Samsung RS2511, RS2630W-XAA, RS2611, RS2631, RS2630SW User Manual

...

SAMSUNG Home Appliance Service

SIDE-BY-SIDE REFRIGERATOR

WARNING

IMPORTANT SAFETY NOTICE

The service guide is for service men with adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or dealer cannot be responsible for the interpretation of this information.

SAMSUNG ELECTRONICS AMERICA, INC.

Technical Service Guide

Copyright 2004

All rights reserved. This service guide may not be reproduced in whole or in part in any form without written permission from the SAMSUNG ELECTRONICS Company.

2

Contents

1.Safety instruction on services ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 4

2.Warranty information ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙9

3.Mechanical Disassembly ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙14

4.Circuit Diagram ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙15

5.Operation Principles By Parts Of Circuit∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙16

6.Introduction |

∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙29 |

|

7. |

Installation |

30 |

8. |

Nomenclature |

31 |

3

1. Safety Instructions on Service

●Unplug the refrigerator before making any repair or any replacement.Avoid the electric shock.

●Use the rated components on the replacement.

Check the correct model number, rated voltage, rated current, operating temperature and so on.

●On repair, be sure that the wires such as harness are bundled tightly and are not exposed by water.

Bundle wires tightly in order not to be detached by the external force.

●On repair, remove completely dust, particles or other things on housing parts, harness parts, and connectors.

Cleaning may prevent fire by tracking or short.

●Check if there is any trace indicating the infitration of water on electrical parts.

If there is kind of trace, change the related components or do the necessary action such as taping using the insulating tape.

●After repair, check the assembled state of parts.

It must be in the same assembled state when compared with the state before disassembly.

●Check the surrounding conditions of the installed refrigerator.

When the refrigerator is located at humid or wet place, or the installed state is unstable, change the location.

●If needed, do the ground.

Especially, if there is a possibility of the electric leakage, this appliance must be properly grounded.

●Do not allow consumers to use one outlet for several plugs.

●Check whether the power cord is placed under other appliance and so, damaged, worm-out squeezed.

Repair immediately the defective power plug or outlet.

Make sure that the power cord is not placed under other appliance or squeezed.

●Do not allow consumers to keep bottles or the likes in the Freezer or to keep foods in unstable position.

●Do not allow consumers to repair the appliance by themselves.

●Do not allow consumers to keep other chemicals except food.

Medicines and other materials for research ; This appliance will not maintain the precisely constant temperature for them.

Volatile material(Alcohol, Benzene, Ether, LP gas etc.) : possibility of explosion

4

2. Warranty information

SAMSUNG REFRIGERATOR

LIMITED WARRANTY TO ORIGINAL PURCHASER

This SAMSUNG brand product, as supplied and distributed by Samsung Electronics America, Inc. (SAMSUNG) and delivered new, in the original carton to the original consumer purchaser, is warranted by SAMSUNG against manufacturing defects in materials and workmanship for a limited warranty period of:

One (1) Year Parts and Labor on Refrigerator

Five (5) Years Parts and Labor on Sealed Refrigeration System Only*

(*Compressor, evaporator, condenser, drier, connecting tubing)

This limited warranty begins on the original date of purchase, and is valid only on products purchased and used in the United States. To receive warranty service, the purchaser must contact SAMSUNG for problem determination and service procedures. Warranty service can only be performed by a SAMSUNG authorized service center. The original dated bill of sale must be presented upon request as proof of purchase to SAMSUNG or SAMSUNG's authorized service center.

SAMSUNG will repair or replace any part found to be defective, at our option and at no charge as stipulated herein, with new or reconditioned parts during the limited warranty period specified above. All replaced parts and products become the property of SAMSUNG and must be returned to SAMSUNG. Replacement parts and products assume the remaining original warranty, or ninety (90) days, whichever is longer.

In-home service will be provided during the warranty labor period subject to availability within the contiguous United States. Inhome service is not available in all areas. To receive in-home service, the product must be unobstructed and accessible from floor level to service personnel. If during in-home service repair cannot be completed, it may be necessary to remove, repair and return the product. If in-home service is unavailable, SAMSUNG may elect, at our option, to provide for transportation of our choice to and from a SAMSUNG authorized service center. Otherwise, transportation to and from the SAMSUNG authorized service center is the responsibility of the purchaser.

This limited warranty covers manufacturing defects in materials and workmanship encountered in normal, noncommercial use of this product, and shall not apply to the following, including, but not limited to: damage which occurs in shipment; delivery and installation; applications and uses for which this product was not intended; altered product or serial numbers; cosmetic damage or exterior finish; accidents, abuse, neglect, fire, water, lightning or other acts of nature; use of products, equipment, systems, utilities, services, parts, supplies, accessories, applications, installations, repairs, external plumbing and leaks, external wiring, circuit breakers, fuses or connectors not supplied and authorized by SAMSUNG, or which damage this product or result in service problems; incorrect electrical line voltage, fluctuations and surges; customer adjustments and failure to follow operating instructions, cleaning, maintenance and environmental instructions that are covered and prescribed in the instruction book; loss of food due to spoilage; consumable items including filters and light bulbs.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE LISTED AND DESCRIBED ABOVE, AND NO WARRANTIES WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL APPLY AFTER THE EXPRESS WARRANTY PERIODS STATED ABOVE, AND NO OTHER EXPRESS WARRANTY OR GUARANTY GIVEN BY ANY PERSON, FIRM OR CORPORATION WITH RESPECT TO THIS PRODUCT SHALL BE BINDING ON SAMSUNG. SAMSUNG SHALL NOT BE LIABLE FOR LOSS OF REVENUE OR PROFITS, FAILURE TO REALIZE SAVINGS OR OTHER BENEFITS, OR ANY OTHER SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED BY THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED, AND EVEN IF SAMSUNG HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. NOR SHALL RECOVERY OF ANY KIND AGAINST SAMSUNG BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD BY SAMSUNG AND CAUSING THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, PURCHASER ASSUMES ALL RISK AND LIABILITY FOR LOSS, DAMAGE OR INJURY TO PURCHASER AND PURCHASER’S PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT SOLD BY SAMSUNG NOT CAUSED DIRECTLY BY THE NEGLIGENCE OF SAMSUNG. THIS LIMITED WARRANTY SHALL NOT EXTEND TO ANYONE OTHER THAN THE ORIGINAL PURCHASER OF THIS PRODUCT, IS NONTRANSFERABLE AND STATES YOUR EXCLUSIVE REMEDY.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

To obtain warranty service, please contact SAMSUNG at:

