforce the seam.

1

Straight Stitch for Topstitching

Straight Stitch for Topstitching

The Straight Stitch can be sewn “on top” of the fabric so that the stitches are

The Straight Stitch can be sewn “on top” of the fabric so that the stitches are

visible. This is different from using the straight stitch to join a seam hidden

visible. This is different from using the straight stitch to join a seam hidden

inside the project. A topstitch provides a decorative touch while holding the  seam allowances flat. It is also sturdy and durable.

seam allowances flat. It is also sturdy and durable.

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

3-4 |

Presser Foot: |

General Purpose Foot |

Needle Position: |

Center |

Materials:

Materials:

(1) 5” x 5” piece of cotton

(1) 5” x 5” piece of cotton

Procedure:

Procedure:

Press a 1” hem on one side of the edge.

Align the folded edge to the edge of the foot.

Sew.

Use the Reverse Button to reinforce the seam.

2

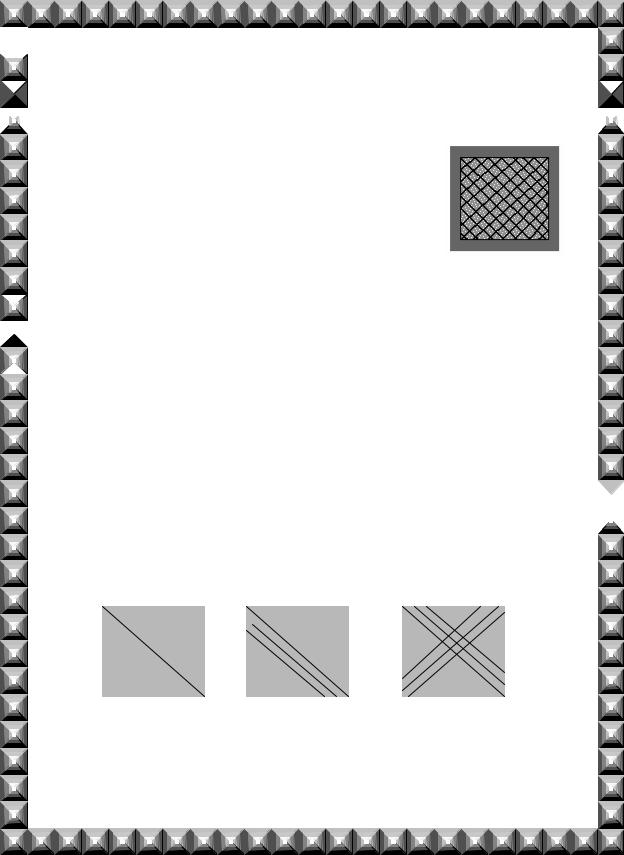

Create Quilted Fabric

Create Quilted Fabric

Create your own quilted fabric with the Straight Stitch. Texture can be added to

Create your own quilted fabric with the Straight Stitch. Texture can be added to

plain fabric by just adding consecutive rows of straight stitches!

plain fabric by just adding consecutive rows of straight stitches!

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

3-4 |

Presser Foot: |

General Purpose Foot |

Needle Position: |

Center |

Materials:

Materials:

(2) 5” x 5” pieces of cotton with batting between the two fabrics,

creating a quilt-type sample

creating a quilt-type sample

Procedure:

Procedure:

Sew diagonally from the top left corner to the bottom right corner.

Use the Reverse Lever to reinforce the seam.

Position the foot’s edge so that it rides on the previous row of stitching.

Sew successive rows using the edge of the foot to ensure even spacing and

straight lines.

straight lines.

Change the direction, sew diagonally from the top right corner to the bottom left corner.

3

Speed Basting

Speed Basting

Basting is used to temporarily hold fabrics together. Stitch length and tension

Basting is used to temporarily hold fabrics together. Stitch length and tension

are adjusted to create a looser stitch. This stitch can easily be removed with a

are adjusted to create a looser stitch. This stitch can easily be removed with a  seam ripper or simply pulled out.

seam ripper or simply pulled out.

