Samsung RF263 Series Repair Manual

- 1/65 -

HA Repair Guide

Refrigerator

AW1(12)-RF263*

- 2/65 -

• NO Ice / Dispensing problem

• Not Enough Ice

No Ice

• No Water / Water Dripping

• Water Leak

No Water

• Evaporator Frost Buildup

Defrost

• Water Hose Noise

• Unit Noise

Noise

• Weak Cooling (F/R)

• Too Much Cooling

COOLING

• Error Code Detail

Error Code

AW1(12)PJT Repair Guide

[ RF263* ]

- 3/65 -

● Ice

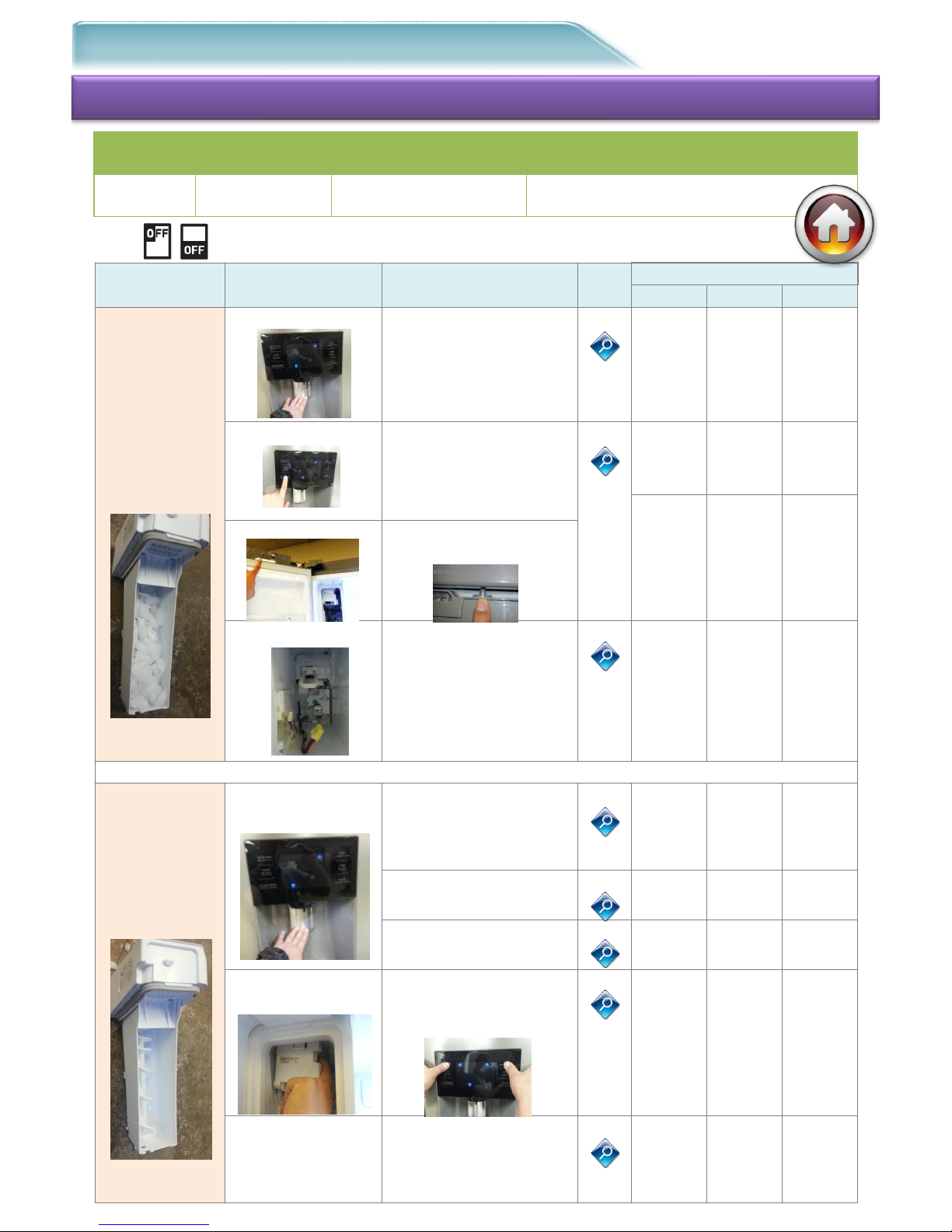

#1. Symptom : No Ice Repair distribution diagram

Check-1

Reason Step

Check-2

Tip

Code

Block

# 1

# 2

# 3

Ice Bucket

Full

(Dispensing

problem)

Display Issue

Inspect Display Water

& Ice selecting

1-1

Panel-

PBA

Wire

Harness

Main

PBA

Lever S/W problem

Inspect Lever S/W

operation

1-2

Panel-

PBA

Wire

Harness

Ice

Bucket

Auger

Motor

S/W

Wire

Harness

Auger S/W failure

Inspect Auger Motor

S/W operation

Auger Motor Prob

Inspect ASSY

Auger Motor

operation

1-3

ASSY

Auger

Motor

Wire

Harness

Main

PBA

Ice Bucket

Empty

(Ice making

problem)

Ice maker water

supply issue

Inspect Water

connection / supply

2-1

External

Conn.

(water

supply)

Water

Hose

Filter

Ice Full sensing

failure

2-2

IR

Sensor

Wire

Inspect Ice Valve

operation

2-3

Wire

Harness

Ice Valve

Ice maker/ Sensor

/ Fan Motor issue

Self-diagnosis

Display “Energy

Saver” +”Alarm”

2-4

Ice

Maker,

Sensor,

Fan

Damper

Wire

Harness

Main

PBA

Cooling power

failure

(Ice melting

in Tray)

Measure cooling

power inspection

Comp / Fan motor

inspection

2-5

Comp

Relay

Cycle

Shield

System

C-fan

Chassis

Project

Basic Model

Type

FDR

AW1-12

RF263*

Direct Ice Maker

※ Check the Display as “ICE off”

- 4/65 -

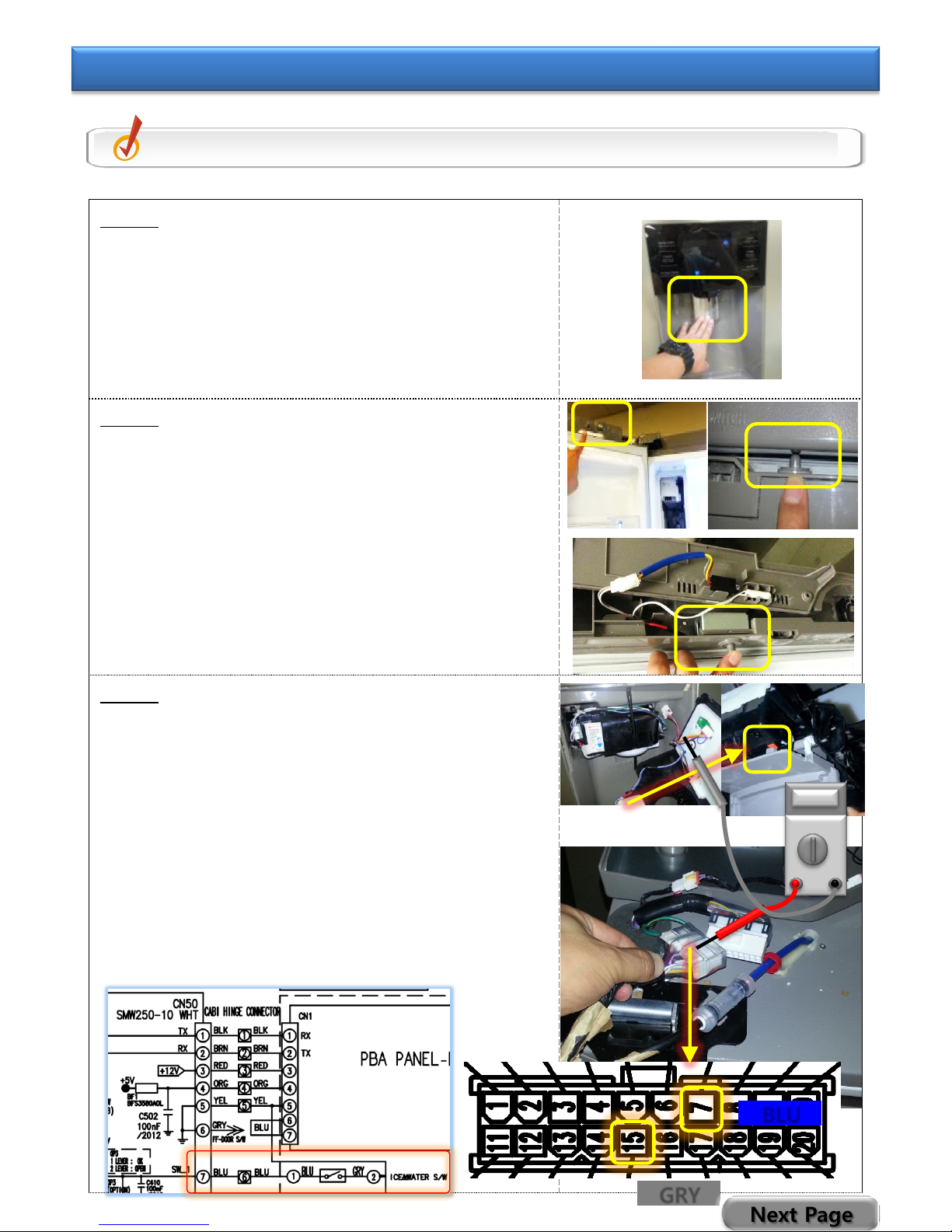

Step 1

① Check for “Child Lock” icon

② Check “Ice Type/Water” Key.