061002

5

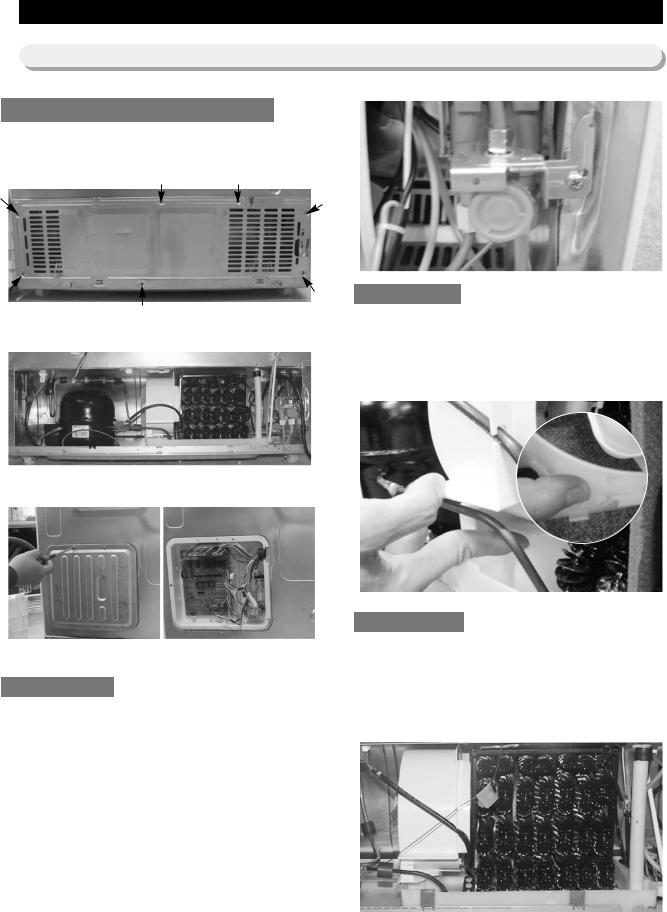

3. Mechanical Disassembly

3-1) Refrigerator Disassembly

Control Panel ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 7 Door Handle ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 7 Door Gasket ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 7 Refrigerator Door Light Switch ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 7 Refrigerator Light ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 8 Tempered Glass Shelf ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 8 Plastic Drawers in Refrigerator ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 8 Gallon Door Bin ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 8 Water Filter ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 8 Damper in the Refrigerator ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 9 Twin cool in the Refrigerator ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 9 Refrigerator Thermistor ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 9

3-2) Freezer Disassembly

Door Bin in Freezer ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 10 Freezer Door Light Switch ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 10

Plastic(Wire) Drawer in Freezer ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 10

Freezer Shelf ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 10 Ice Dispenser Ice Maker ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 10 Auger Motor Case ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 11 Freezer Light ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 12 Evaporator Cover in Freezer∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 12 Evaporator Fan Motor ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 12 Evaporator in Freezer ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 13 Freezer Thermistor ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 13 Ambient Thermistor∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 13 Ice-Maker Thermistor∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙ 13

3-3) Machine Compartment Disassembly

Machine Compartment Electrix Box ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙14

Water Solenoids ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙14 Condenser Fan ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙14 Sub-condenser ∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙∙14

6

3. Mechanical Disassembly

3-1) Refrigerator Disassembly

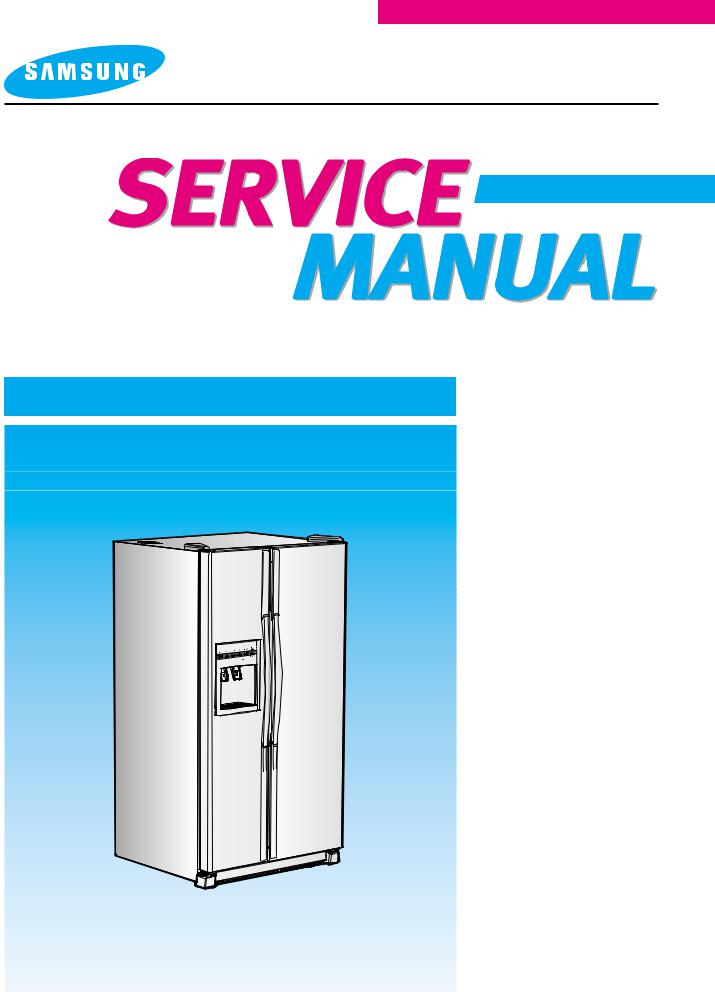

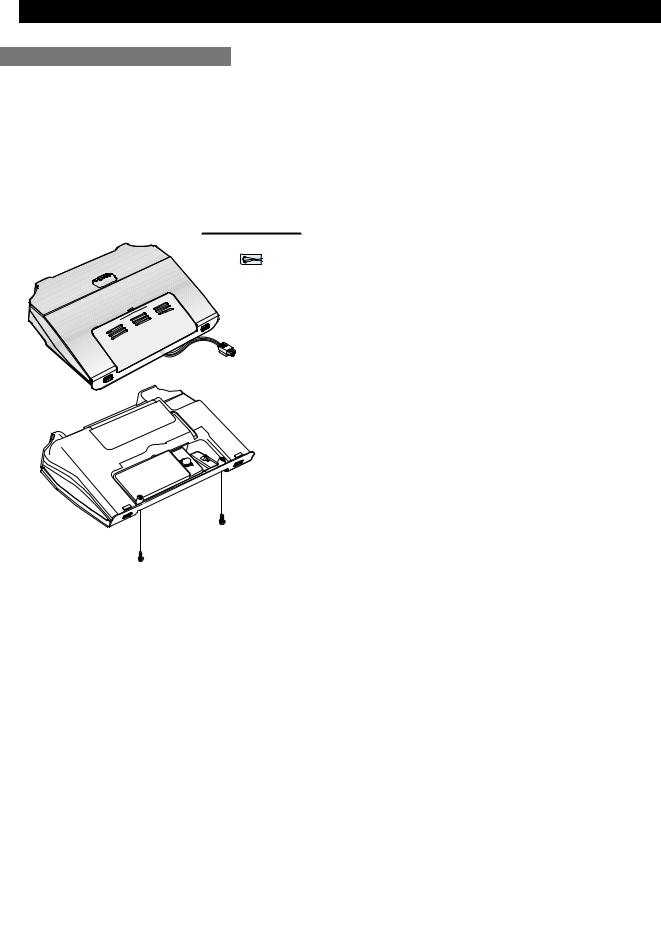

Control Panel

1.Insert a flat-blade screwdriver on the slot as shown, and unlock the tabs.

2.Disconnect the wire connector.

Door Handle

The door handles allow access into the refrigerator and freezer. They are front mounted with Phillips head screws.

1.With a small flat-blade screwdriver, press the small button and pull handle cover out.

