Samsung MXD-K050AN, MXD-X000AN, MXD-K100AN, MXD-K075AN Installation Manual

Air Conditioner

Air Handling Unit

Application Kit

MXD-K025AN

MXD-K050AN

MXD-K075AN

MXD-K100AN

MXD-X000AN

installation manual

imagine the possibilities

Thank you for purchasing this Samsung product.

EN

DB68-03711A-04

Contents

SAFETY INFORMATION

EXTERNAL APPEARANCE

• External Appearance

ACCESSORIES

• Accessories

.....................................

...........................................

BEFORE INSTALLATION

• AHU-KIT Structure Diagram

• Recommended AHU Size

INSTALLATION

• Control-KIT Installation ...................... 8

• Control-KIT Function ......................... 9

• Control-KIT Circuit Diagram .............. 10

• External Controller Diagram .............. 11

• Simple BMS ...................................... 11

• Connecting the Power Terminal ........ 13

• Control-KIT Connections .................. 14

• Brazing the Pipe ................................ 14

• EEV-KIT Installation ........................... 15

• EVA IN/OUT Sensor Installation ......... 16

.....................................

...................

.............

...........................

...................

................

...................

3

5

5

FUNCTION SETTING

• Setting an indoor unit address and

installation option .............................. 19

TROUBLESHOOTING

6

6

7

7

7

• Initial Check-up ................................. 28

• EEPROM Error .................................. 28

• Sensor Error ..................................... 29

• Fan Error ........................................... 31

• How to Inspect Just in Case

the Below Condition is Satisfied ......... 32

• In-tracking Error ................................ 33

8

AFTER INSTALLATION

• AHU-KIT Installation Check ............... 35

• Test Operation .................................. 36

.........................

.......................

......................

19

28

35

2

SAFETY INFORMATION

The following safety precautions must be taken when installing the unit.

Be aware that AHU-KIT has to be combined with DVM S Series outdoor unit only.

Use R410A refrigerant.

When using R410A, moisture or foreign substances may affect the capacity and reliability of the product.

Safety precautions must be taken when installing the refrigerant pipe.

R410A is a quasi-azeotrope of two refrigerants. Make sure to charge liquid one when adding refrigerant.

(If you charge gaseous refrigerant, it may affect the capacity and reliability of the product as a result of

change in formation of the refrigerant.)

WARNING CAUTION

Risk of death or serious personal injury. Potential risk of personal injury or material

damage.

CAUTION

Turn off the power before installation,

service, and cleaning.

Install the outdoor unit correctly according

to the installation manual.

An incorrect installation may cause a water

leakage, electric shock or fire and so on.

Use only rated parts and tools.

If you don’t use the rated parts and tools, it can

cause trouble with the product and bring about

injury.

Use the pipe or flare part for R410A

refrigerant only.

If the power cable or cord is damaged, the

manufacturer, a qualified service technician

must replace it to avoid a potential risk.

The installation must be done by the

manufacturer or its service agent or a

similar qualified person in order to avoid a

hazard.

Installation by an unqualified person may cause a

water leakage, electric shock or fire .

Manufacturer is not responsible for

accidents due to incorrect installation by

unqualified person.

When adding the refrigerant, use the

R410A refrigerant only.

If any gas or impurities except R410A refrigerant

come into the refrigerant pipe, serious problem

may occur and it may cause injury.

When there were leakage during installation,

you must ventilate the area.

Toxic gas may generate when refrigerant gas

contacts with fire.

The electric work must be done by service

agent or similarly qualified persons

according to national wiring regulations

and use only rated cable.

If the capacity of the power cable is insufficient or

electric work is not properly completed, electric

shock or fire may occur.

Arrange the cables between the AHU-KIT

and outdoor unit after connecting.

Attach the cover securely so that the

electrical component box cover does not

get loosen.

If the cover is attached incompletely, it can cause

trouble with a heat generation, electric shock or

fire of the terminal board.

Install designated ELB for AHU when

installing the power cable.

If you do not install designated ELB for AHU,

electric shock or fire may occur.

3

SAFETY INFORMATION (Continued)

CAUTION

Install the cables with supplied cables

firmly. Fix them securely so that external

force is not exerted to the terminal board.

If the connection or fixing is incomplete, it can

cause trouble with a heat generation, electric

Make sure that the power for AHU-KIT

is under maximum, and over minimum

voltage allowed.

It may cause electrical component malfunction

which can damage the product.

shock or fire.

Use the copper wire for the power cable

and use only rated cables and parts.

Make sure electrical circuit is correctly

connected.

Overheating may cause fire.

Make sure there is no leakage after installation.

Toxic gas may generate when refrigerant gas contacts with fire.

WARNING

Make sure of a earthing.

Do not connect the earth wire to the gas pipe,

water pipe, lighting rod or telephone wire.

If earthing is incomplete, electric shock or fire

may occur.

Follow the instructions in this manual

to make sure that the condensed water

dripping from the drain hose runs out

properly and insulate the drain pipe so

that dew condensate does not generate.

Household goods may get wet if the drain pipe

is not properly installed.

Install the power cable and communication cable of the AHU-KIT at least 1m away from

electric appliances.

Noise may heard depending on the electric wave though the cables are installed away from electric

appliances.

Keep the space in front of AHU-KIT for maintenance.

Do not install the AHU-KIT in following places.

The place where there is mineral oil or arsenic acid.

- There is a chance that parts may get damaged due to burned resin.

The place where corrosive gas such as sulfurous acid gas generates from the vent pipe or air outlet.

- The copper pipe or connection pipe may corrode and refrigerant may leak.

The place where there is a machine that generates electromagnetic waves.

- The air conditioner may not operate normally due to control system.

The place where there is a danger of existing combustible gas, thinner or gasoline is handled.