- If it is normal Inspect “Tip 1-2”

- If it is abnormal Inspect Step 2

Step 2

① Check PANEL PBA WIRE HARNESS

Pin connection / switching

- Inspection of 1~5Wire

Verify that the wires are in

the correct order in the connector

① Disassemble the HINGE-UPP COVER, check

the WIRE HARNESS Pin connection/switching

connection and verify the correct sequence

- Inspect BLK / BRN / RED / ORG / YEL

Wire

Step 3

① Disassemble Main PBA Cover in the back

Inspect CN50 ①~⑤Wire Pin contacting and

switching

- BLK / BRN / RED / ORG / YEL Verify that

the wires are in

the correct order in the connector

① If there is no problem on all,

- Replace the PANEL PBA

Check Point

Check the “Ice Type/Water” Key selecting operation.

Tip 1-1. Inspect Display “Ice Type / Water” selecting

CN 50

- 5/65 -

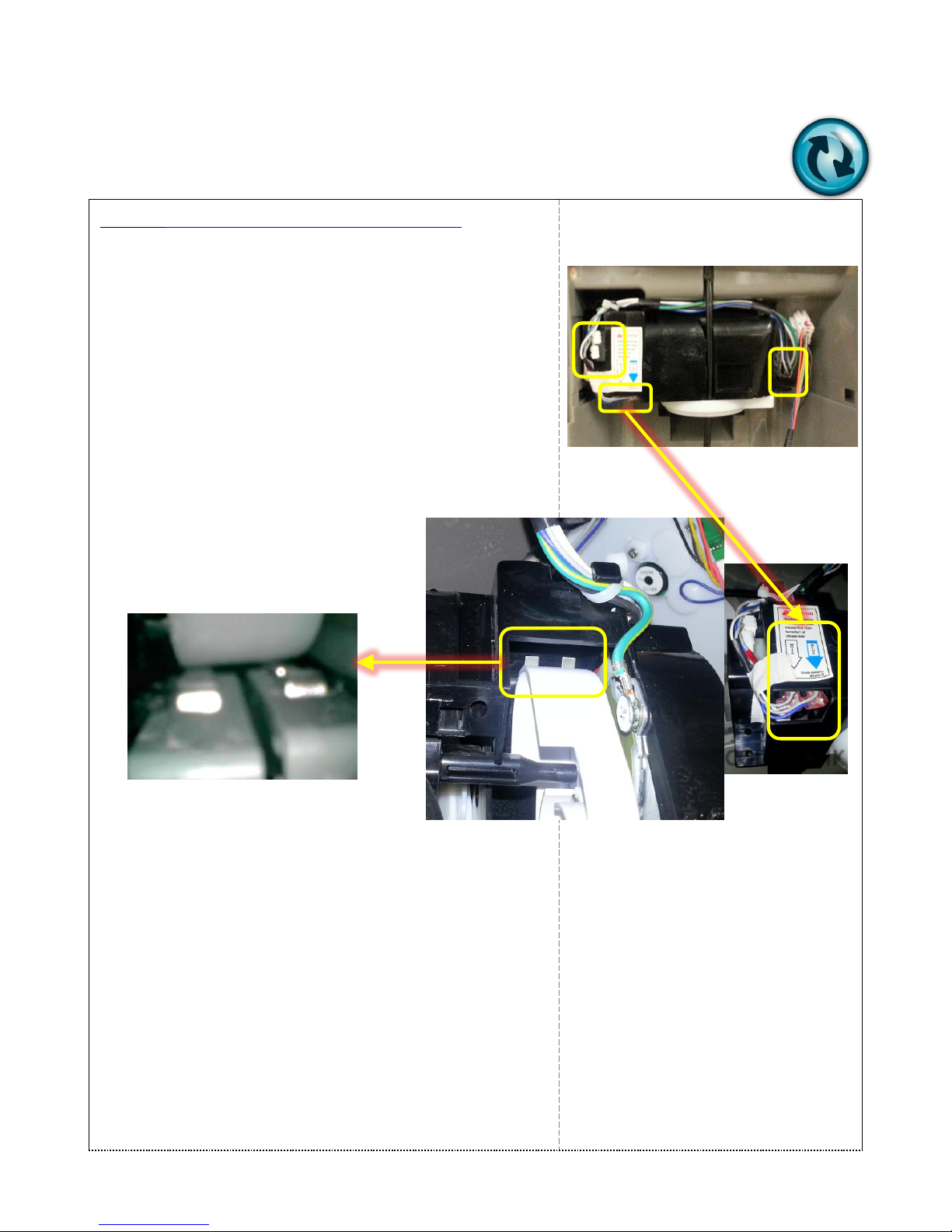

Step 1

① Push the DISPENSER LEVER to check Auger

Motor rotating sound. Auger motor is in

the Ice Room.

- If No operation sound, go to Step 2

inspection

- If operation sound, go to Step 4

inspection

Step 2

① Check Auger Motor S/W that is on the top

of Left FF Section Door.

- Inspect S/W with F room door closed

② Using an Ohmmeter, check for“0Ω” with the

S/W plunger pushed in by hand.

※ If the door S/W has failed, the auger

motor cannot work.

Step 3

① Disassemble the Display and check the Micro

LED S/W, located at the back of the Lever.

※ (Check for broken or stuck switches)

When there is no problem found,

① Disassemble HINGE-UPP COVER, and check

the WIRE HARNESS connection

- Inspect CONNECTOR

No.7(BLU)+No.15(GRY)

② Inspect Main PBA Connector

- Inspect CN50 No.5(YEL) and No.7(BLU)

Wire

Check Point

Inspect the Dispenser Lever S/W operation.

Tip 1-2. Inspect Lever S/W & Auger Motor S/W operation

BLU

GRY

Next Page

- 6/65 -

Step 3 (COVER ICE ROUTE S/W failure)

① When COVER open as failure of operation

② Inspect the CONNECTOR OPEN

③ Inspect the MOTOR S/W TOUCH failure

- Rotate continuously when both 2 S/W are

not pushed

④ Inspect BLUE / WHITE S/W exchanging

⑤ Replace ASSY CASE-LEVER DISP .

COLOR CHK

- 7/65 -

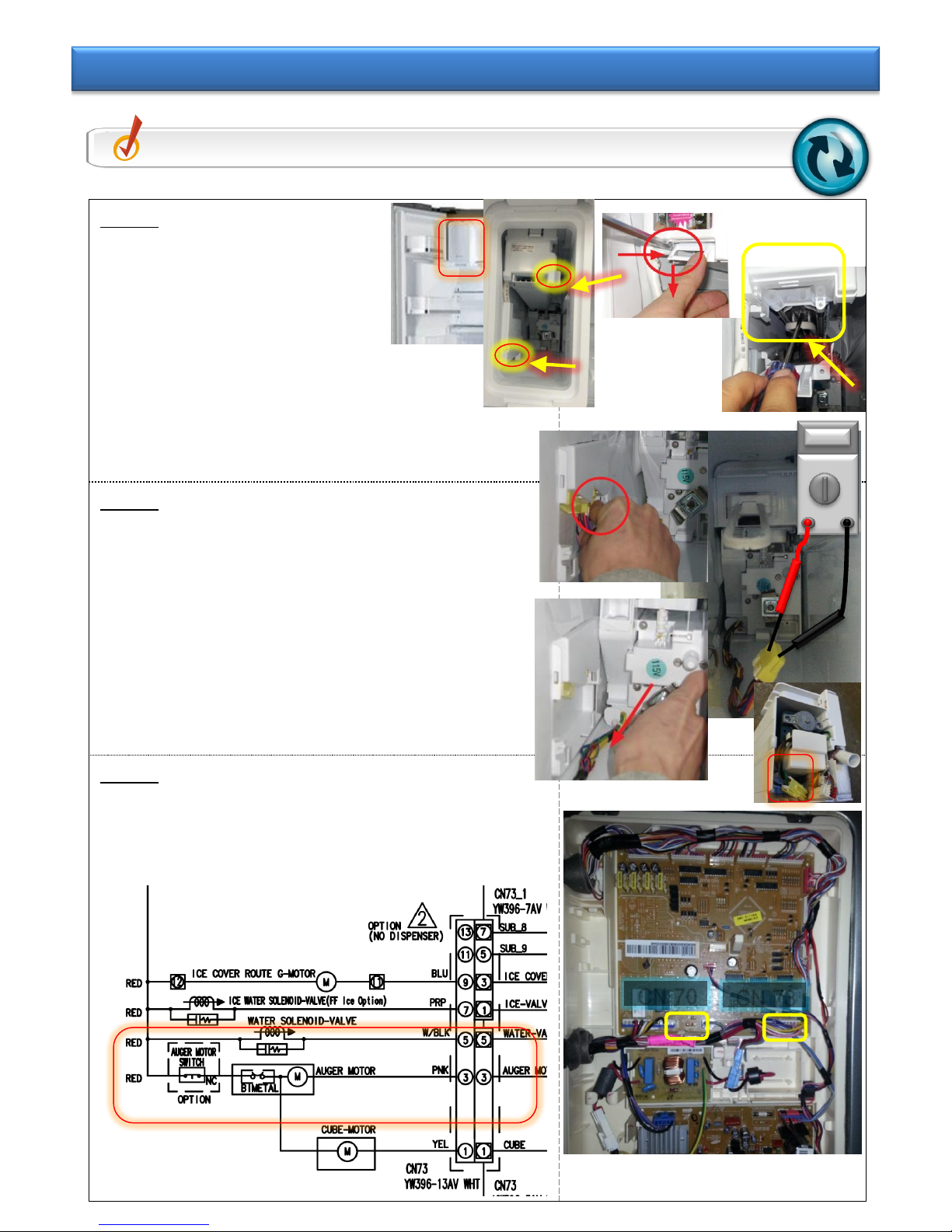

Step 1

① Remove the Ice bucket

in ice room

① Remove 2 screws as shown

② Remove the ice maker after pulling the

cooling pipe which is in the bottom of ice

maker.

