Siemens 420 User Manual

MICROMASTER 420

0.12 kW - 11 kW

Operating Instructions Issue 07/04

User Documentation

6SE6400-5AA00-0BP0

MICROMASTER 420 Documentation

Getting Started Guide

Is for quick commissioning with SDP and BOP.

Operating Instructions

Gives information about features of the MICROMASTER

420, Installation, Commissioning, Control modes, System

Parameter structure, Troubleshooting, Specifications and

available options of the MICROMASTER 420.

Parameter List

The Parameter List contains the description of all

Parameters structured in functional order and a detailed

description. The Parameter list also includes a series of

function plans.

Catalogues

In the catalogue you will find all the necessary information

to select an appropriate inverter, as well as filters, chokes,

operator panels and communication options.

MICROMASTER 420

0.12 kW - 11 kW

Operating Instructions

User Documentation

Overview

Installation

Commissioning

Troubleshooting

MICROMASTER 420

specifications

Options

1

2

3

4

5

6

Valid for Release Issue 07/04

Inverter Type Control Version

MICROMASTER 420 V1.1

0.12 kW - 11 kW

Electro-magnetic

compatibility (EMC)

Appendices

Index

7

A

B

C

D

E

F

Issue 07/04

Further information is available on the Internet under:

http://www.siemens.de/micromaster

Approved Siemens Quality for Software and Training

is to DIN ISO 9001, Reg. No. 2160-01

The reproduction, transmission or use of this document,

or its contents is not permitted unless authorized in

writing. Offenders will be liable for damages. All rights

including rights created by patent grant or registration of a

utility model or design are reserved.

© Siemens AG 2001, 2002, 2004. All Rights Reserved.

MICROMASTER® is a registered trademark of Siemens.

Order Number: 6SE6400-5AA00-0BP0

Other functions not described in this document may be

available. However, this fact shall not constitute an

obligation to supply such functions with a new control, or

when servicing.

We have checked that the contents of this document

correspond to the hardware and software described.

There may be discrepancies nevertheless, and no

guarantee can be given that they are completely identical.

The information contained in this document is reviewed

regularly and any necessary changes will be included in

the next edition. We welcome suggestions for

improvement.

Siemens handbooks are printed on chlorine-free paper

that has been produced from managed sustainable

forests. No solvents have been used in the printing or

binding process.

Document subject to change without prior notice.

Siemens-Aktiengesellschaft

MICROMASTER 420 Operating Instructions

4 6SE6400-5AA00-0BP0

Issue 07/04 Foreword

Foreword

User Documentation

WARNING

Before installing and commissioning, you must read the safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make

sure that the warning labels are kept in a legible condition and replace missing or

damaged labels.

Information is also available from:

Regional Contacts

Please get in touch with your contact for Technical Support in your Region for

questions about services, prices and conditions of Technical Support.

Central Technical Support

The competent consulting service for technical issues with a broad range of

requirements-based services around our products and systems.

Europe / Africa

Tel: +49 (0) 180 5050 222

Fax: +49 (0) 180 5050 223

Email: adsupport@siemens.com

America

Tel: +1 423 262 2522

Fax: +1 423 262 2589

Email: simatic.hotline@sea.siemens.com

Asia / Pacific

Tel: +86 1064 757 575

Fax: +86 1064 747 474

Email: adsupport.asia@siemens.com

Online Service & Support

The comprehensive, generally available information system over the Internet, from

product support to service & support to the support tools in the shop.

http://www.siemens.com/automation/service&support

Contact address

Should any questions or problems arise while reading this manual, please contact

the Siemens office concerned using the form provided at the back this manual.

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

5

Definitions Issue 07/04

f

y

Definitions and Warnings

DANGER

indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

used with the safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

PE

= Ground

CAUTION

used without safety alert symbol indicates a potentially hazardous situation which, i

not avoided, may result in a property damage.

NOTICE

indicates a potential situation which, if not avoided, may result in an undesirable

result or state.

NOTES

For the purpose of this documentation, "Note" indicates important information

relating to the product or highlights part of the documentation for special attention.

Qualified personnel

For the purpose of this Instruction Manual and product labels, a "Qualified person"

is someone who is familiar with the installation, mounting, start-up and operation

of the equipment and the hazards involved. He or she must have the following

qualifications:

1. Trained and authorized to energize, de-energize, clear, ground and tag

circuits and equipment in accordance with established safety procedures.

2. Trained in the proper care and use of protective equipment in accordance with

established safety procedures.

3. Trained in rendering first aid.

♦ PE – Protective Earth uses circuit protective conductors sized for short circuits

where the voltage will not rise in excess of 50 Volts. This connection is normall

used to ground the inverter.

♦

- Is the ground connection where the reference voltage can be the same as

the Earth voltage. This connection is normally used to ground the motor.

Use for intended purpose only

The equipment may be used only for the application stated in the manual and only

in conjunction with devices and components recommended and authorized by

Siemens.

MICROMASTER 420 Operating Instructions

6 6SE6400-5AA00-0BP0

Issue 07/04 Safety Instructions

Safety Instructions

The following Warnings, Cautions and Notes are provided for your safety and as a

means of preventing damage to the product or components in the machines

connected. This section lists Warnings, Cautions and Notes, which apply generally

when handling MICROMASTER 420 Inverters, classified as General, Transport &

Storage, Commissioning, Operation, Repair and Dismantling & Disposal.

Specific Warnings, Cautions and Notes that apply to particular activities are

listed at the beginning of the relevant chapters and are repeated or supplemented

at critical points throughout these chapters.

Please read the information carefully, since it is provided for your personal

safety and will also help prolong the service life of your MICROMASTER 420

Inverter and the equipment you connect to it.

General

WARNING

♦ This equipment contains dangerous voltages and controls potentially

dangerous rotating mechanical parts. Non-compliance with Warnings or

failure to follow the instructions contained in this manual can result in loss of

life, severe personal injury or serious damage to property.

♦ Only suitable qualified personnel should work on this equipment, and only

after becoming familiar with all safety notices, installation, operation and

maintenance procedures contained in this manual. The successful and safe

operation of this equipment is dependent upon its proper handling,

installation, operation and maintenance.

♦ Risk of electric shock. The DC link capacitors remain charged for five minutes

after power has been removed. It is not permissible to open the

equipment until 5 minutes after the power has been removed.

♦ HP ratings are based on the Siemens 1LA motors and are given for

guidance only, they do not necessarily comply with UL or NEMA HP

ratings.

CAUTION

♦ Children and the general public must be prevented from accessing or

approaching the equipment!

♦ This equipment may only be used for the purpose specified by the

manufacturer. Unauthorized modifications and the use of spare parts and

accessories that are not sold or recommended by the manufacturer of the

equipment can cause fires, electric shocks and injuries.

