Samsung MOSCON-E7 User Manual

PREF ACE

Thank for purchasing small general-purpose

multi-functional inverter MOSCON-E7.

MOSCON-E7 is a small and easy to use inverter.

This user’s manual describes installation,

maintenance and inspection, troubleshooting and

specifications of the MOSCON-E7.

Read this user’s manual thoroughly for safe

operation of the system and retain for future

reference.

Samsung Electronics Co., Ltd.

Copyrightⓒ2001 Samsung Electronics Co., Ltd.

MOSCON-E7 is trademarks of Samsung Electronics Co., Ltd.

The software and hardware described i n this manu al is pro tected by the copyright.

No part of this manual may be photocopied or reproduced in part or in whole without the written

consent of Samsung Electronics Co., Ltd.

We will try our best to meet your demands with this manual.

Contact our office stated below in case of bei ng a printing erro r, mistakes and improvement in

this manual.

Contact Office : Samsung Electronics Co., Ltd.

416, Maetan-3 Dong, Paldal-Gu, Suwon City , Kyungki-Do, Korea

TEL : 82-31-200-2489

FAX : 82-31-200-2295

General precautions

• This manual may contain some drawings with the

cover or protective shields removed for more

detail and clear explanation of the device. Make

sure to reassemble the device before operation.

• The information in this manual may be subject to

change without a previous notice in case of

modification or improvement, or changes in

specifications. Such modifications are denoted

by a revised manual number.

• Contact your Samsung representative or the

nearest Samsung sales office to order a copy of

this manual if it has been damaged or lost.

• Samsung is not responsible for any modification

of the product made by the user, since that will

void your guarantee.

This user’s manual uses (Danger), (Caution) or (Note) for the

safety precautions depending on the degree of precautions.

Safety precautions

Installation

• Before starting wiring or inspection, switch power off, wait for

more than 1 minutes, and check for residual voltage between

terminal P/B and N with a meter etc, to avoid a hazard of

electrical shock..

• Do not remove the operator from the main body.

It may cause an electric shock.

• When using the digital operator away from the main body, use the

separated operator(E7OPTR-S).

• Suitable for use in a circuit capable of delivering not more than

5kA rms symmetrical amperes.

DANGER:

Wrong handling may cause a dangerous

situation, which can lead to death or a

severe injury.

!

CAUTION: Wrong handling may cause a dangerous

situation, which can lead to a severe

injury, slight injury, or damage to the

production, or faulty operation

.

!

DANGER

!

Safety precautions

• Do not carry the inverter by holding the plastic parts, but hold the

heatsink.

The heat sink may fall and cause injury.

• Use nonflammable materials such as metal for the part where the

inverter is installed.

• When installing several inverters in a single enclosed space, install

a cooling fan to keep the ambient temperature below 45℃

• Cover the inverter during installation to protect it from metal

chip coming from drilling.

Wiring

• Always turn OFF the input power supply before wiring.

Otherwise, an electric shock or fire may occur.

• Wiring must be performed by qualified personnel.

• Always check if the bolts on the main circuit and control circuit

terminals are properly tightened.

• Turn ON the inverter only after completely assembling the covers.

Do not detach the cover when the power is ON.

Otherwise, an electric shock or fire may occur.

• Ground the ground terminal (200V & 400V class: ground to 100Ω

or less).

Otherwise, an electric shock or fire may occur.

CAUTION

!

DANGER

!

MOSCON E-7 User’s Manual

• Tighten all terminal screws of the main circuit and the control

circuit.

• Check if the voltage of the inverter rated voltage satisfies with the

AC power supply voltage.

Otherwise, it may cause fire or injury

• Do not perform withstand voltage test on the inverter. It may

damage the semi-conductor element.

• When wiring other devices read their manuals carefully. Samsung

is not responsible for any accident resulting from user’s

carelessness.

If not, it may cause injury or fire.

• Do not connect electromagnetic switches or contactors to the

output circuits.

• Never connect an AC power supply to output terminals U/T1,

V/T2, and W/T3.

Otherwise, it may damage the internal circuits of the inverter.

• Never short or ground output terminals: the output terminals

should not be touched with bare hands and also, the output wires

should not have contact with the inverter case

Otherwise, an electric shock or grounding may occur

• Do not connect a phase advancing capacitor or LC/RC noise filter

to an output circuit.

Otherwise, it may damage the inverter or cause a fire.

• Do not connect an electromagnetic switch or MC to an output

circuit.

Otherwise, it will actuate the over current protective circuit in the

inverter.

• Do not disassemble the digital operator.

Otherwise, it may cause a personal injury.

CAUTION

!

Parameter setting

• Set the appropriate parameter. If not, it will not operate or trigger

the protection operation.

• Record the previous parameters (even though Moscon-E7 records

the information of the last parameter), the records can be useful

in case of malfunction or errors.

• When changing the parameters, make small change at a time

especially when controlling the motor parameter, changing the

V/f or max. output frequency. If not, it may damage the

inverter and motor.

CAUTION

!

Safety precautions

MOSCON E-7 User’s Manual

Maintenance and inspection

• Do not remove the digital operator from the unit since it carries

high voltages. Using the cable between operator and unit is also

prohibited, since it is very dangerous.

• Do not touch the terminals since some of them carry high

voltages and are extremely dangerous.

Otherwise, it may cause an electric shock.

• Do not remove the cover when power is being supplied to the

inverter. Always turn off the power to the inverter through the

MCCB when detaching the cover.

Otherwise, the charge remained in the capacitor may cause an

electric shock.

• After turning off the main circuit power supply, wait for a while

before maintenance or inspection since it may remain charged.

Otherwise, it may cause an electric shock.

• Maintenance, inspection, and replacement of parts must be done

only by authorized personnel.

Otherwise, it may result an injury or an accident.

• Remove all metal objects, such as watches and rings, before the

maintenance, inspection, and replacement of parts. Also, always

use grounded tools.

Otherwise, it may cause an electric shock.

• Always turn off the power supply before the inspection

Otherwise, it may cause an electric shock.

DANGER

!

Safety precautions

• Do not touch the COMOS IC in the control board directly.

Otherwise it can be damaged by static electricity.

• Do not change the wiring, or remove the digital operator or

connectors, during operation.

Otherwise, it may cause a personal injury.

CAUTION

!

MOSCON E-7 User’s Manual

Contents -1

Contents

1.Overview

---------------------------------------------------------------------------------------- 1-1

1.1 Main features ------------------------------------------------------------------------------------ 1-3

1.2 System diagram -------------------------------------------------- ---------------------------- 1-5

1.3 Dimensions ---------------------------------------------------------------------------------------- 1-6

1.4 Specifications ------------------------------------------------------------------------------------- 1-8

2. Installation ----------------------------------------------------------------------------------- 2-1

2.1 Receiving ---------------------------------------------------------- --------------------------------- 2-3

2.2 Nameplate information --------------------------------------------------------------- 2-4

2.3 Installation ---------------------------------------------------------------------------------------- 2-5

2.3.1 Precautions for delivery and installation ------------------------------------------------------- 2-5

2.3.2 Installation site --------------------------------------------------------------------------------------- 2-6

2.3.3 Controlling the ambient temperature -------------------------------------------------------- 2-7

2.3.4 Installation space ------------------------------------------------------------------------------------ 2-8

3. Wiring ---------------------------------------------------------------------------------------------- 3-1

3.1 Connection diagram --------------------------------------------------------------------- 3-4

3.2 Terminal block configuration

---------------------------------------------------- 3-6

3.3 Main circuit terminal functions ------------------------------------------------ 3-7

3.4 Control circuit terminal functions ------------------------------------------- 3-8

3.5 Connections to peripheral devices ------------------------------------------- 3-9

3.6 Wiring the main circuits -------------------------------------------------------------- 3-1 0

3.6.1 Wiring on the input side of main circuit ----------------------------------------------------- 3-10

3.6.1.1 Installing a molded-case circuit breaker --------------------------------------------------------- 3-10

3.6.1.2 Installing a magnetic contactor(MC) --------------------------------------------------------- ---------- 3-10

3.6.1.3 Installing an AC reactor/DC reactor ------------------------------------------------------------ 3-11

3.6.1.4 Connecting input power supply --------------------------------------------------------------------- 3-12

3.6.1.5 Installing a surge absorber ------------------------------------------------------------------------- 3-12

3.6.1.6 Installing a noise filter on power supply side --------------------------------------------------- 3-13

3.6.2 Wiring on the output side of main circuit --------------------------------------------------- 3-15

3.6.2.1 Precautions when wiring on the output side of main circuit ----- -------------------------- 3-15

3.6.2.2 Connecting the inverter and motor -------------------------------------------------------------- 3-15

3.6.2.3 Installing a noise filter on the output side ------------------------------------------------------- 3-15

2 - MOSCON-E7 U ser’s Manual

3.6.3 Dealing with inductive noises ------------------------------------------------------------------- 3-16

3.6.4 Dealing with radio interference (RFI) -------------------------------------------------------- 3-16

3.6.5 Cable length between inver ter and motor ---------------------------------------------------- 3-17

3.7 Precautions when wiring -------------------------------------------------------------- 3-18

3.7.1 Control circuit wiring precautions -------------------------------------------------------------- 3-18

3.7.2 Main circuit input/output wiring --------------------------------------------------------------- 3-18

3.8 Grounding ---------------------------------------------------------------------------------------- 3-20

3.9 Cable specification ---------------------------------------------------------------------------------- 3-21

3.10 Wiring check

------------------------------------------------------------------------------------ 3-22

4 Digital operator ------------------------------------------------------------------------- 4-1

4.1 Usage of digital operator -------------------------------------------------------------- 4-4

4.2 Monitoring functions of digital operator -------------------------------- 4-5

4.3 Test run ---------------------------------------------------------------------------------------------- 4-6

5 Parameters ------------------------------------------------------------------------------ 5-1

5.1 Main feature ------------------------------------------------------------------------------------- 5-3

5.1.1 U-parameter : monitoring function ------------------------------------------------------------- 5-4

5.1.2 Monitoring function setting ---------------------------------------------------------------------- 5-8

5.2 Terminal status LED --------------------------------------------------------------------- 5-9

5.3 B-Parameter -------------------------------------------------------------------------------- 5-10

5.3.1 Basic setup ---------------------------------------------------------------------------------------------- 5-10

5.3.1.1 Sel ecting the source of frequency command : B0.01 -------------------------------------------------- 5-10

5.3.1.2 Selecting the source of RUN command : B0.02 ------ ---------------------------------------------- 5-10

5.3.1.3 S electing stopping method : B0.03 ----------------------------------------------------------------- 5-11

5.3.1.4 Prohibiting the reverse rotation : B0.04 --------- ------------------------------------------------------ 5-11

5.3.1.5 Setting the motor direction : B0.05 ---------------------------------------------------------------- 5-12

5.3.1.6 Setting the monitor default : B0.06 ----------------------------------------------------------------- 5-12

5.3.1.7 Setting the automatic start operation : B0.07 ------------------------------------------------------- 5-12

5.3.2 System initialization ----------------------------- ---------------------------------------------------- 5-13

5.3.2.1 Controlling the inverter initialization : B1.01 ---------------------------------------------------------- 5-13

5.3.2.2 Setting and verifying the password : B1.02, B1.03 ---------------------------------------------- 5-14

5.3.3 Setting power capacity ------------------------------------------------------------------------5-14

5.3.3.1 Setting the inverter and motor capacity : B2.01, B2.02 ---------------------------------------- 5-14

5.4 F-Parameter -------------------------------------------------------------------------------------- 5-15

Contents -3

5.4.1 Frequency control functions --------------------------------------------------------------- 5-15

5.4.1.1 Setting the frequency/speed command: F0.01~F0.09 -------------------------------- 5-15

5.4.2 Frequency limit --------------------------------------------------------------------------------- 5-16

5.4.2.1 Setting lower/upper frequency limit : F1.01,F1.02 ------------------------------------- 5-16

5.4.3 Jump frequency to avoid mechanical resonant oscillation ---------------------- 5-16

5.4.3.1 Setting jump frequency : F1.03~F1.06 ---------------------------------------------------- 5-16

5.4.3.2 Selecting the jump mode : F1.07 ----------------------------------------------------------- 5-17

5.4.4 Frequency match detection ---------------------------------------------------------- 5-19

5.4.4.1 Controlling the frequency detection : F1.08. F1.09 --------------------------------------- 5-19

5.4.4.2 Automatic activation of 2nd accel/decel time : F1.10 ---------------------------------- 5-19

5.4.5 accel/decel time ----------------------------------------------------------------------------- 5-20

