Samsung DVD-V940K, DVD-V29000K, SV-DVD240, DVD-V645K, DVD-V25000K Training Manual

...

DVD-VCR COMBINATION

Chassis : Kaiser Karaoke

DVD-V940K/V645K/V642K

DVD-V29000K/V25000K

SV-DVD240

TRAINING

1. Precautions

2. Reference Information

3. Product Specification

4. Operating Instructions

5. Disassembly and Reassembly

6. Alignment and Adjustment

7. Circuit Operating Description

8. VCR Deck Operating Description

9. Troubleshooting

10. Block Diagram

11. Wiring Diagram

12. Schematic Diagrams

Manual

DVD-VCR COMBINATION CONTENTS

TRAINING MANUAL

DVD-V940K/V645K/V642K/V29000K/V25000K, SV-DVD240

ELECTRONICS

© Samsung Electronics Co., Ltd. APR. 2004

Printed in Korea

AK82-00557A

This Service Manual is a property of Samsung Electronics Co .,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

IMPORTANT SERVICE GUIDE

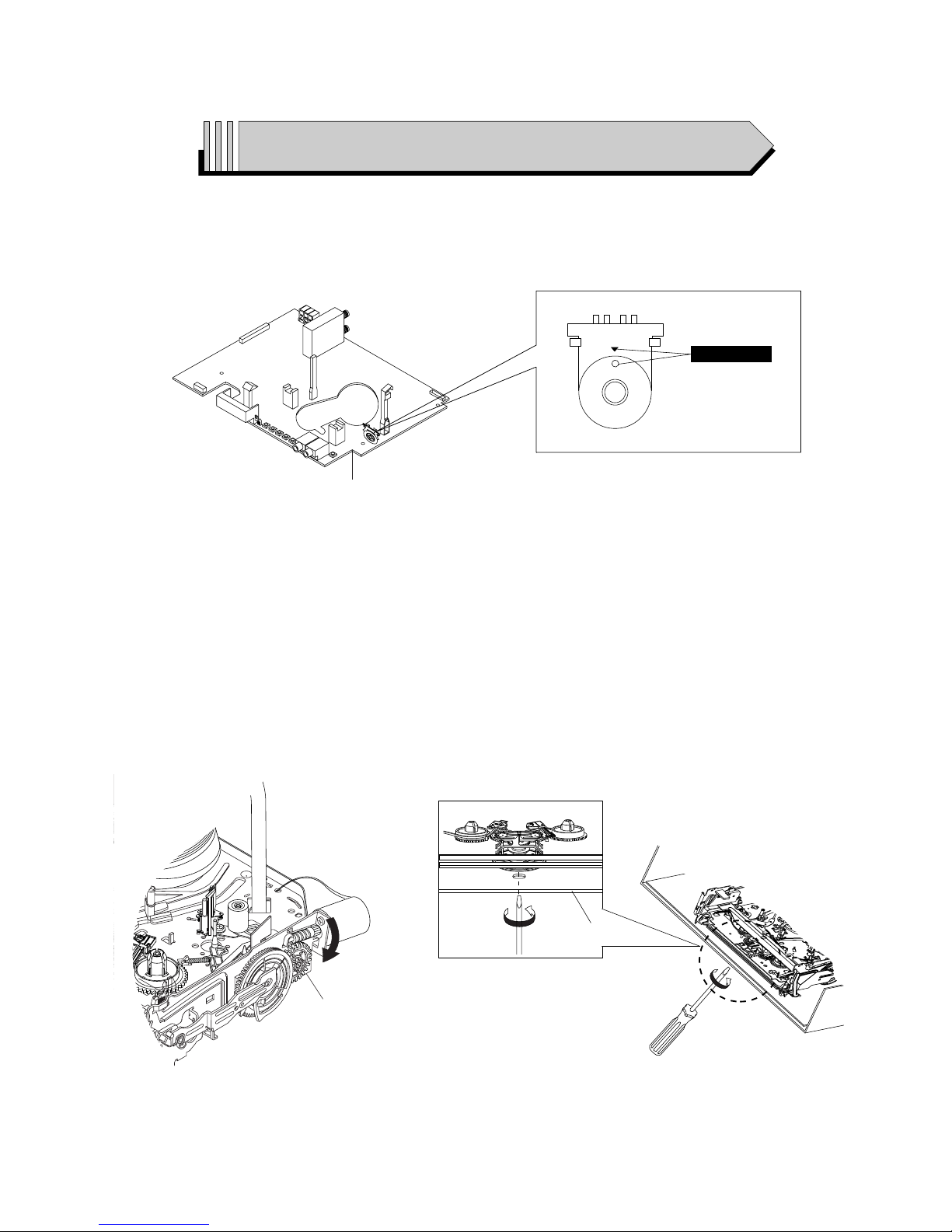

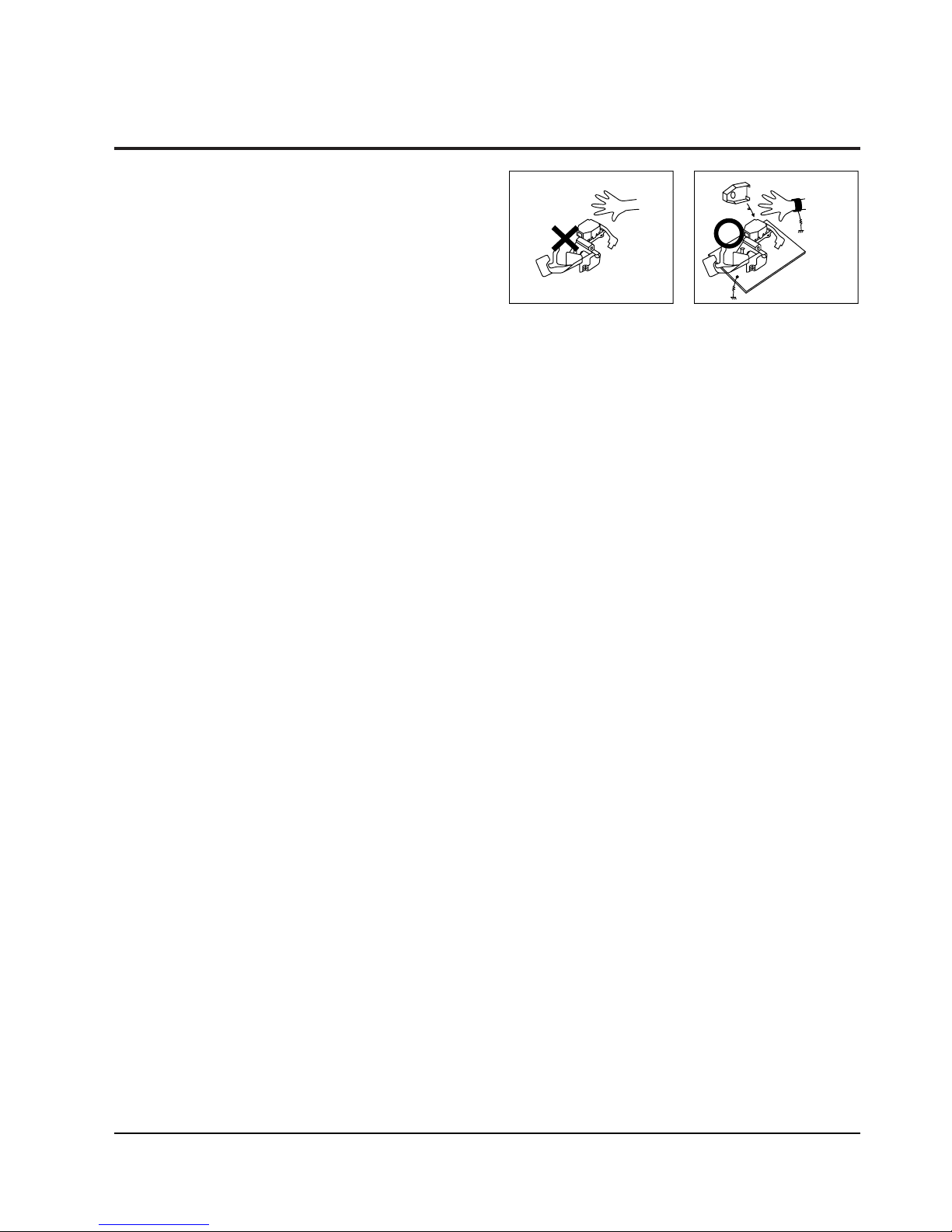

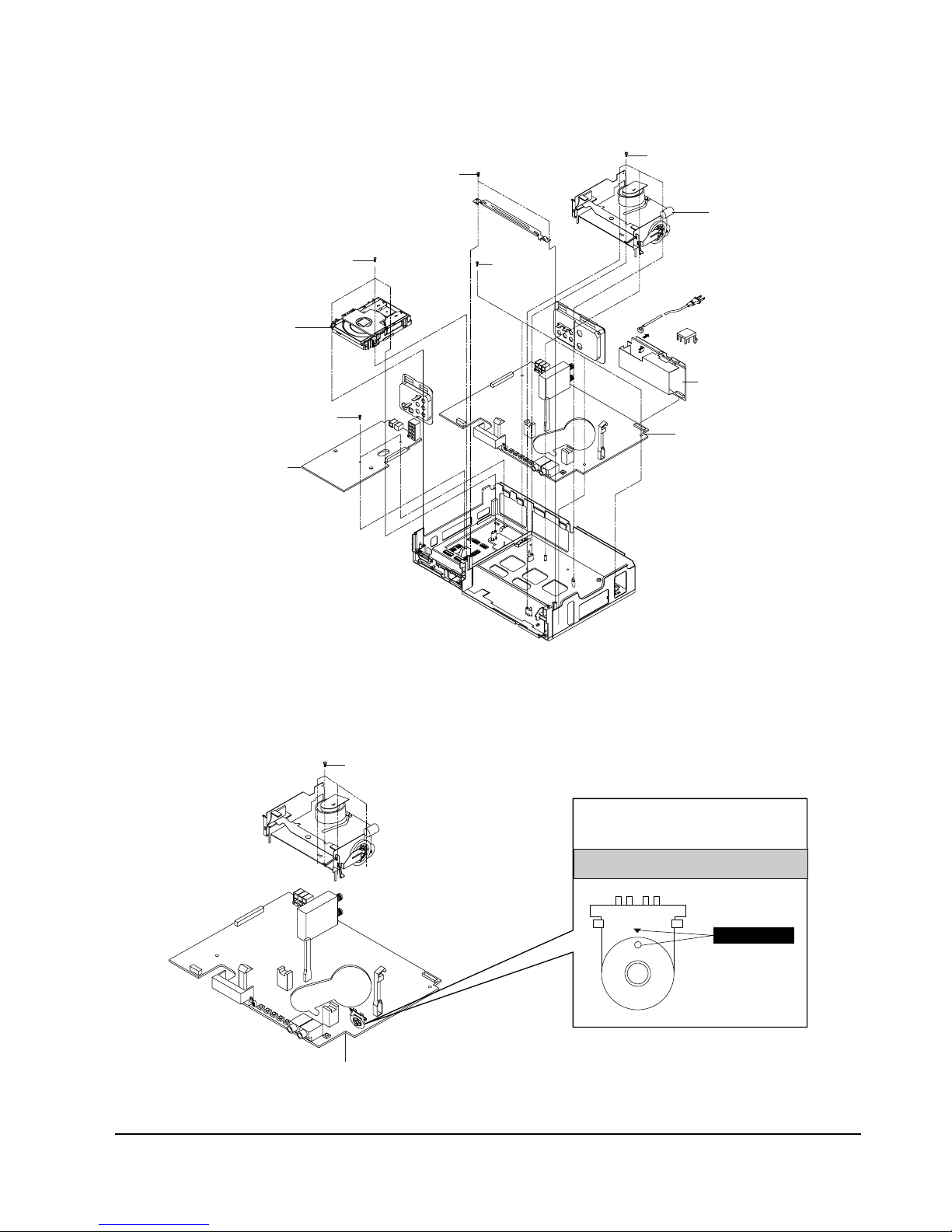

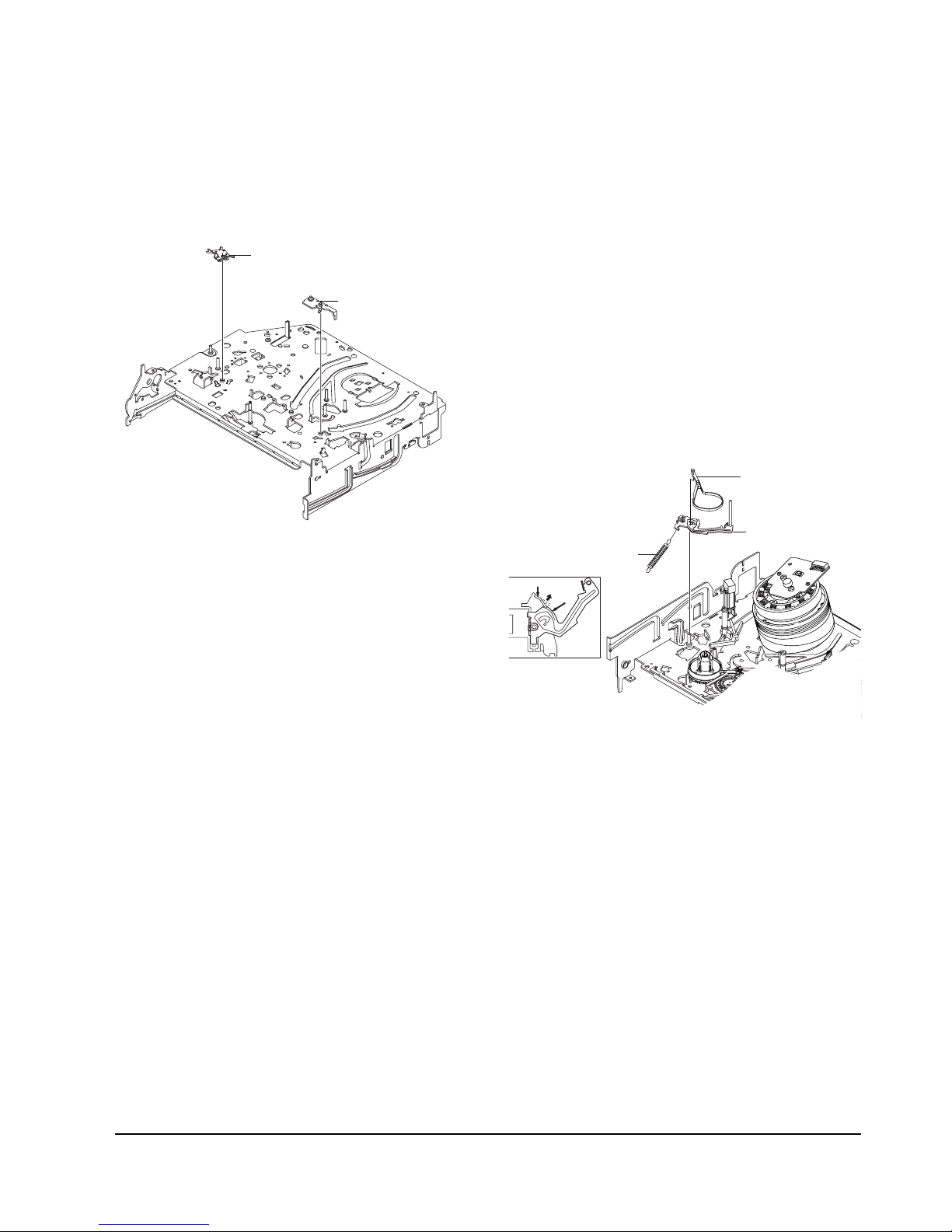

◆ MODE SWITCH (PROGRAM SWITCH) ASSEMBLY POINT

1) When installing the ass’y deck on the Main PCB, be sure to align the assembly point of mode switch.

