Schumacher 98026071, 00-99-000985-1009, 94070A, 00-99-000985 User Manual

ARC WELDER SOUDEUR D’ARC

USER’S GUIDE

GUIDE DE L-UTILISATEUR

READ ENTIRE MANUAL BEFORE

USING THIS PRODUCT

LIRE ENTIÈREMENT LE GUIDE AVANT

D’UTILISER CE PRODUIT

00-99-000985/1009

Table of Contents

SECTIon |

Page |

General SAFETY PrecauTIONs |

1 |

INTRODUCTION |

6 |

OPERATION |

9 |

GENERAL WELDING INFORMATION |

11 |

GENERAL MAINTENANCE |

14 |

REPLACEMENT PARTS LIST |

14 |

LIMITED WARRANTY |

14 |

TABLE DES MATIÈRES

Partie |

Page |

Général Précautions de Sécurité |

16 |

INTRODUCTION |

23 |

UTILISATION |

26 |

L’INFORMATION GÉNÉRALE DE SOUDURE |

28 |

ENTRETIEN DU POSTE À SOUDER |

31 |

LISTE DE PIÈCES DÉTACHÉES |

32 |

GARANTIE LIMITÉE |

32 |

Pursuant to California Proposition 65, this product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Résultant de la Proposition californienne 65, ce produit contient des produits chimiques dont l’état de la Californie reconnaît causer le cancer et des anomalies congénitales ou d’autre danger pour la reproduction.

1.General SAFETY PrecauTIONs

The following safety information is provided as a guideline to help you operate your new welder under the safest possible conditions. Any equipment that uses electrical power can be potentially dangerous to use when safety or safe handling instructions are not known or not followed. The following safety information is provided to give you the information necessary for safe use and operation.

When a WARNING precedes a procedure step, it is an indication that the step contains a procedure that might be injurious to a person if proper safety precautions are not heeded. When a procedure step is preceded by a CAUTION, it is an indication that the step contains a procedure that might damage the equipment being used. A NOTE may be used before or after a procedure step to highlight or explain something in that step.

READ ALL SAFETY INSTRUCTIONS CAREFULLY before attempting to install, operate, or service this welder. Failure to comply with these instructions could result in personal injury and/or property damage.

Published standards on safety are available. They are listed in ADDITIONAL SAFETY INFORMATION at the end of this SAFETY SUMMARY. The National Electrical Code, Occupational Safety and Health Act regulations, local industrial codes and local inspection requirements also provide a basis for equipment installation, use, and service.

1.1SHOCK HAZARDS

WARNING: Electric shock can kill! To reduce the risk of death or serious injury from shock, read, understand, and follow the

following safety instructions. In addition, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area understands and follows these safety instructions as well.

IMPORTANT! TO REDUCE THE RISK OF DEATH, INJURY, OR PROPERTY DAMAGE, DO NOT ATTEMPT OPERATION of this welding equipment until you have read and understand the following safety summary.

•Do not, in any manner, come into physical contact with any part of the welding current circuit. The welding current circuit includes: A. the work piece or any conductive material in contact with it, B. the ground clamp, C. the electrode or welding rod, D. any metal parts on the electrode holder.

•Do not weld in a damp area or come in contact with a moist or wet surface.

•Do not attempt to weld if any part of clothing or body is wet.

•Do not allow the welding equipment to come in contact with water or moisture.

•Do not drag welding cables, wire feed gun, or welder power cord through or allow them to come into contact with water or moisture.

•1 •

•Do not touch welder, attempt to turn welder on or off if any part of the body or clothing is moist or if you are in physical contact with water or moisture.

•Do not attempt to plug the welder into the power source if any part of body or clothing is moist, or if you are in physical contact with water or moisture.

•Do not connect welder ground clamp to or weld on electrical conduit.

•Do not alter power cord or power cord plug in any way.

•Do not attempt to plug the welder into the power source if the ground prong on power cord plug is bent over, broken off, or missing.

•Do not allow the welder to be connected to the power source or attempt to weld if the welder, welding cables, welding site, or welder power cord are exposed to any form of atmospheric precipitation, or salt water spray.

•Do not carry coiled welding cables around shoulders, or any other part of the body, when they are plugged into the welder.

•Do not modify any wiring, ground connections, switches, or fuses in this welding equipment.