Step 2

① Remove the Auger Motor and inspect the

Motor

- Normal = GRY+BLK 3~5 Ω

- Defective = Open or 0 Ω

Step 3

① Inspect the Main PBA + CONNECTOR Wire

- CN73 No.3(PNK) + CN70 No.5(RED)

Check Point

Inspect the Auger Motor .

Tip 1-3. Inspect ASSY Auger Motor operation

CN 73

CN 70

- 8/65 -

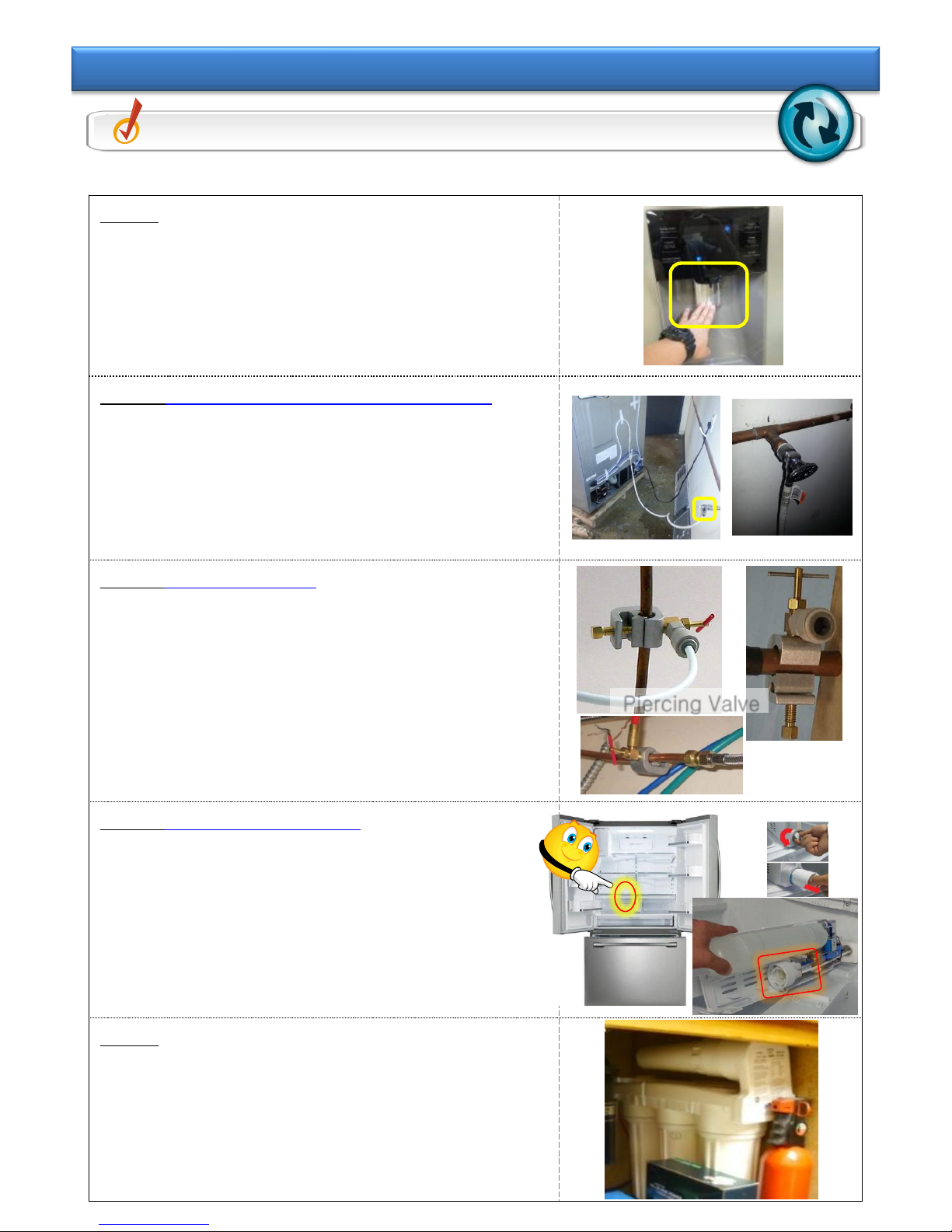

Step 1

① Select Water, then check the water

dispensing when pressing lever.

- When there is no water dispensing Check

Step 2

- When the water is dispensing check TIP 24

Step 2 (Connection problem-Hose kinked)

① Inspect connection between external tap and

the product

- Check if it is connected to water supply

- Check if the tap is closed.

② Check for kinked Water supply line

Step 3 (Piercing Valve )

① Check for water with piercing valve open and

supply hose disconnected.

(Piercing valves are not recommended)

Step 4 (Filter Case problem)

① Remove Water Filter and check dispensing.

If water dispenses ,try a new filter. If

water does not dispense with new filter,

replace the Filter Case.

Step 5

① Minimum water supply pressure should be

20 PSI.

② If pressure is low due to external filter

(reverse osmosis) remove internal filter.

Check Point

Inspect Water supplying failure

Tip 2-1. Inspect water connection/supplying

※ Before first use and after filter replacement, dispense water for 3 min

Piercing Valve

- 9/65 -

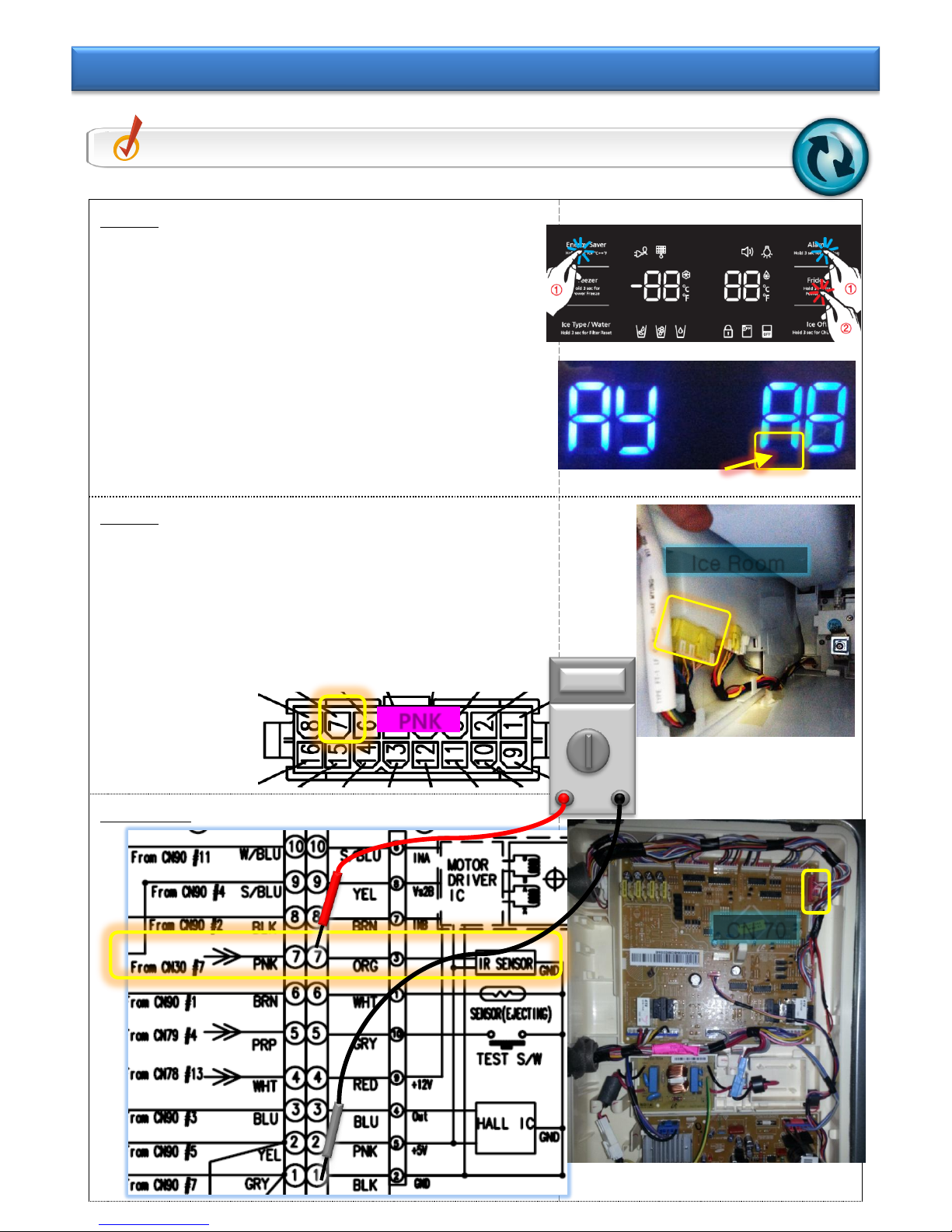

Step 1

① Check the ICE Bucket for the presence of

ice.

② If no ice, Enter After PANEL PBA “Energy

Saver”+”Alarm” Key and touch LED Blink

“Fridge” Key.

