Samsung Duct Type Series, BIG duct AM FNHDCH Series Installation Manual

Duct Type Series

BIG duct : AM✴✴✴FNHDCH✴

Air Conditioner

installation manual

imagine the possibilities

Thank you for purchasing this Samsung product.

Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Accessories .............................................................................................................. 5

Selecting the Installation Location ....................................................................................... 6

Indoor Unit Installation .................................................................................................. 9

Purging the Unit ........................................................................................................ 10

Connecting the Refrigerant Pipe ........................................................................................ 10

Cutting/Flaring the Pipes ................................................................................................ 11

Performing leak test & insulation ........................................................................................ 12

Drain pipe and drain hose installation ................................................................................... 15

Wiring work ............................................................................................................ 19

Setting an indoor unit address and installation option ................................................................... 23

Setting temperature control of discharge air ............................................................................ 36

Final Checks and User Tips .............................................................................................. 36

Troubleshooting ........................................................................................................ 37

Option table ............................................................................................................ 39

2

Safety Precautions

WARNING

• Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

The following safety precautions must be taken when using your air conditioner.

• Risk of electric shock can cause injury or death.

WARNING

• Disconnect all remote electric power supplies before servicing, installing or cleaning.

• Installation must be done by the manufacturer or service agent or a similar qualied

person in order to avoid a hazard.

Installing the unit

f The unit should not be installed by the user. Ask the dealer or authorized company to install the units

f If the unit is installed improperly, water leakage, electric shock or re may result.

f Mount with the lowest moving parts at least 2.5 m (8.2 ft) above the oor or grade level. (If applicable)

f The manufacturer does not assume responsibility for accidents or injury caused by an incorrectly installed air conditioner.

If you are unsure about installation, contact an installation specialist.

f When installing the built-in type air conditioner, keep all electrical cables such as the power cable and the connection

cord in pipe, ducts, cable channels e.t.c to protect them against liquids, outside impacts and so on. The air conditioner

should be used only for the applications for which it has been designed: the indoor unit is not suitable to be installed in

areas used for laundry.

f This appliance is not accessible to the general public. This appliance should be installed according to the provided

installation instruction.

f When installing the air conditioner in a small room, the measure not to exceed the dangerous density is needed.

- When refrigerant leaks and exceeds the dangerous density, suocation may occur.

f If any gas or impurities except R-410A refrigerant come into the refrigerant pipe, serious problem may occur and it may

cause injury.

f Use only rated accessories and install the air conditioner with rated equipments.

- If you dont’t use the rated accessories, the air conditioner may drop from its place, water may leak or electric shock or

re may occur.

f Ventilate your room when refrigerant gas leaks during installation.

- Toxic gas may generate when refrigerant gas contacts with heat.

f Our units must be installed in compliance with the spaces indicated in the installation manual to ensure either

accessibility from both sides or ability to perform routine maintenance and repairs. The units’ components must be

accessible and that can be disassembled in conditions of complete safety either for people or things.

For this reason, where it is not observed as indicated into the Installation Manual, the cost necessary to reach and repair

the unit (in safety, as required by current regulations in force) with slings, trucks, scaolding or any other means of

elevation won’t be considered in-warranty and charged to end user.

f This unit is intended for free-air discharge or for connection to a duct supplying only one room.

ENGLISH

3

Safety precautions

Power supply line or circuit breaker

f If the power cable of this air conditioner is damaged, it must be replaced by service agent or similarly qualied persons in

order to avoid a hazard.

f The unit must be plugged into an independent circuit if applicable or connect the power cable to the auxiliary circuit

breaker. An all pole disconnection from the power supply must be incorporated in the xed wiring with a contact

opening of >3 mm (0.12 inch).

f The air conditioner must be installed in accordance with national wiring regulations and safety regulations wherever

applicable.

f The electric work must be done by service agent or similarly qualied persons according to national wiring regulations

and use only rated cable.

- If the capacity of the power cable is insucient or electric work is not properly completed, electric shock or re may

occur.

f Install the cables with supplied cables rmly. Fix them securely so that external force is not exerted to the terminal board.

- If the connection or xing is incomplete, heat generation, electric shock or re may occur.

f Connect the power cable between the indoor and outdoor unit properly so that the electrical component box cover is

not get loosen and attach the cover securely.