- The place where carbon fiber or flammable dust is.

The place where like spa and shore.

The place with direct contact of sunlight, rain, outdoor humidity, dust and temperature.

The manufacturer is not responsible for the damage occurred by not keeping standard of the installation.

4

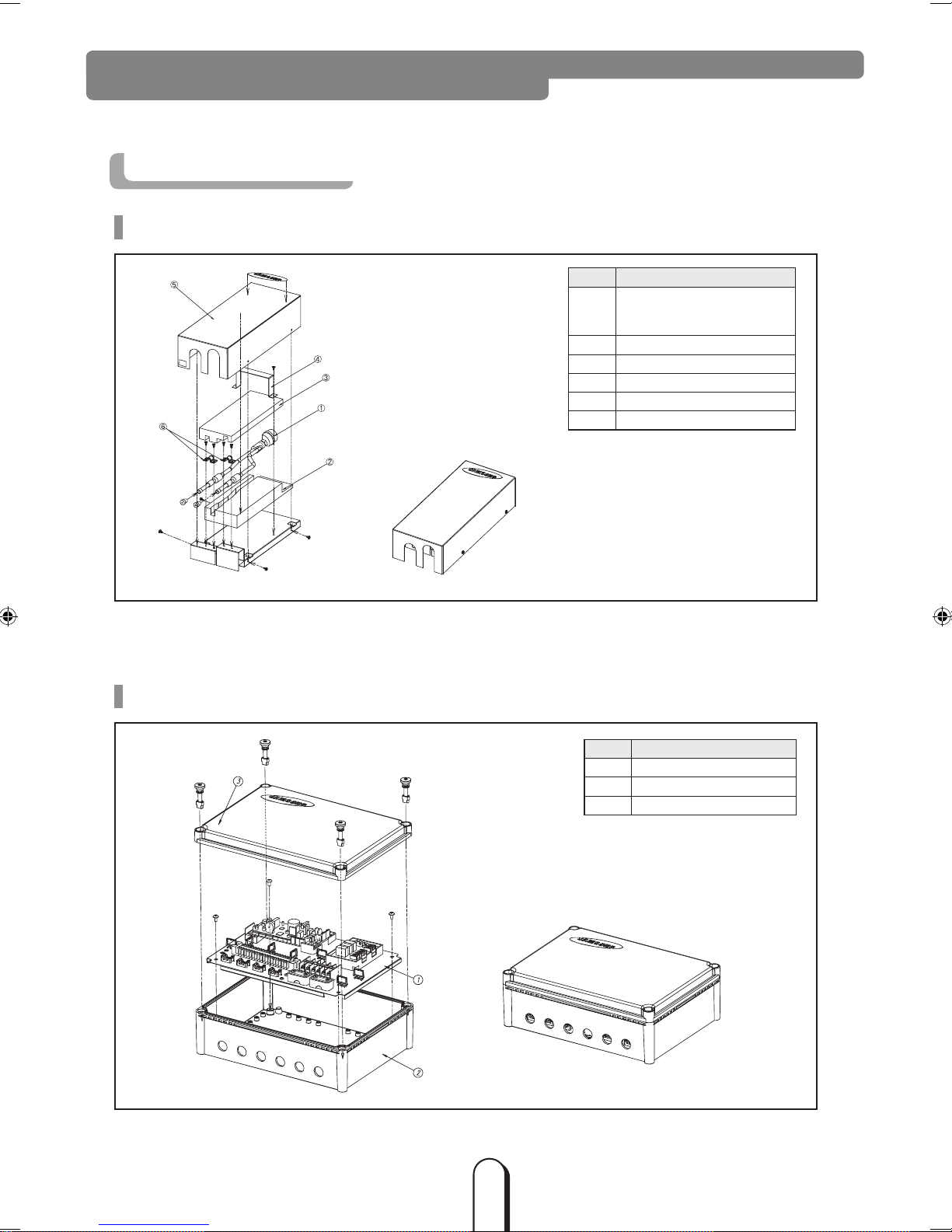

EXTERNAL APPEARANCE

External Appearance

EEV-KIT

No. Parts and components

1

(Coil wire : 2.5/5.0 HP = 2 m

2 Lower insulation

3 Upper insulation

4 Holder

5 Cover

6 Clamp

EEV body

7.5/10.0 HP = 7 m)

EEV -Kit is not included in the Model "MXD-X000AN".

