CAREFULLY READ THE INSTRUCTIONS PROVIDED, OBSERVE THE SIMPLE SAFETY PRECAUTIONS, AND YOU WILL HAVE MANY HOURS OF SATISFACTORY USE FROM YOUR NEW CRAFTSMAN TOOL.

ASSEMBLY, OPERATING INSTRUCTIONS AND PARTS LIST FOR

3/8 INCH ELECTRIC DRILL

REVERSIBLE-VARIABLE SPEED

WITH VARI-TRI-LOCK SWITCH

MODEL NUMBER 315.11350

Every power tool has been 100% inspected while running. Every tool is equipped with the proper grounding device for your safety. Every tool has a complete set of instructions for safer operation. The tool manufacturer is a member of the Power Tool Institute and is a sponsor of the Institute's "Consumer Education Program." COPYRIGHT. 1969. BY POWER TOOL INSTITUTE. INC. ALL RIGHTS RESERVED

Designed exclusively for and sold only by SEARS, ROEBUCK AND CO.—Chicago, Illinois 60607 U.S.A. and SIMPSONS-SEARS LIMITED—Toronto

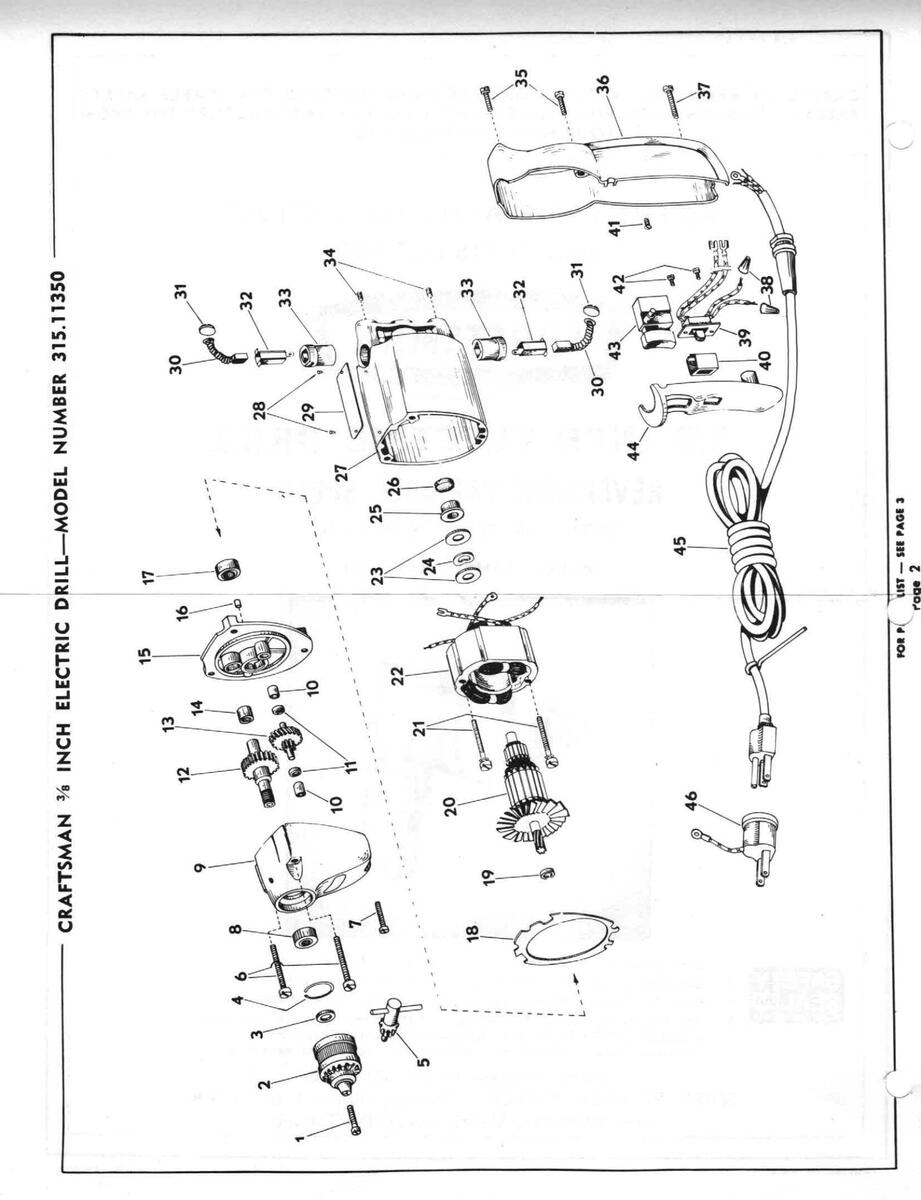

CRAFTSMAN 3/8 INCH ELECTRIC DRILL-MODEL NUMBER 315.11350

The Model Number will be found on a plate attached to the top of the Motor Hous-Always mention the Model Number in all correspondence regarding the 3/8 INCH ing. Always mention the Model Number in all cor ELECTRIC DRILL or when ordering repair parts.

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

Quan. N & 26) Ċ 25 an Head Head crew (#8-32 × 1 Fil. Head) Hex Socket-Headless) Screw (#8-32 × 5/8 Fil. Screw (#6-32 × 5/16 P crew (#6-20 × 1/4 Fil. Set Screw (#8-32 × 1/8 Adapter (Not Supplied Reversing Switch Canadian nstruction Sheet ord Complete Ianae Bearina Motor Housing witch Pad . Brush Holder Handle Cover Drive Screw Brush Tube Cap Nameplate elt Disc Brush rush 1-930150-802 2-614446-03 2-615930-01 4-615532-02 -622897-02 1-706875-00 1-623313-01 2-615322-01 1-614008-01 2-623878-01 2-623877-01 *1-930687-05 1-703432-27 1-615533-02 -703432-55 1-623173-01 1-615519-01 1-930993-01 1-703475-00 4-614336-03 1-795247-06 2-615951-01 Part N-513 -Key Number LISIT 86.0 41 42 332 333 35 35 37 43 44 45 PARTS Quan. KAV LAC-2) | Kev 10) crew (#8-32 × 1-7/8 Fil. Head) × RIC) udes Chuck Key (Cat. No. 2 2058) screw (#8-32 × 7/8 Fil. Head) all Bearing (Hoover 7038 2 2975) Description all Bearing (ND77R6 iear Housing (Includes crew (#8-32 × 1-5/a ield Core Complete Gear Housing Cover 10 & Key 14) . Armature Complete ntermediate Gear Armature Spacer (Cat. No. sleeve Bearing sleeve Bearing (Special) Retaining Ring pring Washer Spacer pindle Gear Searing Plua Vasher Vasher Chuck huck offle crew -703493-804 1-706382-808 -703432-948 -615968-01 614453-03 -623261-00 -614927-02 829994-00 1-623262-00 -623654-00 703432-30 1-621635-01 3-614338-04 620413-00 931055-12 614663-01 623192-01 620597-00 614337-03 -623019-01 740943-01 615940-01 -615923-01 -622347-05 Part Key 10 ~ -3 12 14 15 16 17 8 6 2222 24

Fer Illustration --- 5ee Page 2

Standard Hardware Item-May Be Purchased Locally

Page 3

CRAFTSMAN 3/8 INCH ELECTRIC DRILL-MODEL NUMBER 315.11350

BRUSH REPLACEMENT—(See Fig. 1)—IMPORTANT— BE SURE POWER CORD IS DISCONNECTED FROM POWER SUPPLY. Periodically check the brushes for wear and replace both brushes when either is worn to about 1/4 inch in length. To check length of brushes they must be removed from tool (see instructions below.) Replacement of these relatively inexpensive parts, when necessary, will keep your tool operating more efficiently and prolong the life of the motor.

