Sick V200, V300 User Manual

O P E R A T I N G I N S T R U C T I O N S

V200 Work Station Extended,

V300 Work Station Extended

Safety camera system

en

Operating Instructions

V200/V300

This document is protected by the law of copyright, whereby all rights established therein remain with the company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without the explicit written approval of the company SICK AG.

2 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

|

|

Subject to change without notice |

Operating Instructions

V200/V300

Contents

Contents

1 About this document.................................................................................................... |

5 |

|

1.1 |

Function of this document................................................................................ |

5 |

1.2 |

Target group ..................................................................................................... |

5 |

1.3 |

Information depth............................................................................................. |

5 |

1.4 |

Scope................................................................................................................ |

6 |

1.5 |

Abbreviations used........................................................................................... |

6 |

1.6 |

Symbols used ................................................................................................... |

6 |

2 On safety....................................................................................................................... |

|

8 |

|

2.1 |

Qualified safety personnel................................................................................ |

8 |

|

2.2 |

Applications of the device................................................................................. |

9 |

|

2.3 |

Correct use ....................................................................................................... |

9 |

|

2.4 |

General safety notes and protective measures.............................................. |

10 |

|

2.5 |

Environmental protection ............................................................................... |

11 |

|

|

2.5.1 |

Disposal......................................................................................... |

11 |

|

2.5.2 |

Separation of materials................................................................. |

11 |

3 Product description.................................................................................................... |

12 |

||

3.1 |

Special features.............................................................................................. |

12 |

|

3.2 |

Operating principle of the device.................................................................... |

12 |

|

3.3 |

Application examples...................................................................................... |

13 |

|

3.4 |

Configurable functions.................................................................................... |

14 |

|

|

3.4.1 |

Restart interlock............................................................................ |

14 |

|

3.4.2 |

External device monitoring (EDM) ................................................. |

15 |

3.5 |

Status indicators............................................................................................. |

16 |

|

|

3.5.1 |

Status LEDs of the V200/V300..................................................... |

16 |

|

3.5.2 |

Diagnostics LEDs of the V200/V300............................................. |

17 |

4 Mounting .................................................................................................................... |

|

18 |

|

4.1 |

Checking the dimensions of the protective field............................................. |

18 |

|

|

4.1.1 |

Protective field dimensions allowed at a resolution of |

|

|

|

20 mm........................................................................................... |

18 |

|

4.1.2 |

Protective field dimensions allowed at a resolution of |

|

|

|

24 mm........................................................................................... |

19 |

|

4.1.3 |

Protective field dimensions allowed at a resolution of |

|

|

|

30 mm........................................................................................... |

19 |

4.2 |

Determining the minimum distance ............................................................... |

20 |

|

|

4.2.1 |

Minimum distance according to EN ISO 13 855 and |

|

|

|

EN ISO 13 857............................................................................... |

21 |

|

4.2.2 |

Minimum distance if OSHA and ANSI are applicable..................... |

23 |

4.3 |

Avoiding unmonitored areas........................................................................... |

24 |

|

4.4 |

Steps for mounting the safety camera system ............................................... |

26 |

|

|

4.4.1 |

Mounting on a frame ..................................................................... |

27 |

|

4.4.2 |

Mounting in a frame ...................................................................... |

28 |

|

4.4.3 |

Mounting the reflective tape ......................................................... |

29 |

5 Electrical installation................................................................................................. |

31 |

|

5.1 |

System connection M12 × 8 ........................................................................... |

32 |

5.2Connecting the V200/V300 without external device monitoring (EDM), without internal restart interlock and without external key-operated

pushbutton for teach-in .................................................................................. |

33 |

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

3 |

Subject to change without notice

Contents

Operating Instructions

V200/V300

5.3Connecting the V200/V300 with external device monitoring (EDM),

|

with internal restart interlock and with external key-operated |

|

|

|

pushbutton for teach-in.................................................................................. |

33 |

|

5.4 |

Two V200/V300 with synchronisation........................................................... |

35 |

|

5.5 |

Connection diagrams ..................................................................................... |

36 |

|

|

5.5.1 |

V200/V300 on UE410 Flexi with external device monitoring |

|

|

|

(EDM) and with restart interlock both for V200/V300 as well |

|

|

|

as for emergency switching off ..................................................... |

36 |

|

5.5.2 |

V200/V300 on UE10-3OS with external device monitoring |

|

|

|

(EDM) and internal restart interlock ............................................. |

37 |

6 Application examples................................................................................................ |

38 |

||

6.1 |

Application with one V200/V300................................................................... |

38 |

|

6.2 |

Application with two V200/V300 ................................................................... |

39 |

|

6.3Application with safe access on three sides (ergonomic workplace

|

design) ........................................................................................................... |

40 |

6.4 |

Application with automatic material transport to the workstation ................. |

41 |

7 Commissioning .......................................................................................................... |

42 |

|

7.1 |

Test notes ...................................................................................................... |

42 |

7.2 |

Tests before the initial commissioning .......................................................... |

42 |

7.3Regular inspection of the protective device by qualified safety

|

|

personnel |

....................................................................................................... |

42 |

|

7.4 |

Tests of the protective device by a specialist or authorised personnel .......... |

43 |

|

8 |

Configuration ............................................................................................................. |

|

44 |

|

|

8.1 |

Teach - in ......................................................................................................... |

|

44 |

|

8.2 |

Internal restart ................................................................................interlock |

46 |

|

|

8.3 |

External device .............................................................................monitoring |

47 |

|

|

8.4 |

Locking the ...................................................................internal teach - in key |

48 |

|

9 |

Care and maintenance .............................................................................................. |