- If the the cover is attached incompletely, heat generation, electric shock or re of the terminal board may occur.

f Be sure not to perform power cable modication, extension wiring, and multiple wire connection.

- It may cause electric shock or re due to poor connection, poor insulation, or current limit override.

- When extension wiring is required due to power line damage, refer to “How to connect your extended power cables” in

the installation manual.

• Make sure that you earth the cables.

CAUTION

- Do not connect the ear th wire to the gas pipe, water pipe, lighting rod or telephone wire. If earthing is not

complete, electric shock or re may occur.

• Install the circuit breaker.

- If the circuit breaker is not installed, electric shock or re may occur.

• Make sure that the condensed water dripping from the drain hose runs out properly and safely.

• Install the power cable and communication cable of the indoor and outdoor unit at least 1 m (3.28 ft) away from

the electric appliance.

• Install the indoor unit away from lighting apparatus using the ballast.

- If you use the wireless remote control, reception error may occur due to the ballast of the lighting apparatus.

• Do not install the air conditioner in following places.

- Place where there is mineral oil or arsenic acid. Resin parts ame and the accessories may drop or water may

leak. The capacity of the heat exchanger may reduce or the air conditioner may be out of order.

- The place where corrosive gas such as sulfurous acid gas generates from the vent pipe or air outlet. The copper

pipe or connection pipe may corrode and refrigerant may leak.

- The place where there is a machine that generates electromagnetic waves. The air conditioner may not

operate normally due to control system.

- The place where there is a danger of existing combustible gas, carbon ber or ammable dust. The place

where thinner or gasoline is handled. Gas may leak and it may cause re.