•Wear welding gloves to help insulate hands from welding circuit.

•Keep all liquid containers far enough away from the welder and work area so that if spilled, the liquid can not possibly come in contact with any part of the welder or electrical welding circuit.

•Replace any cracked or damaged parts that are insulated or act as insulators such as welding cables, power cord, or electrode holder IMMEDIATELY.

1.2EMF INFORMATION

WARNING: Welding current will cause electromagnetic fields as it flows through welding cables and internal wiring. There has been and continues to be some concern and research about such fields. Until the final conclusions of the research are reached, you may wish to minimize your exposure to electromagnetic fields when welding or cutting.

To reduce magnetic fields in the workplace:

•Keep cables close together by twisting or taping them.

•Arrange cables to one side and away from you.

•Do not coil or drape cables around your body.

•Keep welding power source and cables as far away from you as practical.

•Connect work clamp to work piece as close to the weld as possible.

About Pacemakers: Pacemaker wearers consult your doctor prior to using any welding equipment. If cleared by your doctor, then following the above procedures is recommended.

• 2 •

1.3FLASH HAZARDS

WARNING: ARC RAYS CAN INJURE EYES AND BURN SKIN! To reduce risk of injury from arc rays, read, understand, and follow the following safety instructions. In addition, make certain that anyone else that uses this welding equipment, or is a bystander in the welding area, understands and follows these safety instructions as well.

•Do not look at an electric arc without proper protection. A welding arc is extremely bright and intense and, with inadequate or no eye protection, the retina can be burned, leaving a permanent dark spot in the field of vision. A shield or helmet with a number 10-shade filter lens (minimum) must be used.

•Do not strike a welding arc until all bystanders and you (the welder) have welding shields and/or helmets in place.

•Do not wear a cracked or broken helmet and replace any cracked or broken filter lenses IMMEDIATELY.

•Do not allow the uninsulated portion of the wire feed gun to touch the ground clamp or grounded work to prevent an arc flash from being created on contact.

•Provide bystanders with shields or helmets fitted with a number 10-shade filter lens.

•Wear protective clothing. The intense light of the welding arc can burn the skin in much the same way as the sun, even through lightweight clothing. Wear dark clothing of heavy material. The shirt worn should be long sleeved and the collar kept buttoned to protect chest and neck.

•Protect against REFLECTED ARC RAYS. Arc rays can be reflected off shiny surfaces such as a glossy painted surface, aluminum, stainless steel, and glass. It is possible for your eyes to be injured by reflected arc rays even when wearing a protective helmet or shield. If welding with a reflective surface behind you, arc rays can bounce off the surface, then off the filter lens on the inside of your helmet or shield, then into your eyes. If a reflective background exists in your welding area, either remove it or cover it with something nonflammable and non-reflective. Reflected arc rays can also cause skin burn in addition to eye injury.

1.4FIRE HAZARDS

WARNING: FIRE OR EXPLOSION CAN CAUSE DEATH, INJURY, AND PROPERTY DAMAGE! To reduce risk of death, injury,

or property damage from fire or explosion, read, understand, and follow the following safety instructions. In addition, make certain that anyone else that uses this welding equipment, or is a bystander in the welding area, understands and follows these safety instructions as well. REMEMBER! Arc welding by nature

produces sparks, hot spatter, molten metal drops, hot slag, and hot metal parts that can start fires, burn skin, and damage eyes.

• 3 •

•Do not wear gloves or other clothing that contain oil, grease, or other flammable substances.

•Do not wear flammable hair preparations.

•Do not weld in an area until it is checked and cleared of combustible and/or flammable materials. BE AWARE that sparks and slag can fly

35 feet and can pass through small cracks and openings. If work and combustibles cannot be separated by a minimum of 35 feet, protect against ignition with suitable, snug-fitting, fire resistant, covers or shields.

•Do not weld on walls until checking for and removing combustibles touching the other side of the walls.

•Do not weld, cut, or perform other such work on used barrels, drums, tanks, or other containers that had contained a flammable or toxic substance. The techniques for removing flammable substances and vapors, to make a used container safe for welding or cutting, are quite complex and require special education and training.

•Do not strike an arc on a compressed gas or air cylinder or other pressure vessel. Doing so will create a brittle area that can result in a violent rupture immediately or at a later time as a result of rough handling.