49 |

||

10 |

Fault diagnosis .......................................................................................................... |

|

50 |

|

|

10.1 |

In the event .......................................................................of faults or errors |

50 |

|

|

10.2 |

SICK support .................................................................................................. |

50 |

|

|

10.3 |

Warnings ....................................................and error messages of the LEDs |

51 |

|

11 |

Technical specifications............................................................................................ |

52 |

||

|

11.1 |

Data sheet ..................................................................................................... |

52 |

|

|

11.2 |

Dimensional ....................................................................................drawings |

56 |

|

|

|

11.2.1 ................................................ |

Dimensional drawing V200/V300 |

56 |

|

|

11.2.2 .............................................. |

Dimensional drawing, mounting kit |

57 |

12 |

Ordering information ................................................................................................. |

58 |

||

|

12.1 |

Safety camera ..................................................................................systems |

58 |

|

|

12.2 |

Accessories .................................................................................................... |

59 |

|

13 |

Annex |

......................................................................................................................... |

|

60 |

|

13.1 ....................................................................... |

Compliance with EU directives |

60 |

|

|

13.2 ...................................................................... |

Checklist for the manufacturer |

61 |

|

|

13.3 .................................................................................................. |

List of tables |

62 |

|

|

13.4 .......................................................................................... |

List of illustrations |

62 |

|

4 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

About this document

Chapter 1

1 About this document

Please read this chapter carefully before working with the documentation and the V200 Work Station Extended or V300 Work Station Extended safety camera system, referred to in the following as V200/V300 for short.

1.1Function of this document

These operating instructions are designed to address the technical personnel of the machine manufacturer or the machine operator in regards to safe mounting, installation, configuration, electrical installation, commissioning, operation and maintenance of the V200/V300 safety camera system.

These operating instructions do not provide instructions for operating machines on which the safety camera system is, or will be, integrated. Information on this is to be found in the operating instructions for the machine.

1.2Target group

These operating instructions are addressed to planning engineers, machine designers and operators of plants and systems which are to be protected by one or several V200/V300 safety camera systems. It also addresses people who integrate the V200/V300 into a machine, initialise its use, or who are in charge of servicing and maintaining the device.

1.3Information depth

These operating instructions contain the following information on the V200/V300 safety camera system:

• |

mounting |

• |

fault diagnosis and troubleshooting |

• |

electrical installation |

• |

part numbers |

• |

commissioning |

• |

conformity and approval |

• |

care and maintenance |

|

|

Planning and using protective devices such as the V200/V300 also require specific technical skills which are not detailed in this documentation.

When operating the V200/V300, the national, local and statutory rules and regulations must be observed.

General information on accident prevention using opto-electronic protective devices can be found in the competence brochure “Guidelines Safe Machinery”.

Note Please refer also to the SICK homepage on the Internet at www.sick.com.

Here you will find information on:

•application examples and application reports that supplement the application examples in chapter 6

•a list of frequently asked questions regarding the V200/V300

•these operating instructions in different languages for viewing and printing

•certificates on the prototype test, the EU declaration of conformity and other documents

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

5 |

Subject to change without notice

Chapter 1

Notes

ANSI

EDM

ESPE

LED

OSSD

V200/V300

Recommendation

Note

ν, Ν, ⌠Ε , ⌠ϑ , ⌠Ι

About this document |

Operating Instructions |

|

V200/V300 |

|

1.4Scope

This document is an original document.

These operating instructions are only applicable to the V200/V300 safety camera system with one of the following entries on the type label in the field Operating Instructions:

•8012225 XF85

•8012225 YY28

•8012225 YT87

This document is part of SICK part number 8012225 (operating instructions “V200/V300

– Safety camera system” in all available languages).

1.5Abbreviations used

American National Standards Institute

External device monitoring

Electro-sensitive protective equipment (e.g. V200/V300)

Light Emitting Diode

Output signal switching device = signal output from the protective device to the controller that is used to stop the dangerous movement

Short code for the V200 Work Station Extended/V300 Work Station Extended safety camera system

1.6Symbols used

Recommendations are designed to give you some assistance in your decision-making process with respect to a certain function or a technical measure.

Refer to notes for special features of the device.

LED symbols describe the status of an LED. Examples:

νThe LED is off.

ΝThe LED is illuminated constantly.

⌠Ε The LED flashes evenly (0.5 seconds on, 0.5 seconds off).

⌠Ι The LED goes off briefly (0.9 seconds on, 0.1 seconds off, …).

⌠ϑ The LED flashes with a short duty cycle (0.9 seconds off, 0.1 seconds on, …).

In combination with the LED symbols, these symbols identify which LED is described:

Ν The LED “Stop” (OSSDs switched off) is illuminated constantly.

⌠Ε The LED “Warning” flashes.

ν The LED “OK” (OSSDs switched on) is off.

=Take action … Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

Warning!A warning notice indicates an actual or potential risk or health hazard. They are designed

WARNING to help you to prevent accidents.

Read carefully and follow the warning notices!

6 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

About this document |

Chapter 1 |

|

|

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and diagrams of this document as a movement of a machine part. In practical operation, there may be a number of different dangerous states:

•machine movements

•electrical conductors

•visible or invisible radiation

•a combination of several risks and hazards

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

7 |

Subject to change without notice

Chapter 2 |

On safety |

|

|

2 On safety

Operating Instructions

V200/V300

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before working with the V200/V300 or with the machine protected by the V200/V300.

2.1Qualified safety personnel

The V200/V300 safety camera system must only be installed, commissioned and serviced by qualified safety personnel. Qualified safety personnel are defined as persons who

•due to their specialist training and experience have adequate knowledge of the powerdriven equipment to be checked

and

•have been instructed by the responsible machine owner in the operation of the machine and the current valid safety guidelines

and

•are sufficiently familiar with the applicable official health and work safety regulations, directives and generally recognized engineering practice (e.g. DIN standards, VDE stipulations, engineering regulations from other EU member states) that they can assess the work safety aspects of the power-driven equipment

and

• have access to these operating instructions and have read them.