2.Remove the Phillips screws (5).

3.Lift the handle with an in and upward motion until it disengages the locking tabs. Pull the handle outward to remove it.

Button

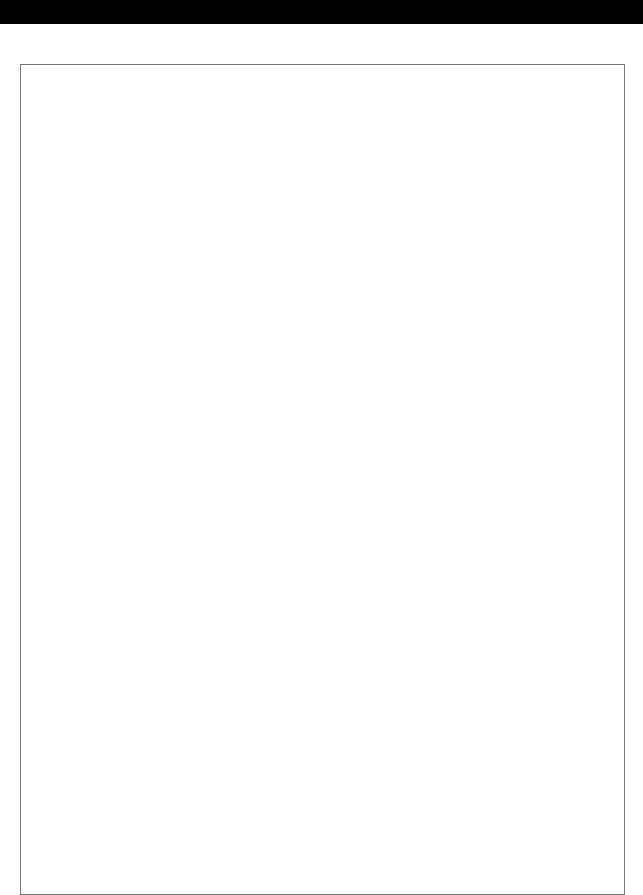

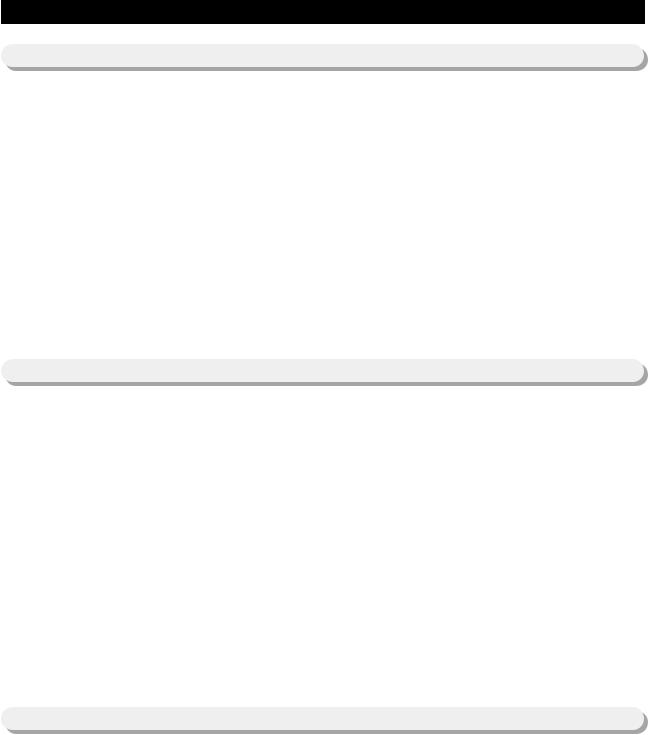

Door Gasket

The door gasket is a molded gasket set into a channel located in the door liner.

1.Open the door.

2.Grasp the gasket and pull in an outward motion until the molded gasket separates from the door liner.

Refrigerator Door Light Switch

The refrigerator has a door light switch located in the upper right corner for the refrigerator.

1.Use a small flat-blade screwdriver to unlock the locking tab and pull the switch out until the wire connector is visible.

7

Mechanical Disassembly

Refrigerator Light

The refrigerator light is located in the upper portion of refrigerator.

1. Pull the tip on the cover.

Tempered Glass Shelf

These shelves allow the storage of larger items and pull out for easy access.

1.Pull the shelf out as far as it goes.

2.Lift it up and remove it.

Gallon Door Bin

The door bins allow storage of perishable items.

1. Push the bin up and slide it out.

Plastic Drawers in Refrigerator

Drawers are designed for storage of fruits, vegetables, and deli items. The drawers are located in the lower portion of the refrigerator.

1.Pull out the drawer as far as it goes.

2.Tilt the drawer up and pull it out until it is removed.

Water Filter

The water filter is located in the bottom left-hand corner of the refrigerator. The water filter filters water for the ice maker and the water dispenser.

1.Turn the water filter 1/2 turn counterclockwise and pull it down.

2.To install the filter, align the indication mark

(unlock position) and push it up while turning 1/2 turn clockwise until the lock position is aligned. Do not over tighten.

8

Mechanical Disassembly

Damper in the Refrigerator

1.Pull out the screw cap and remove the screw.

2.Remove the lamp cover by unlocking the tabs and pulling the cover down.

3.Remove the screw at the cover damper.

4.Take off sensor and lamp wire connector located

on the upper liner.

6. Remove the damper from the refrigerator.

Refrigerator Thermistor

The refrigerator thermistor is located inside of the upper light cover of the refrigerator.

THERMISTOR

Twin cool in the Refrigerator

1. Pull out the Twin cool by unlocking the hooks.

9

Mechanical Disassembly

3-2) Freezer Disassembly

Door Bin in Freezer

The door bins allow storage of perishable items. 1. Push the bin up and slide it out.

Freezer Door Light Switch

This switch is located in the left-hand portion of the freezer and sends a signal to the processor.

1.With a small flat-blade screwdriver, unlock the locking tabs and pull the switch out until the wire connector is visible.

2.Disconnect the wire connector and remove the switch.

Plastic (Wire) Drawer in Freezer

Drawers are designed for storage of meat and dry foods. The drawers are located in the lower portion of the freezer.

1.Pull out the drawer as far as it goes.

2.Tilt the drawer up and pull it out until it is removed.

Freezer Shelf

The shelves slide out for easy access for frozen items.

1.Slide the shelf out until it reaches its stop.

2.Tilt down and slide it out of the compartment.