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

5 |

Presser Foot: |

General Purpose Foot |

Tension: |

Adjust the tension setting to a smaller number |

Needle Position: |

Center |

Materials:

Materials:

(2) 4” x 4” pieces of cotton, right sides together

(2) 4” x 4” pieces of cotton, right sides together

Procedure:

Procedure:

Place under the foot, matching the raw edges with the ⅝” seam guide.

Sew the length of the fabric.

Use the seam ripper to remove a portion of the basting, or simply pull the bobbin thread to completely remove basting.

4

Making Piping

Making Piping

Piping adds a beautiful finish to projects such as pillows, sleeve edges, collars

Piping adds a beautiful finish to projects such as pillows, sleeve edges, collars

and more. The design of the Zipper Foot allows for the needle to stitch very

and more. The design of the Zipper Foot allows for the needle to stitch very

closely to the edge of the foot. This is important when inserting zippers,

applying piping or when topstitching close to the fabric’s edge. Only the

applying piping or when topstitching close to the fabric’s edge. Only the

Straight Stitch can be used when sewing with the Zipper Foot.

Straight Stitch can be used when sewing with the Zipper Foot.

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

3-4 |

Presser Foot: |

Zipper Foot |

Needle Position: |

Center |

Materials:

Materials:

5” x 6” home décor fabric  7” piping cord

7” piping cord

Procedure:

Procedure:

Fold fabric, wrong sides together.

Place piping inside of the fold.

On the right side of the fabric, sew a straight stitch close to the piping.

Note: The Zipper Foot can be attached right or left, allowing for the piping to be inserted from either side.

5

Attaching Purchased Piping

Attaching Purchased Piping

Attach pre-packaged piping to make a bold finish on home decorating

Attach pre-packaged piping to make a bold finish on home decorating  projects, crafts or garments.

projects, crafts or garments.

Machine Set-up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

3-4 |

Presser Foot: |

Zipper Foot |

Needle Position: |

Center |

Materials:

Materials:

(2) 3” x 6” pieces of home décor fabric

7” pre-packaged piping

7” pre-packaged piping

Procedure:

Procedure:

Place fabric right sides together.

Place piping between the fabrics, matching the piping’s raw edge with the fabric’s raw edges.

Piping Raw Edges

Piping Raw Edges

Stitching Line

Raw Edge of Fabric

On the wrong side of the fabric, sew a straight stitch close to the piping.

Note: The Zipper Foot can be attached right or left, allowing for the piping to be inserted from either side.