As a rule these are qualified safety personnel from the ESPE manufacturer or also persons who have been appropriately trained at the ESPE manufacturer, are primarily involved in checking ESPE and are allocated the task by the organisation operating the ESPE.

8 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

On safety

2.2Applications of the device

Chapter 2

Tab. 1: Maximum protective field dimensions as a function of the resolution

WARNING

The V200/V300 safety camera system is an item of electro-sensitive protective equipment (ESPE).

The V200/V300 safety camera system can be operated with 3 resolutions. Depending on the resolution used, the maximum protective field dimensions change:

|

Resolution |

|

Protective field dimensions [m] |

|

|

|

|

|

|

|

|

|

[mm] |

|

Minimum |

Maximum |

Note |

|

|

|

|

|

|

|

20 |

|

0.40 × 0.40 |

1.00 × 1.00 |

On sizing the protective field the |

|

|

|

|

|

ratio for the lengths of the sides |

|

24 |

|

0.40 × 0.40 |

1.20 × 1.20 |

must be considered (see section 4.1 |

|

|

|

|

|

“Checking the dimensions of the |

|

30 |

|

0.60 × 0.60 |

1.50 × 1.50 |

protective field” on page 18 ff.) |

|

|

|

|

|

|

The device is a Type 3 ESPE (V300 Work Station Extended) or a Type 2 (V200 Work Station Extended) according to IEC 61 496-1 and IEC/TR 61 496-4 and is therefore allowed for use with controls in category 3 according to EN ISO 13 849-1. The device is suitable for hazardous point protection (hand protection).

Access to the hazardous point must be allowed only through the protective field. As long as the hazardous point is occupied, the system must not start. Refer to section 3.3 “Application examples” on page 13 for an illustration of the protection modes.

Only use the safety camera system as an indirect protective measure!

An opto-electronic protective device provides indirect protection, e.g. by switching off the power at the source of the hazard. It cannot provide protection from parts thrown out, nor from emitted radiation. Transparent objects are not detected.

Depending on the application, mechanical guards may be required in addition to the safety camera system.

The safety camera system is only intended for use in industrial environments. When used in residential areas it can cause radio interferences.

2.3Correct use

The V200/V300 safety camera system must be used only as defined in section 2.2 “Applications of the device”. It must be used only by qualified personnel and only on the machine where it has been installed and initialised by qualified safety personnel in accordance with these operating instructions.

If the device is used for any other purposes or modified in any way — also during mounting and installation — any warranty claim against SICK AG shall become void.

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

9 |

Subject to change without notice

Chapter 2 |

On safety |

|

|

Operating Instructions

V200/V300

2.4 General safety notes and protective measures

Pay attention to the safety notes!

Please observe the following procedures in order to ensure the correct and safe use of the

WARNING V200/V300 safety camera system.

•The national/international rules and regulations apply to the installation, use and periodic technical inspections of the safety camera system, in particular:

–Machinery Directive

–Work Equipment Directive

–the work safety regulations/safety rules

–other relevant safety regulations

Manufacturers and operators of the machine on which the safety camera system is used are responsible for obtaining and observing all applicable safety regulations and rules.

•The notices, in particular the test regulations (see section 7.1 “Test notes” on page 42) of these operating instructions (e.g. on use, mounting, installation or integration into the existing machine controller) must be observed.

•The tests must be carried out by qualified safety personnel or specially qualified and authorised personnel and must be recorded and documented to ensure that the tests can be reconstructed and retraced at any time.

•Changes to the configuration of the devices can degrade the protective function. After every change to the configuration you must therefore check the effectiveness of the protective device. The person who makes the change is also responsible for the correct protective function of the device.

•The light beams from the camera may be deflected by reflective surfaces. This can result in failure to identify an object. For this reason reflective surfaces on the reflective tape or in the protective field are not allowed.

•The operating instructions must be made available to the operator of the machine where the V200/V300 safety camera system is fitted. The machine operator is to be instructed in the use of the device by qualified safety personnel and must be instructed to read the operating instructions.

•To meet the requirements of the relevant product standards (e.g. IEC 61 496-1), the external voltage supply for the devices (SELV) must be able to bridge a brief mains failure of 20 ms. Power supplies according to EN 60 204-1 satisfy this requirement. Suitable power supplies are available as accessories from SICK (see section 12.2 “Accessories” on page 59).

10 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

Note

WARNING

Tab. 2: Overview on disposal by components

On safety |

Chapter 2 |

|

|

2.5Environmental protection

The V200/V300 safety camera system has been designed to minimise environmental impact. It uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner.

2.5.1Disposal

Always dispose of unserviceable or irreparable devices in compliance with local/ national rules and regulations with respect to waste disposal (e.g. European waste code 16 02 14).

We would be pleased to be of assistance to you on the disposal of these devices. Contact us.

2.5.2Separation of materials

Only qualified safety personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the different materials in the V200/V300.

Separate the housing from the rest of the parts (in particular the circuit board).

Send the separated parts for recycling as appropriate:

Components |

Disposal |

|

|

Product |

|

Housing |

Metal recycling (aluminium) |

Circuit boards, cable, connector and |

Electronic recycling |

electrical connecting pieces |

|

Packaging |

|

Cardboard, paper |

Paper/cardboard recycling |

Polyethylene packaging |

Plastic recycling |

|

|

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

11 |

Subject to change without notice

Chapter 3 |

Product description |

|

|

Operating Instructions

V200/V300

3 Product description

This chapter provides information on the special features and properties of the V200/V300 safety camera system. It describes the construction and the operating principle of the device, in particular the different operating modes.