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

7

Safety Instructions Issue 07/04

NOTICE

♦ Keep these operating instructions within easy reach of the equipment and

make them available to all users

♦ Whenever measuring or testing has to be performed on live equipment, the

regulations of Safety Code VBG 4.0 must be observed, in particular § 8

"Permissible Deviations when Working on Live Parts”. Suitable electronic tools

should be used.

♦ Before installing and commissioning, please read these safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make

sure that the warning labels are kept in a legible condition and replace missing

or damaged labels.

Transport & Storage

WARNING

♦ Correct transport, storage, erection and mounting, as well as careful

operation and maintenance are essential for proper and safe operation of the

equipment.

CAUTION

♦ Protect the inverter against physical shocks and vibration during transport and

storage. Also be sure to protect it against water (rainfall) and excessive

temperatures (see Table 5-1 on page 158).

Commissioning

WARNING

♦ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

♦ Only permanently-wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

♦ If a Residual Current-operated protective Device (RCD) is to be used, it must

be an RCD type B. Machines with a three phase power supply, fitted with

EMC filters, must not be connected to a supply via an ELCB (Earth Leakage

Circuit-Breaker - see DIN VDE 0160, section 5.5.2 and EN50178 section

5.2.11.1).

♦ The following terminals can carry dangerous voltages even if the inverter is

inoperative:

- the power supply terminals L/L1, N/L2, L3.

- the motor terminals U, V, W, DC+, DC-

♦ This equipment must not be used as an ‘emergency stop mechanism’ (see

EN 60204, 9.2.5.4)

CAUTION

The connection of power, motor and control cables to the inverter must be carried

out as shown in Fig. 2-8 on page 33, to prevent inductive and capacitive

interference from affecting the correct functioning of the inverter.

MICROMASTER 420 Operating Instructions

8 6SE6400-5AA00-0BP0

Issue 07/04 Safety Instructions

Operation

WARNING

♦ Motor parameters must be accurately configured for the motor overload

protection to operate correctly.

♦ MICROMASTERS operate at high voltages.

♦ When operating electrical devices, it is impossible to avoid applying

hazardous voltages to certain parts of the equipment.

♦ Emergency Stop facilities according to EN 60204 IEC 204 (VDE 0113) must

remain operative in all operating modes of the control equipment. Any

disengagement of the Emergency Stop facility must not lead to uncontrolled

or undefined restart.

♦ Wherever faults occurring in the control equipment can lead to substantial

material damage or even grievous bodily injury (i.e. potentially dangerous

faults), additional external precautions must be taken or facilities provided to

ensure or enforce safe operation, even when a fault occurs (e.g. independent

limit switches, mechanical interlocks, etc.).

♦ Certain parameter settings may cause the inverter to restart automatically

after an input power failure.

♦ This equipment is capable of providing internal motor overload protection in

accordance with UL508C section 42. Refer to P0610 and P0335, i

2

t is ON by

default. Motor overload protection can also be provided using an external

PTC via a digital input.

♦ This equipment is suitable for use in a circuit capable of delivering not more

than 10,000 symmetrical amperes (rms), for a maximum voltage of

230 V / 460 V when protected by a time delay fuse (see Tables starting on

page 160).

♦ This equipment must not be used as an ‘emergency stop mechanism’ (see

EN 60204, 9.2.5.4)

Repair

WARNING

♦ Repairs on equipment may only be carried out by Siemens Service, by

repair centers authorized by Siemens or by qualified personnel who are

thoroughly acquainted with all the warnings and operating procedures

contained in this manual.

♦ Any defective parts or components must be replaced using parts contained in

the relevant spare parts list.

♦ Disconnect the power supply before opening the equipment for access

Dismantling & Disposal

NOTES

♦ The inverter’s packaging is re-usable. Retain the packaging for future use or

return it to the manufacturer.

♦ Easy-to-release screw and snap connectors allow you to break the unit down

into its component parts. You can then re-cycle these component parts,

dispose of them in accordance with local requirements or return them to

the manufacturer.

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

9

Safety Instructions Issue 07/04

MICROMASTER 420 Operating Instructions

10 6SE6400-5AA00-0BP0

Issue 07/04 Table of Contents

Table of Contents

Overview ................................................................................................................ 17

1

1.1 The MICROMASTER 420....................................................................................... 18

1.2 Features.................................................................................................................. 19

2 Installation ............................................................................................................. 21

2.1 General ................................................................................................................... 23

2.2 Ambient operating conditions ................................................................................. 23

2.3 Mechanical installation............................................................................................ 25

2.4 Electrical installation ............................................................................................... 27

3 Functions............................................................................................................... 35

3.1 Parameters ............................................................................................................. 38

3.2 Operator panels for MICROMASTER..................................................................... 52

3.3 Block diagram ......................................................................................................... 56

3.4 Factory setting ........................................................................................................ 57

3.5 Commissioning ....................................................................................................... 59

3.6 Inputs / outputs ....................................................................................................... 87

3.7 Communications ..................................................................................................... 95

3.8 Fixed frequencies (FF)............................................................................................ 99

3.9 Motorized potentiometer (MOP) ........................................................................... 102

3.10 JOG....................................................................................................................... 104

3.11 PID controller (technological controller)................................................................ 106

3.12 Setpoint channel ................................................................................................... 110

3.13 Motor holding brake (MHB)................................................................................... 119

3.14 Electronic brakes .................................................................................................. 122

3.15 Automatic restart................................................................................................... 127

3.16 Flying restart ......................................................................................................... 129

3.17 Closed-loop Vdc control........................................................................................ 131

3.18 Monitoring functions / messages .......................................................................... 133

3.19 Thermal motor protection and overload responses.............................................. 135

3.20 Power module protection ...................................................................................... 139

3.21 Open-loop/closed-loop control technique ............................................................. 143

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

11

Table of Contents Issue 07/04

4 Troubleshooting.................................................................................................. 151

4.1 Troubleshooting with the SDP .............................................................................. 152

4.2 Troubleshooting with the BOP .............................................................................. 153

4.3 Fault messages and alarm messages .................................................................. 154

5 MICROMASTER 420 specifications................................................................... 157

6 Options ................................................................................................................ 165

6.1 Device-independent options ................................................................................. 165

6.2 Device-dependent options .................................................................................... 165

7 Electro-magnetic compatibility (EMC).............................................................. 167

7.1 Electro-magnetic compatibility (EMC)................................................................... 168

Appendices .............................................................................................................................. 173

A Changing the Operator Panel ............................................................................ 173

B Removing Covers ............................................................................................... 174

B.1 Removing Covers Frame Size A .......................................................................... 174

B.2 Removing Covers Frame Size B and C................................................................ 175

C Removing ‘Y’ Cap ............................................................................................... 176

C.1 Removing ‘Y’ Cap Frame Size A .......................................................................... 176

C.2 Removing ‘Y’ Cap Frame Size B and C................................................................ 177

