Samsung DH140CAV, DH105CAV, UH105CAV, UH140CAV Installation Manual

ENGLISH

System Air Conditioner

(Cooling and Heating)

INSTALLATION

MANUAL

Indoor Unit Outdoor Unit

DH140CAV UH140CAV

DH105CAV UH105CAV

ESPAÑOLFRANÇAIS

DB98-29515A(1)SE F

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-2

Safety Precautions

(Carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment.)

WARNING

• Always disconnect the air conditioner from the power supply before servicing it or

accessing its internal components.

•

Verify that installation and testing operations are performed by qualified personnel.

• Verify that the air conditioner is not installed in an easily accessible area.

GENERAL INFORMATION

Carefully read the content of this manual before installing the air conditioner and store the manual in a safe place in order to be

able to use it as reference after installation.

For maximum safety, installers should always carefully read the following warnings.

Store the operation and installation manual in a safe location and remember to hand it over to the new owner if the

air conditioner is sold or transferred.

This manual explains how to install an indoor unit with a split system with two SAMSUNG units. The use of other types of units

with different control systems may damage the units and invalidate the warranty. The manufacturer shall not be responsible for

damages arising from the use of non compliant units.

The manufacturer shall not be responsible for damage originating from unauthorized changes or the improper connection of

electric and requirements set forth in the “Operating limits” table, included in the manual, shall immediately invalidate the warranty.

The air conditioner should be used only for the applications for which it has been designed: the indoor unit is not suitable to be

installed in areas used for laundry.

Do not use the units if damaged. If problems occur, switch the unit off and disconnect it from the power supply.

In order to prevent electric shocks, fires or injuries, always stop the unit, disable the protection switch and contact SAMSUNG’s

technical support if the unit produces smoke, if the power cable is hot or damaged or if the unit is very noisy.

Always remember to inspect the unit, electric connections, refrigerant tubes and protections regularly. These operations should be

performed by qualified personnel only.

The unit contains moving parts, which should always be kept out of the reach of children.

Do not attempt to repair, move, alter or reinstall the unit. If performed by unauthorized personnel, these operations may cause

electric shocks or fires.

Do not place containers with liquids or other objects on the unit.

All the materials used for the manufacture and packaging of the air conditioner are recyclable.

The packing material and exhaust batteries of the remote control(optional) must be disposed of in accordance with current laws.

The air conditioner contains a refrigerant that has to be disposed of as special waste. At the end of its life cycle, the air conditioner

must be disposed of in authorized centers or returned to the retailer so that it can be disposed of correctly and safely.

INSTALLING THE UNIT

IMPORTANT: When installing the unit, always remember to connect first the refrigerant tubes, then the electrical lines.

Always disassemble the electric lines before the refrigerant tubes.

Upon receipt, inspect the product to verify that it has not been damaged during transport. If the product appears damaged,

DO NOT INSTALL it and immediately report the damage to the carrier or retailer (if the installer or the authorized technician has

collected the material from the retailer.)

After completing the installation, always carry out a functional test and provide the instructions on how to operate

the air conditioner to the user.

Do not use the air conditioner in environments with hazardous substances or close to equipment that release free flames to avoid

the occurrence of fires, explosions or injuries.

POWER SUPPLY LINE, FUSE OR CIRCUIT BREAKER

Always make sure that the power supply is compliant with current safety standards. Always install the air conditioner in compliance

with current local safety standards.

Always verify that a suitable grounding connection is available.

Verify that the voltage and frequency of the power supply comply with the specifications and that the installed power is sufficient

to ensure the operation of any other domestic appliance connected to the same electric lines.

Always verify that the cut-off and protection switches are suitably dimensioned.

Verify that the air conditioner is connected to the power supply in accordance with the instructions provided in the wiring

diagram included in the manual.

Always verify that electric connections (cable entry, section of leads, protections…) are compliant with the electric specifications

and with the instructions provided in the wiring scheme. Always verify that all connections comply with the standards applicable

to the installation of air conditioners.

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-3

ENGLISH

Contents

Preparation for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Deciding on where to install the indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Indoor unit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Purging the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting the refrigerant pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cutting/Flaring the pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Performing leak test & insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drain hose installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting the connection cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjusting air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting up the mode option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Assigning address to indoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Additional functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Filter Replacement(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drain pump installation(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Technical Specification & Product feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Additional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-4

Preparation for installation

When deciding on the location of the air conditioner with the owner,

the following restrictions must be taken into account.

Do NOT install the air conditioner in a location where it will come into

contact with the following elements:

Combustible gases

Saline air

Machine oil

Sulphide gas

Special environmental conditions

If you must install the unit in such conditions, first consult your dealer.