6

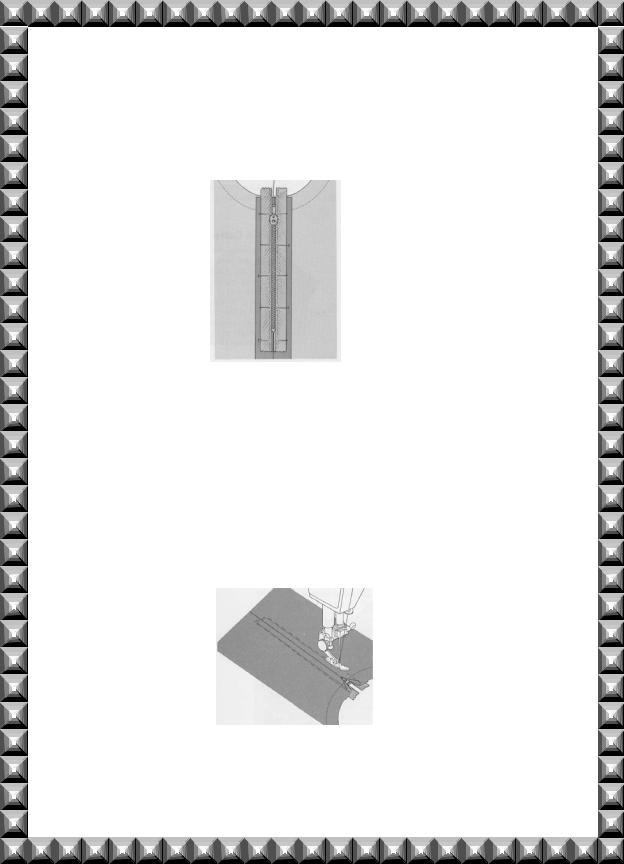

Centered Zippers

Centered Zippers

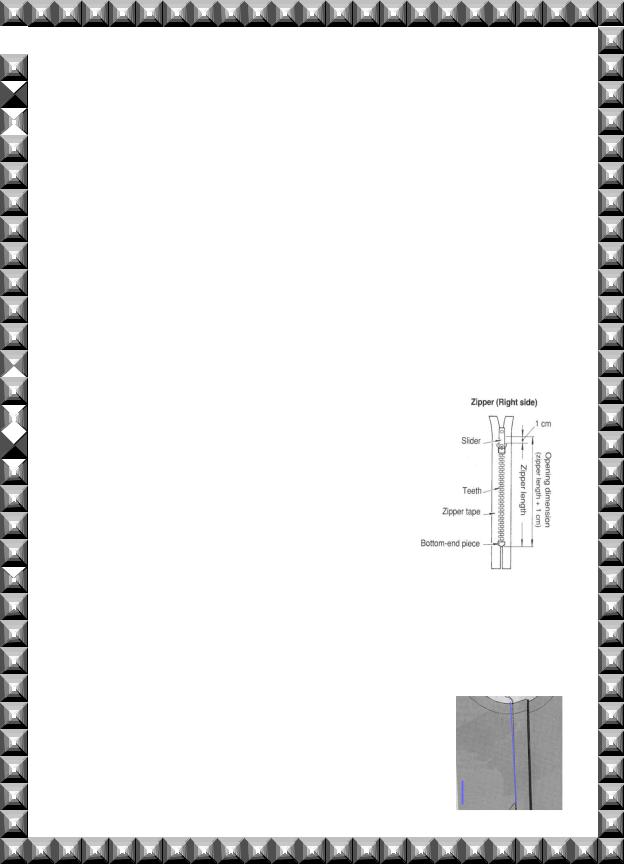

There are several ways of inserting zippers. The pattern envelope of the

There are several ways of inserting zippers. The pattern envelope of the

project or garment will designate the best type of zipper application, as well as

project or garment will designate the best type of zipper application, as well as  the length and type of zipper to use. Most applications require a zipper foot.

the length and type of zipper to use. Most applications require a zipper foot.

Machine Set-Up: |

|

Stitch: |

Straight Stitch |

Pattern Selector: |

A |

Stitch Width: |

1, no width |

Stitch Length: |

For basting: 5 |

|

For stitching: 3-4 |

Presser Foot: |

Zipper Foot |

Tension: |

For basting: loosen the tension |

|

For stitching: 3 |

Needle Position: |

Start with needle in left position |

The needle can be moved to the left or right. This will allow stitching closer to  the zipper than when the needle is in the center position.

the zipper than when the needle is in the center position.

Materials:

Materials:

(1) 7” zipper

(1) 7” zipper

(2) 8” x 4” pieces of medium weight fabric

(2) 8” x 4” pieces of medium weight fabric

Transparent tape

Transparent tape

Fabric glue stick

Procedure:

Procedure:

Place fabric under the foot, matching the raw edges with the ⅝” seam guide.

Starting at the top of the fabric, baste 7”. Then change the stitch length to 3 and finish seaming the remaining length of the fabric.

7

Press the seam open. Finish raw edges if necessary.

Apply glue stick lightly on the right side of the zipper.

Place the zipper face-down, so that the zipper’s coils or teeth are directly over the machine-basted seam. Pin in place, if necessary.