③ In the case of FF-Display Yellow Blink

- Recognized Ice Bucket Full Check STEP 2

- When there is no Blink Check Tip 2-3

Step 2

① Inspect the “YEL 16-PIN” CONNECTOR

No.7(PNK) PIN contact/switching

② Inspect Wire connector

- No.7(PNK) + Main PBA CN 30 No.7(PNK)

Main PBA

Check Point

Inspect ice maker Water supply problem

Tip 2-2. Inspect Ice Full sensing failure

CN 70

Ice Room

PNK

- 10/65 -

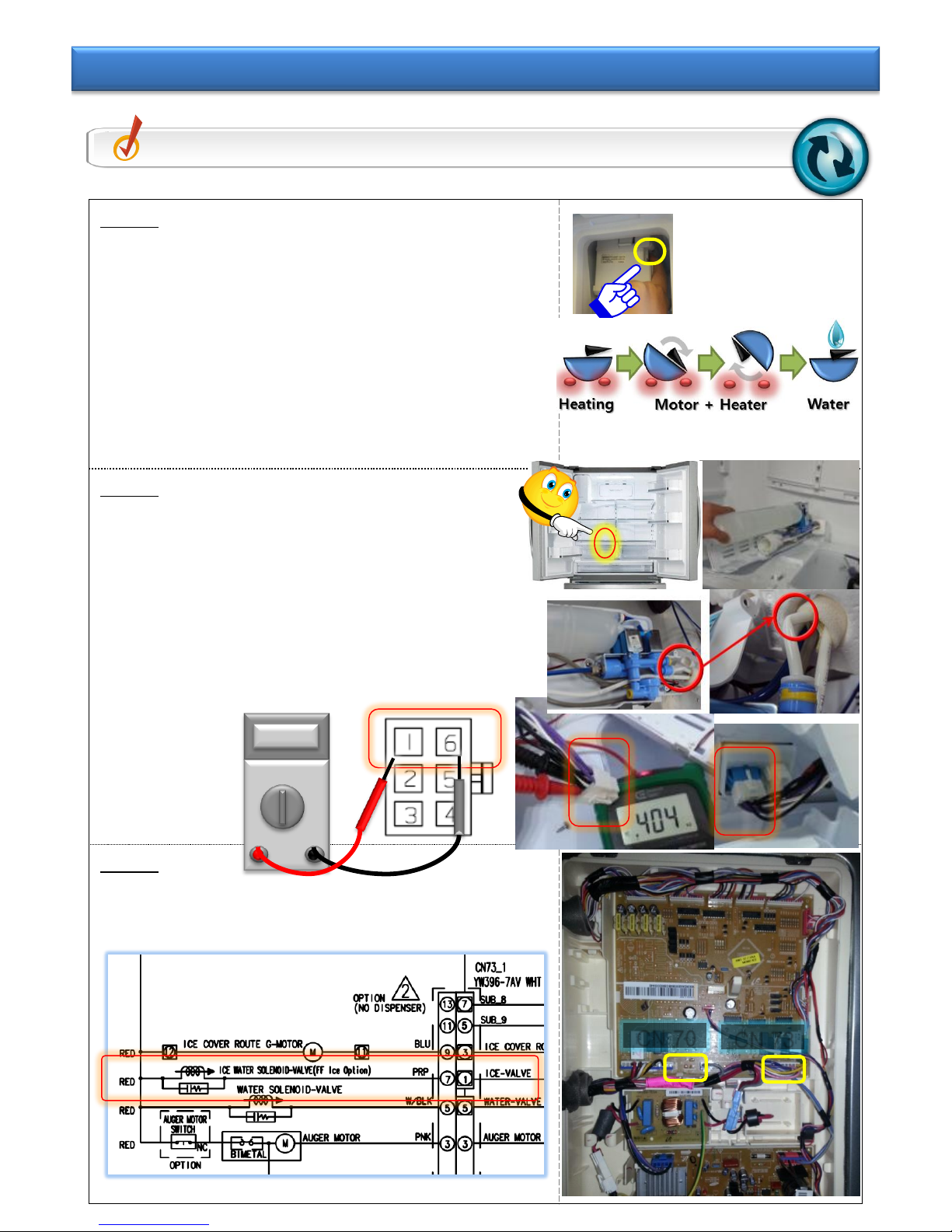

Step 1

① After disassemble the Ice Bucket and ice

maker

Right side button on ice maker turns on for

2 sec

① Takes Max “6 Min” (including Heating

time)

- When the water does not come Check

Step 2

- When the water come Check TIP 2-5

Step 2

① Inspect the WATER HOSE bending

② After disassemble the ASSY Valve, Purple 2

Pin Check

- Normal part : 350~450 Ω

- Failure part : Open or 0 Ω

③ Check the housing No.1(PRP/BLK)

+ No.6(PRP/BLK)

Step 2

① Check MAIN PBA + Liner CONNECTOR

- Check CN70 No.5(RED)+CN73 No.1(PRP)

Check Point

Inspect ICE MAKER Water supply problem

Tip 2-3. Inspect the Ice Valve operation

CN 73

CN 70

- 11/65 -

※ Fan Motor indicates failure in On condition .

Touch the Display “Energy Saver”+Alarm” Key at

the same time for 8 sec.

- After blink All LEDs, touch it until the “chime”

occurs

- Self diagnosis test is normal check TIP 2-5

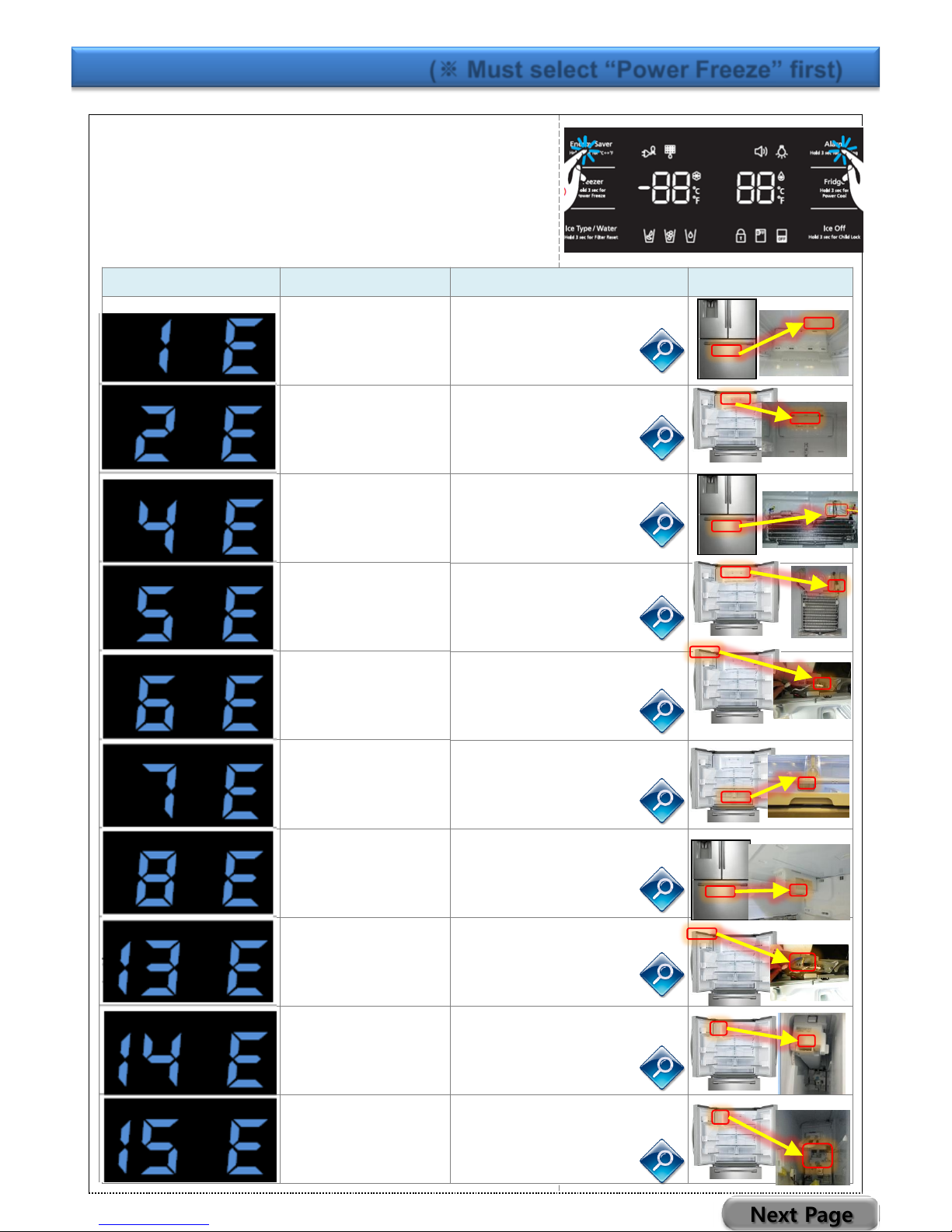

● Inspect self- diagnosis test (※ Must select “Power Freeze” first)

Display (Image)

Error Item

Measure

IMAGE

FZ-Sensor

① FZ-Sensor

② Wire Open Check

FF-Sensor

① FF-Sensor

② Wire Open Check

FZ-DEF-Sensor

① FZ-DEF-Sensor

② Wire Open Check

FF-DEF-Sensor

① FF-DEF-Sensor

② Wire Open Check

Ambient-Sensor

① Ambient-Sensor

② Wire Open Check

Pantry-Sensor

① Pantry-Sensor

② Wire Open Check

Ice Maker(FZ)

-Sensor

① Ice Maker(FZ)-Sensor

② Wire Open Check

Humidity-Sensor

① Humidity-Sensor

② Wire Open Check

Ice Maker(FF)

-Sensor

① Ice Maker(FF)-Sensor

② Wire Open Check

Ice Room(FF)

-Sensor

① Ice Room(FF)-Sensor

② Wire Open Check

Next Page

- 12/65 -

Display (Image)

Error Item

Measure

IMAGE

FZ-Fan Motor

① FZ-Fan Motor FG NG

② Wire Open Check

FF-Fan Motor

① FF-Fan Motor FG NG

② Wire Open Check

C-Fan Motor

① C-Fan Motor FG NG

② Wire Open Check

FZ-DEF-Function

① FZ-Defrost Heater open

② FZ-Defrost Sensor NG

③ Thermo fuse open

④ Wire open check

FF-DEF-Function

① FZ-Defrost Heater open

② FZ-Defrost Sensor NG

③ Thermo fuse open

④ Wire open check

FZ-Ice Maker

-Function

① Ice Maker NG

② Wire Open Check

Pantry Damper

DC Heater

① Pantry Damper DC

Heater Open

② Wire Open Check

FZ-Ice Pipe Heater

① FZ-Ice Pipe DC Heater

Open

② Wire Open Check

FF-Ice Maker

-Function

① Ice Maker Heater Open

② Ice Maker NG

③ Wire Open Check

FF-Ice Room

- Fan Motor

① Ice Fan Motor FG-NG

② Wire Open Check

Panel ↔ Main PBA

Communication

① Panel PBA NG

② Wire Open Check

③ Main PBA

FF-Ice Room Drain

Heater

① FF Ice Room Drain DC

Heater Open

② Wire Open Check

Next Page

- 13/65 -

Display (Image)

Error Item

Measure

IMAGE

FF-Ice Room

DC Heater

① FZ-Fan Motor FG NG

② Wire Open Check

Comp Starting

Failure

① Initial re-operation-rest

7min.