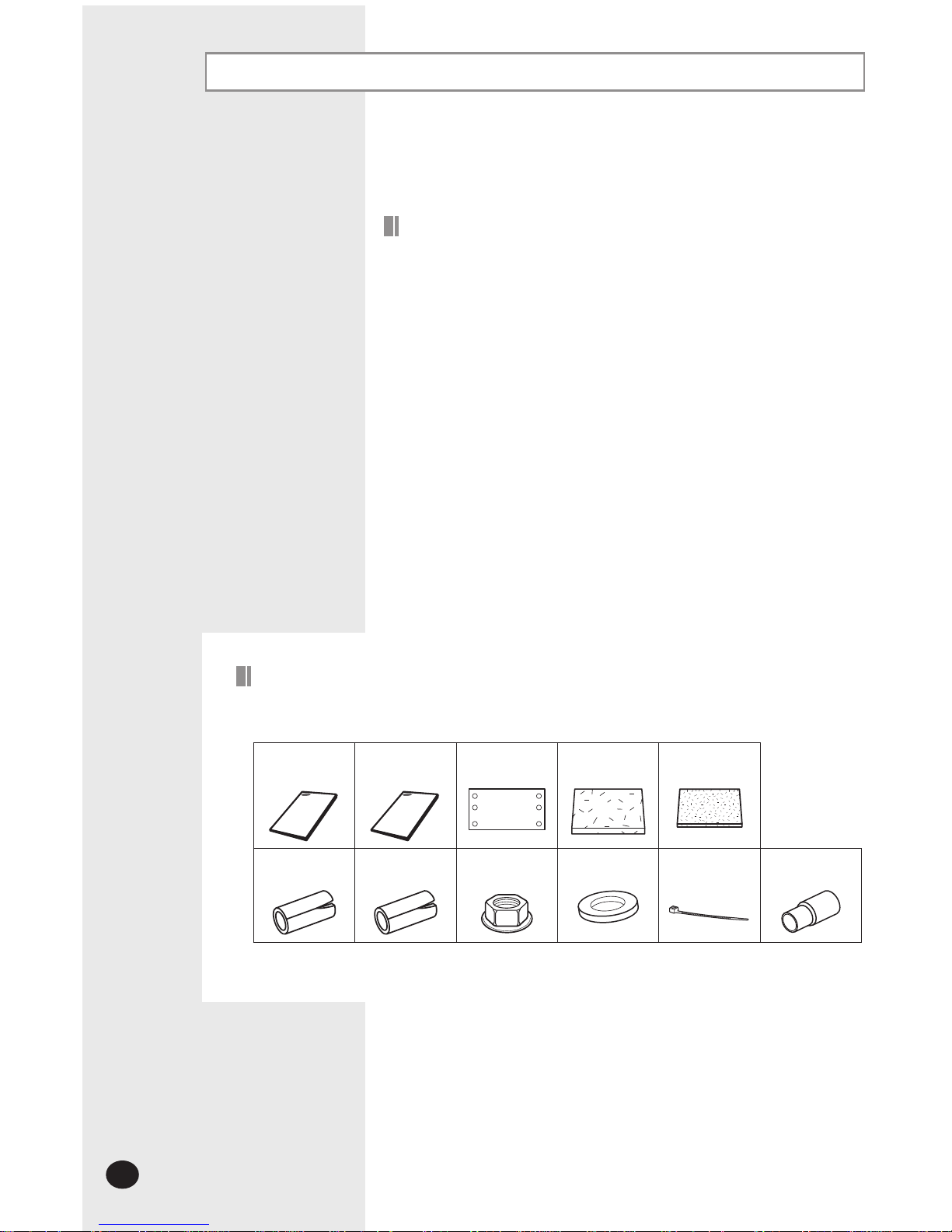

General

Accessories

The following accessories are supplied with the indoor unit.

The type and quantity may differ depending on the specifications.

User’s

manual

Installation

manual

Pattern sheet Insulation drain Insulation

cover pipe

Insulation pipe Insulation

drain pipe

Nut Rubber Cable-tie Drain socket

Avoid installing the air conditioner:

In areas where it is exposed to direct sunlight. Close to heat sources.

In damp areas or locations where it could come into contact with water

(for example rooms used for laundry)

In areas where curtains and furniture could affect the supply and discharge of air.

Without leaving the required minimum space around the unit (as shown in the

drawing).

In scarcely ventilated areas.

On surfaces that are unable to support the weight of the unit without deforming,

breaking or causing vibrations during the use of the air conditioner.

In a position that does not enable the condensate drainage pipe to be correctly

installed (at the end of the installation. It is always essential to check the efficiency

of the drainage system.)