Please read this chapter before mounting, installing and commissioning the device.

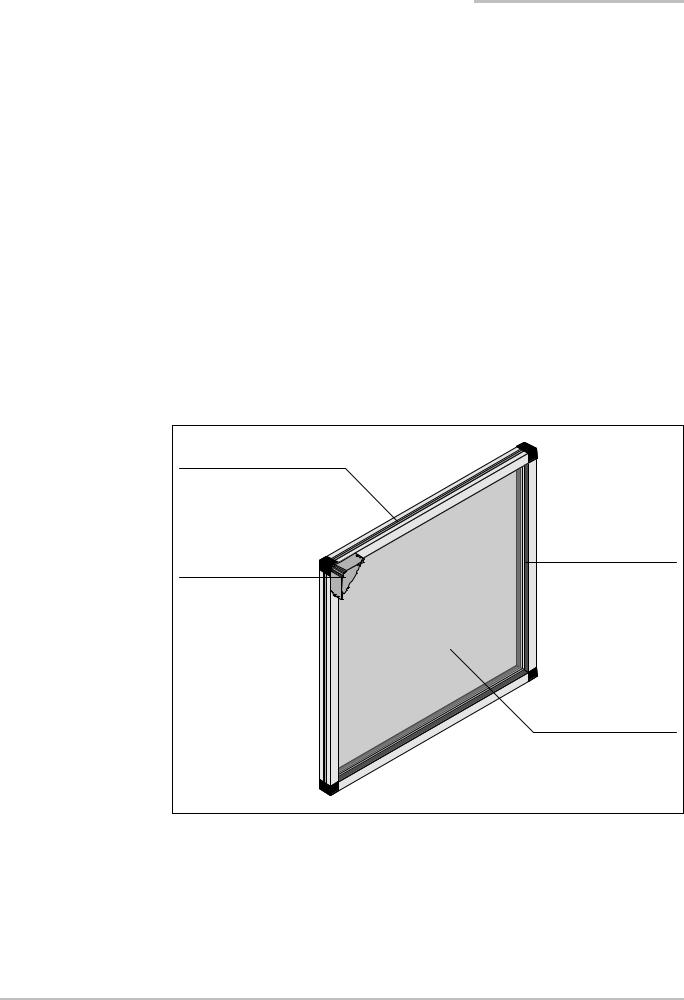

Fig. 1: Operating principle of the V200/V300

3.1Special features

•V200 Work Station Extended: Type 2 ESPE according to IEC 61 496-1

•V300 Work Station Extended: Type 3 ESPE according to IEC 61 496-1 complies with the requirements for the “Control reliable” safety level.

•protective operation with either internal or external (realised on the machine) restart interlock

•facility for connecting a reset button

•facility for connecting an external device monitoring (EDM)

•status indication by LED

3.2Operating principle of the device

Machine-side mounting |

|

profile |

|

|

Reflective tape on the |

Camera |

members opposite the |

|

camera |

|

Protective field |

The V200/V300 safety camera system comprises a camera as well as a reflective tape with which the contour to be monitored is defined.

The camera monitors the area bounded by its field of view and the reflective tape – the protective field – for interruptions. If the V200/V300 detects an interruption in the shape of the protective field, the camera shuts down its safe outputs.

Please refer to chapter 11 “Technical specifications” on page 52 for the data sheet. Please refer to page 56 for the dimensional drawings.

