SIARE HOSPITAL SUPPLIES SIARETRON 1000, SIARETRON 3000, SIARETRON 1100 Service Manual

SIARETRON 1000 – 1100 - 3000

Service Manual

SIARETRON 1000

SIARETRON 1100

SIARETRON 3000

SERVICE MANUAL

SIARETRON_SE3_en

1 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

INDEX

1 USE OF SERVICE MANUAL ........................................................................................................................ 3

1.1 M

1.2 C

1.3 SAFETY NOTES................................................................................................................................................... 3

2 GENERAL MAINTENANCE PROCEDURES................................................................................................ 5

2.1 G

3 TECHNICAL DESCRIPTION......................................................................................................................... 6

3.1 F

3.2 F

3.3 R

3.4 O

3.5 G

ANUAL USERS

ONSULTING NOTES

ENERALITY

RONT VIEW AND PARTS DESCRIPTION

RONT PANEL DESCRIPTION

EAR VIEW AND PARTS DESCRIPTION

PERATING PRINCIPLE

3.4.1 Hardware features....................................................................................................................................... 9

AS ADMINISTRATION AND PROPORTIONING PNEUMATIC SYSTEM

3.5.1 Operation description ................................................................................................................................ 13

....................................................................................................................................................... 3

................................................................................................................................................. 3

............................................................................................................................................................ 5

....................................................................................................................... 6

...................................................................................................................................... 7

......................................................................................................................... 8

............................................................................................................................................. 9

................................................................................ 12

4 CALIBRATION AND TESTING.................................................................................................................... 15

4.1 LV200-MAIN/1 CPU

4.2 LV200 I/O BOARD.............................................................................................................................................. 21

4.3 PANEL BOARD .................................................................................................................................................. 25

4.4 POWER BOARD................................................................................................................................................. 28

4.5 PNEUMATIC CIRCUIT ....................................................................................................................................... 30

4.6 FINAL TESTING ................................................................................................................................................. 33

BOARD

................................................................................................................................. 15

5 PNEUMATIC................................................................................................................................................ 41

5.1 P

5.2 P

5.3 V

NEUMATIC DRAWING

NEUMATIC COMPONENTS LIST

ALVES GROUP

5.3.1 Components list......................................................................................................................................... 44

............................................................................................................................................. 41

................................................................................................................................42

..................................................................................................................................................... 43

6 ELECTRONIC.............................................................................................................................................. 45

6.1 E

LECTRIC DRAWINGS FOR

TEST ATS.098

TOOLS

.................................................................................................... 71

6.2 SIARETRON 1100 - PNEUMATIC DRAWING................................................................................... 72

Warning

SIARE is used throughout the description inside this manual as an abbreviation for

SIARE HOSPITAL SUPPLIES S.r.l.

Via Giulio Pastore, 18 - 40056 Crespellano (BO) - ITALIA

Tel.: 051/969802 / Fax: 051/969101

( rev.3) 30.06.2004

SIARETRON_SE3_en

Manufacturer of the equipment described in the manual hereto

2 / (72 )

SIARETRON 1000 – 1100 - 3000

Service Manual

1 USE OF SERVICE MANUAL

1.1 Manual users

This manual is addressed to SIARE qualified personnel or to technical qualified personnel formerly authorized

by SIARE.

The SIARE authorized technician has the instruments and suitable spare parts and he is instructed to operate

respecting product safety.

SIARE declines any responsibility arising from technical interventions effected on the equipment without its

formal authorization.

The correct and safe use of the equipment both for patient an operator requires the knowledge of

recommendations and instructions contained in the present manual and in the User’s Manual.

1.2 Consulting notes

The mark

and operator.

!

reported next to and instruction individuates an important remark for the safety both of patient

The manual describes the equipment and the operating principle with the aid of electric and pneumatic

drawings.

The User’s Manual is part of this manual, the technician must have a copy of User’s Manual and must know its

content before effecting the operations described in the present manual.

1.3 SAFETY NOTES

WARNINGS !!

The equipment has been manufactured under the warranty and quality conditions of the product and its

components in order to assure the maximum reliability of the equipment and safety for the patient and operator.

Therefore, the safety is guaranteed only in case the technical interventions are effected in conformity to this

manual indications and those contained in the user’s manual which is unseparable par of the product

documentation currently used by the service.

Always in order to grant safety it is necessary to respect the maintenance schedule foreseen in the user’s

manual.

The maintenance and replacement of any part must be effected by personnel formerly authorized by SIARE

using the original SIARE spare parts or checked by the same.

SIARE is not civically or criminally liable in the following cases:

1) Use in conditions and for reasons not stated or prescribed in service and user’s manuals.

2) Lack or omission of scheduled maintenance as described in service and user’s manuals.

3) Maintenance performed by personnel not formerly authorized by SIARE.

4) Use of non original SIARE spare parts or not checked by the same.

5) Connection with equipment that is not in compliance with Safety Norms in effect for intended use.

SIARETRON_SE3_en

3 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

!

Not connect the equipment to the patient by antistatic conductive hoses.

Since the use of antistatic hoses can cause burns when high frequency surgical equipment are used, their use

is not allowed in any application with this equipment.

For general safety of electro medical equipment, we underline the important aspect of interaction existing

between the equipment and the patient, the operator and environment.

For a correct and safe employ of the equipment it is absolutely necessary to follow the indications of the present

manual and user’s manual, observing the supplied indications.

Any operation on equipment presupposes the precise and correct knowledge of the present instructions.

The equipment must be submitted to an inspection and maintenance every 6 (six) months by SIARE qualified

technical personnel. All interventions carried out by qualified personnel are registered on a maintenance report.

Any repairing intervention must be carried out by SIARE qualified personnel or by qualified technical personnel

authorized by SIARE.

SIARE decline any responsibility for direct or indirect damages or prejudices to persons arising from not

authorized technical interventions or from an improper use of the same not in conformity to user’s and service

manual indications.

For repairing the equipment affected by malfunctioning, defect or failures, the dedicated personnel for use of the

equipment must contact SIARE or the local Service authorized to carry out the repairing or eliminate the

malfunctioning. It is necessary that at the moment of intervention request the model and serial number of the

involved equipment must be specified.

Use exclusively the suggested accessories.

It is allowed to use other accessories only in case of formal SIARE authorization, in conformity to safety norms

in force.

The equipment operation is only allowed in rooms equipped in accordance to the safety norms in force.

SIARETRON_SE3_en

4 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

2 GENERAL MAINTENANCE PROCEDURES

2.1 Generality

!

In order to grant both patient and operator safety the equipment must be inspected and checked as soon as

1000 hours operation are reached or in case of not intensive use of the equipment every 6 months at least.

Such inspections and checking’s require a perfect knowledge of involved equipment, so they must be carried

out exclusively by highly qualified personnel and specifically instructed and formerly authorized by SIARE.

It will be care of the Clinician or Anesthetist, to carry out the ordinary maintenance on the equipment as per

indications of the user’s manual.

The cleaning, disinfections, and parts replacement operations will have to be effected respecting the instructions

of the user’s manual in order to avoid damages to the components which could also compromise the patient and

operator safety.

The employed materials have been carefully selected during projecting phase after specific verifications, and

comparative tests.

Furthermore, the same materials are constantly tested during manufacturing cycle in order to obtain the

maximum reliability and safety for patient and operator.

Therefore, any part or circuit must be replaced exclusively with original spare parts supplied or checked by

SIARE.

SIARE assumes all law responsibility foreseen in case the used equipment is submitted to periodic maintenance

in accordance to the modalities indicated in the user’s manual and in this manual. As a proof that maintenance

has been carried out a Maintenance Report made and signed by SIARE authorized technician is necessary.