VCR MAIN PCB

ASSEMBLY POINT

Fig. 1

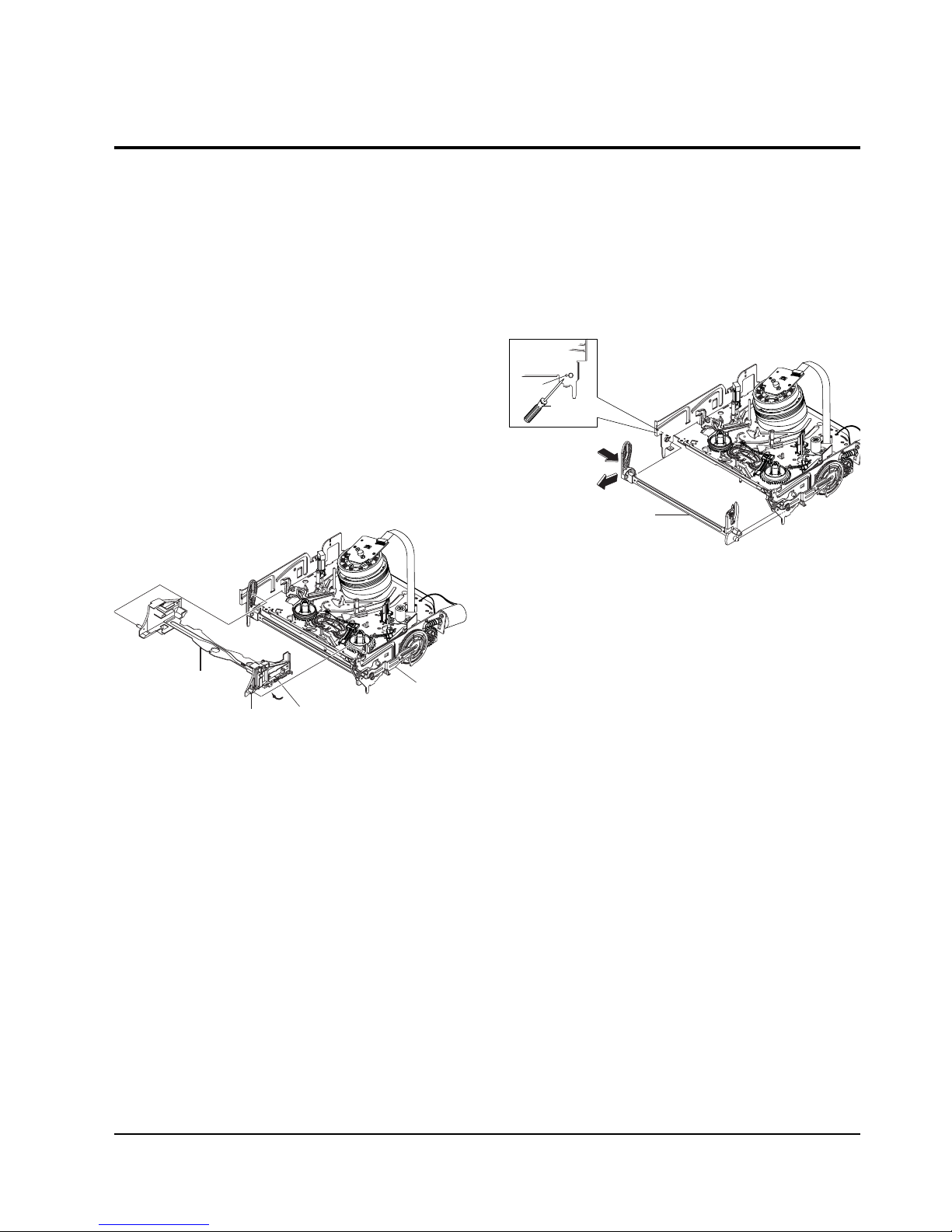

◆ HOW TO EJECT THE CASSETTE TAPE

(If the tape is stuck in the unit)

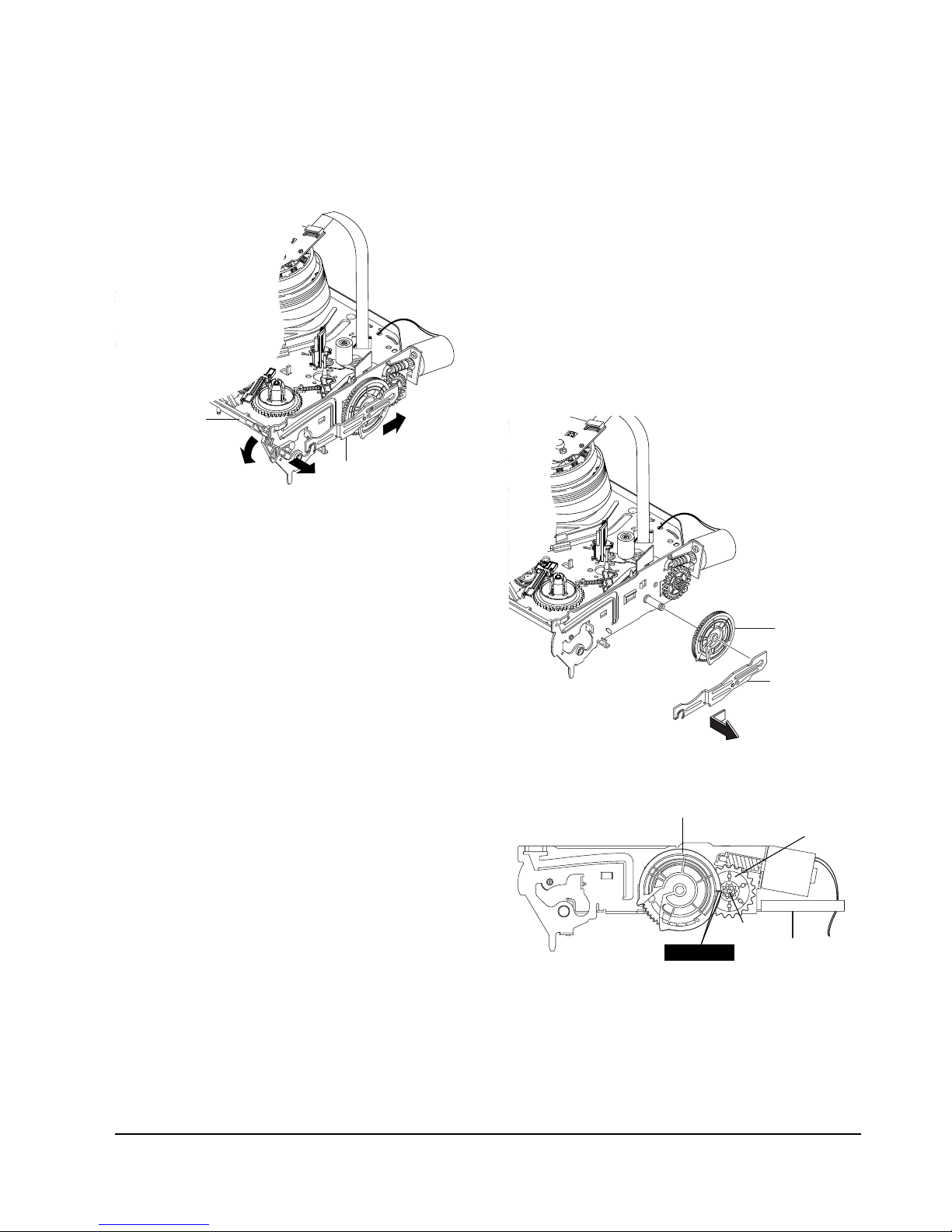

1) Turn the Gear Worm Πclockwise in the direction of arrow with a screwdriver. (See Fig. 2)

(Other method ; Remove the screw of Motor Load Ass’y, Separate the Motor Load Ass’y)

2) When Slider S, T approachs the unloading position, rotate holder Clutch counterclockwise after inserting screwdriver in the

frame’s bottom hole in order to wind the unwound tape. (Refer to Fig. 3)

(If you rotate Gear Worm Πcontinuously when tape is unwinding, you may cause tape contamination by grease and

tape damage. Be sure to wind the unwound tape with the unit in the horizontall position.)

3) Rotate Gear Worm Πclockwise using a screwdriver until the mecha is in the eject state. Remove the tape. (Refer to Fig. 2)

Fig. 2 Fig. 3

ΠGEAR WORM

FRAME

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively wide cabinet ventilation slots, and an improperly fitted and/or incorrectly secured cabinet back

cover.

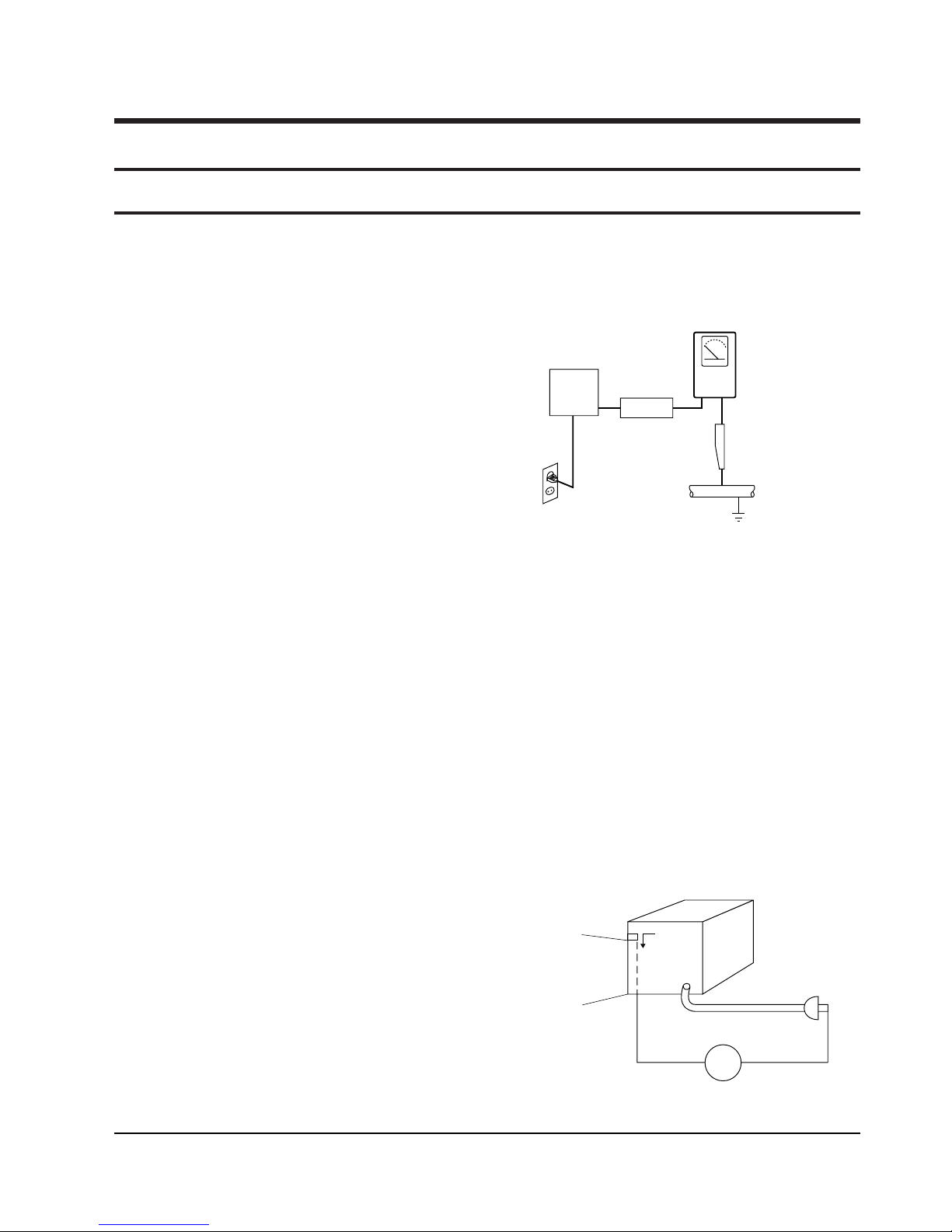

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage

current tester or a metering system that complies

with American National Standards institute (ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinets, screwheads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibility of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Antenna

Terminal

Exposed

Metal Part

ohm

ohmmeter

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this instrument. Design alterations and additions, including

but not limited to, circuit modifications and the

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch thermally hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have special safety characteristics are identified by shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire and/or

other hazards. Product safety is under review continuously and new instructions are issued whenever appropriate.

Precautions

Samsung Electronics 1-3

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note : If unforseen circumstances create conflict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions. Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic capacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage inter-

locks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing, follow the printed or indicated service precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength.

When replacing components, use components

which have the same ratings. Components identified by shading, by( ) or by ( ) in the circuit diagram are important for safety or for the characteristics of the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

Precautions

1-4 Samsung Electronics

1-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devices are integrated circuits and some field-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective ma-

terials from the leads of a replacement ESD device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpack-

aged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ESD device).

Precautions

Samsung Electronics 1-5

1-4 Handling the optical pick-up

The laser diode in the optical pick up may suffer electrostatic breakdown because of potential static electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet(This

gives them the same ground as the sheet.)

(4) Remove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

◆ Be sure to put on a wrist strap grounded to the

sheet.

◆ Be sure to lay a conductive sheet made of copper

etc. Which is grounded to the table.