12 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

Note

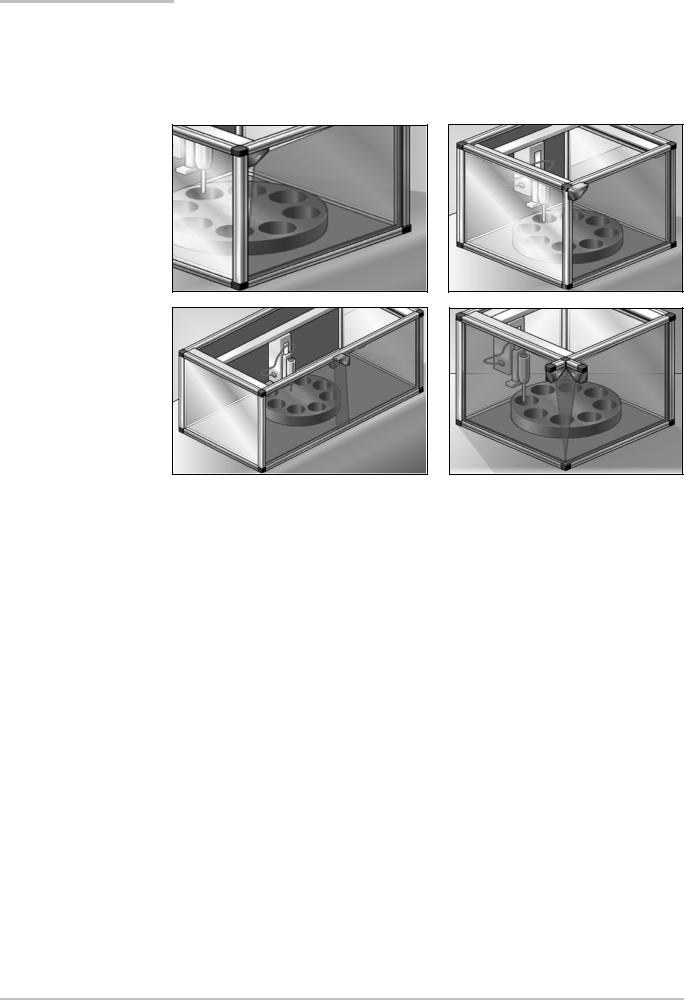

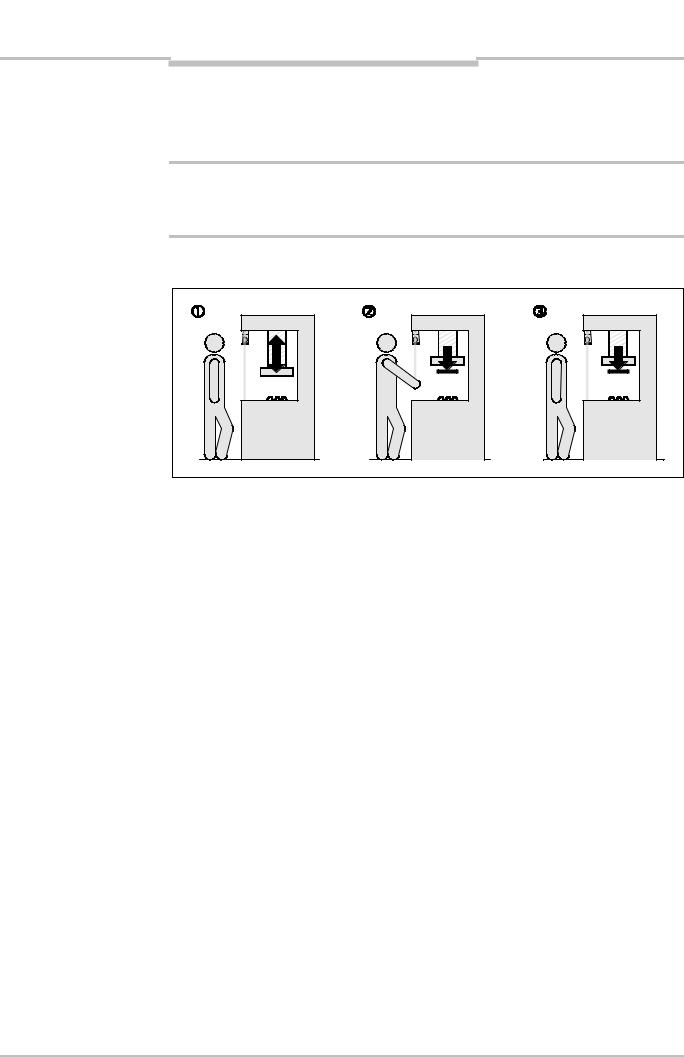

Fig. 2: Hazardous point protection with one V200/V300, mounting in the frame

(left figure)

Fig. 3: Hazardous point protection with one V200/V300, mounting on the frame (right figure)

Fig. 4: Hazardous point protection with two V200/V300, placement in opposite directions (left figure)

Fig. 5: Hazardous point protection with two V200/V300, placement at corner

(right figure)

Product description |

Chapter 3 |

|

|

3.3Application examples

The mounting of the device is only shown schematically in the following figures for reasons of simplicity.

For correct mounting, pay attention to the notes in chapter 4 “Mounting” on page 18.

The V200/V300 safety camera system operates correctly as a protective device only if the following conditions are met:

•The control of the machine must be electrical.

•It must be possible to achieve a safe state on the machine at any time.

•Camera and reflective tape must be so mounted that objects penetrating into the hazardous area are safely identified by the V200/V300.

•The reset button must be fitted outside the hazardous area such that it cannot be operated by a person working inside the hazardous area. When operating the reset button, the operator must have full visual command of the hazardous area.

•The statutory and local rules and regulations must be observed when installing and using the device.

•The necessary protective field dimensions must not exceed the permitted ratio for the lengths of the sides (see section 4.1 “Checking the dimensions of the protective field” on page 18).

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

13 |

Subject to change without notice

Chapter 3

Product description

3.4Configurable functions

Operating Instructions

V200/V300

WARNING

Fig. 6: Outline drawing of the protective operation

Notes

This section describes the functions of the V200/V300 safety camera system that can be configured.

Test the protective device after any changes!

After each modification to the protective device or its connection, you must check the whole protective device for effectiveness (see section 7.1 “Test notes” on page 42).

3.4.1Restart interlock

The V200/V300 has an internal restart interlock. The dangerous state of the machine (0) is interrupted on a protective field interruption (1), and is not re-enabled (2) until the operator presses the reset button.

•If you use the V200/V300 without internal restart interlock, then you must implement the restart interlock externally, i.e. machine-side.

•Do not confuse the restart interlock with the starting interlock on the machine. The starting interlock prevents the machine starting after switching on. The restart interlock prevents the machine starting again after an error or an interruption of the light path.

When using the V200/V300, you can implement the restart interlock in two different ways:

•with the internal restart interlock of the V200/V300: The V200/V300 controls the restart.

•with the restart interlock of the machine (external): The V200/V300 has no control over the restart.

14 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

Tab. 3: Permissible restart interlock configurations on the V200/V300

WARNING

Recommendation

Product description |

Chapter 3 |

|

|

The possible combinations are shown in the following table:

|

Restart interlock |

Restart interlock |

Permissible |

|

of the V200/V300 |

of the machine |

application |

|

|

|

|

|

Deactivated |

Deactivated |

Only if … |

|

|

|

• the safety camera system cannot be |

|

|

|

stood behind. Observe EN 60 204-1! |

|

|

|

• it is ensured no work clothing with |

|

|

|

reflectors is used. |

|

|

|

|

|

Deactivated |

Activated |

All |

|

|

|

|

|

Activated |

Deactivated |

Only if the safety camera system cannot |

|

|

|

be stood behind. Observe EN 60 204-1! |

|

|

|

|

|

Activated |

Activated |

All. Restart interlock of the V200/V300 |

|

|

|

handles the reset function (see “Reset” |

|

|

|

below). |

|

|

|

|

|

|

|

|

Always configure the application with restart interlock!