② COMP U.V.W상 SHORT

③ IPM PIN SHORT

④ INVERTER PBA failure

Inverter PBA

IPM Fault

Comp Abnormal

current Detection

① Inverter PBA CN04

inspection

- changed/OPEN

② COMP WIRE inspection

- changed/OPEN

Motor Locked Over

RPM

① COMP LOCKED

-CYCLE inspection

② COMP LOW rpm

③ Initial re-operation-rest

7min.

④ INVERTER PBA

Comp under

voltage

Comp over

voltage

① Inspect the outlet power

② INVERTER PBA

Ice Defrost Cooling

- 14/65 -

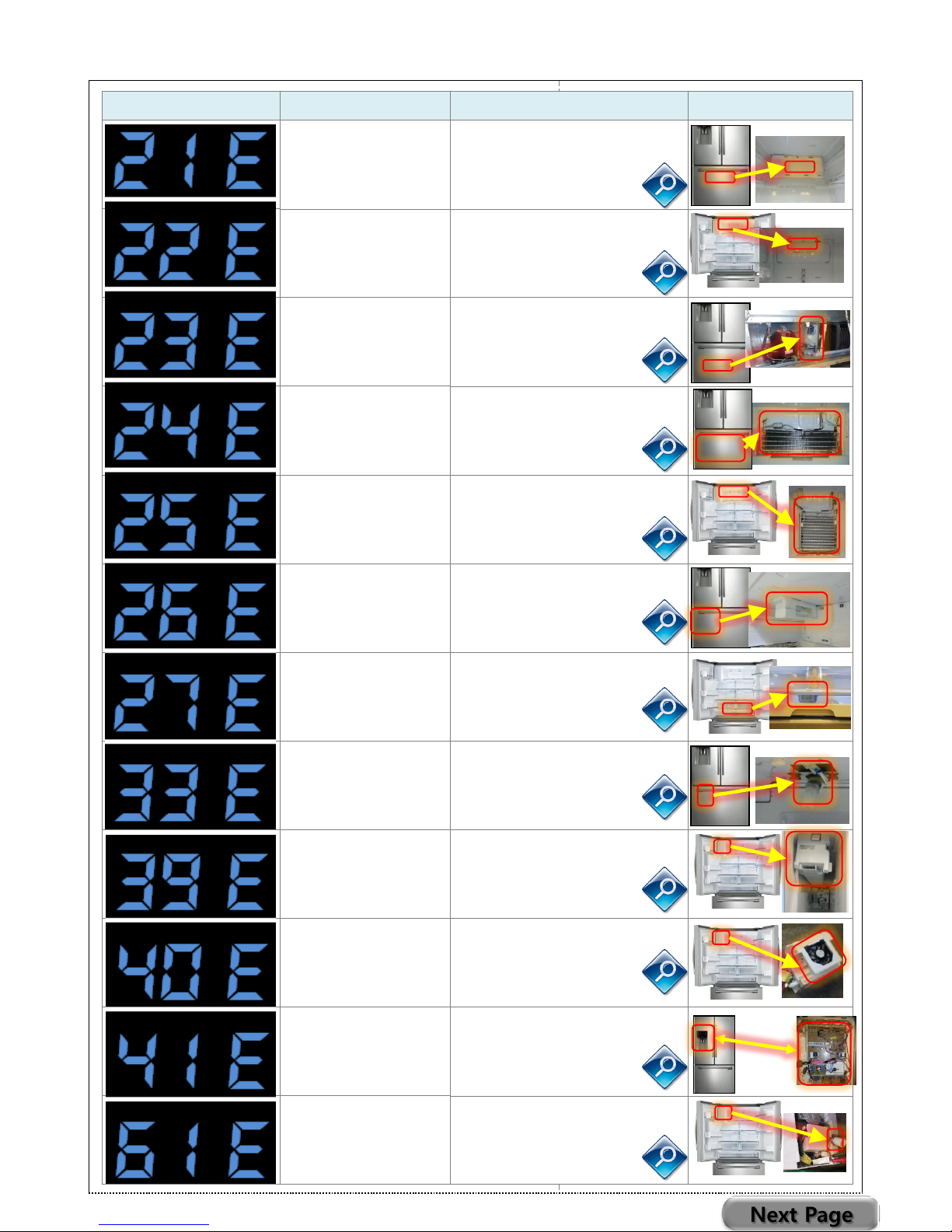

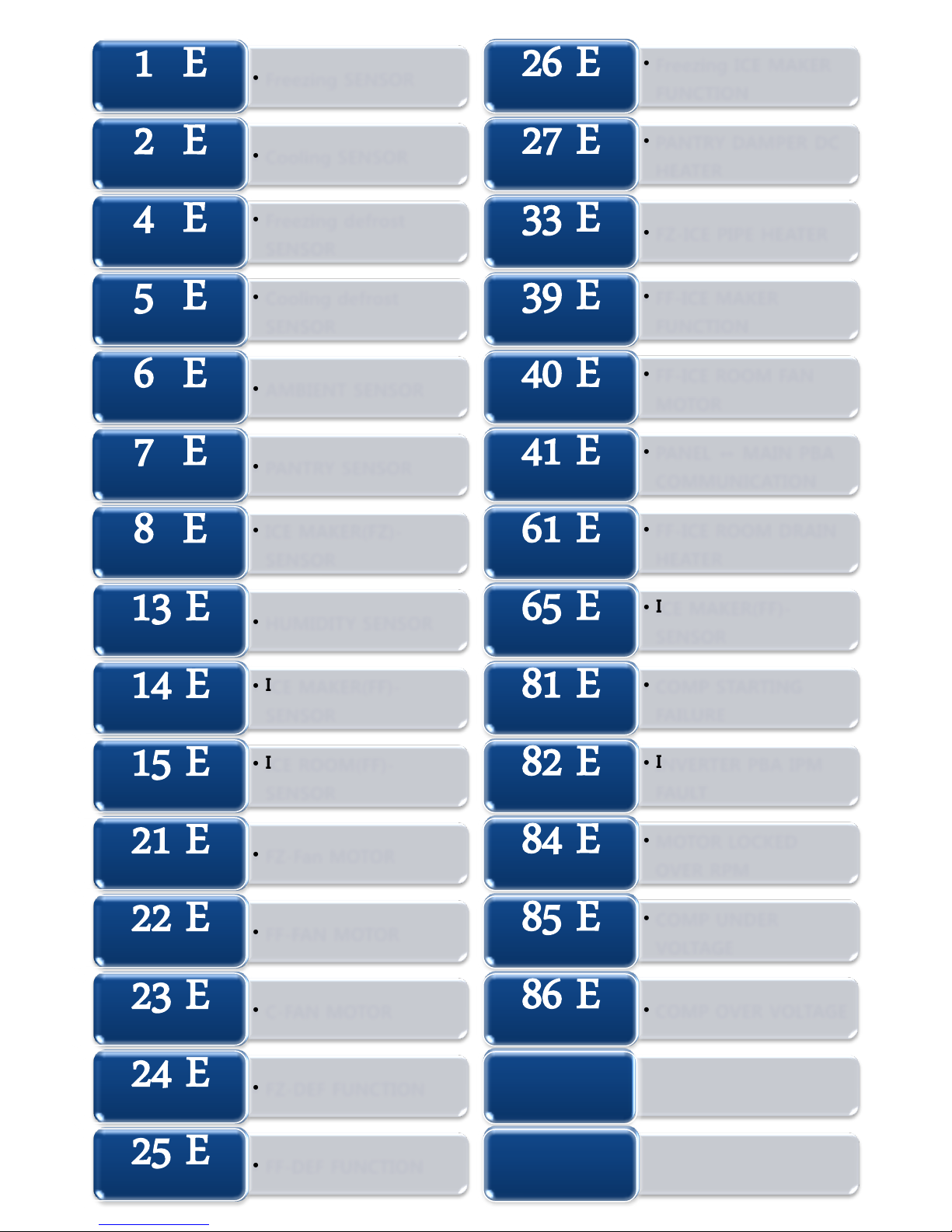

• Freezing SENSOR

1 E

• Cooling SENSOR

2 E

• Freezing defrost

SENSOR

4 E

• Cooling defrost

SENSOR

5 E

• AMBIENT SENSOR

6 E

• PANTRY SENSOR

7 E

• ICE MAKER(FZ)-

SENSOR

8 E

• HUMIDITY SENSOR

13 E

• ICE MAKER(FF)-

SENSOR

14 E

• ICE ROOM(FF)-

SENSOR

15 E

• FZ-Fan MOTOR

21 E

• FF-FAN MOTOR

22 E

• C-FAN MOTOR

23 E

• FZ-DEF FUNCTION

24 E

• FF-DEF FUNCTION

25 E

• Freezing ICE MAKER

FUNCTION

26 E

• PANTRY DAMPER DC

HEATER

27 E

