Samsung AE050JXYDEH, AE090JXYDEH, AE050JXYDEU, AE090JXYDEU, MIM-E03BN Service Manual

...

ECO HEATING SYSTEM CONTENTS

ECO HEATING SYSTEM

OUTDOOR UNIT

CONTROL KIT

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

Model :

AE050JXYDEH/EU MIM-E03BN

Basic Model :

MIM-E03BN

AE090JXYDEH/EU MIM-E03AN

AE050JXYDEH/EU

Contents

1. Precautions ..............................................................................................................................................3

1-1 Precautions for the Service ..........................................................................................................................................3

1-2 Precautions related to static electricity and PL ...................................................................................................3

1-3 Precautions for the Safety ............................................................................................................................................4

1-4 Precautions for handling a system containing refrigerants .........................................................................5

1-5 Precautions for the brazing .........................................................................................................................................5

1-6 Precautions for charging refrigerants .....................................................................................................................5

2. General Overview ................................................................................................................................6

2-1 Features of the System ..................................................................................................................................................6

2-1-1 Key features of the Monobloc ..........................................................................................................................7

2-2 Product Specications ...................................................................................................................................................8

2-2-1 MONO Unit ...............................................................................................................................................................8

2-3 Specications of optional items ................................................................................................................................9

2-3-1 Accessories ................................................................................................................................................................9

3. Disassembly and Reassembly ......................................................................................................................... 11

3-1 EHS Control Kit ...............................................................................................................................................................12

3-2 Outdoor Unit ...................................................................................................................................................................14

4. Troubleshooting............................................................................................................................................................. 23

4-1 Wired remote controller .............................................................................................................................................23

4-2 Troubleshooting by symptoms ..............................................................................................................................26

4-2-1 Communication error after nishing Tracking ......................................................................................26

4-3 Control Kit ........................................................................................................................................................................ 27

4-3-1 EEPROM error .....................................................................................................................................................27

4-3-2

:

Error due to abnormal data of Wired remote controller thermistor value

............................28

4-3-3

: Error due to abnormal data of Water outlet thermistor value ..............................29

4-3-4

: Error due to abnormal data of DHW tank thermistor value ................................... 30

4-3-5 Control Kit temperature sensor(open/short) ........................................................................................31

4-3-6 Communication error after nishing Tracking(Hydro unit) ............................................................32

4-4 Items to check before diagnostics .......................................................................................................................33

4-4-1 Test run mode and view mode ....................................................................................................................33

4-4-2 Troubleshooting for outdoor unit ..............................................................................................................34

4-5 Troubleshooting by symptoms .............................................................................................................................36

4-5-1 Communication error after nishing tracking (E202) ........................................................... 36

4-5-2 Time out (1min.) of communication error between MAIN PBA and INV. PBA (E203)

............ 37

Contents

4-5-3 Temperature sensor error (E221, E231, E251, E320 )

...................................................................... 38

4-5-4 Fan error (E458, E475)

............................................................................................................................. 39

4-5-5 Compressor error (E461, E467) .......................................................................................................41

4-5-6 Current trip error (E462, E463) ........................................................................................................ 42

4-5-7 IPM(IGBT module) over current error (E464) ............................................................................ 43

4-5-8 DC-link voltage under/over error (E466) .................................................................................... 45

4-5-9 GAS leak error(E554) ........................................................................................................................... 46

4-5-10 The other errors .................................................................................................................................. 47

4-5-11 In case of heating at the cooling mode or coolin g at the heating mode .................. 48

4-5-12 Outdoor unit is not powered on – Initial diagnosis ............................................................. 50

4-5-13 Outdoor unit power supply error ............................................................................................... 51

5. PCB Diagram

....................................................................................................................................................................

52

5-1 Control Kit......................................................................................................................................................... 52

5-2 Outdoor Unit ................................................................................................................................................... 54

6. Wiring Diagram ................................................................................................................ 57

6-1 Control Kit......................................................................................................................................................... 57

6-2 Outdoor Unit ................................................................................................................................................... 58

7. Reference Sheet ............................................................................................................... 59

7-1 Index for Model Name................................................................................................................................. 59

7-1-1 Outdoor Unit ......................................................................................................................................... 59

7-2 Refrigerant Circuit Diagram ...................................................................................................................... 60

7-3 FSV data check and update using S-Net Pro2 ...................................................................................61

7-4 EHS FSV Values Import and Export .........................................................................................................62

Samsung Electronics 3

1. Precautions

1-1 Precautions for the Service

Use the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

When repairing the equipment, connection of the harness parts must be firm and solid.

– A loose connection may cause noise or other malfunction.

When assembling and disassembling the equipment while it is laid down, lay it on soft cloth.

– Otherwise it may scratch the back of the exterior of the product.

Remove dust or dirt completely from the housing block, wiring block and service parts during repair.

– This helps prevent the danger of fire caused by tracking or short circuit.

Fasten the valve caps of service valves and charging valves of outdoor unit as much as possible using adjustable wrenches.

Check the status of the components’ assembly after repair service.

– The status must be the same as before the repair service.

1-2 Precautions related to static electricity and PL

The PCB power supply block is susceptible to static electricity. Therefore, care must be taken during repair or measuring

while the power is on.

– Wear insulation gloves for PCB repair or measuring.

Check whether the installation location is at least two meters away from other electronic products such as TV, video, or

audio.

– Otherwise, the video quality might be degraded or noise might be generated.

Do not let end users repair the products themselves.

– Unauthorized disassembly might cause electric shock or fire.

Precautions

4 Samsung Electronics

1-3 Precautions for the Safety

Do not pull any electric wires and do not touch an auxiliary power switch with a wet hand.

– There is a danger of electric shock or fire.

In case any wire or power plug has been damaged, replace it to eliminate any possible danger.

Do not bend the power cord by force and do not put any heavy object on the power cord.

– There is a danger of electric shock or fire.

Do not use multi socket.

– There is a danger of electric shock or fire.

Ground the product if necessary.

– Be sure to ground the product if there is any danger of electric leakage due to water or moisture.

Be sure to turn off the auxiliary power switch or pull out the power plug during replacement or repair of electric parts.

– There is a danger of electric shock.

In case the product will not be in use for a long time, the battery of remote control should be kept separately.

– Leakage of inside fluid can cause break down of remote control.

The installation must be done by the manufacturer or its service agent or a similar qualified person in order to avoid a hazard.

– Installation by an unqualified person may cause a water leakage, electric shock or fire and so on.

The electric work must be done by service agent or similarly qualified persons according to national wiring regulations and use

only rated cable.

– If the capacity of the power cable is insufficient or electric work is not properly completed, electric shock or fire may occur.

Use only rated parts and tools.

– If you don't use the rated parts and tools, it can cause trouble with the air conditioner and bring about injury.

If any gas or impurities except R410A refrigerant come into the refrigerant pipe, serious problem may occur and it may cause

injury.

Leak test must be done using only Nitrogen(NO2)gas.

R410A refrigerant is used for EHS.

– When using R410A, moisture or foreign substances may affect to the capacity and reliability of the product.Safety precautions

must be taken when installing the refrigerant pipe.

– The design pressure of the unit is 4.1MPa. Select appropriate material and thickness according to the regulations.

– R410A is a quasi-azeotrope of two refrigerants.

Make sure to charge liquid one when adding refrigerant.

If you charge gaseous refrigerant, it may affect the capacity and reliability of the product as a result of change formation of the

refrigerant.

