Sharp R-3A88 User Manual

R-3A88

SERVICE MANUAL

S3614R3A88PX/

MICROWAVE OVEN

MODEL R-3A88

In interests of user-safety the oven should be restored to its original condition and only parts identical to those specified should be used.

TABLE OF CONTENTS |

|

|

Page |

CAUTION, MICROWAVE RADIATION ................................................................................................................. |

1 |

WARNING .............................................................................................................................................................. |

1 |

PRODUCT SPECIFICATIONS ............................................................................................................................. |

2 |

GENERAL INFORMATION .................................................................................................................................... |

2 |

APPEARANCE VIEW ........................................................................................................................................... |

3 |

OPERATION SEQUENCE .................................................................................................................................... |

4 |

FUNCTION OF IMPORTANT COMPONENTS ..................................................................................................... |

5 |

SERVICING .......................................................................................................................................................... |

6 |

TEST PROCEDURE ............................................................................................................................................. |

8 |

TOUCH CONTROL PANEL ................................................................................................................................. |

14 |

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE ............................................................... |

18 |

MICROWAVE MEASUREMENT ........................................................................................................................ |

24 |

WIRING DIAGRAM ............................................................................................................................................. |

25 |

PICTORIAL DIAGRAM ....................................................................................................................................... |

26 |

CONTROL PANEL CIRCUIT ............................................................................................................................... |

27 |

PRINTED WIRING BOARD ................................................................................................................................. |

28 |

PARTS LIST ....................................................................................................................................................... |

29 |

SHARP CORPORATION

R-3A88

SERVICE MANUAL

MICROWAVE OVEN

R-3A88

GENERAL IMPORTANT INFORMATION

This Manual has been prepared to provide Sharp Corp. Service engineers with Operation and Service Information.

It is recommended that service engineers carefully study the entire text of this manual, so they will be qualified to render satisfactory customer service.

CAUTION

MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM THE MICROWAVE GENERATOR OR OTHER PARTS CONDUCTING MICROWAVE ENERGY.

Service engineers should not be exposed to the microwave energy which may radiate from the magnetron or other microwave generating devices if it is improperly used or connected. All input and output microwave connections, waveguides, flanges and gaskets must be secured. Never operate the device without a microwave energy absorbing load attached. Never look into an open waveguide or antenna while the device is energized.

WARNING

Never operate the oven until the following points are ensured.

(A)The door is tightly closed.

(B)The door brackets and hinges are not defective.

(C)The door packing is not damaged.

(D)The door is not deformed or warped.

(E)There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained service engineers.

All the parts marked "*" on parts list are used at voltages more than 250V.

Removal of the outer wrap gives access to potentials above 250V.

All the parts marked " " on parts list may cause undue microwave exposure, by themselves, or when they are damaged, loosened or removed.