5.4.5.1 Setting the accel/decel time : F2.01~F2.04 ---------------------------------------------- 5-20

5.4.5.2 Setting the time unit of accel/decel time : F2.05 --------------------------------------- 5-20

5.4.6 Configuring S-curve time : F3.01 --------------------------------------------------- 5-21

5.5 S-Parameter ------------------------------------------------------------------------------ 5-22

5.5.1 DC braking ---------------------------------------------------------------------------- 5-22

5.5.1.1 Controlling DC breaking : S0.01~S0.04 ------------------------------------------------------ 5-22

5.5.2 Speed search ----------------------------------------------------------------------------------- 5-23

5.5.2.1 Controlling the speed search operation : S1.01 ------------------------------------------------ 5-23

5.5.2.2 Speed search level, current and deceleration time --------------------------------------- 5-23

5.5.3 Dwell operation -------------------------------------------------------------------------------- 5-25

5.5.3.1 Controlling the dwell operation : S2.01~S2.04 ----------------------------------------------- 5-25

5.5.4 Energy saving function ---------------------------------------------------------------------- 5-26

5.5.4.1 Setting the energ y saving level : S3.01 ------------------------------------------------------ 5-26

5.5.4.2 Setting the energy-saving frequency : S3.02 ----------------------------------------------- 5-26

5.5.5 Slip compensation ----------------------------------------------------------------------------- 5-27

5.5.5.1 Setting the slip compensation gain : S4.01 ------------------------------ ------------------ 5-27

5.5.5.2 Setting the slip compensation delay : S4.02 ----------------------------------------------- 5-27

5.5.5.3 Slip compensation limit : S4.03 -------------------------------------------------------------- 5-27

5.5.6 Automatic torque boost --------------------------------------------------------------------- 5-29

5.5.6.1 Torque compensation gain : S5.01 ----------------------------------------------------------- 5-29

5.5.6.2 Torque compensation delay : S5.02 --------------------------------------------------------- 5-29

5.5.7 System function compensation ------------------------------------------------------------ 5-30

5.5.7.1 Hunting prevention gain : S6.01 ------------------------------------------------------------- 5-30

5.5.7.2 Boosting brake performance : S6.02 --------------------------------------------------------- 5-3 0

4 - MOSCON-E7 U ser’s Manual

5.6 C-Parameter : H/W functionality setup ----------------------------- 5-31

5.6.1 V/f setting ----------------------------------------------------------------------------------------- 5-31

5.6.1.1 Setting V/f : C0.01 -------------------------- -------------------------------------------------------------- 5-3 1

5.6.1.2 Setting user-programmable V/f pattern ------------------------------------------------------------ 5-37

5.6.2 Carrier frequency setting ------------------------------------------------------------------ 5-38

5.6.2.1 Setting the carri er frequency : C1.01 ----------------------------------------------------------- ------- 5-38

5.6.3 Main motor constants ------------------------------------------------------------------------------------ 5-38

5.6.3.1 Setting the motor line-to-line resistance : C2.01 ------------- --------------------------------------- 5-38

5.6.3.2 Setting the iron loss : C2.02 ------------------------------------------------------------------------------ 5-38

5.6.3.3 Setting the motor rated cur rent : C2.03 -------------------------------------------------------------- 5-39

5.6.3.4 Motor no-load current : C2.04 ----------------------------------- -------------------------------------- 5-39

5.6.3.5 Setting the motor rated slip : C2.05 ----- --------------------------------------------------------------- 5-39

5.6.4 H/W Adjusting data : C3.01~C3.06 ------------------------------------------------------------ 5-40

5.7 H-Parameter : I/O contro l functions ---------------------------------------------- 5-41

5.7.1 Multi-function contact input --------------------------------------------------------------------------- 5-41

5.7.1.1 Set input type of multi-function contact input : H0.01 ----------------------------------------- 5-41

5.7.1.2 Setting the function of contact input : H0.02~H0.05 ----------------------------------------- -- 5-41

5.7.2 Multi-function contact output --------------------------------------------------------------- 5-50

5.7.2.1 Set output type of multi-function output : H1.01 ---------------------------------------------- 5-50

5.7.2.2 Setting the function of multi-function output : H1.02 -------------------------------------- 5-50

5.7.3 Multi-function analog input --------------------------------------------------------------------------- 5-52

5.7.3.1 Analog input form : H2.01 --------------------------------------------------------------------------- 5-52

5.7.3.2 Analog input filter time constant : H2.02 --- --------------------------------------------------- ---- 5-52

5.7.3.3 Adjusting analog inputs : H2.03, H2.04, H2.06, H2.07 ------------------------------------------ 5-53

5.7.3.4 Setting the multi-function analog input ter minal function : H2.05 ---------------------------- 5-54

5.7.4 Multi-function analog output : H3.01~H3.03 ------------------------------------------------------- 5-55

5.7.4.1 Setting multi-function analog output : H3.01 ---------------------------------------------------- 5-55

5.7.4.2 Adjusting the monitor o utput : H3.02, H3.03 --------------------------- -----------------------------5-56

5.7.5 Digital operator setting -------------------------------------------------------------------------------------5-57

5.7.5.1 Setting the display format in U0.07 : H4.01 ------------------------------------------------ 5-57

5.7.5.2 Setting the STOP key enable/disable : H4.02 -------------------------------------------------- 5-57

5.7.5.3 Setting the operation when switching REMOTE→LOCAL : H4.03 ----------------------------5-57

5.7.5.4 Setting the device ID : H4.04 -------------------------------------------------------------------- 5-58

5.7.5.5 Select frequency unit : H4.05 ------------------------------------------------------------------ 5-58

5.7.5.6 Setting the parameter setting mode : H4.06 ------------------------------------------------- 5-59

Contents -5

5.7.5.7 Setting the fan operating method : H4.07 --------------------------------------------------- 5-59

5.8 P-Parameter : Protective functions -------------------------------------------------- 5-60

5.8.1 Motor overload protection --------------------------------------------------- ------------ 5-60

5.8.1.1 Select motor protection : P0.01 -------------------------------------------------------------------- 5-60

5.8.1.2 Motor protection time constants : P0.02 ----------------------------------------------------------------- 5-61

5.8.1.3 Motor selection: P0.03 ---------------------------------------------- --------------------------------------- 5-62

5.8.2 Momentary power failure -------------------------------------------------------------------------- 5-63

5.8.2.1 Operation at power loss : P1.01 --------------------------------------------------------------------- 5-63

5.8.2.2 Compensation time of power loss : P1.02 ----------------------------- ------------------------- 5-63

5.8.2.3 V/f recovery time : P1.03 -------------------------------------------------------------------------- 5-64

5.8.2.4 : Undervoltage level : P1.04 ------------------------------------------------------------------------ 5-64

5.8.3 Stall prevention ----------------------------------------------------------------------------------------- 5-65

5.8.3.1 Stall prevention at start : P2.01 ---------------------------------------------------------------------- 5-65

5.8.3.2 Stall prevention level at start : P2.02 --------------------------------------------------------------- 5-65

5.8.3.3 Stall prevention limit during acceleration : P2.03 ----------------------------------------------- 5-66

5.8.3.4 Stall prevention at stop : P2.04 --------------------------------------------------------------------- 5-67

5.8.3.5 Stall prevention when the motor is running : P2.05 --------------------------------------- ---- 5-68

5.8.3.6 Stall prevention when the motor is r unning at the desired frequency : P2.06 ------------- 5-68

5.8.4 Overtorque detection : P3.01~P3.03 ----------------------------------------------------------- 5-70

5.8.4.1 Overtorque detection : P3.01 ------------------------------------------------------------------------ 5-70

5.8.4.2 Overtorque detection level & overtorque delay time : P3.02,P3.03 ------------------- ------- 5-71

5.8.5 Fault retry -------------------------------------------------------------------------------------------------- 5-72

5.8.5.1 Number of fault retr y : P4.01 ------------------------------------------------------------------- 5-72

5.8.5.2 Output terminal function during retry : P4.02 ---------------------------------------------- 5-73

5.8.5.3 Fan error : P5.01 ------------------------------------------------------------------------------------ 5-73

5.9 Error monitoring ---------------------------------------------------------------------------- 5-74

6. Troubleshooting ----------------------------------------------------------------------- 6-1

6.1 Protective function/error description ---------------------------------------- 6-3

7. Maintenance and inspection -------------------------------------------- 7-1

7.1 Daily inspection ----------------------------------------------------------------------------------- 7-4

7.2 Periodic inspection --------------------------------------------------------------------------- 7-4

7.3 Part replacement ------------------------------------------------------------------------------ 7-6

6 - MOSCON-E7 U ser’s Manual

-------------------------------------MEMO-------------------------------------

List of figures - 1

List of figures

1.Overview

Figure 1.1 System diagram -------------------------------------------------------------------- 1-5

Figure 1.2 Dimensions of 1 phase 20P4 and 3 phase 20P4, 20P7 ------------------------ 1-6

Figure 1.3 Dimensions of 1 phase 20P7, 21P5 and 3 phase 21P5~22P2, 40P4~41P5 -- 1-6

Figure 1.4 Dimensions of 1 phase 22P2 and 3 phase 23P7, 42P2~43P7 --------------------1-7

2. Installation

Figure 2.1 Example of nameplate ---------------------------------------------------------- 2-3

Figure 2.2 Installation space ------------------------------------------------------------------- 2-8

3. Wiring

Figure 3.1 Connection diagram (200V class) ----------------------------------------- 3-4

Figure 3.2 Connection diagram (400V class) ------------------------------------------- 3-5

Figure 3.3 Terminal configuration ------------------------------------------------------- 3-6

Figure 3.4 Peripheral devices ------------------------------------------------------------- 3-9

Figure 3.5 Reactor installation ---------------------------------------------------------- 3-11

Figure 3.6 Power supply noise filter installation ------------------------------------- 3-14

Figure 3.7 Noise filter on the output side --------------------------------------------- 3-15

Figure 3.8 Dealing with inductive noise ------------------------------------------------- 3-16

Figure 3.9 Dealing with radio interference ----------------------------------------------- 3-16

Figure 3.10 Ends of twisted-pair cables ------------------------------------------------- 3-18

Figure 3.11 Direction of motor’s rotation ------------------------------------------- 3-18

Figure 3.12 Multiple grounding ---------------------------------------------------------- 3-20

4. Digital operator

Figure 4.1 Monitoring functions of digital operator ---------------------------------- 4-5

Figure 4.2 Test run using digital operator ---------------------------------------------- 4-7

5. Parameters

Figure 5.1 Parameter setting method --------------------------------------------------------- 5-7

Figure 5.2 Selecting monitoring group (U) --------------------------------------------------- 5-8

Figure 5.3 Timing chart for multi-step and JOG operation --------------------------- 5-15

Figure 5.4 Upper and lower limits of the frequency reference ------------------------ 5-16

2 - MOSCON-E7 U ser’s Manual

Figure 5.5 Setting jumping frequencies -------------------------------------------------- 5-18

Figure 5.6 Acceleration/deceleration time switching frequency --------------------- 5-19

Figure 5.7 Setting S-curve characteristics ---------------------------------------------- 5-21

Figure 5.8 DC braking timing chart -------------------------------------------------------- 5-22

Figure 5.9 Speed search timing chart -------------------------------------------------------- 5-24

Figure 5.10 Timing chart for dwell function -------------------------------------------- 5-25

Figure 5.11 Slip compensation limit -------------------------------------------------------- 5-28

Figure 5.12.1 V/f pattern : settings 0~14 & setting15 -------------------------------- 5-33

Figure 5.12.2 V/f pattern : settings 0~14 & setting15 ---------------------------------- 5-34

Figure 5.13.1 V/f pattern : settings 0~14 & setting15 ---------------------------------- 5-35

Figure 5.13.2 V/f pattern : settings 0~14 & setting15 ----------------------------------- 5-36

Figure 5.14 User-defined V/f pattern ------------------------------------------------------- 5-37

Figure 5.15 3-wire sequence wiring example ------------------------------------------------ 5-43

Figure 5.16 Time chart for 3-wire sequence ----------------------------------------------- 5-43

Figure 5.17 Using two accel/decel time ------------------------------------------------------ 5-45

Figure 5.18 Acceleration/deceleration jamp hold -------------------------------------------- 5-46

Figure 5.19 Timing chart for up and down commands ------------------------------------- 5-47

Figure 5.20 Timing chart for DC injection braking command ------------------------------- 5-48

Figure 5.21 Timing chart for the external search command ------------------------------- 5-49

Figure 5.22 Gain and bias ------------------------------------------------------------------------- 5-53

Figure 5.23 Monitor output adjustments ----------------------------------------------------- 5-56

Figure 5.24 Motor protection operating time ------------------------------------------------- 5-61

Figure 5.25 Acceleration stall prevention function : P2.01=1 ----------------------------- 5-66

Figure 5.26 Stall prevention limit during acceleration ---------------------------------------- 5-66

Figure 5.27 Deceleration stall prevention function : P2.04=1 ------------------------------ 5-67

Figure 5.28 Run stall prevention function : P3.05=1 or 2 ------------------------------------- 5-69

Figure 5.29 Timing chart for overtorque detection ------------------------------------------- 5-71

List of tables -1

List of tables

1.Overview

Table 1.1 Dimensions of FARA MOSCON-E7 -------------------------------------------- 1-7

Table 1.2 Specifications for 200V class -------------------------- ------------------------------- 1-8

Table 1.3 Specifications for 400V class -------------------------------------------------------- 1-10

3. Wiring

Table 3.1 200V class main circuit terminal functions --------------------- ------------------- 3-7

Table 3.2 400V class main circuit terminal functions ---------------------------- -------------- 3-7

Table 3.3 Cable circuit terminal block -------

---------

---------------------------------------- ----- 3-8

Table 3.4 MCCB and Magnetic Contactor ---------------------------- -------------------------- 3-11

Table 3.5 DC Reactor -------------------------------------------------- ----------------------------- 3-12

Table 3.6 AC Reactor ------------------------------------------------------------ ------------------- 3-12

Table 3.7 Application of the surge absorber ---------------- -------------------------------- ---- 3-13

Table 3.8 Cable length.vs.carrier frequency -------------------------------- -------------------- 3-17

Table 3.9 Cable size -------------------------------------------------------------------------------- 3-21

5. Parameters

Table 5.1 Functions of each group -- ------------------------------------------------------------ 5-3

Table 5.2 Operation status ------------------------------------------------------------------------- 5-4

Table 5.3 Inverter operation status on last fault --------------------------------- -------------- 5-5

Table 5.4 Fault list ---------------------------------------------------------------------------------- 5-5

Table 5.5 Parameter check list -------------------------------------------- ------------------------- 5-5

6. Troubleshooting

Table 6.1 Fau lt dis play a nd cont ents ( Faults in inv erter ) ---- ----- -------- -------------------- 6-3

Table 6.2 Fault display and contents (Warning on inverter) : Blinking display ----------- 6-6

Table 6.3 Fault display and contents (Communication fault) ----------------------------------- 6-7

7. Maintenance and Inspection

Table 7.1 Periodic inspection --------------------------------------------------------------------- 7-5

Table 7.2 Part replacement -------------------------------- ----------------------------------------- 7-6

2 - MOSCON-E7 U ser’s Manual

-------------------------------------MEMO-------------------------------------

1. Overview 1-1

1. Overview

An overview of the MOSCON-E7 and its functions are

described in this chapter.