Precautions

Samsung Electronics 5

1-4 Precautions for handling a system containing refrigerants

All system containing refrigerants shall be removed under regional regulations prior to the disposal to

prevent the potential health and environmental consequences.

Harmful for human body

– When emitted liquid refrigerant contacts human body, contacted area may get frostbite, blister or become numb.

If refrigerant leaks in airtight area, lack of oxygen may cause suffocation. When refrigerant is heated, it may generate harmful gas.

Precautions for handling container

– Do not apply shock or heat to the refrigerant container.

1-5 Precautions for the brazing

Clear any dangerous or inflammable materials in surrounding environment.

Make sure to empty the remaining refrigerant in the product or pipe before brazing.

– Brazing with the refrigerant still remaining in the product or pipe may cause poor result and generate harmful gas. Furthermore,

pressure of the refrigerant may increase and cause damage to the leaking part. This may lead harmful refrigerant and oil to spurt

out which can be dangerous for service personnel.

Use nitrogen gas to get rid of the oxide forming during brazing.

– Using other type of gas may cause damage to the product or the exterior.

1-6 Precautions for charging refrigerants

Add quantity of the refrigerant using a scale and perform a test operation with S-net.

– Product performance may decrease if you add excessive amount of refrigerant.

Do not charge refrigerants while heating the container up.

– The container may get damaged by the heat and result in explosions.

Do not operate the product without pressure switch(for product protection) and sensor.

– If there are any internal blockage, high refrigerant pressure increase may damage the product or exterior.

6 Samsung Electronics

2. General Overview

2-1 Features of the System

POWER SAVING

EHS(Eco Heating System) considers the trend in air conditioner use. It optimizes the

energy efficiency of loads ranging from partial to full. It achieves an excellent energy

effect for the users of the air conditioner.

Samsung patented compressor

Samsung has been researching and developing compressors since the 70's.

It has developed power saving compressors for more than thirty years.

The EHS(Eco Heating System) compressor adopts a double-rotor BLDC compressor with permanent magnets made by Samsung.

Electricity for the compressor rotor is obtained from a neodium-iron-boron permanent magnetic material (boron magnet can attract iron

material weighing 1000 times its own weight.) It strengthens the rotary moment of the compressor to maximize the entire efficiency of the

compressor.

BLDC electricity

Permanent magnet, strong magnetic rotor

Double rotor compression cylinder

Nd-Fe-B Neodium-Iron-Boron magnet

SAMSUNG's double-rotor compressor has the upper and lower rotors designed symmetrically.

The double rotor in symmetry can remove vibrations caused by the eccentric design of the cylinder.

2 rotors balancing the rotary moment

Centered symmetry

Upper rotor

Permanent magnet rotor

Lower cylinder

Upper cylinder

Lower rotor

General Overview

Samsung Electronics 7

2-1-1 Key features of the Monobloc

Easy installation

No need to install the refrigerant lines in the system. Users can run the system after connecting water pipes only.

Integrated Heating & Cooling system

Plate Heat exchanger is a integral part in heating & cooling system. For user’s convenience, PHE is integrated into the system.

This concept will help space saving and lower costs for pipe line reduction.

Running Costs-Reduction of Up to 32.4%

Samsung EHS, known for its world class efficiency (12kW floor heating system with COP of 4.51), can reduce 32.4% of your run-

ning costs as compared to a gas boiler.

High Performance at Low Temperature

Samsung EHS is made up of an inverter compressor optimally operated according to the outdoor temperature, offering heating

performance of 90% at -10°C and reliable frost protection at -25°C.

8 Samsung Electronics

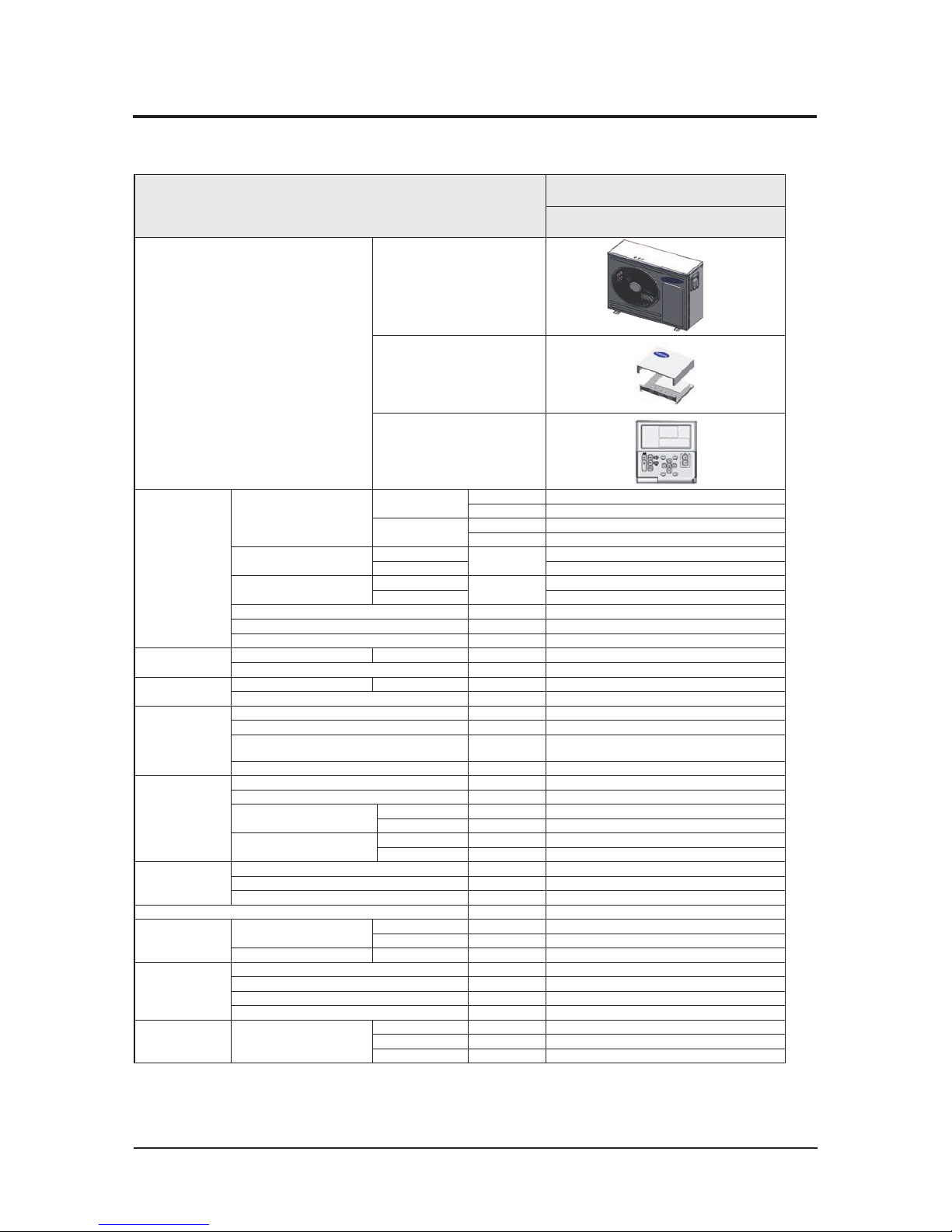

2-2 Product Specifications

2-2-1 MONO Unit

Item

AE050JXYDEH

1phase 5kW

Image

Outdoor unit

Control Kit

Remote Controller

A2W

Condition #1.