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-5

ENGLISH

Deciding on where to install the indoor unit

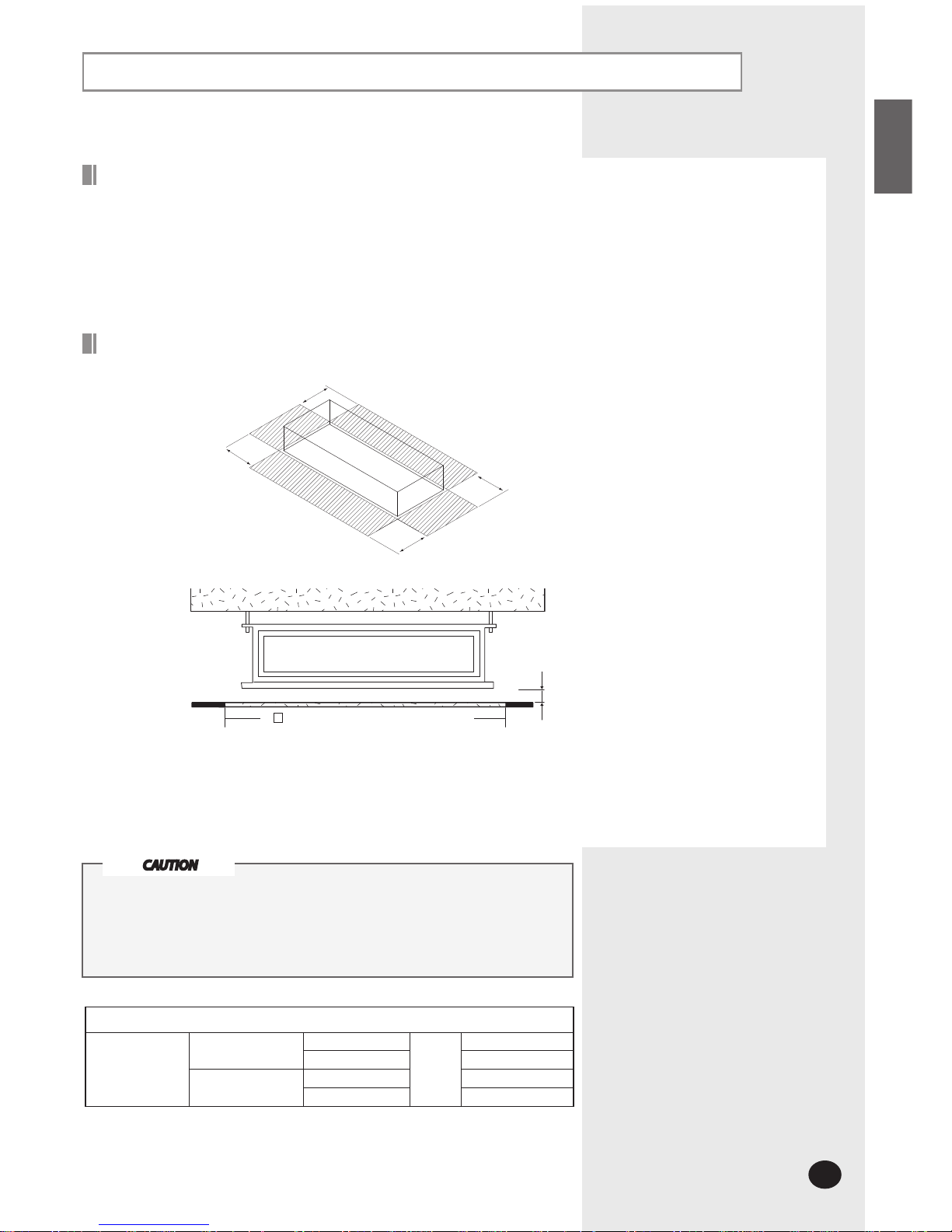

Indoor unit

There must be no obstacles near the air inlet and outlet.

Install the indoor unit on a ceiling that can support its weight.

Maintain sufficient clearance around the indoor unit.

Make sure that the water dripping from the drain hose runs away correctly and safely.

The indoor unit must be installed in this way, that they are out of public access. (Not touchable by the users)

After connecting a chamber, insulate the connection part between the indoor unit and the chamber with t10 or

thicker insulation. Otherwise, there can be air leak or dew from the connection part.

Space requirements for indoor unit

0.196inch(5mm)

You must have 1.969inch(5mm) or more space between the ceiling and the bottom of indoor unit. Otherwise, the noise from the

vibration of indoor unit may bother the user.When the ceiling is under construction, the hole for check-up must be made to take

service, clean and repair the unit.

It is possible to install the unit at an height of between 7.2ft(2.2m) ~ 8.2ft(2.5m)from the ground, if the unit has a duct with a well

defined lenght (1ft(304.8mm) or more), to avoid fan motor blower contact.

4.58ft(1398mm) X 1.3ft(400mm) or more

(A space for repair and service)

The units must be installed according to distances declared, in order to

permit accessibility from each side, either to guarantee correct operation

of maintenance or repairing products.

The unit’s parts must be reachable and removable completely under

safety condition (for people or things).

CAUTION

Weight

Net weight

Indoor Unit

DH105CAV

kg(Ib)

39(86)

DH140CAV 55(121.1)

Outdoor Unit

UH105CAV 90(198.4)

UH140CAV 94(207.2)