Ensure that there is always a restart interlock. The V200/V300 is unable to verify if the restart interlock of the machine is connected. If you deactivate both the internal and the external restart interlock, the users and operators of the machine will be at acute risk of injury.

Reset

If you activate the restart interlock on the V200/V300 (internal) and also realise a restart interlock on the machine (external), then each restart interlock gets its own button.

When actuating the reset button (for the internal restart interlock) …

•the V200/V300 activates the output signal switching devices.

•switches the V200/V300 to green.

Only the external restart interlock prevents the machine from restarting. After pressing the reset button for the V200/V300, the operator must also press the restart button for the machine. If the reset button and the restart button are not pressed in the specified sequence, the dangerous state must remain disrupted.

The reset button prevents the accidental and inadvertent operation of the external restart button. The operator must first acknowledge the safe state with the reset button.

The electrical connection of the reset button is described in section 5.3 on page 33. The configuration of the internal restart interlock is described in section 8.2 “Internal restart interlock” on page 46.

3.4.2External device monitoring (EDM)

The V200/V300 has external device monitoring. If you activate the external device monitoring, then the V200/V300 checks whether the contactors are actually de-energized when the protective device triggers. If, after an attempted Reset/restart, the EDM does not detect a response from the switched device within 300 ms, the EDM will deactivate the output signal switching devices again. In this case the safety camera system signals as follows:

•The system remains at red. The status LED Ν illuminates.

•The status LED ⌠ϑ flashes with a short duty cycle

•The diagnostics LED 2 ⌠ϑ flashes with a short duty cycle.

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

15 |

Subject to change without notice

Chapter 3 |

Product description |

|

|

Operating Instructions

V200/V300

Note If the system is unable to change to a safe operational state (e.g. after contactor failure), the system locks and shuts down completely (“lock-out”, see page 50). The electrical connection for the external device monitoring is described in section 5.3 on page 33. The configuration of the external device monitoring is described in chapter 8 “Configuration” on page 44.

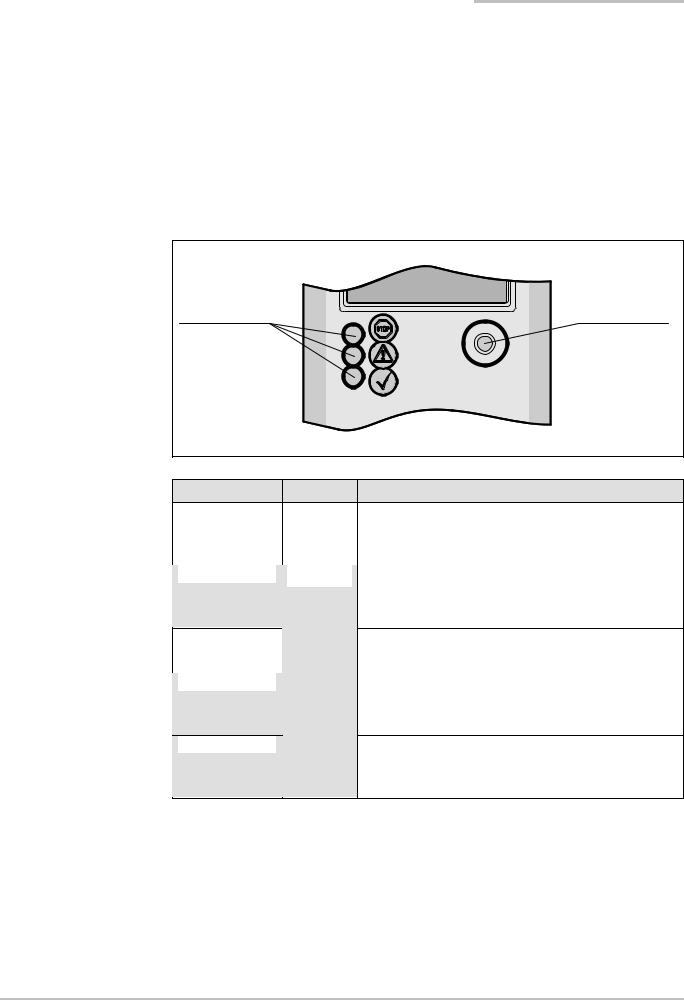

Fig. 7: Status LEDs

of the V200/V300

Tab. 4: Meaning of the status LEDs of the V200/V300

3.5Status indicators

The light emitting diodes (LEDs) on the V200/V300 signal its operating status.

3.5.1Status LEDs of the V200/V300

Status LEDs |

|

Internal |

“Stop” |

|

teach-in key |

“Warning” |

|

|

“OK” |

|

|

Display |

Colour |

Meaning |

|

Ν |

|

Red |

|

OSSDs shut down (e.g. if object in protective field or |

|

|

|

|

|

“lock-out”) |

|

Ν |

|

Green |

|

OSSDs activated. Protective field unoccupied |

|

|

|

|

|

|

|

Ν |

|

Yellow |

|

No valid configuration taught-in (default delivery status) |

|

|

|

|

|

|

Perform the teach-in procedure (see section 8.1 “Teach-in” on page 44).

|

⌠Ε |

|

|

Even flashing: reset required |

|

|

|

|

Press the reset button. |

|

⌠Ι |

|

|

Warning |

Carry out a fault diagnosis (see chapter 10 “Fault diagnosis” on page 50).

⌠ϑ |

Error |

Carry out a fault diagnosis (see chapter 10 “Fault diagnosis” on page 50).