(A7/W35) *1

Nominal Capacity

Heating

W 5,000

Btu/h 17,100

Cooling

W 5,000

Btu/h 17,100

Power Input(Nominal)

Heating

W

1,0 60

Cooling 1,210

Current Input(Nominal)

Heating

A

5.1

Cooling 5.7

COP (Nominal He ating) W/W 4.72

EER (Nominal Co oling) W/W 4 .13

SCOP A+++

A2/ W35

Capacity Heating W 4,500

COP W/W 3.46

A-7/ W35

Capacity Heating W 4,700

COP W/W 2.69

Field

Wiring

MCA A 20

MFA A 25

Power Source Wire

㎡

L<10 m, 2. 5↑

10m<L<20m, 4.0↑

Transmission Cable

㎡

0.75↑

Water

Connections

Water Flow Rate (Heating/Cooling) LPM 14. 5/14.5

Water Pressure (Max) bar 3

Water Pipe

Inlet Φ, in ch BSPP male 1"

Outlet Φ, in ch BSPP male 1"

Leaving Water Temperature

Heating °C 25~55

Cooling °C 5 ~25

Refrigerant

Typ e - R410 A

Control Method - EEV

Factory Charging g 1,150

Power Supply Φ, #, V, Hz E(220~240V, 50Hz, 1Ф)

Sound *3

Sound

Pressure

Heating Std High dB(A) 45

Cooling Std High dB(A) 45

Sound Power Heating Std High dB 61

External

Dimension

Net Weight kg 59

Shipping Weight kg 63

Net Dimensions (WxHxD) mm 880 x 798 x 310

Shipping Dimensions (WxHxD) mm 1,023 x 904 x 413

Operating

Temp. Range

A2W

Heating

℃

-25~35

Cooling

℃

10~ 46

D.Hot Water

℃

-25~ 43

*1) A2W Condition #1 : (Heating) Water I n/Out 30℃/35℃, Outdoor Air 7℃D B/6℃WB; (Cooling) Water In/Out 23℃/18℃, Outdoor Air 35℃DB.

*2) Sound pressu re was acquired in an anecho ic room. Thus actual noise level may be dif ferent depending on the installation conditions.