Control-KIT

No. Parts and components

1 Controller board

2 Case

3 Cover

5

110㎜

85㎜

110㎜

85㎜

170㎜

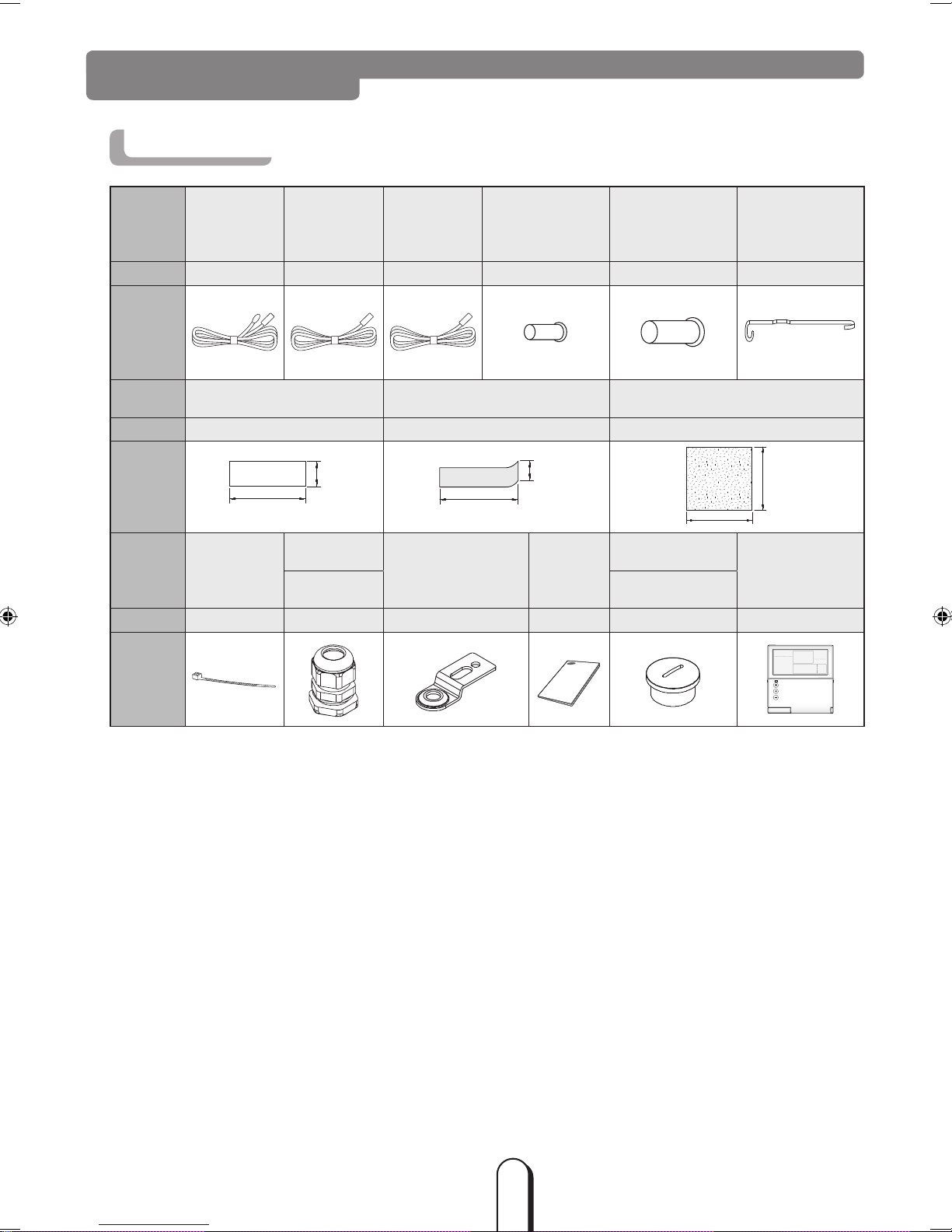

ACCESSORIES

Accessories

ITEM

QUANTITY 1 1 1 1 1 2

IMAGE

ITEM Aluminum tape Rubber tape Insulator

QUANTITY 4 2 2

IMAGE

ITEM Cable-tie

QUANTITY

Room/EVA IN

sensor

(10 m)

8 6 4 1 2

EVA OUT

sensor

(10 m)

Cable-nut

G

16 PG16

P

sch. sensor

Di

(10 m)

Bracket Base

EVA IN sensor holder

(OD Ø 6.8 mm)

Installation

Manual

A OUT sensor

EV

holder

(OD Ø 7.8 mm)

c

rew plug

S

e

nsor clip

S

100㎜

Wired Remote

Controller

(optional)

1

IMAGE

The Room/EVA IN/EVA OUT/Disch. sensors & Cable-nuts are not included in the Model “MXD-X000AN”.