Fig.1-3

(6) Short the short terminal on the PCB, which is in-

side the Pick-Up ASS’Y, before replacing the PickUp. (The short terminal is shorted when the PickUp Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short termi-

nal on the PCB.

THE UNIT

WRIST-STRAP

FOR GROUNDING

1M

1M

CONDUCTIVE SHEET

Precautions

1-6 Samsung Electronics

1-5 Pick-up disassembly and reassembly

1-5-1 Disassembly

1) Remove the power cord.

2) Disassemble the Deck-Assy.

3) Make solder land 2 points short on Pick-up.

(See Fig. 1-4)

4) Disassemble the Pick-up.

1-5-2 Assembly

1) Replace the Pick-up.

2) Remove the soldering 2 points on Pick-up.

3) Reassemble the Deck-Assy.

PICK-UP ASS'Y

SOLDER LAND 2 POINTS SHORT

Note : If the assembly and disassembly are not done in correct sequence, the Pick-up may be damaged.

Fig. 1-4

Samsung Electronics 2-1

2. Reference Information

2-1 Introduction to DVD

2-1-1 The Definition of DVD

DVD is the next generation medium and is the acronym of the Digital Versatile Disc or the Digital Video Disc,

which maximizes the saving density of the disk surface using the MPEG-2 compression technology to enable the

storage of 17G bytes of data on the same size CD.

1) 7 times the storage capacity of the conventional CD

◆ Minimized the track pitch and pit size to 1/2 of conventional CD.

◆ Uses red laser with short-wavelenght of 650nm (635nm).

⌘ DVD Vs. CD-ROM

DVD

CD-ROM

Single-Layer Dual-Layer

Laser Wavelength 650nm (635nm) 780nm

Track Pitch 0.75um 1.6um

Disc Diameter 120mm

Disc Thickness 1.2 (0.6 x 2) mm 1.2mm

Linear Velocity 3.49m/s 3.84m/s 1.2 ~ 1.4m/s

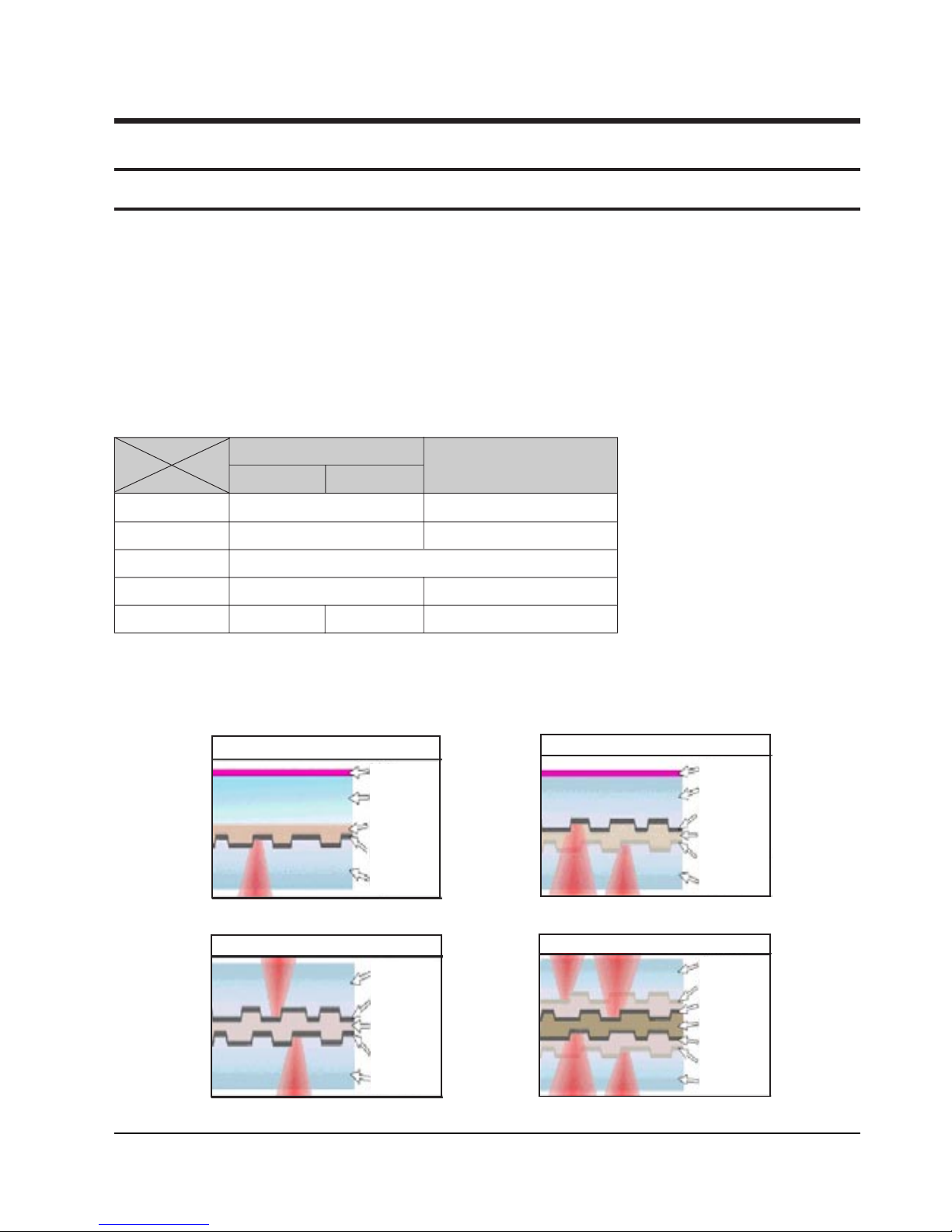

2) Disc Formats

DVD consists of two 0.6mm discs attached together, enabling access to the upper and lower side of the disk,

and 4 sides could be used at maximum.

Single Layer : 4.7GByte

Polycarbonate

Label

Bonding layer

Reflective layer

Polycarbonate

Label

Polycarbonate

Bonding layer

Reflective layer

Semi-reflective layer

Polycarbonate

Dual Layer : 8.5GByte

Bonding layer

Reflective layer

Reflective layer

Polycarbonate

Polycarbonate

Dual Side Single Layer : 9.5GByte

Polycarbonate

Bonding layer

Reflective layer

Reflective layer

Semi-reflective layer

Semi-reflective layer

Polycarbonate

Dual Side Dual Layer : 17GByte

Reference Information

2-2 Samsung Electronics

2-1-2 DVD Types

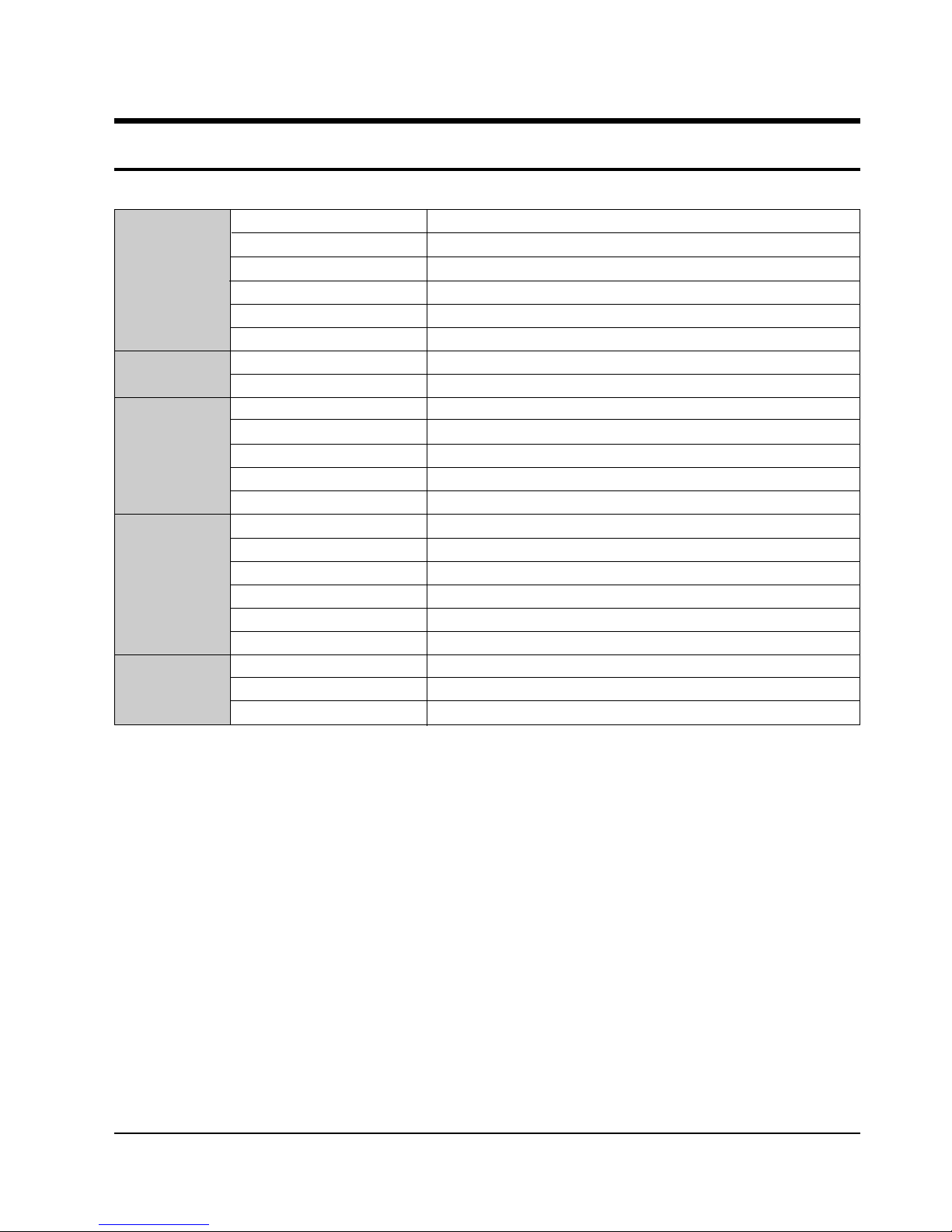

FORMAT TYPE APPLICATIONS

DVD-Video Playback Only High quality image and sound for movies and other video media.

DVD-ROM Read Only Multi-functional, multi-midia software that requires large storage capacity.

DVD-Audio Playback Only High quality sound that exceeds the CD, multi-channel Audio.

DVD-R 1 Time Recording Storage media for the computer.

DVD-RAM Rewritable Data access/storage media for the computer.

Reference Information

Samsung Electronics 2-3

2-2 DVD-Video Fromat

2-2-1 Main Features

1) Able to store up to 160 minutes of Movie by utilizing the MPEG-2 compression technology. ( Aver. 133min.)

2) Enables more than 500 lines of horizontal resolution. (Class corresponding to the Master Tapes used in

broadcasting stations)

3) Provides Dolby Digital 5.1ch Surround 3D sound, which enables theater quality sound (NTSC area).

◆ For PALareas, 1 of either MPEG-2 Audio or Dolby Digital must be selected.

4) Multi-Language

◆ Able to store up to 8 languages of dubbing.

◆ Able to store up to 32 subtitle languages.

5) Milti-Aspect Ratio

3TV Mode alternatives ; 16:9 Wide Screen (DVD Basic)/4:3 Pan & Scan/Letter Box.

6) Multi-Story

Possible to implement Interactive Viewing which enables the user to select the scenario.

7) Multi-Angle

Able to view the camera angle you selected among the scenes recorded with multiple camera angles.

Note ; The above media features must have the DVD Title that contains the appropriate contents to function

properly.

2-2-2 Audio & Video Specifications

Classification DVD-Video Video-CD LD

Compression MPEG-2 MPEG-1

Analog

Pixel 720 x 480 352 x 240

VIDEO

Horizontal resolution Max. 500 Lines Max. 250 Lines Max.420 Lines

Compression rate 1/40 1/140

Analog

Transmission speed Max. 9.8Mbps (variable) 1.15Mbps (fixed)

TV aspect 16:9 / 4:3 4:3 4:3

Audio Max. 8 streams 2CH stereo

Recording type Dolby Digital Linear PCM MPEG-1 Layer 2

AUDIO Transmission rate 448Kbps/stream 6.144Mbps/stream 224Kbps

or

Channel 5.1CH/stream 8CH/stream 2CH

Sampling frequency 48KHz 16, 20, 24Bit/48, 96KHz 16Bit/44.1KHz

2 Analog CH.

2 Digital CH.

(16Bit/44.1KHz)

1 Analog CH.

1 Stream of Dolby Digital

2 Digital CH.

(16Bit/44.1KHz)

Reference Information

2-4 Samsung Electronics

2-2-3 Detailed Feature

As the storage capacity increases, the DVD-Video separates the main data and the additional data such as the

Multi-Function into different data areas, enabling the control of time-data ratio to provide the format that enables

the flexible Software development

◆ 1 Movie (3.5Mbps)

+ Subtitle (1 Language)

+ Surround Audio (1 Language)

= 160min storage (4.673Gbytes)

◆ 1 Movie (3.5Mbps)

+ Subtitle (4 Language)

+ Surround Audio (4 Language)

= 160min storage (4.680Gbytes)

◆ 1 Music Video (4Mbps)

+ 2ch High quality Audio (96kHz/24bit)

= 72min storage (4.648Gbytes)

DVD-Video Feature 1 When Developing the DVD Software, various addition and modification is possible.

DVD-Video uses the variable compresion technology, the MPEG-2 to compress the moving image optimally, minimizing the Data loss to Provide a clear, natural screen while increasing the storage time.

