Samsung MIM-E03 N Series Installation Manual

MIM-E03N

SAMSUNG CONTROL KIT

installation manual

imagine the possibilities

Thank you for purchasing this Samsung product.

EN

ES FRITPT

EHS MONO Kit-EU_IM_05388A-04_EN.indd 1 2016-06-23 오후 3:42:55

DE

DB68-05388A-04

Contents

Safety precautions ....................................................................................................... 3

Product specications ................................................................................................... 4

Main components ....................................................................................................... 5

Installing the unit ........................................................................................................ 6

Wiring works ............................................................................................................ 9

Wiring schematics ...................................................................................................... 33

Self-test mode of wired remote controller ............................................................................... 34

Troubleshooting ........................................................................................................ 36

Error codes ............................................................................................................. 39

Mixing Valve ............................................................................................................ 41

Concrete curing function ................................................................................................ 44

Installation option setting ............................................................................................... 45

COMMISSION REGULATION (EU) No 813/2013

COMMISSION DELEGATED REGULATION (EU) No 811/2013

I

) ......................................................................... 47

i

) ............................................................. 68

2

EHS MONO Kit-EU_IM_05388A-04_EN.indd 2 2016-06-23 오후 3:42:55

Safety precautions

ENGLISH

Carefully follow the precautions listed as below because they are essential to guarantee the safety of SAMSUNG product.

• Always disconnect a power supply of Air-Water Heat Pump before servicing it or accessing

components inside the unit.

WARNING

Warning

Carefully read the contents of this manual before installing the control kit and store the manual in a safe place in order to

be able to use it as reference after installation.

For maximum safety, installers should always carefully read the following warnings.

Store the manual in a safe location and remember to hand it over to the new owner if the kit is sold or transferred.

The kit is compliant with the requirements of the Low Voltage Directive (72/23/EEC), the EMC Directive (89/336/EEC) and

the Directive on pressurized equipment (97/23/EEC).

The manufacturer shall not be responsible for damage originating from unauthorized changes or the improper

connection of electric and hydraulic lines. Failure to comply with these instructions or to comply with the requirements

set forth in the “Operating limits” table, included in the manual, shall immediately invalidate the warranty.

Do not use the units if you see some damages on the units and recognize something bad such as loud noisy, smell of

burning.

In order to prevent electric shocks, res or injuries, always stop the unit, disable the protection switch and contact

SAMSUNG’s technical support if the unit produces smoke, if the power cable is hot or damaged or if the unit is very noisy.

Always remember to inspect the unit, electric connections, and protections regularly. These operations shall be

performed by qualied personnel only.

The unit contains various electric parts, which should be kept out of the reach of children.

Do not attempt to repair, move, alter or reinstall the unit by unauthorized personnel, these operations may cause product

damage, electric shocks and res.

Do not place containers with liquids or other objects on the unit.

All the materials used for the manufacture and packaging of the air to water heat pump are recyclable.

The packing materials must be disposed of in accordance with local regulations.

Wear protective gloves to unpack, move, install, and service the unit to avoid your hands being injured by the edge of the

parts.

Do not touch the internal parts while running the units.

Inspect the product shipped and check if damaged during transport. If the product has some damages, DO NOT INSTALL

and immediately discuss about the damages with the carrier or retailer (if the installer or the authorized technician has

collected the material from the retailer.)

Our units shall be installed in compliance with the spaces described in the installation manual, to ensure accessibility

from both sides and allow repairs or maintenance operations to be carried out. If the units installed without complying

with procedures described in manual, additional expenses can be asked because special harnesses, ladders, scaolding

or any other elevation system for repair service will NOT be considered part of the warranty and will be charged to the

end customer.

When service works required, make sure to disconnect the power supply at least 1 minute to prevent electric shocks.

- Always check the voltage at the terminals of main PCB before trying to touch.

Use electric wires which manual designated. Connections between wires and terminals shall be assembled without any

tension. If the assembly works is not implemented well, it can lead to have product damages and res.

After wiring works, terminal block cover shall be xed rmly. Without cover, it can cause to have product damage and re.

Be sure not to perform power cable modication, midway wiring, and multiple wire connection.

- It may cause electric shock or re due to poor connection or insulation and current limit override.

- When midway wiring is required due to power line damage, refer to "How to connect your extended power cables" in

the installation manual.

• Verify that installation and testing operations shall be performed by qualied personnel.

• To prevent serious damage on the system and injuries to users, precautions and other

notices shall be observed.

3

EHS MONO Kit-EU_IM_05388A-04_EN.indd 3 2016-06-23 오후 3:42:55

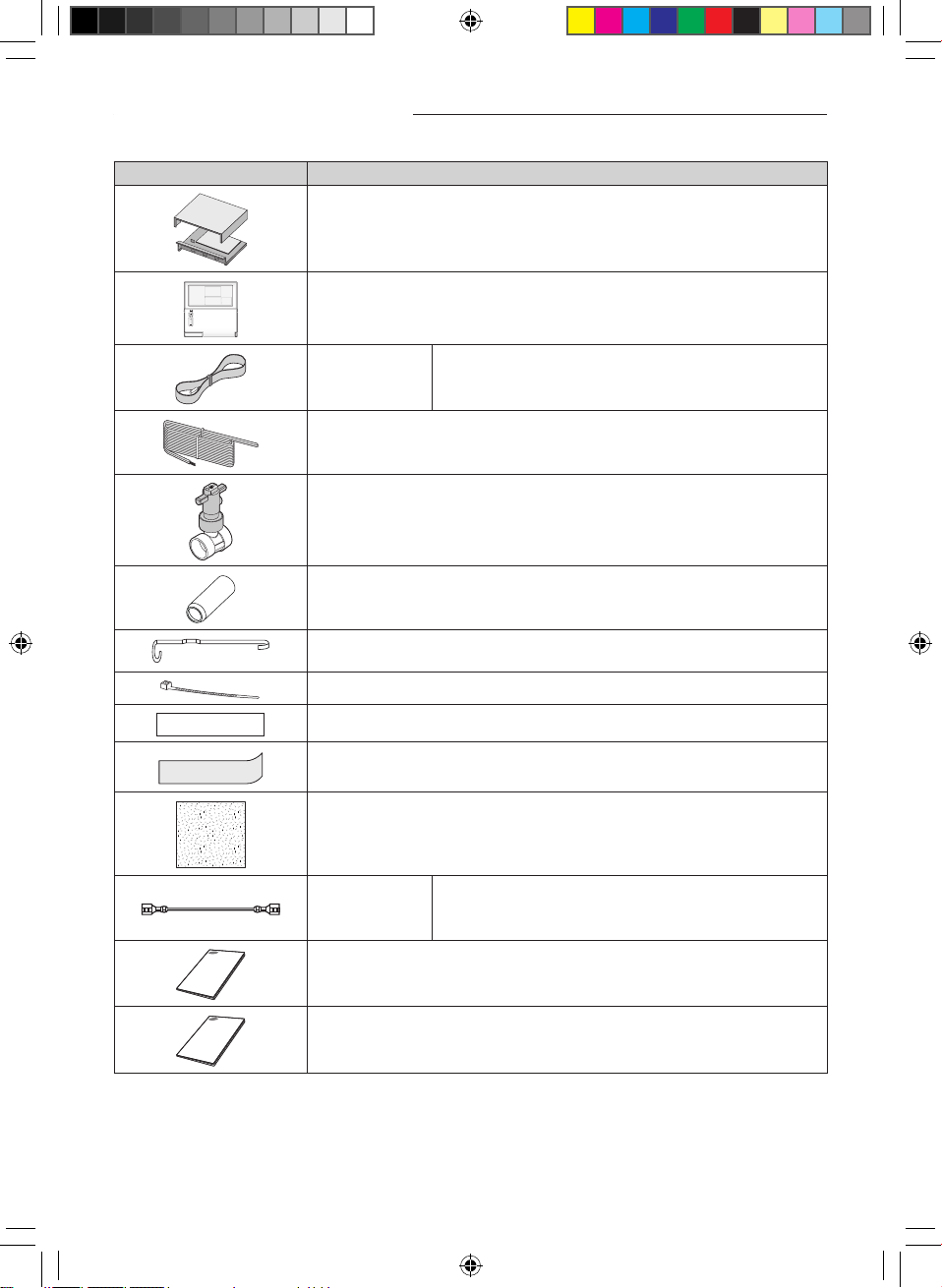

Product specications

Item Description

Temp. Sensor

MIM-E03N

Wired remote controller

Temp. Sensor for DHW Tank (15m, YEL) (1EA)

Temp. Sensor for Mixing Valve (15m, BLU) (1EA)

Temp. Sensor for Heater (15m, BLK) (1EA)

Smart Grid cable (Red, 2 m, 1EA)

Flow Switch (1EA, 2m)

Sensor holder (2EA, OD 7.8mm)

Sensor clip (2EA)

Cable tie (4EA)

Aluminum tape (2EA)

Rubber tape (2EA)

Insulartor (2EA)

Back-up heater conector (Red)

LEAD CONNECTOR

Back-up heater conector (Brown)

Back-up heater conector (White)

Installation manual

User manual

Temp. sensor = Temperature sensor

MIM-E03AN : 9/12/14/16 kW outdoor unit

MIM-E03BN : 5 kW outdoor unit

4

EHS MONO Kit-EU_IM_05388A-04_EN.indd 4 2016-06-23 오후 3:42:56

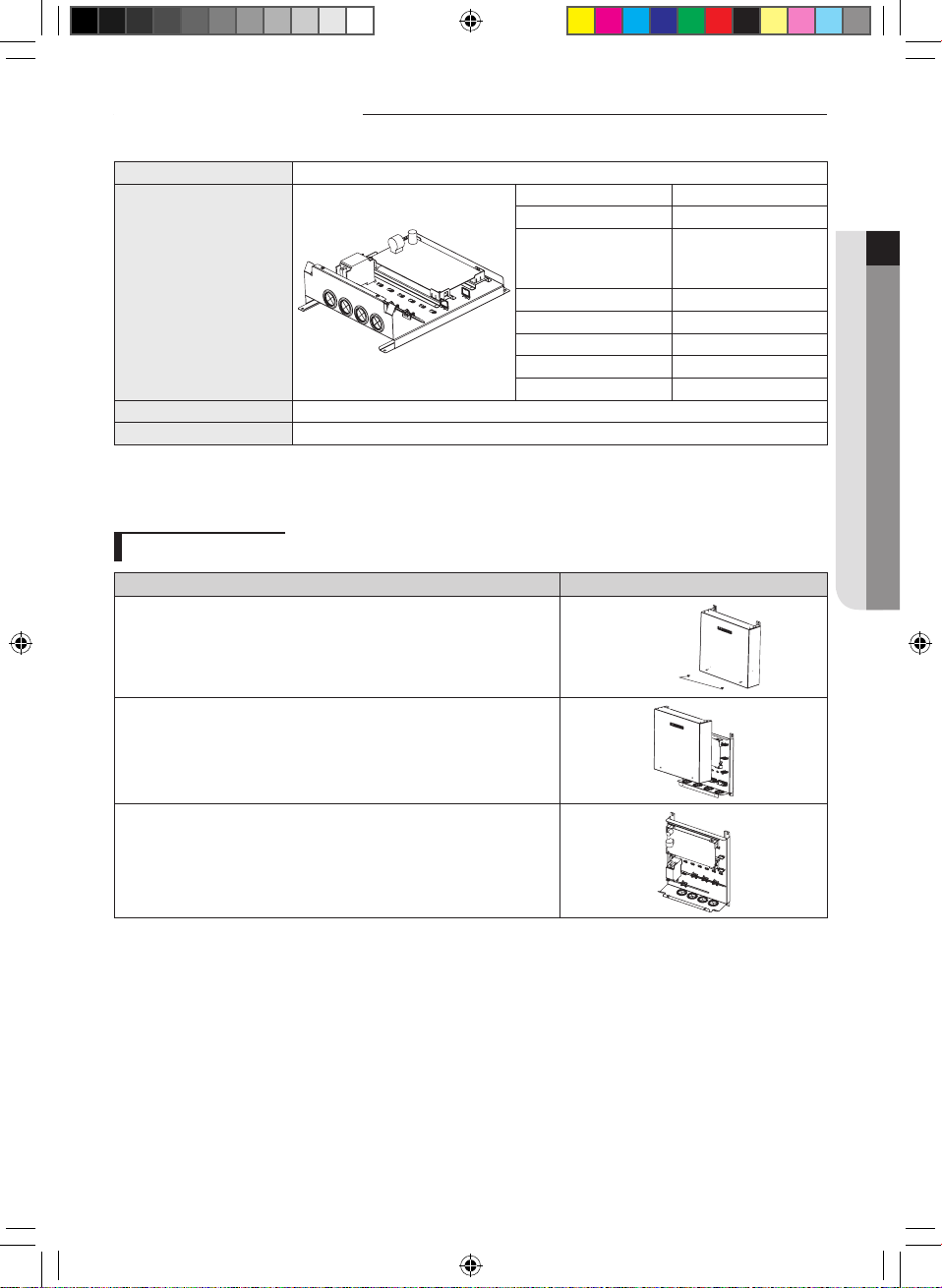

Main components

ENGLISH

Model name MIM-E03N

Parts Qty.