To replace carbon brushes (Key #30)—See parts list, page 3— Remove two handle fastening screws (Key #35) and slide back handle to expose lower brush cap. The upper brush cap is readily accessible from the top of the drill. Unscrew brush cap (Key #31) and remove old brush and spring. Replace both brushes making sure when inserting that curvature of brush matches curvature of the surface of the motor to which it is mated. Make sure brushes move freely in holder.

Replace handle making sure leads (wires) are not in position to be pinched between handle and motor housing.

LUBRICATION —All of the bearings in this tool are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions, therefore, no further lubrication is required.

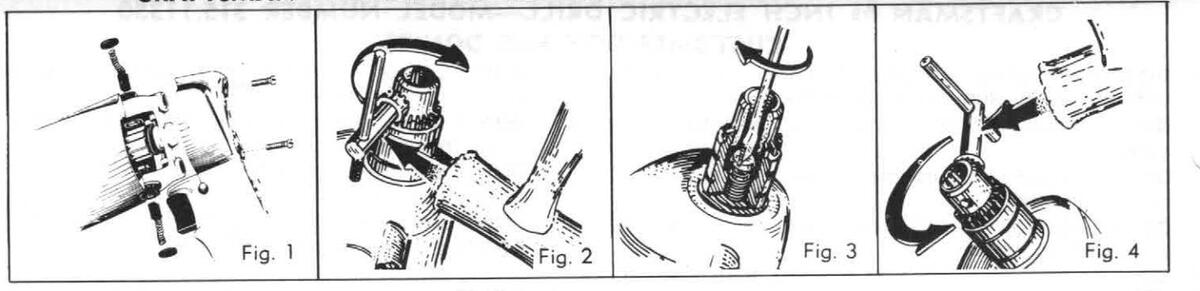

CHUCK REMOVAL—(See Figures 2, 3 & 4)—IMPORT-ANT—BE SURE POWER CORD IS DISCONNECTED FROM POWER SUPPLY. Insert lock pin into gear housing spindle lock hole. Rotate the chuck slowly to insure lock pin engages hole in spindle shaft. Close the chuck jaws. Insert chuck key in chuck and tap sharply with a soft mallet in a clock-wise direction, as shown in Figure 2. This tends to loosen chuck screw.

Open chuck jaws wide and remove chuck screw by turning in a clock-wise direction. See Figure 3. This screw has left hand threads.

Again insert chuck key in chuck and tap sharply in a counterclock-wise direction to loosen, as shown in Figure 4. Chuck can now be unscrewed by hand.

When replacing chuck make sure chuck spacer is in place on spindle against bearing and firmly secure chuck on spindle before tightening screw.

EXTENSION CORDS —The use of any extension cord will cause some loss of power. To keep this to a minimum and to prevent overheating and motor burn-out, use the table below to determine the MINIMUM wire size (A.W.G.) Extension Cord.

Extension Cord Length 25-100 Feet 100-200 Feet

Wire Size A.W.G.

Extension cords suitable for use with your drill are available at your nearest Sears Catalog Order or Retail Store.

- 1. KNOW YOUR POWER TOOL Read owner's manual carefully. Learn its applications and limitations as well as the specific potential hazards peculiar to this tool.

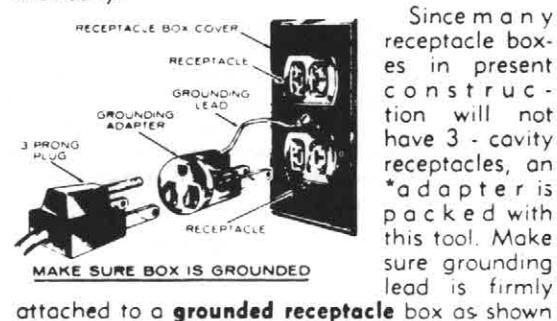

- GROUND ALL TOOLS UNLESS DOUBLE-INSULATED. If tool is equipped with three-prong plug, it should be plugged into a three-hole electrical receptacle. If adapter is used to accommodate two-prong receptacle, the adapter wire must be attached to a known ground. (Usually the screw securing the receptacle cover plate.) Never remove third prong.