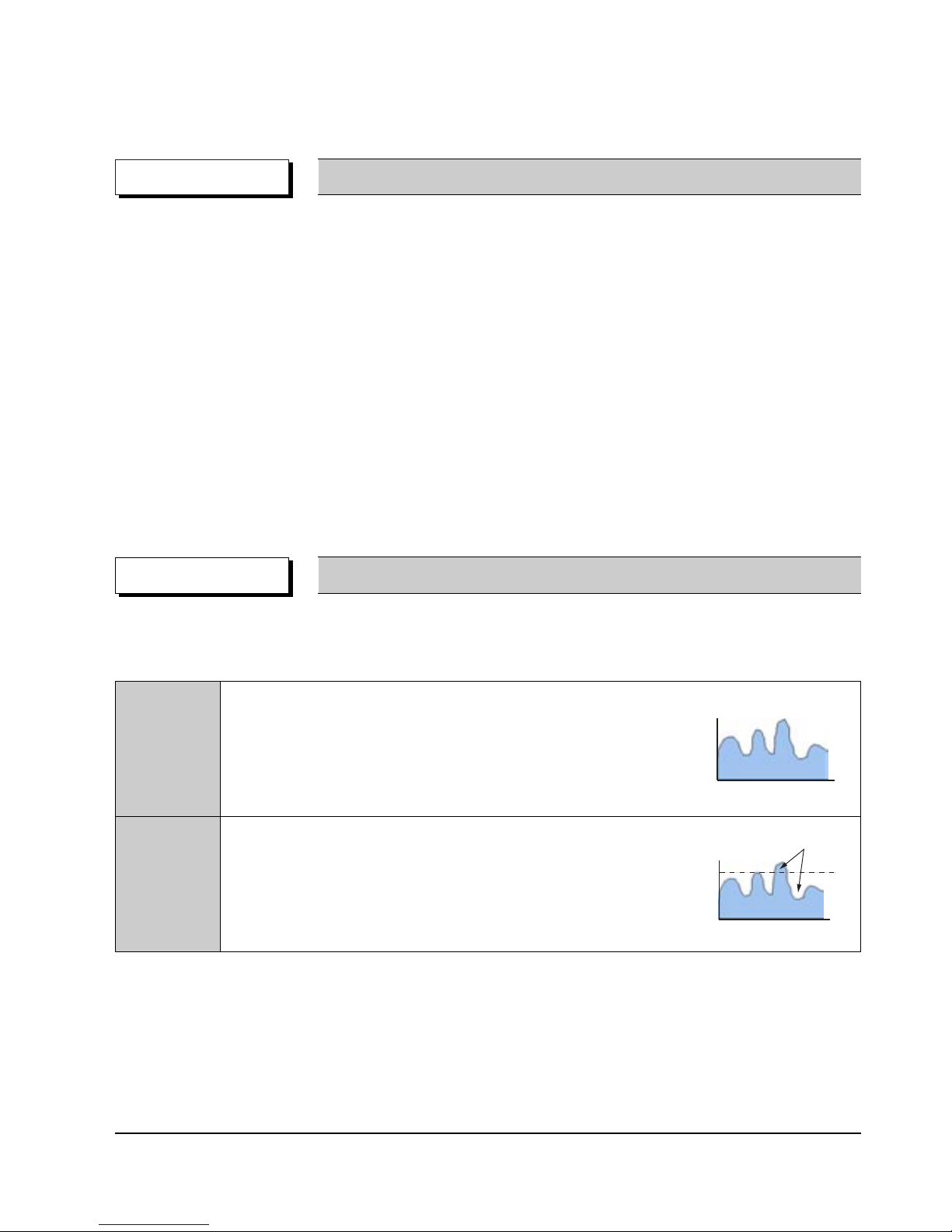

DVD-Video Feature 2 Application of the MPEG-2 compression technology.

◆ MPEG-2 (Variable compression : Max. 1/40)

✓ Field unit compression.

DVD-Video

✓ Compression rate change according to the amount of Data.

✓ Differentiates the still image anf the moving image

compression rete, reducing Data loss and enables

efficient compression.

◆ MPEG-1 (Fixed compression : Max. 1/140)

✓ Frame unit compression.

Video-CD

✓ Compresses all data using the same ratio.

- Fast movements are jagged, and unnatural

Time

Amount of data

Time

Amount of data

Loss area

Reference Information

Samsung Electronics 2-5

DVD-Video can store the audio using the 5.1ch Dolby Digital compression or the advanced Liner PCM method,

providing the better-than-CD quality and theater like audio quality.

◆ Dolby Digital (AC-3)

✓ Unlike the traditional Dolby pro-Logic method, the Dolby Digital method separates all 5 main channels

(Front L/R, Center, Surround (Rear) L/R)and the Sub woofer to provide live surround audio.

✓ Using the Down Mix method, the conventional Dolby Pro-Logic and Stereo are all compatible.

✓ Each separated channels are played back at CD quality sound. (Frequency band: 20Hz ~ 20KHz)

◆ Linear PCM (Pulse Code Modulation)

✓ Provides the high quality Digital sound without the audio data compression.

✓ Various Digital Recordings are possible as shown in the table to the right.

DVD-Video Feature 3 High quality surround audio.

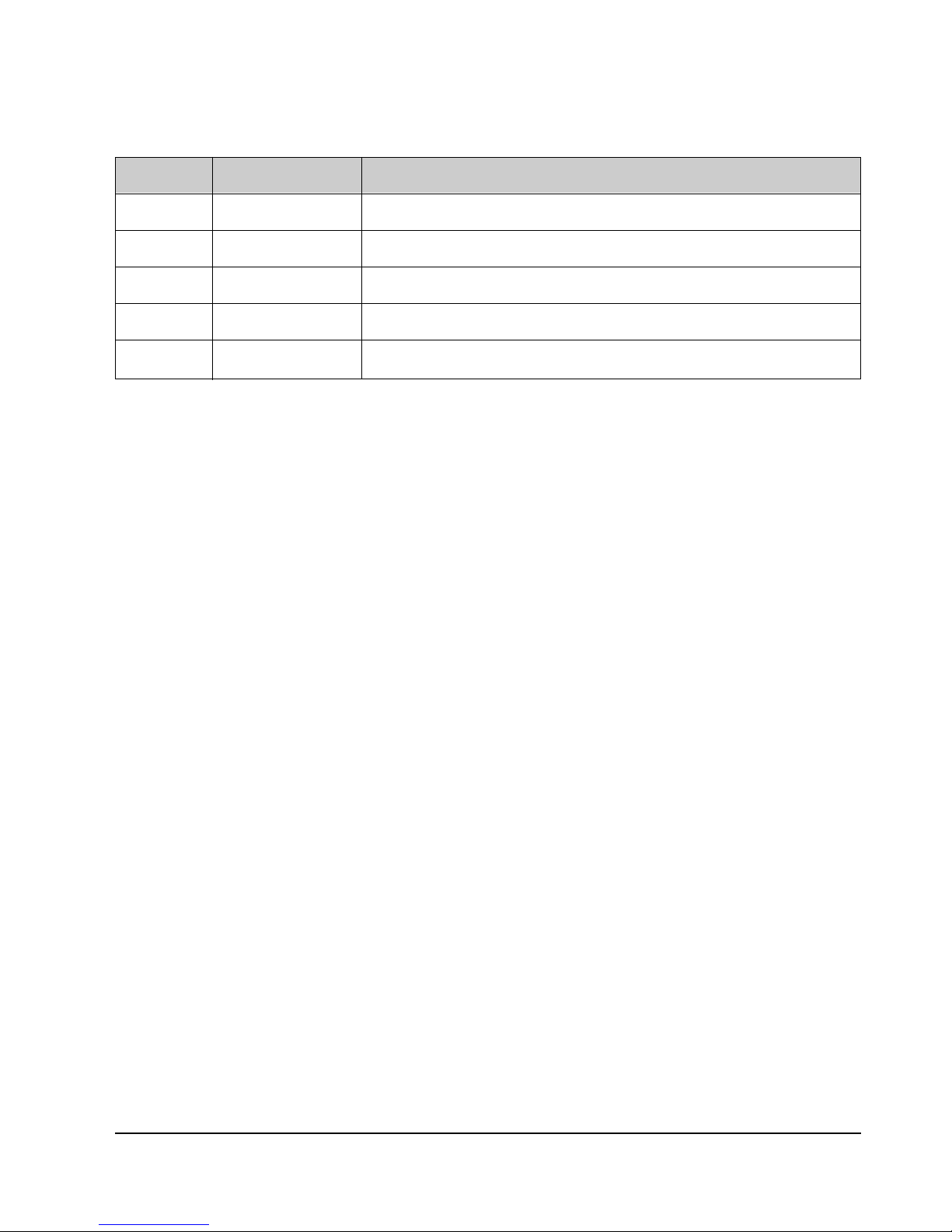

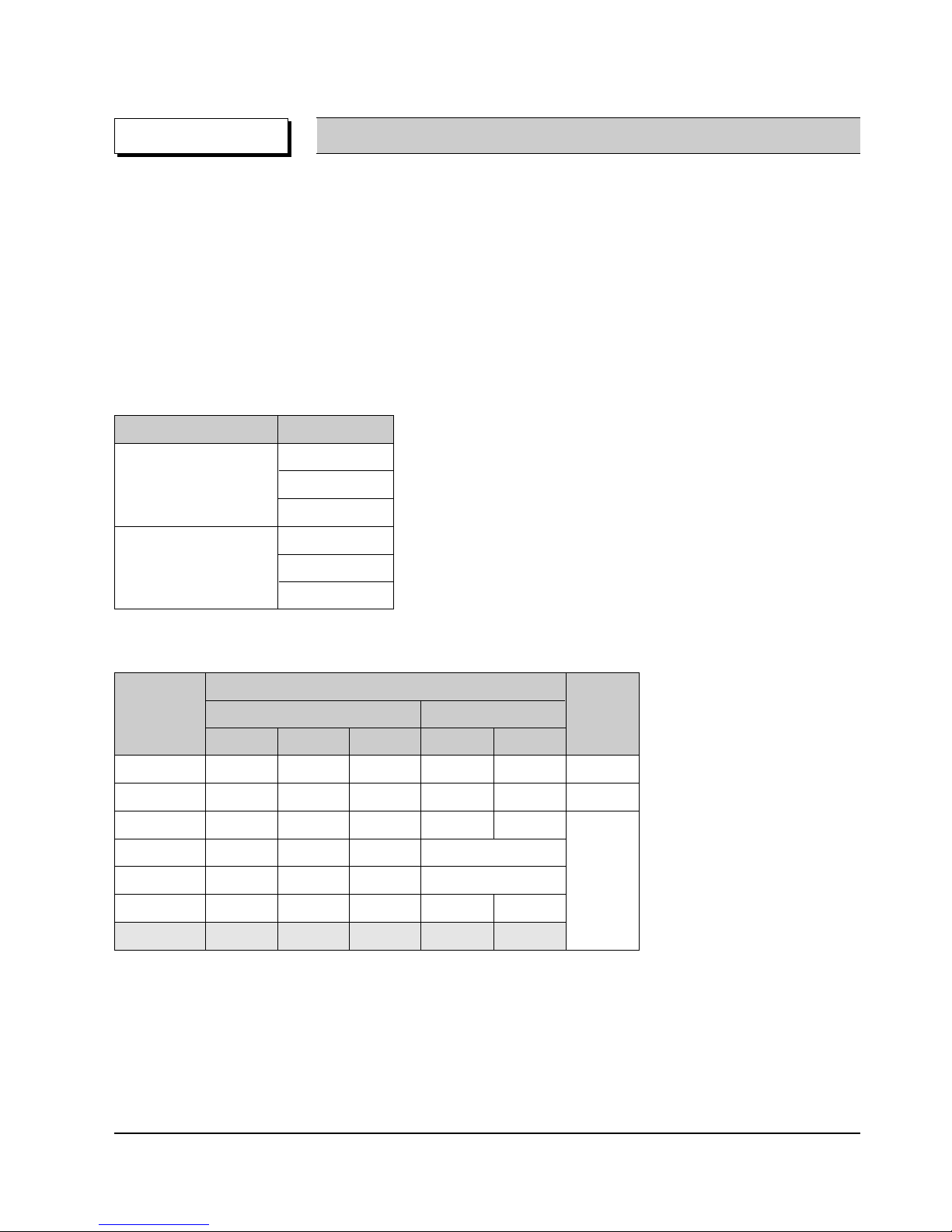

Sampling Frequency Bit Rate

16bit

48KHz 20bit

24bit

16bit

96KHz 20bit

24bit

◆ Dolby Digital compatible Audio Mode

Audio Coding

Channel Format

Mode

Front Surround (Rear) Remark

LCRLR

1/0 O Mono

2/0 OO Stereo

3/0 OOO

2/1 OOMono

3/1 OOO Mono Surround

2/2 OOOO

3/2 OOOOO

Reference Information

2-6 Samsung Electronics

◆ Audio Dubbing - Max. 8 Languages

◆ Subtitle - Max. 32 Languages. Capable of storing, and selectiong.

◆ Linear PCM (Pulse Code Modulation)

DVD-Video Feature 4 Multi-Language

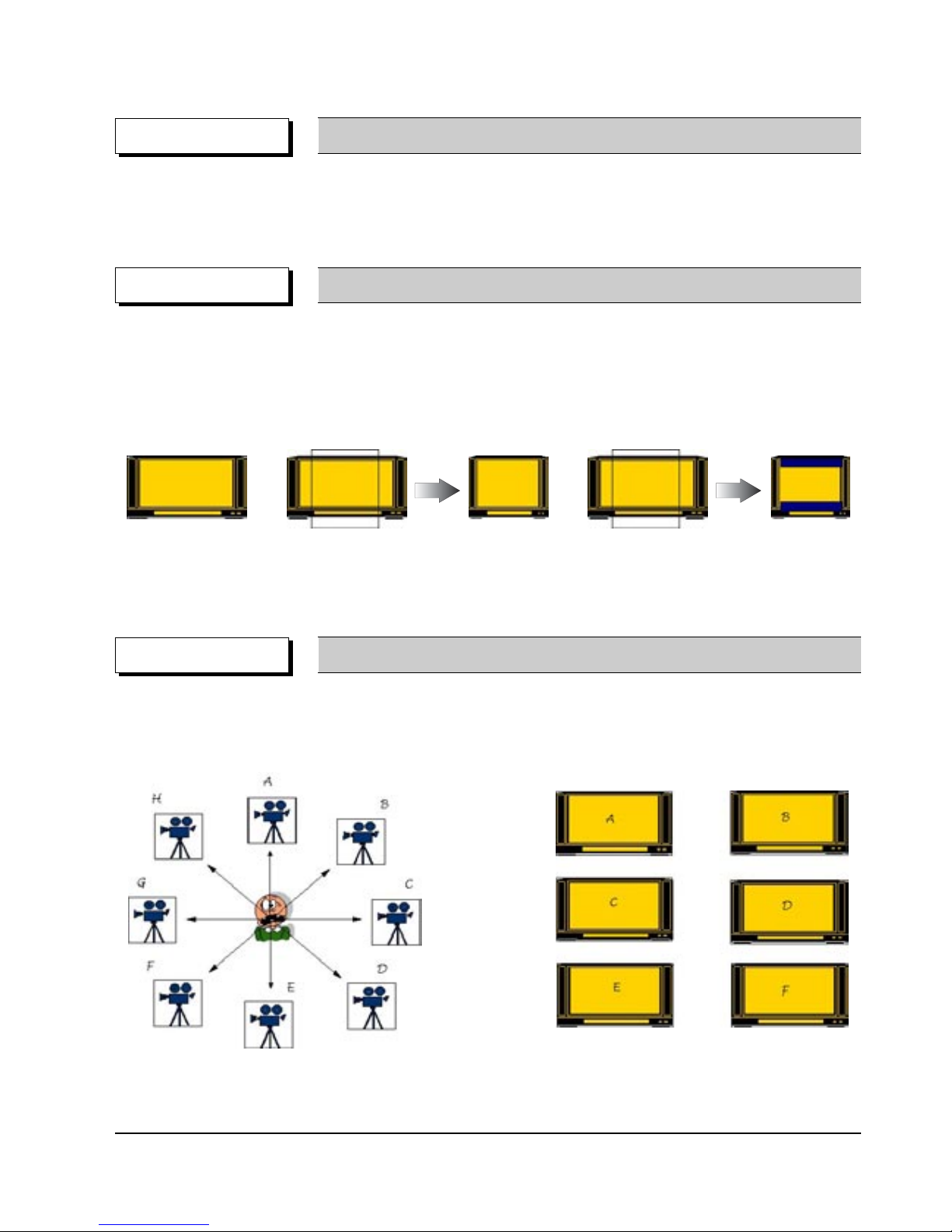

◆ Unlike the conventional VCD or LD, DVD-Video has the default of 16:9 Wide, and can be viewed using the

conventional 4:3 TV, enabling the expansion of viewer selection capabilities.