4

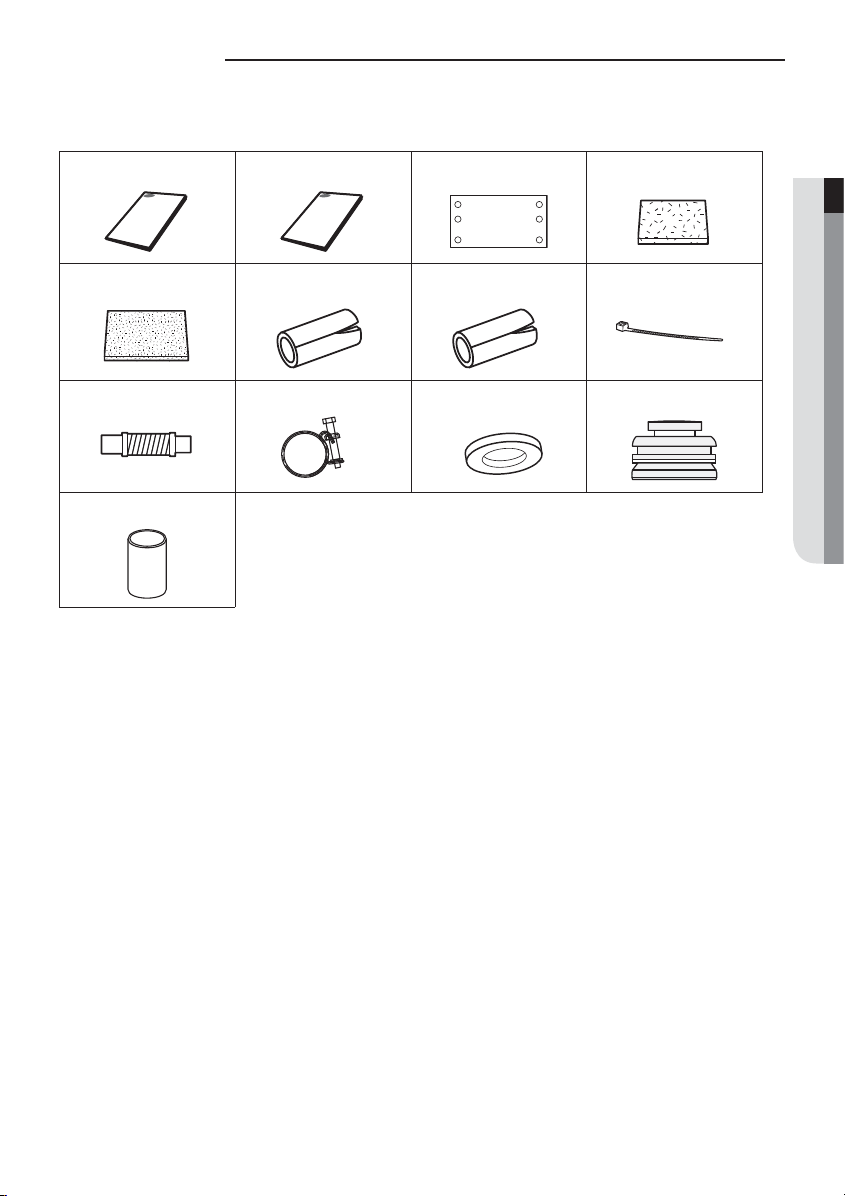

Accessories

The following accessories are supplied with the indoor unit.

The type and quantity may dier depending on the specications.

User's manual Installation manual Pattern sheet Insulation cover pipe in

Insulation cover pipe out Pipe insulation (A) Pipe insulation (B) Cable tie

Flexible hose Clamp hose Washer Rubber

Sleeve

ENGLISH

5

Selecting the Installation Location

Indoor Unit

f There must be no obstacles near the air inlet and outlet.

f Install the indoor unit on a ceiling that can support its weight.

f Maintain sucient clearance around the indoor unit.

f Make sure that the water dripping from the drain hose runs away correctly and safely.

f The indoor unit must be installed in this way, that they are out of public access. (Not touchable by the users)

f After connecting a chamber, insulate the connection part between the indoor unit and the chamber with t10 mm(3/8")

or thicker insulation. Otherwise, there can be air leak or dew from the connection part.

f Rigid wall without vibration.

f Where it is not exposed to direct sunshine.

f Where the air lter can be removed and cleaned easily.