10

Mechanical Disassembly

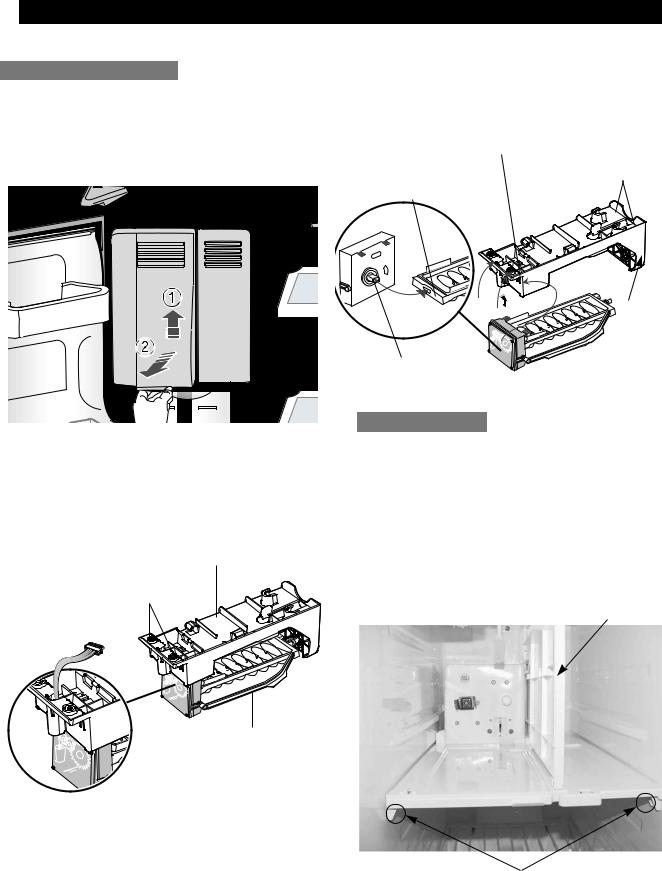

Ice Dispenser & Ice Maker

The ice dispenser is located in the upper portion of the freezer. This assembly stores ice made by the icemaker and dispenses ice.

1. Lift the ice bucket up and slide out the ice dispenser assembly .

The ice maker is located inside of the ice dispenser assembly.

1.Remove ice maker support screws (2), and slide out.

2.Disconnect the ice maker wire connector.

3.Unlock the locking tabs to separate the ice maker kit.

SUPPORT OF ICE-MAKER

LOCKING TAB

WIRE CONNECTOR

ICE-MAKER KIT

In order to assemble the icemaker kit.

1.Assemble the geared motor shaft and the front of ice tray.

2.Lift the front locking tab and assemble the ice maker kit.

3.Connect the ice maker wire connector.

4.Match the tab holes and tabs(2) located on the

top of the liner, and slide the ice maker in.

5. Tighten the screws (2) of the ice maker support.

FRONT LOCKING TAB

TAB HOLES

FRONT OF ICE TRAY

GEARED MOTOR SHAFT

Auger Motor Case

This shelf is designed to support the ice maker ice dispensed and Xtra SpaceTM.

1.Remove the Xtra SpaceTM cover to push it down and pull front.

2.Slide the partition out.

3.Remove the screws (2) on the bottom front of the case.

4.Slide out the case while disconnecting the wire connect.

PARTITION

SCREWS

11

Mechanical Disassembly

Freezer Light

The freezer light is located in the bottom of the auger motor case. The light is covered by an opaque cover.

1. Remove the screw and the light cover.

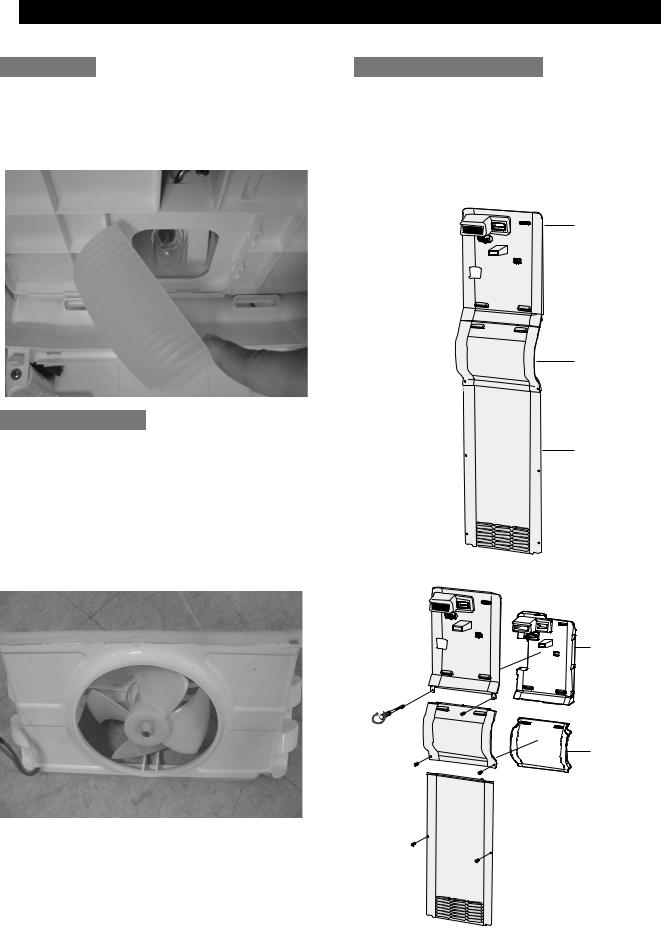

Evaporator Fan Motor

The evaporator fan is located in the middle rear of refrigerator. This fan circulates cold air in the refrigerator.

1.Remove the fan spring, and than remove fan and protector motor.

2.Remove screw located at the four corners of the fan bracket.

3.Take the fan motor assembly off.

Evaporator Cover in Freezer

1.Remove screw (6).

2.Remove the assy cover multi fre.

3.Remove the assy cover supt motor fre.

4.Remove screw (2).

5.Remove the cover evap front.

6.Disconnect the sensor wire connector.

ASSY COVER MULTI FRE

ASSY COVER SUPT

MOTOR FRE

COVER EVAP FRONT

INS MULTI FRE

INS SUPT

MOTOR FRE

12

Mechanical Disassembly

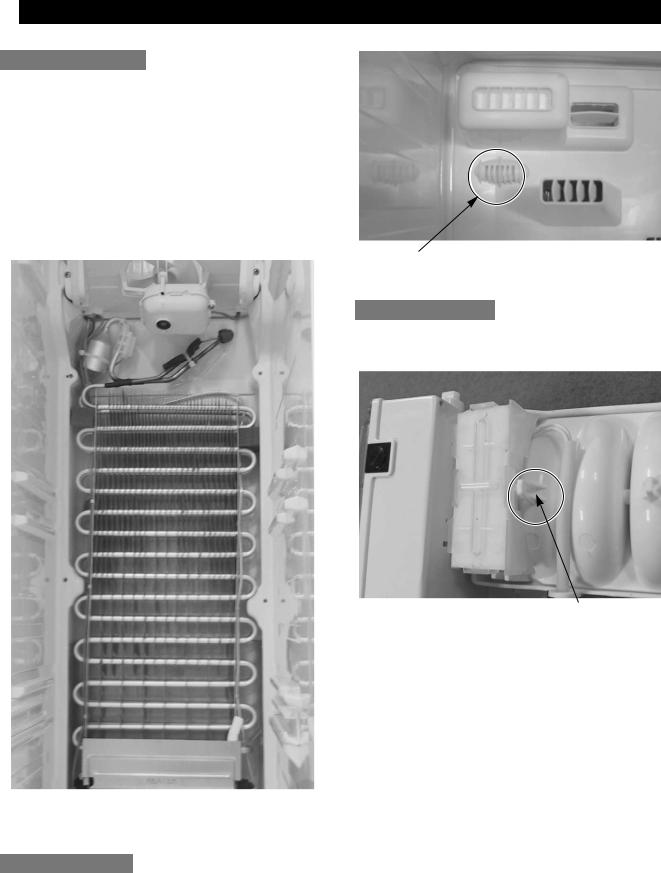

Evaporator in Freezer

Evaporator is located in the bottom of freezer to produce cold air driven across the evaporator coils.