6

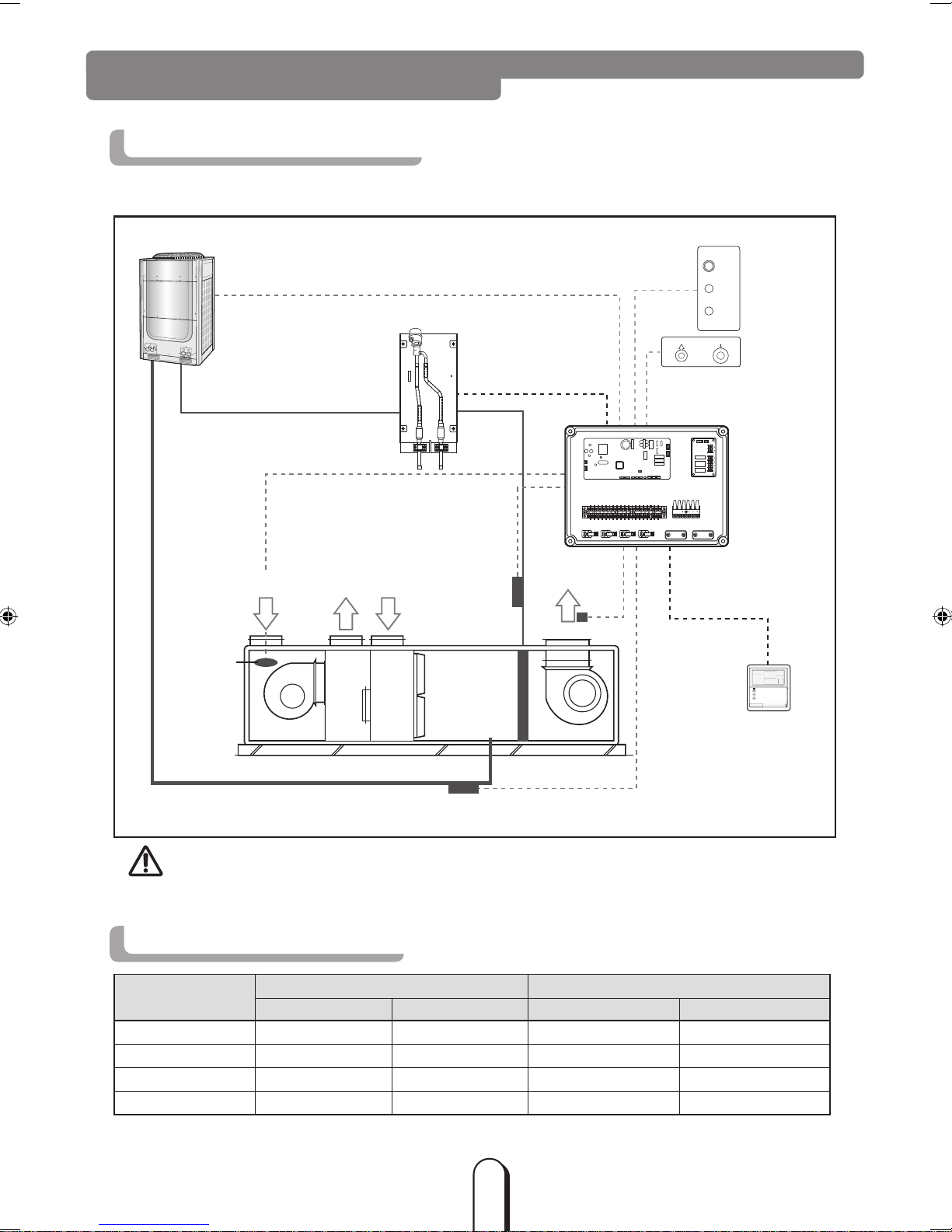

BEFORE INSTALLATION

AHU-KIT Structure Diagram

This Diagram is the example of VRF System with AHU Kit (MXD-K025/050/075/100AN).

Outdoor Unit

Communication F1, F2

EEV Kit

EEV Control

Liquid pipe

External Controller

(field supply)

POWER-OFF

COOLING HEATING

Simple BMS

(field supply)

1(L) 1(N)

ON/OFF SWITCH

OPERATION LAMP

ERROR LAMP

23℃

24℃

22℃

25℃

21℃

26℃

20℃

27℃

19℃

28℃

18℃

3

8NC

8NC

1

RY75 RY76 RY77

Fresh AirReturn Air Exhaust Air

EVA IN

Supply Air

Sensor

Disch. sensor(optional)

Room Sensor

Remote Controller

Gas pipe

EVA OUT

Sensor

• When the controllers (External Controller, simple BMS, Remote Controller) are installed simultaneously,

AHU-KIT doesn’t have the priority of control and operates according to the final signal.

(SIMPLE BMS may indicate the different condition of AHU, if AHU was controlled by other controller finally.)

Recommended AHU Size

Model

AHU Capacity (㎾)

Min Max Min Max

MXD-K025AN 6.3 8.8 1200 2000

MXD-K050AN 12.6 17.5 2400 4000

MXD-K075AN 18.9 24.9 4100 6000

MXD-K100AN 25.2 35.0 6100 8000

Heat Exchanger Volume (㎤)

(optional)

※Evaporating Temperature : 7˚C, Superheat : 1˚C, Air temperature : 27 ˚CDB/19 ˚CWB