•Do not weld or cut in an area where the air may contain flammable dust (such as grain dust), gas, or liquid vapors (such as gasoline).

•Do not handle hot metal, such as the workpiece or electrode stubs, with bare hands.

•Wear leather gloves, heavy long sleeve shirt, cuffless trousers, hightopped shoes, helmet, and cap. As necessary, use additional protective clothing such as leather jacket or sleeves, fire resistant leggings, or apron. Hot sparks or metal can lodge in rolled up sleeves, trouser cuffs, or pockets. Sleeves and collars should be kept buttoned and pockets eliminated from the shirtfront.

•Have fire-extinguishing equipment handy for immediate use! A portable chemical fire extinguisher, type ABC, is recommended.

•Wear earplugs when welding overhead to prevent spatter or slag from falling into ear.

•Make sure welding area has a good, solid, safe floor, preferably concrete or masonry, not tiled, carpeted, or made of any other flammable material.

•Protect flammable walls, ceilings, and floors with heat resistant covers or shields.

•Check welding area to make sure it is free of sparks, glowing metal or slag, and flames before leaving the welding area.

•4 •

1.5FUME HAZARDS

WARNING: FUMES, GASES, AND VAPORS CAN CAUSE DISCOMFORT, ILLNESS, AND DEATH! To reduce risk of discomfort, illness, or death, read, understand, and follow the following safety instructions. In addition, make certain that anyone else that uses this welding equipment or is a bystander in the welding area, understands and follows these safety instructions as well.

•Do not weld in an area until it is checked for adequate ventilation as described in ANSI standard #Z49.1. If ventilation is not adequate to exchange all fumes and gasses generated during the welding process with fresh air, do not weld unless you (the welder) and all bystanders are wearing air-supplied respirators.

•Do not heat metals coated with, or that contain, materials that produce toxic fumes (such as galvanized steel), unless the coating is removed.

Make certain the area is well ventilated, and the operator and all bystanders are wearing air-supplied respirators.

•Do not weld, cut, or heat lead, zinc, cadmium, mercury, beryllium, or similar metals without seeking professional advice and inspection of the ventilation of the welding area. These metals produce EXTREMELY TOXIC fumes that can cause discomfort, illness, and death.

•Do not weld or cut in areas that are near chlorinated solvents. Vapors from chlorinated hydrocarbons, such as trichloroethylene and

perchloroethylene, can be decomposed by the heat of an electric arc or its ultraviolet radiation. These actions can cause PHOSGENE, a HIGHLY TOXIC gas to form, along with other lung and eye-irritating gases. Do not weld or cut where these solvent vapors can be drawn into the work area or where the ultraviolet radiation can penetrate to areas containing even very small amounts of these vapors.

•Do not weld in a confined area unless it is being ventilated and the operator (and anyone else in the area) is wearing an air-supplied respirator.

•Stop welding immediately if you develop momentary eye, nose, or throat irritation as this indicates inadequate ventilation. Stop work and take necessary steps to improve ventilation in the welding area. Do not resume welding if physical discomfort persists.

1.6ADDITIONAL SAFETY INFORMATION

For additional information concerning welding safety, refer to the following standards and comply with them as applicable.

•ANSI Standard Z49.1 — SAFETY IN WELDING AND CUTTING — obtainable from the American Welding Society, 550 NW Le Jeune Road,

Miami, FL 33126 Telephone (800) 443-9353, Fax (305) 443-7559 - www. amweld.org or www.aws.org

•5 •

•ANSI Standard Z87.1 — SAFE PRACTICE FOR OCCUPATION AND

EDUCATIONAL EYE AND FACE PROTECTION — obtainable from the American National Standards Institute, 11 West 42nd St., New York, NY

10036 Telephone (212) 642-4900, Fax (212) 398-0023 - www.ansi.org

•NFPA Standard 51B — CUTTING AND WELDING PROCESS — obtainable from the National Fire Protection Association, 1 Batterymarch

Park, P.O. Box 9101, Quincy, MA 02269-9101 Telephone (617) 770-3000, Fax (617) 770-0700 - www.nfpa.org

•OSHA Standard 29 CFR, Part 1910, Subpart Q., WELDING, CUTTING

AND BRAZING — obtainable from your state OSHA office or U. S. Dept. of Labor OSHA, Office of Public Affairs, Room N3647, 200 Constitution