Main PBA 1

ELCB

- Rated current : 30A

Detail components

Weight (Net) 3.5kg

Packing size (W x H x D) 329mm x 439mm x 168mm

Flow Switch Set Point

MIM-E03AN (9/12/14/16 kW outdoor unit) : 16LPM

MIM-E03BN (5 kW outdoor unit) : 7LPM

Mounting the unit

Procedure Remark

1. Remove 2 screw from the unit.

2. Open the top cover and install 4 screws on the wall.

- Leakage current : 30mA

Grounding screw 8

Rubber 4

Base plate 1

Top cover plate 1

Case screw 2

1

Screw

3. Close the top cover and install 2 screw again into the unit.

5

EHS MONO Kit-EU_IM_05388A-04_EN.indd 5 2016-06-23 오후 3:42:56

Installing the unit

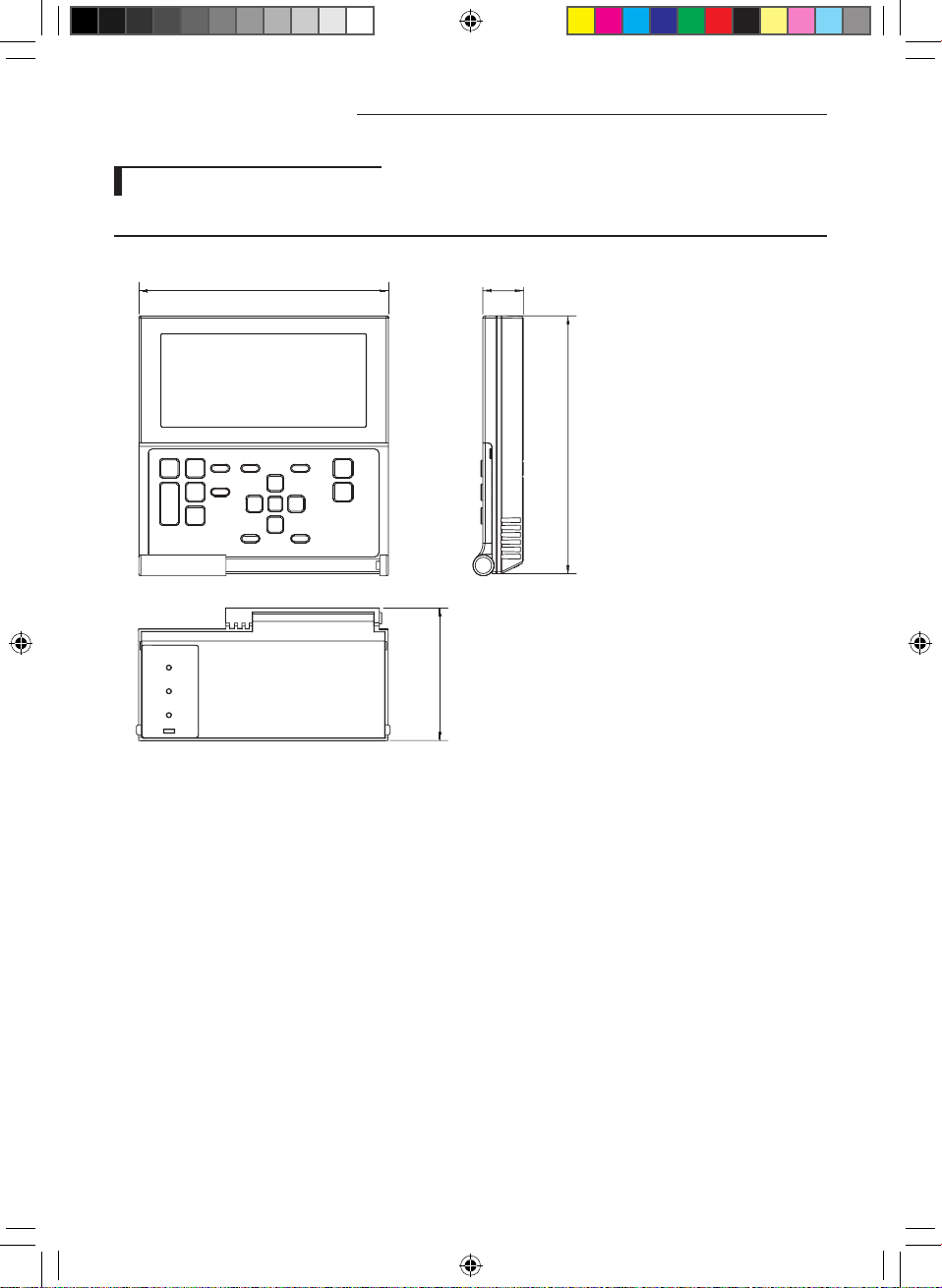

Installing the remote controller

Dimension

120

(Unit : mm)

19.5

124

63.8

6

EHS MONO Kit-EU_IM_05388A-04_EN.indd 6 2016-06-23 오후 3:42:56

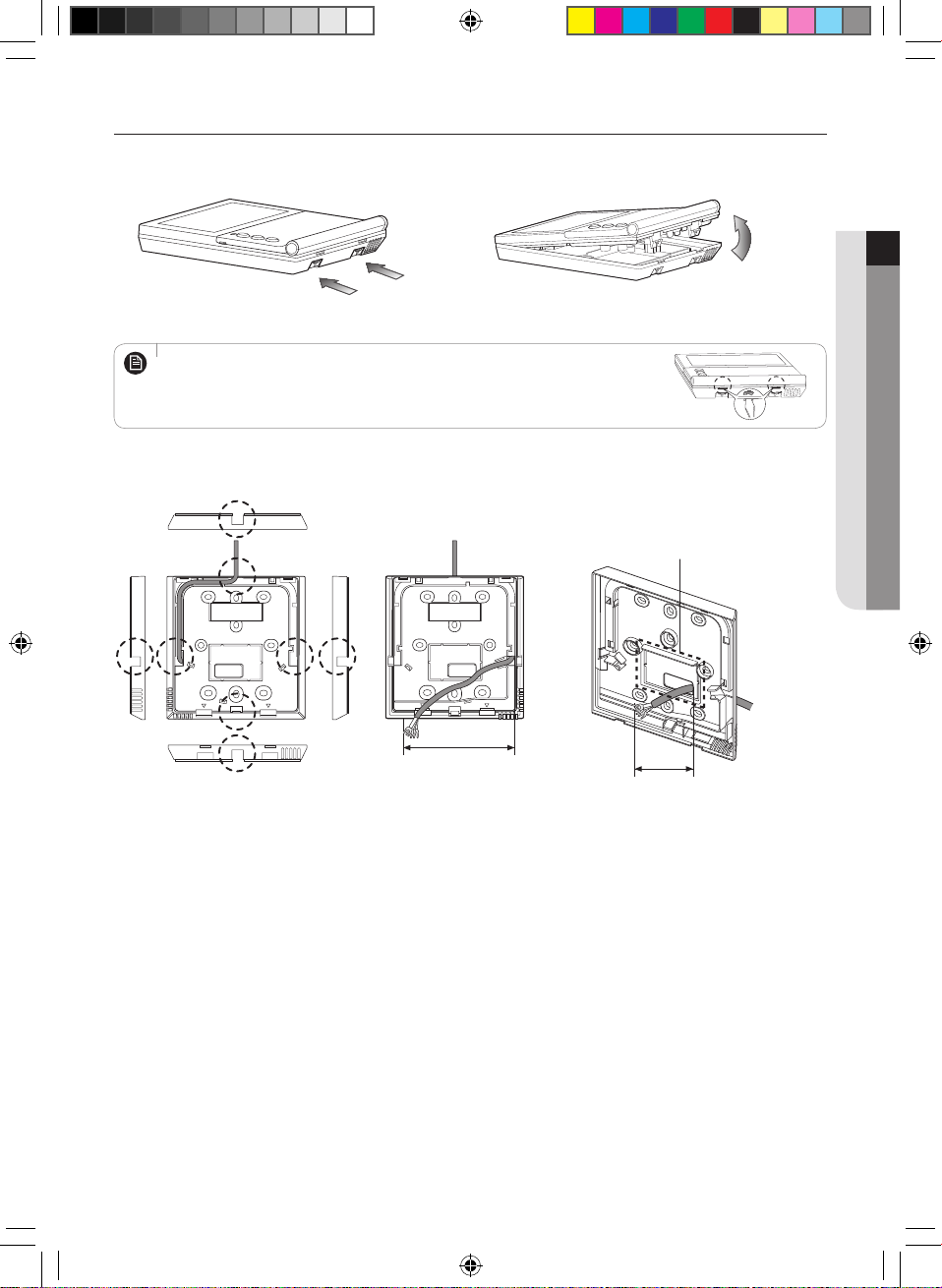

Installation

ENGLISH

1. Push the two hooks at the bottom of your Wired Remote Controller at the same time, and then pull up the front cover to

separate it from the rear cover.

Push the two hooks at the same time.

• Insert a at head screwdriver into the square groove in the upper area of the hook

to disassemble it easily.

NOTE

2. Arrange the communication cable so that they t in the housing along the edges of the rear cover.

If you need more space for the wiring

work, you can take it o.