7

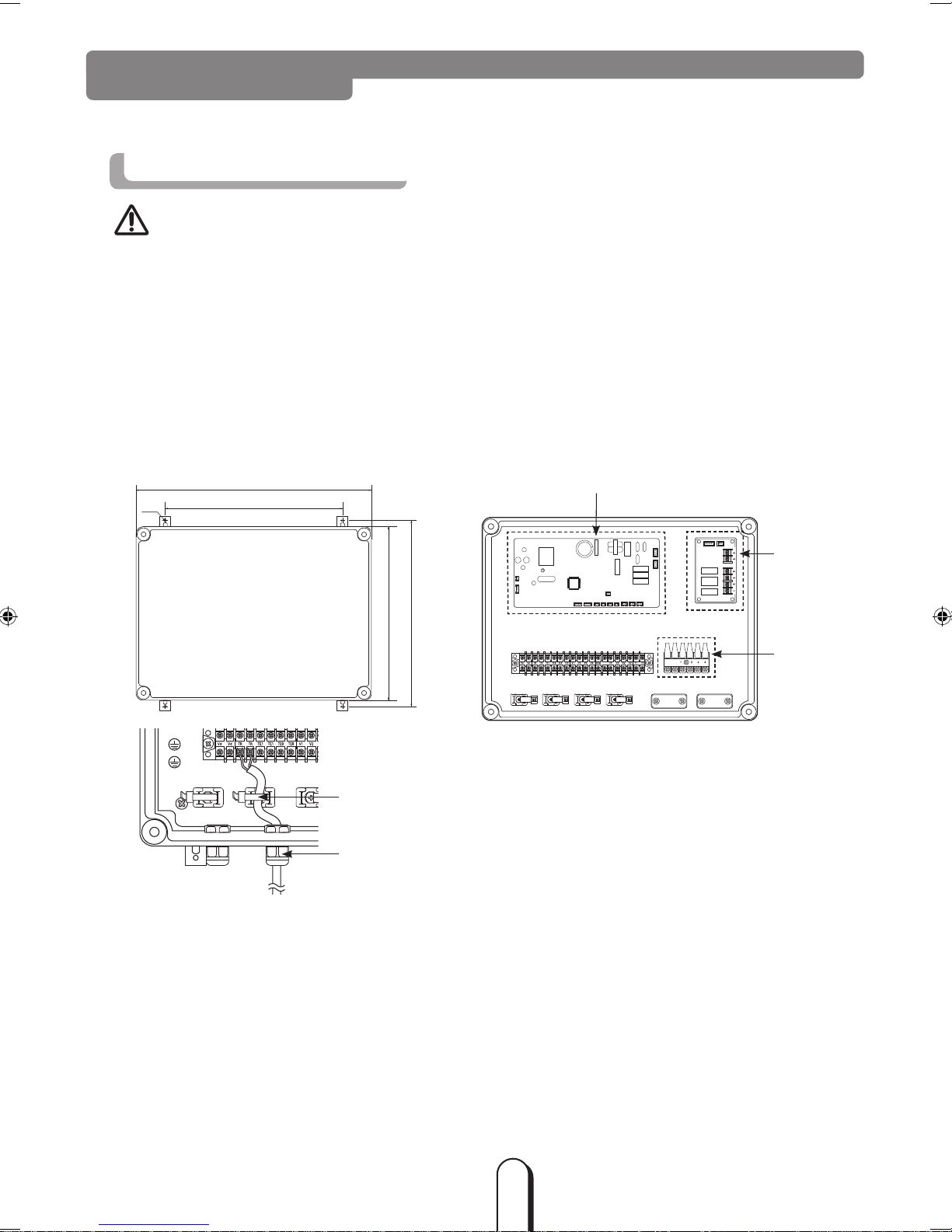

INSTALLATION

1 2 3 4 1 2 3 4 1 2 3 4

Control-KIT Installation

• Make sure that Control-KIT should be installed within short distance from the EEV-KIT.

- Supplied sensor in the Accessory box is 10 m.

- 2.5/5.0HP EEV wire is 2 m

- 7.5/10.0HP EEV wire is 7 m

• Close the box with the cover and cable-nut securely so that Control-KIT is fireproofed.

• Avoid installing the unit in a location exposed to direct sunlight or rain.

1) Drill 4 holes on the correct position of the wall and fix the Control-KIT securely.

(refer to the dimension of figure below.)

2) Open the box and connect the cables according to the diagram.

( Wires should be pulled through the Cable-nut, before connecting to the terminal.

Refer to the figure below.)

3) Fix the cable firmly with Cable-tie after connecting.

4) Close the box.

ø4.5

380

286

(Unit : mm)

Main PBA

3

8NC

8NC

1

RY75 RY76 RY77

External Controller

(MIM-B14)

Cable-tie

Cable-nut

280

300

1(L) 1(N)

Terminal Block

8

INSTALLATION (Continued)

Control-KIT Function

• Control-KIT uses EEV to control the amount of refrigerant flow and controls the system through outdoor unit and

wired remote controller.

• Control-KIT outputs the contact signal for AHU fan operation.

Terminal block 1, 2 (Refer to page 10) outputs the AHU fan ON contact signal 220 - 240 V(208 - 230 V for US) for

AHU when operating in Cool/Heat/Fan mode. This contact signal output can not be used as power supply for the

motor.

• Terminal block 3, 4 (Refer to page 10) is for AHU-KIT control to receive the fan operation status. This input signal

should be simple OPEN/SHORT signal without any extra voltage.

- Normal fan operation : Terminal block 3, 4 is in SHORT.

- Fan is not in operation : Terminal block 3, 4 is in OPEN.

- To use fan feedback to protect your system, set the 05 series installation option SEG21(Refer to page 26) to “1”.

• Connect 220 - 240 V, 50 / 60 Hz (208 - 230 V, 60 Hz for US) to terminal block 1(L)/2(N).

• You should connect outdoor unit communication cable to communication line (F1, F2)(Refer to page 10).

• F3, F4(Refer to page 10) is communication line for wired remote controller(12 V).

9

INSTALLATION (Continued)