D Removing fan ...................................................................................................... 178

D.1 Removing fan, Frame Size A................................................................................ 178

D.2 Removing fan, Frame Sizes B and C ................................................................... 179

E Applicable Standards ......................................................................................... 180

F List of Abbreviations.......................................................................................... 181

Index .............................................................................................................................. 184

MICROMASTER 420 Operating Instructions

12 6SE6400-5AA00-0BP0

Issue 07/04 Table of Contents

List of Illustrations

Fig. 2-1 Forming ................................................................................................................................23

Fig. 2-2 Ambient operating temperature ............................................................................................ 23

Fig. 2-3 Installation altitude................................................................................................................ 24

Fig. 2-4 Drill pattern for MICROMASTER 420 ...................................................................................25

Fig. 2-5 MICROMASTER 420 connection terminals.......................................................................... 29

Fig. 2-6 Motor and Power Connections ............................................................................................. 30

Fig. 2-7 Control terminals of MICROMASTER 420............................................................................ 31

Fig. 2-8 Wiring Guidelines to Minimize the Effects of EMI ................................................................. 33

Fig. 3-1 Parameter types ................................................................................................................... 38

Fig. 3-2 Header line for parameter P0305 .........................................................................................42

Fig. 3-3 Parameter grouping / access................................................................................................ 43

Fig. 3-4 Binectors ..............................................................................................................................47

Fig. 3-5 Connectors ........................................................................................................................... 48

Fig. 3-6 BICO connections (examples).............................................................................................. 49

Fig. 3-7 Normalization / de-normalization .......................................................................................... 51

Fig. 3-8 Operator panels.................................................................................................................... 52

Fig. 3-9 Operator panel keys .............................................................................................................54

Fig. 3-10 Changing parameters using the BOP................................................................................... 55

Fig. 3-11 MICROMASTER 420 – block diagram .................................................................................56

Fig. 3-12 Status Display Panel (SDP).................................................................................................. 57

Fig. 3-13 Recommended wiring for the factory setting ........................................................................58

Fig. 3-14 Procedure when commissioning........................................................................................... 59

Fig. 3-15 DIP switch to change-over between 50/60 Hz...................................................................... 61

Fig. 3-16 Mode of operation of the 50/60 Hz DIP switch in conjunction with P0100............................ 61

Fig. 3-17 Example of a typical motor rating plate ................................................................................ 65

Fig. 3-18 Motor terminal box................................................................................................................ 66

Fig. 3-19 Star / delta circuit configurations .......................................................................................... 67

Fig. 3-20 V/f characteristic................................................................................................................... 67

Fig. 3-21 Upread / download using AOP and PC Tools....................................................................... 84

Fig. 3-22 Digital inputs......................................................................................................................... 87

Fig. 3-23 Digital output ........................................................................................................................90

Fig. 3-24 Connection example for ADC voltage input.......................................................................... 92

Fig. 3-25 ADC channel ........................................................................................................................92

Fig. 3-26 Wire breakage monitoring .................................................................................................... 93

Fig. 3-27 Signal output through the DAC channel ............................................................................... 94

Fig. 3-28 DAC channel ........................................................................................................................94

Fig. 3-29 Serial communication interfaces - BOP link and COM link ................................................... 95

Fig. 3-30 RS485 Terminator ................................................................................................................98

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

13

Table of Contents Issue 07/04

Fig. 3-31 USS bus configuration.......................................................................................................... 98

Fig. 3-32 Example for directly selecting FF1 via DIN1 and FF2 via DIN2.......................................... 100

Fig. 3-33 Example for selecting FF1 via DIN1 and FF2 via DIN2 using the binary-coded method .... 101

Fig. 3-34 Motorized potentiometer..................................................................................................... 102

Fig. 3-35 JOG counter-clockwise and JOG clockwise ....................................................................... 104

Fig. 3-36 Structure of the technological controller (PID controller) ....................................................106

Fig. 3-37 PID controller...................................................................................................................... 107

Fig. 3-38 Example to directly select the PID fixed frequency of fixed frequency 1 via DIN1.............. 109

Fig. 3-39 Setpoint channel................................................................................................................. 110

Fig. 3-40 Summation .........................................................................................................................111

Fig. 3-41 Modifying the frequency setpoint........................................................................................ 111

Fig. 3-42 Ramp-function generator.................................................................................................... 112

Fig. 3-43 Rounding off after an OFF1 command ...............................................................................113

Fig. 3-44 OFF1 .................................................................................................................................. 115

Fig. 3-45 OFF2 .................................................................................................................................. 116

Fig. 3-46 OFF3 .................................................................................................................................. 116

Fig. 3-47 Changing-over using the BICO parameter P0810 .............................................................. 117

Fig. 3-48 Motor holding brake after ON / OFF1 ................................................................................. 119

Fig. 3-49 Motor holding brake after OFF2 ......................................................................................... 120

Fig. 3-50 Inter-dependency of the electronic brakes.......................................................................... 122

Fig. 3-51 DC braking after OFF1 / OFF3 ........................................................................................... 123

Fig. 3-52 DC braking after external selection .................................................................................... 124

Fig. 3-53 Compound braking .............................................................................................................125

Fig. 3-54 Flying restart....................................................................................................................... 130

Fig. 3-55 Vdc_max controller............................................................................................................. 131

Fig. 3-56 Drive inverter response ...................................................................................................... 136

Fig. 3-57 PTC characteristic for 1LG / 1LA motors........................................................................... 137

Fig. 3-58 Connecting a temperature sensor to MICROMASTER 420................................................ 138

Fig. 3-59 Drive inverter response to an overload condition ............................................................... 140

Fig. 3-60 Overload response of the drive inverter (P0290)................................................................ 141

Fig. 3-61 Operating ranges and characteristics of an induction motor when fed from a drive inverter144

Fig. 3-62 Slip compensation ..............................................................................................................148

Fig. 3-63 Effect of V/f resonance damping ........................................................................................ 149

Fig. 3-64 Imax controller.................................................................................................................... 150

MICROMASTER 420 Operating Instructions

14 6SE6400-5AA00-0BP0

Issue 07/04 Table of Contents

List of Tables

Table 2-1 Dimensions and Torques of MICROMASTER 420............................................................... 25

Table 3-1 Parameter attributes............................................................................................................. 40

Table 3-2 Parameter P0700 .................................................................................................................44

Table 3-3 Parameter P1000 .................................................................................................................45

Table 3-4 Parameter P0719 .................................................................................................................46

Table 3-5 Normalized interfaces...........................................................................................................50

Table 3-6 Normalization functions ........................................................................................................ 50

Table 3-7 Pre-assignment of the digital inputs ..................................................................................... 57

Table 3-8 Example 1LA7060-4AB10 ....................................................................................................68

Table 3-9 Parameter for motor/control data.......................................................................................... 69

Table 3-10 Parameters P0701 – P0706 ................................................................................................. 88