15cm

10cm

<When the cable is not concealed> <When the cable is concealed>

7

EHS MONO Kit-EU_IM_05388A-04_EN.indd 7 2016-06-23 오후 3:42:57

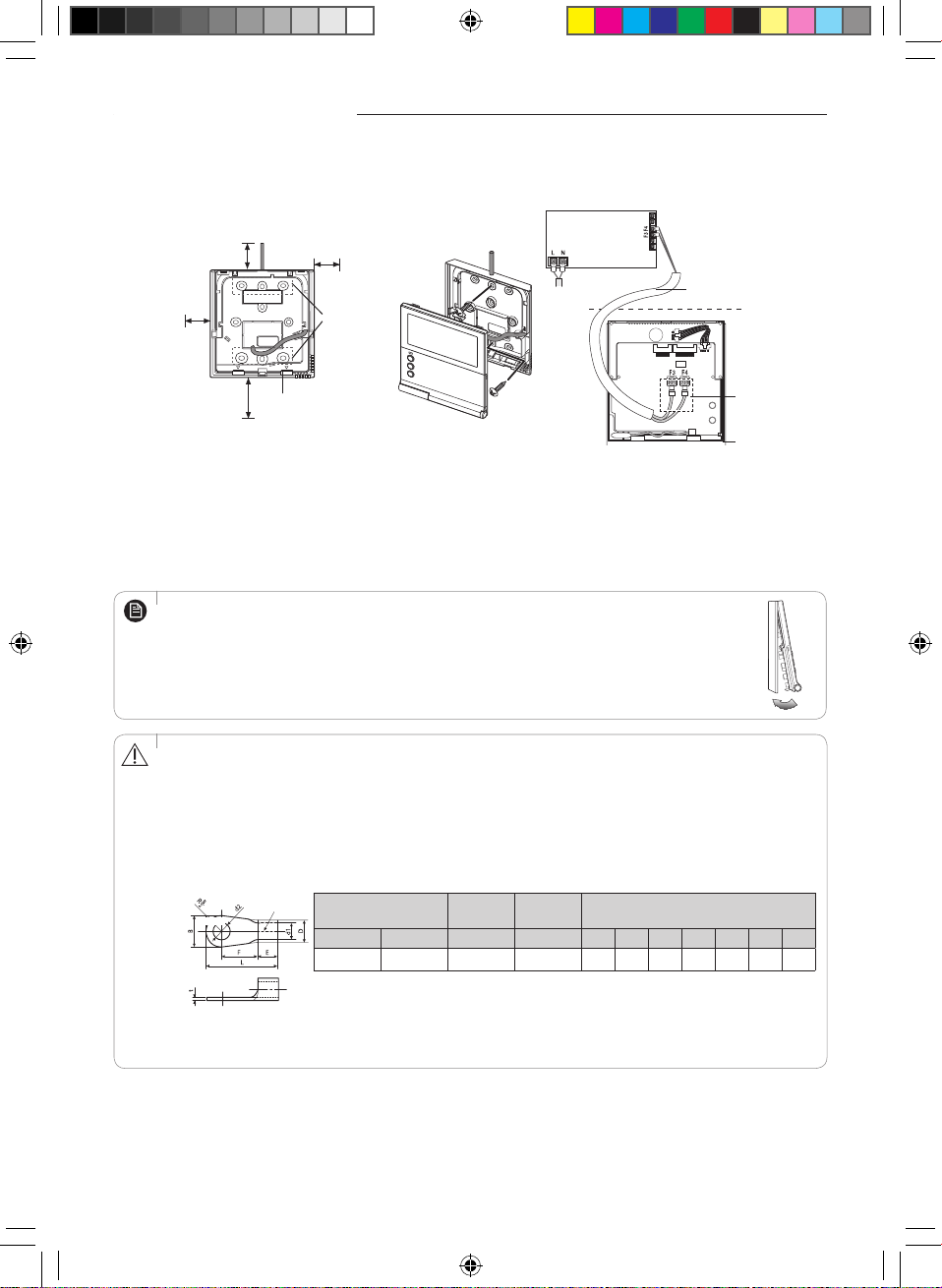

Installing the unit

3. Using more than two screws, rmly ax the rear cover of the remote controller to the wall, and then connect

communication cables(F3, F4), making sure these cables have reasonable length, to the terminal at the back of the cover.

10mm or more

10mm or more

50mm or more

10mm or more

Rear cover

Before xing the rear cover, allow at

least 10mm space of upper side, left

Screw hole

You must t the screws into the

screw holes.

Do not tighten the screws on the

PCB terminal with excessive force.

Control kit

side, right side, and 50mm space of

bottom side.

4. Reassemble your wired remote controller.

• Align the controller with the upper groove rst, and insert it by turning it downward as shown in the

gure. After assembly, check and conrm that no wires are stuck in the gap between the rear and

NOTE

front cover.

• When installing your wired remote controller on the wall, consider the size of the wire hole, and select a wire

with a proper thickness.

CAUTION

• Wire that is connectable to wired remote controller PCB.

- If you install the wired remote controller by reclaiming, install it according to ring terminal cable specication.

- If you install the wired remote controller by using four pieces of PVC wire, remove the 30cm of the sheath of

the cable and install it only with the four pieces of wires. (Recommended specication: AWG21)

- The followings are the specs of the compressed ring terminal connectable to your wired remote controller PCB

Stud

Range of Permitted

Wires

AWG mm

22 ~ 16 0.25 ~ 1.65 1.5 3 0.7 3.8 10.0 4.5 6.5 6.0 21.2

Rated Size Stud Size Basic Size (mm)

2

mm

2

mm t øD G E F W L

Maximum distance of communication cable : 100m

Wire (not supplied)

Wired remote

controller

PCB terminal

Front cover

- ScrewsonthePCBterminalmustbetightenedwithlessthan0.75N•mtighteningtorque.Ifthetightening

torque is greater, it may damage the screw thread.

8

EHS MONO Kit-EU_IM_05388A-04_EN.indd 8 2016-06-23 오후 3:42:57

Wiring works

ENGLISH

• Field-supplied electrical components such as power switch, circuit breakers, wires, terminal blocks, etc must be

properly chosen with compliance with national legislation or regulation.

CAUTION

• Switch o the power supply before making any connections.

• All eld wiring and components must be installed by a licensed electrician.

• Use a dedicated power supply.

• All power connections must be protected from dew condensation by thermal insulation.

• The system shall be earthed. Do not earth the unit to a utility pipe, surge absorber or telephone earth.

Incomplete earth may cause electrical problems.