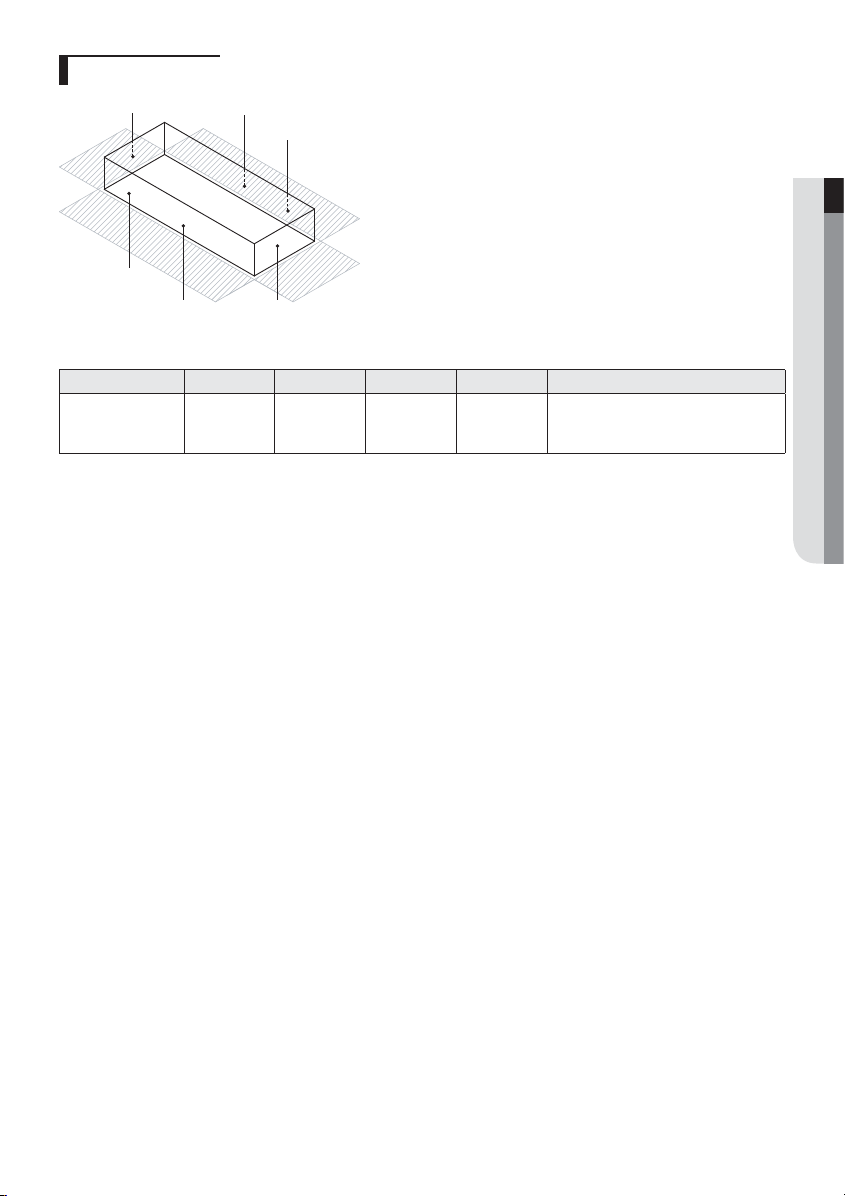

Space requirements for installation & service

Unit Width(W)

Unit Depth(D)+50 mm (1.97 inch)

“A”=W+100 mm(3.94 inch)

“B”=500 mm(19.69 inch)

20 mm(0.79 inch) or more

20 mm(0.79 inch) or more

f You must have 20 mm(0.79 inch) or more space between the ceiling and the bottom of indoor unit. Otherwise, the noise

from the vibration of indoor unit may bother the user. When the ceiling is under construction, the hole for check-up must

be made to take service, clean and repair the unit.

f It is possible to install the unit at an height of between 2.2(7.22 ft) ~ 2.5 m(8.20 ft) from the ground, if the unit has a duct

with a well dened lenght[300 mm(0.98 ft) or more], to avoid fan motor blower contact.

6

Insulation Guide

D

Front

Front

A

Thickness: more than 10 mm(0.39inch)

Indoor Unit A B C D Front/Back

1240x470x1040

(48.8x18.5x40.9)

f Insulate the end of the pipe and some curved area by using separate insulation.

f Insulate the discharge and suction part at the same time when you insulate connection duct.

400x190

(15.7x7.5)

B

Back

Back

C

1240x1040

(48.8x40.9)

470x1040

(18.5x40.9)

470x1040

(18.5x40.9)

Insulate the front and back side in proper

size at the same time when insulating the

suction duct and discharge duct.

ENGLISH

mm(inch)

