sherline PN 8900 User Manual

Installing the Air Spindle into the Headstock

Insert the air spindle body into the hole in the headstock

body and slide it down until the part of the body below

the knurled silver speed control portion is approximately

centered in the headstock. Using the 7/64" hex key provided,

tighten the 6-32 socket head screw to secure the spindle in

the headstock body.

Mounting the Headstock to the Saddle

Fit the headstock/spindle unit over the pin on the mill column

saddle. Make sure the alignment key (P/N 40260) is seated

in the slot in the saddle and align the corresponding slot in

the back of the headstock to fi t over the key. Tighten the

tab (P/N 89024). The point of the set screw will engage the

tapered groove in the pin to pull the headstock down tightly

against the saddle, using the alignment key to align it.

Connecting the High Speed Spindle Air Line

It is very important that you provide clean, dry air to run

your high speed spindle. Dirty and/or wet air will cause the

spindle to wear out prematurely. Follow the manufacturer's

instructions included with the spindle when connecting the

air lines. A compressor of at least 1.5 horsepower producing

about 90 PSI of air pressure is appropriate for this spindle.

Continuous high speed use requires about 3 cu.ft/min of air

volume. The manufacturer recommends a break-in period

for the fi rst 2-3 hours of use. During this period, restrict air

pressure to 50-55 PSI. Once broken in, do not use pressures

over 90 PSI, as this will also cause excessive wear.

If extending the air line provided, use 1/4" line up to 25' in

length. If length longer than that is needed, it is recommended

that you increase the line size to 3/8" to provide suffi cient

volume of air for the tool.

Precautions When Using the Spindle

Do not overload the carbide cutter by taking too heavy a cut.

In most cases it is not necessary to use the full 54,000 RPM

capacity of the spindle. 40,000-45,000 RPM will usually do

just as good a job, and the lower speed will extend the life

of your spindle bearings. Because you are using a brittle

carbide tool and the extremely high RPM, the wearing of

proper eye protection is of utmost importance.

Lubrication

The spindle manufacturer recommends using an air line

lubricator supplying SAE #10 oil at a rate of two drops per

SHERLINE

INCORPORATED 1974

8/1/12

SHERLINE PRODUCTS INC.