SHARP CORPORATION

OSAKA, JAPAN

1

R-3A88

PRODUCT SPECIFICATIONS

APPEARANCE VIEW

OPERATING SEQUENCE

FUNCTION OF IMPORTANT COMPONENTS

SERVICING AND TROUBLESHOOTING CHART

TEST PROCEDURE

TOUCH CONTROL PANEL

ASSEMBLY

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

MICROWAVE MEASUREMENT

WIRING DIAGRAM

PARTS LIST

R-3A88

|

PRODUCT SPECIFICATIONS |

|||

|

|

|

|

|

ITEM |

|

|

|

DESCRIPTION |

Power Requirements |

220 Volts |

|

||

|

50 Hertz |

|

||

|

Single phase, 3 wire earthed |

|||

|

|

|

|

|

Power Consumption |

1.35 kW |

|

||

|

|

|

|

|

Power Output |

850 watts nominal of RF microwave energy (IEC 705) |

|||

|

Operating fequency 2450 MHz |

|||

|

|

|

|

|

Case Dimensions |

Width 520 mm |

|

||

|

Height 305 mm |

|

||

|

Depth 389mm |

|

||

|

|

|

|

|

Cooking Cavity Dimensions |

Width 348 mm |

|

||

|

Height 197 mm |

|

||

|

Depth 368 mm |

|

||

|

|

|

|

|

Turntable diameter |

325mm |

|

||

|

|

|

|

|

Control Complement |

Touch Control System |

|||

|

Clock ( 1:00 - 12:59) |

|||

|

Timer (0 - 99 minutes 99 seconds) |

|||

|

Microwave Power for Variable Cooking |

|||

|

Repetition Rate; |

|

||

|

HIGH ............................................... |

Full power throughout the cooking time |

||

|

MEDIUM HIGH .................................................. |

approx. 70% of Full Power |

||

|

MEDIUM ............................................................. |

approx. 50% of Full Power |

||

|

MEDIUM LOW .................................................... |

approx. 30% of Full Power |

||

|

LOW .................................................................... |

approx. 10% of Full Power |

||

|

HELP pad, REHEAT pad |

|||

|

RICE COOK pad |

|

||

|

STEAM MENU pad |

|||

|

MORE, LESS pads |

|||

|

INTERNATIONAL MENU pads |

|||

|

SLOW COOK pad |

|

||

|

EASY DEFROST pad |

|||

|

NUMBER pads, |

|

||

|

POWER LEVEL pad |

|||

|

AUTO START/ |

|

|

pad |

|

|

|||

|

|

|||

|

STOP/CLEAR pad |

|

||

|

INSTANT COOK/START pad |

|||

|

|

|

||

Set Weight |

Approx. 15 kg |

|

||

|

|

|

|

|

GENERAL INFORMATION

WARNING

THIS APPLIANCE MUST BE EARTHED

IMPOTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW |

: EARTH |

BLUE |

: NEUTRAL |

BROWN |

: LIVE |

2

R-3A88

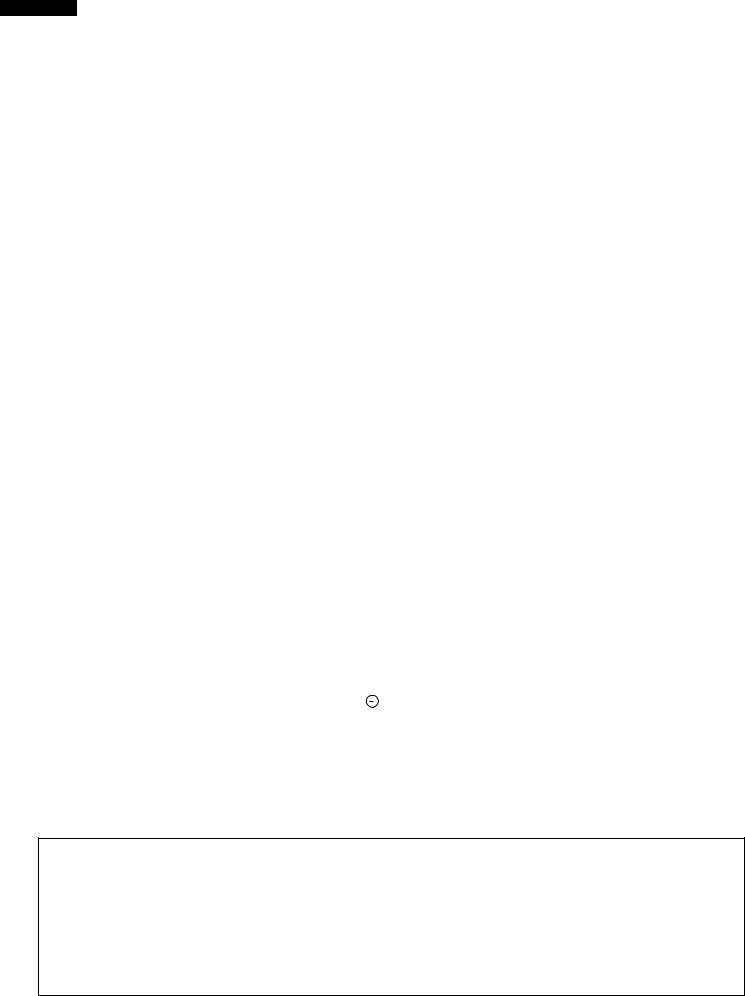

APPEARANCE VIEW

1.Ventilation openings

2.Oven lamp

3.Door hinges

4.Door safety latches

5.See through door

6.Door seals and sealing surfaces

7.Coupling

8.Door open button

9.Touch control panel 10.Digital readout 11.Wave guide cover 12.Power supply cord 13.Rating label 14.Earth wire