4.9ft or more

4.9ft or more

4.9ft or more

4.9ft or more

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-6

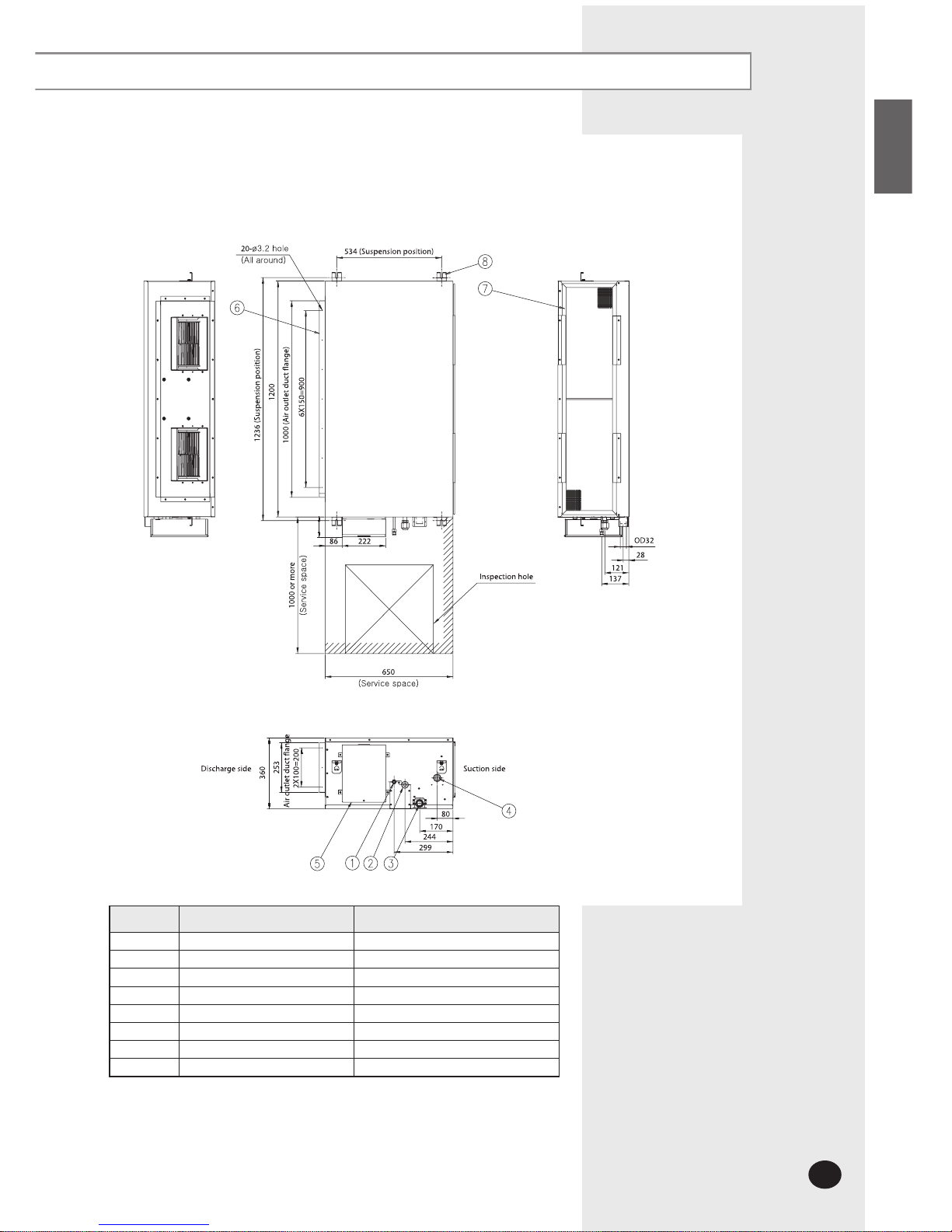

Drawing of the indoor unit

Unit : mm

No. Name Description

1 Liquid pipe connection ø9.52

2 Gas pipe connection ø15.88

3 Drain pipe connection OD32 ID26(without drain pump)

4 Drain pipe connection Using drain pump (Optional)

5 Power supply connection

6 Air discharge flange

7 Air filter

8 Hook M8~M10

102

Deciding on where to install the indoor unit (Continued)

DH105CAV

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-7

ENGLISH

102

No. Name Description

1 Liquid pipe connection ø9.52

2 Gas pipe connection ø19.05

3 Drain pipe connection OD32 ID26(without drain pump)

4 Drain pipe connection Using drain pump (Optional)

5 Power supply connection

6 Air discharge flange

7 Air filter

8 Hook M8~M10

Unit : mm

DH140CAV

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-8

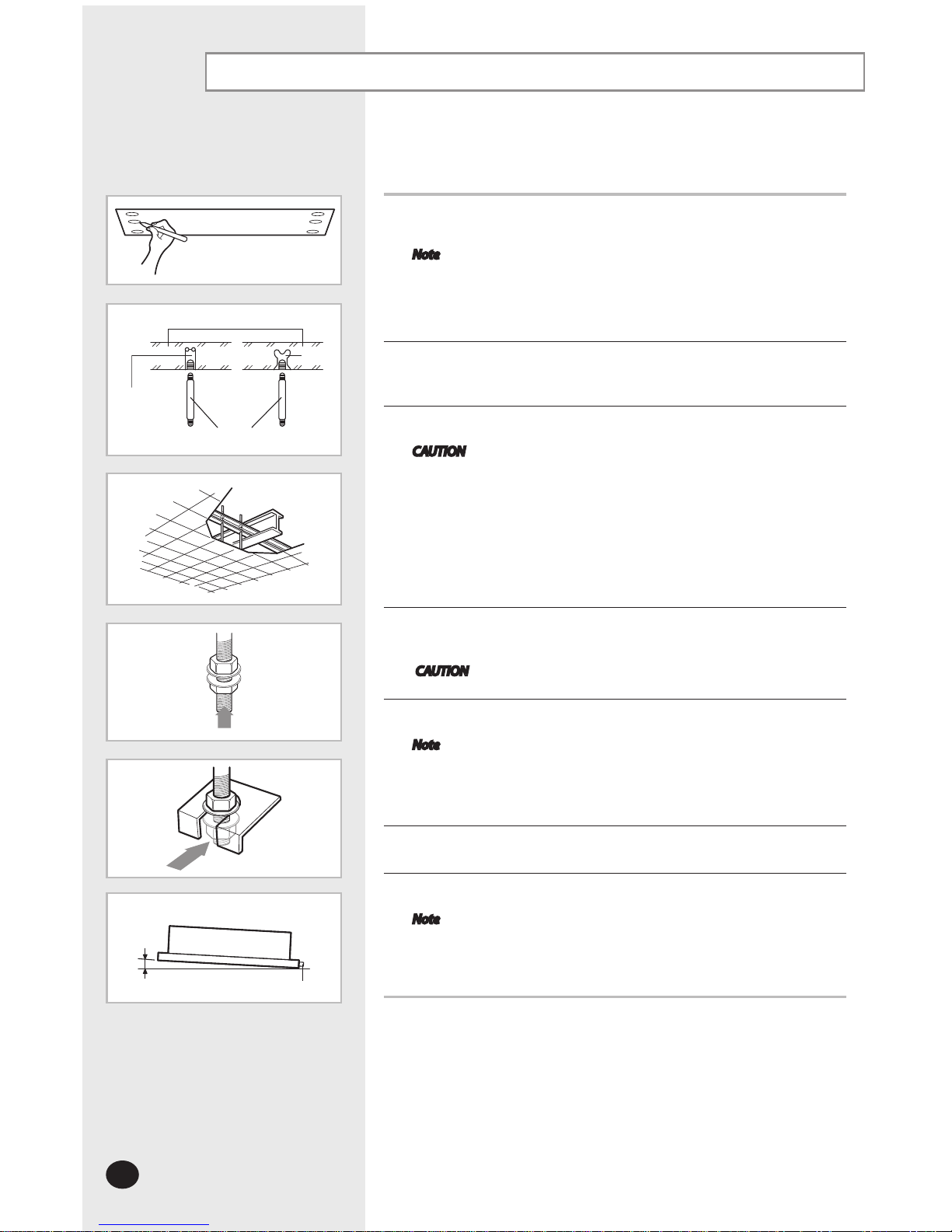

Indoor unit installation

1

Place the pattern sheet on the ceiling at the spot where you want to install

the indoor unit.

Note Since the diagram is made of paper, it may shrink or stretch

slightly due to temperature or humidity. For this reason,

before drilling the holes maintain the correct dimensions

between the markings.