SIARETRON_SE3_en

5 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

3 TECHNICAL DESCRIPTION

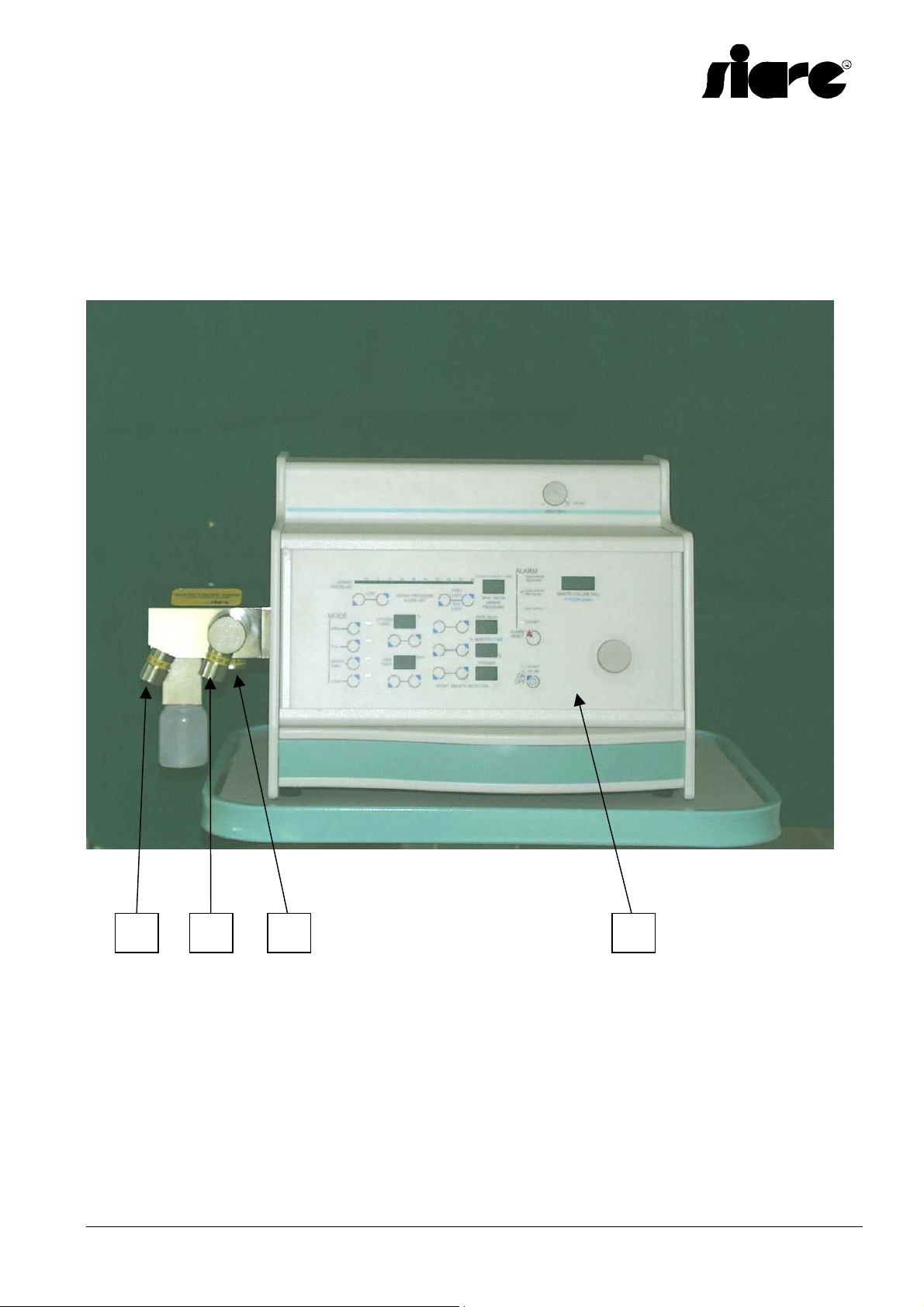

3.1 Front view and parts description

1 - Front panel

2 - Ambient air safety valve

3 - Inspiratory valve

4 - Expiratory valve

1 2 3 4

1 - Front panel

2 - Ambient air safety valve

3 - Inspiratory valve

4 - Expiratory valve

SIARETRON_SE3_en

6 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

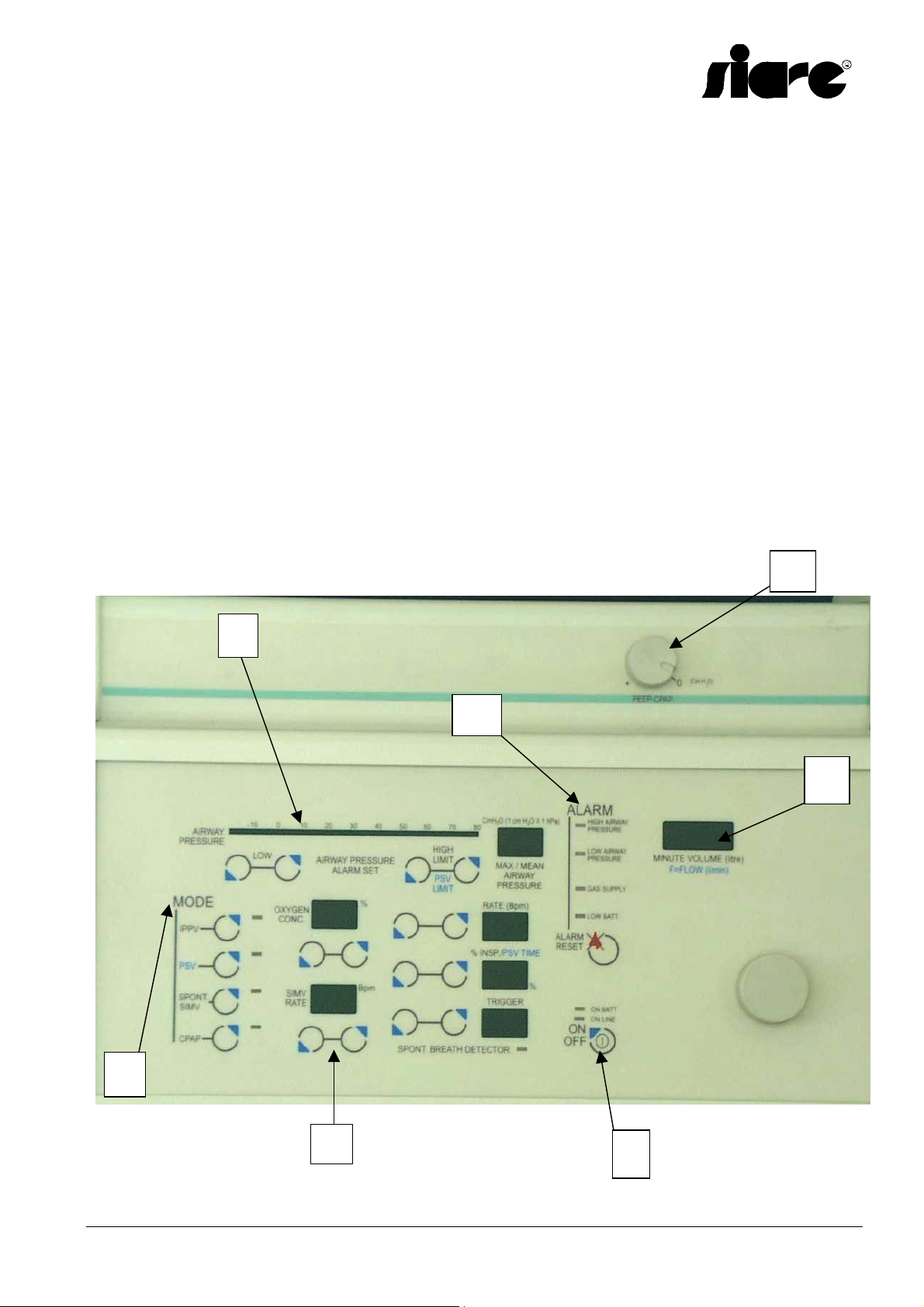

3.2 Front panel description

For a better individuation of regulations and messages the control panel is divided in 7 sections listed here

below (from left to right and from top to bottom):

A) AIRWAY PRESSURE: airways pressure monitoring and control;

B) ALARMS: or indicators of alarm conditions and of acoustic alarm suspension;

C) MINUTE VOLUME: section of regulation of minute volume delivered to patient and CPAP flow;

D) MODE or section of operative modalities;

E) VENTILATION PARAMETERS REGULATIONS: for the regulation and displaying of ventilation

parameters such as: O2 Concentration, Breathing Rate, Inspiration percentage, SIMV Rate,

Sensitivity of spontaneous patient activity detection.

F) POWER SUPPLY: for the turn-on and off of equipment, as well as displaying of equipment

power supply modalities.

G) PEEP / CPAP: for end expiration positive pressure regulation or CPAP.

A

G

B

C

D

SIARETRON_SE3_en

E

7 / (72 )

F

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

A

Service Manual

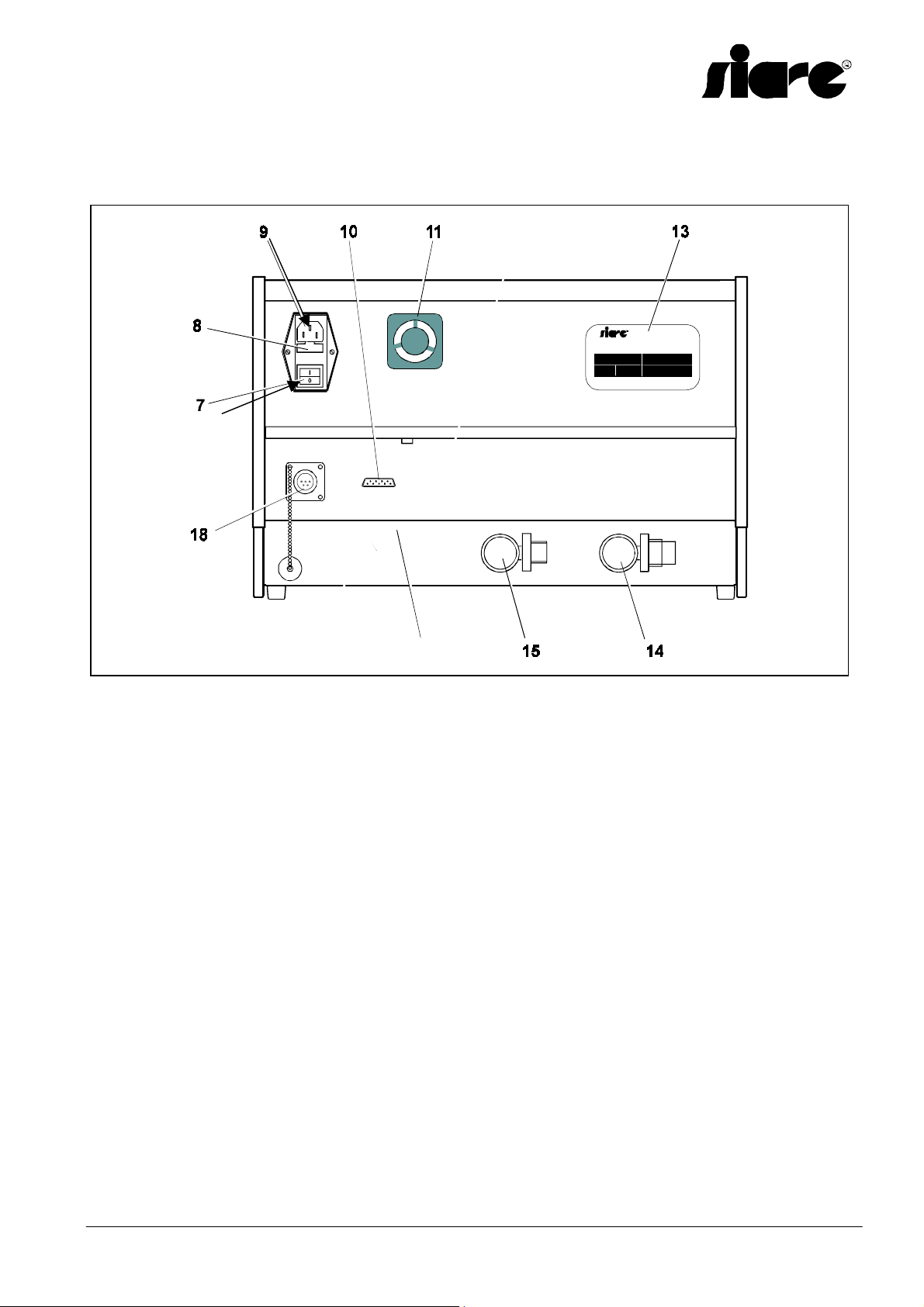

3.3 Rear view and parts description

HOSPITAL SUPPLIES

Crespellano (BOLOGNA) ITALY

TEL. 051 - 969802 FAX 051 - 969366

Mod.