✓ 16 : 9 TV : Wide Mode (16:9 Wide Full Screen)

✓ 4 : 3 TV : Letter Box Mode, Pan & Scan Mode

DVD-Video Feature 5 Multi-Aspect

4:3 Pan & Scan

16:9 Wide

4:3 Letter Box

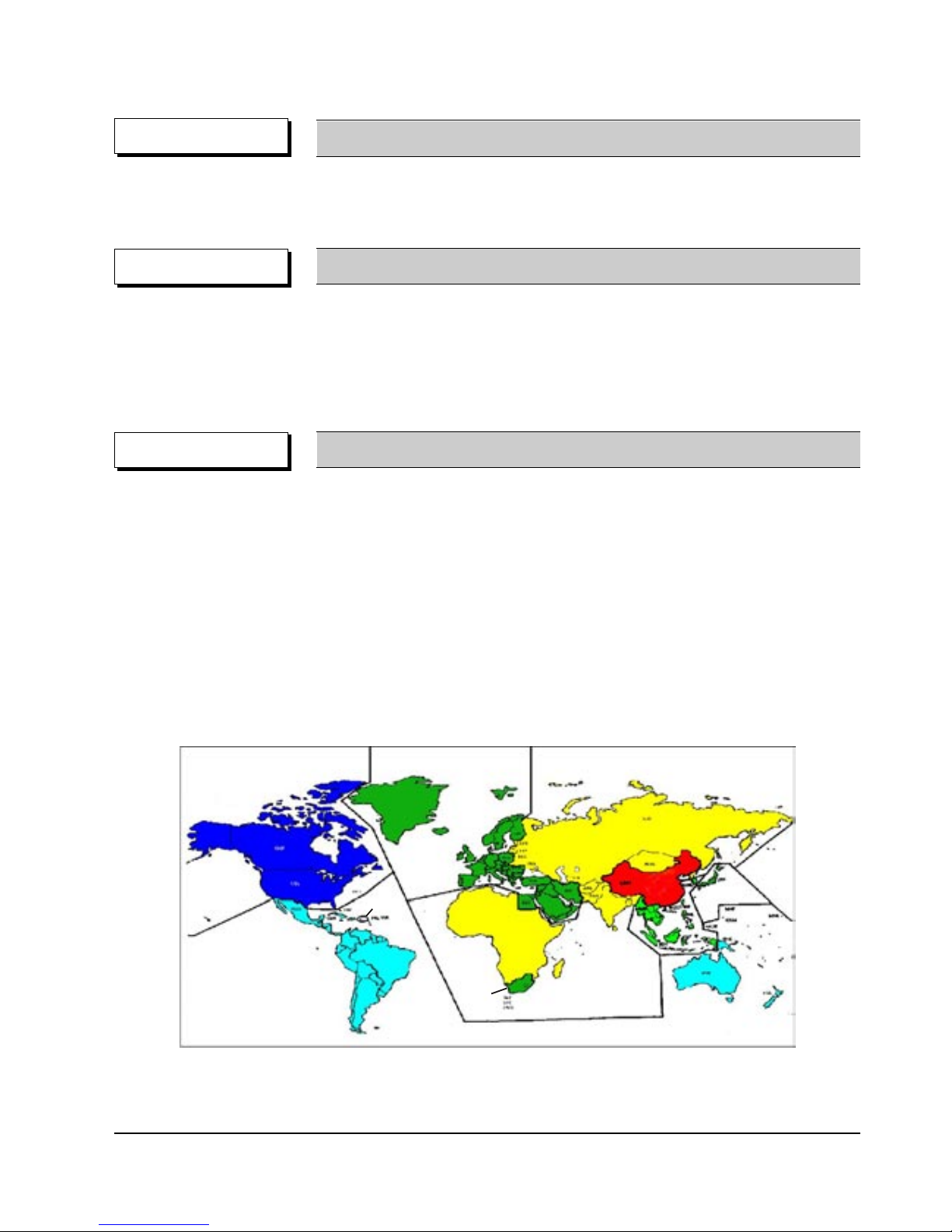

◆ Up to 9 angles of view may be stored, enabling the viewer to select a specific viewpoint at a given time.

--> Especially, for the Music Video and Sports Title, this provides a more lively image of the scene.

DVD-Video Feature 6 Multi-Angle

Note ; Only enable to be worked correctly by an appropriate data supported this function in Disc.

Note ; Only enable to be worked correctly by an appropriate data supported this function in Disc.

Reference Information

Samsung Electronics 2-7

◆ DVD-Video provides the enviroment suitable for the bi-directional Software develoment, providing multiple

scenarios. This feature enables the Multi-Story function.

DVD-Video Feature 7

Multi-Story

◆ For the titles that are not suitable for children viewing, Parental Locks are set, requesting user defined

passwords for viewing

◆ Parential Locks may be set on specific frames of the Title, enabling the player to skip those frames during

playback.

OPTION Parental Lock

◆ Classify the world into 6 regions, and if the DVD Title and the Player’s “Reginal Code” do not agree, playback

is prohibited.

⌘ Regionnal Coding is optional for the Soft developers (Region 0 All Code), but the Hardware developers

must adopt the appropriate regionnal code for sale.

✓ Region 1 : The United States and its territories, Canada.

✓ Region 2 : Europe, Japan, Greenland, Egypt, South Africa, the Middle East.

✓ Region 3 : Taiwan, Hongkong, Korea, South East Asia.

✓ Region 4 : Mexico, South America, Australia, New Zealand.

✓ Region 5 : Russia, Eastern Europe, India, Africa.

✓ Region 6 : China.

✓ Region 0 : Worldwide (All Code)

COPYRIGHT Regional Code & Macrovision

◆ Adoptation of the Macrovision System disables the copying on to other media.

Œ

Œ

¨

¨

Œ

´

ˇ

ˆ

Ø

´

´

ˆ

Reference Information

2-8 Samsung Electronics

◆ The image quality of the DVD-Video may vary accoring to the quality of the Master and the Authoring Process

✓ The image quality of the DVD-Video varies according to the Digital Mastering Source such as the

conventional LD, VCD, or Original Film.

✓ Different Authoring Process are used accoring to the Software developers, and this may affect the

DVD image quality.

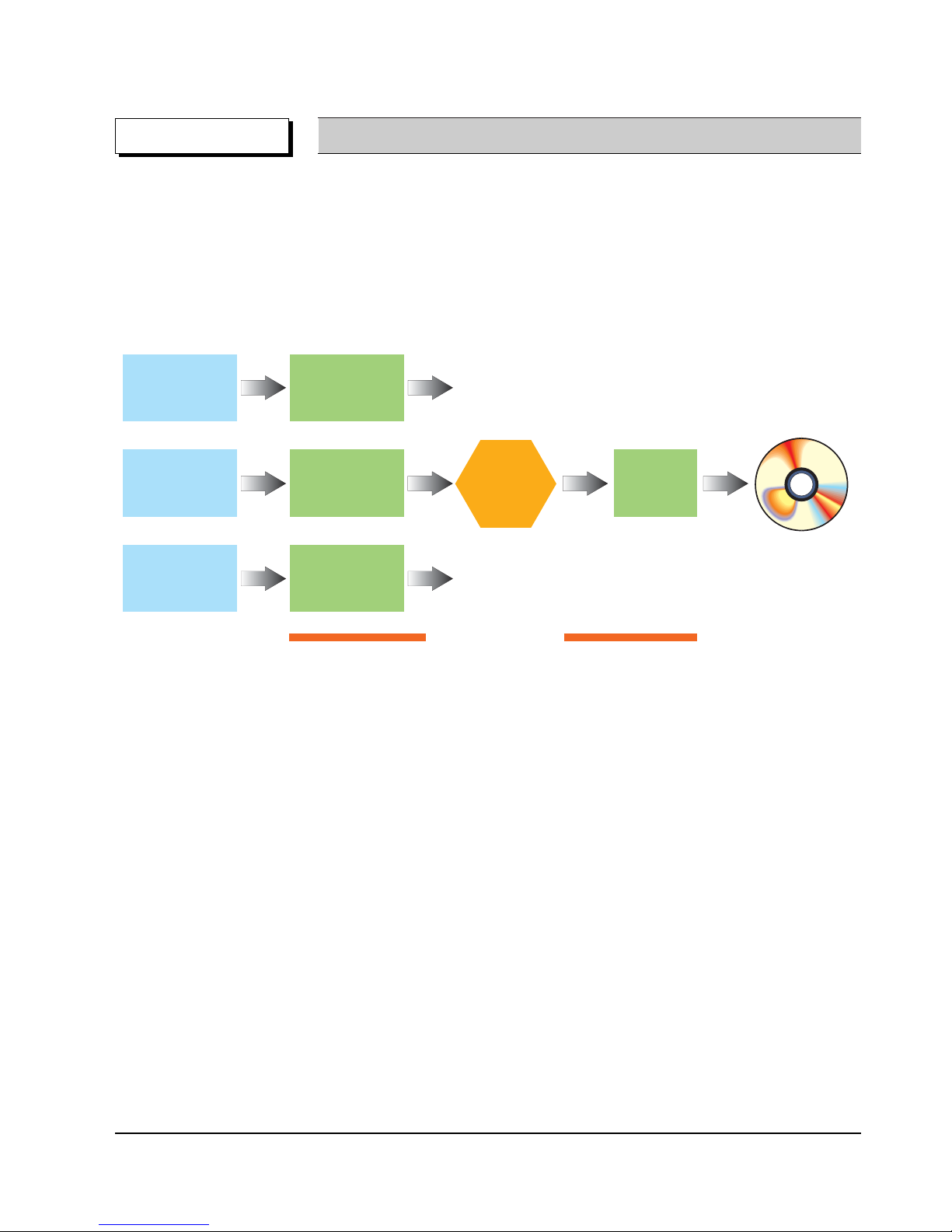

⌘ Authoring Process

Remark DVD-Video Authoring Process

Video/Audio

Master

Surround Audio

Master

Subtitle

Master

MPEG-2

Encoding

AC-3/MPEG Audio

Encoding

Cutting

Master

Disc

Production

Subtitle

Encoding

Authoring Process

Video/Audio

Subtitle

Multiplexing

bit stream

bit stream

bit stream

Samsung Electronics 3-1

3. Product Specification

Rated Voltage 220 - 240V, 50Hz

General Power Consumption 19 Watts

Weight 3.8Kg

Size 430mm x 282mm x 82mm

Operating ambient Temperature +5°C ~ +35°C

Installation Conditions Operation position : Horizontal, Relative humidity : Below 75%

Input

Video input (Rear) Euro Scart socket : 1.0Vp-p (unbalanced) 75ohm

Audio input (Rear) Euro Scart socket : -8dBm, 47Kohm unbalnced

RF out UHF 28-69 (lnitial CH36)

Audio (DVD, VCR) RCA jack

Output Audio (DVD only) Digital audio out (OPTICAL, COAXIAL, RCA jack)

Video (DVD, VCR) RCA jack

Video (DVD only) S-Video out, COMPONENT out : RCA jack

Tape format VHS type video tape, S-VHS type video tape (Playback only)

Color system PAL, NTSC4.43, MESECAM, NTSC playback on PAL TV

VCR Video S/N Above 43dB (standard recording)

Resolution Above 240 lines (standard recording)

Audio S/N Above 50dB (Hi-Fi), 39dB (Mono)

Audio frequency characteristics 20Hz - 20KHz (Hi-Fi)