• FZ-ICE PIPE HEATER

33 E

• FF-ICE MAKER

FUNCTION

39 E

• FF-ICE ROOM FAN

MOTOR

40 E

• PANEL ↔ MAIN PBA

COMMUNICATION

41 E

• FF-ICE ROOM DRAIN

HEATER

61 E

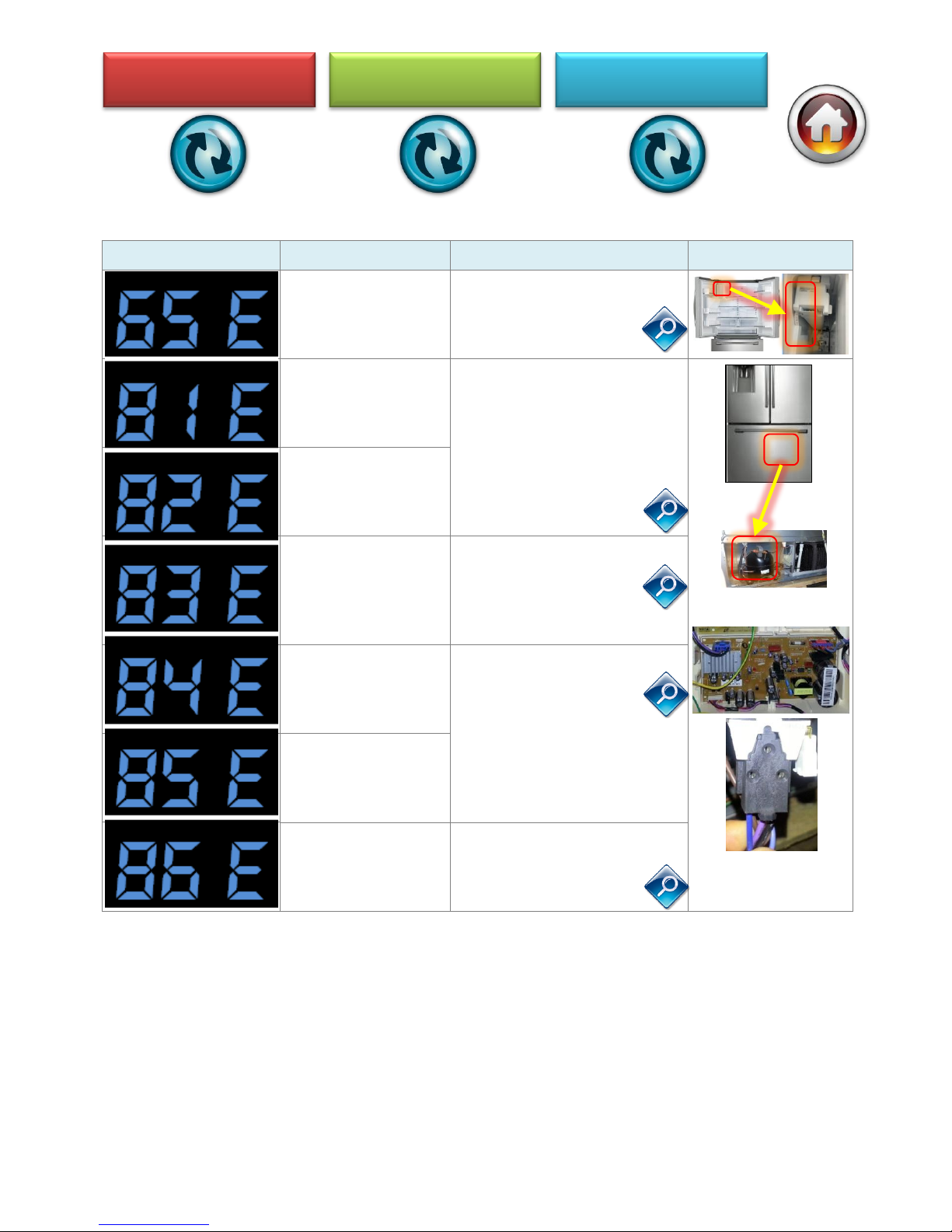

• ICE MAKER(FF)-

SENSOR

65 E

• COMP STARTING

FAILURE

81 E

• INVERTER PBA IPM

FAULT

82 E

• MOTOR LOCKED

OVER RPM

84 E

• COMP UNDER

VOLTAGE

85 E

• COMP OVER VOLTAGE

86 E

- 15/65 -

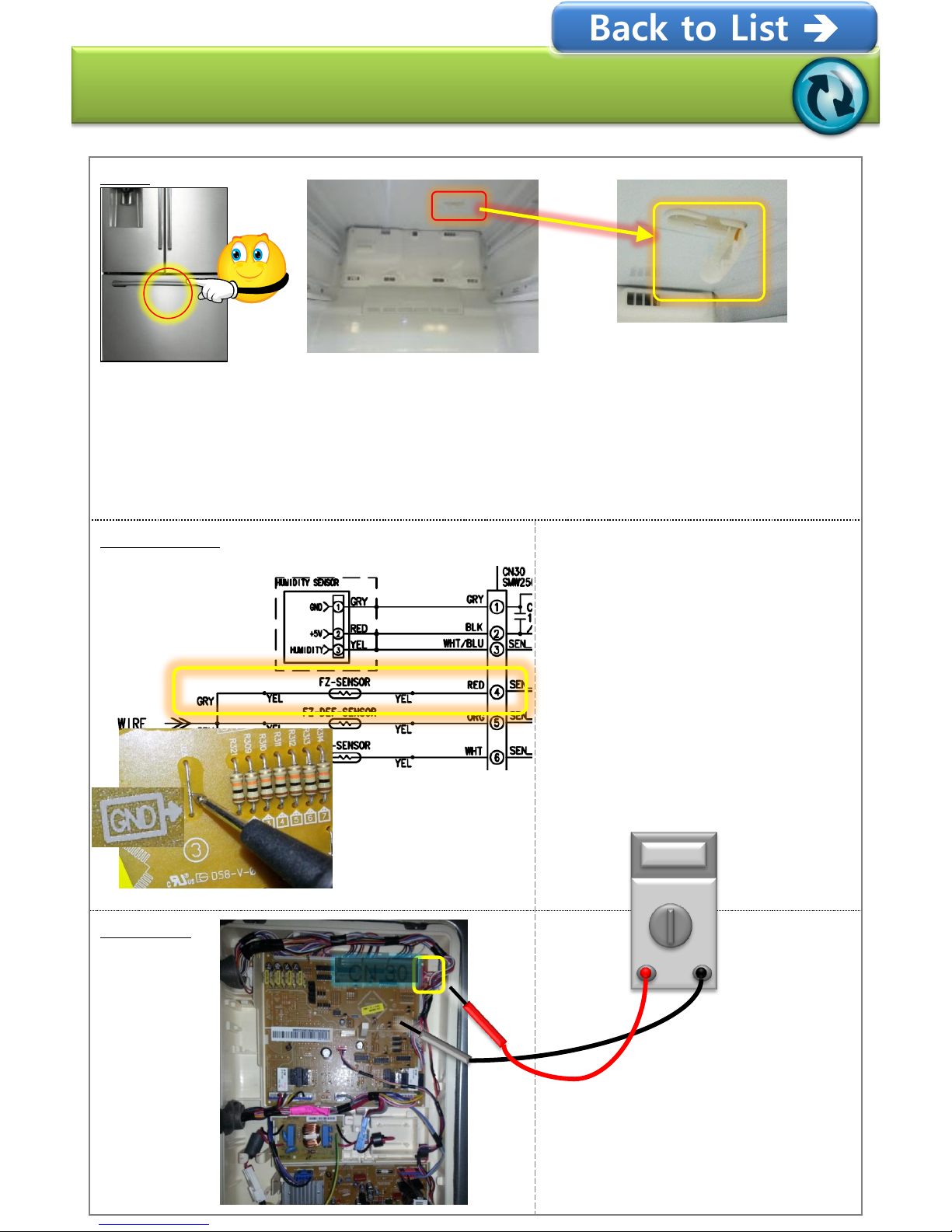

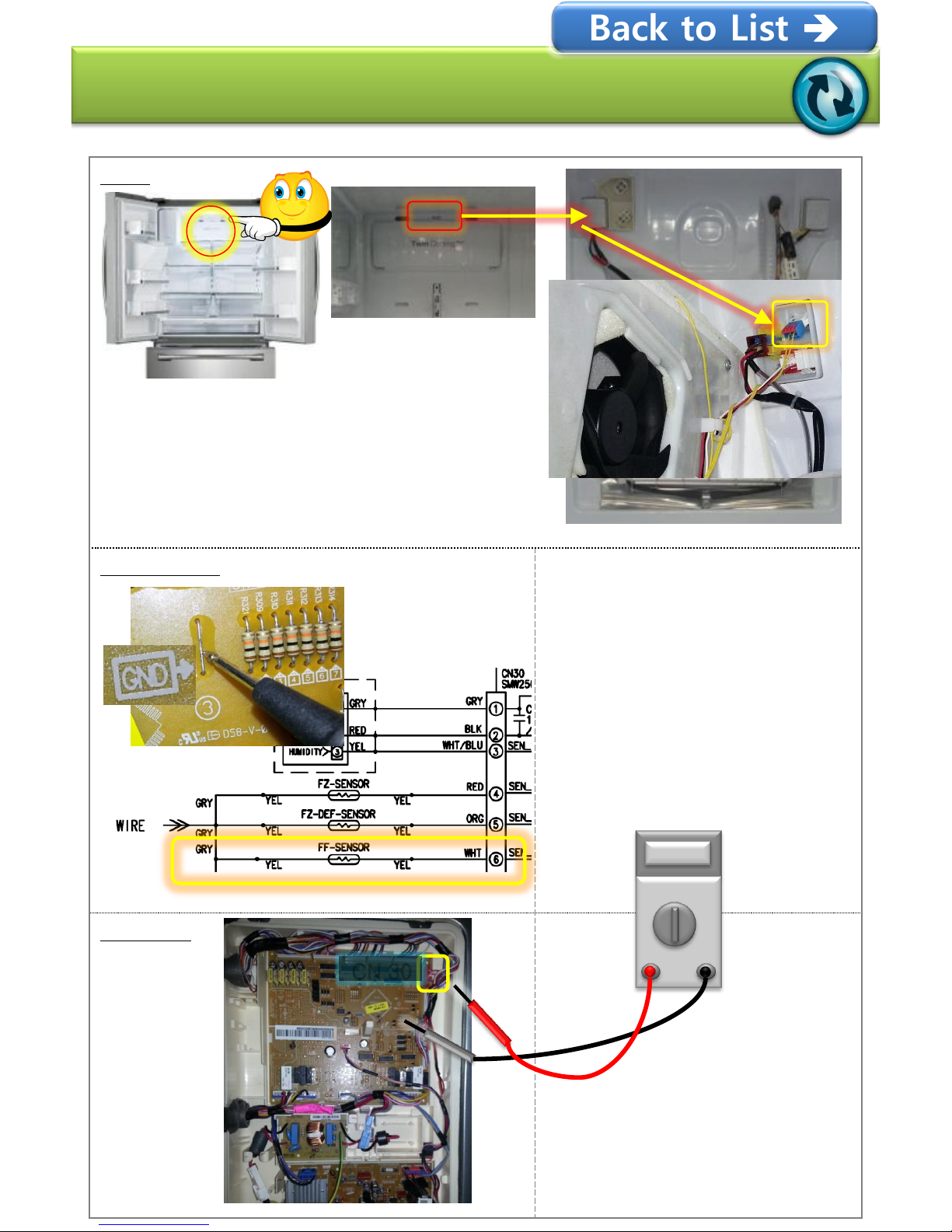

Error-code : 1 E

FZ-Room Sensor Error

Block

① Disassemble the FZ-Room BOX

② After disassemble the Sensor Cover and inspect the Wire Open

③ Measure the Main PBA DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑ Inspect bottom WIRE

CONNECTOR

① Inspect the Main PBA CN30

No.4(RED)+

PBA “GND” marked area

and DC voltage measuring

- Normal: DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 30

Back to List

- 16/65 -

Error-code : 2 E

FF-Room Sensor Error

Block

① Disassemble the FF-Room EVAP COVER