1.1 Main features............................................................................ 1-3

1.2 System diagram.........................................................................1-5

1.3 Dimensions............................................................................... 1-6

1.4 Specifications............. ............................................................... 1-8

1-2 MOSCON-E7 User’s Manual

1. Overview 1-3

1.1 Main features

Easy to use

• Digital operator with digital volume allows simplified and easy

operation.

• Built-in automatic speed controller and many automatic functions

provide a smooth and powerful operation.

• More than 150 parameters for configuring the functions of MosconE7 are segmented into 7 groups according to its function for

convenience.

Small size & uniform height

•

Small size & weight allows convenient installation and easy

maintenance.

•

The height of Moscon-E7 is 128mm regardless of its rating.

This allows optimal utilization of installation area.

High performance

• Built-in digital speed controller adopting 32bit RISC micro-processor

allows high precision & high performance frequency and voltage

control. (Frequency resolution : 0.01Hz, Voltage resolution : 0.1V)

• Built-in automatic torque boost & speed control algorithm provides

smooth and improved speed control characteristics.

Various operational functions

• Various built-in functions that are compatible to various operation

method : Dwell, DC-Brake, Up/Down operation, etc.

• 4 multi-functional, and 2 fixed contact input terminals

(19 input types)

• 2 multi-functional analog input terminals

• 1 multi-functional analog contact

• Multi-functional contact output (11 output functions)

• Application-specific function can be supported if needed.

1-4 MOSCON-E7 User’s Manual

Various built-in input devices for command

• Keypad in digital operator

• Digital volume in digital operator

• Analog voltage (0~10V) & current (4~20mA) input through term inal

block (Resolution : 1/1024 of maximum frequency)

• Communication supports (RS-485)

Practical and versatile protection function

• Prevents malfunctioning by detecting 17 types of errors.

• Recent 4 errors are reported.

• The last operational status of the inverter is provided.

1. Overview 1-5

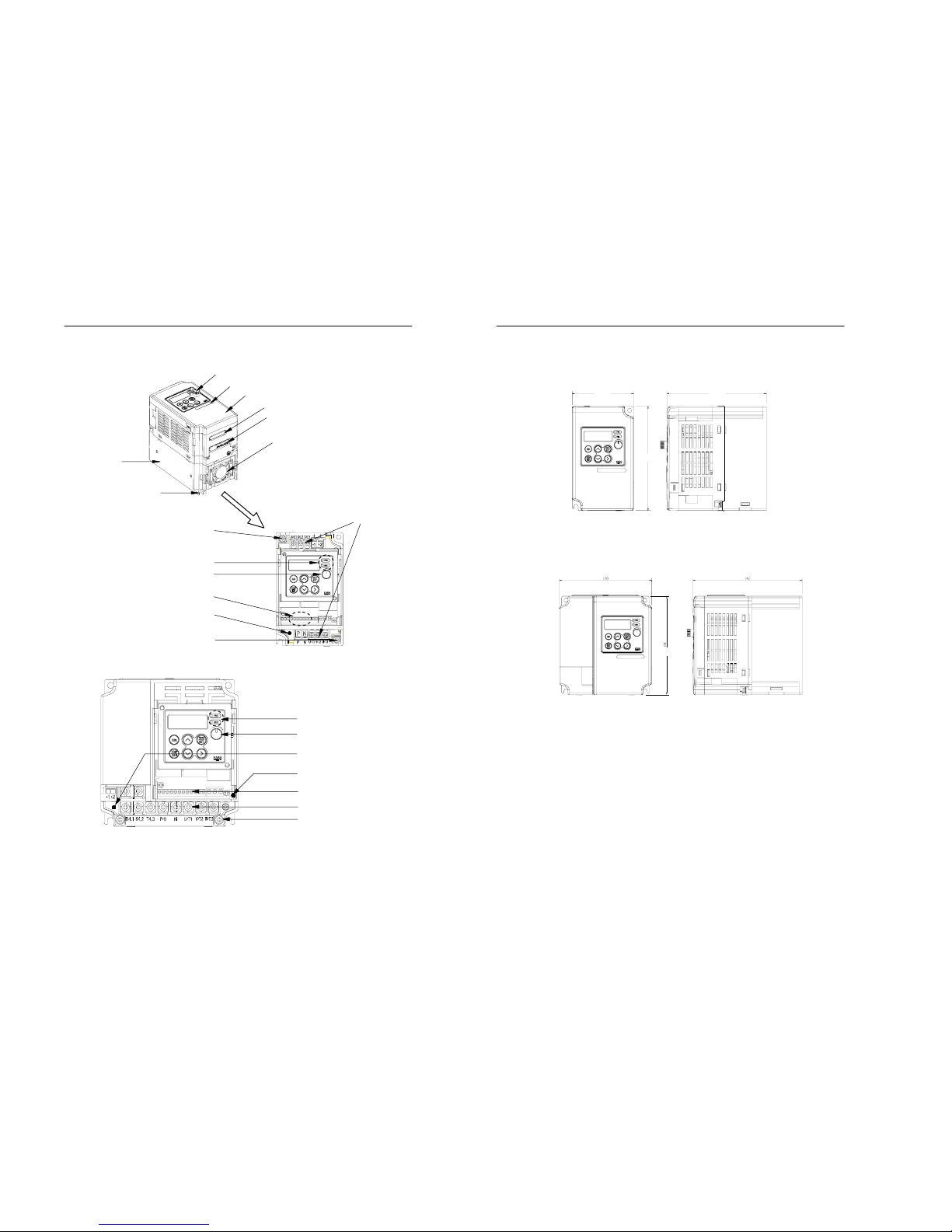

1.2 System diagram

Figure 1.1 System d i ag r am

Digital operator

Heatsink

Front cover

W

iring holes for main circuit

Cooling fan

Mounting hole

Sticker marked capacit

y

W

iring holes for control circuit

Ground terminal

Status indicating lamp

Main circuit terminal block

Control circuit terminal block

Digital volume

Ground terminal

Charge lamp

[1 phase 20P4S and 3 phase 20P4, 20P7]

Status indicating lamp

Digital volume

Control circuit terminal block

Main circuit terminal block

Ground terminal

Charge lamp (400V class)

Charge lamp (200V class)

[1 phase 20P7S, 21P5S, 22P2S and

3 phase 21P5, 22P2, 23P7, 40P4~43P7]

Opening the covers

1-6 MOSCON-E7 User’s Manual

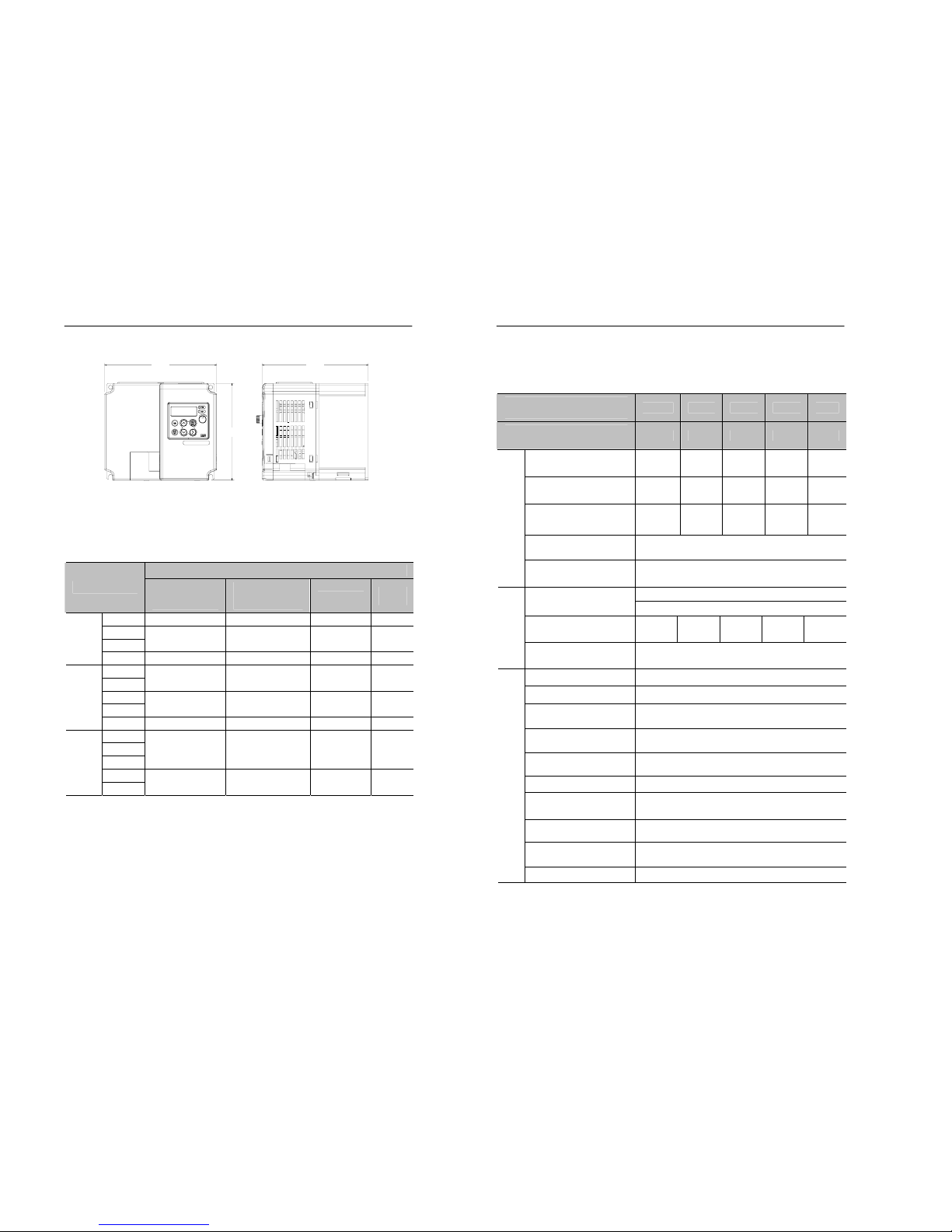

1.3 Dimensions

Figure 1.2 Dimensions of 1 phase 20P4 and 3 phase 20P4, 20P7

Figure 1.3 Dimensions of 1 phase 20P7, 21P5 and 3 phase 21P5,

22P2, 40P4~41P5

76 123

128

120 142

128

1. Overview 1-7

Figure 1.4 Dimension of 1 phase 22P2 and 3 phase 23P7, 42P2~43P7

Table 1.1 Dimensions of FARA MOSCON E-7

MOSCON-E7

Type

External

Dimension

(W×H ×D)

Installation

Dimension

W1×H1, Φ

Volume (㎣)

Weight

(㎏)