6 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

10 |

|

|

|

|

|

14 |

|

3 |

|

|

|

9 |

|

|

|

|

|

8 |

|

4 |

5 |

7 |

2 |

12 |

13 |

11 4 |

|

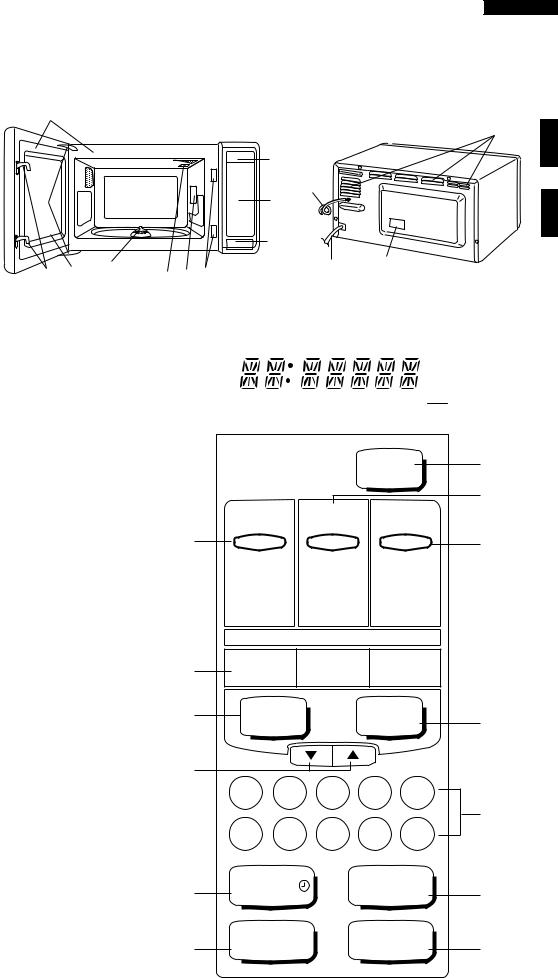

TOUCH CONTROL PANEL

aHELP PAD

Touch to select child lock, language or demonstration modes. Touch to get cooking information.

bREHEAT PAD

Touch to reheat 3 popular menus.

cRICE COOK PAD

Touch to cook rice, congee or porridge.

dSTEAM MENU PAD

Touch to cook steam menus.

e.INTERNATIONAL MENUE OADS Touch to cook 3 international menus.

fSLOW COOK PAD

Touch to cook slowly and longer time.

gEASY DEFROST PAD

Touch to defrost meat by entering weight.

hMORE ( ), LESS (

), LESS ( ) PADS

) PADS

Touch to adjust the doneness of food in one minute increments during cooking or to increase/decrease the time whilst programming the REHEAT, RICE COOK, STEAM MENU, INTERNATIONAL MENU or EASY DEFROST modes.

iNUMBER PADS

Touch to enter cooking times, clock time, weight or quantity of food.

jAUTO START/CLOCK PAD

Touch to set clock or Auto Start time.

kPOWER LEVEL PAD

Touch to select microwave power setting.

If not touched, HIGH is automatically selected.

lSTOP/CLEAR PAD

Touch to clear during programming.

Touch once to stop operation of oven during cooking; touch twice to cancel cooking programme.

mINSTANT COOK/START PAD

Touch once to cook for 1 minute at HIGH or increase by 1 minute multiples each time this pad is touched during cooking. Touch to start oven after setting programmes.

COOK |

KG DEF HELP |

Indicator |

|

|

|

|

INTERACTIVE |

|

HELP |

|

a |

||

|

DISPLAY |

|

|

|

c |

||

|

|

|

|

|

|

|

|

b |

REHEAT |

RICE COOK |

STEAM MENU |

d |

|||

|

|

|

|

|

|

||

|

1 Dishes |

|

1 Rice |

|

1 Fish |

|

|

|

2 Beverage |

2 Congee |

2 Meat |

|

|||

|

3 Bread |

|

3 Porridge |

3 Dumpling |

|

||

e |

INTERNATIONAL MENU |

|

|

||||

Mini pizza |

Tom Yum Kung |

Sukiyaki |

|

||||

|

|

||||||

f |

SLOW COOK |

EASYDEFROST |

g |

||||

|

|||||||

h |

1 |

2 |

3 |

|

4 |

5 |

|

|

|

i |

|||||

|

6 |

7 |

8 |

|

9 O |

||

|

|

|

|||||

j |

AUTO START/ |

|

POWER LEVEL |

k |

|||

|

|

|

|||||

l |

STOP / CLEAR |

INSTANTCOOK/START |

m |

||||

|

|

|

|

|

|

||

3

R-3A88

OPERATION SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches (1st. latch switch and 2nd. interlock relay control switch).

IMPORTANT

When the oven door is closed, the monitor switch contacts (COM-NC) must be open.

When the microwave oven is plugged in a wall outlet, rated voltage is supplied to the point A3+A5 in the control unit.

The circuits to the power transformer, fan motor and turntable motor are cut off when the 1st. latch switch and 2nd. interlock relay control switch are made open. The oven lamp remains on even if the oven door is opened after the cooking cycle has been interrupted, because the relay RY1 stays closed. Shown in the display is the remaining time.

Figure O-1 on page 25

1. The display shows SHARP , MICRO- , WAVE and OVEN .

2.To set any programmes or set the clock, you must first touch the STOP/CLEAR pad.

3.: appears in the display.

NOTE: When the oven door is opened, the oven lamp comes on at this time.

MICROWAVE COOKING CONDITION

HIGH COOKING

Enter a desired cooking time with the touching NUMBER pad and start the oven with touching START pad.