2

Insert bolt anchors. Use existing ceiling supports or construct a suitable

support as shown in figure.

3

Install the suspension bolts depending on the ceiling type.

CAUTION Ensure that the ceiling is strong enough to support the

weight of the indoor unit. Before hanging the unit, test the

strength of each attached suspension bolt.

If the length of suspension bolt is more than 4.92ft(1.5m),

it is required to prevent vibration.

If this is not possible, create an opening on the false ceiling

in order to be able to use it to perform the required operations on the indoor unit.

4

Screw eight nuts to the suspension bolts making space for hanging the

indoor unit.

CAUTION You must install all the suspension rods.

5

Hang the indoor unit to the suspension bolts between two nuts.

Note Piping must be laid and connected inside the ceiling when

suspending the unit. If the ceiling is already constructed,

lay the piping into position for connection to the unit before

placing the unit inside the ceiling.

6

Screw the nuts to suspend the unit.

7

Adjust level of the unit by using measurement plate for all 4 sides.

Note For proper drainage of condensate, give a 0.118inch(3mm) slant

to the left or right side of the unit which will be connected with

the drain hose, as shown in the figure. Make a tilt when you wish

to install the drain pump, too.

It is recommended to install the refnet joint before installing the indoor unit.

Concrete

Suspension bolt(M8)-field supply

Hole in anchor

hole in plug

Ceiling support

When the drain hose is installed to the right.

Drain hose port

0.118inch(3mm)

Insert

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-9

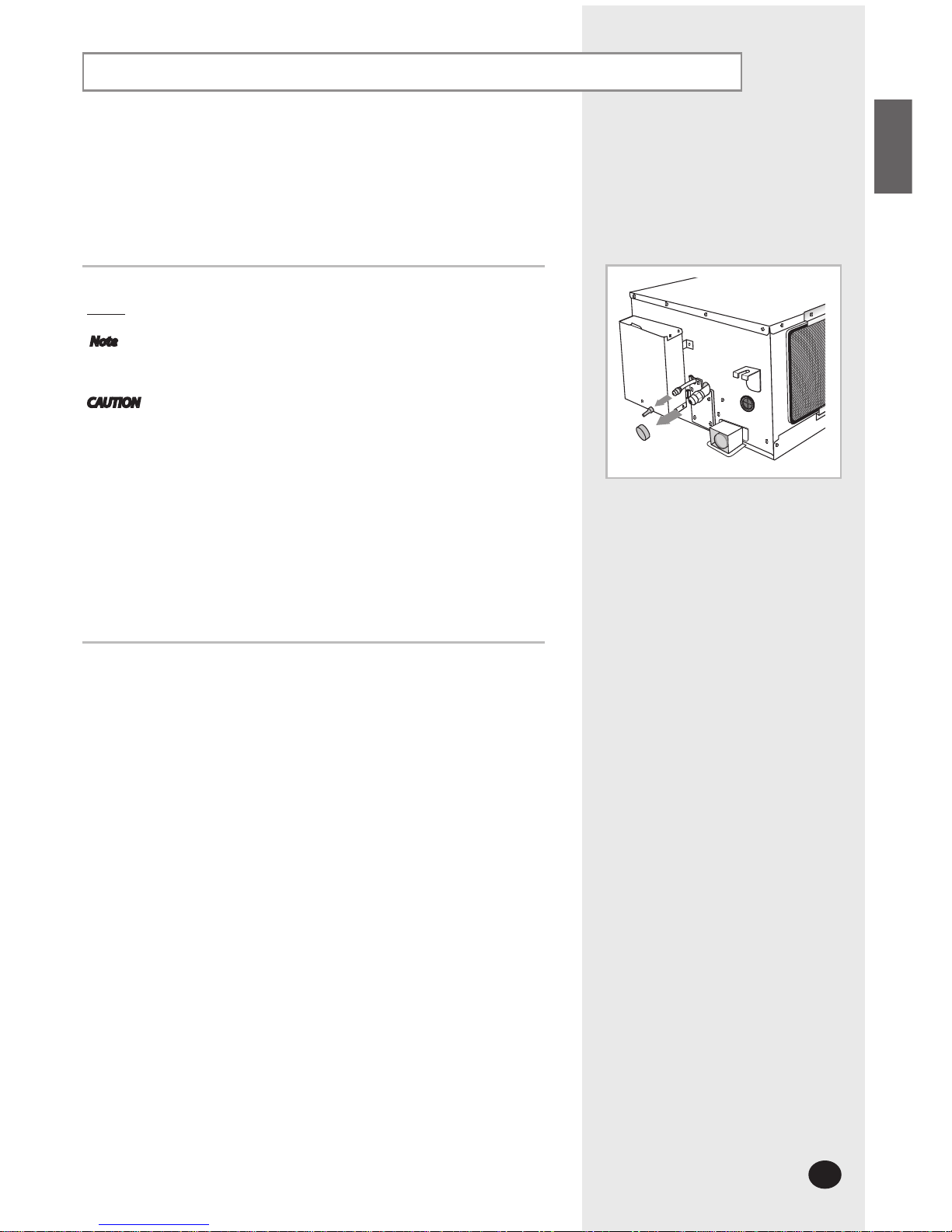

ENGLISH

From factory the unit is supplied and set with a pre-charge of nitrogen gas

(insert gas). Therefore, all insert gas must be purged before connecting the

assembly piping.

Unscrew the pinch pipe at the end of each refrigerant pipe.

Result: All inert gas escapes from the indoor unit.

Note To prevent dirt or foreign objects from getting into the pipes

during installation, do NOT remove the pinch pipe completely until

you are ready to connect the piping.

CAUTION Connect the indoor and outdoor units using pipes with flared

connections(not supplied). For the lines, use insulated,

unwelded, degreased and deoxidized copper pipe,(Cu DHP

type to ISO 1337), suitable for operating pressures of at least

4200kPa and for a burst pressure of at least 20700kPa. Copper

pipe for hydro-sanitary applications is completely unsuitable.