20P4S 76×128×123 66×118, M4 1,186,816 0.95

20P7S

21P5S

120×128×142 103×118, M4 2,150,400 1.6

200V

1phase

22P2S 150×128×142 134×118, M4 2,150,400 2.0

20P4

20P7

76×128×123 66×118, M4 1,186,816 0.95

21P5

22P2

120×128×142 103×118, M4 2,150,400 1.6

200V

3phase

23P7 150×128×142 134×118, M4 2,150,400 2.0

40P4

40P7

41P5

120×128×142 103×118, M4 2,150,400 1.6

42P2

400V

3phase

43P7

150×128×142 134×118, M4 2,688,000 2.0

150

142

128

1-8 MOSCON-E7 User’s Manual

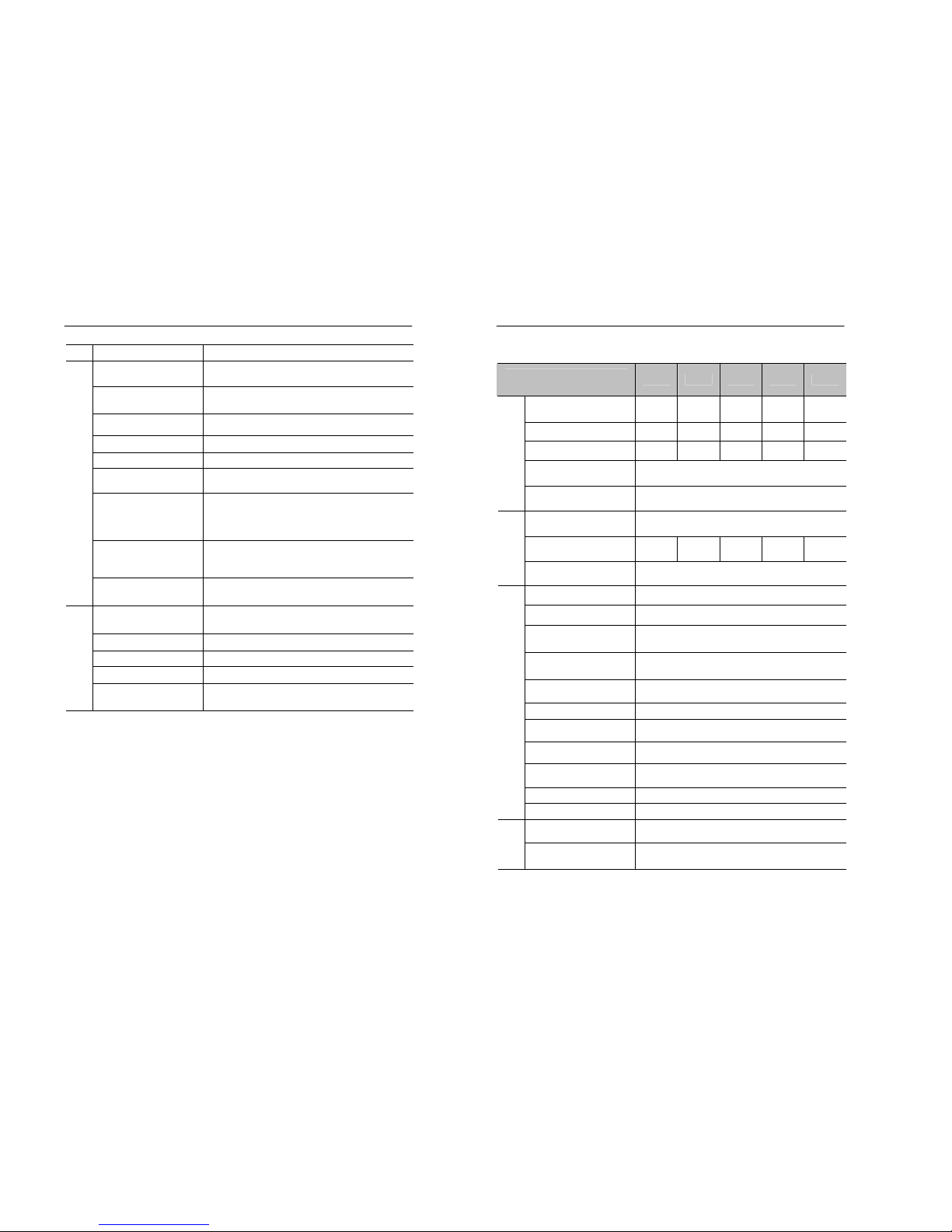

1.4 Specifications

Table 1.2 Specifications for 200V class

SI-E7

3 phase

20P4 20P7 21P5 22P2 23P7

SI-E7S

1 phase

20P4S 20P7S 21P5S 22P2S -

Max. Applicable

Motor Capacity[kW]

*1

0.4 0.7 1.5 2.2 3.7

Inverter Capacity[kVA]

(1 phase)

1.1

(1.1)

1.9

(1.7)

3.0

(2.7)

4.2

(3.7)

6.7

( - )

Rated Output Current[A]

(1 phase)

3.2

(3.2)

5.0

(4.6)

8.0

(7.2)

11.0

(9.6)

17.5

( - )

Rated Output Voltage[V]

3 phase, 200~230Vac

(Proportional to input voltage)

Output

Max. Output Frequency

[Hz]

600Hz

3Phase, 200~230Vac, 50/60Hz

Input Voltage and

Frequency

Single phase, 200~230Vac, 50/60Hz

Rated Input Current[A]

(1 phase)

3.9

(6.4)

6.4

(11.0)

11.0

(15.1)

15.1

(24.0)

24.0

( - )

Input

Allowable Fluctuation

Voltage: -15% ~ +10%,

Frequency: ±5%

Control Method Space vector PWM, VVVF method

Frequency Control Range 0.01 ~ 600Hz*2

Frequency Control

Accuracy

Digital :±0.01% (-10 ~ 50℃)*2

Analog :±0.5% (25℃±10℃)

Frequency Setting

Resolution

Digital (operator) : 0.01Hz

Analog:0.06/60Hz(1/1,024:10-bit)

Output Frequency

Resolution

0.01Hz

Overload Capacity 150% of rated current for 1min

Frequency Setting Signal

DC0~10V (Input impedence:20 ㏀)

DC4~20mA (

Input impedence

:250Ω)

Accel/Decel Time

0.1~3000.0sec (uni t of 0.1sec setting )

2 sets available

Continuous Regenerative

Torque

20% of rated torque

Control Characteristic

V/f Pattern 15 of fixed pattern and 1 of optional pattern

1. Overview 1-9

Starting Torque 150%/3Hz

Motor Overload

Motor stops in 1 minute at approx. 150% of

motor rated current.

Instantaneous

Overcurrent

Motor stops immediately at 200% of inverter

rated current.

Inverter Overload

Motor coasts to stop in 1 minute at approx.

150% of inverter rated curren t.

Overvoltage Motor stops at 410V or higher.

Undervoltage Motor stops at 190V or lower.

Cooling Fin

Overheat

Motor stops if the temper ature of the co oling

fin is higher than approximately 90℃.

Momentary Power Loss

Motor stops if power loss is 15ms or longer,

by selecting the momentary power loss mode,

operation can be continued if power is

restored within 500ms.

Stall Prevention

Automatic setting during acceleration,

deceleration, and constant speed operation

(Individual setting is possible).

Protective Functions

Power Charge

Indication

LED is ON until the DC bus voltage be comes

50V or less.

Location

Indoor

(Free from corrosive gas, dust, or oil)

Ambient Temperature -10 ~ 40℃

Humidity 90% RH or less

Storage Temperature -20 ~ 60℃*3

Environmental

condition

Vibration

Normally 0.2G or less, less than 20Hz, 1G

max.

*1. The maximum applicable motor capacity is for a standard 4-pole

motor. When selecting the motor and inverter, make sure that the

Inverter’s rated current is applicable for the motor’s rated current.

*2. Tuning may be required.

*3.

The storage temperature refers to the temperature during the

transportation for a short period of time.

1-10 MOSCON-E7 User’s Manual

Table 1.3 Specifications for 400V class

SI- E7

3 phase

40P4 40P7 41P5 42P2 43P7

Max. Applicable

Motor Capacity[kW]

*1

0.4 0.7 1.5 2.2 3.7

Inverter Capacity[kVA] 1.4 2.6 3.7 4.2 6.5

Rated Output Current[A] 1.8 3.4 4.8 5.5 8.6

Rated Output Voltage[V]

3phase, 380~460Vac

(Proportional to input voltage)

Output

Max. Output Frequency

[Hz]

600Hz

Input Voltage

and Frequency

3 Phase, 380~460Vac, 50/60Hz

Rated Input Current[A] 2.4 4.7 7.0 8.1 12 .0

Input

Allowable Fluctuation

Voltage: -15% ~ +10%,

Frequency: ±5%

Control Method Space vector PWM, VVVF method

Frequency Control Range 0.01 ~ 600Hz*2

Frequency Accuracy

Digital : ±0.01% (-10 ~ 50℃)

*2

Analog : ±0.5% (25℃±10℃)

Frequency Setting

Resolution

Digital (operator): 0.01Hz

Analog: 0.06/60Hz (1/1,024:10-bit)

Output Frequency

Resolution

0.01Hz

Overload Capacity 150% of rated current for 1min

Frequency Setting Signal

DC0~10V(

Input impedence

:20 ㏀)

DC4~20mA(

Input impedence

:250Ω)

Accel/Decel Time

0.1~3000.0sec (uni t of 0.1sec setting)

Includes 2-set each.

Continuous Regenerative

Torque

20% of rated torque

V/f Pattern 15 of fixed pattern and 1 of optional pattern

Control Characteristics

Starting Torque 150%/3Hz

Motor Overload

Protection

Motor stops in 1 minute at approx. 150% of

motor rated current.

Protective

Function

Instantaneous

Overcurrent

Motor stops immediately at 200% of inverter

rated current.

1. Overview 1-11

Inverter Overload

Motor coasts to stop in 1 minute at approx.

150% of inverter rated curren t.

Overvoltage Motor stops at 820V or higher.

Undervoltage Motor stops at 380V or lower.

Cooling Fin

Overheat

Motor stops if the temperature of the

cooling fin is h igher than 90℃.

Momentary Power Loss

Motor stops if power loss is 15ms or longer,

by selecting the momentary power loss

mode, operation can be continued if power

is restored within 500ms.

Stall Prevention

Automatic setting during acceleration,

deceleration, and constant speed operation

(individual setting is possible).

Power Charge

Indication

LED is ON until the DC bu s voltage

becomes 50V or less.

Location

Indoor

(Free from corrosive gas, dust, or oil)

Ambient Temperature -10 ~ 40℃

Humidity 90% RH or less

Storage Temperature -20 ~ 60℃*3

Environmental

condition

Vibration

Normally 0.2G or less, less than 20Hz, 1G

max.

*1. The maximum applicable motor capacity is for a standard 4-pole

motor. When selecting the motor and inverter, make sure that the

inverter’s rated current is applicable fro the motor’s rated current.

*2. Tuning may be required.

*3. The storage temperature refers to the temperature during the

transportation for a short period of time.

1-12 MOSCON-E7 User’s Manual

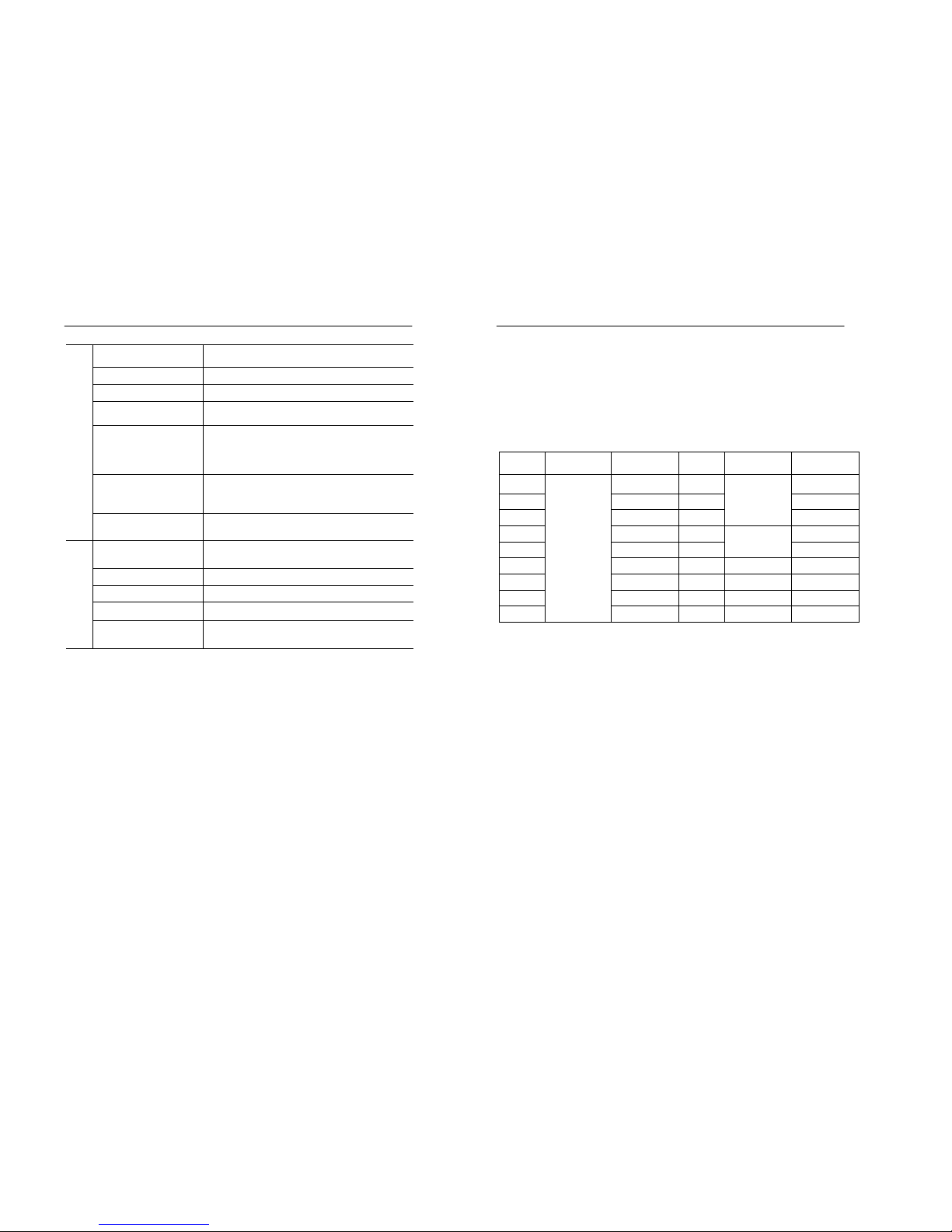

1.5 Short circuit rations

Suitable for use in a circuit capable of delivering not more than 5kA rms

symmetrical amperes.