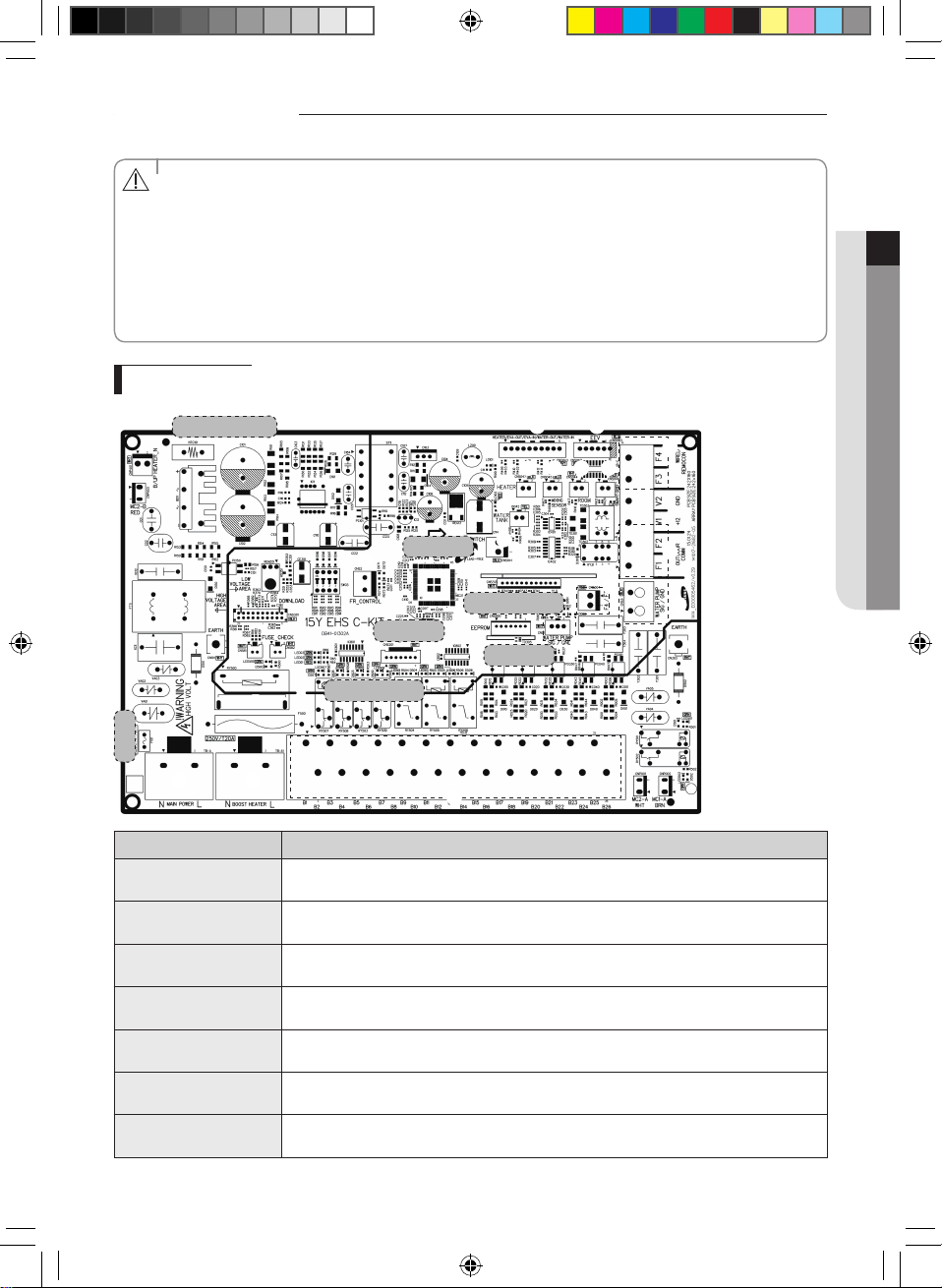

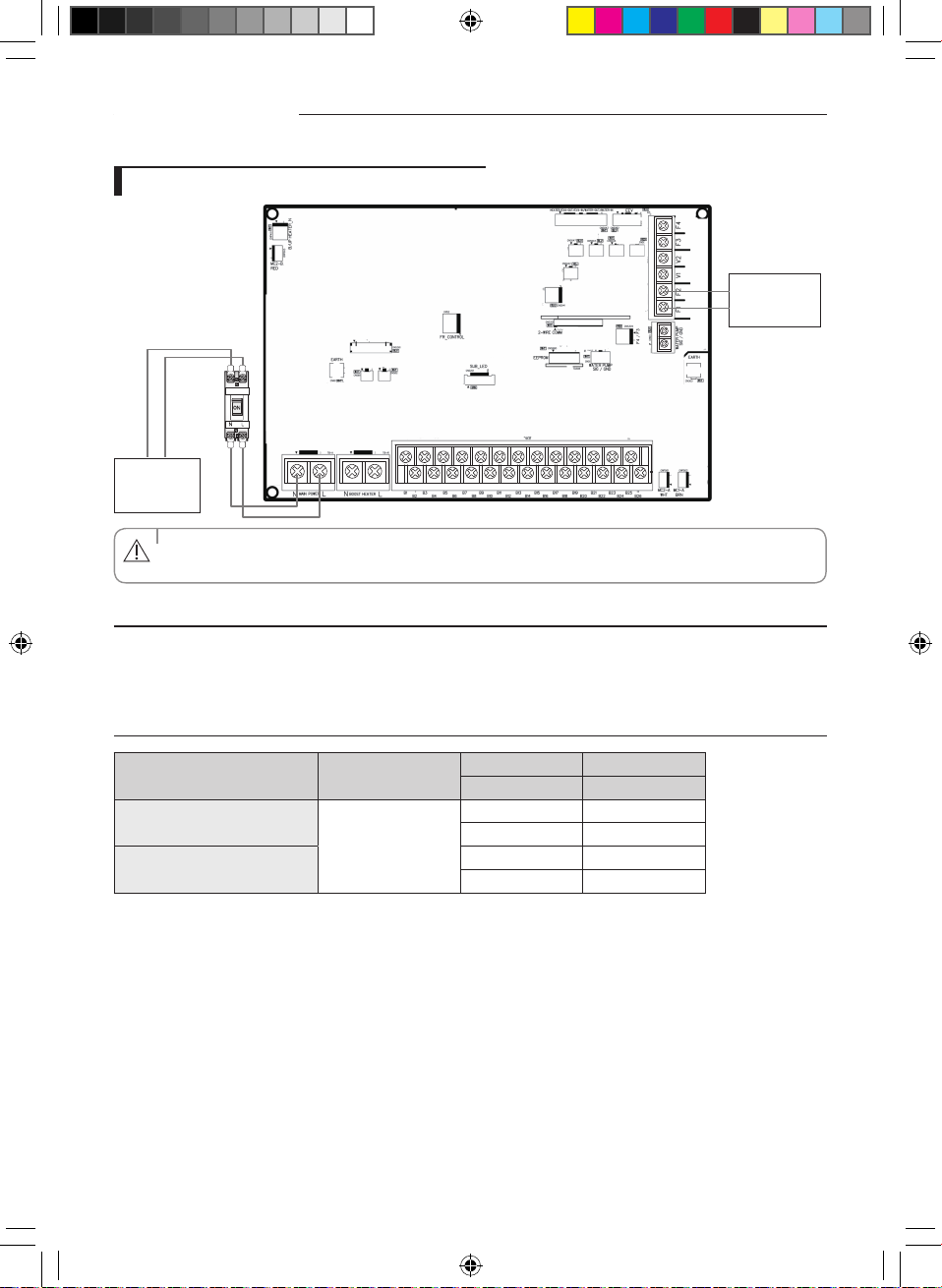

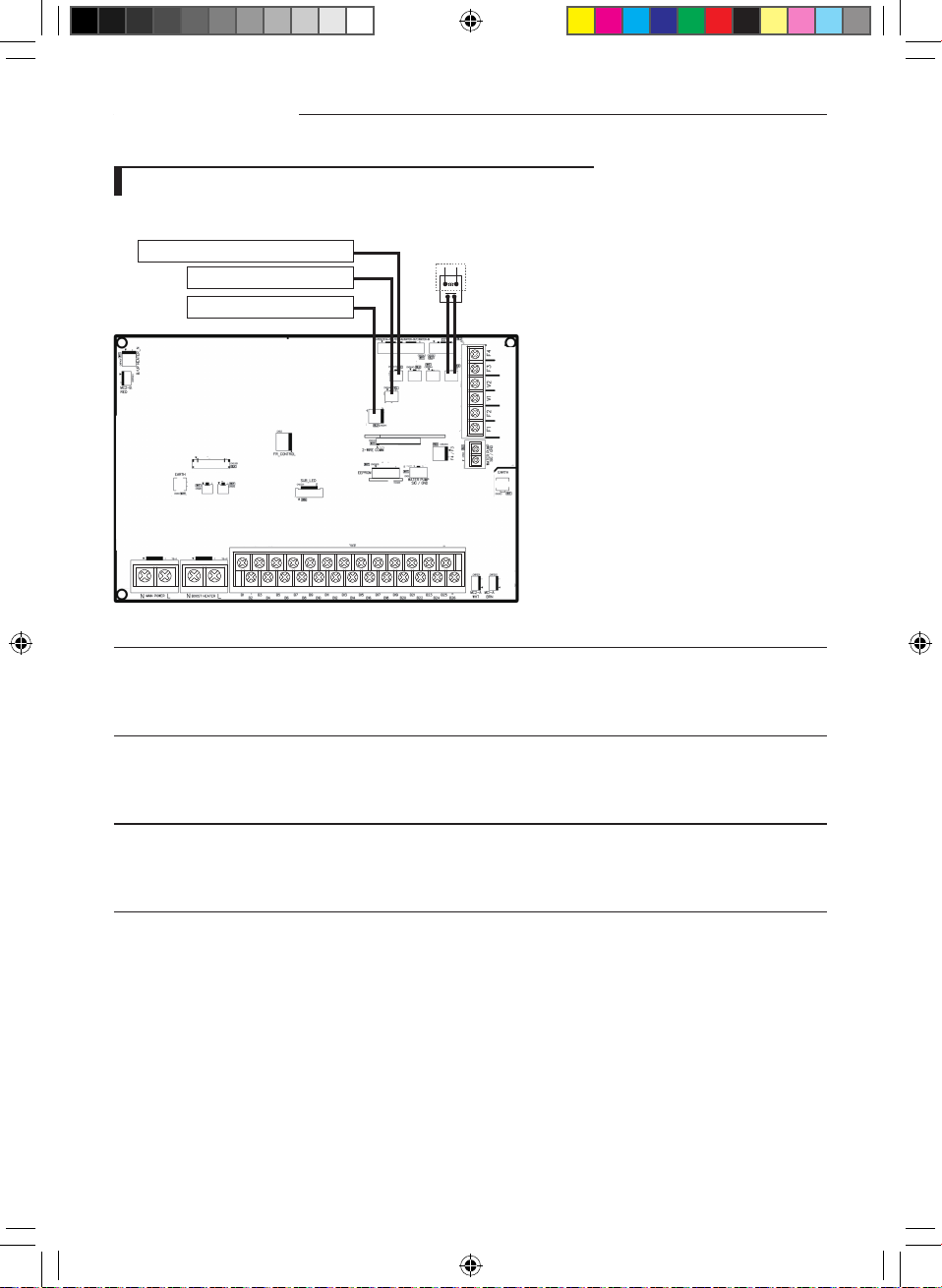

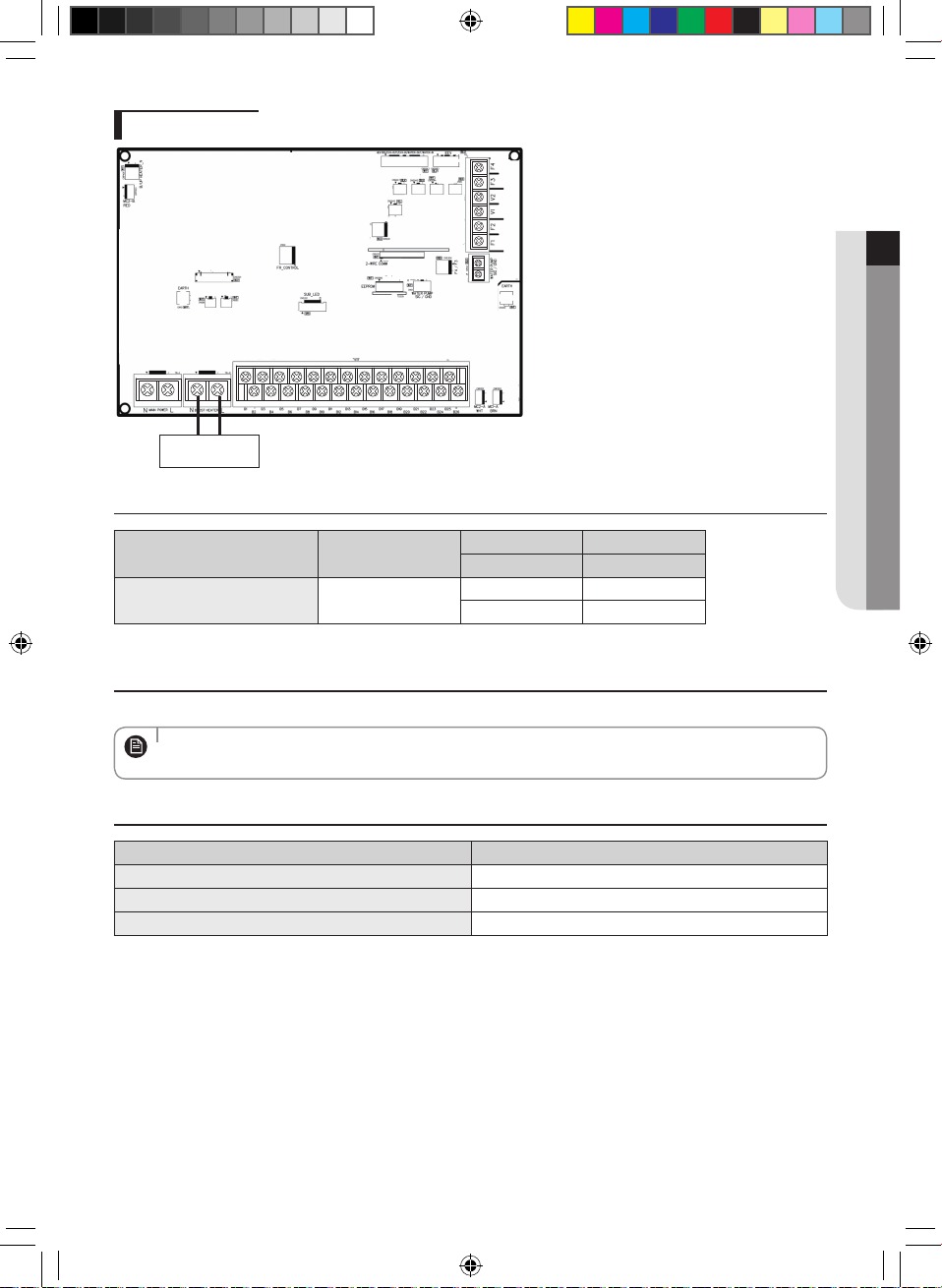

Layout of PCB

Fuse

SMPS circuit

③

①

Load control

⑭ ⑬

No. Note

①

②

③

④

⑤

⑥

⑦

FR Control

CNS2(Green)

Flow Switch

CNS041(Blue)

Water Tank

CNS042(Yellow)

Heater Out(Mono)

CNS047(Black)

Mixing Sensor

CNS045(Blue)

Room Sensor

CNS044(White)

Smart Grid

CNS046(Red)

Micom

LED

②

2-WIRE COMM

EEPROM

⑮

⑧ ⑨

⑩

④ ⑤ ⑥ ⑦

⑪

⑯

⑰

⑫

9

EHS MONO Kit-EU_IM_05388A-04_EN.indd 9 2016-06-23 오후 3:42:57

Wiring works

No. Note

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

CNS043(White)

1-2:Heater Out

3-4:Eva Out

5-6:Eva in

7-8:Water Out

9-10:Water In

EEV

CNS062(Blue)

TB-C (Black)

F3-F4:COMM2 (Wired Remocon)

INPUT/OUTPUT, DC, 210 mA(per each controller)

TB-C (Black)

F1-F2:COMM1 (IN-OUT COMM)

INPUT/OUTPUT, DC, 10 mA

CNS1(White)

1:Signal

3:Gnd

Boost Heater TB-A1 (Black)

L-N, OUTPUT AC

Main Power TB-A(Black)

L-N, INPUT, AC

TB-B(Black)

B1: Neutral_INV PUMP, OUTPUT, AC

B2: Mixing Valve_CW, OUTPUT, AC

B3: Mixing Valve_CCW, OUTPUT, AC

B4: Boiler, OUTPUT, AC

B5: Neutral, OUTPUT, AC

B6: Lived_INV PUMP, OUTPUT, AC

B7: Neutral, OUTPUT, AC

B8: Lived, OUTPUT, AC

B9: 2WAY1_NO, OUTPUT, AC

B10: 2WAY1_NC, OUTPUT, AC

B11: Neutral, OUTPUT, AC

B12: Lived, OUTPUT, AC

B13: 2WAY2_NO, OUTPUT, AC

CNS304(RED)

F3-F4:COMM2 (Wired Remote controller)

CNS3(Black)