Volt

SERIE

.

Fuse

Fuse

CLA SSE 1 TIP O B CEI 62-5 DE L 199 1

MADE IN ITALY

7 - Main switch

8 - Protection fuses

9 - 220V power supply outlet

10 - RS 232 interface

11 - Cooling fan wheel

13 - Identification label

14 - Air inlet connection

15 - Oxygen inlet connection

18 - 12Vdc power supply inlet connector

If the fan wheel stops for a failure or an obstruction, an acoustic alarm sounds.

The same occurs in case of power failure.

SIARETRON_SE3_en

8 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

3.4 Operating principle

The lung ventilators of SIARETRON series are devices for assisted ventilation equipped with a microprocessor

control system composed of a 5 printed circuits kit; such a system controls the pneumatic circuit which delivers

the medical gas to the patient and permits to the operator the setting of operating parameters by a button panel

and a display.

The printed circuits composing the control system are:

•

•

•

•

3.4.1 Hardware features

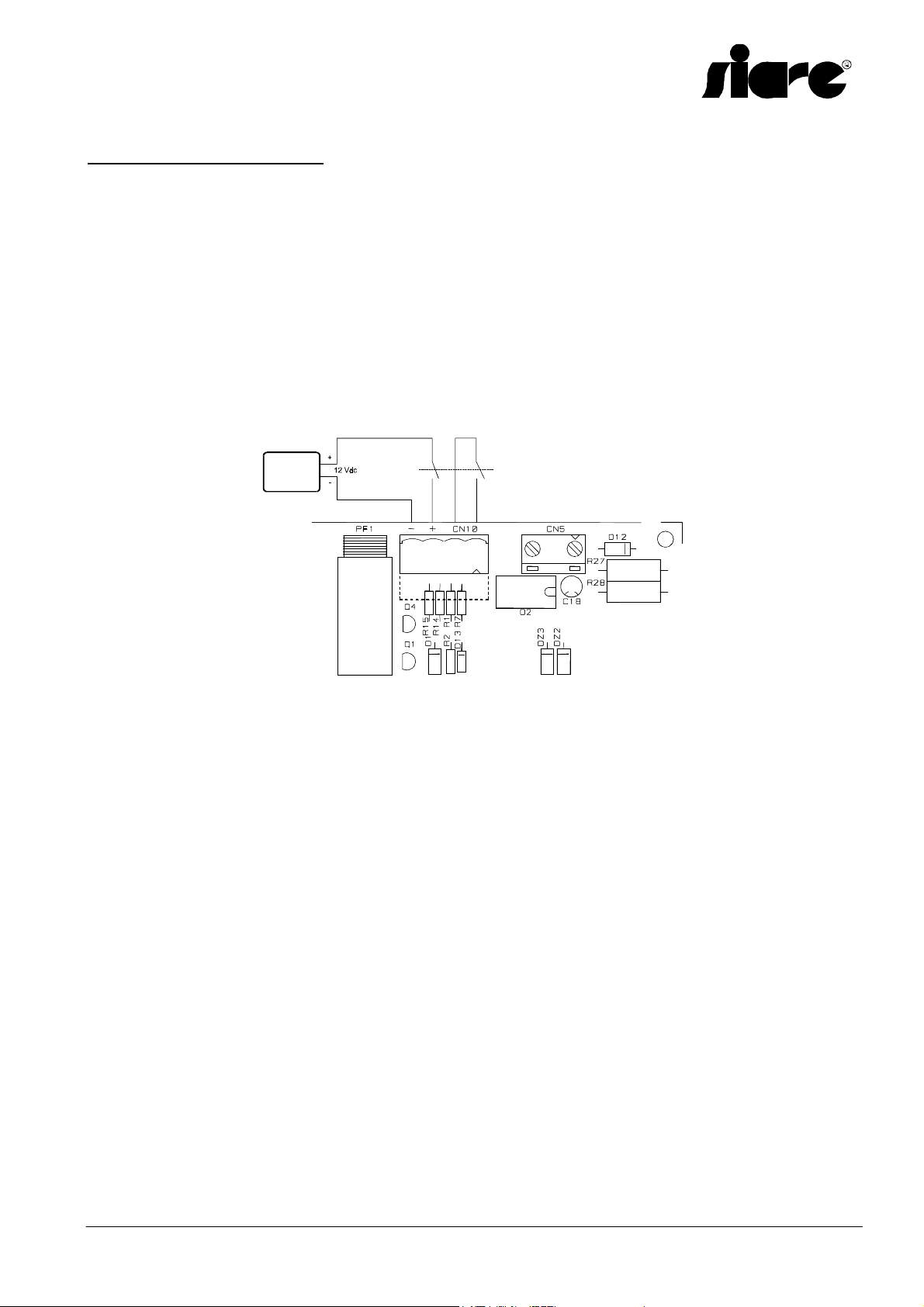

POWER (POWER SUPPLY)

Device power supply board. It controls three different power sources:

1.

Power supply (POWER)

cpu (LV200-MAIN/1)

panel and panel control (PANEL)

input/output (LV200I/O)

12 Vdc (external battery: it needs a “presence contact”, or a staple closed between two clamps)

2.

3.

12 Vac (secondary of a main powered transformer at 220V/50Hz)

12 Vdc (rechargeable internal battery)

Here below listed in decreasing priority order; on the board two 2,5A fuses are present on the inlets of the two

batteries, while the main inlet is protected by fuses on 220 V power line at the level of the main switch block.

In case of main power supply the board provide to recharging internal battery in a maximum of 10 hours; such a

recharging can be effected also when the machine is off, provided that main switch (on the rear side) is on.

The start-up of the machine (which is made by pressing the ON/OFF button on the front panel) and the choice

of power supply source are made by dedicate relay present on the board.

The board generates the following tensions:

•

•

•

•

+ 5 V / 1 A for the logic part of the system,

+ 8 V / 1,5 A for displays and panel leds powering;

20 V not stabilized for the polarization of analog electronic presents on LV200I/O board;

12 ÷ 15 V not stabilized (depends on which source is used) for powering of pneumatic circuit

electro valves, fan wheel, buzzer and relays.