1.6 Fuse

The fuse used on the input side should be any of the UL Class K5 fuses having

The ratings as listed below.

Model

Rated

Voltage(V)

Rated

Current(A)

Model Rated

Voltage(V)

Rated

Current(A)

20P4 10 40P4 16

20P7 10 40P7 16

21P5 20 41P5

500

16

22P2 20 42P2 20

23P7 30 43P7

600

20

20P4S 20

20P7S 20

21P5S 20

22P2S

250

30

2. Installation 2-1

2. Installation

Nameplate information and installation site are described in this

chapter.

2.1 Receiving............................................................... ....................2-3

2.2 Nameplate Information .......................................................... 2-4

2.3 Installation.................................................................................2-5

2-2 MOSCON-E7 User’s Manual

2. Installation 2-3

2.1 Receiving

Confirm the following upon delivery of the Moscon-E7:

• Verify the model number to check if the correct item has been

delivered.

• Check if any physical damage has occurred during shipping.

If there is any damage or missing part, call the place where you

purchased the product or sales office for service immediately.

• Don’t install the inverter that there is any damage or missing part.

It may be cause injury.

CAUTION

!

2-4 MOSCON-E7 User’s Manual

2.2 Nameplate information

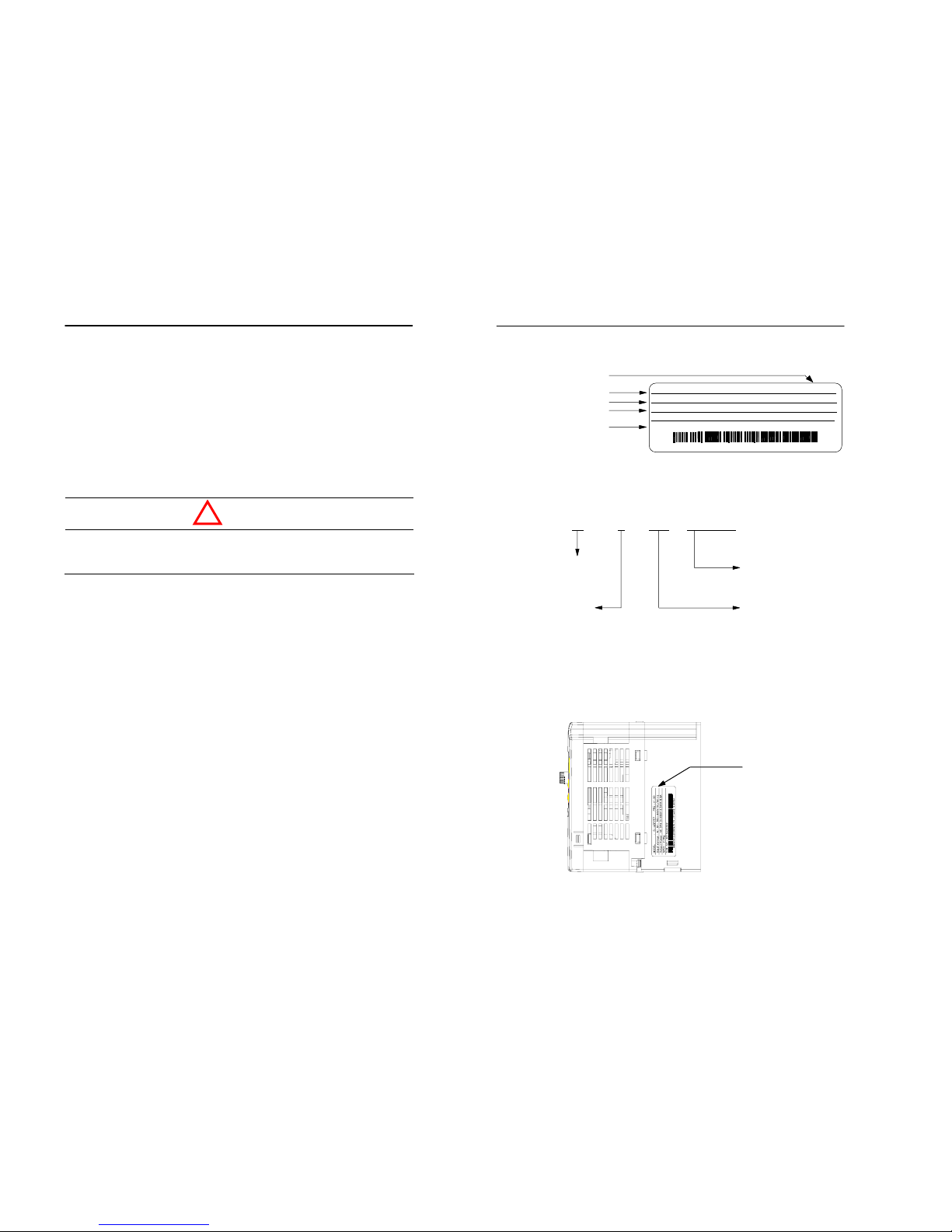

Figure 2.1 Example of nameplate

Inverter model number

Name plate location

Max. motor capacity

0P4:0.4kW

0P7:0.7kW

1P5:1.5kW

2P2:2.2kW

3P7:3.7kW

Samsung inverter

SI 4 3P7 E7/EXP

Voltage cl ass

2 : 200V class

4 : 400V class

E7 series

E7/EXP : 3 phase

E7/EXS : 1 phase

MODEL : SI43P7E7/EXP PRG:V019

Input Voltage : A C3PH 380-460V 50/60Hz 12.0A

Output Power: AC3PH 0-460V 6.5kVA 8.6A 0.01-600Hz

IP20 INSTALLATION CATEGORY Ⅱ MASS : 2.0kg

SER. NO : 2Q15A20002

SAMSUNG ELECTRONICS CO., LTD. MADE IN KOREA

Program version

Model number

Input specifications

Output specifications

Serial number

Name plate

(Attachment an the right side)

2. Installation 2-5

2.3 Installation

2.3.1 Precautions for delivery and installation

• Do not inspect components unless inside “Charge” lamp is off.

It may cause an electric shock.

• Do not remove the operator from the main body.

It may cause an electric shock.

• When using the digital operator away from the main body, use the

separated operator (E7OPTR-S).

• Be careful not to be damaged the inverter in delivering.

• Do not carry the inverter by holding the plastic parts, but hold the

heat sink.

Otherwise, the heat sink may fall and cause injury.

• Use nonflammable materials such as metal for the part where the

inverter is installed.

• When installing several inverters in a single enclosed space, install a

cooling fan to keep the ambient temperature below 45℃.

• Cover the inverter during installation to protect it from metal chip

coming from drilling.

DANGER

!

CAUTION

!

2-6 MOSCON-E7 User’s Manual

2.3.2 Installation site

Free from direct

sunlight

Free from harmful

gases and liquids

Free from oil mist and

dust

Free from chlorides

F

ree from rain and

wind, water

(In case of enclosed

wall mount t

yp

e)

Free from dust

(In case of enclosed

wall mount type)

Without excessive

vibration

Low ambient

temperature

Ambient temperature of

– 10℃~40℃

Without

any magnetic

noises

(e.g. Free from a welding

machine or power supply)

Free from radioactive

material

Free from combustible

material

2. Installation 2-7

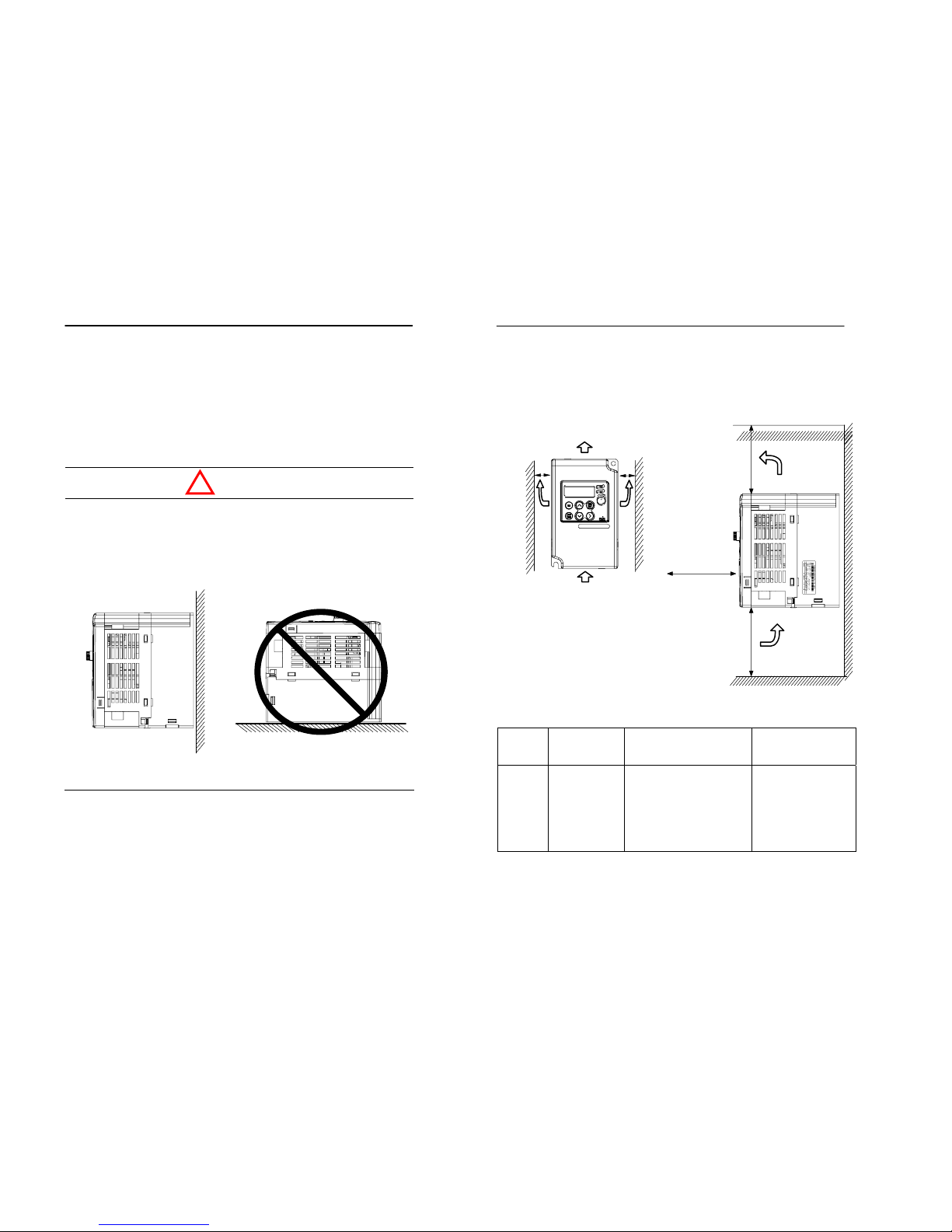

2.3.3 Controlling the ambient temperature

To maintain the optimum condition, the inverter should be installed at

the ambient temperature of –10℃~40℃. If installed in a closed

environment (e.g. enclosed panel), install a cooling fan or air conditioner

to avoid any extreme temperature increases and to maintain the internal

air temperature within the range.

• If installed in a closed environment (e.g. enclosed panel), we

strongly recommend the inverter to be installed on a vertical space.

If it is installed on a horizontal space, its internal temperature may

increase excessively and thus, reducing its durability.

CAUTION

!

Vertical mounting Herizontal mounting

2-8 MOSCON-E7 User’s Manual

2.3.4 Installation space

Install the inverter on a vertical surface to enhance the cooling effect.

When installing the inverter, always leave enough space around it to

provide normal heat dissipation.