7

Selecting the Installation Location

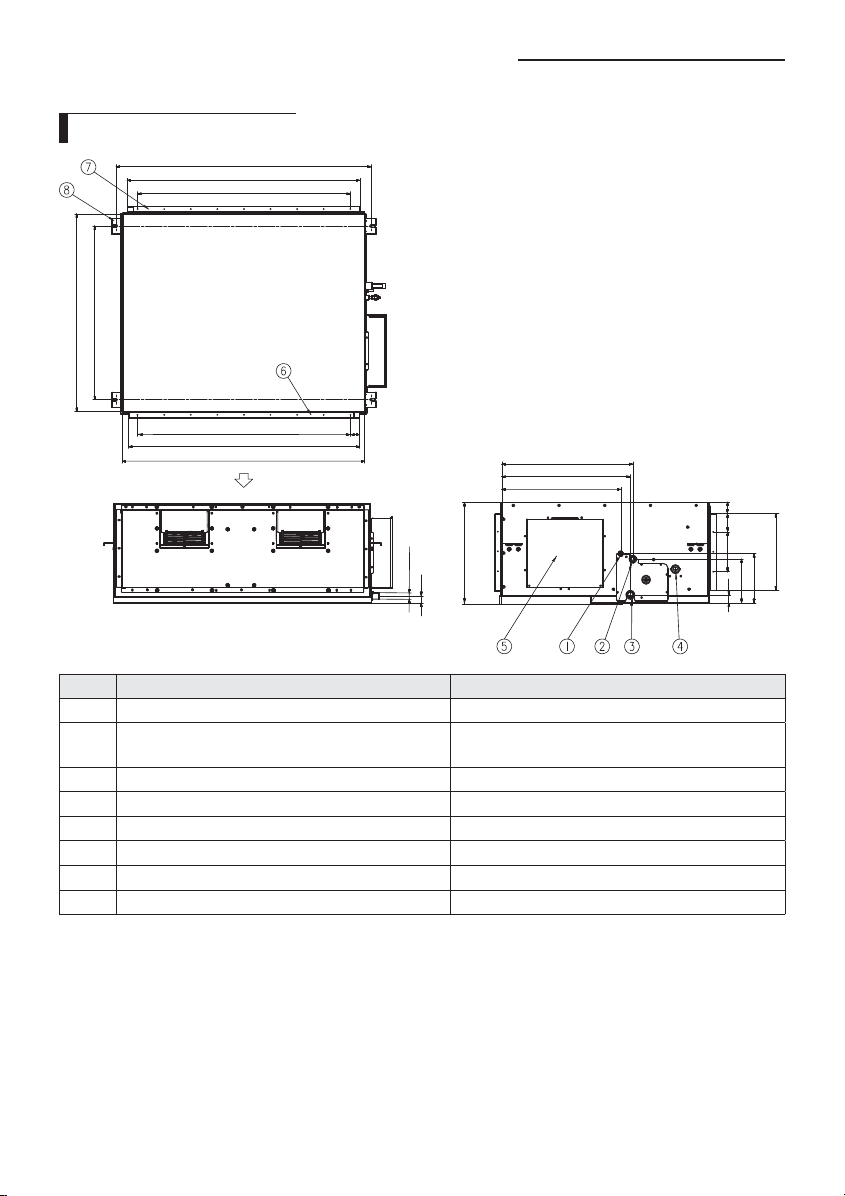

Drawing of the indoor unit

1306(51.42) Suspension position

1188(46.77) Air inlet duct ange

140X8=1120(44.09)

1040(40.94)

914 Suspension position

Unit : mm(inch)

140X8=1120(44.09)

1188(46.77) Air outlet duct ange

1240(48.82)

No. Name Description

①

②

③

④

⑤

⑥

⑦

⑧

Liquid pipe connection ø9.52(3/8")

Gas pipe connection AM076✴✴✴ : ø19.05(3/4")

Drain pipe connection VP25[OD ø32(1.26"), ID ø25(0.98")]

Drain pipe connection (Option drain pump) VP25[OD ø32(1.26"), ID ø25(0.98")]

Power supply/Communication connection

Air discharge grille ange

Air suction ange

Hook ø9.52(3/8") or M10

34

660(25.98)

647(25.47)

598(23.54)

470(18.50)

OD Ø32

35

Discharge side

AM096✴✴✴ : ø22.22(7/8")

22(0.87)

93

100X2=200

29(1.14)

Suction side

(3.66)

(7.87)

385(15.16)

209(8.23)

236(9.29)