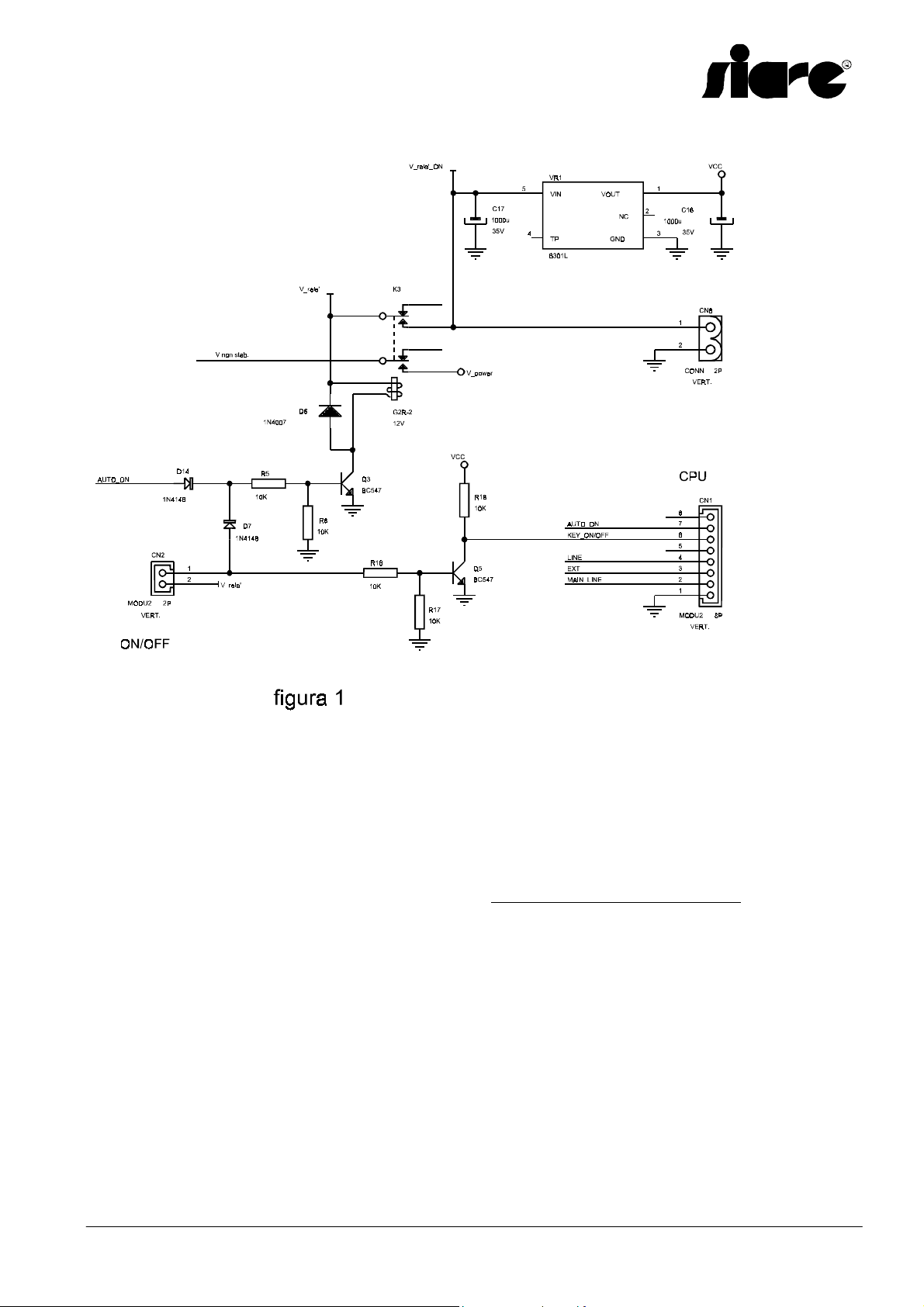

The turn-on/off mechanism is effected by the circuit indicated in figure 1; with the ON/OFF switch of the panel

the two clamps get in contact the two CN2 connector clamps, starting up the Q3 transistor whom excites the K3

relay. Hence, the Vcc tension is generated (through the 8301L stabilizer) whom supply the micro controller on

the CPU board, this generates by its side an high logic level (Vcc) on the line denominated AUTO_ON whom

maintains the K3 relay excited (and so all the device is powered).

The turn-off by ON/OFF switch is possible thanks to the Q5 transistor, through whom the micro controller knows

switch status, the software carries out the turn-off when it reads the pressed switch for more than one second,

generating a low logic level (0 V) on the AUTO_ON line and turning-off all peripheral devices (display and

electro valves). The machine remains, anyway, physically powered since the ON/OFF switch is released.

SIARETRON_SE3_en

9 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

COOLING FAN WHEEL

LV200-MAIN/1 (CPU)

The Main board containing the control microprocessor (Hitachi H8/532 at 16 bit), an EPROM of program (max.

dimension 64 KB), a data RAM of 32 KB, a GAL 16V8 for addresses decodification, some I/O gate mapped on

the bus (among them an UART for panel communication) and a serial E

operating parameters of the machine. The clock rate of microprocessor is generated by a quartz at 19,6608

MHz.

The board is equipped with a WATCH DOG circuit. This is not sensible to electric power supply

with an NE555; such a circuit is able to generate a resetting of microprocessor if it not periodically “refreshed” by

the software, retaking the machine in a know status in case of not correct performance of the working program.

2

PROM of 128 byte for the storage of

and it is realized

PANEL

Front panel containing a 7 segments display, indication leds and buttons. The keyboard is composed of 20

buttons and 4 dip switches organized in a 5 x 5 mother; on the board there also are the writing latch (374) and

the reading buffer (244).

The displays and leds are controlled by three M5451 integrated circuits, each of them drives two multiplexate

led groups.

These integrated circuits are serie/parallel converter which shares the clock signal keeping the data lines

separated; on the board there are three trimmers for the light intensity regulation of leds piloted by each

integrated circuit and adjusting them it is possible to conform the three groups.

SIARETRON_SE3_en

10 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

PANEL (PANEL MANAGER)

The panel control board, contains an Hitachi H8/325 micro controller which effects the keyboard reading and

displays management.

It communicates with the main micro controller (H8/532 on the LV200-MAIN/1 board) through a serial port; it

forwards the acquired buttons and receives the data to be displayed using an internal protocol.

The board is equipped with WATCH DOG circuit not sensible to electric power supply

such a circuit is able to generate a microprocessor reset if it is not periodically “refreshed” by the software,

retaking the machine in a know status in case of not correct performance of working program.

The program, which is located in an EPROM inside the micro controller, performs a complete scanning of

keyboard approx. each 260 µs and manages the displays with a multiplexer frequency of approx. 47 Hz.

LV200I/O (INPUT/OUTPUT)

Input/output board managing the pneumatic circuit.

The printed circuit is divided in two sections, whom are kept separate as most as possible, an analog and a

digital one.

realized with an NE555;

In the analog part there are stabilizers for the necessary electric power supplies (+10 V, -10 V) and all circuits

for input signals conditioning, namely the amplifiers, filters, protection devices.

The analog inlets are:

•

•

• MINUTE VOLUME setting signal (from potentiometer on the panel);

•

pressure signal (from transducer MPX10 mounted on board edge);

O2 concentration signal (from an external oxymetry sensor);

measurement signals of O2 and AIR flows (from two external flow meters).

The mass of the analog section is physically kept separate from the mass of digital section; the only contact

point of these two masses is on the LV200-MAIN/1 board on the microprocessor pins.

The digital section of the board includes:

•

•

•

•

•

two digital inlets (contact cleaned by the two pressure switches);

an outlet for signaling buzzer

an ON/OFF electro valve outlet for medical gas commutation flow;

two outlets for flow by-pass;

two control outlets for proportional electro valves which regulate the flow of the two medical gas.

The proportional electro valves control is performed in PWM by two integrated circuits TL494, arranged on a

commutation frequency of approx. 30 KHz. The feedback of each of these integrated circuits is made on the

electric power of the relevant proportional electro valve; the set point (as electric power) is supplied by main

micro controller (H8/532 of LV200-MAIN/1 board) through an integrated low frequency signal PWM.

SIARETRON_SE3_en

11 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

A

A

A

Service Manual

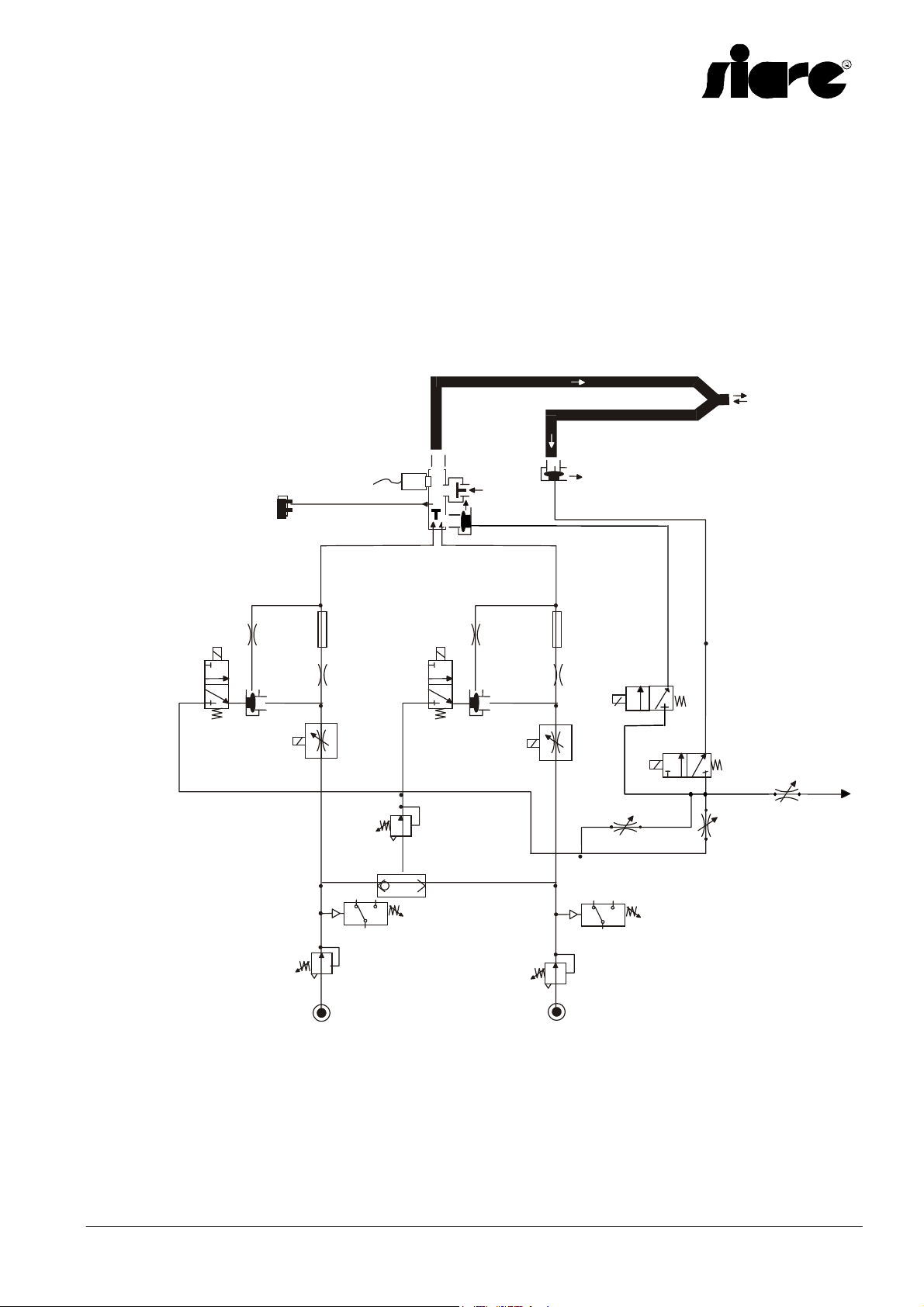

3.5 Gas administration and proportioning pneumatic system

The gas administration and proportioning pneumatic system is represented in the following figure and

mechanical study.