- 3. KEEP GUARDS IN PLACE and in working order

- 4. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet locations. And keep work area well lit.

- 6. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

- STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked-up place out of reach of children.

- 8. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- 9. USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty tool. WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving parts. Rubber

- aloves and footwear are recommended when working outdoors.

- 11. USE SAFETY GLASSES with most tools. Also face or dust mask if cutting operation is dusty.

- 12. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil and sharp edges.

- SECURE WORK. Use clamps or a vise to hold work. It's safer than using your hand and it frees both hands to operate tool.

- 14. DON'T OVERREACH. Keep proper footing and balance at all times.

- MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

- DISCONNECT TOOLS. When not in use, before servicing; when changing attachments, blades, bits, cutters, etc.

- REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

- AVOID ACCIDENTAL STARTING. Don't carry plugged-in tool with finger on switch. COPYRIGHT. 1969. BY POWER TOOL INSTITUTE. INC. ALL RIGHTS RESERVED

CRAFTSMAN 3/8 INCH FLECTRIC DRILL-MODEL NUMBER 315,11350 CUSTOMER DO'S AND DON'TS

- 1. DO be sure that the voltage of the power supply agrees with the name plate marking on the tool.

- 2. DO insert drill bits into the chuck the full length of the jaws

- 3. DO replace both brushes when either is worn to about 1/4 inch in length.

- 4. DO use light oil on drill bits to prevent overheating when drilling metal.

- 5. DO drill small pilot hole first when drilling holes 3/8" in metals.

- 1 DON'T use an auger bit (screw pointed)—use types which must be pressure fed.

- 2. DON'T use a twist drill larger than the capacity the chuck indicates

- 3 DON'T use drill as a router or try to elongate a hole by twisting the bit.

- 4 DON'T use a wrench to tighten the chuck.

- DON'T support weight of drill with drill bit when drill-

- 6. DON'T change direction while drill is runnina.

CAUTION-

WHEN ELECTRIC TOOLS ARE LISED ON FIBERGLASS BOATS. sports cars, etc., it has been found that they are subject to accelerated wear and possible premature failure, as the fiberglass chips and grindings are highly abrasive to bearings, brushes, commutator, etc. Consequently it is not recommended that this tool be used for continuous production work on any fiberalass material. During any use on fiberalass it is extremely important that the tool is cleaned frequently by blowing with an air jet.

THIS PRODUCT, or any electrical product, requires extreme care when service repairs are made. A dangerous electrical hazard can be created by tampering with the electrical or insulating systems or in the replacement or substitution of repair parts. Repairs should be made only by a qualified technician. If service is required we suggest you return the tool to your nearest Sears store for approved service with original factory replacement parts.

DISASSEMBLY of this tool can result in danaerous electrical hazard if any leads (wires) are pinched against metal surfaces or if grounding connection is not secure when tool is reassembled.

GROUNDING—This tool is equipped with an Underwriters' Laboratories approved 3 prong plug for your safety. If your outlet is a grounded 3cavity type, your tool will be arounded auto-

Sincemany receptacle boxes in present tion will not have 3 - cavity receptacles, an *adapter is this tool Make sure grounding lead is firmly

above, before attempting to operate tool Extension cords should also be 3-wire

*( Not used in Canada)

CRAFTSMAN

Reg. Trade Mark

3/8 INCH ELECTRIC DRILL REVERSIBLE-VARIABLE SPEED WITH VARI-TRI-LOCK SWITCH MODEL NUMBER 315.11350

REVERSIBLE —This drill has the unique feature of being reversible. The rotational direction is controlled by a slide switch located below the trigger switch. When this switch is in the DOWN position, the drill runs in its normal drilling direction. The drill direction is reversed when the switch is in the "R" position. THE DIRECTION MUST NOT BE CHANGED WHILE THE TOOL IS RUNNING. Change direction only after the trigger switch is released and drill has completely stopped.