Samsung Electronics 9

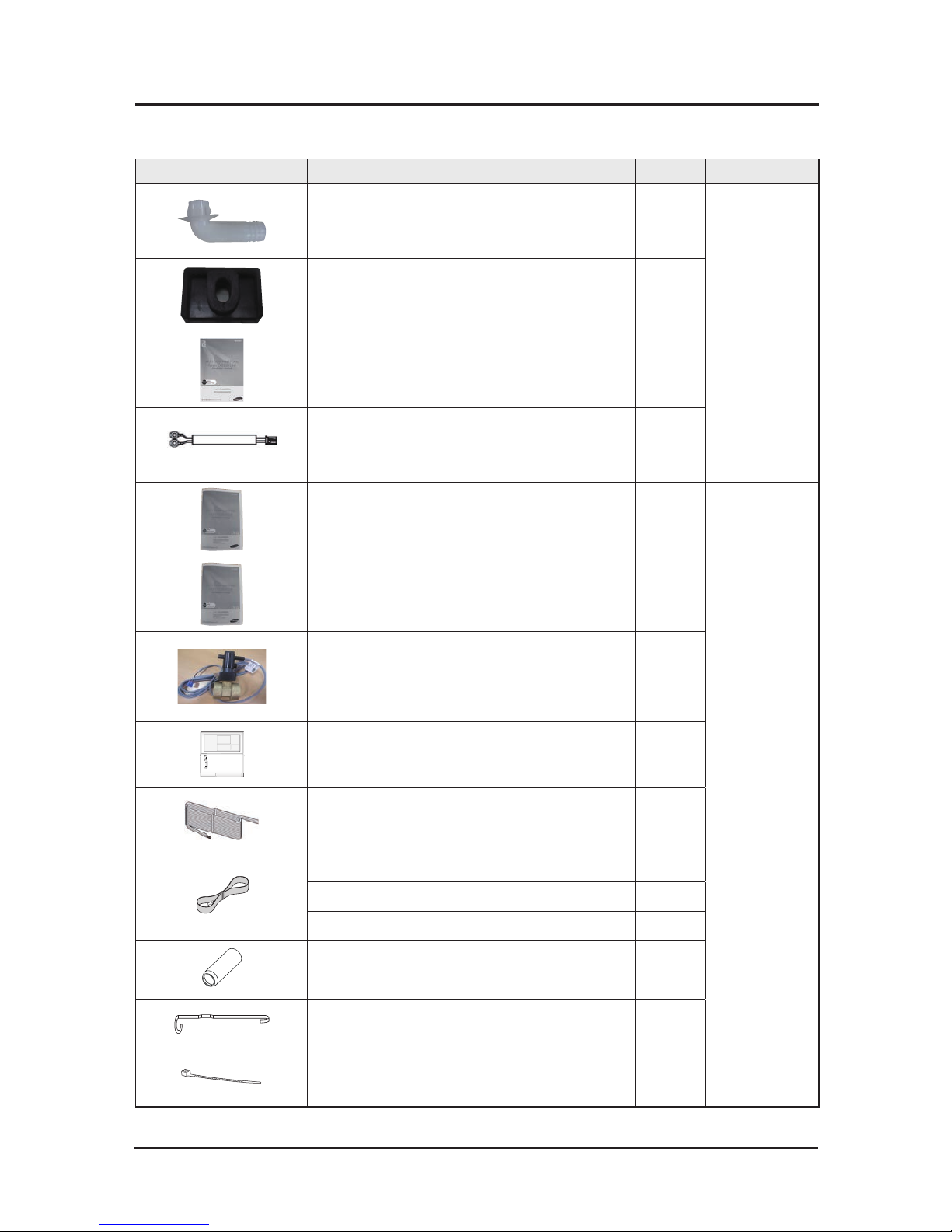

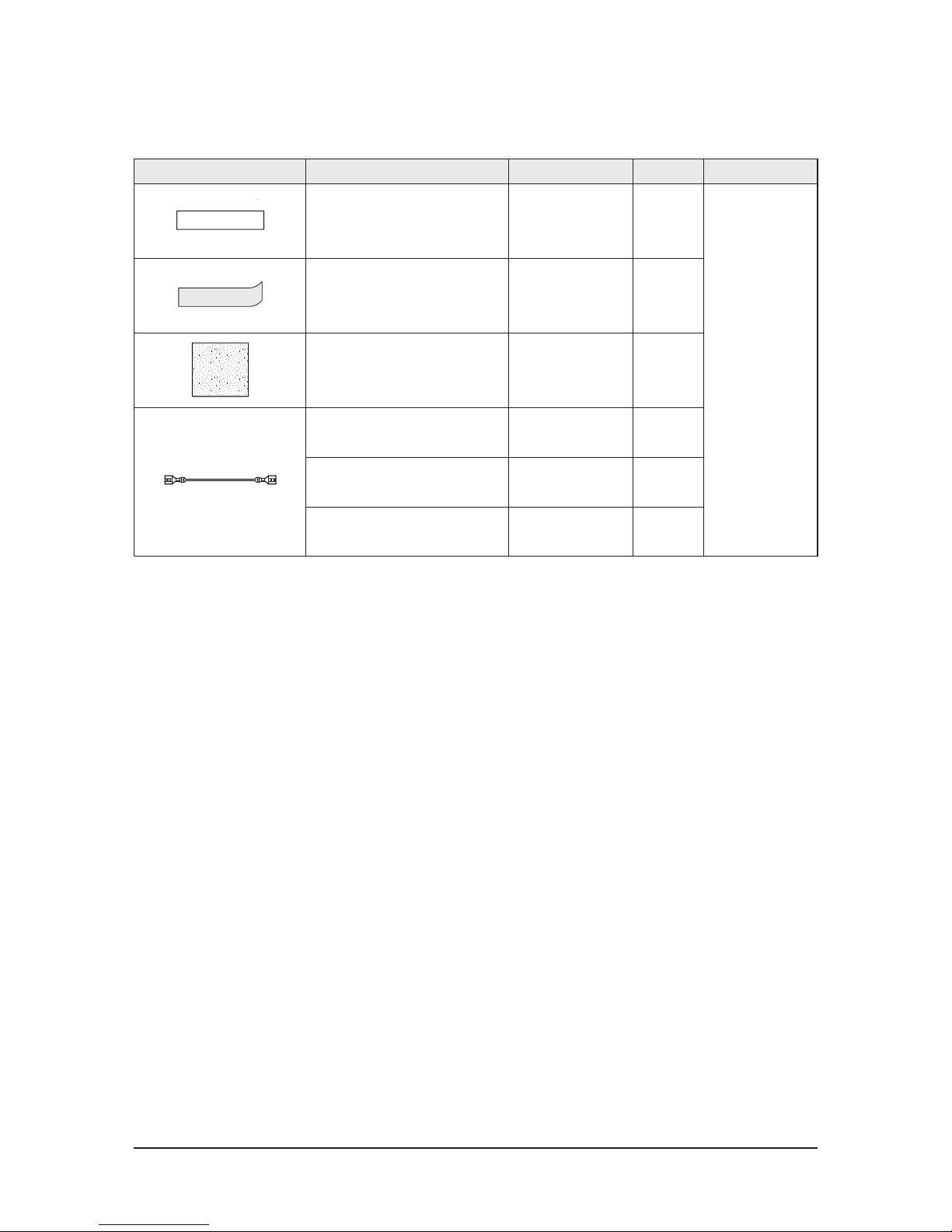

Item Description Code No. Q’ty Remark

Drain Plug DB6 7-20 011A 1

Essential Offer

(Outdoor Unit)

Rubber Leg DB73-20134A 4

MANUAL INSTALL (Outdoor Unit) DB 68-0 5133A 1

Assy Connector Wire

(Wire for Silent mode)

DB93-08678A

1

MANUAL USERS (CONTROL KIT) DB68-05402A 1

Essential Offer

(Control Kit)

MANUAL INSTALL (CONTROL KIT) DB68-05388A 1

Switch-Flow DB34-00084A 1

Wired remote controller DB9 3-1125 1L 1

Connector Wire

(Smart Grid, 2000mm)

DB 93 -13255A 1

SENSOR TEMP DB 32- 00213A 1

Thermistor (Water Tank) DB95-05023A 1

SENSOR TEMP DB32- 00217A 1

HOLDER SENSOR DB 61- 05217A 2

SPRING ETC-SENSOR DB81-00635A 2

CABLE TIE DB 65-100 88C 4

2-3 Specifications of optional items

2-3-1 Accessories

10 Samsung Electronics

Accessories

Item Description Code No. Q’ty Remark

TAPE-HANDLE CABI SIDE DB74-00039D 2

Essential Offer

(Control Kit)

RUBBER-PIPE DB73-00436B 2

INSULATION-BASE DB72-00 401F 2

ASSY CONNECTOR WIRE-CLIP

(Back-up heater connector(Brown))

DB93-08924R 1

LEAD CONNECTOR

(Back-up heater connector (Red))

DB39-0 0941A 1

LEAD CONNECTOR

(Back-up heater connector(White))

DB39-0 0941B 1

Samsung Electronics 11

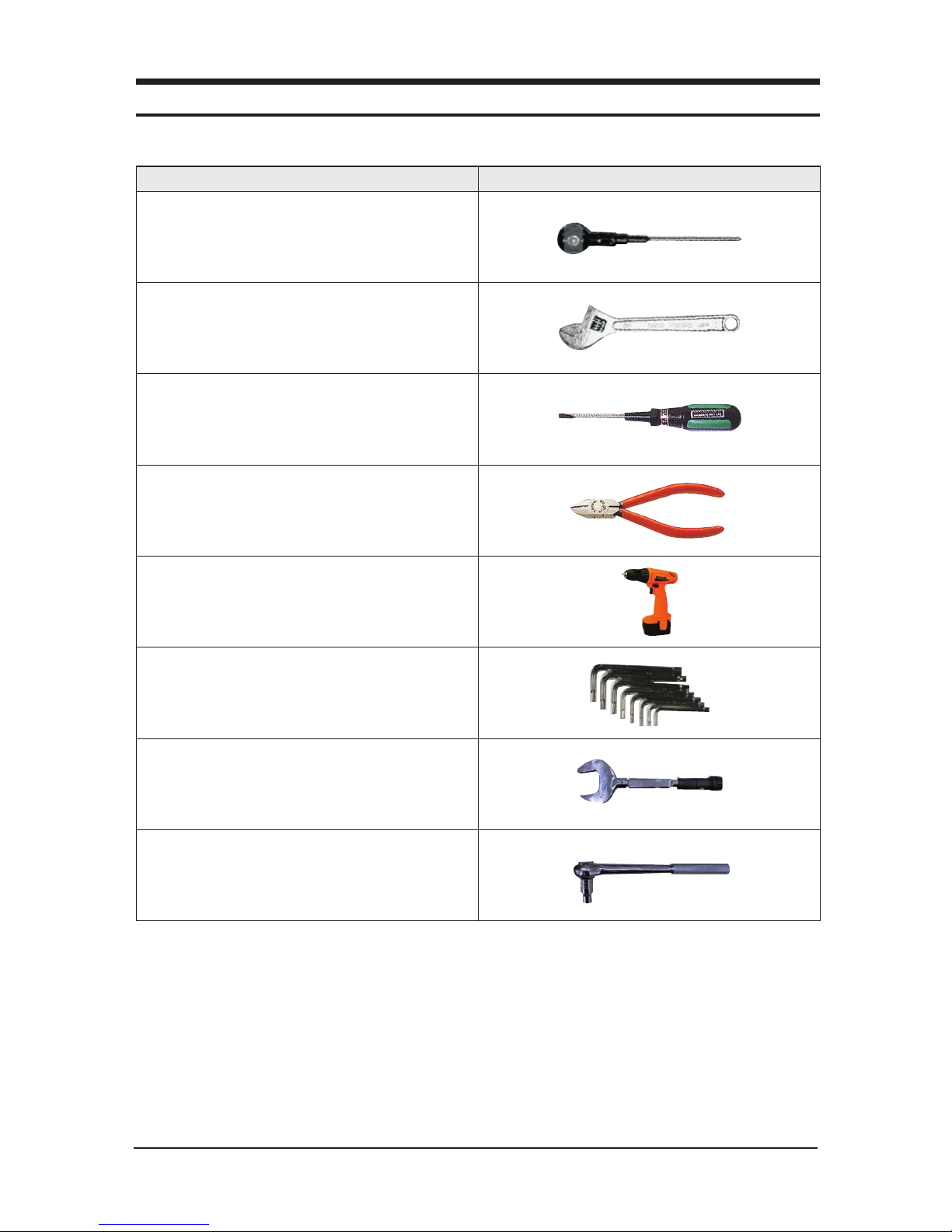

Hand Tool sets

3. Disassembly and Reassembly

Item Remark

+Screw Driver

Adjustable wrench

–Screw Driver

Nipper

Electric Motion Driver

L-Wrench

Torque Lench

Latchet Lench

12 Samsung Electronics

No Parts Procedure Remark

1 CABINET TOP

You must turn off the power before

disassembling.