16 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

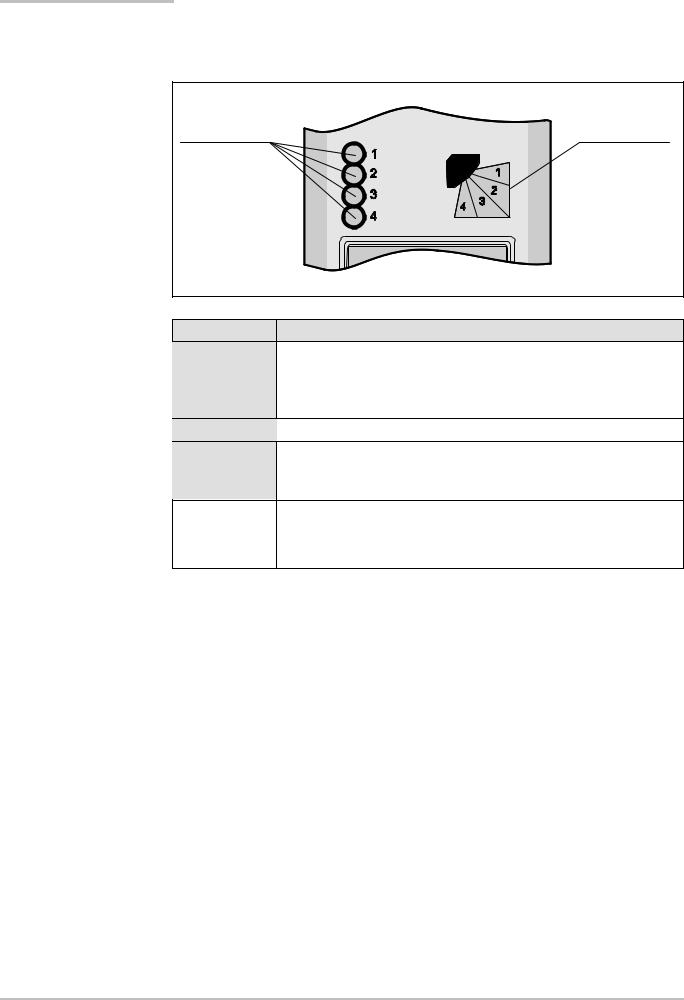

Fig. 8: Diagnostics LEDs

of the V200/V300

Tab. 5: Meaning of the diagnostics LEDs

Product description |

Chapter 3 |

|

|

3.5.2Diagnostics LEDs of the V200/V300

The camera indicates diagnostic information with the aid of four LEDs.

Diagnostics LEDs |

Allocation of the |

|

diagnostics LEDs |

|

to the protective |

|

field sector |

Display |

Meaning |

Ν 1 Power-up sequence: After switching on the V200/V300 and after each

…Ν 2 teach-in, the power up sequence runs. Starting with the diagnostics

…Ν 3 LED 1, the next diagnostics LED illuminates after one second and so

…Ν 4 on until all 4 diagnostics LEDs are illuminated.

νProtective field sector free

ΝInterruption of the protective field in the allocated protective field sector (see Fig. 8). A protective field sector represents one quarter of the field of view of the V200/V300.

⌠Ε |

Teach-in mode (see section 8.1 “Teach-in” on page 44) |

|

⌠Ι |

Warning (see chapter |

10 “Fault diagnosis” on page 50) |

⌠ϑ |

Error (see chapter 10 |

“Fault diagnosis” on page 50) |

|

|

|

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

17 |

Subject to change without notice

Chapter 4 |

Mounting |

|

|

4 Mounting

Operating Instructions

V200/V300

This chapter describes the preparation and completion of the mounting of the V200/V300 safety camera system. Mounting requires the following steps:

•checking the dimensions of the protective field (see below)

•determining the minimum distance (see page 20)

•mounting of the camera (see page 24)

•mounting the reflective tape (see page 29)

The following steps are necessary after mounting:

•completing the electrical connections (see chapter 5 on page 31)

•testing the installation (see section 7.1 on page 42)

4.1 Checking the dimensions of the protective field

Only use the V200/V300 safety camera system if the ratio allowed for the lengths of the sides of the protective field can be met!

WARNING If the maximum ratio of the lengths of the sides is exceeded, the safety camera system may not operate correctly. This would mean that the operator is at risk.

Note Applicable to all resolutions:

•The ratio of the lengths of the sides of a protective field monitored must not exceed 2:1.

•If you require a larger protective field than is possible with a single V200/V300, you can mount two V200/V300 in parallel in opposite directions. In this way you can generate two overlapping protective fields (see 6.2 “Application with two V200/V300” on

page 39).

Tab. 6: Protective field dimensions allowed for a rectangular protective field at a resolution of 20 mm (intermediate values are allowed)

4.1.1Protective field dimensions allowed at a resolution of 20 mm

The lengths of the sides of a protective field monitored must not be shorter than 0.40 m and not longer than 1.00 m.

|

Shorter side of the |

|

Longer side of the protective field |

|

|

protective field |

|

Minimum |

Maximum |

|

|

|

||

|

|

|

|

|

|

″ 0.40 m … < 0.50 m |

= shorter side |

2 × shorter side |

|

|

″ 0.50 m … ′ 1.00 m |

= shorter side |

1.00 m |

|

|

|

|

|

|

Example 1: The shorter side is 0.43 m long. Then the longer side must be at least 0.43 m and is allowed to be a maximum of 2 × 0.43 m = 0.86 m long.

Example 2: The shorter side is 0.78 m long. Then the longer side must be at least 0.78 m and is allowed to be a maximum of 1.00 m long.