Ave. NW Washhington, DC 20210 - www.osha.gov

•CSA Standard W117.2 — Code for SAFETY IN WELDING AND CUTTING. — obtainable from Canadian Standards Association, 178

Rexdale Blvd. Etobicoke, Ontario M9W 1R3 - www.csa.ca

•American Welding Society Standard A6.0. WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES. — obtainable from the American Welding Society, 550 NW Le Jeune Road, Miami, FL

33126 Telephone (800) 443-9353, Fax (305) 443-7559 - www.amweld.org or www.aws.org

2.INTRODUCTION

2.1DESCRIPTION

Your new welder is designed for general repair, maintenance, and metal fabrication. The welder consists of a single-phase power transformer, and control switch. This welder is capable of welding with 1/16”, 5/64”, and 3/32” general purpose mild steel electrodes.

Now you can weld 18-gauge steel sheet metal up to 1/8” with a single pass. Welds thicker metal with beveling and multiple passes.

2.2WELDER PERFORMANCE

Your welder has been designed to weld on steel from approximately 18 gauge up to 1/8” thick. Thinner and thicker material can be welded

depending on the experience and technique of the welder and the type of welding rod being used.

• 6 •

2.3 SPECIFICATIONS

Input Voltage |

120 volt 60 Hz. Single Phase |

Input Amps @ Rated Output |

20 AAC |

Input Plug Style |

120 volt 15 amp |

Power Cord Length |

6-ft. |

Rated Output Amps |

70 AAC |

Max Output Amps |

80 AAC |

Rated Output Volts |

27 VAC |

Rated Duty Cycle |

10% |

Max Open Circuit Voltage |

40 VAC |

Agency Listing |

cULus |

Output Settings |

2 |

2.4POWER REQUIREMENTS

WARNING: This welding machine must be connected to a power source in accordance with applicable electrical codes.

This welder intermittently draws more than 15 amps of current. We recommend that you either install a 20 amp circuit or do not run anything else on the same circuit as the welder or you may trip the breaker supplying the AC power. If you modify the power cord in any way, other than attaching the proper input plug, you will void the manufacturer’s warranty. It is recommended that a qualified electrician verify the actual voltage at the receptacle into which the welder will be plugged and confirm that the receptacle is properly fused and grounded. The use of the proper circuit size can eliminate nuisance circuit breaker tripping while welding.

DO NOT OPERATE THIS WELDER if the actual power source voltage is less than 100 volts AC or greater than 125 volts AC. Contact a qualified electrician if this problem exists. Improper performance, damage to the welder, property damage and/or personal injury can result if operated on inadequate or excessive power.

WARNING: ELECTRIC SHOCK CAN KILL! FIRE CAN KILL, INJURE, AND CAUSE PROPERTY DAMAGE!

•To reduce the risk of electric shock and fire, connect only to properly grounded and fused outlets.

•Never alter the AC power cord provided on the welder. Never alter an extension cord or extension cord plugs.

•7 •

2.5EXTENSION CORD USE

For optimum welder performance, an extension cord should not be used unless absolutely necessary. If necessary, care must be taken in selecting an extension cord appropriate for use with your specific welder.

Select a properly grounded extension cord that will mate the AC power cord of the welder with the AC power source receptacle directly, without the use of adapters. Make sure the extension cord is properly wired and in good electrical condition.

For an extension cord not exceeding 25 feet in length, choose the same AWG wire size as that of the power cord on the welder. Extension cord lengths longer than 25 feet will require heavier wire gauges to compensate for voltage losses.

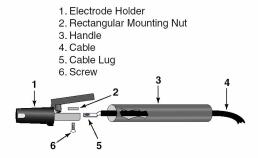

2.6INSTALLING THE ELECTRODE HOLDER

Attach the electrode holder to the electrode cable according to the following steps.

1.Remove the handle (3) from the electrode holder (1) by removing the screw holding the handle (not shown) and sliding the handle off.

2.Remove the screw (6) from the electrode holder (1).

3.Push the cable (4) through the handle (3).

4.Insert the screw (6) through the hole in the electrode holder, then through the cable lug (5) and thread into the Rectangular Mounting Nut

(2).

5.Slide the handle back onto the electrode holder body (when it is aligned properly it will slide on easily). Press the two parts together and reinsert the screw to hold the handle in place.

• 8 •

Loading...

Loading...