Function sequence

Figure O-2 on page 25

CONNECTED COMPONENTS |

RELAY |

Oven lamp, Fan motor, Turntable motor |

RY1 |

|

|

Power transformer |

RY2 |

1.Rated voltage. is supplied to the primary winding of the power transformer. The voltage is converted to about 3.3 volts A.C. output on the filament winding and high voltage of approximately 2000 volts A.C. on the secondary winding.

2.The filament winding voltage (3.3 volts) heats the magnetron filament and the high voltage (2000 volts) is sent to the voltage doubling circuit, where it is doubled to negative voltage of approximately 4000 volts D.C..

3.The 2450 MHz microwave energy produced in the magnetron generates a wave length of 12.24 cm. This energy is channelled through the waveguide (transport channel) into the oven cavity, where the food is placed to be cooked.

4.When the cooking time is up, a signal tone is heard and the relays RY1+RY2 go back to their home position. The circuits to the oven lamp, power transformer, fan motor and turntable motor are cut off.

5.When the door is opened during a cook cycle, the switches come to the following condition

|

|

CONDITION |

|

|

|

DURING |

DOOR OPEN |

SWITCH |

CONTACT |

COOKING |

(NO COOKING) |

|

|

|

|

1st. latch switch |

COM-NO |

Closed |

Open |

|

|

|

|

2nd. interlock relay |

|

|

|

control switch |

COM-NO |

Closed |

Open |

Monitor switch |

COM-NC |

Open |

Closed |

|

|

|

|

6.MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by oven door, and monitors the operation of the 1st latch switch and 2nd. interlock relay.

6-1 When the oven door is opened during or after the cycle of a cooking program, the 1st. latch switch and 2nd. interlock relay control switch must open their contacts first.

After that the contacts (COM-NC) of the monitor switch can be closed.

6-2. When the oven door is closed, the contacts (COM-NC) of the monitor switch must be opened. After that the contacts of the 1st. latch switch and 2nd. interlock relay control switch are closed.

6-3. When the oven door is opened and the contacts of the 1st. latch switch and 2nd. interlock relay remain closed. The fuse M8A will blow, because the monitor switch is closed and a short circuit is caused.

MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW COOKING

When the microwave oven is preset for variable cooking power, rated voltage is supplied to the power transformer intermittently within a 32-second time base through the relay contact which is coupled with the current-limiting relay. The following levels of microwave power are given.

SETTING;

32 sec. ON

HIGH

|

24 sec. ON |

8 sec. OFF |

||||

MEDIUM HIGH |

|

|

|

|

|

Approx. 70% |

|

18 sec. ON |

14 sec. OFF |

||||

MEDIUM |

|

|

|

|

|

Approx. 50% |

|

12 sec. ON |

20 sec. OFF |

||||

MEDIUM LOW |

|

|

|

|

|

Approx. 30% |

|

6 sec. ON |

26 sec. OFF |

||||

LOW |

|

|

|

|

|

Approx. 10% |

NOTE: The ON/OFF time ratio does not exactly correspond to the percentage of microwave power, because approx. 2 seconds are needed for heating up the magnetron filament.

4

R-3A88

FUNCTION OF IMPORTANT COMPONENTS

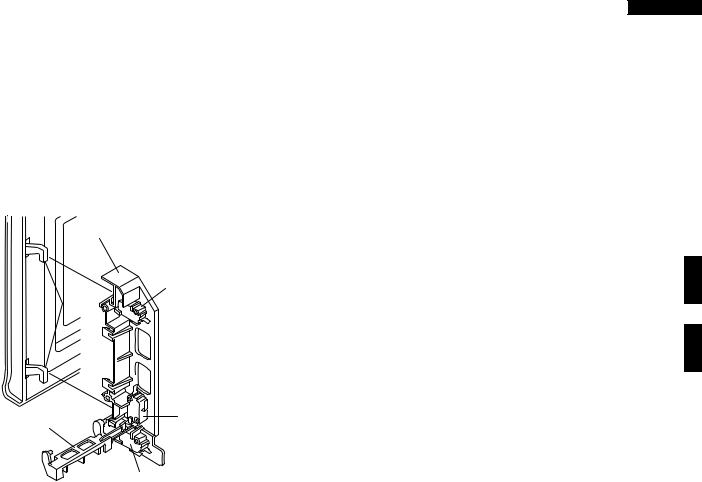

DOOR OPEN MECHANISM

The door is opened by pushing the open button on the control panel, refer to the Figure D-1.