For sizing and limits (height difference, line length, max. bends,

refrigerant charge, etc.) see the outdoor unit installation

manual.

All refrigerant connection must be accessible, in order to

permit either unit maintenance or removing it completely.

Purging the unit

The designs and shape are subject to

change according to the model.

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-10

Connecting the refrigerant pipe

There are two refrigerant pipes of different diameters:

A smaller one for the liquid refrigerant

A larger one for the gas refrigerant

The thickness of tube should not be less than 0.039inch(1mm).

The inside of copper tube must be clean & has no dust.

The connection procedure for the refrigerant pipes varies according to the

exit position of the pipes from the indoor unit, as seen when facing the indoor

in the “A” side.

Liquid refrigerant port

Gas refrigerant port

Drain hose connection port

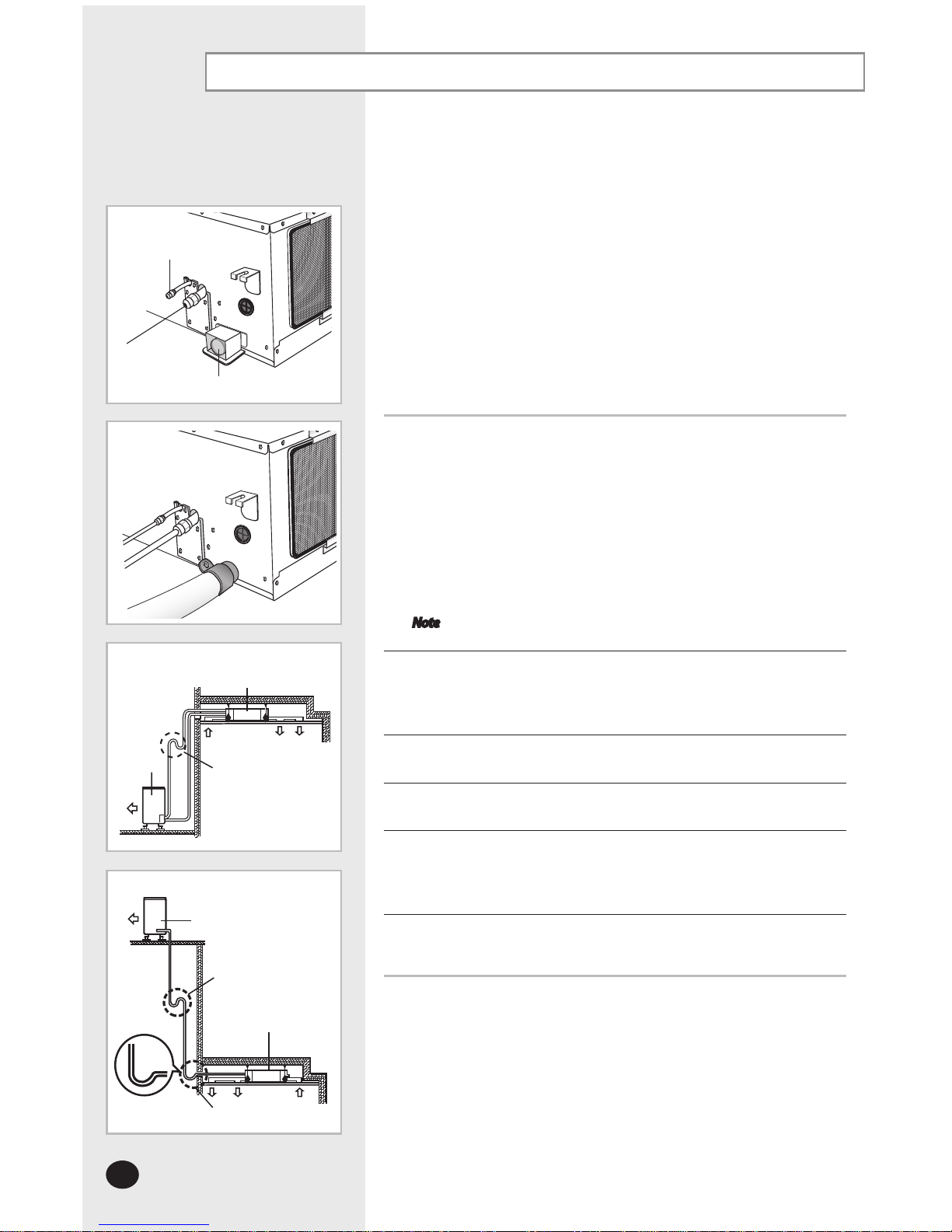

1

Remove the pinch pipe on the pipes and connect the assembly pipes

to each pipe, tightening the nuts, first manually and then with a torque

wrench, a spanner applying the following torque.

Outer Diameter Torque (ft.lb)

6.35 mm (1/4”)

9.52 mm (3/8”)

12.70 mm (1/2”)

15.88 mm (5/8”)

19.05 mm (3/4”)

13.2

31.0

40.6

48.0

73.6

Note If the pipes must be shortened refer to page 11.

2

Must use insulator which is thick enough to cover the refrigerant tube to

protect the condensate water on the outside of pipe falling onto the floor

and the efficiency of the unit will be better.

3

Cut off any excess foam insulation.

4

Be sure that there must be no crack or wave on the bended area.

5

It would be necessary to double the insulation thickness(0.393inch(10mm)or

more)to prevent condensation even on the insulator when if the installed area

is warm and humid.

6

Shape an oil trap as shown in figure the oil trap must be fomed every level

difference of 32.8ft(10m).