Table 3-11 Parameter P0731 (frequently used functions / states).......................................................... 91

Table 3-12 BOP link ...............................................................................................................................96

Table 3-13 COM link............................................................................................................................... 96

Table 3-14 Example for direct coding via digital inputs........................................................................... 99

Table 3-15 Example for binary coding via digital inputs........................................................................ 101

Table 3-16 Mode of operation of the MOP ........................................................................................... 103

Table 3-17 Selecting the motorized potentiometer ...............................................................................103

Table 3-18 Correspondence between the parameters ......................................................................... 108

Table 3-19 BICO parameters for ramp-function generator ................................................................... 114

Table 3-20 Examples for the parameter settings of P0810................................................................... 117

Table 3-21 Possible parameter settings for P0719............................................................................... 118

Table 3-22 Automatic restarts ..............................................................................................................127

Table 3-23 Settings for parameter P1200............................................................................................. 129

Table 3-24 Partial excerpt of monitoring functions / messages ............................................................ 134

Table 3-25 Thermal classes ................................................................................................................. 137

Table 3-26 General protection of the power components..................................................................... 139

Table 3-27 V/f characteristic (parameter P1300).................................................................................. 144

Table 3-28 Voltage boost ..................................................................................................................... 145

Table 4-1 Inverter conditions indicated by the LEDs on the SDP ....................................................... 152

Table 5-1 MICROMASTER Performance Ratings.............................................................................. 158

Table 5-2 Dimensions, required cooling air flow and tightening torques for power terminals .............159

Table 5-3 Current reduction depending on pulse frequency............................................................... 159

Table 5-4 MICROMASTER 420 Specifications .................................................................................. 160

Table 7-1 Permissible harmonic current emissions ............................................................................ 169

Table 7-2 Class 1 - General Industrial................................................................................................ 170

Table 7-3 Class 2 - Filtered Industrial................................................................................................. 170

Table 7-4 Class 3 - Filtered for Residential, Commercial and Light Industry ...................................... 171

Table 7-5 Compliance Table .............................................................................................................. 172

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

15

Table of Contents Issue 07/04

MICROMASTER 420 Operating Instructions

16 6SE6400-5AA00-0BP0

Issue 07/04 1 Overview

1 Overview

This Chapter contains:

A summary of the major features of the MICROMASTER 420 range.

1.1

The MICROMASTER 420....................................................................................... 18

1.2 Features.................................................................................................................. 19

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

17

1 Overview Issue 07/04

1.1 The MICROMASTER 420

The MICROMASTER 420s are a range of frequency inverters for controlling the

speed of three phase AC motors. The various models available range from the

120 W single-phase input to the 11 kW three-phase input.

The inverters are microprocessor-controlled and use state-of-the-art Insulated Gate

BipoIar Transistor (IGBT) technology. This makes them reliable and versatile. A

special pulse-width modulation method with selectable Pulse frequency permits

quiet motor operation. Comprehensive protective functions provide excellent

inverter and motor protection.

The MICROMASTER 420 with its default factory settings, is ideal for a large range

of simple motor control applications. The MICROMASTER 420 can also be used

for more advanced motor control applications via its comprehensive parameter

lists.

The MICROMASTER 420 can be used in both 'stand-alone' applications as well as

being integrated into 'Automation Systems'.

MICROMASTER 420 Operating Instructions

18 6SE6400-5AA00-0BP0

Issue 07/04 1 Overview

1.2 Features

Main Characteristics

Easy installation

Easy commissioning

Rugged EMC design

Can be operated on IT line supplies

Fast repeatable response time to control signals

Comprehensive range of parameters enabling configuration for a wide range of

applications

Simple cable connection

1 Output relay

1 Analog output (0 – 20 mA)

3 Isolated and switchable NPN/PNP digital inputs

1 Analog input, ADC: 0 – 10 V

The analog input can be used as the 4

BICO technology

Modular design for extremely flexible configuration

High switching frequencies for low-noise motor operation

Detailed status information and integrated message functions

th

digital input

Performance Characteristics

V/f Control

♦ Flux Current Control (FCC) for improved dynamic response and motor

control

♦ Multi-point V/f characteristic

Automatic restart

Flying restart

Slip compensation

Fast Current Limitation (FCL) for trip-free operation

Motor holding brake

Built-in DC injection brake

Compound braking to improve braking performance

Setpoint input via:

♦ Analog input

♦ Communication interface

♦ JOG function

♦ Motorized potentiometer

♦ Fixed frequencies

Ramp function generator

♦ With smoothing

♦ Without smoothing

Closed-loop control with proportional-integral controller function (PI)

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

19

1 Overview Issue 07/04

Protection characteristics

Overvoltage/undervoltage protection

Overtemperature protection for the inverter

Ground fault protection

Short-circuit protection

2

i

t thermal motor protection

PTC for motor protection

Options

Refer to Chapter 6

MICROMASTER 420 Operating Instructions

20 6SE6400-5AA00-0BP0

Issue 07/04 2 Installation

2 Installation

This Chapter contains:

General data relating to installation

Dimensions of Inverter

Wiring guidelines to minimize the effects of EMI

Details concerning electrical installation

2.1

General ................................................................................................................... 23

2.2 Ambient operating conditions ................................................................................. 23

2.3 Mechanical installation............................................................................................ 24

2.4 Electrical installation ............................................................................................... 27

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

21

2 Installation Issue 07/04

WARNING

♦ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

♦ Only permanently-wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

♦ If a Residual Current-operated protective Device (RCD) is to be used, it must

be an RCD type B. Machines with a three-phase power supply, fitted with

EMC filters, must not be connected to a supply via an ELCB (Earth Leakage

Circuit-Breaker EN50178 Section 5.2.11.1).

♦ The following terminals can carry dangerous voltages even if the inverter is

inoperative:

- the power supply terminals L/L1, N/L2, L3.

- the motor terminals U, V, W, DC+, DC-

♦ Always wait 5 minutes to allow the unit to discharge after switching off before

carrying out any installation work.

♦ This equipment must not be used as an ‘emergency stop mechanism’ (see

EN 60204, 9.2.5.4)

CAUTION

The connection of power, motor and control cables to the inverter must be carried

out as shown in Fig. 2-8 on page 33, to prevent inductive and capacitive

interference from affecting the correct functioning of the inverter.

MICROMASTER 420 Operating Instructions

22 6SE6400-5AA00-0BP0

Issue 07/04 2 Installation

2.1 General

Installation after a Period of Storage

Following a prolonged period of storage, you must reform the capacitors in the

inverter. The requirements are listed below.