1:Signal

2:Gnd

B14: 2WAY2_NC, OUTPUT, AC

B15: Neutral, OUTPUT, AC

B16: Lived, OUTPUT, AC

B17: 3WAY_NO, OUTPUT, AC

B18: 3WAY_NC, OUTPUT, AC

B19: Neutral, OUTPUT, AC

B20: Lived, OUTPUT, AC

B21: THERM01_C, INPUT, AC

B22: THERM01_H, INPUT, AC

B23: THERM02_C, INPUT, AC

B24: THERM02_H, INPUT, AC

B25: Solar/Thermostat_N, INPUT, AC

B26: Solar/Thermostat_L, INPUT, AC

10

EHS MONO Kit-EU_IM_05388A-04_EN.indd 10 2016-06-23 오후 3:42:58

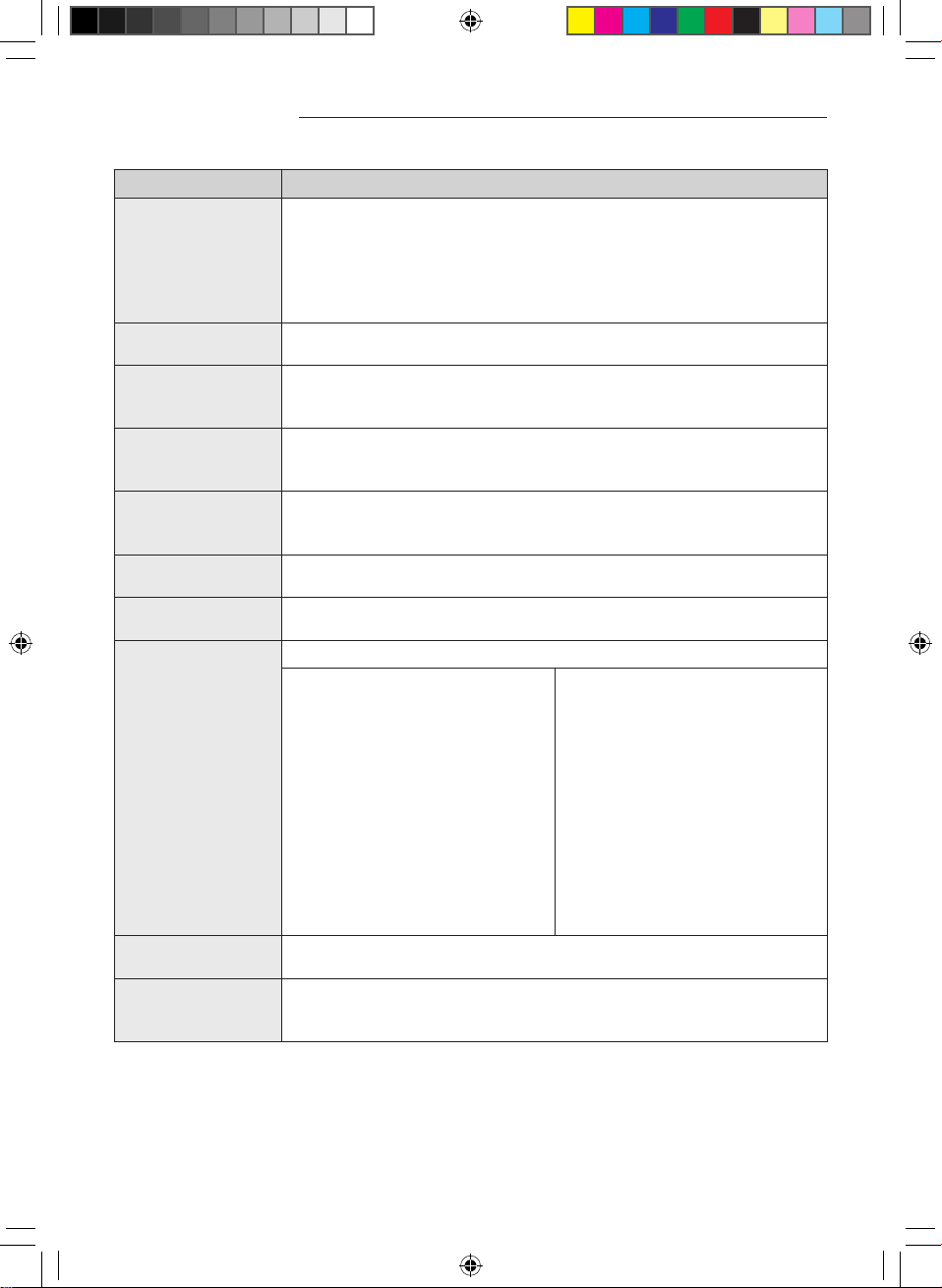

Selecting solderless ring terminal

ENGLISH

Select a solderless ring terminal of a connecting power cable based on a nominal dimensions for cable.

Cover a solderless ring terminal and a connector part of the power cable and then connect it.

Silver solder

Nominal dimensions for cable (mm) 1.5 2.5 4/6 10

Nominal dimensions for screw (mm) 4 4 4 8 8

B

D

d1

E Min. 4.1 4.1 6 7.9

F Min. 6 7 5 9 9

L Max. 16 17.5 20 28.5 30

d2

t Min. 0.7 0.8 0.9 1.15

Standard dimension (mm) 8 9.5 9.5 12 12

Allowance (mm) ±0.2 ±0.2 ±0.2 ±0.2

Standard dimension (mm) 3.4 4.2 5.6 7.1

Allowance (mm)

Standard dimension (mm) 1.7 2.3 3.4 4.5

Allowance (mm) ±0.2 ±0.2 ±0.2 ±0.2

Standard dimension (mm) 4.3 5.3 4.3 8.4 8.4

Allowance (mm)

+0.3

-0.2

+ 0.2

0

+0.3

-0.2

+ 0.2

0

+ 0.2

0

+0.3

-0.2

+0.4

0

+0.3

-0.2

+0.4

0

11

EHS MONO Kit-EU_IM_05388A-04_EN.indd 11 2016-06-23 오후 3:42:58

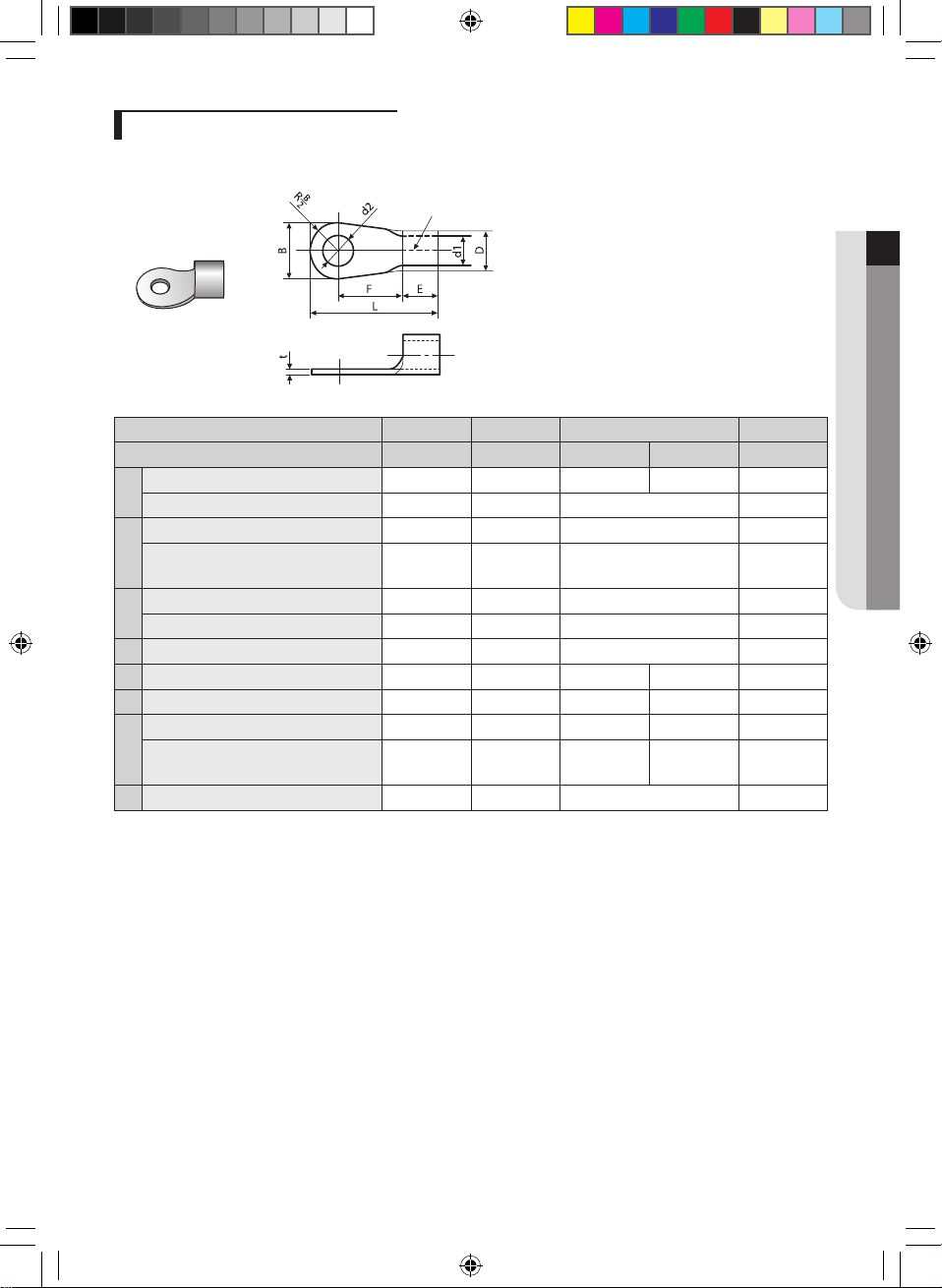

Wiring works

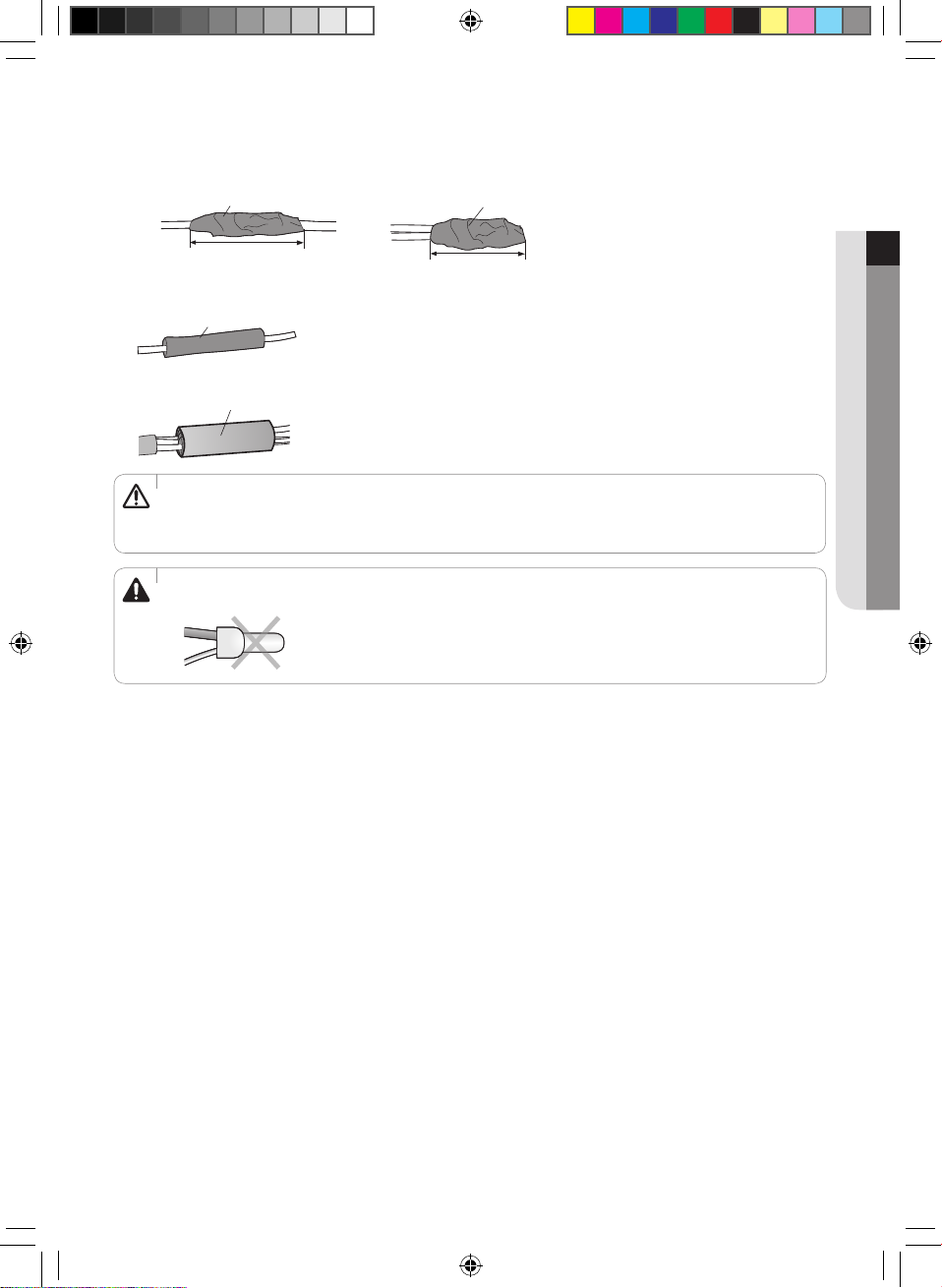

How to connect your extended power cables

1. Prepare the following tools.

Tools Crimping pliers Connection sleeve (mm) Insulation tape Contraction tube (mm)

Spec MH-14 20xØ6.5(HxOD) Width 19mm 70xØ8.0(LxOD)

Shape

2. As shown in the gure, peel o the shields from the rubber and wire of the

power cable.

- Peel o 20 mm of cable shields from the pre-installed tube.

• For information about the power cable specications for indoor and

outdoor units, refer to the installation manual.

CAUTION

• After peeling o cable wires from the pre-installed tube, insert a

contraction tube.

Power cable

120

180

Pre-installed tube for the power cable

20

202020

60

(Unit: mm)

3. Insert both sides of core wire of the power cable into the connection sleeve.

Method 1

Push the core wire into the sleeve from both sides.

Connection sleeve

Method 2

Twist the wire cores together and push it into the sleeve.

Connection sleeve

4. Using a crimping tool, compress the two points and ip it over and compress another two points in the same location.

- The compression dimension should be 8.0.

- After compressing it, pull both sides of the wire to make sure it is rmly pressed.

Compression

dimension

Method 1

Compress it 4 times.

Method 2

Compress it 4 times.