1) Unscrew and remove the two screws

on the CABINET TOP.

(Use '+' type screw driver)

2) Remove the CABINET TOP.

2 ELCB 1) Unscrew and remove the two screws of the

power supply cable on the terminal block.

(Use '+' type screw driver)

2) Unscrew and remove the two screws on the

top & bottom of the ELCB.

(Use '+' type screw driver)

3-1 EHS Control Kit

Be sure that the power switch is in the OFF and the power source cord shall be unplugged prior to disassembly and reassembly works.

Disassembly and Reassembly

Samsung Electronics 13

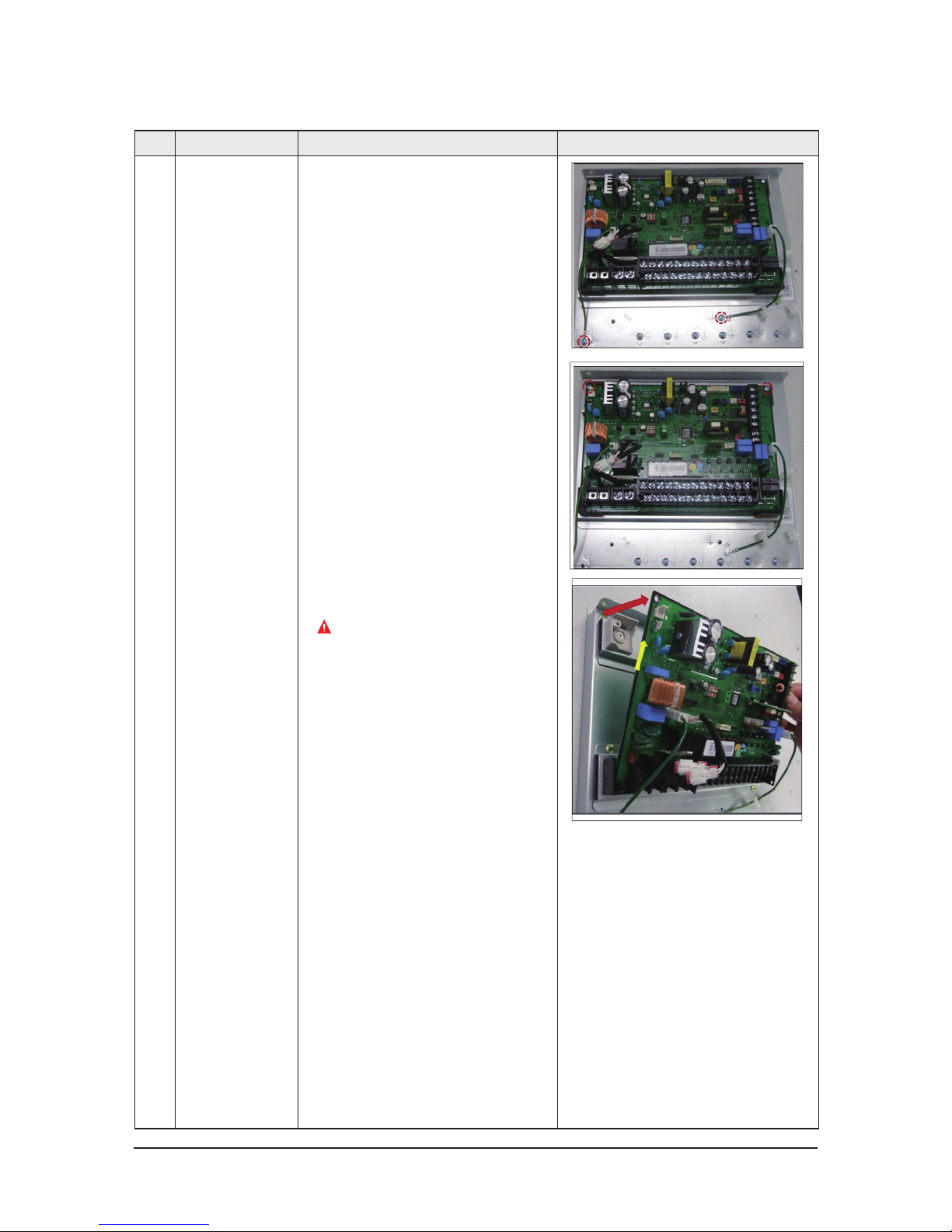

No Parts Procedure Remark

3 ASSY PCB MAIN OUT 1) Unscrew and remove the earth screw

on the CABINET BOTTOM.

(Use '+' type screw driver)

2) Unscrew and remove the two screws.

(Use ‘+’type screw driver)

3) Firstly pull the PCB along red arrow ,then pull

the PCB out along yellow arrow.

Please note that PCB support may be

broken by your excessive pulling.