18 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Operating Instructions

V200/V300

Tab. 7: Protective field dimensions allowed for a rectangular protective field at a resolution of 24 mm (intermediate values are allowed)

Tab. 8: Protective field dimensions allowed for a rectangular protective field at a resolution of 30 mm (intermediate values are allowed)

Mounting |

Chapter 4 |

|

|

4.1.2Protective field dimensions allowed at a resolution of 24 mm

The lengths of the sides of a protective field monitored must not be shorter than 0.40 m and not longer than 1.20 m.

|

Shorter side of the |

|

Longer side of the protective field |

|

|

protective field |

|

Minimum |

Maximum |

|

|

|

||

|

|

|

|

|

|

″ 0.40 m … < 0.60 m |

= shorter side |

2 × shorter side |

|

|

″ 0.60 m … ′ 1.20 m |

= shorter side |

1.20 m |

|

|

|

|

|

|

Example 1: The shorter side is 0.43 m long. Then the longer side must be at least 0.43 m and is allowed to be a maximum of 2 × 0.43 m = 0.86 m long.

Example 2: The shorter side is 0.78 m long. Then the longer side must be at least 0.78 m and is allowed to be a maximum of 1.20 m long.

4.1.3Protective field dimensions allowed at a resolution of 30 mm

The lengths of the sides of a protective field monitored must not be shorter than 0.60 m and not longer than 1.50 m.

|

Shorter side of the |

|

Longer side of the protective field |

|

|

protective field |

|

Minimum |

Maximum |

|

|

|

||

|

|

|

|

|

|

″ 0.60 m … < 0.75 m |

= shorter side |

2 × shorter side |

|

|

″ 0.75 m … ′ 1.50 m |

= shorter side |

1.50 m |

|

|

|

|

|

|

Example 1: The shorter side is 0.63 m long. Then the longer side must be at least 0.63 m and is allowed to be a maximum of 2 × 0.63 m = 1.26 m long.

Example 2: The shorter side is 0.78 m long. Then the longer side must be at least 0.78 m and is allowed to be a maximum of 1.50 m long.

8012227/YT87/2016-03-29 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

19 |

Subject to change without notice

Chapter 4

WARNING

Note

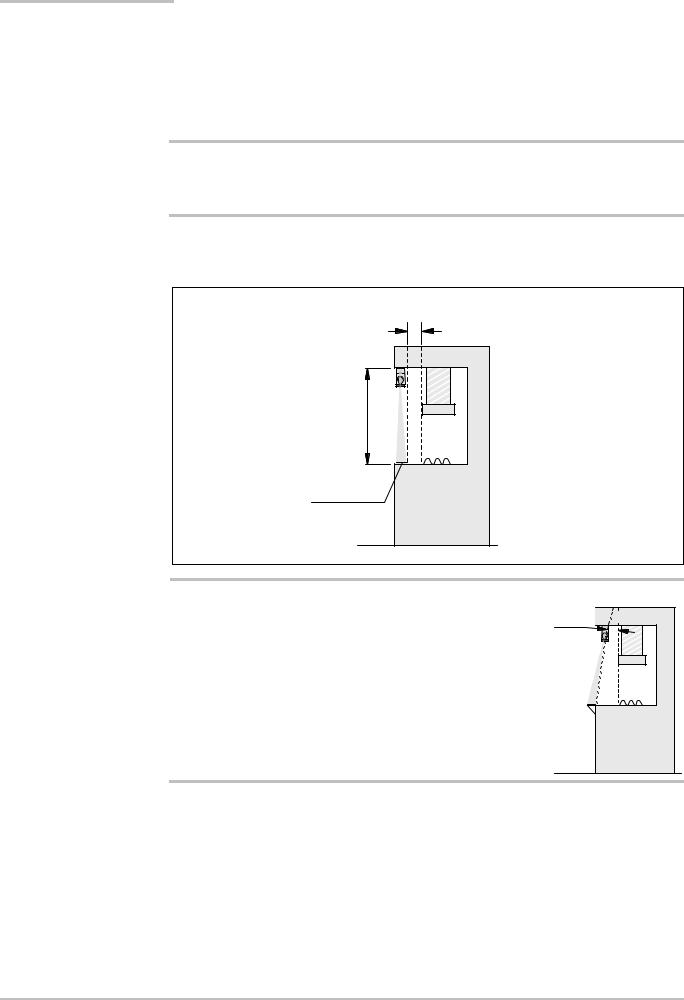

Fig. 9: Minimum distance from the hazardous point

Mounting |

Operating Instructions |

|

V200/V300 |

|

4.2Determining the minimum distance

The safety camera system must be mounted with an adequate minimum distance between the protective field and the hazardous point. This minimum distance ensures that the hazardous point can only be reached after the dangerous state of the machine has been completely stopped.

No protective function without sufficient minimum distance!

The reliable protective effect of the safety camera system depends on the safety camera system being mounted with the correct minimum distance from the hazardous point.

If mounted vertically, the protective field is from the centre of the camera lens to the edge of the reflective tape that is closest to the hazardous point. (The reference point for the minimum distance S is therefore not the middle of the reflective tape. Cf. Fig. 9.)

Minimum distance S (Ds)

Protective field |

|

height |

Hazardous |

|

point |

All-round |

|

reflective tape |

|

If the protective field is at an angle, pay special attention to the minimum distance!

Ensure the necessary minimum distance between the S (Ds)

WARNING access point and the hazardous point is met at all parts of the protective field at an angle.

Note that different rules may apply to the calculation of the minimum distance for protective fields at an angle.

Your SICK-subsidiary will be pleased to assist you with the implementation of special applications.

20 |

© SICK AG • Industrial Safety Systems • Germany • All rights reserved |

8012227/YT87/2016-03-29 |

Subject to change without notice

Loading...

Loading...