Disc DVD, CD (12Cm), CD (8Cm),

DVD Audio S/N 95dB

Audio dynamic range 105dB

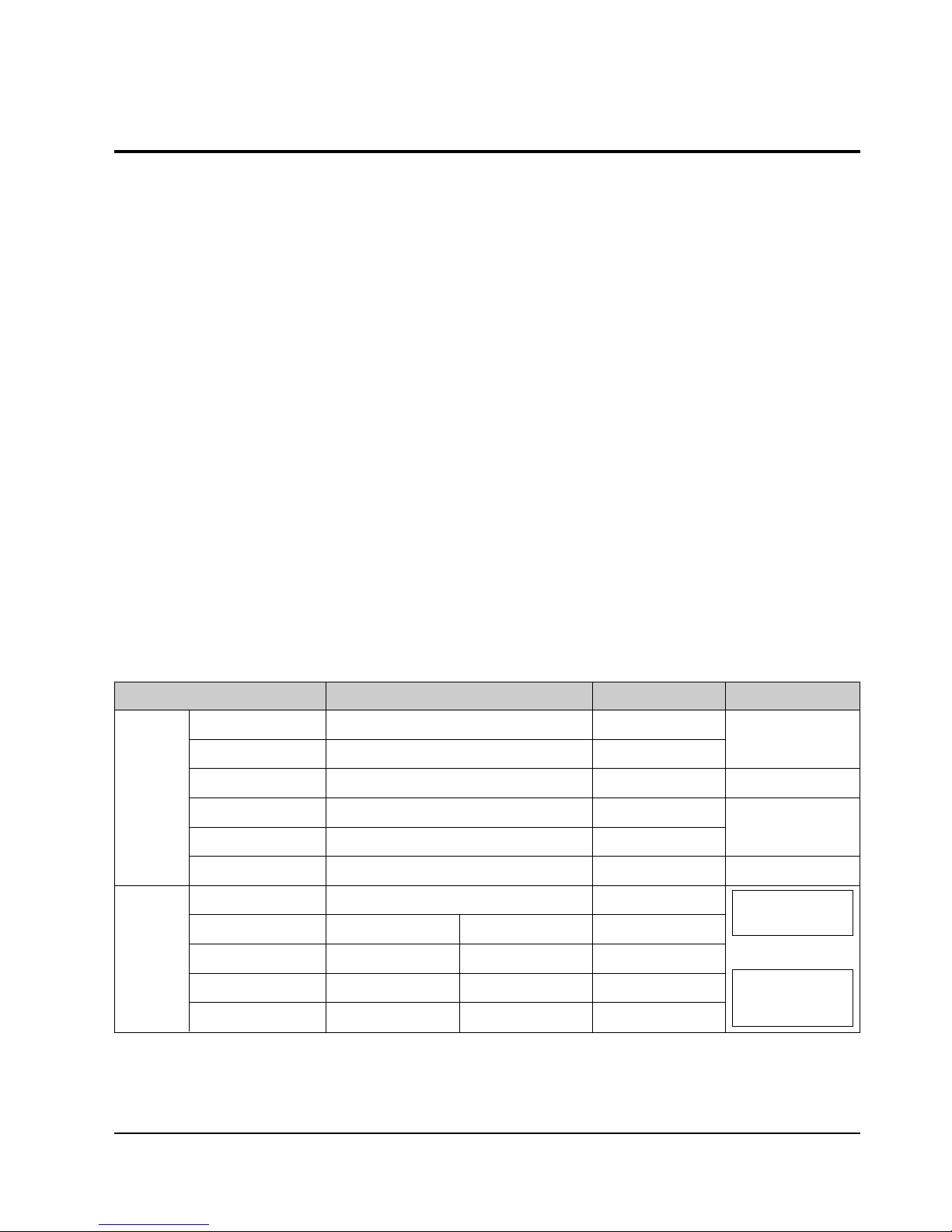

Samsung Electronics 5-1

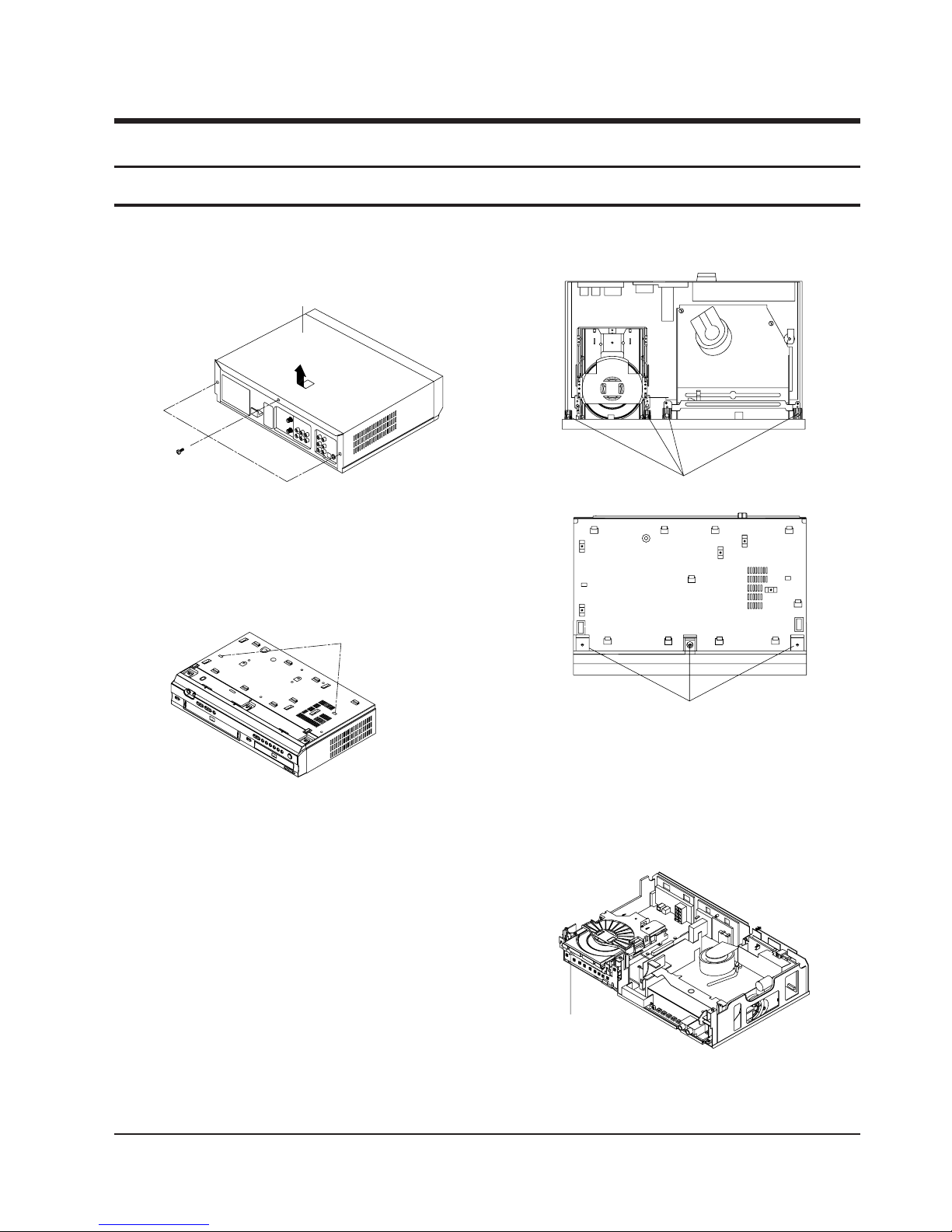

5. Disassembly and Reassembly

5-1 Cabinet and PCB

5-1-1 Cabinet Top Removal

ΠREMOVE 3 SCREWS

´ Lift up the Cabinet Top in the direction of arrow.

Fig. 5-1 Cabinet Top Removal

5-1-2 Ass’y Bottom Cover Removal

ΠRELEASE 2 HOOKS

(Bottom View)

5-1-4 Function PCB Removal

ΠRELEASE 1 HOOK

Fig. 5-4 Function PCB Removal

Fig. 5-2 Ass’y Bottom Cover Removal

´ RELEASE 3 HOOKS

(Bottom View)

ΠRELEASE 4 HOOKS

(Top View)

Fig. 5-3 Ass’y Front Panel Removal

5-1-3 Ass’y Front Panel Removal

5-2

Disassembly and Reassembly

Samsung Electronics

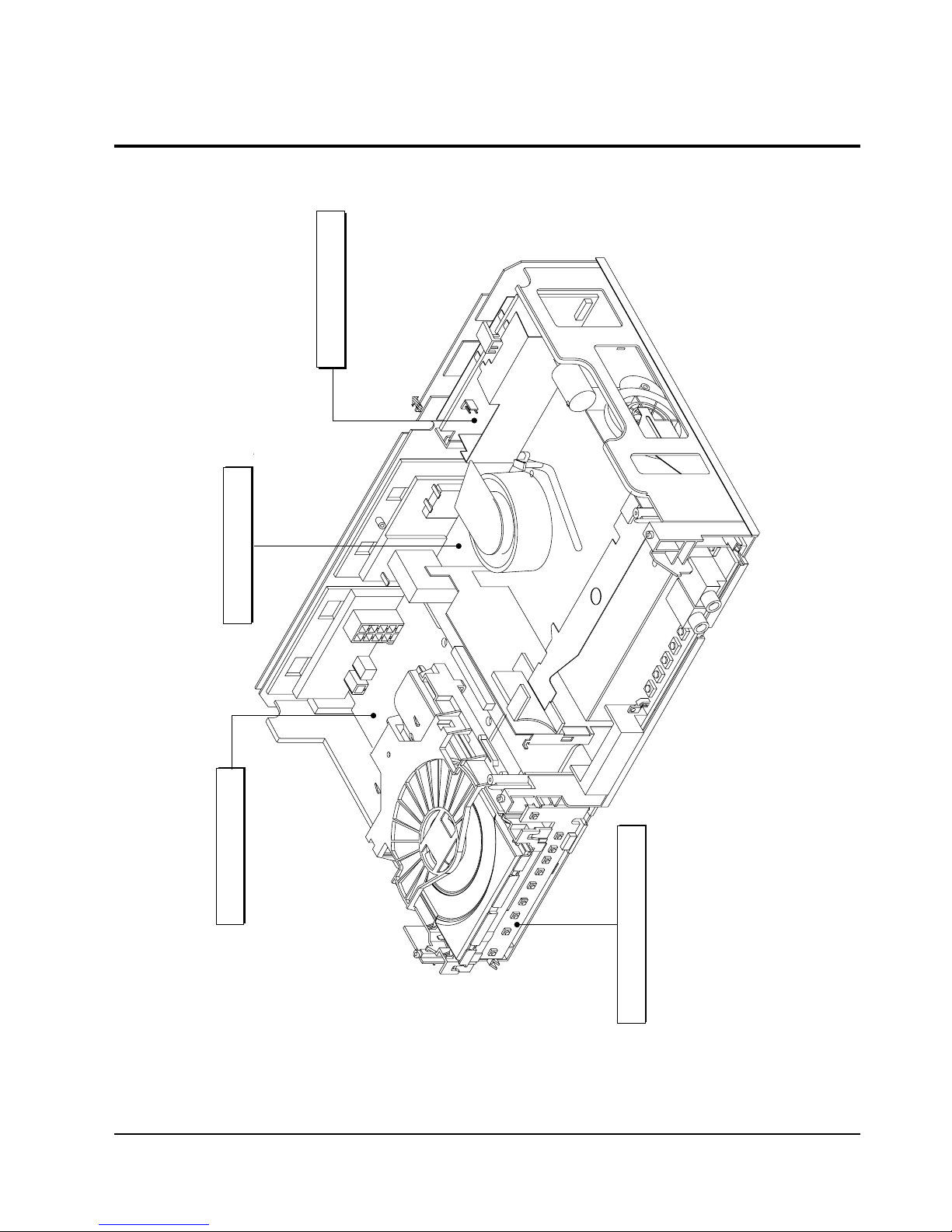

5-1-5 Chassis Removal

VCR MAIN PCB

S.M.P.S PCB

DVD DECK

VCR DECK

DVD MAIN PCB

ΠREMOVE 2 SCREWS

´ REMOVE 4 SCREWS

ˇ REMOVE 3 SCREWS

¨ REMOVE 2 SCREWS

ˆ REMOVE

3 SCREWS

Fig. 5-5 Chassis Removal

5-1-6 VCR Main PCB Removal

ΠREMOVE 4 SCREWS

VCR MAIN PCB

MODE SWITCH

When installing the ass'y full deck on the Main PCB,

be sure to align the assembly point of mode switch.