14 Samsung Electronics

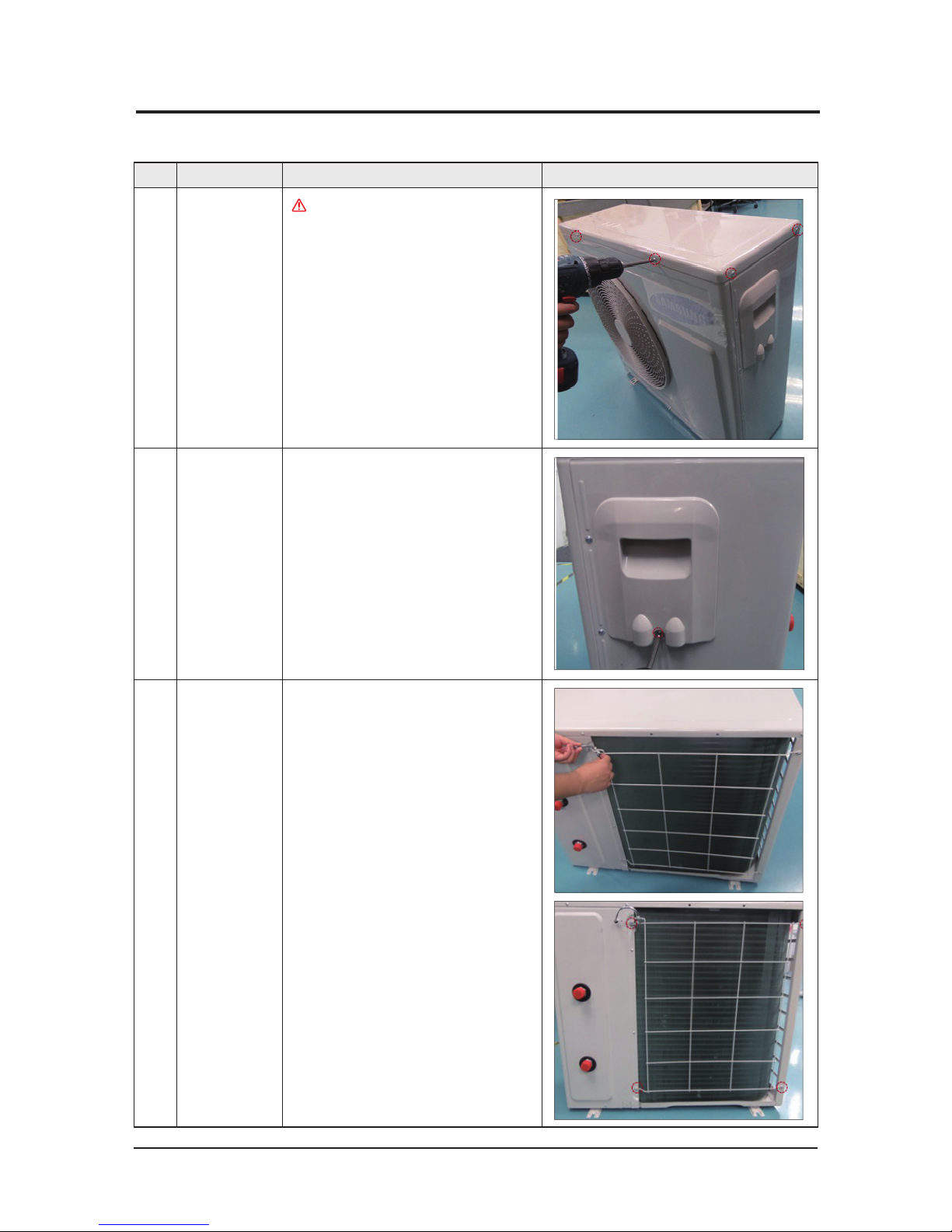

No Parts Procedure Remark

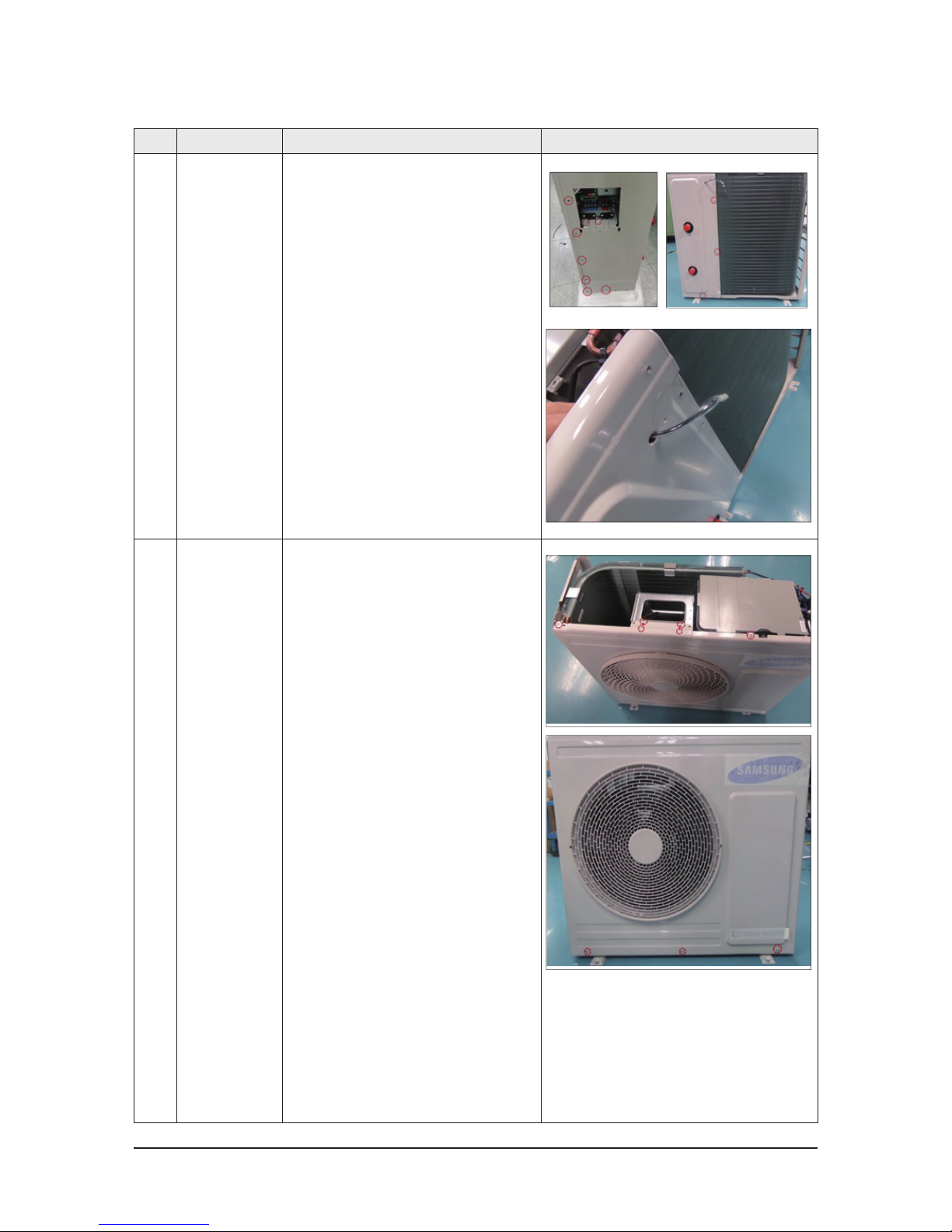

1 CABI TOP

You must turn off the power before

disassembling.

1) Unscrew and remove the ten screws on each

side of the CABI TOP.

(Use '+' type screw driver)

2 ASSY COVER

CONTROL

1) Unscrew and remove the one screw

on the ASSY COVER CONTROL.

(Use '+' type screw driver)

3 GUARD COND 1) Pull the sensor from Guard Cond.

2) Unscrew and remove the four screws

on the GUARD COND.

(Use ‘+’type screw driver)

AE050JXYDEH

3-2 Outdoor Unit

Disassembly and Reassembly

Samsung Electronics 15

No Parts Procedure Remark

4 CABI SIDE RH 1) Unscrew and remove the eleven screws

on each side of the CABI BACK RH.

(Use '+' type screw driver)

2) Pull the sensor from the CABI SIDE RH.

5 CABI FRONT 1) Unscrew and remove the 9 screws

on the CABI FRONT.

(Use '+' type screw driver)

Disassembly and Reassembly

16 Samsung Electronics

No Parts Procedure Remark

5 CABI FRONT 1) Unscrew and remove the 9 screws on each side

the CABI FRONT.

(Use '+' type screw driver)

6 FAN 1) Turn the one nut as shown in the picture and

remove it.

(Use adjustable wrench)