Drain hose connection port

Liquid refrigerant port

Gas refrigerant

port

A

a. When the indoor unit is above the outdoor unit

Indoor unit

Oil trap (Must be installed

every 32.8f

t(10m))

Outdoor unit

b. When the outdoor unit is above the indoor unit

Outdoor unit

Oil trap

(Must be installed

every 32.8f

t(10m))

Oil trap

(suction tube)

indoor unit

Radius

1.968inch

(50mm)

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-11

ENGLISH

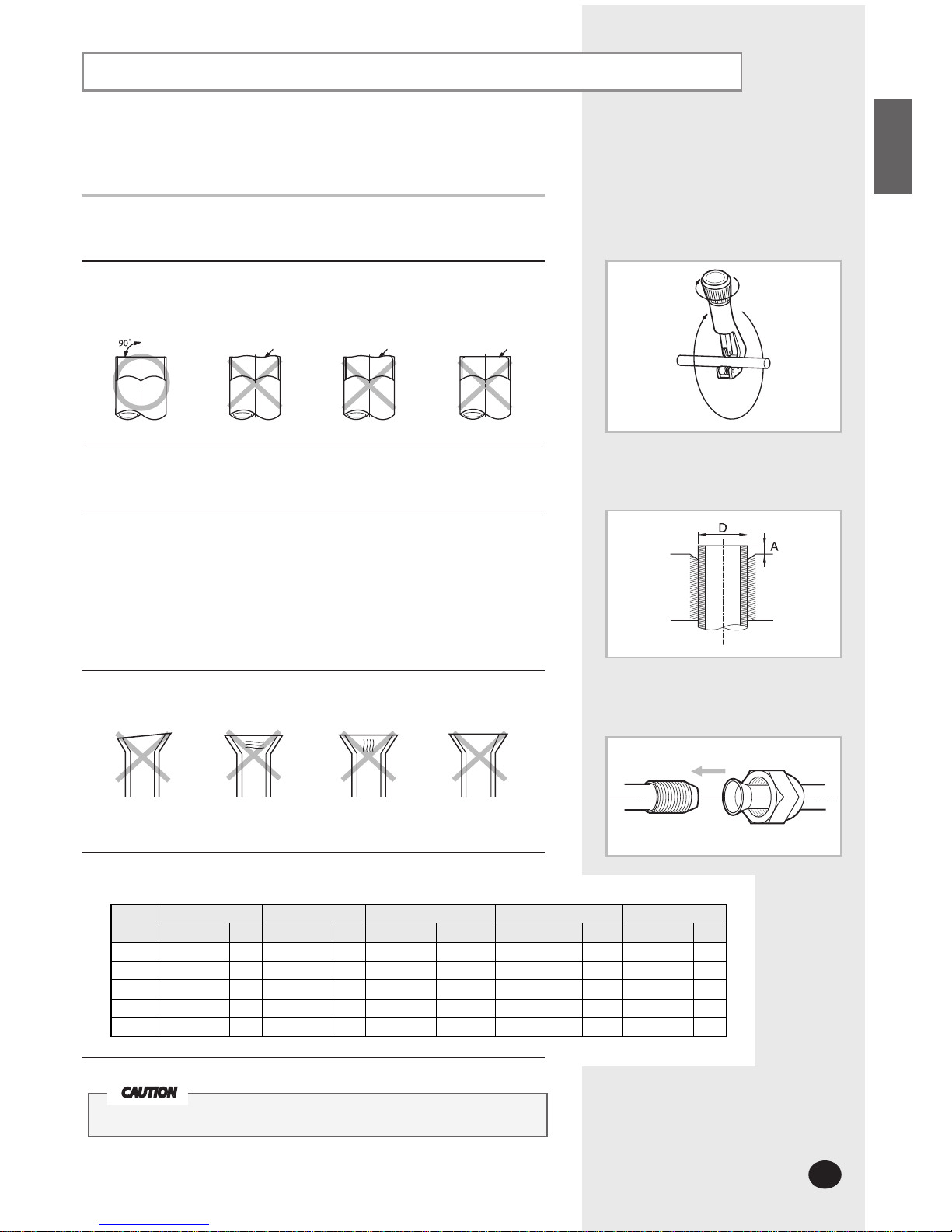

Cutting/Flaring the pipes

CAUTION

In case of welding the pipe, you must weld with nitrogen gas blowing.

Inclined Damaged Surface Cracked Uneven Thickness

Oblique Rough Burr

1

Make sure that you have the required tools available.

(pipe cutter, reamer, flaring tool and pipe holder).

2

If you wish to shorten the pipes, cut it with a pipe cutter, taking care to ensure

that the cut edge remains at a 90° angle with the side of the pipe. Refer to the

illustrations below for examples of edges cut correctly and incorrectly.

3

To prevent any gas from leaking out, remove all burrs at the cut edge of the

pipe, using a reamer.

4

Slide a flare nut on to the pipe and modify the flare.

Outer diameter (D) Depth (A)

6.35 mm (1/4”)

9.52 mm (3/8”)

12.70 mm (1/2”)

15.88 mm (5/8”)

19.05 mm (3/4”)

0.051 inch

0.070 inch

0.078 inch

0.086 inch

0.086 inch

5

Check that the flaring is correct, referring to the illustrations below for

examples of incorrect flaring.

6

Align the pipes and tighten the flare nuts first manually and then with

a torque wrench, applying the following torque.