ASSEMBLY POINT

Fig. 5-6 VCR Main PCB Removal

Disassembly and Reassembly

5-3Samsung Electronics

5-2 Circuit Board Locations

DVD MAIN PCB

FUNCTION PCB

VCR MAIN PCB

S.M.P.S PCB

Fig. 5-7 Circuit Board Locations

5-4

Disassembly and Reassembly

Samsung Electronics

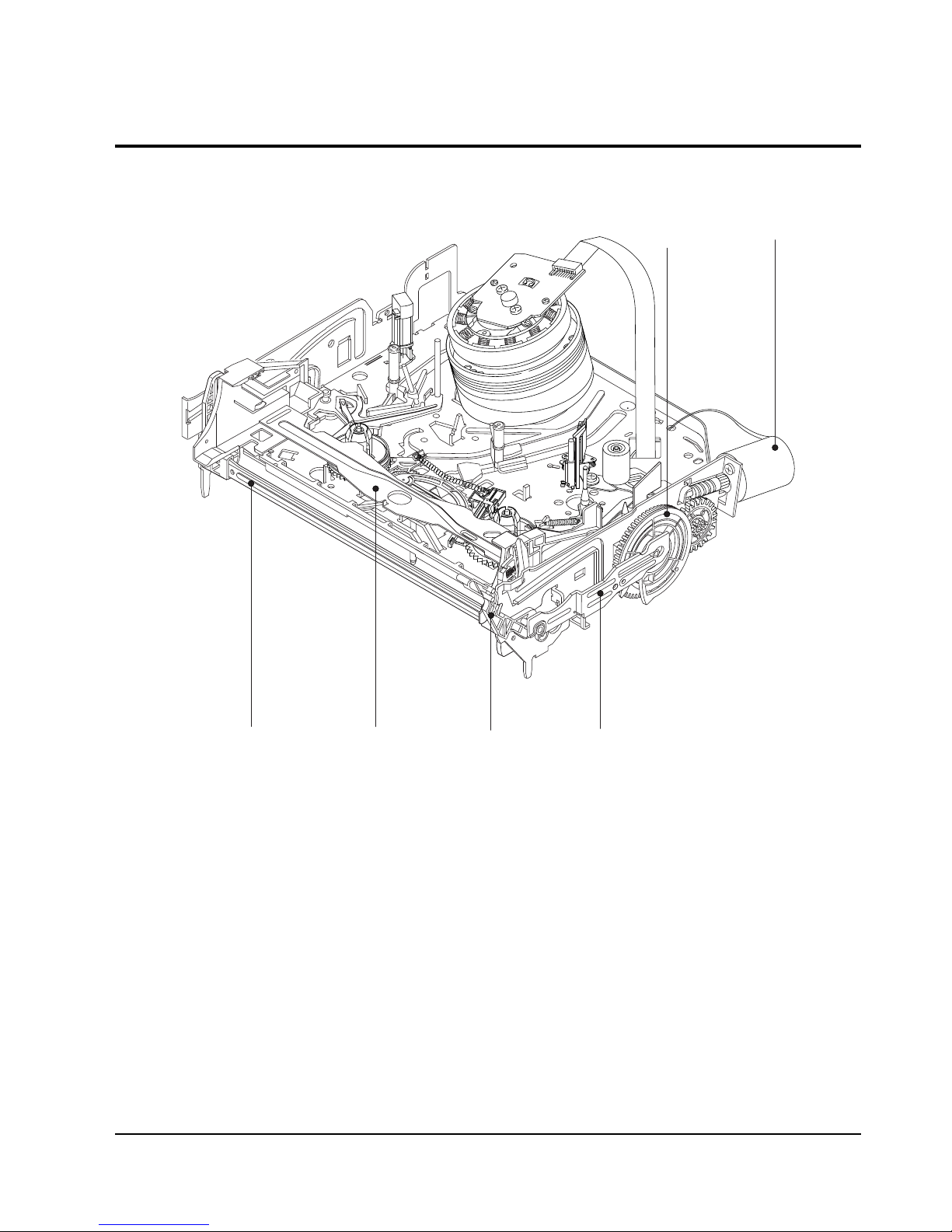

5-3 VCR Deck Parts Locations

5-3-1 Top View

Œ

´

ˆ

Ø

ˇ

¨

Fig. 5-8 Top parts Location-1

ΠGEAR FL CAM

´ MOTOR LOADING ASS’Y

ˇ LEVER FL ARM ASS’Y

¨ HOLDER FL CASSETTE ASS’Y

ˆ LEVER FL DOOR

Ø SLIDER FL DRIVE

Disassembly and Reassembly

5-5Samsung Electronics

Œ

´

Ø

∏”’ Ô˝

Ò

˝

ˇ¨

ˆ

Fig. 5-9 Top Parts Location-2

ΠFE HEAD

´ CYLINDER ASS’Y

ˇ ACE HEAD ASS’Y

¨ LEVER UNIT PINCH ASS’Y

ˆ LEVER #9 GUIDE ASS’Y

Ø LEVER TENSION ASS’Y

∏ BAND BRAKE ASS’Y

” DISK S REEL

’ LEVER S BRAKE ASS’Y

˝ GEAR IDLE

Ô LEVER IDLE

LEVER T BRAKE ASS’Y

Ò DISK T REEL

5-6

Disassembly and Reassembly

Samsung Electronics

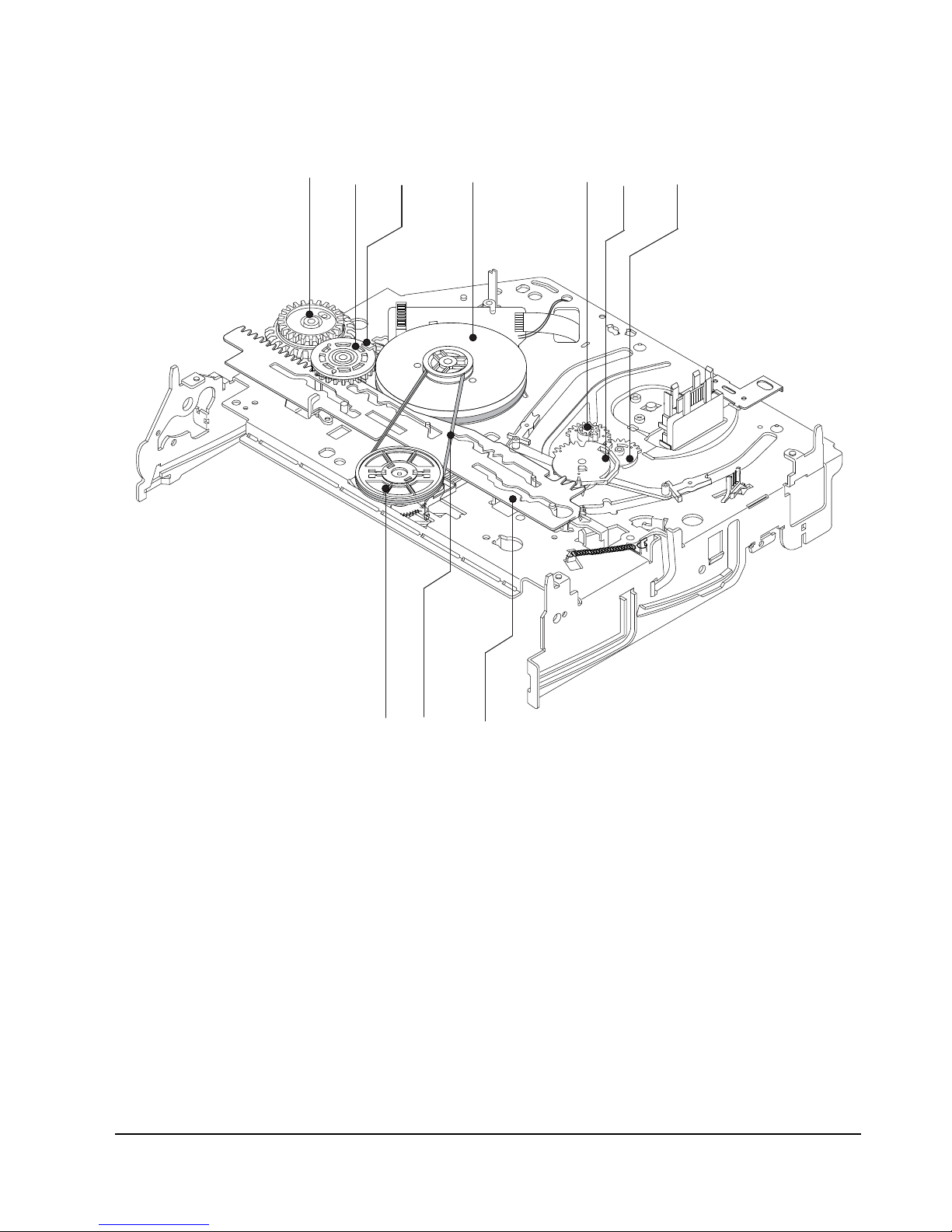

5-3-2 Bottom View

Œ

´ˇ

¨

ˆ

Ø

∏

”

’

˝

Fig. 5-10 Bottom Parts Location

ΠGEAR JOINT 1

´ GEAR JOINT 2

ˇ BRAKET GEAR

¨ MOTOR CAPSTAN ASS’Y

ˆ LEVER T LOAD ASS’Y

Ø GEAR LOADING DRIVE

∏ LEVER S LOAD ASS’Y

” HOLDER CLUTCH ASS’Y

’ BELT PULLEY

˝ SLIDER CAM

Disassembly and Reassembly

5-7Samsung Electronics

5-4 VCR Deck

ΠLEVER FL ARM ASS'Y

"C"

"B"

PIN

HOLE "A"

5-4-1 Holder FL Cassette Ass’y Removal

1) Pull the Holder FL Cassette Ass'y Πto the eject

position.

2) Pull the Holder FL Cassette Ass'y Πas grasping

the Holder FL Cassette Ass'y Πand Lever FL

Cassette-R ´ in the same time to release hooking

from Main Base until the Boss [A] of Holder FL

Cassette Ass'y Πis taken out from the Rail [B].

3) Lift the Holder FL Cassette Ass'y Œ, in this time,

you have to grasp the Lever FL Cassette-R ´

Continuously until the Holder FL Cassette Ass'y

Πis taken out completely.

Note : Be sure to insert Lever FL Cassette-R ´ in the

direction of “A” to prevent separation and breakage

of the Lever FL Cassette-R ´ at disassembling and

reassembling.

RAIL [B]

BOSS [A]

´ LEVER FL CASSETTEE -R

"A"

ΠHOLDER FL

CASSETTEE ASS'Y

Fig. 5-11 Holder FL Cassette Ass’y Removal

5-4-2 Lever FL Arm Ass’y Removal

1) Push the hole “A” in the direction of arrow “B”

use the pin.(about Dia. 2.5)

2) Pull out the Lever FL Arm Ass'y Πfrom the Boss

of Main Base.

3) Remove the Lever FL Arm Ass'y Πin the direction

of arrow “C”.

Fig. 5-12 Lever FL Arm Ass’y Removal

5-8

Disassembly and Reassembly

Samsung Electronics

ΠGEAR FL CAM

GEAR WORM WHEEL

POST

TIMING POINT

Fig. 5-15 Gear FL Cam, Gear Worm

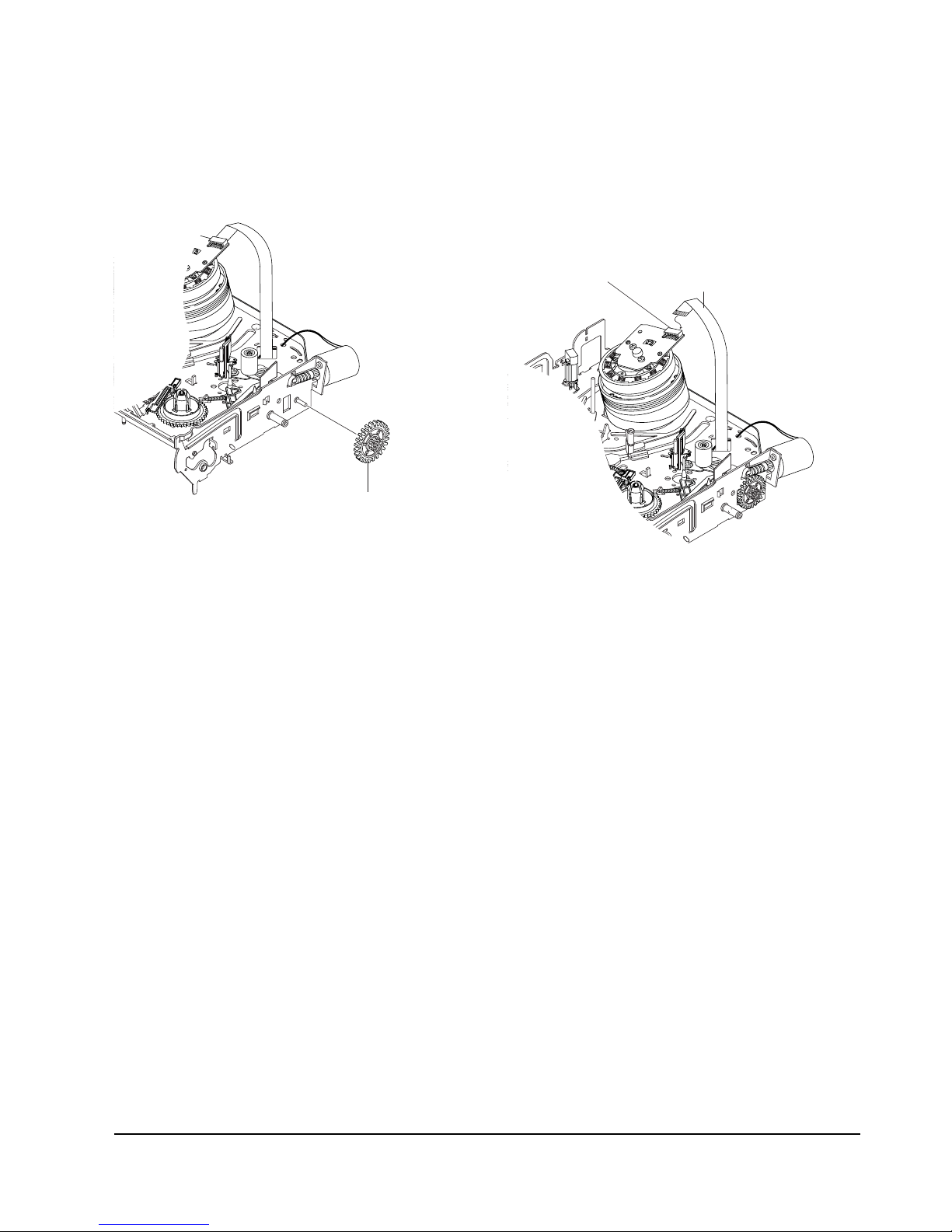

5-4-4 Slider FL Drive, Gear FL Cam Removal

1) Pull the Slider FL Drive Πto the front direction.

2) Remove the Slider FL Drive Πin the direction of

arrow. (Refer to Fig. 5-13)

3) Remove the Gear FL cam ´.

Note : When reinstalling be sure to reassemble Slider

FL drive Πafter you insert the Boss of Lever FL

ARM-R in Groove of Slider Fl drive Œ.

Assembly : Align the Gear FL Cam Πwith the Gear

worm wheel Post as shown drawing.

(Refer to Timing point)

ΠSLIDER FL DRIVE

´ GEAR FL CAM

Fig. 5-14 Slider FL Drive Removal

5-4-3 Lever FL Door Removal

1) Release the Hook ´ and Remove the Lever FL

Door Œ in the direction of arrow “A”.

Fig. 5-13 Lever FL Door Removal

"B"

"C"

"A"

´ LEVER FL DOOR

ΠSLIDER FL DRIVE

Disassembly and Reassembly

5-9Samsung Electronics

5-4-5 Gear Worm Wheel Removal

1) Remove the Gear Worm wheel Œ.

ΠGEAR WORM WHEEL

Fig. 5-16 Gear Worm Wheel Removal

5-4-6 Cable Flat Removal

1) Remove the Drum connecting part of Cable Flat Œ

from Connector Waffer ´.