The system has the function to administrate in a correct and safe way the breathing gas to the patient, under the

total control of electronic system.

LPV2

OXIGEN

SENSOR

AIR SAFETY

VALVE

EXP. VALVE

AIRWAY

PRESSURE

PATIENT

R1

FS 1

O2 FLOW

SENSOR

R2

R1.1

R2.1

FS 2

IR FLOW

SENSOR

EV4

EV PART. 1

O2

O2

EV PART. 2

IR

PR 3

EV PROP. 2 INSP.

IR

FR 3 PEEP/CPAP

EV 3

V.EXP.

FR 3

MAX PAW

FR3.1

CSV 1

GAS SELECTOR

PSW 1

PR 1

VALVE

PSW 2

PR 2

INLET O2 3.5 bar +/- 0.75

INLET AIR 3.5 bar +/- 0.75

SIARETRON_SE3_en

12 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

3.5.1 Operation description

O2 INLET – AIR INLET Medical gas inlets (Medical OXYGEN and AIR, coming from the central piping system

or from cylinders).

PR1 - PR2. Pressure reducers. They have the function to reduce the inlet gas pressure to the stable value of

approx. 2.6 bar.

PSW1 - PSW2. Pressure switches. They have the function of signaling the eventual gas failure or low gas

pressure.

CSV1. Circuit selecting valve. It has the function to guarantee the operation of pneumatic devices supplied by

PR3 reducer also with only one gas in the inlet.

PR3 Pressure reducer. It has the function to reduce the pressure of the gas coming from CSV1 to the stable

value of approx.1.5 bar.

Only for SIARETRON 1000 and SIARETRON 3000

EV PART 1 O2 - EV PART 2 AIR. 12 V Pilot electrovalve. These valves are supplied from PR3 and have the

function to control the opening and closure of pneumatic by-passes for the measurement of flows over 15 l/min.

(see description of gas proportioning assembly). They are controlled by microprocessor.

EV PROP 1 INSP O2 - EV PROP 2 INSP AIR. 6V 0-120 l/min proportional electro valves. These valves regulate

the gas delivered to the patient allowing to control both the O2-AIR concentration and the FLOW. They are

controlled by microprocessor through a feedback system on the flow guaranteed by PS1 and PS2 flow sensors

Only for SIARETRON 1000 and SIARETRON 3000

R1.1 - R1 - R2.1 - R2. Pneumatic resistances. They are made of holes calibrated in accordance to the function

of distributing the flow coming from the proportional valves.

When the flow is lower or equal to 15 l/min the EV PART 1 and 2 valves are excited and the communication

with R1 and R2 is interrupted. In this way the flow will completely pass through the PS1 and PS2 sensors for

measurement.

When the flow is higher than 15 l/min the EV PART 1 and 2 valves are disexcited and the communication with

R1 and R2 is open. The special connection between the holes’ diameters and the form of channels, permit to a

know portion of the flow to bypass PS1 and PS2 and to the remaining part to pass through them for the

measurement. In this way it is possible to measure the flow since from 0.1 to 99 l/min with sensors from 0.1 to

15 l/min.

AIR SAFETY VALVE. Unidirectional mechanic valve. It has the function to allow to the patient to breath ambient

air in emergency case. It opens with a depression of approx. 2 mBar.

OXIGEN SENSOR. It has the function of measure the real oxygen concentration delivered to the patient.

AIRWAY PRESSURE TRANSDUCER. Pressure transducer with semiconductor. It has the function to

continuously measure the pressure inside the breathing circuit.

SIARETRON_SE3_en

13 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

FR3 PEEP/CPAP. Flow regulator. It has the function to keep inflated the LPV2 expiratory valve, during the

expiration phase in CPAP modality, so that the patient CFR (residual functional capacity) will rise.

FR3 MAX PAW. Flow regulator. It has the function to keep inflated the LPV2 expiratory valve during the

inspiration phase, so that the circuit discharge will be closed and the lungs inflating will be possible. This

regulator is tared in combination with FR3.1 regulator, so that the expiratory valve will automatically open if the

airways pressure is higher than 80 mBar.

EV3 V. EXP. 12 V pilot electrovalve. It has the function to activate the LPV2 expiratory valve in accordance with

the inspiratory and expiratory cycle. It is microprocessor controlled.

EV4. DISCHARGE. 12V pilot electrovalve. It has the function to discharge in the environment the exceeding

inspiratory portion during PS and CPAP. It is microprocessor controlled.

FR3.1. Flow regulator. It has the function to regulate the discharge of LPV2 expiratory valve inflating system; it

works in combination with FR3 and FR3 MAX PAW.

FS1 O

measure the air and O2 flows delivered to the patient. Thanks to R1.1, R1, R2.1 and R2 it is possible the flow

measurement from 0.1 to 99 l/min with sensors from 0.1 to 15 l/min.

FLOW SENSOR, FS1 AIR FLOW SENSOR. Flow capacity transducers. They have the function to