Spread fabric flat, right side up and place ½” wide transparent or perforated marking tape on top of the centered seam line. The tape should be the length of the zipper (7” long for this exercise).

Replace the Standard Presser Foot with the Zipper Foot. Adjust the foot to the left of the needle.

On the right side of the fabric, stitch around the zipper. Pivot the fabric on the needle at the corners, using the edge of the tape as a guide.

Turn fabric to right side and remove the tape and the basting. Press.

8

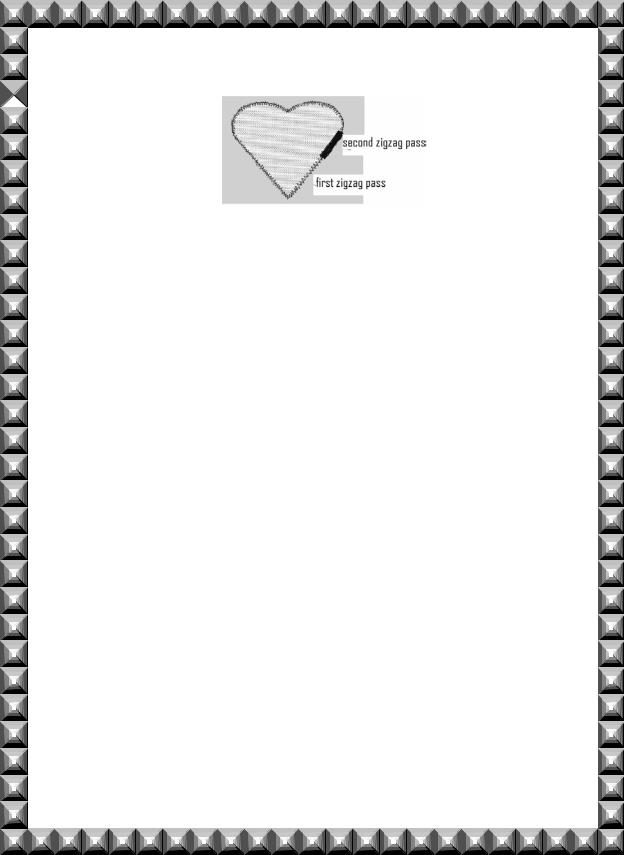

Satin Stitch Appliqué

Satin Stitch Appliqué

Satin Stitching is a series of closely spaced zig-zag stitches. Satin Stitching

Satin Stitching is a series of closely spaced zig-zag stitches. Satin Stitching

can be used for monograms, embroidery and appliqué work to produce a

can be used for monograms, embroidery and appliqué work to produce a

smooth satin-like appearance. Try a rayon thread for a smoother looking  finish.

finish.

Machine Set-Up: |

|

Stitch: |

Zigzag Stitch |

Pattern Selector: |

B |

Stitch Width: |

2-3 |

Stitch Length: |

0.5-1 |

Presser Foot: |

Special Purpose Foot (J) |

Needle Position: |

Center |

Materials:

Materials:

2” x 3” cotton fabric for appliqué

2” x 3” cotton fabric for appliqué

2” x 3” fusible stabilizer

6” x 6” cotton foundation fabric

6” x 6” cotton foundation fabric

6” x 6” tear-away stabilizer

6” x 6” tear-away stabilizer

Procedure:

Procedure:

Press the fusible stabilizer onto the appliqué.

Fuse the appliqué onto the cotton foundation fabric.

(Fusing the appliqué into place will keep the appliqué from shifting while stitching.)

Place a tear-away stabilizer underneath the fabric. (This is used to ensure quality stitching when using dense stitches.)

Place the applique under the foot, so that half of the stitch will form on the applique and half on the base fabric.

Sew around the applique.

Widen the stitch width to 4 and change the stitch length to below 1.

.

.

9

Sewing around the applique again, covering the previous stitching.

.

.

Sewing over an applique twice is not always necessary, however, it does give a beautiful full-covered effect.

10

Loading...

Loading...