1.Take off the ductwork in Freezer.

2.Disconnect the wire connector (Heater, Bimental, and Thermistor).

3.Desolder the inlet and outlet tubes.

4.Remove the evaporator.

5.Take the same steps to seal the system as mentioned earlier.

THERMISTOR

Ice-MakerThermistor

The Ice-Maker thermistor is located in its bottom.

The temperature signal sends the micro-processor.

THERMISTOR

Freezer Thermistor

The freezer thermistor is located at the top left of freezer vent. It sends temperature signals to the micro-processor.

13

Mechanical Disassembly

3-3) Machine Compartment Disassembly

Machine Compartment Electric Box

1.Disconnect the power cord of the refrigerator.

2.Remove the fixed screws (6) of compressor cover.

3.Slide up and take off the compressor cover to see the machine compartment.

4. Remove screw (2) on the cover.

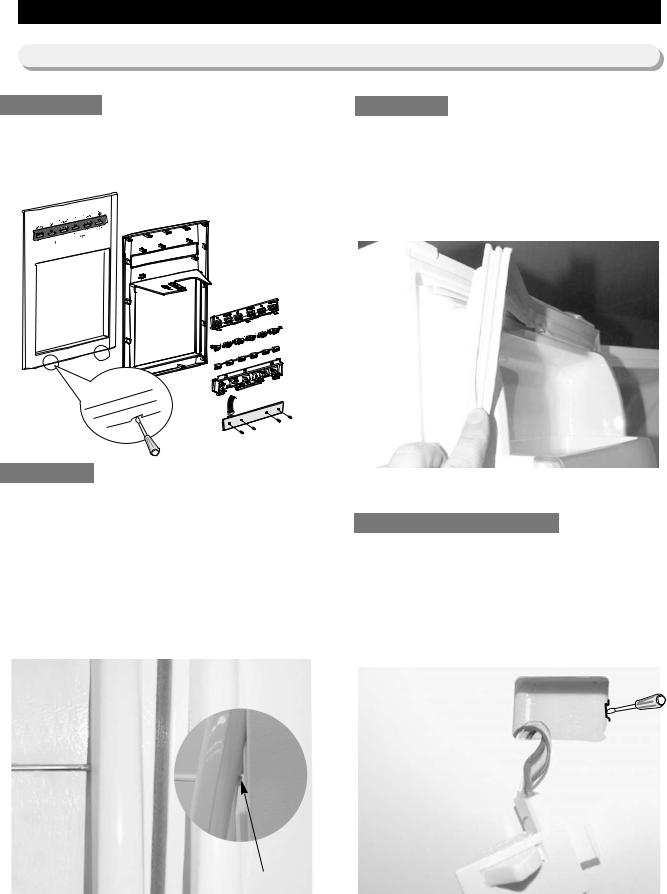

Water Solenoids

When the solenoids receive a signal from the microprocessor, they supply water to the water dispenser or the ice maker.

1.Remove bracket screw on cabinet.

2.Take the solenoids assembly out.

3.Disconnect water tubes.

Condenser Fan

The condenser Fan is located in the middle of machine compartment. It cools down the subcondenser and the compressor.

1.Lift up the rib under the support motor.

2.Pull the support motor.

Condenser

The condenser is located in the machine compartment. The heat is extracted by condenser fan.

1.Desolder the compressor discharge the condenser outlet.

2.Take out the condenser.

14

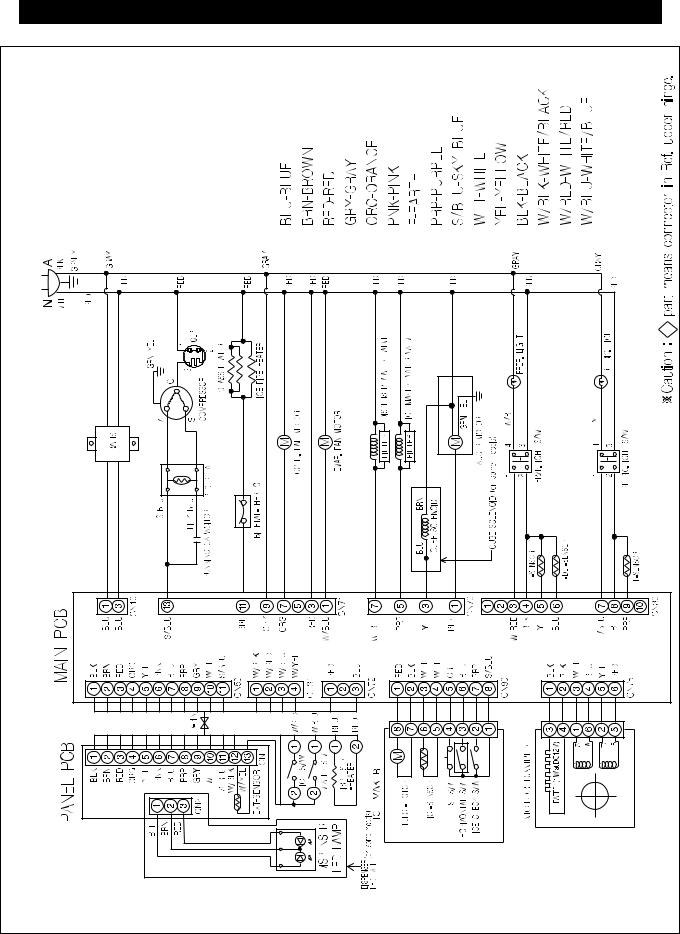

4. CIRCUIT DIAGRAM

15 |

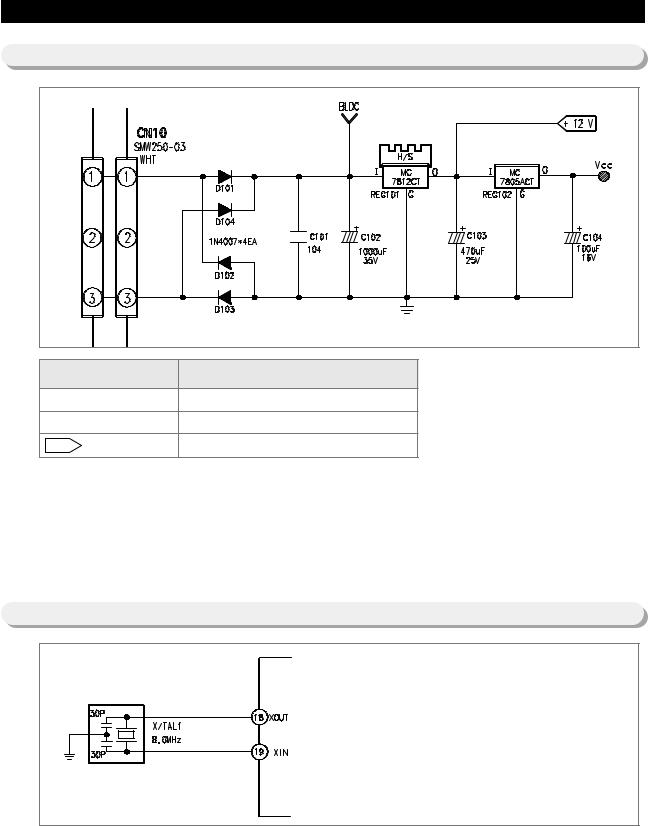

5. OPERATION PRINCIPLES BY PARTS OF CIRCUIT

5-1) POWER |

|

Terminal |

Oscillation Frequency |

●Vcc(DC 5V) |

MICOM POWER AND SENSORS |

<< BLDC |

BLDC MOTOR POWER(NOT USE) |

+12V(DC 12V) |

RELAY,PANEL POWER |

●When turned on, rectified AC voltage which is stepped down on 2nd transformer flows between and at about AC 15V, goes through the diode D101 and D104 is changed to DC, and provide constant 12V.