2

SIARETRON_SE3_en

14 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

(

c

cn-8

Service Manual

4 CALIBRATION AND TESTING

4.1 LV200-MAIN/1 CPU board

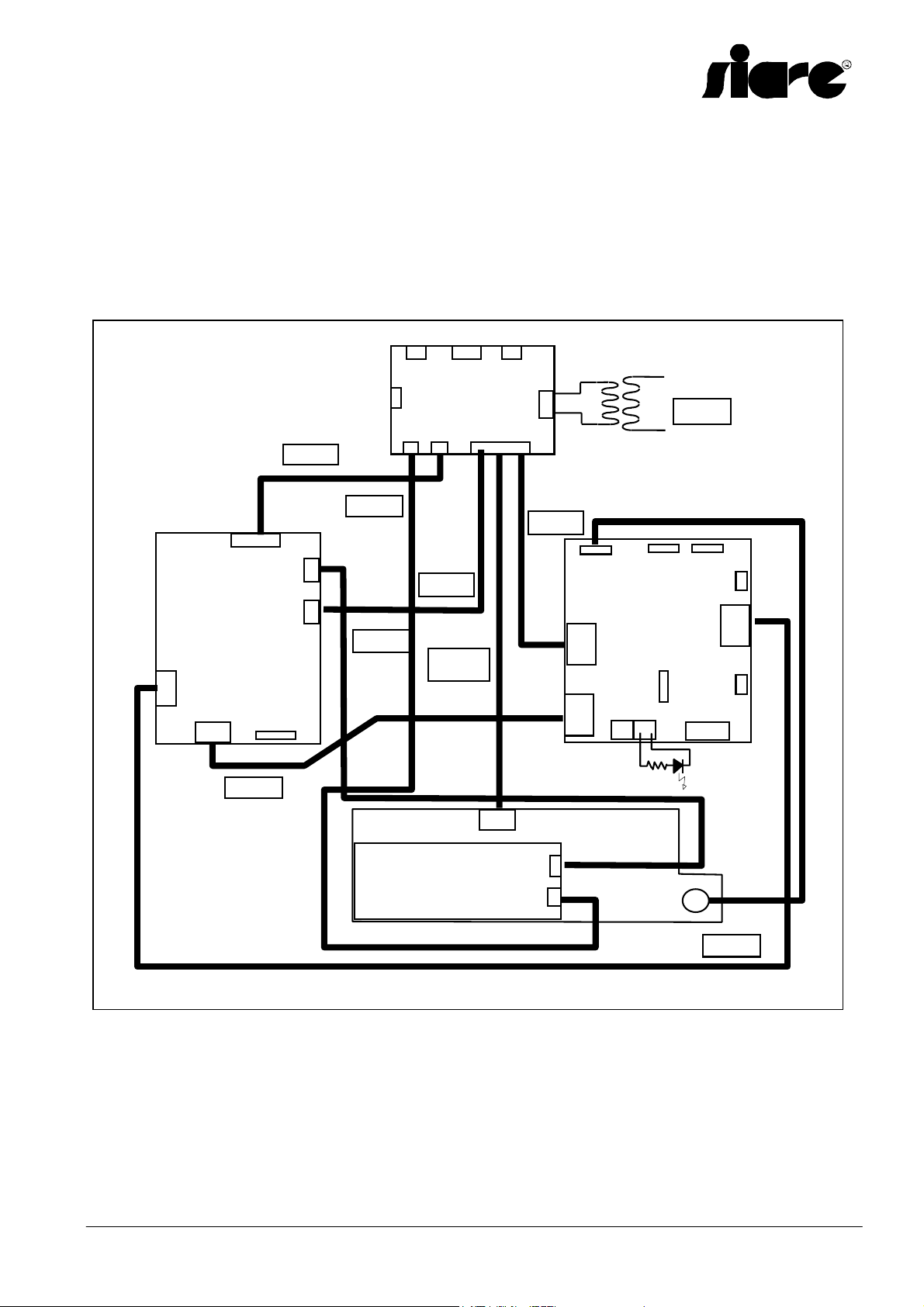

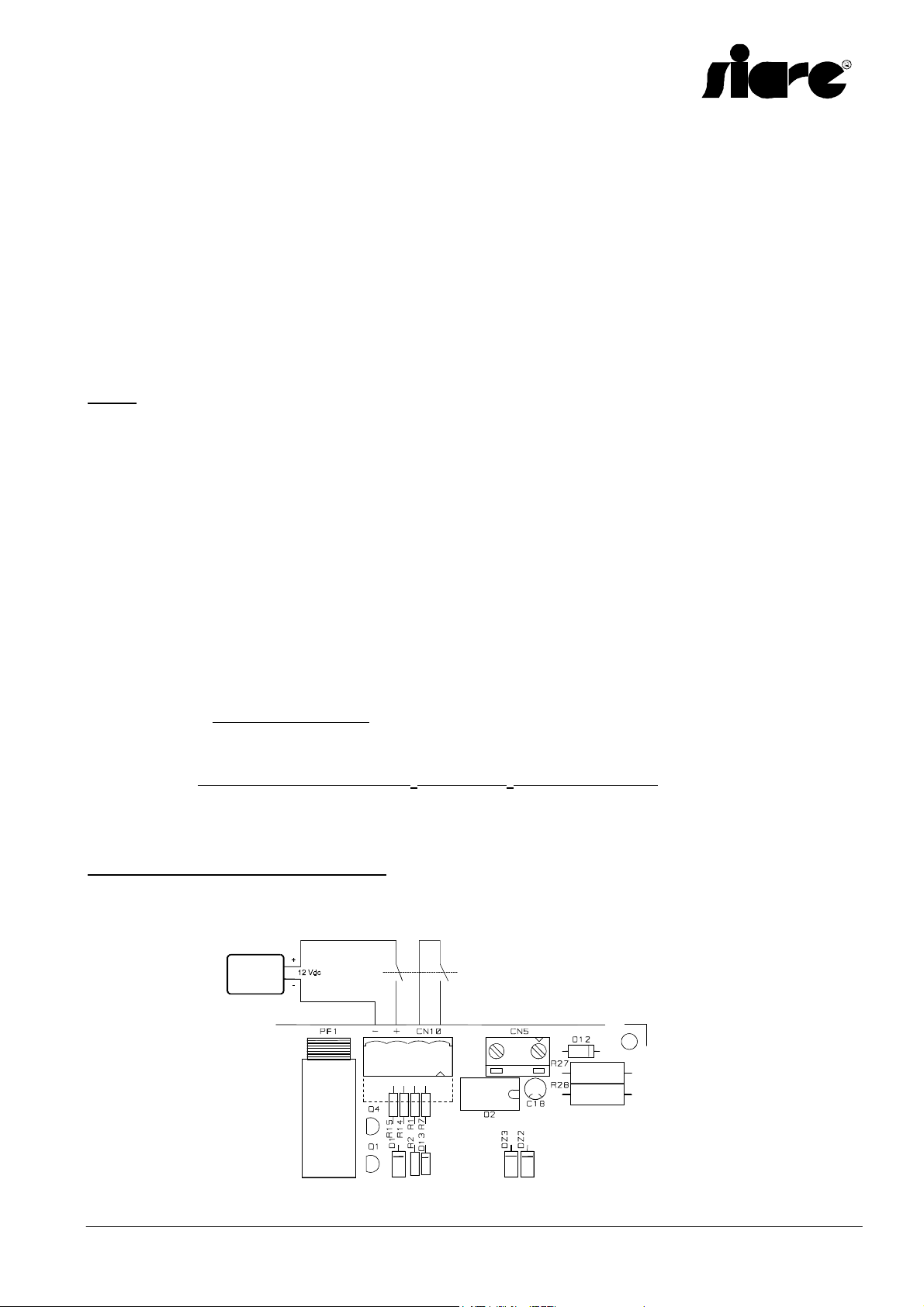

Connect the POWER, PANEL and LV200I/O boards (already tested) and the board to be tested by the

appropriate cables kit; referring to the following connecting drawings:

cn-2

LV200PW

cn-1

CVL-072

CVL-071

n-7

Transformer

220Vac - 12 Vac)

CVL-058

cn-8

cn-3

cn-5

220Vac

cn-1

-

-

P-10

-

LV200_MAIN1

P-8

CVL-052

P-2

P-5

P-4

CVL-054

EV ON/OFF

JP1

-

P-3

JP1

LV100-P/1

CVL-055

Connect the secondary of transformer to CN7 POWER connector; supply the primary of transformer.

To enter the testing program, press the ON/OFF switch keeping pressed the LOW AIRWAY PRESS.

Í

AIRWAY PRESS

keys until hearing a short sound, hence release the above indicated switches and press

Í

and HI

the ALARM RESET key within 5 seconds. Another short acoustic signal will occur, on the MINUTE VOLUME

display message TESTING will scroll once, after that on the same display will appear alternatively the

messages: I-O | ofG .

SIARETRON_SE3_en

15 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

Testing Performance Procedure

Acting on the PANEL board, while the alternated scripts: I-O | ofG (on DS13/14/15) appear, perform the

following checks (the referrals under brakes are relevant to the positions on the PANEL board):

• By the AUT. TIME CYCLED (SW7) button the ON/OFF electrovalve must light ON and OFF

following the status of the LED (LD1) next to the (LED ON, LED OFF) button.

•

•

•

By the AUT. PRESS CYCLED (SW2) button the BUZZER must light ON and OFF following the

status of LED (LD2) next to the (LED ON, LED OFF) button.

With the main power supply the green ON LINE LED (LD12) must be light on.

With the external battery the yellow ON BATT LED (LD11) must be light on, simulate the

external battery with power supply regulated at 12 Vdc connected as follows:

Power

supply

•

Verify the connection of LOW BATT (LD10) alarm LED lowering the external power supply

whom simulates the battery. At an electric power between 10.5 and 11.2Vdc the alarm must

intervene.

•

By pressing the ON/OFF switch (SW1) the yellow SPONT. BREATH DETECTOR LED (LD5)

must light on.

•

Short-circuiting the CN6 connector feet of the LV200I/O board (Air inlet pressure switch) the red

LOW AIRWAY PRESS (APNEA).LED (LD7) must light off.

•

Short-circuiting the CN7 connector feet of LV200I/O board (O2 inlet pressure switch) the red

GAS SUPPLY.LED (LD9) must light off.

SIARETRON_SE3_en

16 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

A/D channels testing.

The testing phase of A/D channels starts by pressing the ALARM RESET (SW20) button. On O

(DS9/10) and SIMV RATE (DS11/12) displays respectively appear messages: An and In , on RATE (DS3/4)

display appears message: Ch , on % INSP (DS5/6) display appears the channel on which the monitoring is

effected and on MINUTE VOLUME (DS13/14/15) display appears the analog/digital conversion value. With

Í

the % INSP

following checks:

a) Ch 0 (pressure): vary the inlet pressure of MPX10 sensor on the LV200I/O board from 0 to 80 cm of

b) Ch 1 (oxymeter): apply to the CN12 connector an electric power variable from 0 to 75 mV between

c) Ch 2 (MINUTE VOLUME potentiometer): rotate the potentiometer (POT) of MINUTE VOLUME

d) Ch 4 (AIR flowmeter): apply to the CN13 connector an electric power variable from 0 to 5 V between

(SW14) and Î (SW17) switches the A/D channel can be adjusted from 0 to 5; perform the

H2O and verify that the A/D value on the MINUTE VOLUME (DS13/14/15) display changes from 20

± 1 to 100 ± 2.

the pin 4 (+) and the pin 1 (GND); verify that the corresponding A/D value changes from 0 to 225 ± 2.

regulation and verify that the corresponding A/D value changes from 0 to 1023 (023 on display).

Ch 3 : not used.

the 4 (+) pin and the 2 (GND) pin; verify that the corresponding A/D value changes from 0 to

1000 ± 2.

CONC

2

e) Ch 5 (O2 flowmeter): apply to the CN14 connector an electric power variable from 0 to 5 V between

the pin 4 (+) and the pin 2 (GND); verify that the corresponding A/D value changes from 0 to

1000 ± 2.

After the test verify the machine switch-off by pressing ON/OFF (SW1) button.

5) If the testing result is positive, put on the board a green label indicating the identification number, the date

and tester technician signature.