Figure 2.2 Installation space

Table 2.1 Cabinet Size

Inverter

Cabinet

(enclosure)

Size(Unit:mm)

Vent Hole Area Cooling Fan

23P7 270x328x222

· 55% of both the side

of the cabinet

· width of each slit :

3.2mm

· To be provided on each

of the upper side areas

Installed at the

enclosure top to suck

air from inside the

enclosure to the

outside.

(Fan air flow : 2x0.59

m

3

/min or more

100mm or more

Inlet Temp.

-10~+40℃

30mm or more

Airflow

30mm or more

100mm or more

80mm or more

3.Wiring 3-1

3. Wiring

Wiring specifications, terminals, main circuit terminal

connection, peripheral device connection and

precautions in wiring are described in this chapter.

3.1 Connection diagram ................................................................ 3-4

3.2 Terminal block configuration ................................................. 3-6

3.3 Main circuit terminal functions.............................................. 3-7

3.4 Control circuit terminal functions ......................................... 3-8

3.5 Connections to peripheral devices .........................................3-9

3.6 Wiring the main circuits........................................................ 3-10

3.7 Precautions when wiring....................................................... 3-18

3.8 Grounding...............................................................................3-20

3.9 Cable specification ................................................................. 3-21

3.10 Wiring check......................................................................... 3-22

3-2 MOSCON-E7 User’s Manual

3.Wiring 3-3

• Always turn OFF the input power supply before wiring.

Otherwise, an electric shock or fire may occur.

• Wiring must be performed by a qualified personnel.

• Always check if the volts on the main circuit and control circuit

terminals are properly tightened.

• Be sure to ground the ground terminal.

Otherwise, an electric shock or fire may occur.

• Turn ON the inverter only after completely assembling the covers.

Do not detach the cover when the power is ON.

Otherwise, an electric shock or fire may occur.

• Ground the ground terminal (200V & 400V class: ground to 100

or less). Otherwise, an electric shock or fire may occur.

• Tighten all terminal screws of the main circuit and the control

circuit.

• Check if the voltage of the inverter rated voltage satisfies with the

AC power su pply volta ge.

Otherwise, it may cause fire or injury.

• Do not perform withstand voltage test on the inverter. It may

damage the semi-conductor element.

• When wiring other devices, read their manuals carefully. Samsung

is not responsible for any accident resulting from user’s carelessness.

If not, it may cause injury or fire.

• Do not connect AC power to output terminal U, V and W.

Otherwise, it may damage the inverter.

• Do not connect electromagnetic switches or contactors to the

output circuits.

DANGER

!

CAUTION

!

3-4 MOSCON-E7 User’s Manual

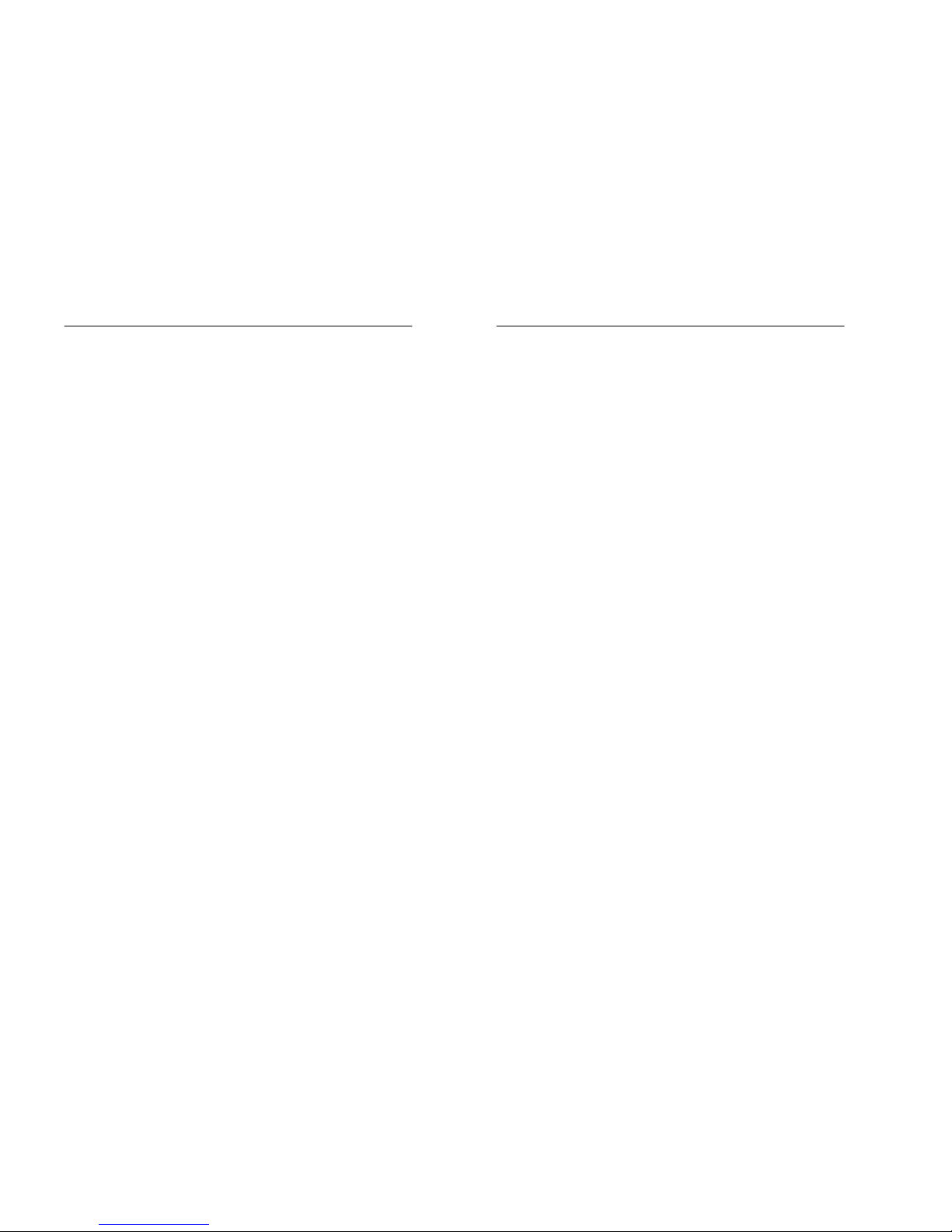

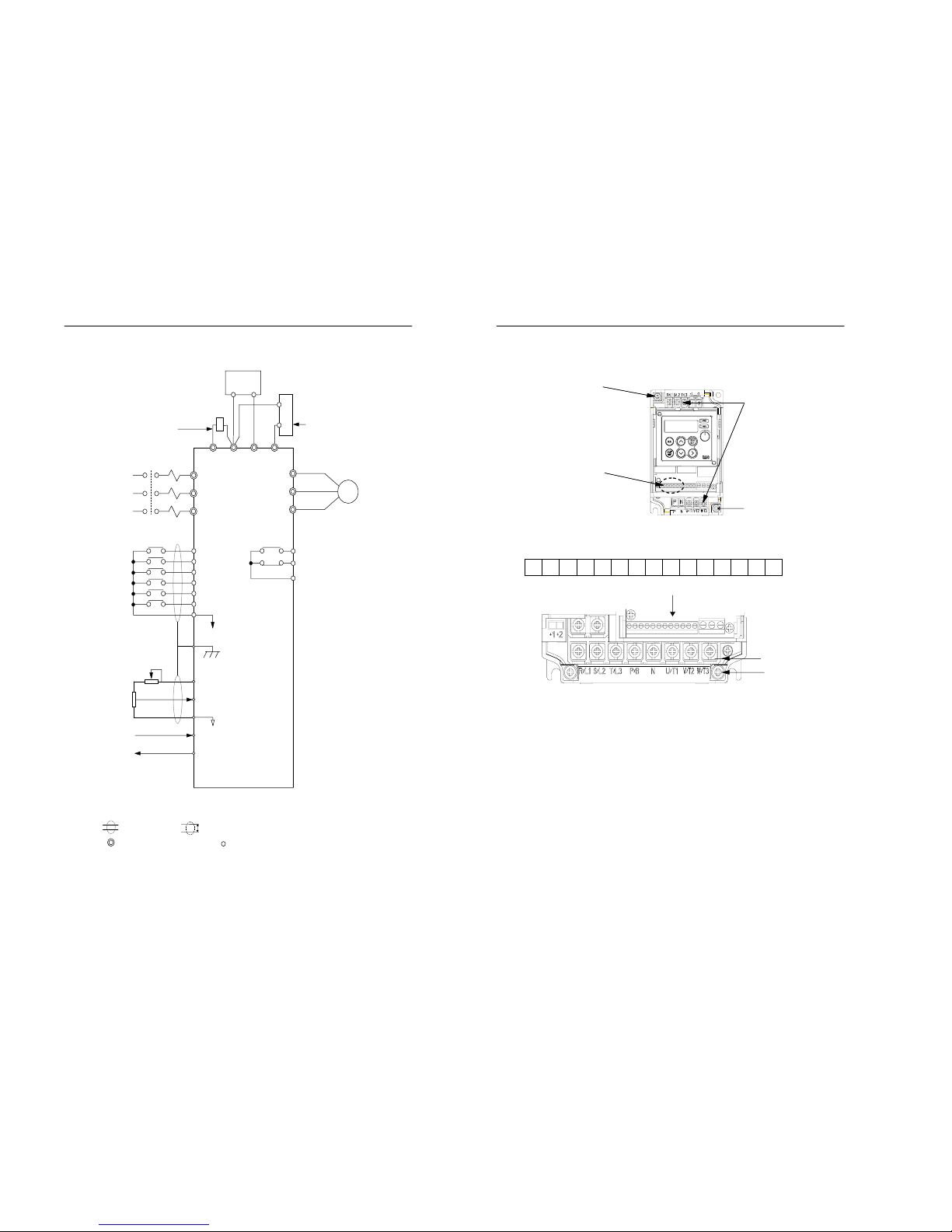

3.1 Connection diagram

The connection diagram of the Moscon-E7 is shown below.

When using the digital operator, the motor can be operated by wiring

only the main circuits.

Figure 3.1 Connection diagram (200V class)

Note 1) : Shield wire, : Twisted pair shield wire.

2) : Main circuit terminal, : Control circuit terminal.

3) Max. current value for +12V voltage of the control circuit terminal No.8 is 20㎃.

External Braking Unit (optional)

There is no built-in internal

braking unit for the 200V

class. Thus, external bra king

unit should be used.

External DC reactor to

improve power factor.

(op

tional

)

+1

Input power

MCCB

E

8

9

12

10

11

Multi-function

contact input

Multi-function

contact output

DC 30V 1A max

AC 250V 1A max

(basic setting : fault)

1k

2k

Power for speed command

(+12V 20mA)

Sequence Command

Ground

S

peed comman

d

(0~10V 20k)

Analogcommand

S

peed comman

d

(4~20mA 250)

Analog

monitor output

(0~10V)

+2

NP/B

Motor

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

Forward run/stop

Reverse r un/stop

External fault

Fault r eset

Multi-step command1

Jogg ing

1

2

3

4

A1

B1

C1

7

6

5

M

p

3.Wiring 3-5

Figure 3.2 Connection diagram (400V class)

Note 1) : Shield wire, : Twisted pair shield wire.

2) : Main circuit terminal, : Control circuit ter minal.

3) Max. current value for +12V voltage of the control circuit terminal No.8 is 20㎃.

+1

MCCB

+2

N P/B

Built-in braking unit is available

for the 400V class. Thus, the

external braking resistor can be

installed as an option. External

braking unit is an option

External DC reactor to

improve power factor.