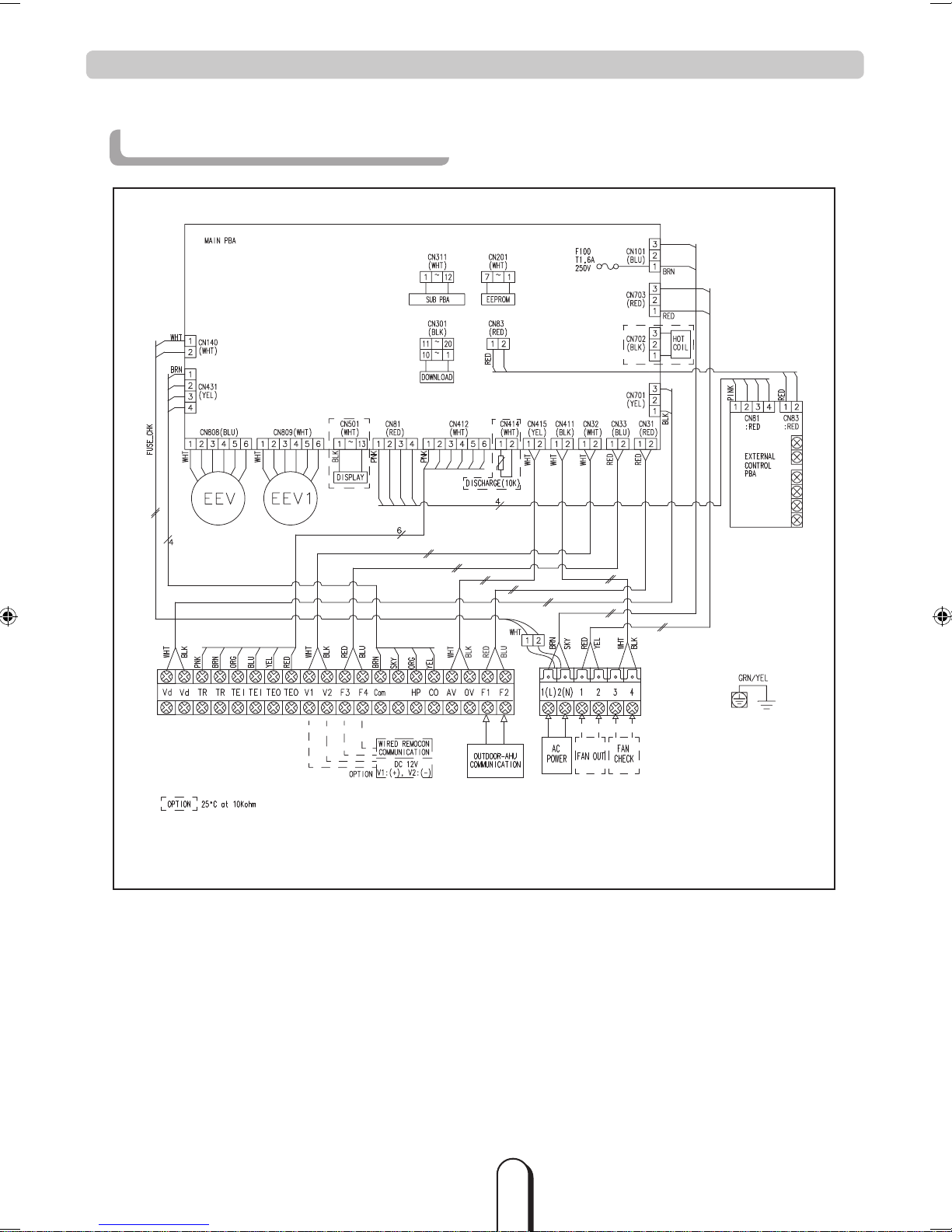

Control-KIT Circuit Diagram

AHU-KIT sensor has approximately 10㏀ of resistance value at indoor temperature of 25˚C.

10

INSTALLATION (Continued)

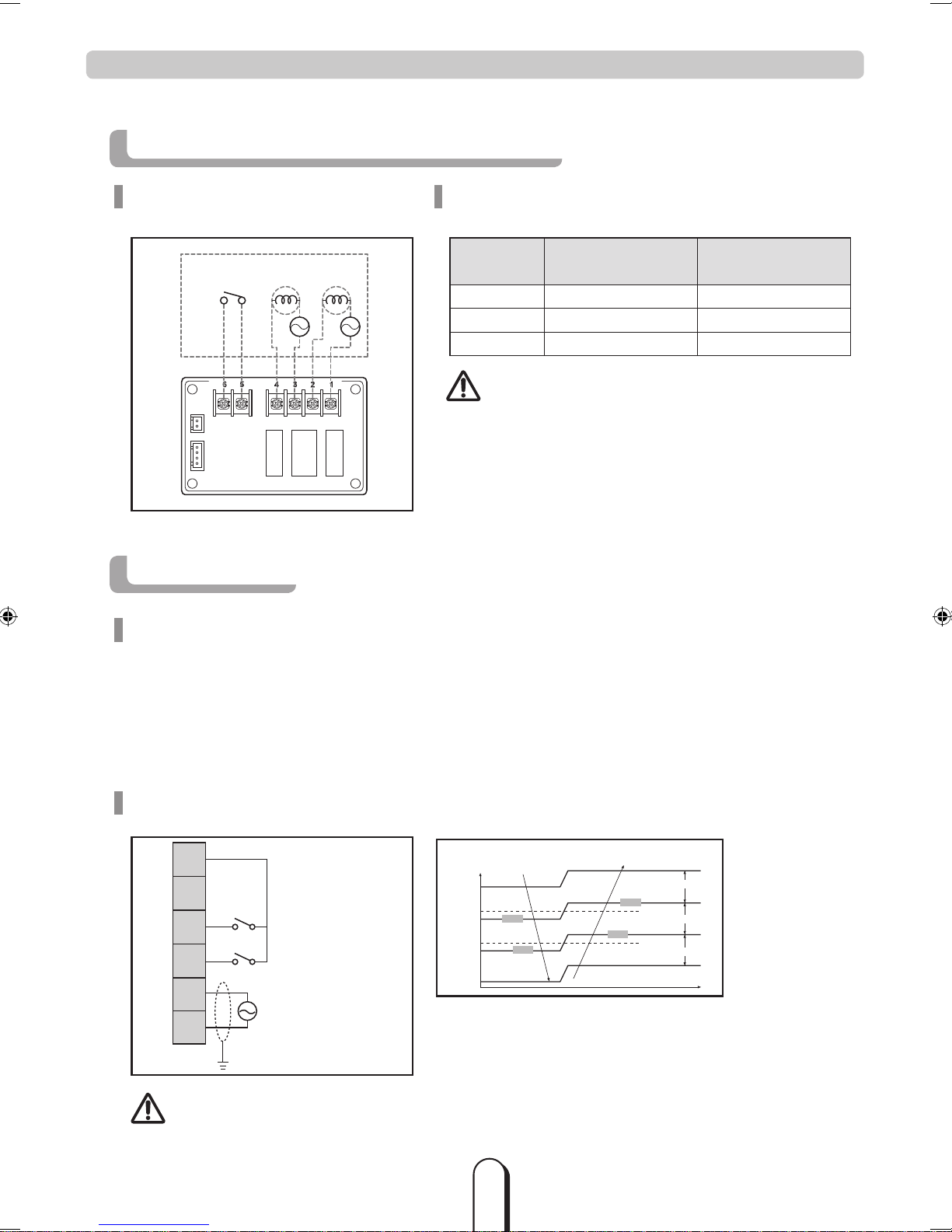

External Controller Diagram (MIM-B14)

Circuit diagram of external

controller’s output

S/W

38NC

18NC

GND

AC LAMP

RY75 RY76 RY77

Simple BMS

Simple BMS setting

Operation specification according to

AHU-KIT PBA Install option set up

WIRE NO. Signal Install option

1, 2 Error check output -

3, 4 Operation check output SEG 15

5, 6 ON/OFF input SEG 14

•

In order for AHU-KIT to be controlled by External control,

change a digit of indoor unit installation option,

set the SEG14 as “1”. (ON / OFF control)

• Simple BMS can control Room temperature or Discharge temperature by setting SEG17 of 5 series Installation option.