When the open button is pushed, the open button pushes up the switch lever, and then the switch lever pushes up the latch head. The latch heads are moved upward and released from latch hook. Now the door will open.

|

LATCH HOOK |

|

2ND. INTERLOCK |

LATCH |

RELAY CONTROL |

SWITCH |

|

HEADS |

|

SWITCH |

MONITOR |

SWITCH |

|

LEVER |

|

1ST. LATCH SWITCH

Figure D-1. Door Open Mechanism

1ST. LATCH SWITCH AND 2ND. INTERLOCK RELAY CONTROL SWITCH

1.When the oven door is closed, the contacts (COM-NO) must be closed.

2.When the oven door is opened, the contacts .(COM-NO) must be opened.

MONITOR SWITCH

1.When the oven door is closed, the contacts (COM-NC) must be opened.

2.When the oven door is opened, the contacts (COM-NC) must be closed.

3.If the oven door is opened and the contacts (COM-NO) of the 1st. latch switch and 2nd. interlock relay fail to open, the fuse M8A blows simultaneously with closing the contacts (COM-NC) of the monitor switch.

CAUTION: BEFORE REPLACING A BLOWN FUSE M8A TEST THE 1ST. LATCH SWITCH, 2ND. INTERLOCK RELAY, 2ND. INTERLOCK RELAY CONTROL SWITCH, MONITOR SWITCH AND MONITOR RESISTOR FOR PROPER OPERATION.

MONITOR RESISTOR R 0.8Ω 20W

The monitor resistor prevents the fuse M8A bursting when the fuse M8A blows due to the operation of the monitor switch.

FUSE M8A

1.The fuse M8A blows when the contacts (COM-NO) of the 1st. latch switch and 2nd. interlock relay remain closed with the oven door open and when the monitor switch closes.

2.If the wire harness or electrical components are shortcircuited, this fuse M8A blows to prevent an electric shock or fire hazard.

THERMAL CUT-OUT TC 145˚C (MG)

This thermal cut-out protects the magnetron against overheating. If the temperature goes up higher than 145˚C because the fan motor is interrupted, the ventilation openings are blocked, the thermal cut-out will open and the line voltage to the power transformer will be cut off and the operation of the magnetron will be stopped.

The defective thermal cut-out must be replaced with new one.

THERMAL CUT-OUT TC 145˚C (OVEN)

The thermal cut-out located on the top of the oven cavity is designed to prevent damage to the oven if the foods in the oven catch fire due to over heating produced by improper setting of cook time or failure of control unit. Under normal operation, the oven thermal cut-out remains closed. However, when abnormally high temperatures are reached within the oven cavity, the oven thermal cut-out will open at 145˚C, causing the oven to shut down. The defective thermal cut-out must be replace with new one.

THERMAL CUT-OUT 95˚C (FAN MOTOR)

The thermal cut-out protect the fan motor against overheating. If its temperature goes up higher than 95˚C because the fan motor is locked or the ventilation operating are blocked, the contacts of the thermal cut-out will open and switch off the oven. When the oven cools itself down to 75˚C, the contacts of the thermal cut-out will close again.

TURNTABLE MOTOR

The turntable motor drives the turntable roller assembly to rotate the turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool air. This cool air is directed through the air vanes surrounding the magnetron and cools the magnetron. This air is channelled through the oven cavity to remove steam and vapours given off from the heating foods. It is then exhausted through the exhausting air vents at the oven cavity

5

R-3A88

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with any part of the high voltage circuit will result in electrocution. High voltage capacitor, Power transformer, Magnetron, High voltage rectifier assembly, High voltage harness.

REMEMBER TO CHECK 3D

1)Disconnect the supply.

2)Door opened, and wedged open.

3)Discharge high voltage capacitor.

WARNING: AGAINST THE CHARGE OF THE HIGH-VOLTAGE CAPACITOR

The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60 seconds and then short-circuit the connection of the high-voltage capacitor (that is, of the connecting lead of the high-voltage rectifier) against the chassis with the use of an insulated screwdriver.

Sharp recommend that wherever possible fault-finding is carried out with the supply disconnected. It may in, some cases, be necessary to connect the supply after the outer case has been removed, in this event carry out 3D checks and then disconnect the leads to the primary of the power transformer. Ensure that these leads remain isolated from other components and the oven chassis. (Use insulation tape if necessary.) When the testing is completed carry out 3D checks and reconnect the leads to the primary of the power transformer.

REMEMBER TO CHECK 4R

1)Reconnect all leads removed from components during testing.

2)Replace the outer case (cabinet).

3)Reconnect the supply.

4)Run the oven. Check all functions.

Microwave ovens should not be run empty. To test for the presence of microwave energy within a cavity, place a cup of cold water on the oven turntable, close the door and set the microwave timer for two (2) minutes. Set the power level to HIGH and push the START button. When the two minutes has elapsed (timer at zero) carefully check that the water is now hot. If the water remains cold carry out 3D checks and re-examine the connections to the component being tested.