It provides 5V to MICOM and other circuits via regulator REG102 (MC7805ACT), and make entire PCB operate.

5-2) OSCILLATION CIRCUIT

Terminal |

Oscillation Frequency |

|

|

Xin(#19) |

8.0MHz |

|

|

Xout(#18) |

8.0MHz |

|

|

●It is an Oscillation Circuit for synchronism clock generation and time calculation on the information sending & receiving of the MICOM internal logic elements and when specifications for Resonator change, the timing system of MICOM changes resulting in errors. (Rated parts must be used)

16

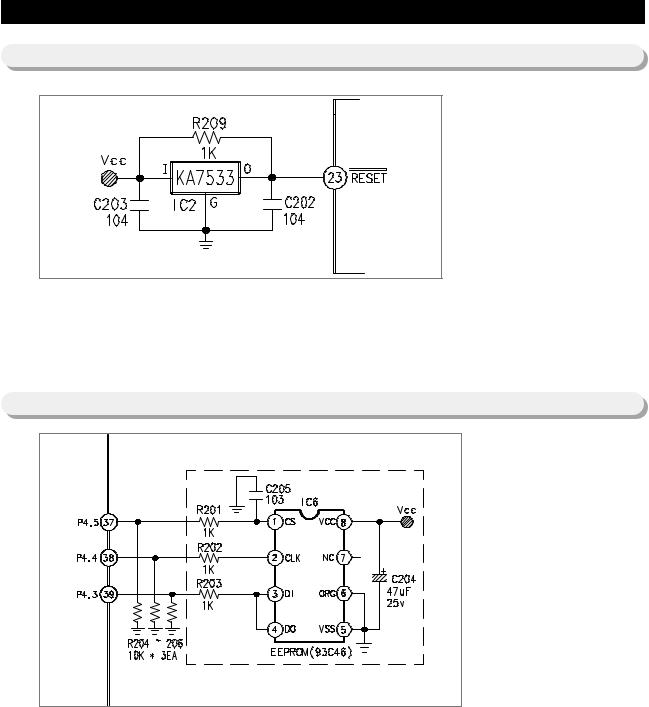

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

5-3) RESET CIRCUIT

●RESET Circuit allows the whole program to go back to the initial setting by initializing parts such as the RAM in MICOM with the power supply into MICOM or with an instant power failure.

Upon the power supply, the reset terminal voltage becomes "LOW" for several tens of compared to Vcc voltage(DC 5V) at MICOM, and it maintains "HIGH"(Vcc Voltage) during normal operation.

But, when Vcc drops down to 3.4~3.7V, the reset terminal voltage becomes "LOW".

5-4) EEPROM DETECTION CIRCUIT

● A semiconductor memory EEPROM stores data remembering previous settings regardless of power-off, which are indispensable especially in power fluctuating areas. Also, EEPROM sets and uses other options in principle.

17

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

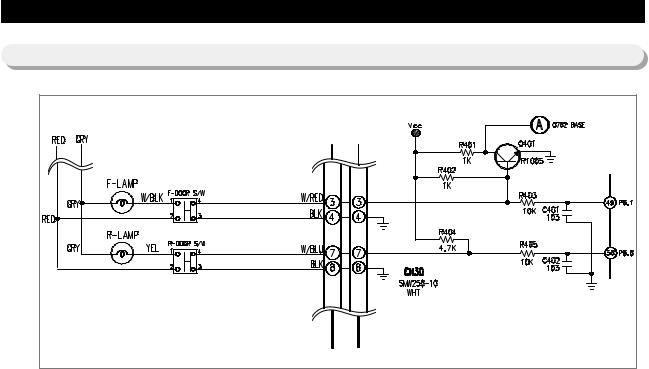

5-5) DOOR SWITCH DETECTON CIRCUIT

1)If R-Door is opened, the contact point of the door switch (4-3) becomes open, and the current of PCB line comes through R404 and R405 and provides 5 volt which is recognized as door is opened, and turn off the fan at different load. When the door is closed, the voltage goes out from R404 to Switch, the MICOM is applied with OV and the door is recognized as closed.

2)If F-Door is opened, the contact point of the door switch (4-3) becomes open, and the current of PCB line comes through R402 and R403 and provides 5 volt which is recognized as door is opened, and turn off the fan at different load. When the door is closed, the voltage goes out from R402 to Switch, the MICOM is applied with OV and the door is recognized as closed.

3)Q401 is the circuit to turn off the auger motor operation when the door is opened. If the door is closed, Vcc voltage of R402 works as ground via door switch, OV is applied to the base of Q401, and Q401 becomes operable, Vcc voltage on "A" part Q702 base works as emitter on Q401 collector and creates OV. (Check the operable condition for other parts at load terminals)

4)Condition for door open is the opposite of condition 3 above.

Category |

Door |

DOOR S/W Contact Point |

MICOM PORT NO |

MICOM INPUT |

|

|

|

|

|

|

|

F |

CLOSE |

CLOSE |

#50 |

"LOW" |

|

OPEN |

OPEN |

"HIGH" |

|||

|

|

||||

R |

CLOSE |

CLOSE |

#49 |

"LOW" |

|

|

|

|

|||

OPEN |

OPEN |

"HIGH" |

|||

|

|

||||

|

|

|

|

|

18

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

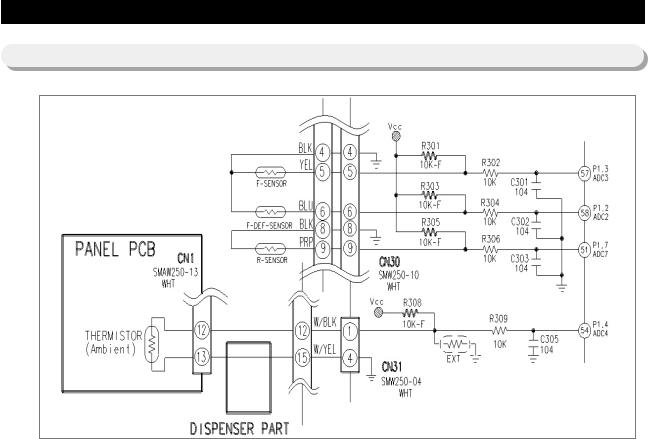

5-6) TEMP SENSING CIRCUIT

1)Sensor uses a thermistor which has a temp coefficient of negative resistance and controls resistance. When the heat goes up, the resistance gets down and vice versa. R302, 4, 6, 9 and C301~C303, C305 are parts for noise prevention but they are not related to temp sensing characteristics.