5 mm

5 mm

12

EHS MONO Kit-EU_IM_05388A-04_EN.indd 12 2016-06-23 오후 3:42:58

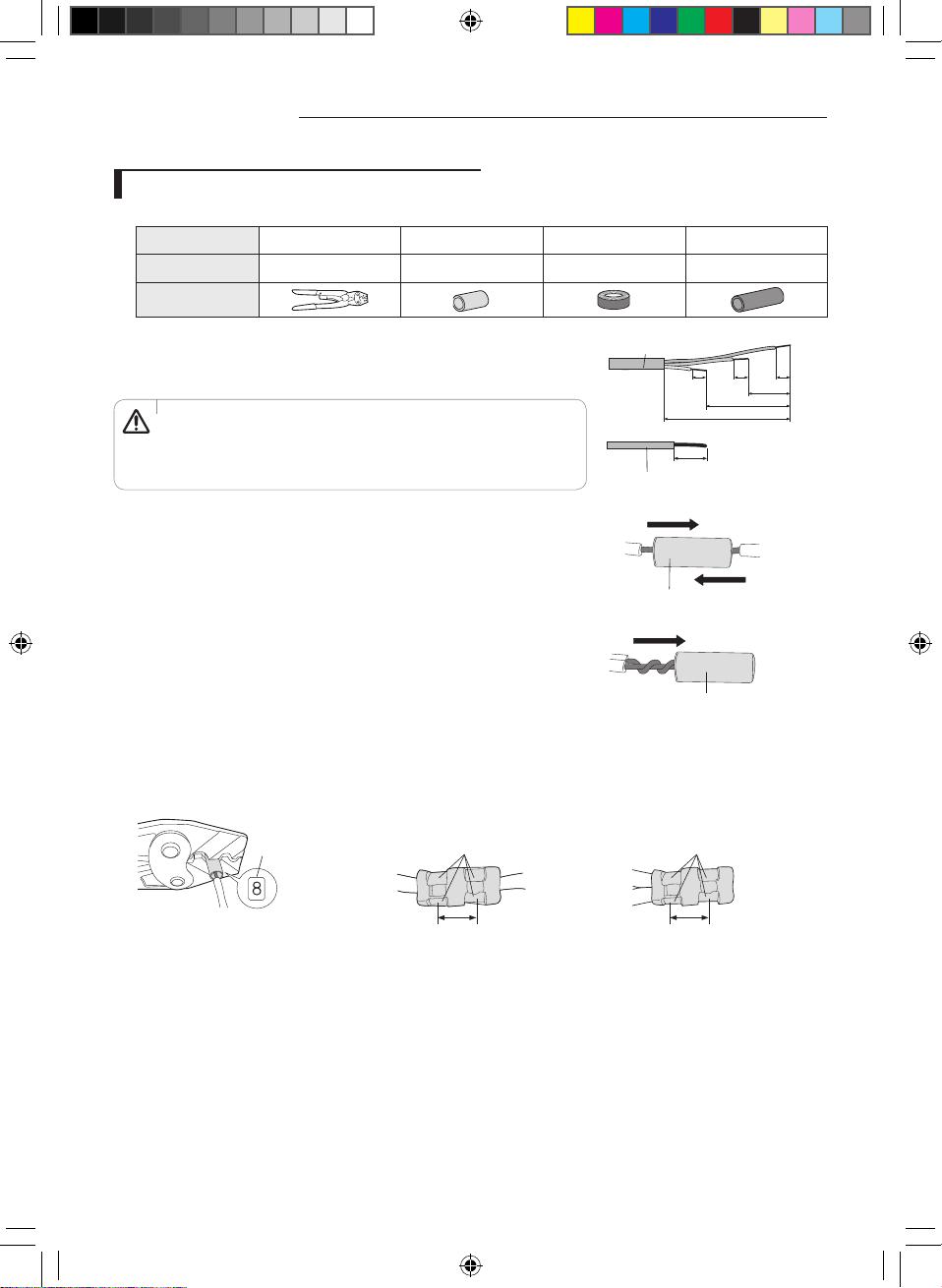

5. Wrap it with the insulation tape twice or more and position your contraction tube in the middle of the insulation tape.

ENGLISH

Three or more layers of insulation are required.

Method 1

Insulation tape

Method 2

Insulation tape

40 mm

35 mm

6. Apply heat to the contraction tube to contract it.

Contraction tube

7. After tube contraction work is completed, wrap it with the insulation tape to nish.

Insulation tape

• Make sure that the connection parts are not exposed to outside.

CAUTION

• Be sure to use insulation tape and a contraction tube made of approved reinforced insulating materials that have

the same level of withstand voltage with the power cable. (Comply with the local regulations on extensions.)

• In case of extending the electric wire, please DO NOT use a round-shaped Pressing socket.

WARNING

- Incomplete wire connections can cause electric shock or a re.

13

EHS MONO Kit-EU_IM_05388A-04_EN.indd 13 2016-06-23 오후 3:42:58

Wiring works

Selection for the power and booster heater wire terminal

Connect the cables to the terminal board using the solderless ring terminal.

Use certied and veried cables.

Connect using a driver which is able to apply the rated torque to the screws.

If the terminal is loose, re may occur caused by arc.

If the terminal is connected too rmly, the terminal may be damaged.

External force should not be applied to the terminal block and wires.

The cable ties to fasten the wire should be an incombustible material, V0 or above.

(The cable ties should be used to fasten the power wire and they are supplied with the unit.)

Tightening Torque (kgf • cm)

M3 0.5 ~ 0.75

M3.5 8 ~ 12

M4 12 ~ 18

M5 20 ~ 30

Main PCB

M3.5 Screw

M3 Screw

M4 Screw

ELCB

M3.5 Screw

M5 Screw

14

EHS MONO Kit-EU_IM_05388A-04_EN.indd 14 2016-06-23 오후 3:42:59

Grounding work

ENGLISH

Grounding must be done by a qualied installer for your safety.

Grounding the power cable

The standard of grounding may vary according to the rated voltage and installation place of a heating pump.

Ground the power cable according to the following.

Installation place

Power condition

Electrical potential of lower than 150V

Electrical potential of higher than 150V

High humidity Average humidity Low humidity

Perform the grounding

Must perform the grounding work 3.

(In case of installing circuit breaker)

work 3.

Note 1)

Perform the grounding work 3 if

possible for your safety.

Note 1)

Note 1) Grounding work 3

• Grounding must be done by your installation specialist.

• Check if the grounding resistance is lower than 100Ω.

When installing a circuit breaker that can cut the electric circuit in case of a short circuit, the allowable grounding

resistance can be 30~500Ω.

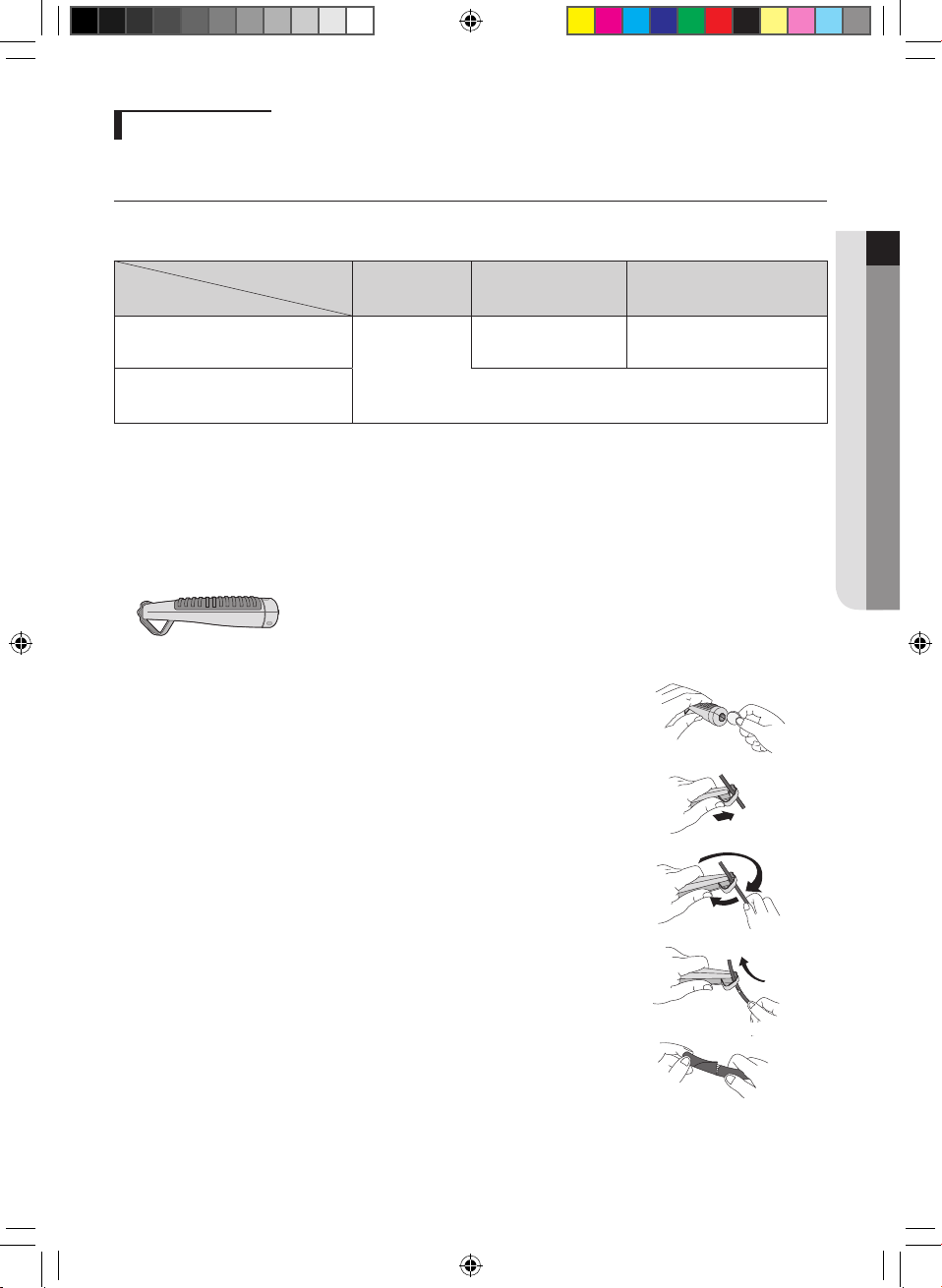

Examples to use cable striper

<Cable striper>

1. Adjust the blade position by coin(the controller is at the bottom side of the tool). Fix the

blade position according to the outer sheath thickness of the power cable.

2. Fix the power cable and tool by using the hook at the top side of the tool.

Note 1)

3. Cut out the outer sheath of the power cable by revolving the tool in the direction of the

arrow, two or three times.

4. At this situation, cut out the outer sheath of the power cable by moving the tool toward

the arrow direction expressed.

5. Slightly bend the wire and pull out the cut part of the outer sheath.

15

EHS MONO Kit-EU_IM_05388A-04_EN.indd 15 2016-06-23 오후 3:42:59

Wiring works

Power and communication with outdoor unit

ELCB

N L

Power Wire

• Be careful when connecting L, N.

CAUTION

Connecting the power wire

1. Connect ‘Live’ and 'Neutral’ power line with ‘L, N’ of a ELCB.

2. Connect ‘L,N’ of a ELCB with ‘A1 and A2’ in TB-A.

3. Connect ‘Protective Earth’ line with ‘Earth screw’ In case.

Communication

Wire

Recommended wire specication

Load Power Supply

Do NOT use Heater (Water Pump,

Valve, Wired RMC)

Use Booster Heater (Max. 3kW)

1Ø, 220-240V, 50Hz

The power cable is not supplied with Air to water heat pump.

This equipment with "IEC 61000-3-12".