- For controlling Room temperature : SEG17 of 5 series Installation option → 0

- For controlling Discharge temperature : SEG17 of 5 series Installation option → 1

• Discharge temperature can be set by DMS.

• Simple BMS control is not influenced by DMS’s restrictions on operation mode, set temperature or remote controller usage.

• If you want to set Room temperature or Discharge temperature by using Simple BMS, setting Buzzer control option as

“Disuse buzzer” is recommended.

Circuit diagram of Simple BMS

COM

HP

CO

AV

OV

Shielding

• Hysteresis is applied to the end of voltage range in order to stabilize the analog input.

The amount of Hysteresis

- Room temperature setting: 0.15 V

- Discharge temperature setting: 0.08 V

Ex) setting up 22℃(Simple BMS : Room temperature setting)

[Voltage]

decreasing temperature

4.8V

4.6V

4.4V

4.65V

4.25V

increasing temperature

The areas of 23℃

4.95V

The areas of 22℃

4.55V

The areas of 21℃

11

INSTALLATION (Continued)

Operational Voltage range against Setting temperature

Room temperature setting Discharge temperature setting

Simple BMS

Voltage Range

Set Temperature

Heating Cooling

10.0 V ~ 9.6 V 30 ˚C 30 ˚C

9.6 V ~ 9.2 V 30 ˚C 30 ˚C

9.2 V ~ 8.8 V 30 ˚C 30 ˚C

8.8 V ~ 8.4 V 30 ˚C 30 ˚C

8.4 V ~ 8.0 V 30 ˚C 30 ˚C

8.0 V ~ 7.6 V 30 ˚C 30 ˚C

7.6 V ~ 7.2 V 29 ˚C 29 ˚C

7.2 V ~ 6.8 V 28 ˚C 28 ˚C

6.8 V ~ 6.4 V 27 ˚C 27 ˚C

6.4 V ~ 6.0 V 26 ˚C 26 ˚C

6.0 V ~ 5.6 V 25 ˚C 25 ˚C

5.6 V ~ 5.2 V 24 ˚C 24 ˚C

5.2 V ~ 4.8 V 23 ˚C 23 ˚C

4.8 V ~ 4.4 V 22 ˚C 22 ˚C

4.4 V ~ 4.0 V 21 ˚C 21 ˚C

4.0 V ~ 3.6 V 20 ˚C 20 ˚C

3.6 V ~ 3.2 V 19 ˚C 19 ˚C

3.2 V ~ 2.8 V 18 ˚C 18 ˚C

2.8 V ~ 2.4 V 18 ˚C 18 ˚C

2.4 V ~ 2.0 V 18 ˚C 18 ˚C

2.0 V ~ 1.6 V 18 ˚C 18 ˚C

1.6 V ~ 1.2 V 18 ˚C 18 ˚C

1.2 V ~ 0.8 V 18 ˚C 18 ˚C

0.8 V ~ 0.4 V 18 ˚C 18 ˚C

0.4 V ~ 0.0 V 18 ˚C 18 ˚C

Setting the temperature

Simple BMS

Voltage Range

10.00 V ~ 9.75 V 43 ˚C 43 ˚C

9.75 V ~ 9.50 V 42 ˚C 42 ˚C

9.50 V ~ 9.25 V 41 ˚C 41 ˚C

9.25 V~ 9.00 V 40 ˚C 40 ˚C

9.00 V ~ 8.75 V 39 ˚C 39 ˚C

8.75 V ~ 8.50 V 38 ˚C 38 ˚C

8.5 V ~ 8.25 V 37 ˚C 37 ˚C

8.25 V ~ 8.00 V 36 ˚C 36 ˚C

8.00 V ~ 7.75 V 35 ˚C 35 ˚C

7.75 V ~ 7.50 V 34 ˚C 34 ˚C

7.50 V ~ 7.25 V 33 ˚C 33 ˚C

7.25 V ~ 7.00 V 32 ˚C 32 ˚C

7.00 V ~ 6.75 V 31 ˚C 31 ˚C

6.75 V ~ 6.50 V 30 ˚C 30 ˚C

6.50 V ~ 6.25 V 29 ˚C 29 ˚C

6.25 V ~ 6.00 V 28 ˚C 28 ˚C

6.00 V ~ 5.75 V 27 ˚C 27 ˚C

5.75 V ~ 5.50 V 26 ˚C 26 ˚C

5.50 V ~ 5.25 V 25 ˚C 25 ˚C

5.25 V ~ 5.00 V 24 ˚C 24 ˚C

• Range of Discharge temperature setting

the contr

Set Temperature

Heating

Cooling

- Cooling : 8 ~ 25 ˚C

- Heating : 18 ~ 43 ˚C

- If the voltage value is beyond the range of discharge temperature

setting, the temperature is controlled by maximum/minimum

value which meets the setting range.