Disassembly and Reassembly

Samsung Electronics 17

No Parts Procedure Remark

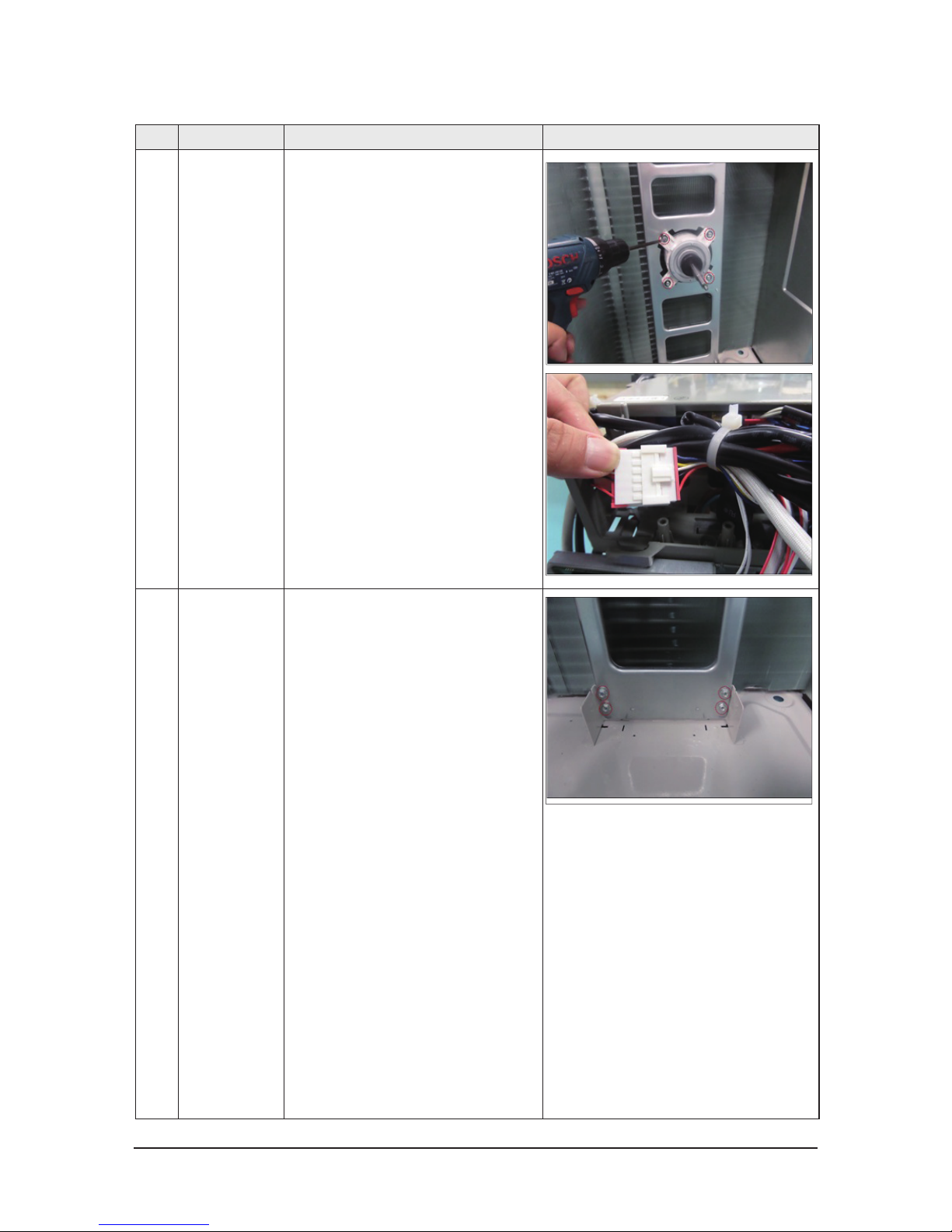

7 MOTOR 1) Remove the fan.

2) Unscrew and remove the four motor screws.

(Use '+' type screw driver)

3) Disconnect the motor wire from the Ass'y

Control Out.

8 BRACKET 1) Unscrew and remove the two screws on the

BRACKET MOTOR.

(Use '+' type screw driver)

Disassembly and Reassembly

18 Samsung Electronics

No Parts Procedure Remark

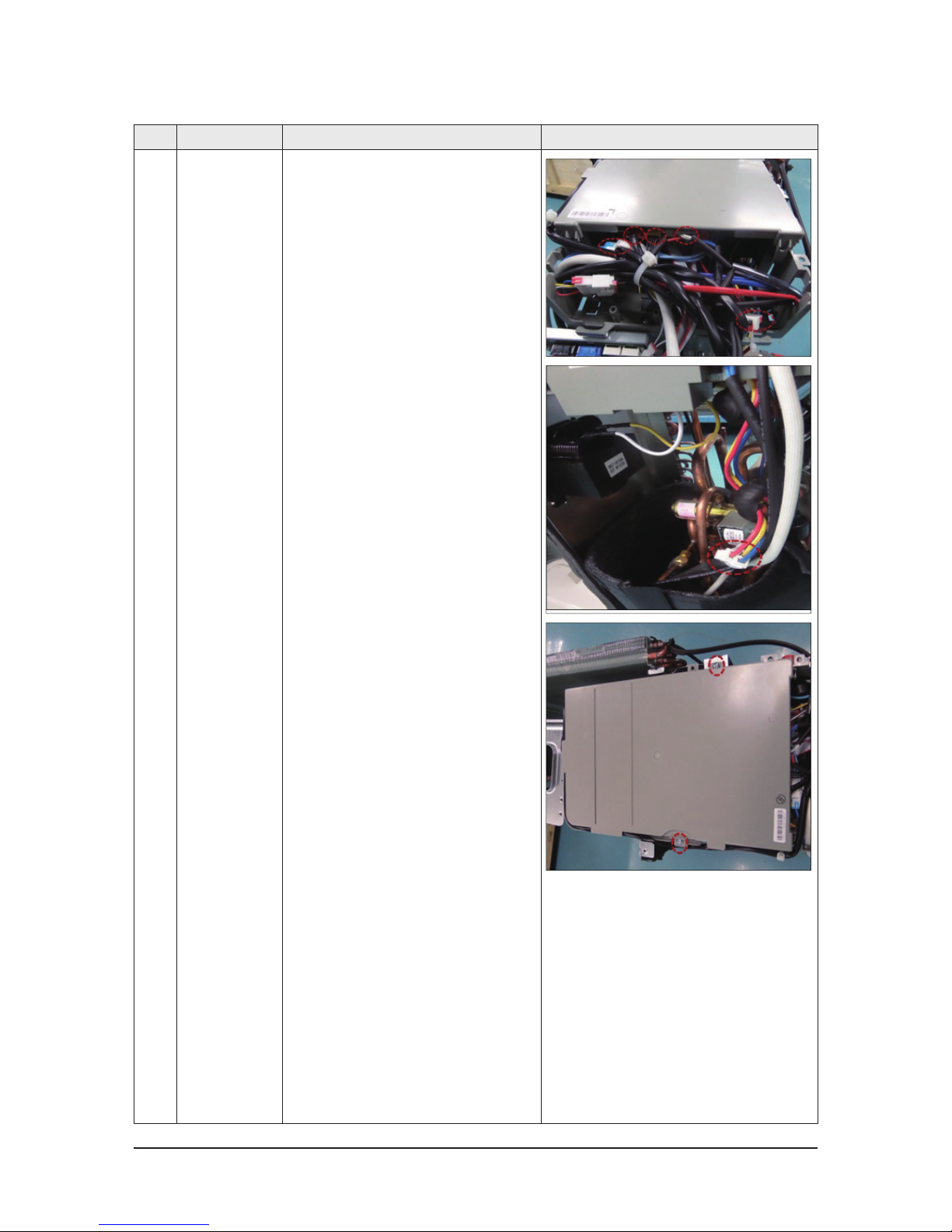

9 CONTROL OUT 1) Disconnect the six connectors from the ASSY

CONTROL OUT.

2) Unscrew and remove the two screws on the

CONTROL OUT.