´ CONNECTOR WAFER

ΠCABLE FLAT

Fig. 5-17 Cable Flat Removal

5-10

Disassembly and Reassembly

Samsung Electronics

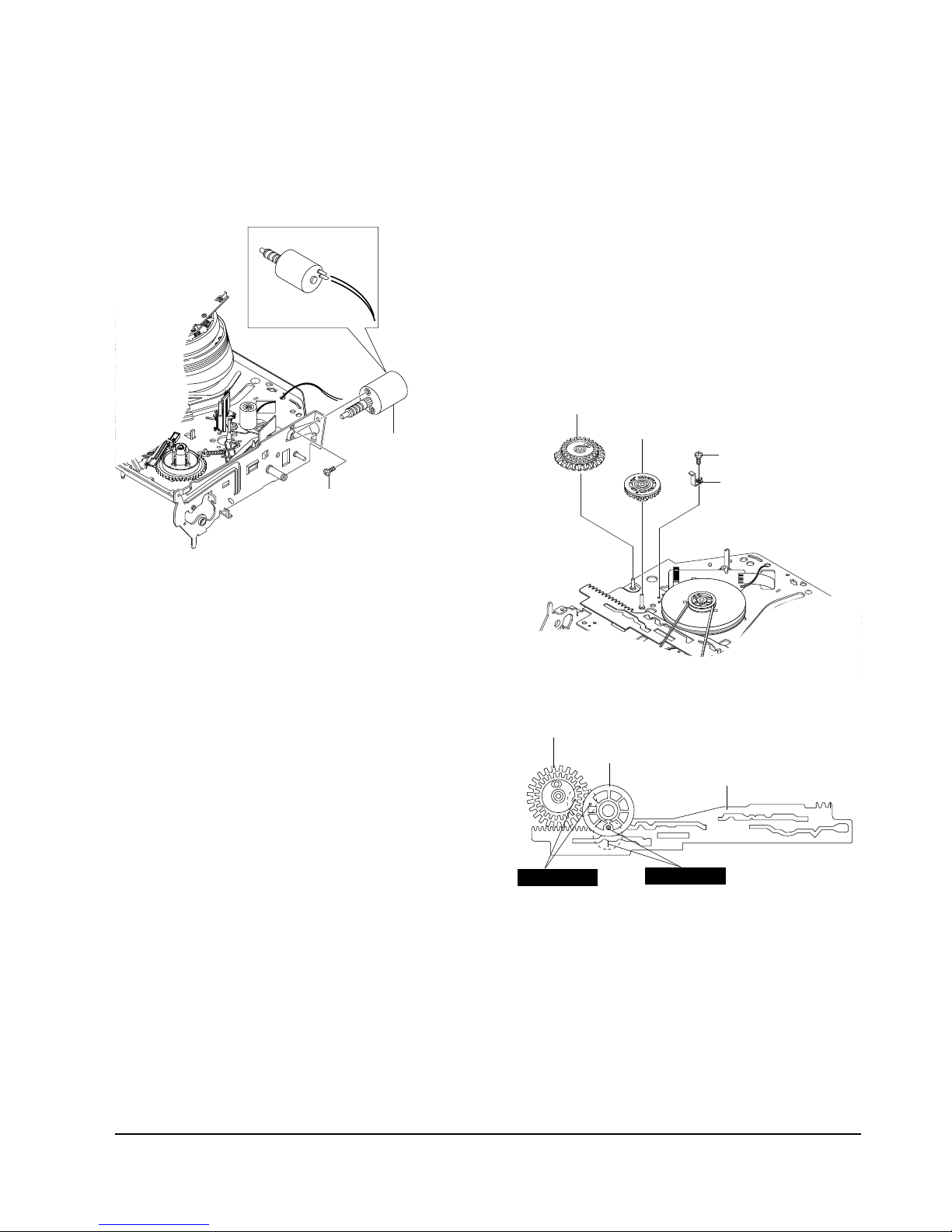

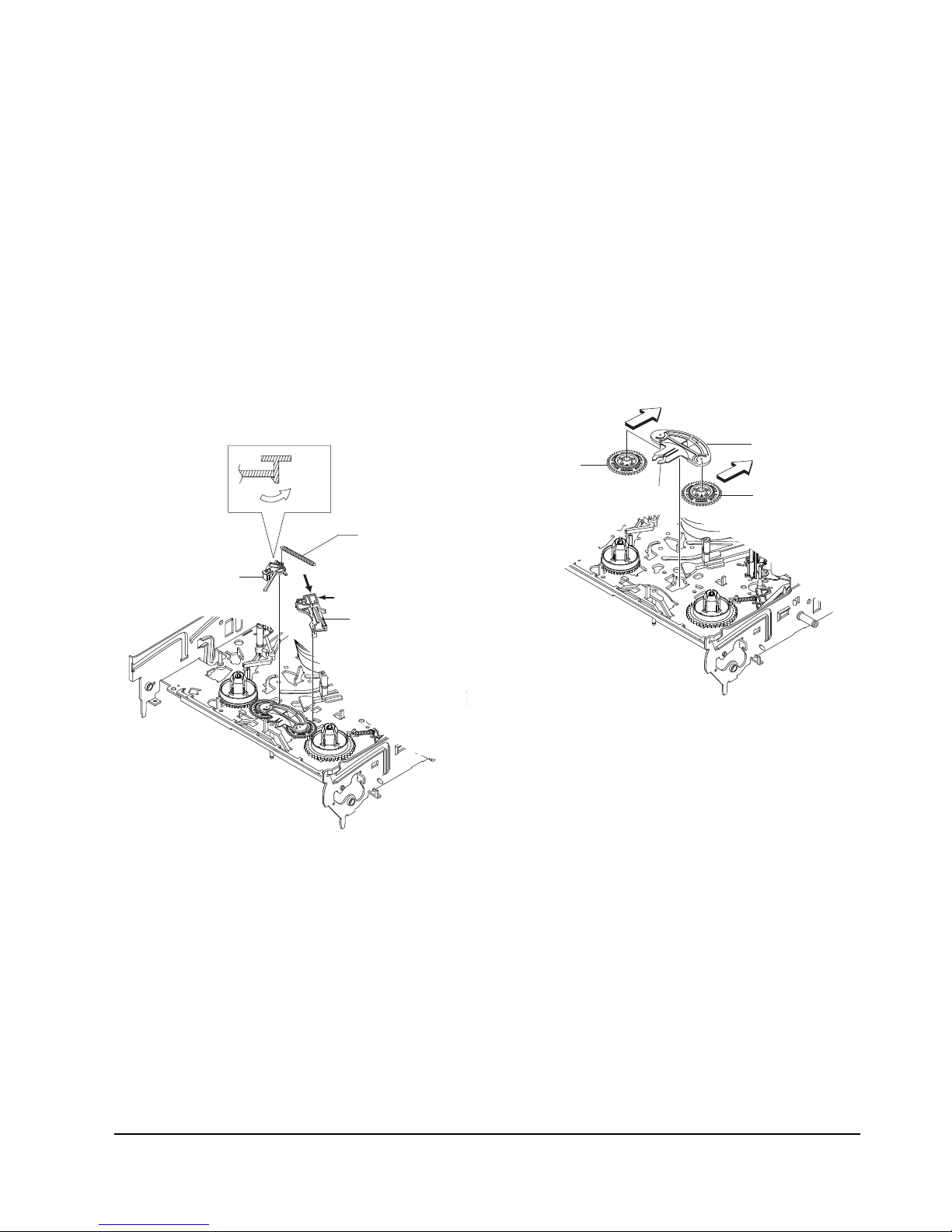

5-4-8 Bracket Gear, Gear Joint 2, 1 Removal

1) Remove the SCREW Œ.

2) Remove the Bracket Gear ´.

3) Remove the Gear Joint 2 ˇ.

4) Remove the Gear Joint 1 ¨.

Assembly :

1) Be sure to align dot mark of Gear Joint 1 Œwith

dot mark of Gear Joint 2 ´ as shown Fig 5-20.

(Refer to Timing point1)

2) Confirm the Timing Point 2 of the Gear Joint 2 ´

and Slider Cam ˇ.

ΠSCREW

´ BRAKET GEAR

¨ GEAR JOINT 1

ˇ GEAR JOINT 2

Fig. 5-19 Bracket Gear, Gear Joint 1,2 Removal

ΠGEAR JOINT1

´ GEAR JOINT2

ˇ SLIDER CAM

TIMING POINT 1

TIMING POINT 2

Fig. 5-20 Gear Joint 1,2 Assembly

5-4-7 Motor Loading Ass’y Removal

1) Remove the screw Œ.

2) Remove the Motor Loading Ass’y ´.

´ MOTOR LOADING ASS`Y

ΠSCREW

Fig.5-18 Motor Loading Ass’y Removal

Disassembly and Reassembly

5-11Samsung Electronics

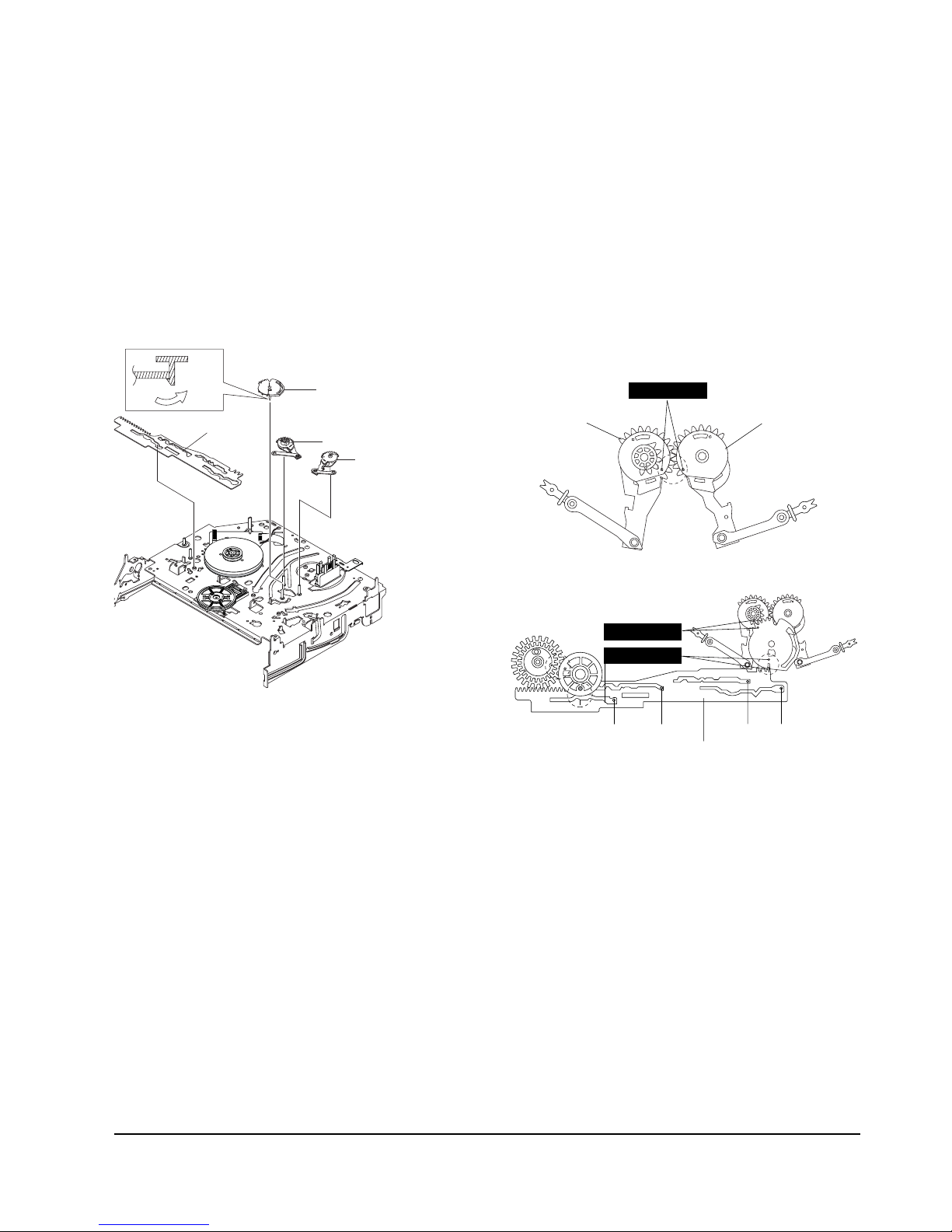

5-4-10 Gear Loading Drive, Slider Cam,

Lever Load S, T Ass’y Assembly

1) When reinstalling, be sure to align dot of Lever

Load T Ass'y Œwith dot of Lever Load S Ass'y ´

as shown in drawing, (Refer to Timing Point 1).

2) Insert the Pin A,B,C,D into the Slider Cam ˇhole,

3) Be sure to align dot of Lever Load T Πand dot of

Gear Loading Drive ¨, (Refer to Timing Point 2).

4) Aline dot of Gear Loading drive ¨ with mark of

Slider Cam ˇ as shown in drawing(Refer to

Timing Point 3).

´ LEVER LOAD S

Œ

LEVER LOAD T

PIN A

PIN C

PIN B

PIN D

ˇ SLIDER CAM

TIMING POINT 2

TIMING POINT 1

TIMING POINT 3

Fig. 5-22 Gear Loading Drive, Slider Cam,

Lever Load S, T Ass’y Assembly

5-4-9 Gear Loading Drive, Slider Cam,

Lever Load S, T Ass’y Removal

1) Remove the Belt Pulley. (Refer to Fig. 5-38)

2) Remove the Gear Loading Drive Πafter releasing

Hook [A] in the direction arrow as shown in detail

drawing.

3) Remove the Slider Cam ´.

4) Remove the Lever Load S Ass’y ˇ & Lever Load T

Ass’y ¨.

ΠGEAR LOADING DRIVE

ˇ LEVER LOAD S ASS'Y

¨ LEVER LOAD T ASS'Y

´ SLIDE CAM

HOOK(A)

Fig. 5-21 Gear Loading Drive, Slider Cam,

Lever T, S Load Ass’y Removal

5-12

Disassembly and Reassembly

Samsung Electronics

5-4-12 Lever Tension Ass’y,

Band Brake Ass’y Removal

1) Remove the Lever Brake S Ass'y (Refer to Fig 5-25).

2) Remove the Spring Tension Lever Œ.

3) Rotate stopper of Main Base in the direction of

arrow “A”.

4) Lift the Lever Tension Ass'y ´ & Band brake

Ass'y ˇ.

Note :

1) When replacing the Lever Tension Ass'y ´, be sure

to apply Grease on the post,

2) Take care not to touch stain on the felt side, and not

to be folder and broken Band brake Ass'y

3) After Lever Tension Ass'y seated, Rotate stopper of

Main Base to the Mark[B].

ΠSPRING TENTION LEVER

´ LEVER TENTION ASS`Y

ˇ BAND BRAKE ASS`Y

STOPPER

MARK[B]

"A"

Fig. 5-24 Lever Tension Ass’y,

Band Brake Ass’y Removal

5-4-11 Lever Pinch Drive,

Lever Tension Drive Removal

1) Remove the Lever Pinch Drive Œ, Lever Tension

Drive ´.

ΠLEVER PINCH DRIVE

´ LEVER TENSION DRIVE

Fig. 5-23 Lever Pinch Drive,

Lever Tension Drive Removal

Disassembly and Reassembly

5-13Samsung Electronics

5-4-14 Gear Idle Ass’y Removal

1) Push the Lever Idle Πin the direction of arrow

“A”, “B”.

2) Lift the Lever Idle Œ.

Assembly :

1) Apply oil in two Bosses of Lever Idle Œ.

2) Assemble the Gear Idle ´ with the Lever Idle Œ.

Note : When replacing the Gear Idle ´, be sure to

add oil in the boss of Lever Idle Œ.

´ GEAR IDLE

"B"

ΠLEVER IDLE

´ GEAR IDLE

"A"

HOOK "C"

Fig. 5-26 Gear Idle Ass’y Removal

5-4

-13 Lever Brake S, T Ass’y

Removal

1) Release the Hook [A] and the Hook [B], [C] in the

direction of arrow as shown in Fig 5-25.

2) Lift the Lever S, T Brake Ass'y Œ, ´ with spring

brake ˇ.

Assembly :

1)Assembly the Lever S Brake Ass'y Πon the Main

Base.

2)Assembly the Lever T Brake Ass'y ´ with spring

brake ˇ.

Note : Take extreme care not to be folded and

transformed Spring Brake at removing or reinstalling.

HOOK(A)

´ LEVER T BRAKE ASS`Y

ΠLEVER S BRAKE ASS'Y

HOOK(B)

HOOK(C)

ˇ SPRING BRAKE

Fig. 5-25 Lever Brake S, T Ass’y Removal

Loading...

Loading...