SIARETRON_SE3_en

17 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

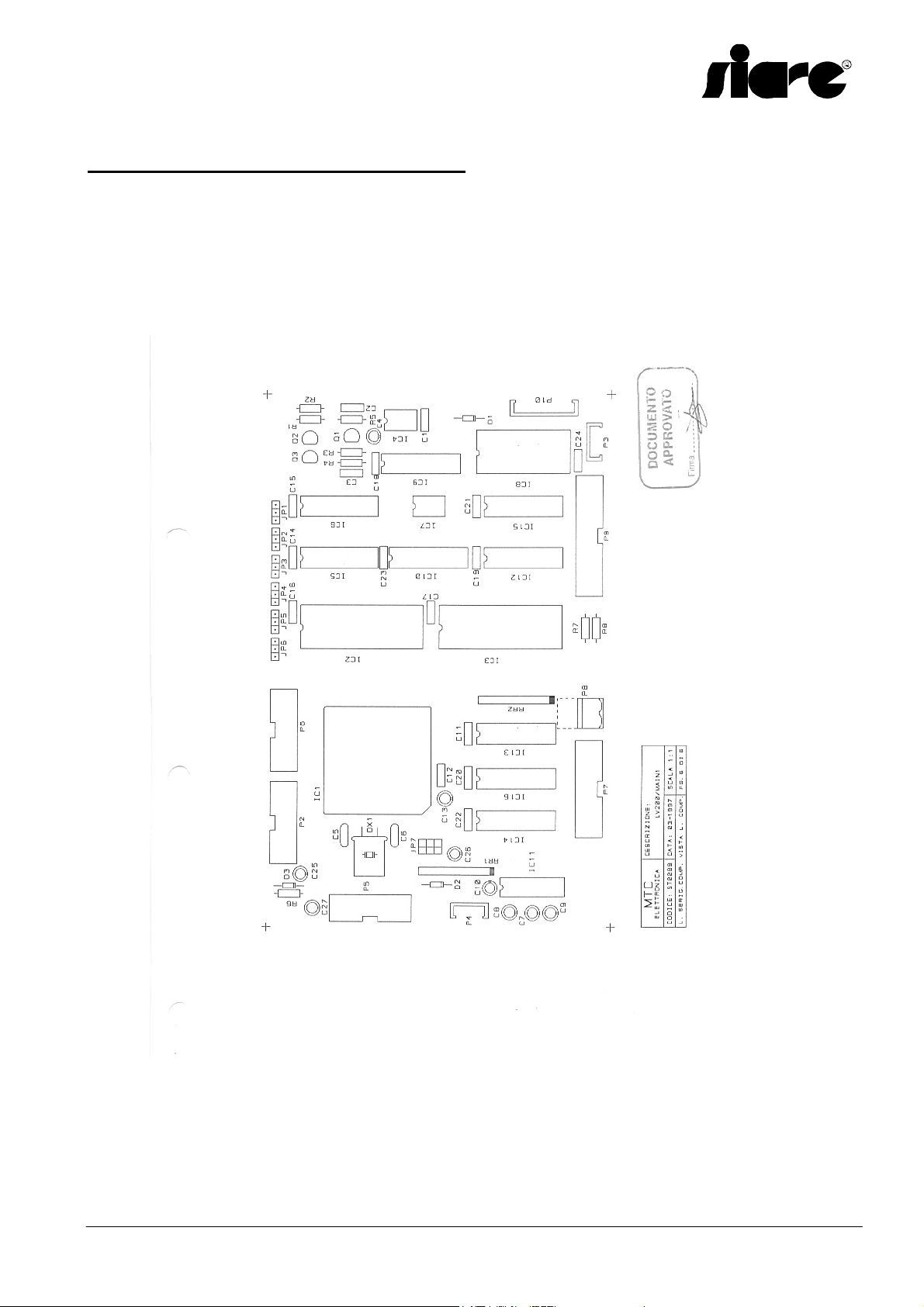

Component lay out of LV200-MAIN/1 board

SIARETRON_SE3_en

18 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

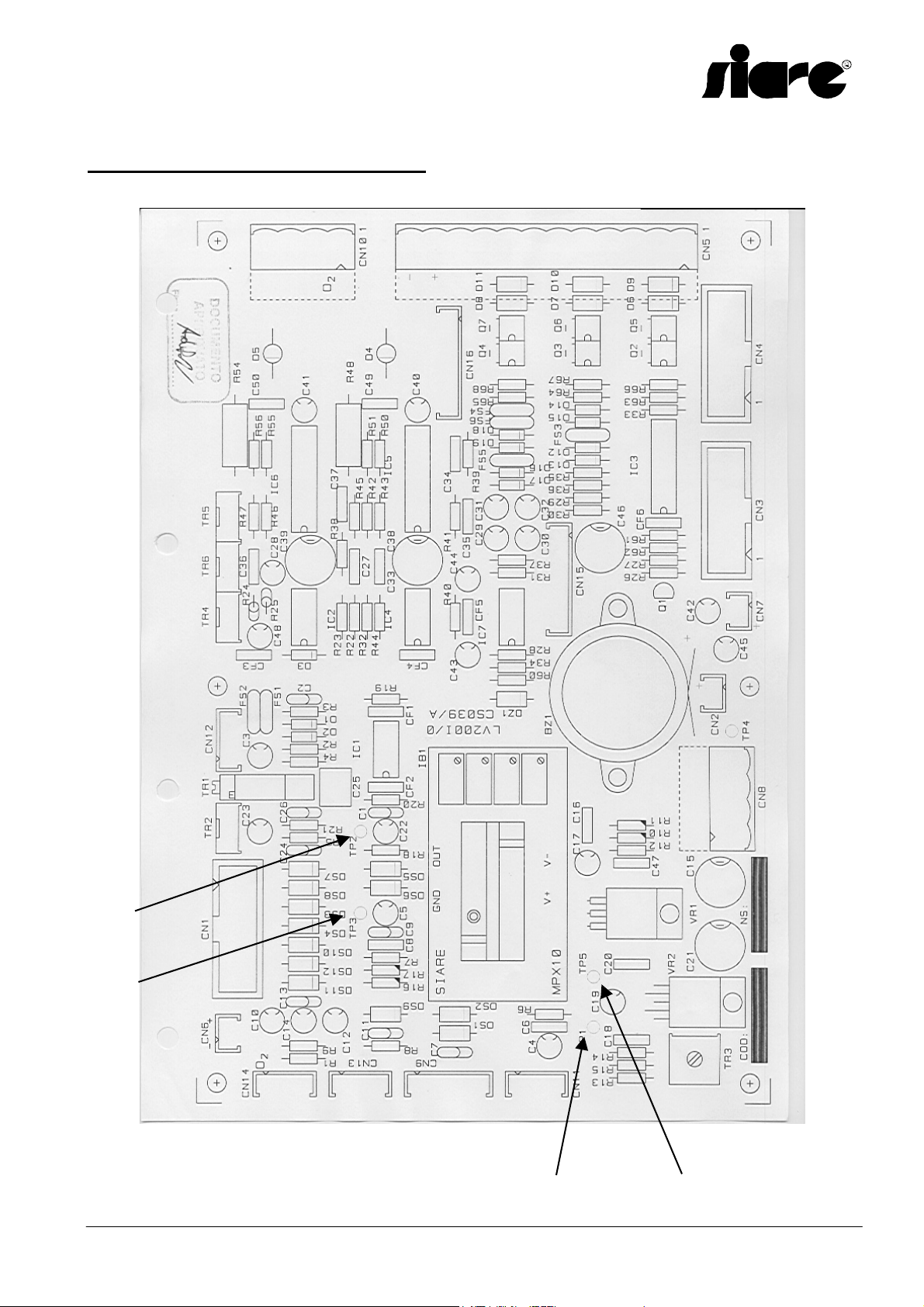

Component lay out of LV200 I/O board

H

I

G

B

C

TP2

TP3

TP1 TP5

SIARETRON_SE3_en

19 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

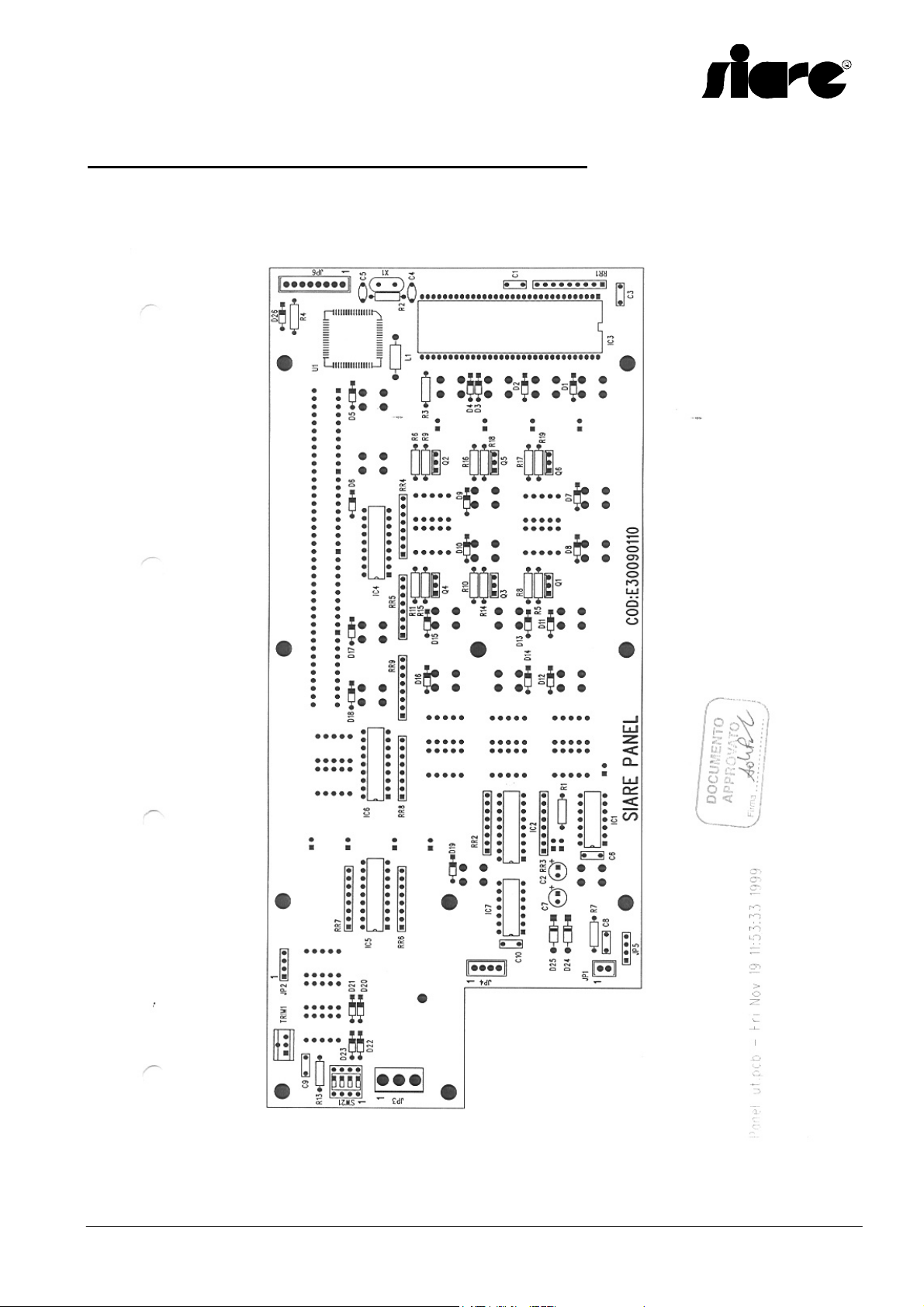

Component lay out of PANEL BOARD (component side):

SIARETRON_SE3_en

20 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

4.2 LV200 I/O BOARD

Connect the POWER, PANEL and LV200I/O boards referring to the connecting drawings of

figure 4.1

Then verify that the secondary of transformer is connected to CN7 POWER connector; finally supply the main of

transformer.