(Use '+' type screw driver)

3) Separate the ASSY CONTROL OUT

Disassembly and Reassembly

Samsung Electronics 19

No Parts Procedure Remark

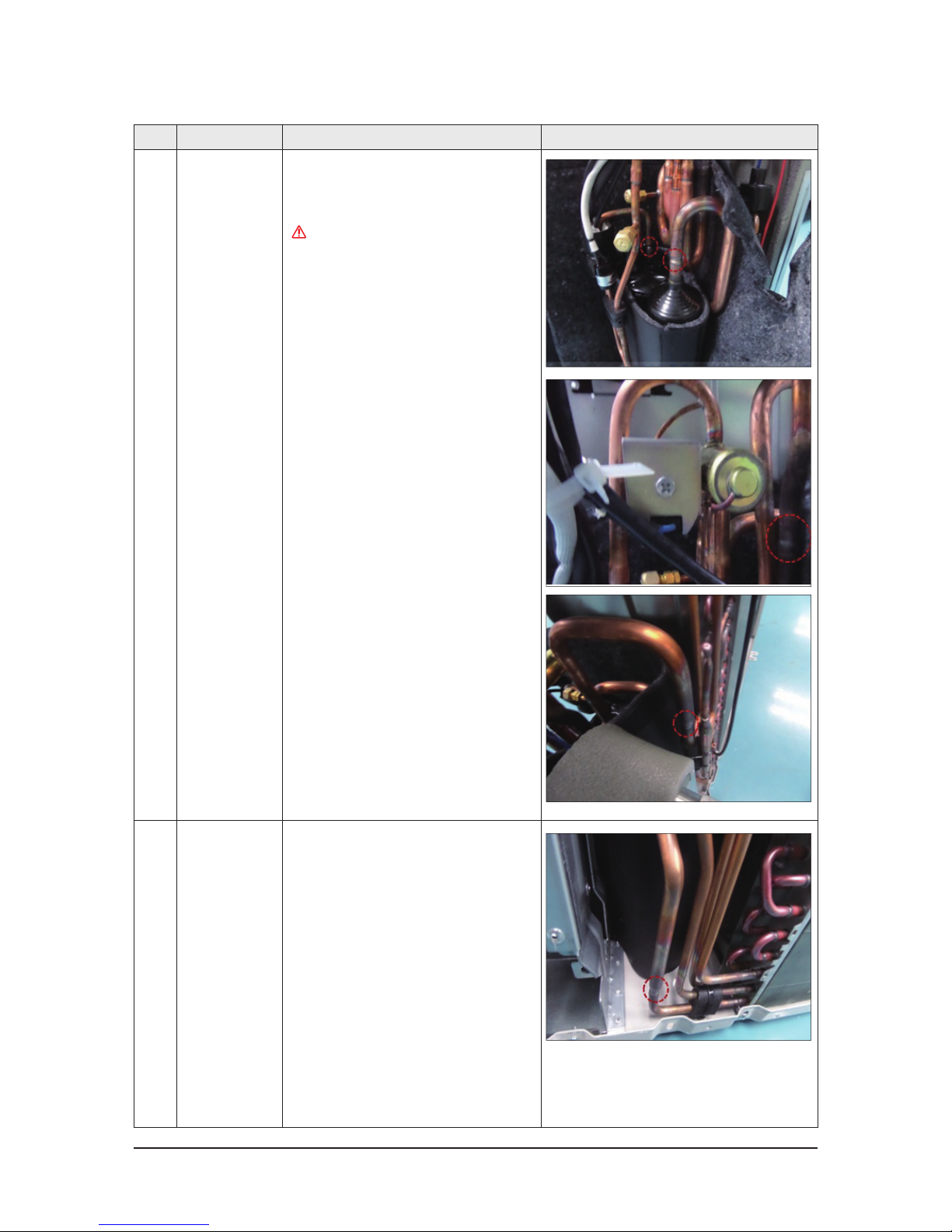

10 ASSY-VALVE 4WAY 1) Purge the coolant first.

2) Separate the pipe from the Entrance/Exit using

a welder.

When removing the compressor,heat

exchanger and pipe, purge the completely

and remove the pipe with a welding flame.

11 ASSY TUBE-WATER 1) Purge the coolant first.

Disassembly and Reassembly

20 Samsung Electronics

No Parts Procedure Remark

2) Turn the two nuts as shown in the picture and

remove them.

(Use adjustable wrench)

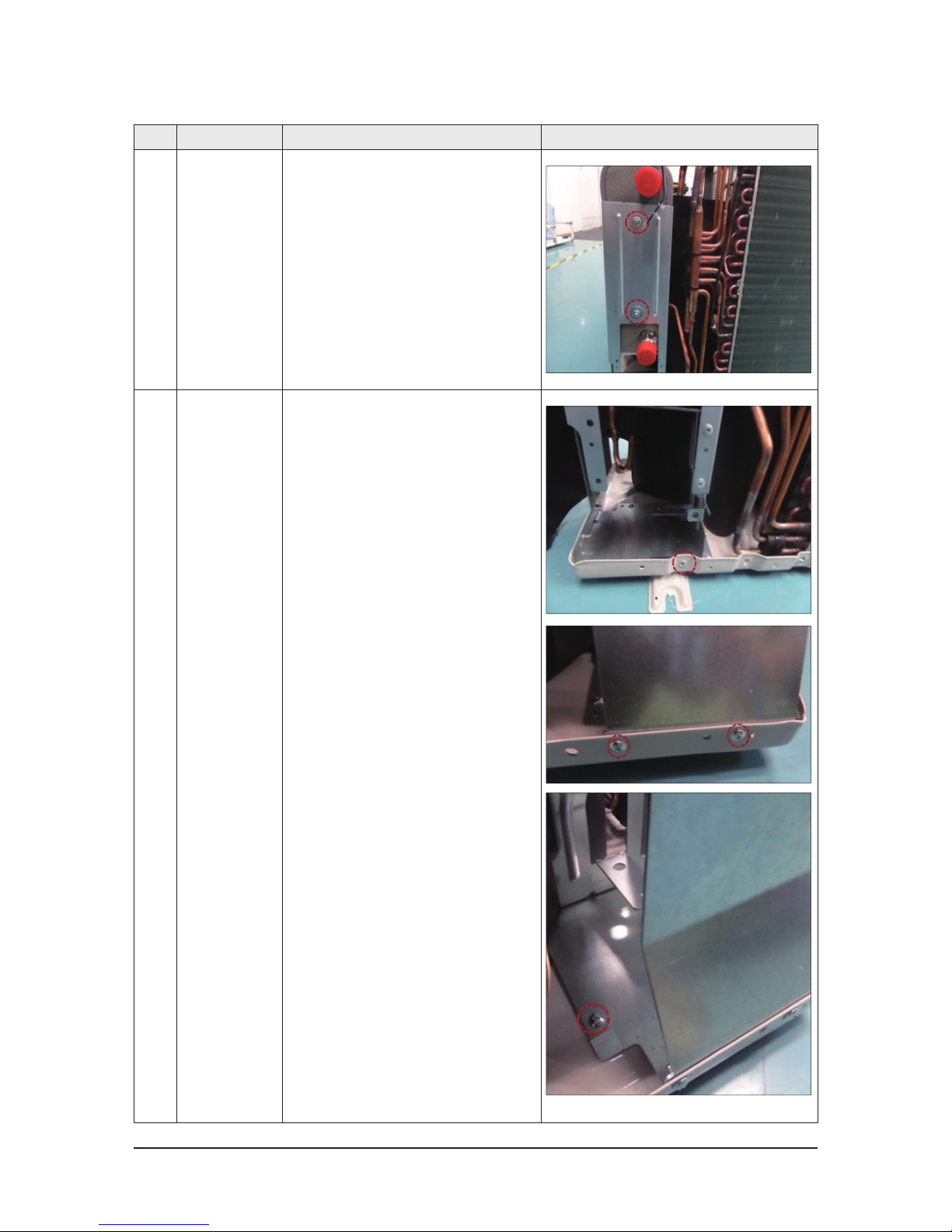

12

ASSY BRACKET PHE

1) Unscrew and remove the 4 screws on the ASSY

BRACKET PHE.

(Use '+' type screw driver)

Loading...

Loading...