Supply cords of parts of appliances for control kit use shall not be lighter than polychloroprene sheathed exible cord

(Code designation IEC:60245 IEC 57 / CENELEC:H05RN-F)

Power Cable Max. Length

2

, wires m

mm

1.5 / 3 L < 10m

2.5 / 3 10m < L

4.0 / 3 L < 10m

6.0 / 3 10m < L

16

EHS MONO Kit-EU_IM_05388A-04_EN.indd 16 2016-06-23 오후 3:43:00

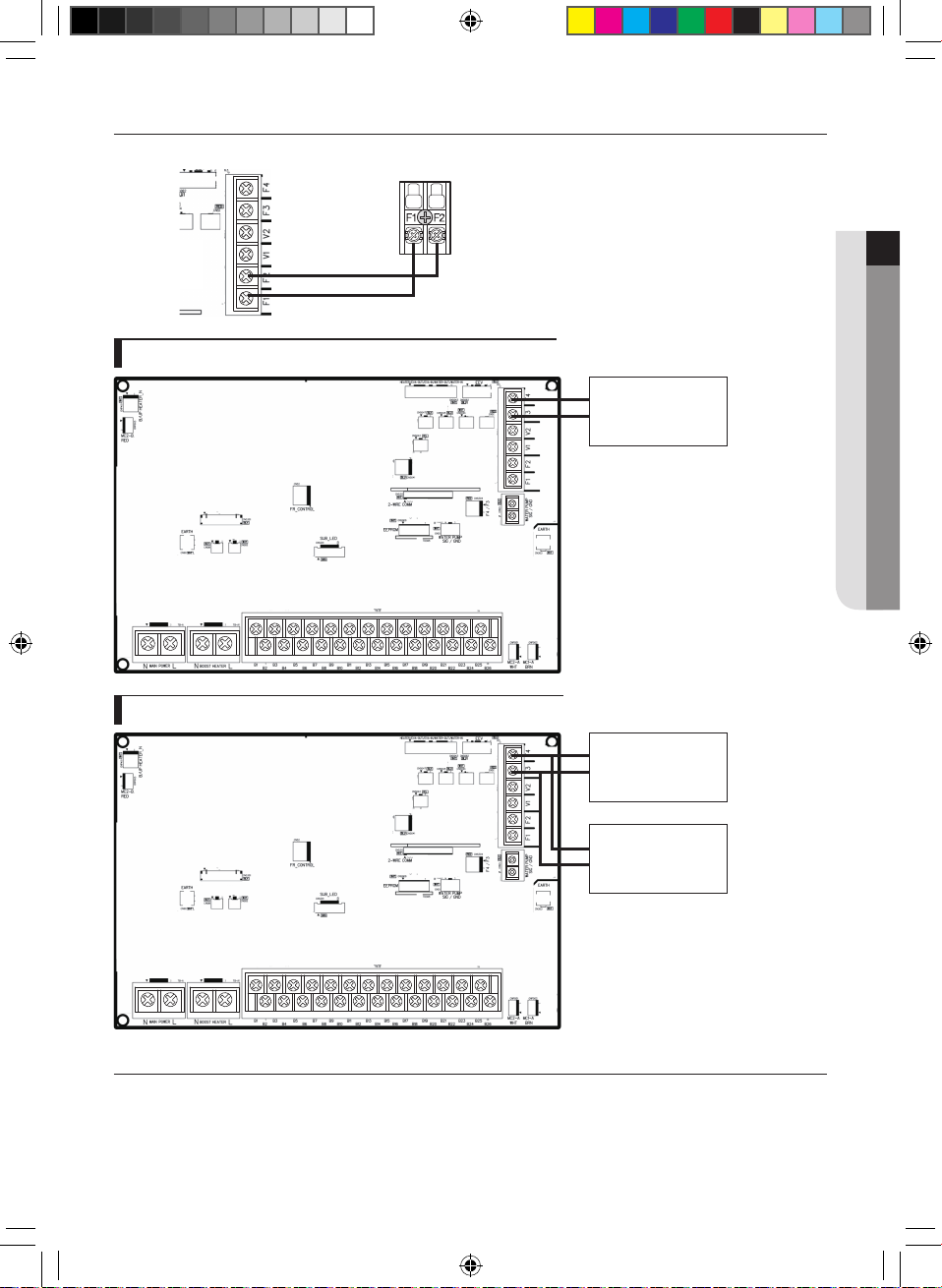

Connecting the communication wire

ENGLISH

Connect ‘outdoor unit’s F1&F2’ with ‘control kit’s F1&F2 in TB-C’ by 2 core cable.

Outdoor Unit

(at Control Plate)

Control Kit

Communication with a wired remote controller (1 unit)

Wired Remote Controller

(Master)

Communication with a wired remote controller (2 units)

Wired Remote Controller

(Slave)

Wired Remote Controller

(Master)

Connecting a wired remote controller

1. Connect 'F3, F4' of TB-C kit with 'F3, F4' of a wired remote controller.

2 units (wired remote controllers) are able to be installed on TB-C.

When 2 units are installed, either one shall has "Master" setting and another one shall have "Slave" settings on a wired

remote controller.

17

EHS MONO Kit-EU_IM_05388A-04_EN.indd 17 2016-06-23 오후 3:43:00

Wiring works

Temp. Sensor for DHW, Backup heater and a water Flow S/W

External wiring to control a switch of relay by a installer

Temp. sensor for backup heater

Temp. sensor for DHW

Flow s/w

Connecting a temp. sensor wire into DHW

1. Put the sensor side of a temp. sensor wire into the designated location in a DHW.

2. Connect the other side of the line at CNS042.

Relay

Connecting a temp. sensor wire to outlet of backup heater

1. Put the sensor side of a temp. sensor wire into the designated location in a backup heater.

2. Connect the other side of the line at CNS047.

Connecting a ow switch

1. Install a ow switch in water line.

2. Connect a wire of a ow switch into 'CNS041' connector.

Connecting a S/G(Smart grid)

1. Install as above diagram.

18

EHS MONO Kit-EU_IM_05388A-04_EN.indd 18 2016-06-23 오후 3:43:01

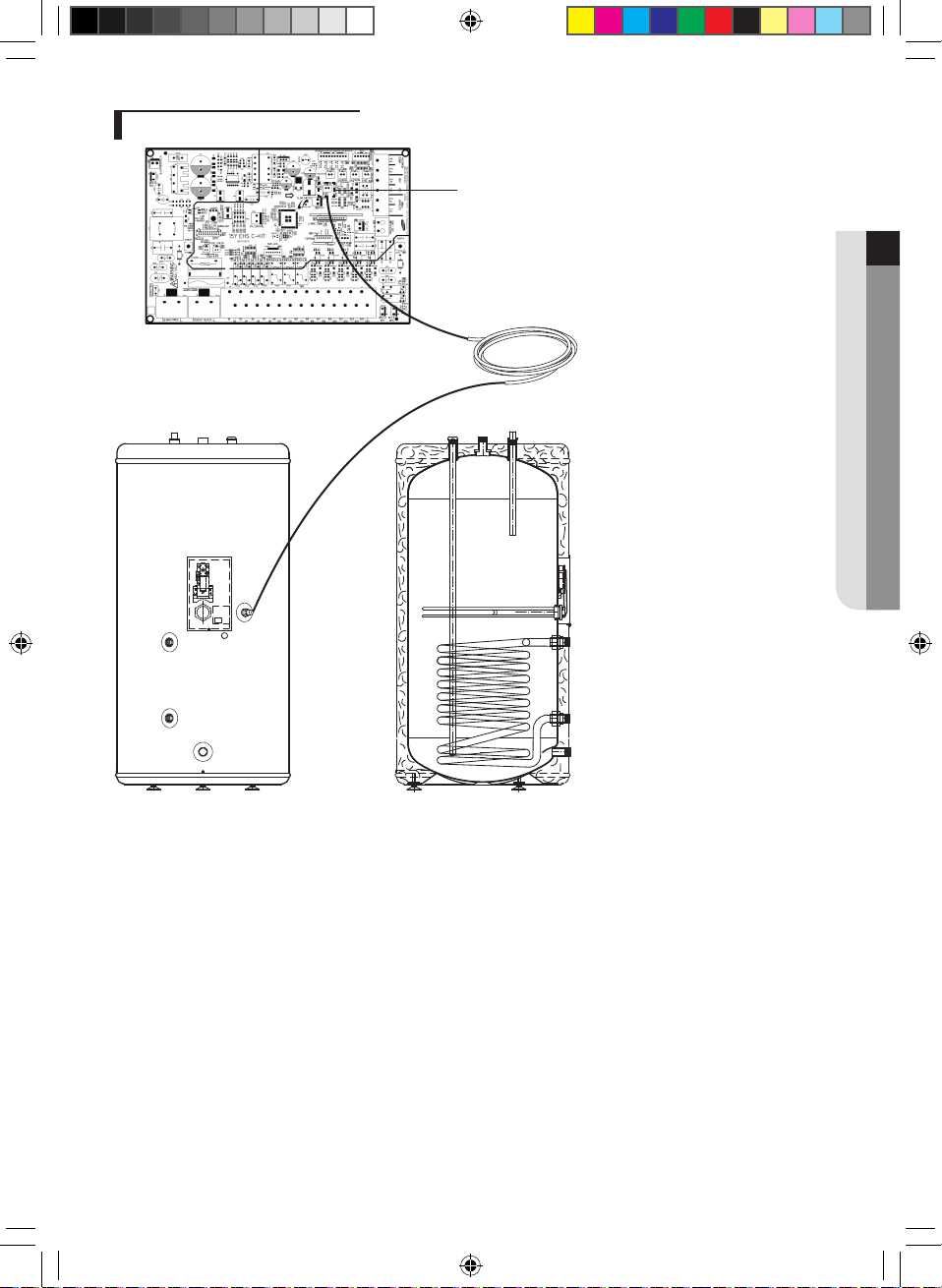

DHW tank Switch box layout

ENGLISH

DHW Tank Temp. (15m) CNS042(YEL)

Use a correct sensor pocket which is t for the DHW tank sensor(OD Ø6).

If the gap between the supplied sensor and DHW tank sensor pocket is big, use thermal grease.

19

EHS MONO Kit-EU_IM_05388A-04_EN.indd 19 2016-06-23 오후 3:43:01

DHW tank

Electrical connections

Procedure

• Switch o the power supply before making any connections.

WARNING

• Use a thermal grease in thermistor pocket after installing electric connections.

Connections to be made in the electrical box of DHW tank

1. Connect the booster heater power supply and thermal protection cable.

2. Make sure to ensure strain relief of the cable.

Connections to be made in the electrical box of indoor units

3. Plug the thermistor cable connector in the connector CNS042 on the pcb.

4. Connect the booster heater power supply and thermal protection cable(eld supply) to terminal TB-A1 and earth on the

terminal block.

5. Connector the loose ends of the TB-A1 on the terminal block and the connector CNS042 on the PCB.

6. Plug the thermistor cable connector in the socket X9A on the PCB.

7. Connect the booster heater power supply and thermal protection cable (eld supply) to terminal 7, 8, 21, 22 and earth on

the terminal block.

8. Connect the booster heater power supply cable to the circuit breaker and earthing screw.

9. Fix the cables to the cable tie mountings with cable ties to ensure strain relief.

• It is of great importance that the heater is lled with water before the electricity is hooked up, or else- the

warranty is not valid. If the heater is installed and not used, it must be ushed with water once a week.