3235 Executive Ridge

Vista

California 92081-8527

FAX: (760) 727-7857

Toll Free Order Line: (800) 541-0735

International/Local/Tech. Assistance: (760) 727-5857

Internet: www.sherline.com

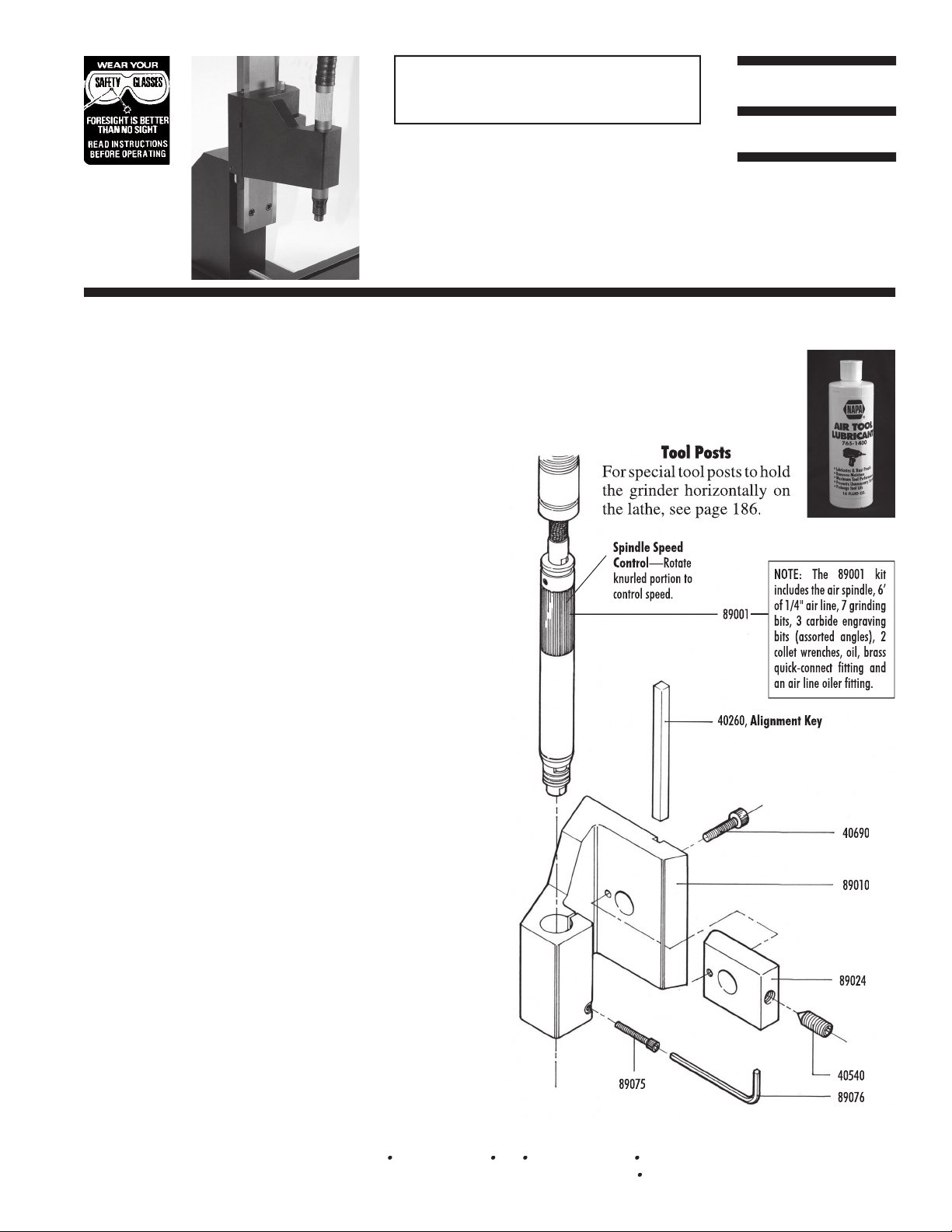

FIGURE 1—Exploded view with part numbers.

89001

40690

89010

89024

40540

89076

89075

40260,

Alignment Key

NOTE: The 89001 kit

includes the air spindle, 6'

of 1/4" air line, 7 grinding

bits, 3 carbide engraving

bits (assorted angles), 2

collet wrenches, oil, brass

quick-connect fitting and

an air line oiler fitting.

Spindle Speed

Control

—Rotate

knurled portion to

control speed.

minute. A lubricator fi tting is supplied with your spindle

kit. Also included is a small bottle of oil to get your started.

For long term use we recommend an air

tool lubricant such as the one available in

as NAPA part number 765-1400 or the

equivalent from any other supplier.

Tool Posts

For special tool posts to hold

the grinder horizontally on

the lathe, see page 186.

spindles this product is recommended for engraving,

polishing and grinding only and not for machining.

Here are a couple of free or low cost programs that

can get you started in engraving type, line art and even

pictures. Sherline does not offer technical support for

these programs, but we felt it would be helpful to our

customers to let you know these resources exist. The fi rst

program offers a great start and a lot of good features for

free. As your needs increase you may want to upgrade

to the second program which offers more sophisticated

features at a very reasonable price.

DeskEngrave (Free)

DeskEngrave allows you to enter text in any TrueType

font and export to a DXF fi le or create G-code directly

from the outline of the entered text. Text can be straight or

wrapped around a radius. When creating G-code directly

from DeskEngrave, engraving depth, rapid height, feed

rate, plunge rate, and the precision of the created text

are all controllable parameters. Exporting to a DXF (the

standard for vector drawings) gives you the opportunity

to combine multiple texts with a CAD program, allowing

for highly-complex engraving designs, which can then be

saved as a single vector image and converted to G-code

by any number of DXF-to-G-code converters.

DeskEngrave is small, easy to install, and should run

on any Windows-based system (Win95 or better). It is

included in the Utilities folder on the backup instruction

CD included with Sherline CNC systems or 8760 driver

boxes. You can also download DeskEngrave at: http://

www.deskam.com/deskengrave.html.

Direct download is at: http://www.deskam.com/DLOAD/

DeskEngrave.Exe.

Using DeskEngrave

When you open the DeskEngrave program, use the Help

feature to fi nd instructions for its use. This is a very simple

program to get started with.

DeskART—Free 30-Day Demo

DeskART is a more full-featured program than

DeskEngrave. While not free past the 30-day trial, it does

offer a larger range of features. (Current price is about

$175.00 for purchase of download version.) It can take

the most common graphics fi le formats (JPG, BMP, GIF,

TIF, and PCX) and, using the levels of brightness in the

image as a topographical projection, create G-code to mill

a 3D engraving (black areas are engraved deepest; white

areas are set as ZØ and not engraved). When creating the

G-code, the image can be rescaled to match the size of

the engraving you wish to make, and parameters such as

engraving depth, depth per pass, feed rate, rapid height,

and axis increment size can be set.

More details about DeskART and a 30-day demo, are

available at: http://www.deskam.com/deskart.html

Direct download is at: http://www.deskam.com/

DLOAD/DeskART.Exe

Using DeskART

Instructions for use of

DeskArt

are available from the

Help menu once you have installed the program. The size

of the increments you enter will determine the detail of

your image. Engraving a one-inch square image in .005

increments, for instance, will give you a more detailed

picture than one done in .010 increments, but the duration

of the engraving process will also be twice as long, since

you will be milling the image in two hundred passes

instead of one hundred.

NOTE: DeskART reduces the size of the engraving by

25%, so you will have to increase the size of the picture

you want to convert to G-code by 133% to compensate.

9/21/10

Loading...

Loading...