(optional)

Input power

E

8

9

12

10

11

Multi-function

contact input

Multi-function

contact output

DC 30V 1A max

AC 250V 1A max

(

basic settin

g

: fault

)

1k

2k

Power for speed command

(+12V 20mA)

Sequence Command

Ground

S

peed command

(0~10V 20k)

Analog command

S

peed command

(4~20mA 250)

Analog

monitor output

(0~10V)

Motor

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

Forwa rd run/ stop

Reverse r un/stop

External fault

Fault r eset

Multi-step command1

Jogg ing

1

2

3

4

A1

B1

C1

7

6

5

Braking resistor

Unit

(optional)

Braking Unit or Auxiliary Capacitor

(optional)

M

p

3-6 MOSCON-E7 User’s Manual

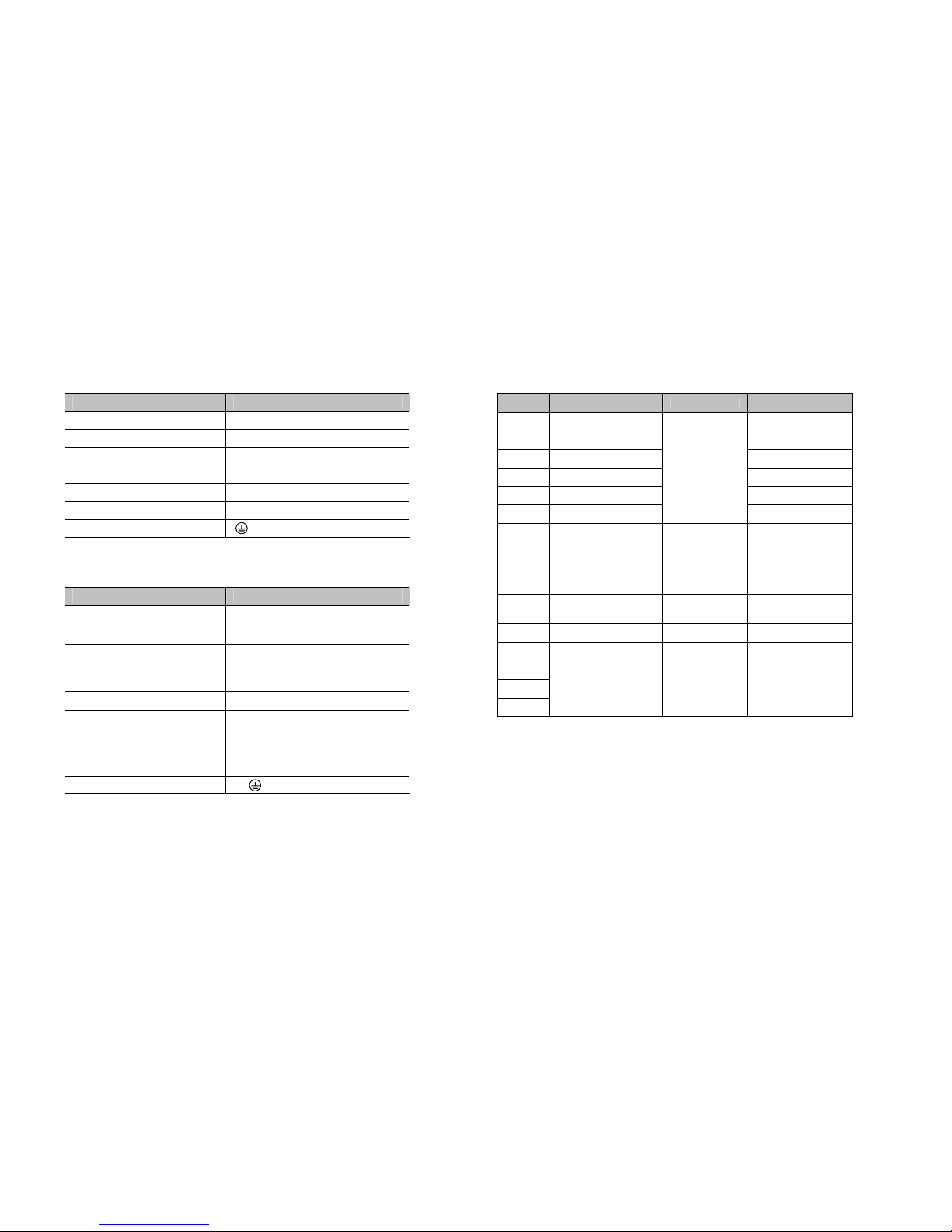

3.2 Terminal block configuration

1 2 3 4 5 6 7 8 9 10 11 12 A1 B1 C1

[21P5 – 23P7, 40P4 – 43P7]

Figure 3.3 Terminal configuration

Ground terminal

Control circuit

terminal block

Ground terminal

Main circuit terminal

block

[20P4, 20P7]

Control circuit ter minal

Main circuit terminal

Ground terminal

[20P4, 20P7]

3.Wiring 3-7

3.3 Main circuit terminal functions

Table 3.1 200V class main circuit terminal functions

Purpose Symbol

Main circuit power input R/L1, S/L2, T/L3

Inverter outputs U/T1, V/T2, W/T3

DC power input +1, N

DC reactor connection +1, +2 (Remove short-bar)*

Braking unit connection P/B, N (No internal braking unit)

Auxiliary capacitor (+): P/B (-):N

Ground

*Short-bar must be removed when connecting the DC reactor.

Table 3.2 400V class main circuit terminal functions

Purpose Terminal Symbol

Main circuit power input R/L1, S/L2, T/L3

Inverter output U/T1, V/T2, W/T3

DC power input

+2, N (Additional circuit is needed to

prevent the damage caused by inrush

current.)

DC reactor connection +1, +2(Remove short-bar)*

Braking resistor unit

+2, P/B (used for the internal braking

unit)

Braking unit +2, N

Auxiliary capacitor (+) : +2 (-) : N

Ground

*Short-bar must be removed when connecting the DC reactor.

3-8 MOSCON-E7 User’s Manual

3.4 Control circuit terminal f unctions

Table 3.3 Control ci rc u it t erminal block

Ter minal Function Signal level Default setting

1 Forward run/stop command -

2 Reverse run/stop command -

3 Multi-function input 1 External fault

4 Multi-function input 2 Fault reset

5 Multi-function input 3 Multi-step speed1 command

6 Multi-function input 4

Photo-Coupler input

+24V, 10mA

Jogg ing comma nd

7

Sequence control input

common

+24V Ground Sequence 0V

8 Power for freq. command +12V(Max 20mA) -

9

Voltage command for output

frequency

DC 0~+10V(25Ω) -

10

Current command for

output frequency

4~20mA(250Ω) -

11 Analog monitor output 0V 12 Common for control DC 0 ~ +10V (Output frequency)

A1

B1

C1

Multi-function output

Contact :

AC 250V, 1A or below

DC 30V, 1A or below

Fault occu rred

Note) Be attentive to below mention when changing output frequency in using the

external frequency command terminal.

- Voltage command input terminal is set only in factory setting.

- Change setting value of parameter H2.01 from 0 to 1 in using the current

command input terminal.

- In setting the function of contact input, H0.02~H0.05, parameter H2.01

is regardless if voltage current command transfer(14) is set.

3.Wiring 3-9

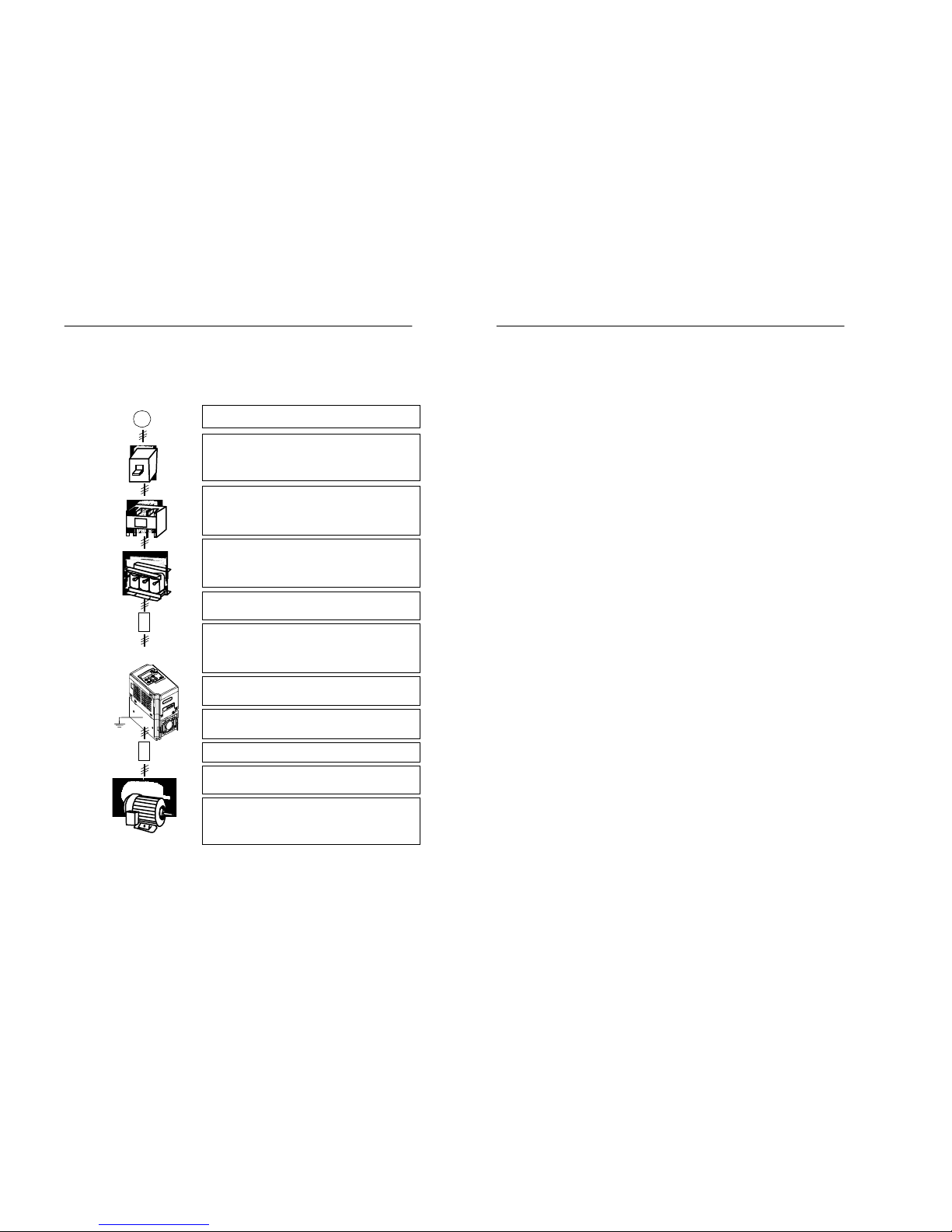

3.5 Connections to peripheral devices

Examples of connections between the Moscon-E7 and peripheral

devices are shown in the figure below

.

Figure 3.4 Peripheral devices

Power supply

Follow the specification on power supply.

Molded-case circuit breaker or leakage current

circuit breaker

Large inrush current flows when power is supplied thus,

use appropriate breaker, which is tolerant to high

frequency.

Magnetic contactor

Installed to remote control the supply/block of the

power. Frequent start/stop of the inverter through this

device reduces durability of the inverter. Install the

surge absorber on the coil.

AC/DC reactor for power factor improvement

AC/DC reactor is required when improving the power

factor or when the inverter is connected to a largecapacity power transformer whose capacity is 600kVA or

more. If not, invert may be damaged.

Input noise filter

Install it close to the inverter to reduce the noise from the

wire.

Input wiring

Inappropriate wiring damages the inverter. Do not

connect input power R, S, and T to output U/T1, V/T2,

and W/T3. Keep enough distance between the control

signal line and main circuit to prevent the effect of noise.

Installation area

Install in a place free from gas and dust. Maintain the

ambient temperature within the specified range.

Output noise filter

Install the output noise filter close to the inverter to

reduce the noise from output wire of the inverter.

Motor

Follow the specification when running the motor.

Grounding

Ground the inverter and motor to prevent any electric

shock.

Wiring between the inverter and motor

Keep the wire between the inverter and motor short.

If not, it may decrease the carrier frequency.

Leakage current from the cable affects the inverter and

other peripheral devices.

~

접 지

Power supply

Molded-case

circuit breaker or

leakage current

circuit breaker

Magnetic contactor

AC/DC reactor

for power factor

im

p

rovement

Input noise filter

MOSCON-E7

Ground

Output noise filter

Motor

Ground

3-10 MOSCON-E7 Us er’s Manual

3.6 Wiring the main circuits

3.6.1 Wiring on the input side of main circuit

3.6.1.1 Installing a molded-case circuit breaker

• Always connect the input power terminals (R/L1, S/L2 and T/L3) via

an appropriate MCCB.

•

Large inrush current flows when power-up, thus, use appropriate

breaker. Use the one that is tolerant to high frequency.

• MCCB with a capacity of 1.5 to 2 times greater than the rated current

of the inverter should be used.

• When one MCCB is used for more than one device (e.g. inverter), the

sequence must be set up so that the power supply is turned off by a

fault output.

3.6.1.2 Installing a magn etic contactor (MC)

• The inverter is able to use without the magnetic contactor of power

supply side.

• In case of installing the magnetic contactor to input power supply in

order to prevent an accident occurred by the automatic restart

operation after the recovery from a power interruption, frequent

start/stop of the inverter through this device reduces durability of the

inverter.

• When the digital operator is used, unless the inverter operation mode is

set to the automatic start operation, it cannot be automatically started

after the recovery rom a power interruption.

• Install the surge absorber on the coil.