(Ex : The voltage value of cooling discharge temperture 30 ˚C →

olled value : 25 ˚C)

Simple BMS

Voltage Range

Set Temperature

Heating

Cooling

5.00 V ~ 4.75 V 23 ˚C 23 ˚C

4.75 V ~ 4.50 V 22 ˚C 22 ˚C

4.50 V ~ 4.25 V 21 ˚C 21 ˚C

4.25 V ~ 4.00 V 20 ˚C 20 ˚C

4.00 V ~ 3.75 V 19 ˚C 19 ˚C

3.75 V ~ 3.50 V 18 ˚C 18 ˚C

3.50 V ~ 3.25 V 17 ˚C 17 ˚C

3.25 V ~ 3.00 V 16 ˚C 16 ˚C

3.00 V ~ 2.75 V 15 ˚C 15 ˚C

2.75 V ~ 2.50 V 14 ˚C 14 ˚C

2.50 V ~ 2.25 V 13 ˚C 13 ˚C

2.25 V ~ 2.00 V 12 ˚C 12 ˚C

2.00 V ~ 1.75 V 11 ˚C 11 ˚C

1.75 V ~ 1.50 V 10 ˚C 10 ˚C

1.50 V ~ 1.25 V 9 ˚C 9 ˚C

1.25 V ~ 1.00 V 8 ˚C 8 ˚C

1.00 V ~ 0.75 V 8 ˚C 8 ˚C

0.75 V ~ 0.50 V 8 ˚C 8 ˚C

0.50 V ~ 0.25 V 8 ˚C 8 ˚C

0.25 V ~ 0.00 V 8 ˚C 8 ˚C

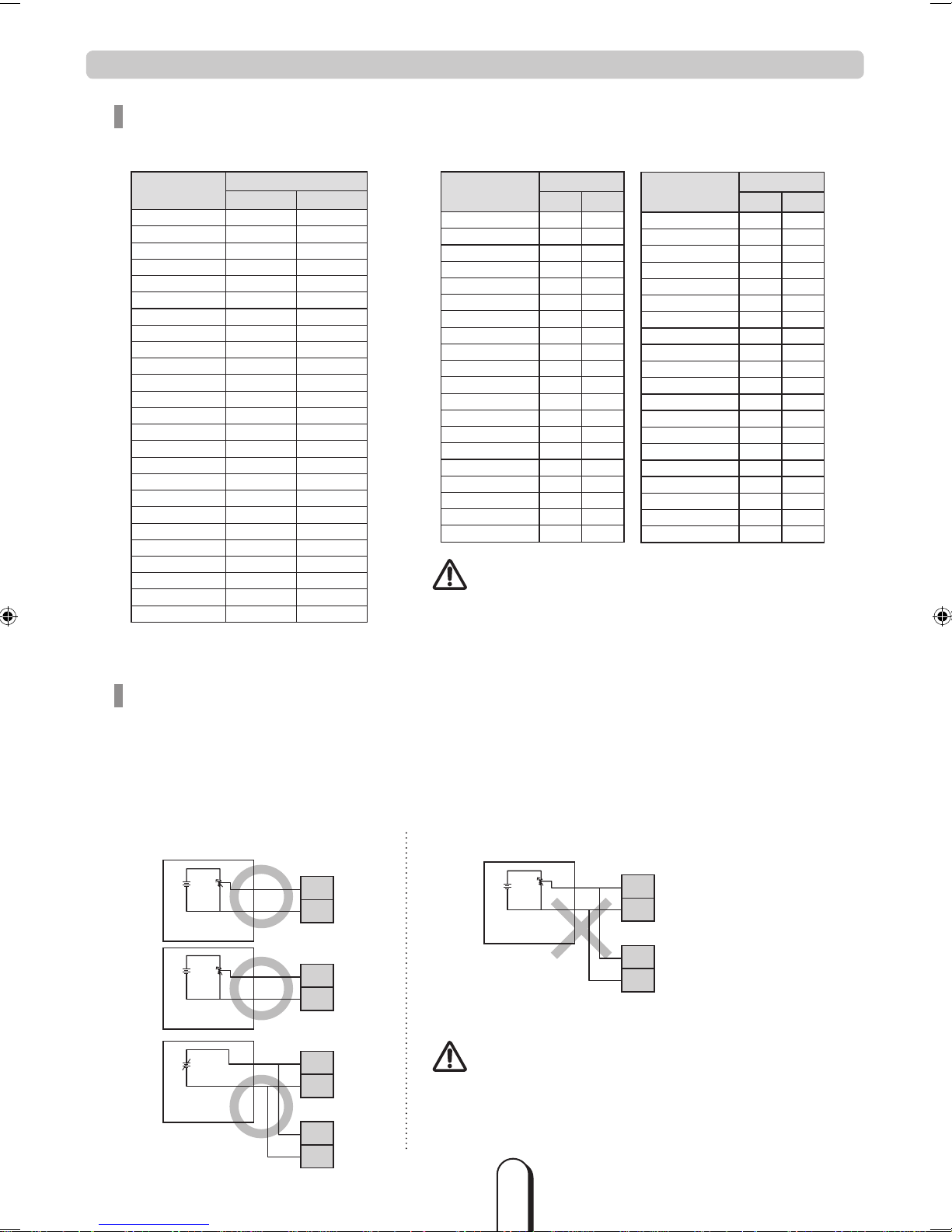

• Keep the power supply of Simple BMS in 10 V ± 0.2 V.

• If the Simple BMS uses variable resistor(VR), make the electric resistance of VR under 1㏀.

• Simple BMS which uses variable resistor(VR) need to be connected to the AHU-KIT with 1:1 link.

• Use the Simple BMS which outputs voltage so that one Simple BMS controls several AHU-KIT at the

same time.

Available

DC10V

BMS_Temp.Set

DC10V

BMS_Temp.Set

DC0V ~

DC10V

BMS_Temp.Set

R1

+

V1

-

1K

R2

+

V2

-

1K

+

V1

-

AV

OV

AV

OV

AV

OV

AV

OV

Not Available

DC10V

BMS_Temp.Set

• Make sure that Simple BMS is connected to

DC power supply before installing.

Never connect Simple BMS to AC power supply .

R1

+

1K

V1

-

AV

OV

AV

OV

12

Loading...

Loading...