② Inspect the BLUE CONNECTOR(2-WIRE)

③ Measure Main PBA DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Check bottom WIRE

CONNECTOR

① Inspect Main PBA CN30

No.6(WHT)+

PBA “GND” marked area

and DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 30

Back to List

- 17/65 -

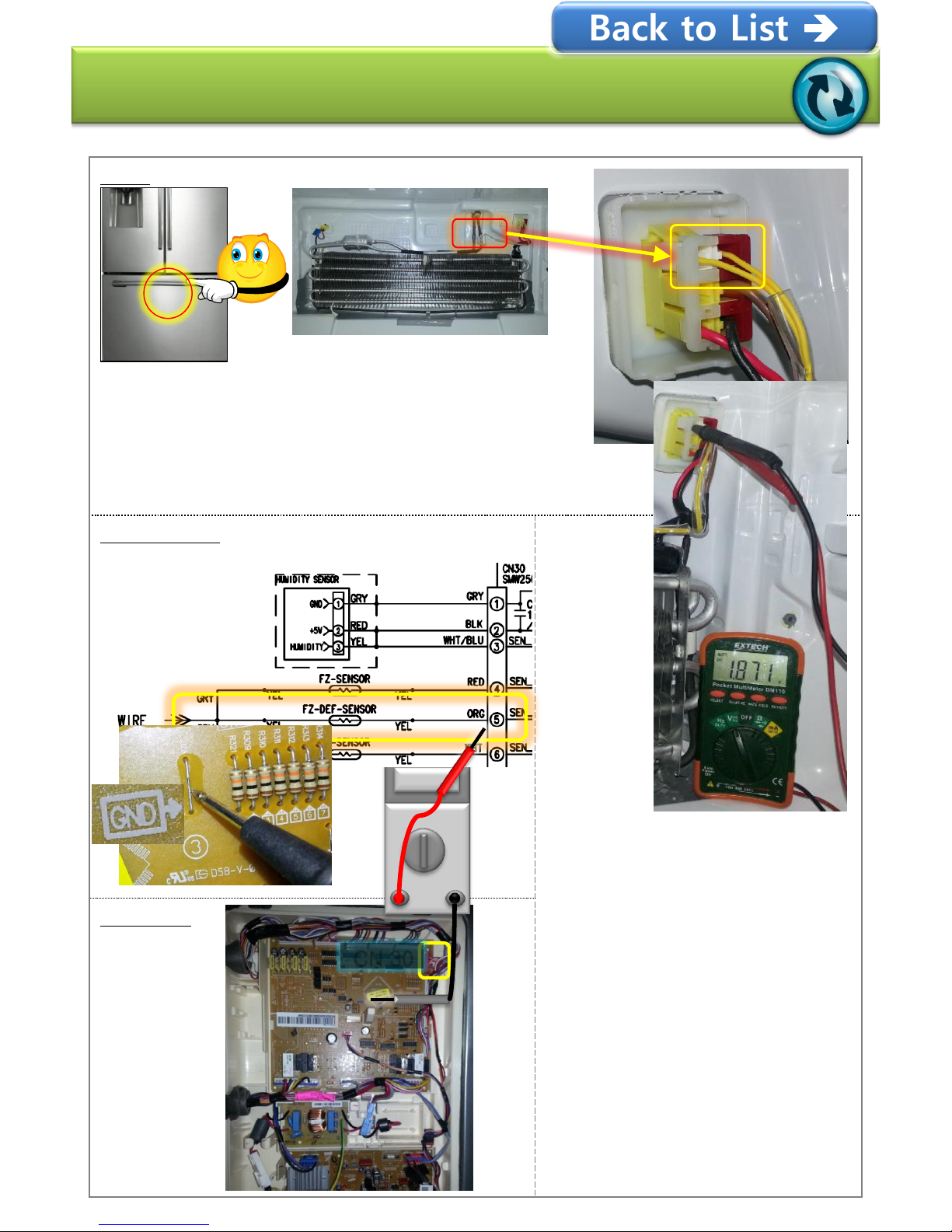

Error-code : 4 E

FZ-Defrost Sensor Error

Block

① After disassemble the EVAP COVER and inspect

Wire Open

② Measure the Liner CONNECTOR DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑ Inspect the bottom WIRE

CONNECTOR

① Inspect the Main PBA CN30

No.5(ORG)+

PBA “GND” marked area

and DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 30

Back to List

- 18/65 -

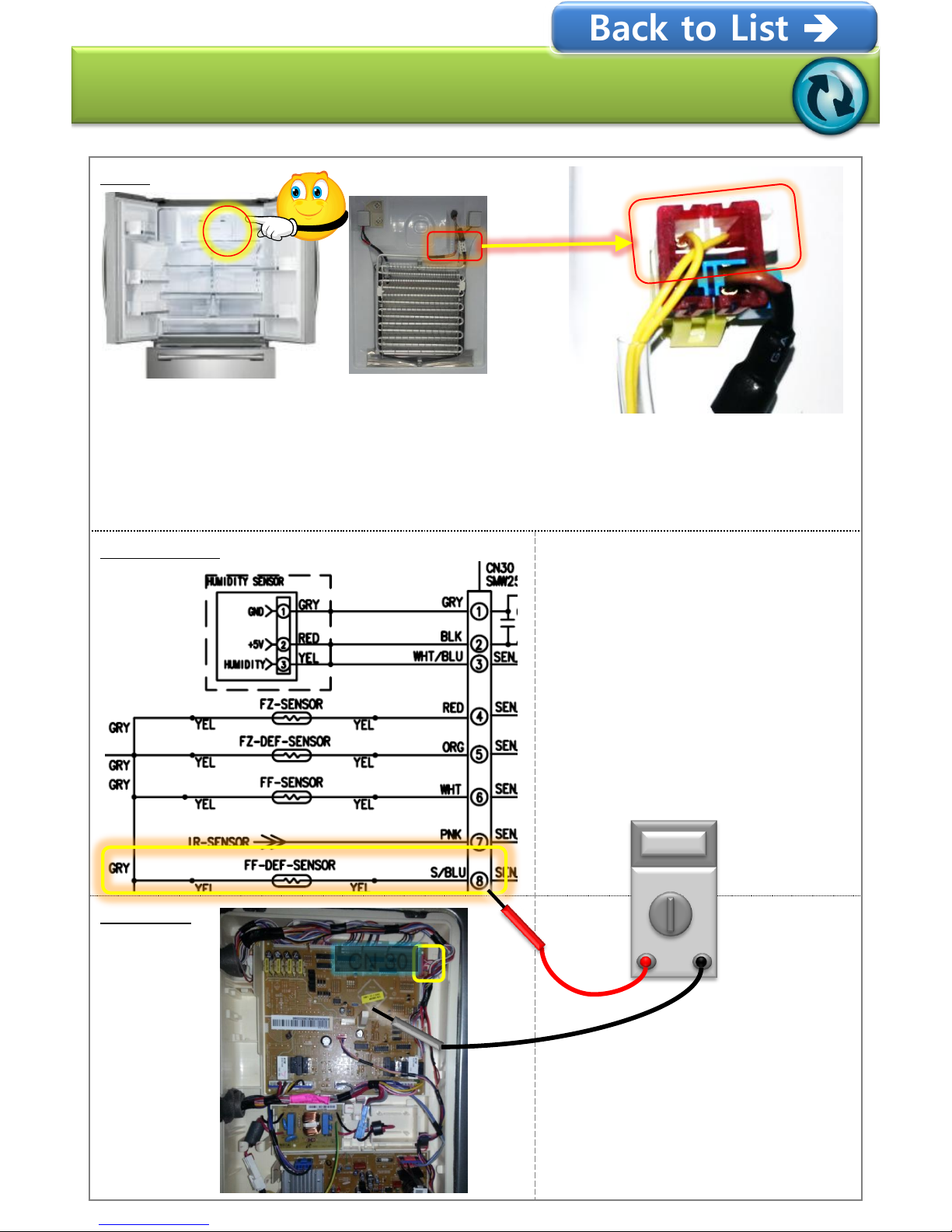

Error-code : 5 E

FF-Defrost Sensor Error

Block

① Disassemble the FF-Room EVAP COVER

② Inspect the YELLOW CONNECTOR(2-WIRE) Open

③ Measure the Main PBA DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑ Inspect the bottom WIRE