2)If Vf is the incoming voltage to MICOM in case of F-Sensor, Vf equals (Rth * Vcc)/ ((R301 + Rth). Where Rth is resistance of THERMISTOR corresponding to Temp. Please refer to the Appendix Temp-to-Sensor Resistance/Voltage conversion table(Temp-to-MICOM Terminal Voltage included) on A/S. (Next page)

19

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

Temp to Resistance of Sensor & MICOM PORT Voltage Sensor CHIP : PX41C Standard

Temp. |

Resistance( ) |

Voltage(V) |

Temp. |

Resistance( ) |

Voltage(V) |

Temp. |

Resistance( ) |

Voltage(V) |

Temp. |

Resistance( ) |

Voltage(V) |

|

|

|

|

|

|

|

|

|

|

|

|

-50°F/-45.6°C |

153319 |

4.694 |

-19°F/-28.3°C |

30752 |

3.773 |

12°F/-11.1°C |

8200 |

2.253 |

43°F/6.1°C |

2714 |

1.068 |

|

|

|

|

|

|

|

|

|

|

|

|

-49°F/-45.0°C |

144794 |

4.677 |

-18°F/-27.8°C |

29350 |

3.729 |

13°F/-10.6°C |

7888 |

2.205 |

44°F/6.7°C |

2627 |

1.04 |

-48°F/-44.4°C |

136798 |

4.659 |

-17°F/-27.2°C |

28021 |

3.685 |

14°F/-10.0°C |

7590 |

2.158 |

45°F/7.2°C |

2543 |

1.014 |

|

|

|

|

|

|

|

|

|

|

|

|

-47°F/-43.9°C |

129294 |

4.641 |

-16°F/-26.7°C |

26760 |

3.64 |

15°F/-9.4°C |

7305 |

2.111 |

46°F/7.8°C |

2462 |

0.988 |

|

|

|

|

|

|

|

|

|

|

|

|

-46°F/-43.3°C |

122248 |

4.622 |

-15°F/-26.1°C |

25562 |

3.594 |

16°F/-8.9°C |

7032 |

2.064 |

47°F/8.3°C |

2384 |

0.963 |

-45°F/-42.8°C |

115631 |

4.602 |

-14°F/-25.6°C |

24425 |

3.548 |

17°F/-8.3°C |

6771 |

2.019 |

48°F/8.9°C |

2309 |

0.938 |

|

|

|

|

|

|

|

|

|

|

|

|

-44°F/-42.2°C |

109413 |

4.581 |

-13°F/-25.0°C |

23345 |

3.501 |

18°F/-7.8°C |

6521 |

1.974 |

49°F/9.4°C |

2237 |

0.914 |

|

|

|

|

|

|

|

|

|

|

|

|

-43°F/-41.7°C |

103569 |

4.56 |

-12°F/-24.4°C |

22320 |

3.453 |

19°F/-7.2°C |

6281 |

1.929 |

50°F/10.0°C |

2167 |

0.891 |

-42°F/-41.1°C |

98073 |

4.537 |

-11°F/-23.9°C |

21345 |

3.405 |

20°F/-6.7°C |

6052 |

1.885 |

51°F/10.6°C |

2100 |

0.868 |

|

|

|

|

|

|

|

|

|

|

|

|

-41°F/-40.6°C |

92903 |

4.514 |

-10°F/-23.3°C |

20418 |

3.356 |

21°F/-6.1°C |

5832 |

1.842 |

52°F/11.1°C |

2036 |

0.846 |

|

|

|

|

|

|

|

|

|

|

|

|

-40°F/-40.0°C |

88037 |

4.49 |

-9°F/-22.8°C |

19537 |

3.307 |

22°F/-5.6°C |

5621 |

1.799 |

53°F/11.7°C |

1973 |

0.824 |

-39°F/-39.4°C |

83456 |

4.465 |

-8°F/-22.2°C |

18698 |

3.258 |

23°F/-5.0°C |

5419 |

1.757 |

54°F/12.2°C |

1913 |

0.803 |

|

|

|

|

|

|

|

|

|

|

|

|

-38°F/-38.9°C |

79142 |

4.439 |

-7°F/-21.7°C |

17901 |

3.208 |

24°F/-4.4°C |

5225 |

1.716 |

55°F/12.8°C |

1855 |

0.783 |

|

|

|

|

|

|

|

|

|

|

|

|

-37°F/-38.3°C |

75077 |

4.412 |

-6°F/-20.6°C |

17142 |

3.158 |

25°F/-3.9°C |

5000 |

1.675 |

56°F/13.3°C |

1799 |

0.762 |

|

|

|

|

|

|

|

|

|

|

|

|

-36°F/-37.8°C |

71246 |

4.385 |

-5°F/-20.0°C |

16419 |

3.107 |

26°F/-3.3°C |

4861 |

1.636 |

57°F/13.9°C |

1745 |

0.743 |

|

|

|

|

|

|

|

|

|

|

|

|

-35°F/-37.2°C |

67634 |

4.356 |

-4°F/-45.6°C |

15731 |

3.057 |

27°F/-2.8°C |

4690 |

1.596 |

58°F/14.4°C |

1693 |

0.724 |

|

|

|

|

|

|

|

|

|

|

|

|

-34°F/-36.7°C |

64227 |

4.326 |

-3°F/-19.4°C |

15076 |

3.006 |

28°F/-2.2°C |

4526 |

1.558 |

59°F/15.0°C |

1642 |

0.706 |

-33°F/-36.1°C |

61012 |

4.296 |

-2°F/-18.9°C |

14452 |

2.955 |

29°F/-1.7°C |

4369 |

1.52 |

60°F/15.6°C |

1594 |

0.688 |

|

|

|

|

|

|

|

|

|

|

|

|

-32°F/-35.6°C |

57977 |

4.264 |

-1°F/-18.3°C |

13857 |

2.904 |

30°F/-1.1°C |

4218 |

1.483 |

61°F/16.1°C |

1547 |

0.67 |

|

|

|

|

|

|

|

|

|

|

|

|

-31°F/-35.0°C |

55112 |

4.232 |

0°F/-17.8°C |

13290 |

2.853 |

31°F/-0.6°C |

4072 |

1.447 |

62°F/16.7°C |