Valve

Flare nut Valve cap Pressure port cap Valve needle Pressure port

Wrench(inch)

ft.lb

Wrench(inch)

ft.lb

Wrench(inch)

ft.lb

Wrench(inch)

ft.lb

Wrench(inch)

ft.lb

1/4" 0.67 13.2 0.91 14.8 0.7 11.8~13.3 Allen(hex.) 0.2 6.64 - 0.25

3/8" 0.87 31.0 0.91 14.8 0.7 11.8~13.3 Allen(hex.) 0.2 6.64 - 0.25

1/2" 1.02 40.6 1.14 29.5 0.7 11.8~13.3 Allen(hex.) 0.2 9.59 - 0.25

5/8" 1.14 48.0 1.14 29.5 0.7 11.8~13.3 Allen(hex.) 0.2 9.59 - 0.25

3/4" 1.42 73.6 1.5 29.5 0.7 11.8~13.3 Allen (hex.) 0.2 9.59 - 0.25

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

E-12

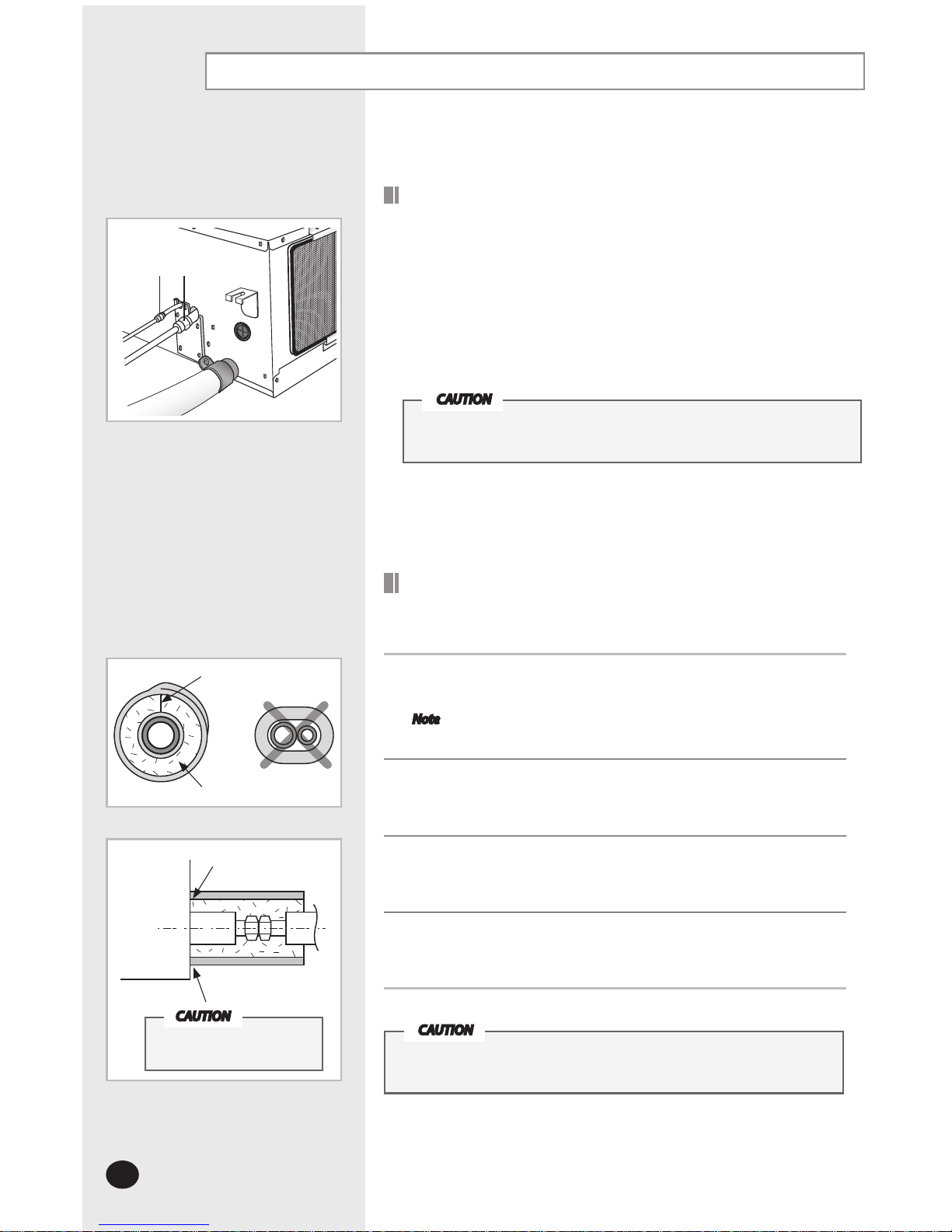

Performing leak test & insulation

A B

No gap

NBR(0.511inch(13mm)or

thicker)

Insulation cover pipe

Indoor unit

Be sure to overlap

the insulation

CAUTION

Must fit tightly against body

without any gap.

Insulation

Once you have checked that there are no leaks in the system,

you can insulate the piping and hose.

1

To avoid condensation problems, place T0.511inch(13mm) or thicker

Acrylonitrile Butadien Rubber separately around each refrigerant pipe.

Note Always make the seam of pipes face upwards.

2

Wind insulating tape around the pipes and drain hose avoiding to compress

the insulation too much.

3

Finish wrapping insulating tape around the rest of the pipes leading to the

outdoor unit.

4

The pipes and electrical cables connecting the indoor unit with the outdoor

unit must be fixed to the wall with suitable ducts.

All refrigerant connection must be accessible, in order to permit

either unit maintenance or removing it completely.

CAUTION

LEAK TEST WITH NITROGEN (before opening valves)

In order to detect basic refrigerant leaks, before recreating the vacuum and

recirculating the R-410A, it’s responsable of installer to pressurize the whole

system with nitrogen (using a cylinder with pressure reducer)

at a pressure above 30 bar (gauge).

LEAK TEST WITH R-410A (after opening valves)

Before opening valves, discharge all the nitrogen into the system and create

vacuum. After opening valves check leaks using a leak detector for refrigerant

R-410A.

Leak test

Discharge all the nitrogen to create a vacuum and charge

the system.

CAUTION

Air Marketing Group LLC

141 Kinderkamack Rd, Park Ridge, NJ 07656 Tel: 201-782-1782 Fax: 201-782-1783 Web: www.amgair.com Email: info@amgair.com

Loading...

Loading...