When all service work is completed, and the oven is fully assembled, the microwave power output should be checked and microwave leakage test carried out

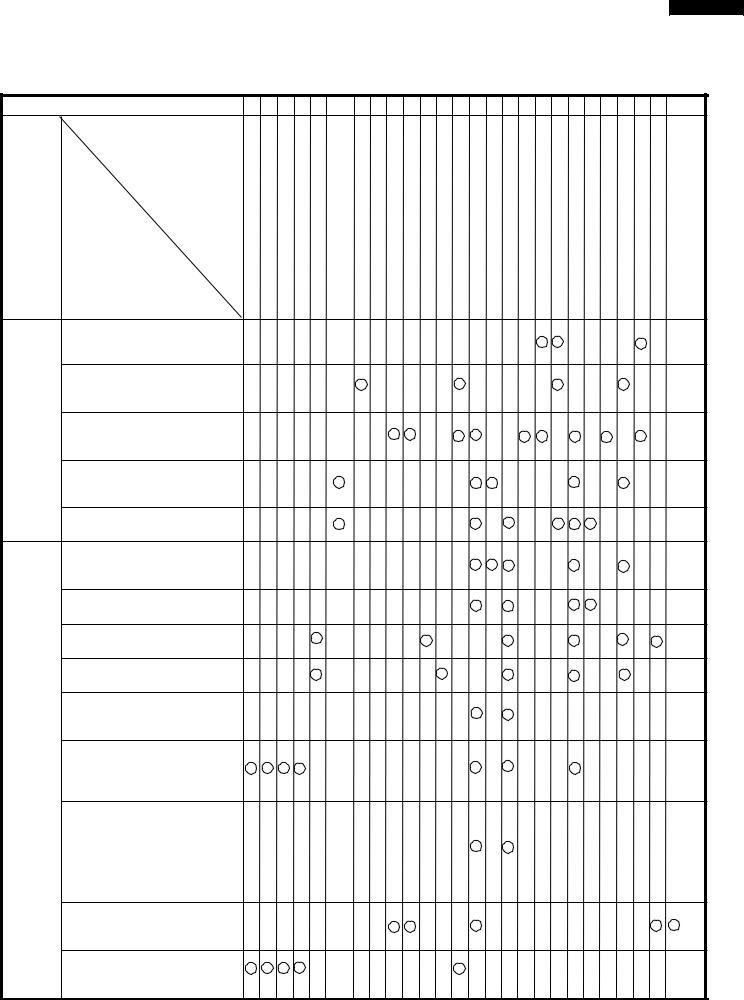

TROUBLESHOOTING GUIDE

When troubleshooting the microwave oven, it is helpful to |

IMPORTANT: If the oven becomes inoperative because |

follow the Sequence of Operation in performing the |

of a blown fuse M8A in the 1st. latch switch |

checks. Many of the possible causes of trouble will require |

- 2nd. interlock relay - monitor switch - |

that a specific test be performed. These tests are given a |

monitor resistor circuit, check the 1st. latch |

procedure letter which will be found in the "Test |

switch, 2nd. interlock relay, 2nd. interlock |

Procedure"section. |

relay control switch, monitor switch and |

|

monitor resistor before replacing the fuse |

|

M8A. |

6

R-3A88

CK = Check / RE = Replace

TEST PROCEDURE

POSSIBLE CAUSE

AND

DEFECTIVE PARTS

CONDITION PROBLEM

|

Home fuse blows when power |

|

|

supply cord is plugged into wall |

|

|

outlet. |

|

|

FUSE M8A blows when power |

|

|

supply cord is plugged into wall |

|

|

outlet. |

|

OFF |

Display does not show anything |

|

CONDITION |

when power supply cord is plugged |

|

|

||

|

into wall outlet. |

|

|

Display does not operate prop- |

|

|

erly when STOP/CLEAR pad is |

|

|

touched. |

|

|

Oven lamp does not light at door |

|

|

opened. (Display appears.) |

|

|

Oven does not start when the |

|

|

START pad is touched. (Display |

|

|

appears) |

|

|

Oven lamp does not light (Display |

|

|

appears.) |

|

|

Fan motor does not operate. (Dis- |

|

|

play appears.) |

|

|

Turntable motor assembly does |

|

|

not operate. (Display appears.) |

|

|

Oven or any electrical parts does |

|

|

not stop when cooking time is 0 or |

|

|

STOP/CLEAR pad is touched. |

|

ON |

Oven seems to be operating but |

|

little or no heat is produced in |

||

CONDITION |

||

|

oven load. (Microwave power level |

|

|

is set at HIGH) |