VARIABLE SPEED —Electronic trigger control switch delivers higher speed and higher torque with increased trigger pressure. The speed of your drill is controlled by the amount of switch trigger depression. Trigger switch is double pole for added safety and has safety release for added utility. Trigger depression disengages locking mechanism at either position.

For your convenience and ease of operation the trigger switch is designed with 'Vari-Tri-Lock' feature. This unique feature allows switch to be locked 'on' at three different speeds; 'Lo', 'Medium' and 'Hi'. The following guidelines may be used in determining correct speed for various applications.

'Lo' speed is ideal for starting holes without center punching, paint mixing, drilling ceramics, as well as other applications where minimum speed and power is required.

'Medium' speed is suitable for drilling ferrous metals, plastics and laminates.

'Hi' speed produces best results in drilling wood, non-ferrous metals such as aluminum as well as driving accessories which require high speeds and maximum power.

AVOID RUNNING AT SLOW SPEEDS FOR EXTENDED PERIOD OF TIME WHEN POSSIBLE. AT SLOWER SPEEDS UNDER CONSTANT PROLONGED USAGE, THE UNIT MAY BECOME OVERHEATED. SHOULD THIS OCCUR: RUN TOOL WITH NO LOAD AT MAXIMUM SPEED TO COOL THE UNIT. THIS WILL ACCELERATE COOLING PROCESS.

GUARANTEE: We guarantee all Craftsman portable electric tools to be free from defects in material and workmanship. When properly used, cared for, and maintained, we will replace or repair at our option, and install without cost to you, for a period of one (1) year from date of sale, any part which proves, upon our examination, to be defective under normal use.

The guarantee does not cover: burnouts due to low or improper voltage or from the tool being forced or otherwise improperly used; blades, cords or any other parts subjected to abuse; or tools used in rental service. SEARS, ROEBUCK AND CO.

REPAIR SERVICE AND PARTS —All fine tools, on occasion, may require service or the replacement of parts due to wear from normal use. To prolong the life of your tool when repairs are needed, call on your nearest Sears Catalog Order or Retail Store. Please don't risk possible electrical hazards, additional cost or damage to the tool through inexperienced repairs.

The Model Number will be found on a plate attached to the top of the motor housing. Always mention the Model Number in all correspondence regarding your 3/8 INCH ELECTRIC DRILL or when ordering repair parts.

HOW TO ORDER REPAIR PARTS

All parts listed herein may be ordered through SEARS, ROEBUCK AND CO. or SIMPSONS-SEARS LIMITED. When ordering parts by mail from the catalog order house which serves the territory in which you live, selling prices.will be furnished on request or parts will be shipped at prevailing prices and you will be billed accordingly.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION AS SHOWN IN THIS LIST

- 1. The PART NUMBER

- 2. The PART NAME

- 3. The MODEL NUMBER 315.11350

- 4. The NAME of item 3/8 INCH ELECTRIC DRILL

COAST TO COAST NATION-WIDE SERVICE FROM SEARS

FOR YOUR CRAFTSMAN ELECTRIC DRILL

SEARS, ROEBUCK AND CO. and SIMPSONS-SEARS LIMITED in Canada back up your investment with quick, expert mechanical service and genuine CRAFTS-MAN replacement parts.

If and when you need repairs or service, call on us to protect your investment in this fine piece of equipment.

SEARS, ROEBUCK AND CO.—Chicago, Illinois 60607 U.S.A. and SIMPSONS-SEARS LIMITED—Toronto

Loading...

Loading...