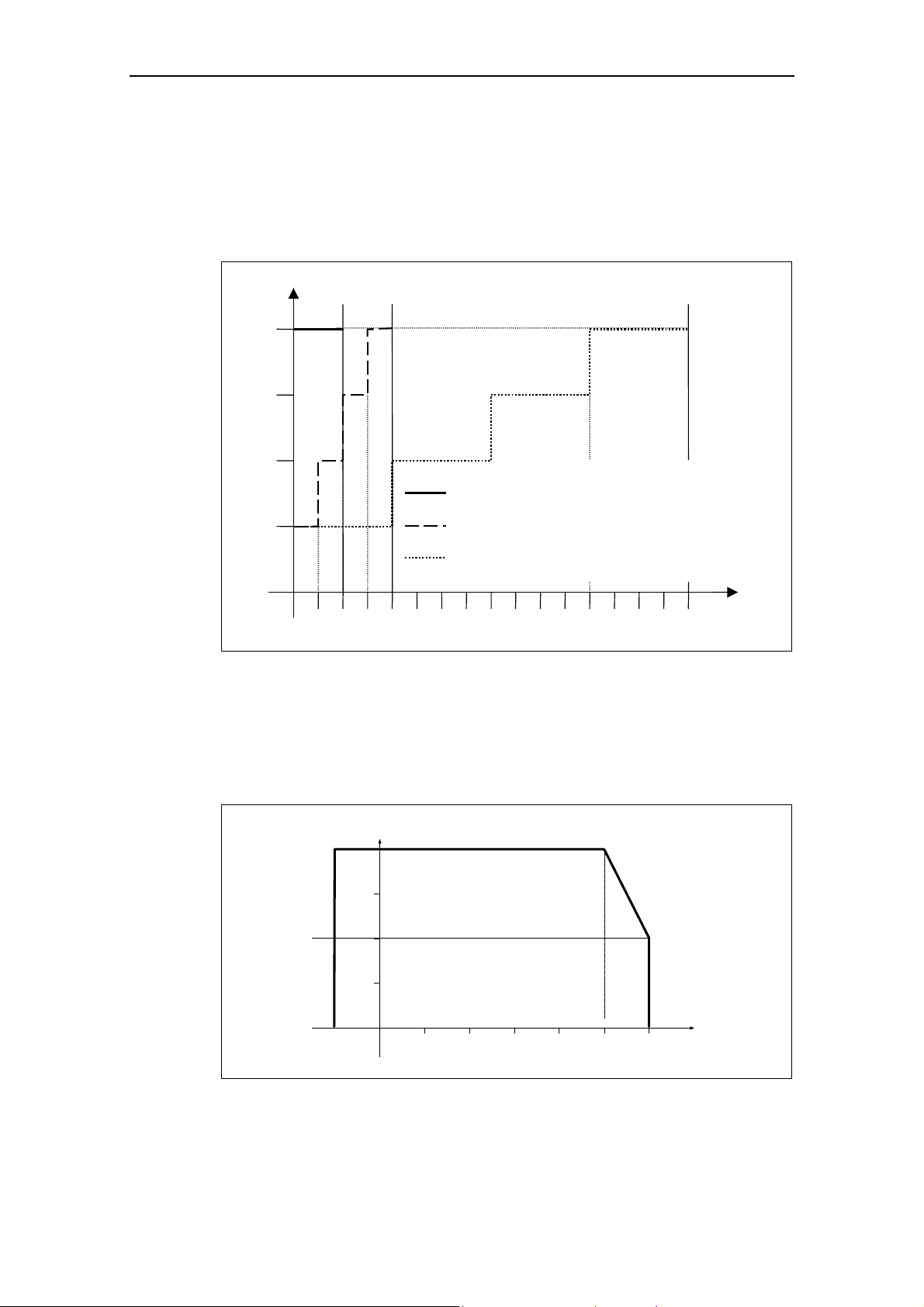

Voltage

[%]

100

75

50

0,5 1

2468

Storage period less than 1 year:

Storage period 1 to 2 years Prior to energizing, connect to

Storage period 2 to 3 years Prior to energizing, form

Storage period 3 and more years Prior to energizing, form

Fig. 2-1 Forming

2.2 Ambient operating conditions

Temperature

Permissible output current

100

[%]

75

No action necessary

voltage for one hour

according to the curve

according to the curve

Time t [h]

50

25

-10

0

20 301040

Operating temperature

50

60

[°C]