|

|

Oven does not seems to be oper- |

|

|

ating properly when MEDIUM |

|

|

HIGH, MEDIUM, MEDIUM LOW |

|

|

or LOW is set. (Oven operates |

|

|

properly at HIGH and when the |

|

|

STOP/CLEAR pad is touched the |

|

|

oven stops.) |

|

|

Oven goes into cook cycle but |

|

|

shuts down before end of cooking |

|

|

cycle. |

|

|

Oven stops as soon as the START |

|

|

pad is touched. |

A B C D E E E G F F H H I K L M N RECKCKRE CK CKCKCK CK

MAGNETRON |

POWER TRANSFORMER |

H.V. RECTIFIER ASSEMBLY |

HIGH VOLTAGE CAPACITOR |

1ST. LATCH SWITCH |

2ND. INTERLOCK RELAY CONTROL SWITCH |

MONITOR SWITCH |

MONITOR RESISTOR |

THERMAL CUT-OUT 95˚C |

THERMAL CUT-OUT 145˚C |

FAN MOTOR |

TURNTABLE MOTOR |

FUSE M8A |

TOUCH CONTROL PANEL |

KEY UNIT |

RELAY (RY-1, RY-2) |

FOIL PATTERN ON P.W.B. |

POWER SUPPLY CORD |

SHORTED WIRE HARNESS |

OPENED WIRE HARNESS |

OVEN LAMP OR SOCKET |

WALL OUTLET |

MISADJUSTMENT SWITCH |

HOME FUSE OR BREAKER |

BLOCKED COOLING FAN |

BLOCKED VENTILATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

R-3A88

|

TEST PROCEDURES |

|

|

|

|

PROCEDURE |

|

|

LETTER |

COMPONENT TEST |

|

|

|

|

A |

MAGNETRON TEST |

|

|

|

|

|

NEVER TOUCH ANY PART IN THE CIRCUIT WITH YOUR HAND OR AN INSULATED TOOL |

|

|

WHILE THE OVEN IS IN OPERATION. |

|

|

|

|

|

CARRY OUT 3D CHECK. |

|

|

Isolate the magnetron from high voltage circuit by removing all leads connected to filament terminal. |

|

|

To test for an open circuit filament use an ohmmeter to make a continuity test between the magnetron |

|

|

filament terminals, the meter should show a reading of less than 1 ohm. |

|

|

To test for short filament to anode condition, connect ohmmeter between one of the filament terminals |

|

|

and the case of the magnetron (ground). This test should be indicated an infinite resistance. If a low or |

|

|

zero resistance reading is obtained then the magnetron should be replaced. |

|

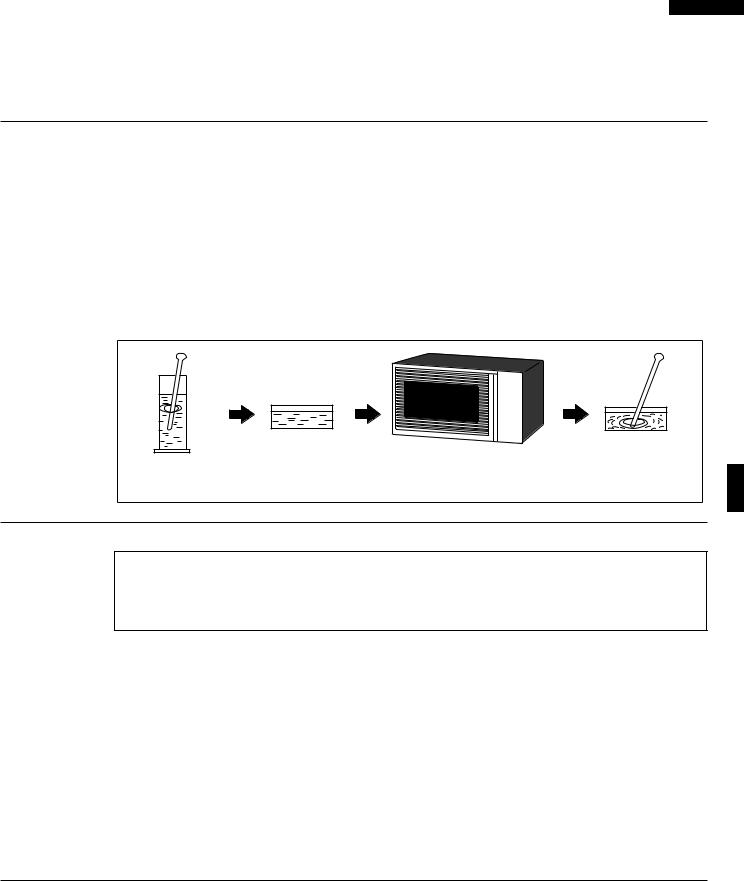

MICROWAVE OUTPUT POWER (IEC 705)