8

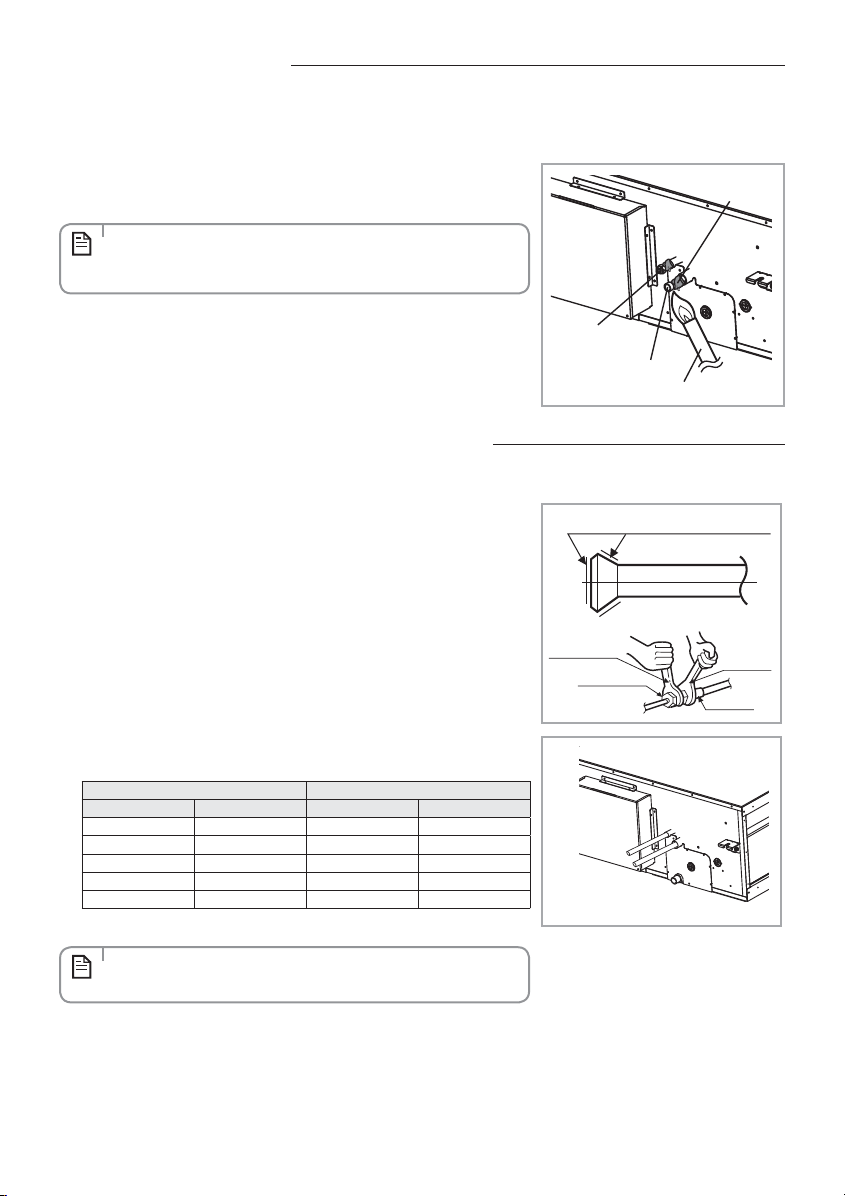

Indoor Unit Installation

It is recommended to install theY-joint before installing the indoor unit.

1. Place the pattern sheet on the ceiling at the spot where you want to install

the indoor unit.

• Since the diagram is made of paper, it may shrink or stretch slightly

due to temperature or humidity. For this reason, before drilling the

NOTE

holes maintain the correct dimensions between the markings.

ENGLISH

2. Insert bolt anchors, use existing ceiling supports or construct a suitable

support as shown in gure.

3. Install the suspension bolts depending on the ceiling type.

• Ensure that the ceiling is strong enough to support the weight of

the indoor unit. Before hanging the unit, test the strength of each

CAUTION

attached suspension bolt.

• If the length of suspension bolt is more than 1.5 m(4.92 ft), it is

required to prevent vibration.

• If this is not possible, create an opening on the false ceiling in order

to be able to use it to perform the required operations on the indoor

unit.

4. Screw eight nuts to the suspension bolts making space for hanging the

indoor unit.

• You must install the suspension bolts more than four when

installing the indoor unit.

CAUTION

5. Hang the indoor unit to the suspension bolts between two nuts.

• Piping must be laid and connected inside the ceiling when

suspending the unit. If the ceiling is already constructed, lay the

NOTE

piping into position for connection to the unit before placing the

unit inside the ceiling.

6. Screw the nuts to suspend the unit.

7. Adjust level of the unit by using measurement plate for all 4 sides.

• For proper drainage of condensate, give a 1° slant to the left or right

side of the unit which will be connected with the drain hose, as

NOTE

shown in the gure. Make a tilt when you wish to install the drain

pump, too.

Concrete

Hole in anchor

Hole in plug

Suspension bolt(Φ9.52(3/8") or M10)