CAUTION

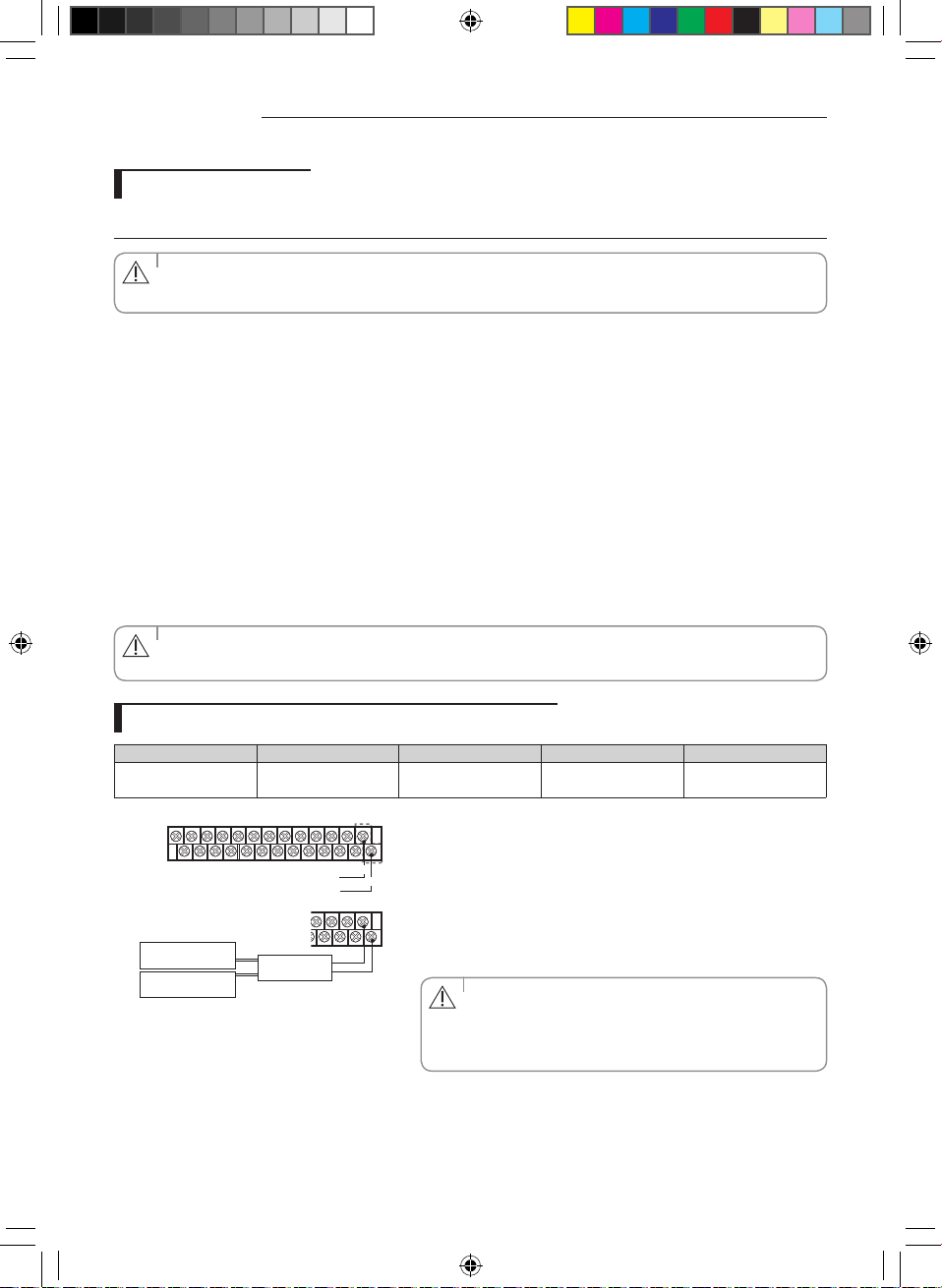

Connection of the solar circulation pump for DHW tank

Description No. of wires Max. A Thickness Supply Scope

Solar pump 2+ground 10 mA

1. Before the installation, control kit should be turned o.

2. Using the appropriate equipment to correct position of terminal

SOLAR PUMP (N)

SOLAR PUMP (L)

B25

B26

block as shown on the diagram.

3. It is for control kit to inform that the pump is operating.

4. Solar pump is controlled by installer’s handling. And it send the

signal to control kit depending on solar pump conditions. In

Solar pump

Power

Controller

operating mode, signal shall be around 230Vac B/W N&L. In nonoperating mode, signal shall be around 0Vac B/W N&L.

• Maximun allwable current of each terminal is below

10mA.

CAUTION

• Ports number B25, B26 are for input port for detection and

they do not supply power to a solar pump.

0.75mm

2

H05RN-F or

H07RN-F

Field supply (230V~,

Input)

20

EHS MONO Kit-EU_IM_05388A-04_EN.indd 20 2016-06-23 오후 3:43:01

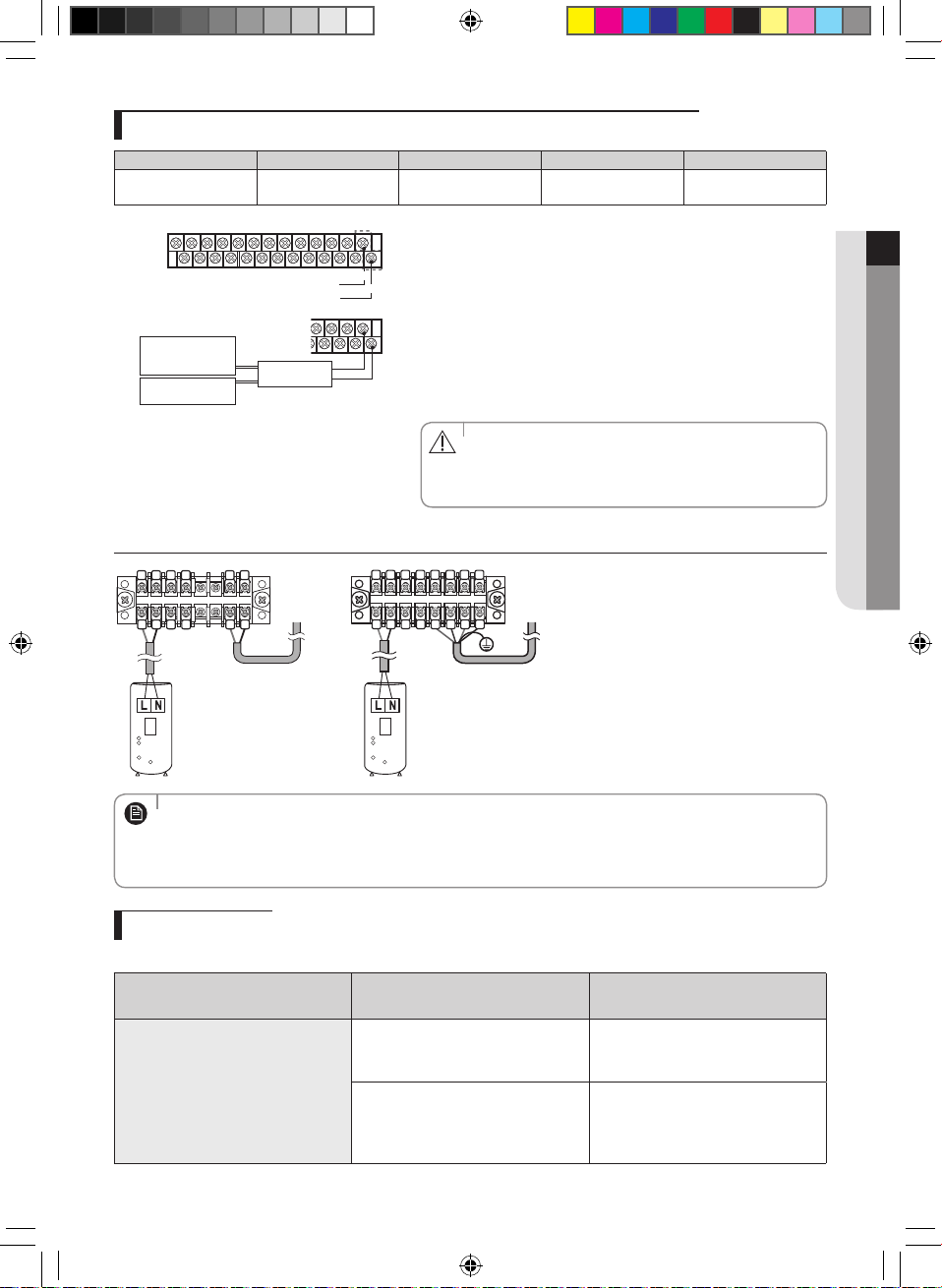

Connection of the solar circulation pump / DHW Thermostat for DHW tank

ENGLISH

Description No. of wires Max. A Thickness Supply Scope

Solar pump /

DHW Thermostat

2+ground 10 mA

1. Before the installation, control kit should be turned o.

2. Using the appropriate equipment to correct position of terminal

SOLAR PUMP / DHW Thermostat (N)

SOLAR PUMP / DHW Thermostat (L)

B25

B26

block as shown on the diagram.

3. It is for control kit to inform that the Solar pump / DHW Thermostat

is operating.

4. Solar pump / DHW Thermostat is controlled by installer’s handling.

SOLAR PUMP /

DHW Thermostat

Power

Controller

And it send the signal to control kit depending on Solar pump /

DHW Thermostat conditions. In operating mode, signal shall be

around 230Vac B/W N&L. In non-operating mode, signal shall be

around 0Vac B/W N&L.

• Maximun allwable current of each terminal is below 10mA.

• Ports number B25, B26 are for input port for detection

CAUTION

and they do not supply power to a Solar pump / DHW

Thermostat.

0.75mm

2

H05RN-F or

H07RN-F

Field supply (230V~,

Power connection

Input)

N L N L N L

DHW Tank DHW Tank

1 phase

230V~

N L N L L1(R) L2(S) L3(T) N

3 phase

380V~

• It is important that the 3-way valve is tted correctly: When the 3-way valve is idle (not activated) the space

heating circuit should be selected, when the 3-way valve is activated the sanitary heating circuit should be

NOTE

selected.

• The booster heater that will be connected should be 3kW or lower.

Troubleshooting

IMPORTANT: All maintenance or repair work must be executed by an approved installer.

Problem Possible cause Solution

Check if there is any power on the power

supply terminal on the thermostat.

Reduce thermostat setting by 5°C and

press the reset button.

Hot water is not coming out.

No power supply to the water heater

The thermostat may be set too high

and cause the fuse or safety cut-o to

operate.

21

EHS MONO Kit-EU_IM_05388A-04_EN.indd 21 2016-06-23 오후 3:43:02

DHW tank

Problem Possible cause Solution

Heating is not working

Heating element or internal electrical

wiring is out of order.

Check if there is any power on the power

supply on the connector of the heating

element between black and yellow/

green wires. If this is OK, press the reset

button on the fuse/safety cut-o.

Adjust the thermostat up using a

standard screwdriver.

Check the resistance of the heating

element on the connector of the heater

bundle, and the condition of the internal

wiring.

Adjust the UX mixing valve correctly to

the preferred temperature.

If drip from the SV is severe, it might

need to be replaced. Some dripping

is normal. Alternatively an expansion

vessel can be tted.

Check the heating element o-ring seal

and all connections.

Contact the installer/supplier regarding

any other failure.

Water is not warm enough

Safety valve(SV) is dripping.

Leak warning outlet is dripping.

Other problems, or if none of the above

solves the problem.

Thermostat is set too low.

Heating element or the internal electrical

wiring is partially out of order.

UX mixing valve(tted on top) is

incorrectly adjusted.

Water expands when heated. If there

is no consumption of hot water over

a period of time pressure builds up,

causing the safety valve to open.

The heating element may not be

properly tightened.

There may be a leak.

-

Incorrect handling of thermostat, safety valve or other valves may lead to tank rupture. When servicing the unit

follow instructions carefully:

WARNING

• Always turn o main power supply when water supply is being shut o.

• Test the free operation of the safety valve regularly by opening the valve ensuring the water ows freely.

• Electrical connection and all servicing of the electrical components should only be carried out by an authorized

electrician.

• Fitting and all servicing of plumbing xtures should only be carried out by an authorized installer.

• When replacing the thermostat, safety valve or any other valve or part supplied with this unit, use only approved

parts of the same specication.

• Before resetting the safety cut-o or altering the thermostat setting, always remember to isolate the electrical

supply to the unit. This must be done prior to removing the electrical box lid.

CAUTION

• If the electric element or thermostat is defective, contact authorized electrician.

• After adjustments are completed, ensure the lid to the electrical box is retted correctly and that the retaining

screw is properly tted.

22

EHS MONO Kit-EU_IM_05388A-04_EN.indd 22 2016-06-23 오후 3:43:02

Booster heater

ENGLISH

Booster heater

Recommended wire specication

Load Power Supply

Use Booster Heater (Max. 3kW) 1Ø, 220-240V, 50Hz

Power Cable Max. Length

2

, wires m

mm

4.0 / 3 L < 10m

6.0 / 3 10m < L

Code designation IEC: 60245 IEC 57/ CENELEC: H05RN-F

Connecting a booster heater (PTC heater – allowed limit : Max. 3kW)

1. Directly connect a ‘Booster heater’ with ‘A3 and A4 ’ in TB-A.

• Wire spec : 6.0 mm2 (regardless of distance)

• Code designation IEC : 60245 IEC 57 / CENELEC : H05RN-F

NOTE

Specication table

Part Specication

Terminal Block (output) N, L of TB-A1

Connection load Direct connection a booster heater

Output (N, L) AC 230V (MAX 20A)

23

EHS MONO Kit-EU_IM_05388A-04_EN.indd 23 2016-06-23 오후 3:43:02

Loading...

Loading...