The following test procedure should be carried out with the microwave oven in a fully assembled condition (outer case fitted). Microwave output power from the magnetron can be measured by way of IEC 705, i.e. it can be measured by using water load how much it can be absorbed by the water load. To measure the microwave output power in the microwave oven, the relation of calorie and watt is used. When P(W) heating works for t(second), approximately P x t/4.187 calorie is generated. On the other

hand, if the temperature of the water with V(ml) rises |

T (°C) during this microwave heating period, the |

||||

calorie of the water is V x |

T. |

|

|

|

|

|

|

|

|

|

|

The formula is as follows; |

|

|

|

|

|

P x t / 4.187 = V x |

T |

P (W) = 4.187 x V x |

T / t |

|

|

Our condition for water load is as follows: |

|

|

|||

Room temperature.............. |

|

around 20°C |

Power supply Voltage |

.........Rated voltage |

|

Water load......... |

1000 g |

Initial temperature........... |

10±2°C Heating time......... |

49 sec. |

|

P = 85 x T |

|

|

|

|

|

|

|

|

|

|

|

Measuring condition:

1.Container

The water container must be a cylindrical borosilicate glass vessel having a maximum material thickness of 3 mm and an outside diameter of approximately 190 mm.

2.Temperature of the oven and vessel

The oven and the empty vessel are at ambient temperature prior to the start the test.

3.Temperature of the water

The initial temperature of the water is (10±2)°C.

4.Select the initial and final water temperature so that the maximum difference between the final water temperature and the ambient temperature is 5˚C.

5.Select stirring devices and measuring instruments in order to minimize addition or removal of heat.

6.The graduation of the thermometer must be scaled by 0.1°C at minimum and accurate thermometer.

7.The water load must be (1000±5) g.

8.“t” is measured while the microwave generator is operating at full power. Magnetron filament heatup time is not included.

NOTE: The operation time of the microwave oven is “t + 2” sec. 2 sec. is magnetron filament heat-up time.

Measuring method:

1.Measure the initial temperature of the water before the water is added to the vessel. (Example: The initial temperature T1 = 11°C)

2.Add the 1 litre water to the vessel.

3.Place the load on the centre of the shelf.

4. |

Operate the microwave oven at HIGH for the temperature of the water rises by a value T of |

|

(10 ± 2)˚C. |

5. |

Stir the water to equalize temperature throughout the vessel. |

8

R-3A88

|

TEST PROCEDURES |

|

|

PROCEDURE |

|

LETTER |

COMPONENT TEST |

6. |

Measure the final water temperature. (Example: The final temperature T2 = 21°C) |

|

7. |

Calculate the microwave power output P in watts from above formula. |

|

|

|

|

|

Initial temperature .................................................................................................. |

T1 = 11°C |

|

Temperature after (49 + 2) = 51 sec. ..................................................................... |

T2 = 21°C |

|

Temperature difference Cold-Warm.................................................................... |

T1 = 10°C |

|

Measured output power |

P = 85 x 10°C = 850 Watts |

|

The equation is “P = 85 x T” ...................................................... |

|

|

|

|

JUDGMENT: The measured output power should be at least ± 15 % of the rated output power.

CAUTION: 1°C CORRESPONDS TO 85 WATTS REPEAT MEASUREMENT IF THE POWER IS INSUFFICIENT.

1000g |

|

|

|

1000g |

1000g |

|

|

|

T1˚C |

|

T2˚C |

|

|

Heat up for51 sec.

B POWER TRANSFORMER TEST

WARNING: High voltages and large currents are present at the secondary winding and filament winding of the power transformer. It is very dangerous to work near this part when the oven is on. NEVER make any voltage measurements of the high-voltage circuits, including the magnetron filament.

CARRY OUT 3D CHECKS.

Disconnect the leads to the primary winding of the power transformer. Disconnect the filament and secondary winding connections from the rest of the HV circuitry. Using an ohmmeter, set on a low range, it is possible to check the continuity of all three windings. The following readings should be obtained:

a.Primary winding ....................approx. 1.4 Ω

b.Secondary winding ............... approx. 98 Ω

c.Filament winding ................... less than 1Ω

If the reading obtained are not stated as above, then the power transformer is probably faulty and should be replaced.

CARRY OUT 4R CHECKS.

CHIGH VOLTAGE RECTIFIER ASSEMBLY TEST

HIGH VOLTAGE RECTIFIER TEST CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The high voltage rectifier can be tested using an ohmmeter set to its highest range. Connect the ohmmeter across the terminal B+C of the high

voltage rectifier and note the reading obtained. Reverse the meter leads and note this second reading. The normal resistance is infinite in one direction and more than 100 kΩ in the other direction.

9

Loading...

Loading...