Fig. 2-2 Ambient operating temperature

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

23

2 Installation Issue 07/04

Humidity

Relative air humidity ≤ 95% Non-condensing

Altitude

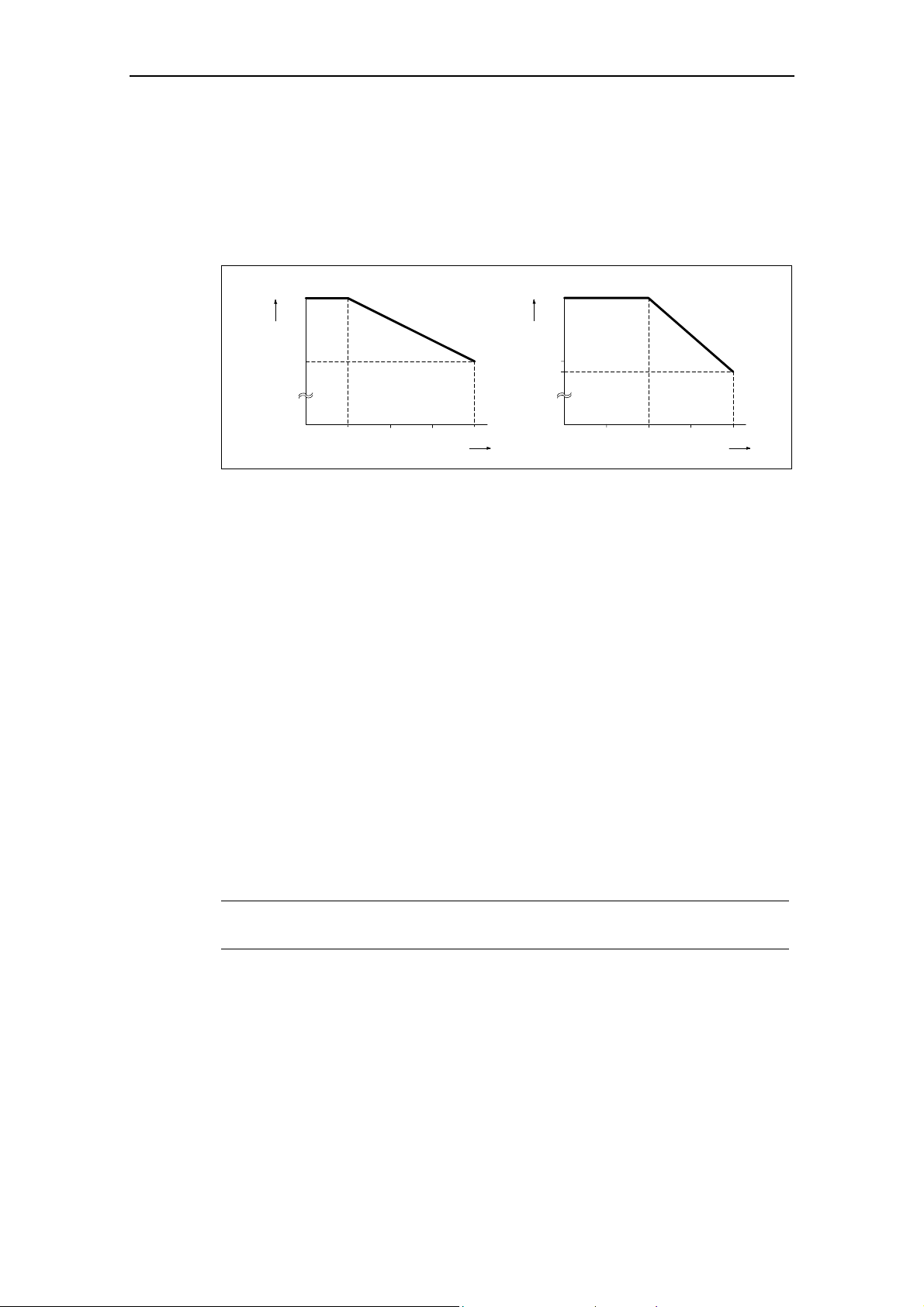

If the inverter is to be installed at an altitude > 1000 m or > 2000 m above sea

level, derating will be required:

Permissible output current

100

%

80

01000

Installation altitude in m above sea level

Fig. 2-3 Installation altitude

Shock and Vibration

Do not drop the inverter or expose to sudden shock. Do not install the inverter in an

area where it is likely to be exposed to constant vibration.

Mechanical strength to DIN IEC 68-2-6

Deflection: 0.075 mm (10 ... 58 Hz)

Acceleration: 9.8 m/s

Electromagnetic Radiation

Do not install the inverter near sources of electromagnetic radiation.

Atmospheric Pollution

Do not install the inverter in an environment, which contains atmospheric pollutants

such as dust, corrosive gases, etc.

2000

3000 4000

2

(> 58 ... 500 Hz)

Permissible input voltage

100

%

80

77

01000

Installation altitude in m above sea level

2000

3000 4000

Water

Take care to site the inverter away from potential water hazards, e.g. do not install

the inverter beneath pipes that are subject to condensation. Avoid installing the

inverter where excessive humidity and condensation may occur.

Installation and cooling

MICROMASTER 420 Operating Instructions

24 6SE6400-5AA00-0BP0

CAUTION

The inverters MUST NOT be mounted horizontally.

The inverters can be mounted without any clearance at either side.

Allow 100 mm clearance above and below the inverter. Make sure that the cooling

vents in the inverter are positioned correctly to allow free movement of air.

Issue 07/04 2 Installation

2.3 Mechanical installation

WARNING

♦ To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

♦ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN

50178), as well as the relevant regulations regarding the correct use of tools

and personal protective gear.

♦ The mains input, DC and motor terminals, can carry dangerous voltages even

if the inverter is inoperative; wait 5 minutes to allow the unit to discharge after

switching off before carrying out any installation work.

♦ The inverters can be mounted adjacent to each other. If they are mounted on

top of each other, however, a clearance of 100 mm has to be observed.

4

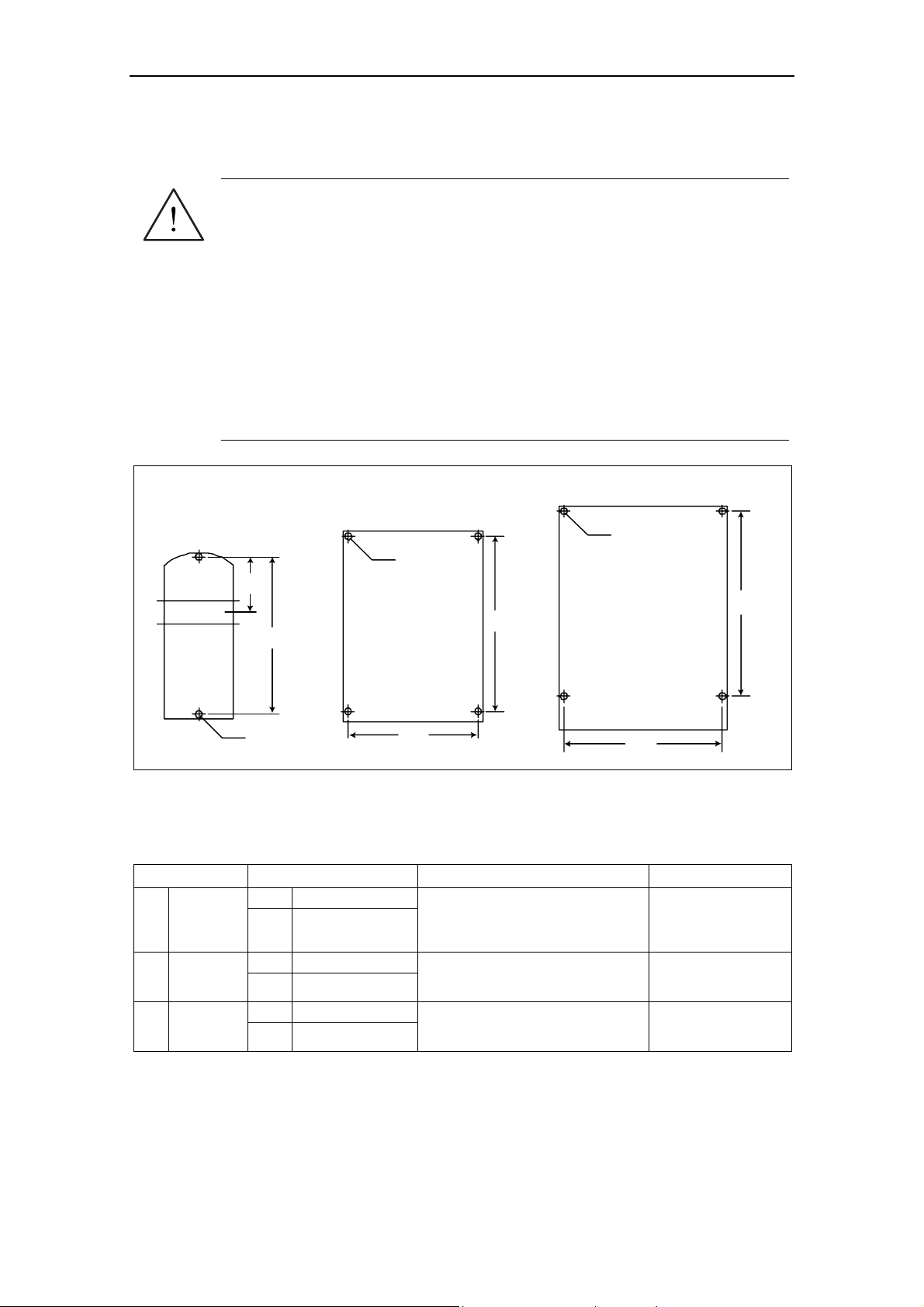

Frame Size A Frame Size B

Ø 4.8 mm

55 mm

2.2"