1502 |

0.653 |

-30°F/-34.4°C |

52406 |

4.199 |

1°F/-17.2°C |

12749 |

2.802 |

32°F/0.0°C |

3933 |

1.412 |

63°F/17.2°C |

1458 |

0.636 |

|

|

|

|

|

|

|

|

|

|

|

|

-29°F/-33.9°C |

49848 |

4.165 |

2°F/-16.7°C |

12233 |

2.751 |

33°F/0.6°C |

3799 |

1.377 |

64°F/17.8°C |

1416 |

0.62 |

|

|

|

|

|

|

|

|

|

|

|

|

-28°F/-33.3°C |

47431 |

4.129 |

3°F/-16.1°C |

11741 |

2.7 |

34°F/1.1°C |

3670 |

1.343 |

65°F/18.3°C |

1375 |

0.604 |

|

|

|

|

|

|

|

|

|

|

|

|

-27°F/-32.8°C |

45146 |

4.093 |

4°F/-15.6°C |

11271 |

2.649 |

35°F/1.7°C |

3547 |

1.309 |

66°F/18.9°C |

1335 |

0.589 |

|

|

|

|

|

|

|

|

|

|

|

|

-26°F/-32.2°C |

42984 |

4.056 |

5°F/-15.0°C |

10823 |

2.599 |

36°F/2.2°C |

3428 |

1.277 |

67°F/19.4°C |

1297 |

0.574 |

|

|

|

|

|

|

|

|

|

|

|

|

-25°F/-31.7°C |

40938 |

4.018 |

6°F/-14.4°C |

10395 |

2.548 |

37°F/2.8°C |

3344 |

1.253 |

68°F/20.0°C |

1260 |

0.56 |

|

|

|

|

|

|

|

|

|

|

|

|

-24°F/-31.1°C |

39002 |

3.98 |

7°F/-13.9°C |

9986 |

2.498 |

38°F/3.3°C |

3204 |

1.213 |

69°F/-45.6°C |

1225 |

0.546 |

|

|

|

|

|

|

|

|

|

|

|

|

-23°F/-30.6°C |

37169 |

3.94 |

8°F/-13.3°C |

9596 |

2.449 |

39°F/3.9°C |

3098 |

1.183 |

70°F/20.6°C |

1190 |

0.532 |

|

|

|

|

|

|

|

|

|

|

|

|

-22°F/-30.0°C |

35433 |

3.899 |

9°F/-12.8°C |

9223 |

2.399 |

40°F/4.4°C |

2997 |

1.153 |

71°F/21.7°C |

1157 |

0.519 |

|

|

|

|

|

|

|

|

|

|

|

|

-21°F/-29.4°C |

33788 |

3.858 |

10°F/-12.2°C |

8867 |

2.35 |

41°F/5.0°C |

2899 |

1.124 |

72°F/22.2°C |

1125 |

0.506 |

|

|

|

|

|

|

|

|

|

|

|

|

-20°F/-28.9°C |

32230 |

3.816 |

11°F/-11.7°C |

8526 |

2.301 |

42°F/5.6°C |

2805 |

1.095 |

73°F/22.8°C |

1093 |

0.493 |

20

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

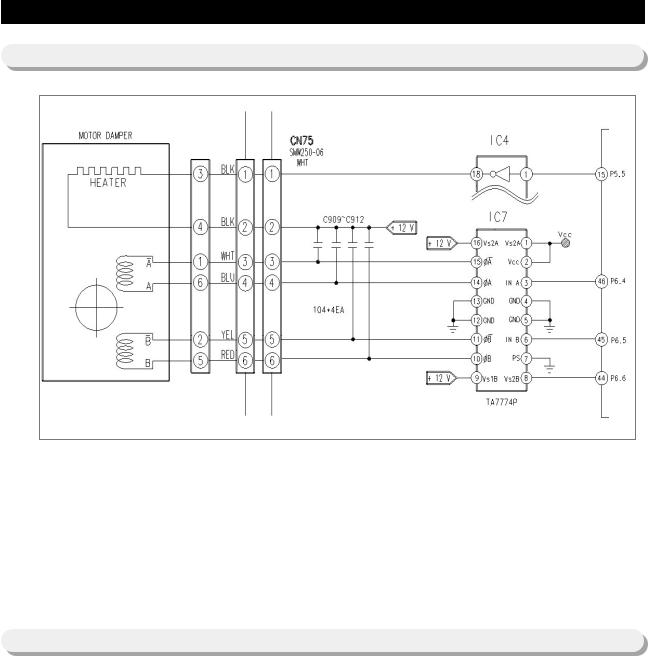

5-7) DAMPER CIRCUIT

1)The temperature of R-room is controlled by opening and closing of damper with stepping motor, supplying & blocking cold air.

2)TA7774P (IC07) operates the damper. TA7774P is the driver IC only for step motor. If the regular signal is provided to TA7774P from Micom, send combined signal to Quad-Polar step motor to rotate on certain direction. This makes clockwise or counter clockwise rotation to make the damper open or close.

3)Since the damper always touches the cold air, DC 12V/1W heater is installed, always on to prevent the malfunction from moisture and is controlled on conditions. (Operation conditions can be changed). Micon #15 pin connected to IC4 controls the damper heater like category 3.

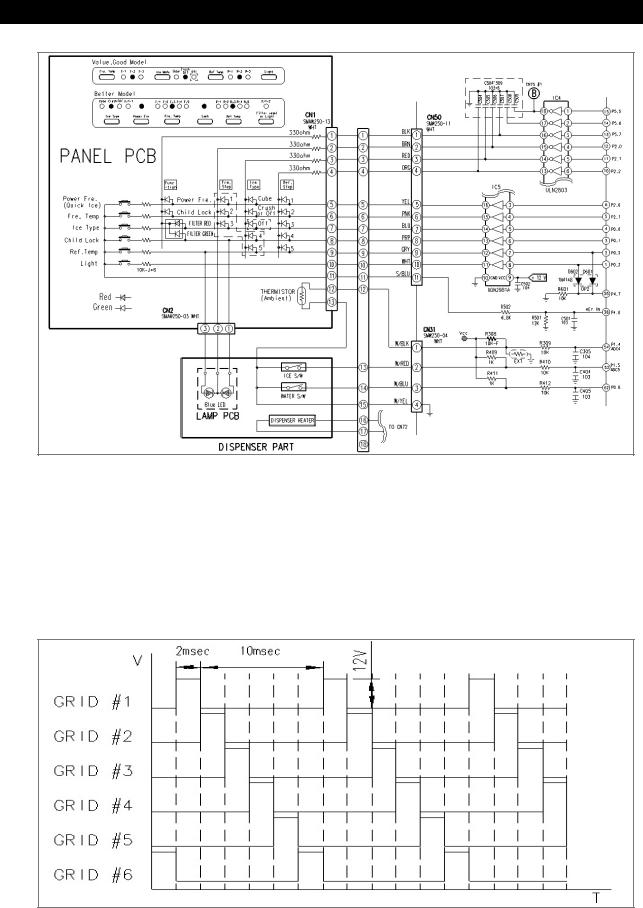

5-8) DISPLAY Circuit

1) KEY SCAN

When Grid #6 is output, this signal goes through PCB resistance 10 and provided to power frequency.

When the switch is pressed, R502(6.8 ) and R501 (12 ) decrease the signal and less than 5.1V peak to peak signal is provided to MICOM, the MICOM recognizes the grid #6 is provided, and change the function corresponding to switch key. [Refer the circuit diagram below]

21

OPERATION PRINCIPLES BY PARTS OF CIRCUIT

2) DISPLAY OPERATION

Like the signal diagram below, Micom sends “ high ” signal through MICOM 6 terminals of NO #1→ 2 → 3 → 4

→ 5 → 6 for 2ms every 12ms. This signal goes to output terminal via input terminal of IC5 (KID65783AP or TD62783AP). Output wave always goes through LED input terminal with DC11~12V on every period. At this time, if SINK signal comes out at IC4, DC11~ 12V is applied to LED input terminal and output terminal sinks to OV which turn on LED for 2ms For example, to turn on "Power Fre." LED, IC4 #16 pin sinks to 0V when IC5 #16 becomes DC 11~12V making "Power Fre" LED turn on.

GRID WAVE PATTERN

22

Loading...

Loading...