3.Wiring 3-11

Table 3.4 MCCB and magnetic contactor

MCCB

Model

Capacity

(kVA)

Rated

Output

Current(A)

AF AT

Magnetic

Contactor

Rated Current(A)

20P4 1.1 3.2 30A 5A 10A

20P7 1.9 5.0 30A 10A 10A

21P5 3.0 8.0 30A 20A 10A

22P2 4.2 11.0 30A 20A 20A

23P7 6.7 17.5 30A 30A 20A

40P4 1.4 1.8 30A 5A 10A

40P7 2.6 3.4 30A 5A 10A

41P5 3.7 4.8 30A 10A 10A

42P2 4.2 5.5 30A 10A 10A

43P7 6.5 8.6 30A 20A 10A

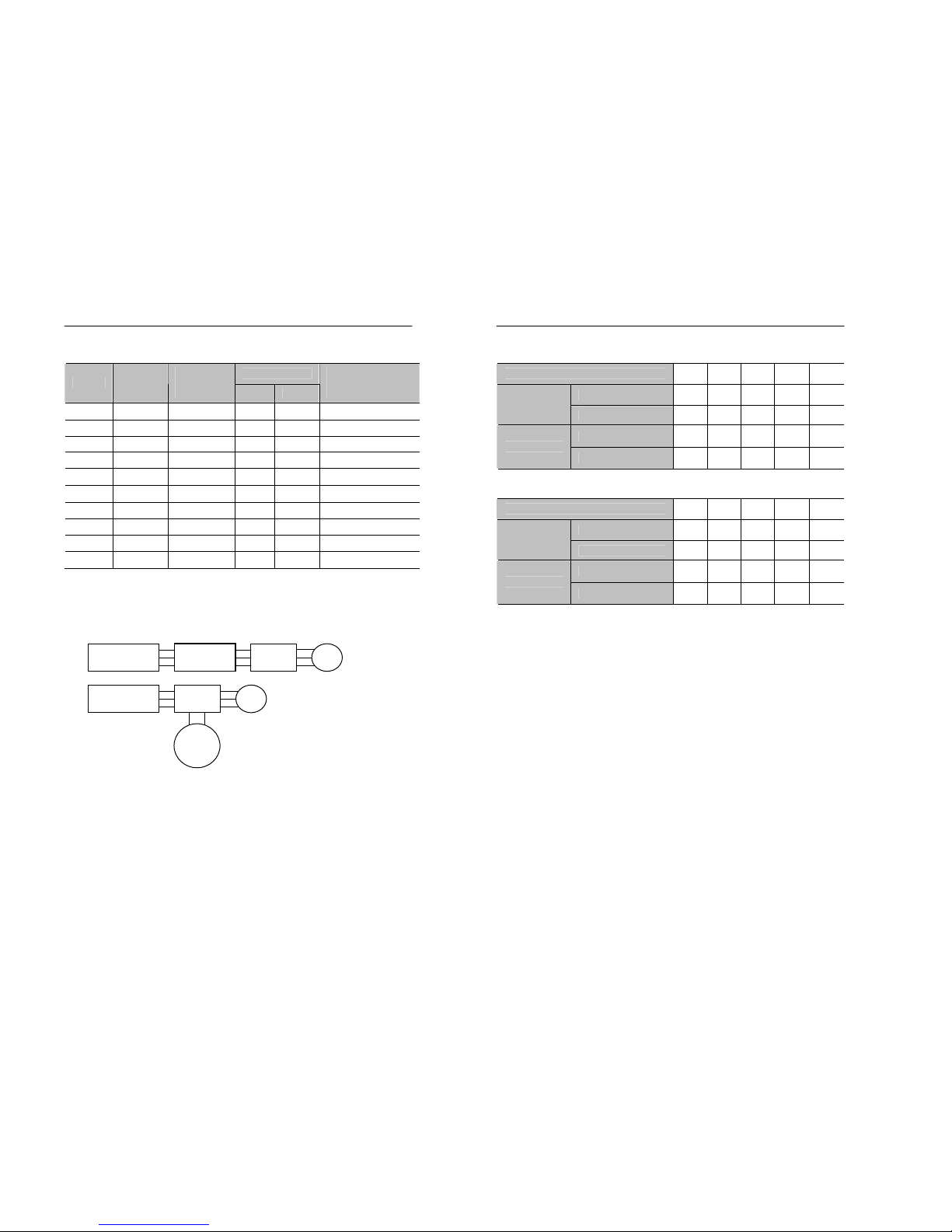

3.6.1.3 Installing an AC reactor/DC reactor

• Two options are available when the inverter is connected to a largecapacity power transformer whose capacity is 600kVA or higher:

Figure 3.5 Reactor installation

• If not, inverter may be damaged due to an excessive peak current flow

through the input power circuit.

• AC reactor/DC reactor also can be used to improve the power factor

on input power supply side.

Transformeter

AC Reactor

Inverter

Transformeter

M

DC

Reactor

M

Inverter

3-12 MOSCON-E7 Us er’s Manual

Table 3.5 DC Reactor

Inverter capacity(kW) 0.4 0.7 1.5 2.2 3.7

Current[A] 5.4 5.4 18 18 18

200V Class

Inductance[mH] 8 8 3 3 3

Current[A] 3.2 3.2 5.7 5.7 12

400V Class

Inductance[mH] 28 28 11 11 6.3

Table 3.6 AC Reactor

Inverter capacity(kW) 0.4 0.7 1.5 2.2 3.7

Current[A] 2.5 5 10 15 20

200V Class

Inductance[mH] 4.1 2.1 1.1 0.71 0.53

Current[A] 1.3 2.5 5 7.5 10

400V Class

Inductance[mH] 28 8.4 4.2 3.6 2.2

3.6.1.4 Connecting input power supply

• Input power supply can be connected to any terminal R/L1, S/L2, or

T/L3 on the terminal block; the phase sequences of input power

supply are irrelevant.

3.6.1.5 Installing a surge absorber

• A surge absorber must be used for inductive loads near the FARA

MOSCON-E7. Otherwise, it may damage the devices or cause

malfunctioning.

• These inductive loads includes:

- MC,

- Electromagnetic relay,

- Solenoid valves and solenoids,

- MCCB

3.Wiring 3-13

Table 3.7 Application of the surge absorber

Description Model Specification

Large Capacity Coil

except Relay

DCR2-50A 22E AC250V 0.5u ㎌ 200Ω

200

~230V

Control Relay DCR2-10A 25C AC250V 0.1 ㎌ 100Ω

380~460V Devices DCR2-50D 100B DC 1000V 0.5 ㎌ 220Ω

Note) The above surge absorbers are the product of MARCON. Use the recommend product or

equivalents.

3.6.1.6 Installing a noise filter on power supply side

• Install the noise filter in order to eliminate noise transmitted from the

power line to the inverter.

(a) Wiring example 1 (Correct)

(b) Wiring example 2

IM

◠

◠

◠

~

MCCB

◠

◠

MCCB

Control

circuit

E7

※Use the noise filter

designed specifically

for the inverter

Power

Noise filter

IM

◠

◠

◠

~

MCCB

E7

Power

Noise filter

※Noise filter is not

necessary if the inverter

and power is used 1:1

3-14 MOSCON-E7 Us er’s Manual

(c) Wiring example 3

(d) Incorrect wiring example

Figure 3.6 Power supply noise filter installation

IM

◠

◠

◠

~

MCCB

◠

◠

MCCB

Control

circuit

E7

Power

General

noise

filter

IM

◠

◠

◠

General

noise

filter

~

MCCB

◠

◠

MCCB

Control

circuit

E7

※Usin

g

the general noise

filter is not effective.

Power

IM

◠

◠

◠

~

MCCB

◠

◠

MCCB

Control

circuit

E7

Power

※Connecting the insulating

transformer to power

supply of the control

circuit is same effective of

the noise filter.

3.Wiring 3-15

3.6.2 Wiring on the output side of main circuit

3.6.2.1

Precautions when wiring on the output side of main circuit

• Never connect a power supply to output terminals U/T1, V/T2,

and W/T3.

Otherwise, it may damage the internal circuits of the inverter.

• Never short or ground output terminals.

• The output wires should not have contact with the inverter heatsink.

• Do not connect a phase advancing capacitor or LC/RC noise

filter to an output circuit.

Otherwise, it may damage the inverter or cause a fire.

• Do not connect an electromagnetic switch or MC to an output

circuit.

Otherwise, it will actuate the overcurrent protection circuit of the

inverter.

3.6.2.2 Connecting the inverter and motor

• Connect output terminals U/T1, V/T2, and W/T3 to motor wires U, V,

and W respectively.

•

Check if the motor rotates in correct direction according to the

command. If not (motor rotating in reverse with the forward run

command), switch any of two output terminals to each other and

reconnected them.

3.6.2.3 Installing a noise filter on the output side

Install a noise filter to reduce radio noise and inductive noise.

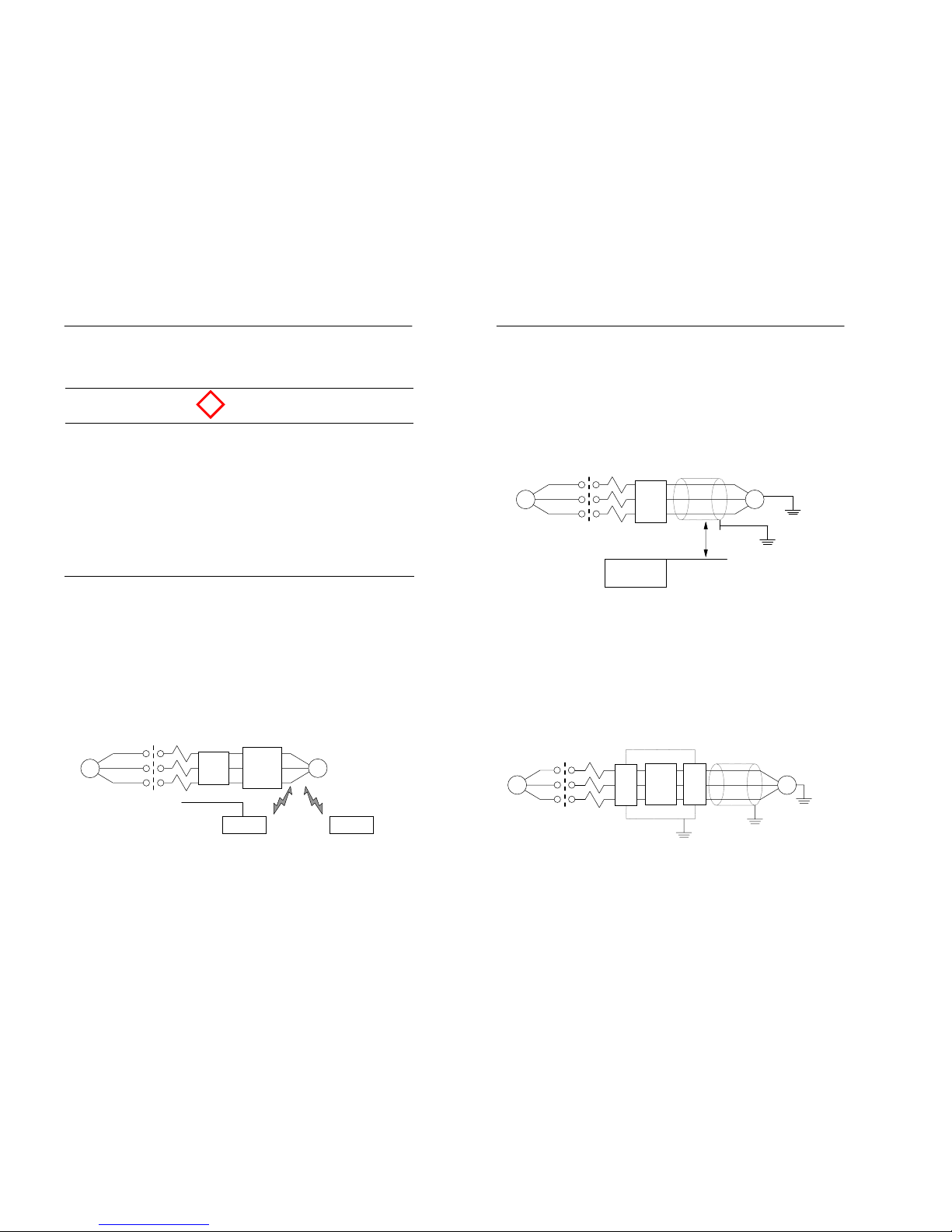

Figure 3.7 Noise filter on the output side

IM

◠

◠

◠

Noise

filter

~

MCCB

E7

Power

Controller

AM radio

Radio noise

Inductive

noise

Signal

line

DANGER

!

Inductive noise: Noise generated on the signal line by electromagnetic

induction. It causes the controller to malfunction.

Radio noise: High-freq uency noise generated from the inverter and cables.

3-16 MOSCON-E7 Us er’s Manual

3.6.3 Dealing with inductive noises

• As mentioned previously, noise filter can be used to prevent the

inductive noise generated on the output side.

• As an option, cables can be routed through a grounded metal pipe to

prevent inductive noise.

• If the metal pipe and the signal line are at least 30cm apart, the

inductive noise can be considerably reduced

.

Figure 3.8 Dealing with inductive noise

3.6.4 Dealing with radio interference (RFI)

• Radio noise is generated from the inverter as well as the input/output

lines.

• The radio noise can be reduced by installing the noise filters on both

input and output sides, and also installing the inverter in an enclosed

and grounded steel box.

• Make the cable between the inverter and motor as short as possible.

Figure 3.9 Dealing with radio interference

IM

◠

◠

◠

~

MCCB

Power

Noise

filter

Noise

filter

E7

Metal pipe

◠

◠

◠

~

MCCB

Power

IM

Controller

30cm Min.

Signal line

Metal pipe

E7

Loading...

Loading...