To enter the testing program, press the ON/OFF switch keeping pressed the LOW AIRWAY PRESS.

AIRWAY PRESS

press ALARM RESET button within 5 seconds. Another short signal will sound, on MINUTE VOLUME display

message TESTIING will appear once, after that on the same display the alternated script: I-O | ofG will appear.

NOTE:

to LV200I/O integrated circuit.

Regulations (take the mass reference of multimeter on TP1 test point):

.

Í

and HI

Í

buttons until a short sounds will occur, hence release the above mentioned buttons and e

from now and on all references to components and specific points of mounting plan have to be referred

A) Regulate the +V_ANA electric power (TP5 of mounting plan) at +10 V ± 0,05 V turning the TR3

Trimmer (point A of mounting plan).

B) Regulate the offset of acquisition channel of oxymetry cell; short-circuit the pin 1 and pin 4 of

AMP 4 leads CN12 connector; take at maximum gain by turning the TR1 multirevolution trimmer

(point B of mounting plan) clockwise; regulate the electric power of TP3 point of mounting plan

at 0 V ± 0,01 V by turning the TR2 trimmer (point C of mounting plan).

C) Apply to CN12 connector an electric power of 75 mV between pin 4 (+) and pin 1 (GND);

regulate the electric power of point TP3 of mounting plan at 4,5 V ± 0,05 V turning the TR1

multirevolution trimmer (point B of mounting plan).

Regulate the pressure acquisition channel (MPX10: mass reference of multimeter on GND):

A) At atmospheric pressure, regulate the electric power AD0 (TP2 of mounting plan) at +1V ± 10

mV by turning the TR1 multirevolution trimmer of offset on MPX10 hybrid circuit (point D of

mounting plan).

B) Apply a pressure of 40 cm H

regulate the electric power AD0 (TP2 of mounting plan) at +3V ± 50 mV turning the TR2

multirevolution trimmer of gain on MPX10 hybrid circuit (point F of mounting plan).

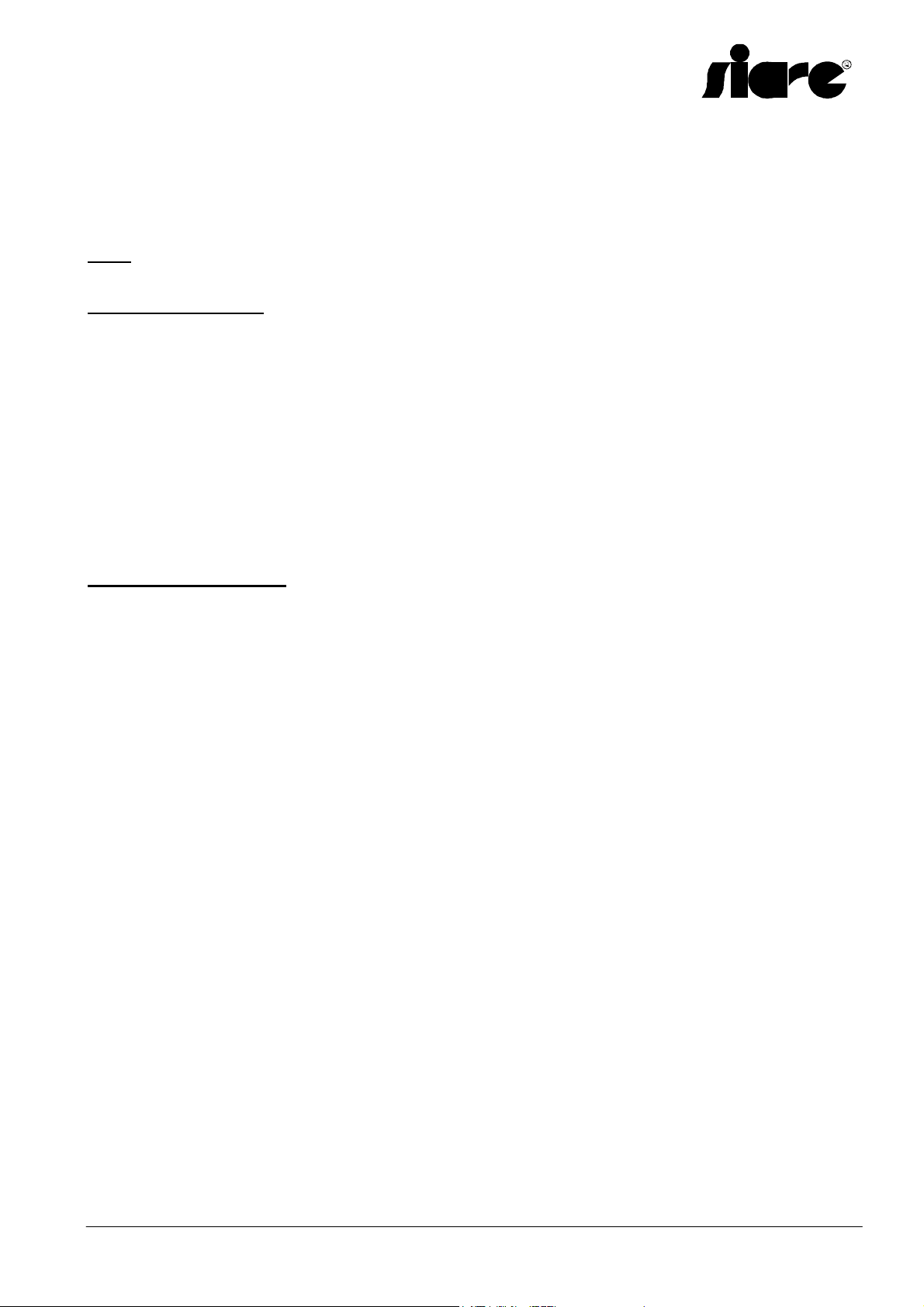

Regulation of battery alarm threshold

O ± 1 cm H2O to MPX10 sensor (point E of mounting plan);

2

: from panel, while the alternated scripts: I-O | ofG appears,

connect to the under testing board the battery simulator as per the following drawing:

Power

supply

SIARETRON_SE3_en

21 / (72 )

( rev.3) 30.06.2004

SIARETRON 1000 – 1100 - 3000

Service Manual

•

: the references under brakes of the following point are relevant to the positions on LV100-P/1 board.

NOTE

Testing of digital part

ofG appear (on DS13/14/15), perform the following checks (the references under brakes are relevant

to the positions on the LV100-P/1 board):

•

•

•

•

LOW BATT alarm threshold regulation: activate the supply from external battery (with power

supply adjusted at 10,9-11.0 V). hence turn the TR4 monorevolution trimmer (point G of

mounting plan) anticlockwise, until the red LOW BATT LED will light on. Hence, lightly turn the

trimmer clockwise and stop as soon as the LOW BATT. LED lights off. Verify that at decreasing

of electric power of power supply the LED lights on between 10.8 and 10.9 V.

: acting on LV100-P/1 panel board, while the alternated scripts alternate: I-O |

By the AUT. TIME CYCLED (SW7) key, the ON/OFF electovalve must light-on and off following

the status of the LED (LD1) next to LED ON/OFF switch.

By the AUT. PRESS CYCLED (SW2) key the BUZZER must light-on and off following the status

of LED (LD2) next to LED ON/ OFF switch.

Short-circuiting the CN6 connector feet of LV200I/O board (AIR inlet pressure switch) the red

LOW AIRWAY PRESS (APNEA LED (LD7) must light-off.

Short-circuiting CN7 connector feet of LV200I/O board (O2 inlet pressure switch) the red GAS

SUPPLY LED (LD9) must switch-off.

Verify the A/D channels:

acquisition channels. On

by pressing the ALARM RESET (SW20) key it is possible to verify the A/D

O2 CONC display

(DS9/10)

and SIMV RATE display

(DS11/12) appear

respectively the following scripts: An and In , on RATE display (DS3/4) appears message: Ch , on

% INSP display (DS5/6) it’s shown the channel on which the monitoring is performed and on MINUTE

VOLUME display (DS13/14/15) it is shown the analog/digital conversion value. With the % INSP Í

(SW14) and Î (SW17) keys it is possible to adjust the A/D channel from 0 to 5; perform the following

checks:

a) Ch 0 (pressure): vary the inlet pressure of MPX10 sensor on the LV200I/O board from 0 to 80

cm of H2O and verify that the A/D value on display MINUTE VOLUME display (DS13/14/15)

changes from 20 ± 1 to 100 ± 2.

b) Ch 1 (oxymeter): apply to CN12 connector an electric supply adjustable from 0 to 75 mV

between pin 4 (+) and pin 1 (GND); verify that the corresponding A/D value changes from 0 to

225 ± 2.

c) Ch 2 (MINUTE VOLUME potentiometer): turn the potentiometer (POT) of MINUTE VOLUME

regulation and verify that the corresponding A/D value changes from 0 to 1023 (displayed as

023).

d) Ch 3 : not used.

e) Ch 4 (AIR flowmeter): apply to CN13 connector an electric power adjustable from 0 to 5 V

between pin 4 (+) and pin 2 (GND); verify that the corresponding A/D value changes from 0 to

1000 ± 2.

f) Ch 5 (O

between pin 4 (+) and pin 2 (GND); verify that the corresponding A/D value changes from 0 to

1000 ± 2.

flowmeter): apply to CN14 connector an electric power adjustable from 0 to 5 V

2

SIARETRON_SE3_en

22 / (72 )

( rev.3) 30.06.2004

Loading...

Loading...