160 mm

6.30"

Ø 4.5 mm

0.17"

0.19"

138 mm

5.43"

174 mm

6.85"

Frame Size C

Ø 5.5 mm

0.22"

174 mm

6.85"

204 mm

8.03"

Fig. 2-4 Drill pattern for MICROMASTER 420

Table 2-1 Dimensions and Torques of MICROMASTER 420

Frame-Size Overall Dimensions Fixing Method Tightening Torque

2 x M4 Bolts

2 x M4 Nuts

2 x M4 Washers for mounting on

standard rail

4 x M4 Bolts

4 x M4 Nuts

4 x M4 Washers

4 x M5 Bolts

4 x M5 Nuts

4 x M5 Washers

2.5 Nm

with washers fitted

2.5 Nm

with washers fitted

2.5 Nm

with washers fitted

A

B

C

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

mm 73 x 173 x 149

inch 2.87 x 6.81 x 5.87

mm 149 x 202 x 172

inch 5.87 x 7.95 x 6.77

mm 185 x 245 x 195

inch 7.28 x 9.65 x 7.68

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

25

2 Installation Issue 07/04

2.3.1 Mounting on standard rail, Frame Size A

Fitting the Inverter to a 35 mm standard rail (EN 50022)

Release Mechanism

Upper

rail latch

Lower

rail latch

Removing the Inverter from the rail

1. To disengaged the release mechanism of the inverter, insert a screwdriver into

the release mechanism.

2. Apply a downward pressure and the lower rail latch will disengage.

3. Pull the inverter from the rail.

1. Fit the inverter to the rail using the upper rail

latch.

2. Push the

inverter

against the

rail and the

lower rail

latch should

click into

place.

MICROMASTER 420 Operating Instructions

26 6SE6400-5AA00-0BP0

Issue 07/04 2 Installation

2.4 Electrical installation

WARNING

The inverter must always be grounded.

♦ To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

♦ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN

50178), as well as the relevant regulations regarding the correct use of tools

and personal protective gear.

♦ Never use high voltage insulation test equipment on cables connected to the

inverter.

♦ The mains input, DC and motor terminals, can carry dangerous voltages even

if the inverter is inoperative; wait 5 minutes to allow the unit to discharge

after switching off before carrying out any installation work.

CAUTION

The control, power supply and motor leads must be laid separately. Do not feed

them through the same cable conduit/trunking.

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

27

2 Installation Issue 07/04

2.4.1 General

WARNING

The inverter must always be grounded. If the inverter is not grounded correctly,

extremely dangerous conditions may arise within the inverter, which could prove

potentially fatal.

Operation with ungrounded (IT) supplies

It is not permissible to connect MICROMASTER 4 drive converters equipped with

integrated filter to non-grounded line supplies.

If connected to non-grounded line supplies, the 'Y' capacitor must be disabled in

the device. The procedure is described in Attachment B.2.

The MICROMASTER operates on non-grounded line supplies and remains

operational if an input or output phase is connected to ground. In this particular

case, an output reactor must be installed.

Operation with Residual Current Device

If an RCD (also referred to as ELCB or RCCB) is fitted, the MICROMASTER

inverters will operate without nuisance tripping, provided that:

A type B RCD is used.

The trip limit of the RCD is 300mA.

The neutral of the supply is grounded.

Only one inverter is supplied from each RCD.

The output cables are less than 50m (screened) or 100m (unscreened).

Operation with long cables

All inverters will operate at full specification with cable lengths up to 50 m screened

or 100 m unscreened.

When using output reactors as shown in Catalog DA 51.2, the following cable

lengths are possible for all of the types of construction/sizes:

Shielded: 200 m

Non-shielded: 300 m

MICROMASTER 420 Operating Instructions

28 6SE6400-5AA00-0BP0

Issue 07/04 2 Installation

2.4.2 Power and motor connections

WARNING

The inverter must always be grounded.

♦ Isolate the mains electrical supply before making or changing connections to

the unit.

♦ Ensure that the motor is configured for the correct supply voltage: single /

three-phase 230 V MICROMASTERS must not be connected to a 400 V

three-phase supply.

♦ When synchronous motors are connected or when coupling several motors in

parallel, the inverter must be operated with voltage/frequency control

characteristic (P1300 = 0, 2 or 3).

CAUTION

After connecting the power and motor cables to the proper terminals, make sure

that the covers have been replaced properly before supplying power to the unit!

NOTICE

♦ Ensure that the appropriate circuit-breakers/fuses with the specified current

rating are connected between the power supply and inverter (see chapter 5,

Tables starting on page 160).

♦ Use Class 1 60/75

o

C copper wire only (for UL compliance). For tightening

torque see Table 5-2, page 159.