CONNECTOR

① Inspect the Main PBA CN30

No.8(S/BLU)

+ PBA “GND” marked area

and DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 30

Back to List

- 19/65 -

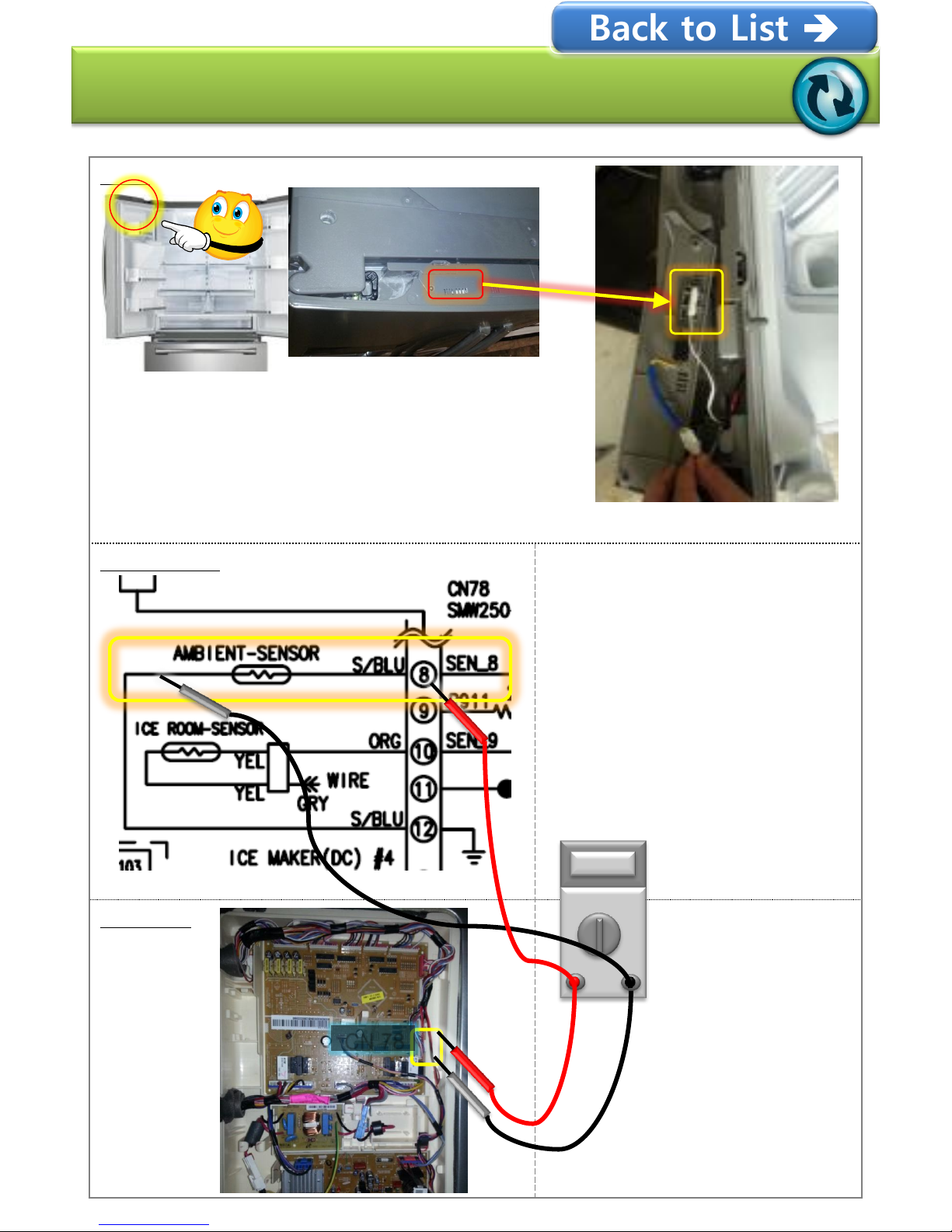

Error-code : 6 E

Ambient- Sensor Error

Block

① Disassemble the FF-DOOR L UPP COVER

② Inspect the WHITE WIRE Open

③ Measure the Main PBA DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Inspect the bottom WIRE

CONNECTOR

① Inspect the Main PBA CN78

No.8(S/BLU)

+ No.12(S/BLU)

DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 78

Back to List

- 20/65 -

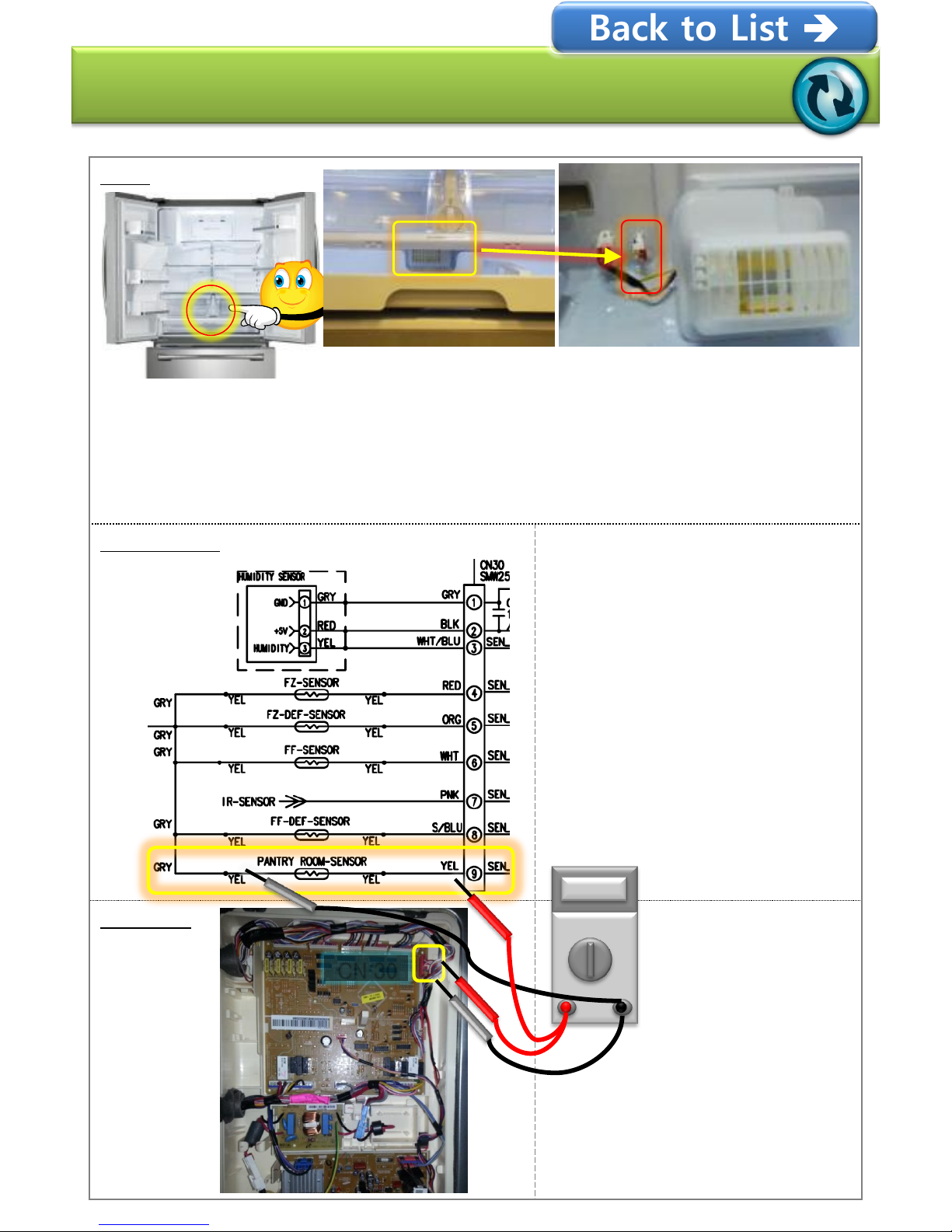

Error-code : 7 E

Pantry Sensor Error

Block

① Disassemble the VEG BOX and Pantry

② Inspect the Yellow 2-WIRE CONNECTOR

③ Measure the Main PBA DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑ Inspect the bottom WIRE

CONNECTOR

① Inspect the Main PBA CN30

No.9(YEL)+

PBA “GND” marked area

and DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

② Inspect the same Liner part

CONNECTOR

DC voltage measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

Main PBA

CN 30

Back to List

- 21/65 -

Error-code : 8 E

Ice Maker(FZ) Sensor Error

Block

① Disassemble the BOX

② Inspect the Ice Maker Bottom Sensor /

Wire OPEN

③ Measure Main PBA CN90 No.8+No.9 DC voltage

- Normal : DC 1.2V(100℉) ~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑ Inspect the bottom WIRE

CONNECTOR

① Inspect Main PBA CN90

No.8(WHT)+

No.9(RED) DC voltage

measuring

- Normal : DC 1.2V(100℉)

~ 4.0V(-13℉)

- Failure : DC 1.3V ↓,4V↑

② Inspect Liner part

CONNECTOR No.5+CN90

No.9(RED)

Liner part CONNECTOR

No.6+CN90 No.8(WHT)

WIRE OPEN

Main PBA

CN 90

Back to List

Loading...

Loading...