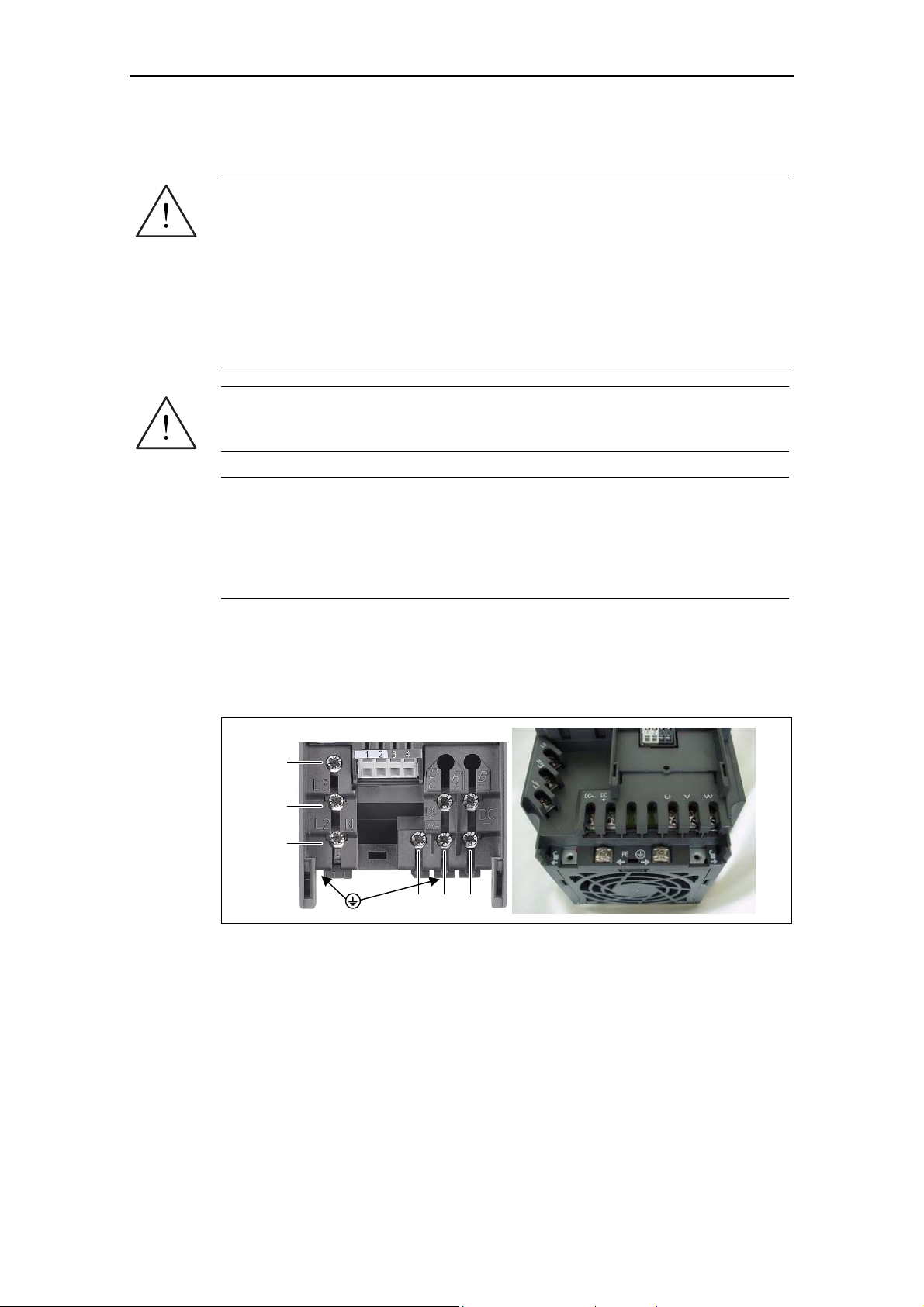

Access to the power and motor terminals

You can gain access to the mains and motor terminals by removing the covers

(see also Appendices A and B).

The mains and motor connections must be made as shown in Fig. 2-6.

L3

L2/N

L1/L

UVW

Fig. 2-5 MICROMASTER 420 connection terminals

MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

29

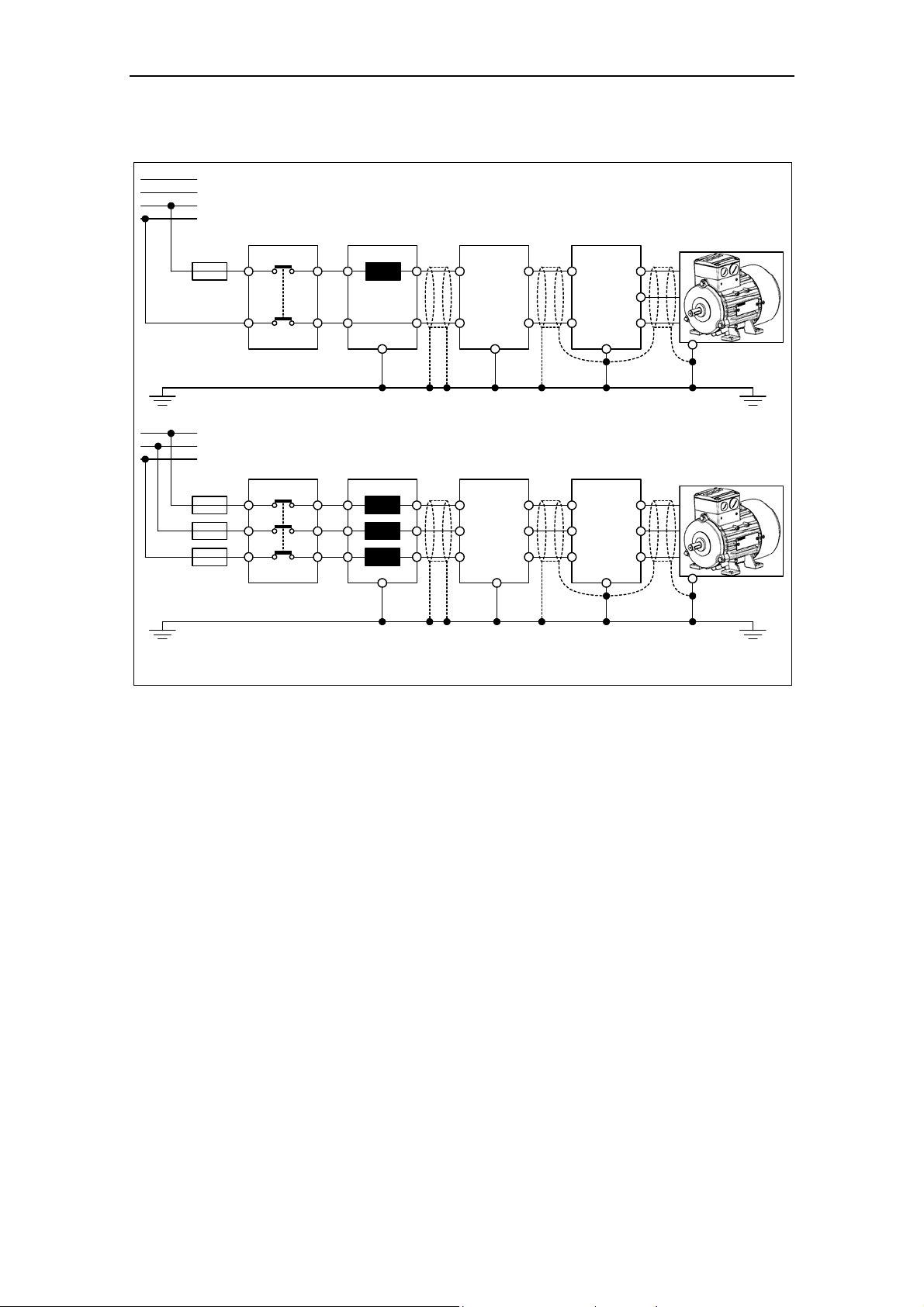

2 Installation Issue 07/04

L3

L2

L1

N

Fuse

L3

L2

L1

Fuse

Contactor

Contactor

Single Phase

Optional

line choke

PE

Three Phase

Optional

line choke

PE

Optional

Filter

PE

Optional

Filter

PE

MICROMASTER

L/L1

U

V

N/L2

W

PE

MICROMASTER

L3

U

L2

V

L1

W

PE

1)

1)

Motor

Motor

1) with and without filter

Fig. 2-6 Motor and Power Connections

MICROMASTER 420 Operating Instructions

30 6SE6400-5AA00-0BP0

Loading...

Loading...