Ceiling support

Rubber

Insert

1°

Drain hose port

9

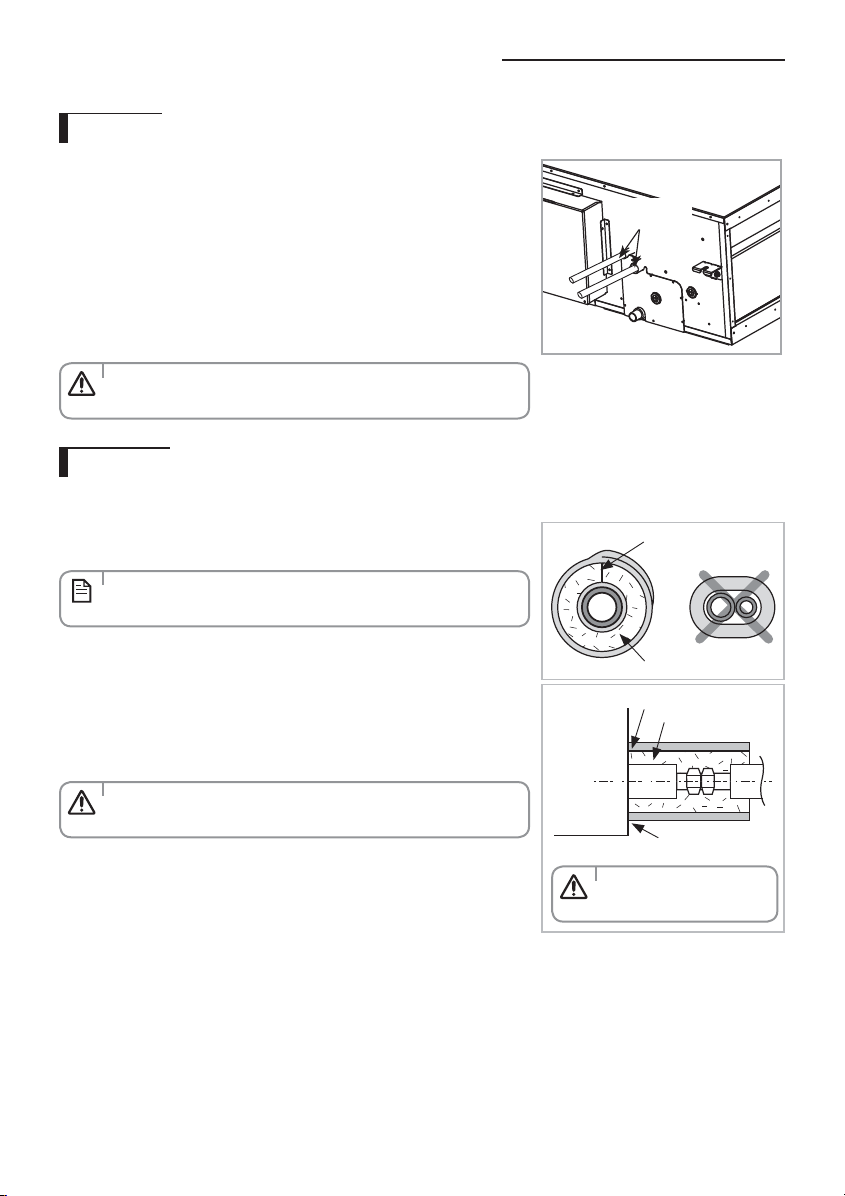

Purging the Unit

On delivery, the indoor unit is loaded with inert gas. All this gas must therefore be purged before connecting the assembly

piping. To purge the inert gas, proceed as follows.

Unscrew the pinch pipe at the end of each refrigerant pipe.

Result : All inert gas escapes from the indoor unit.

• To prevent dirt or foreign objects from getting into the pipes during

installation, do NOT remove the pinch pipe completely until you are

NOTE

ready to connect the piping.

Liquid refrigerant

port

Gas refrigerant port

Welding ame

Wet cloth

Connecting the Refrigerant Pipe

There are two refrigerant pipes of diering diameters:

f A smaller one for the liquid refrigerant

f A larger one for the gas refrigerant

f The inside of copper pipe must be clean & has no dust.

The connection procedure for the refrigerant pipes varies according to the

exit position of the pipes from the indoor unit, as seen when facing the indoor

in the “A” side.

f Liquid refrigerant port

f Gas refrigerant port

f Drain hose port

1. Remove the pinch pipe on the pipes and connect the assembly pipes to each

pipe, tightening the nuts, rst manually and then with a torque wrench, a

spanner applying the following torque.

Outer diameter Torque

mm inch N•m Ibf•ft

6.35 1/4 14 ~ 18 10.3 ~ 13.3

9.52 3/8 34 ~ 42 25.1 ~ 31.0

12.7 1/2 49 ~ 61 36.1 ~ 45.0

15.88 5/8 68 ~ 82 50.2 ~ 60.5

19.05 3/4 100 ~ 120 73.8 ~ 88.5

• Must apply refrigerant oil on the aring area to prevent a leak.

NOTE

2. Be sure that there must be no crack or kink on the bended area.

Refrigerant oil

Torque wrench

Flare nut

Spanner

Union

A

❋ The designs and shape are subject

to change according to the model.

10

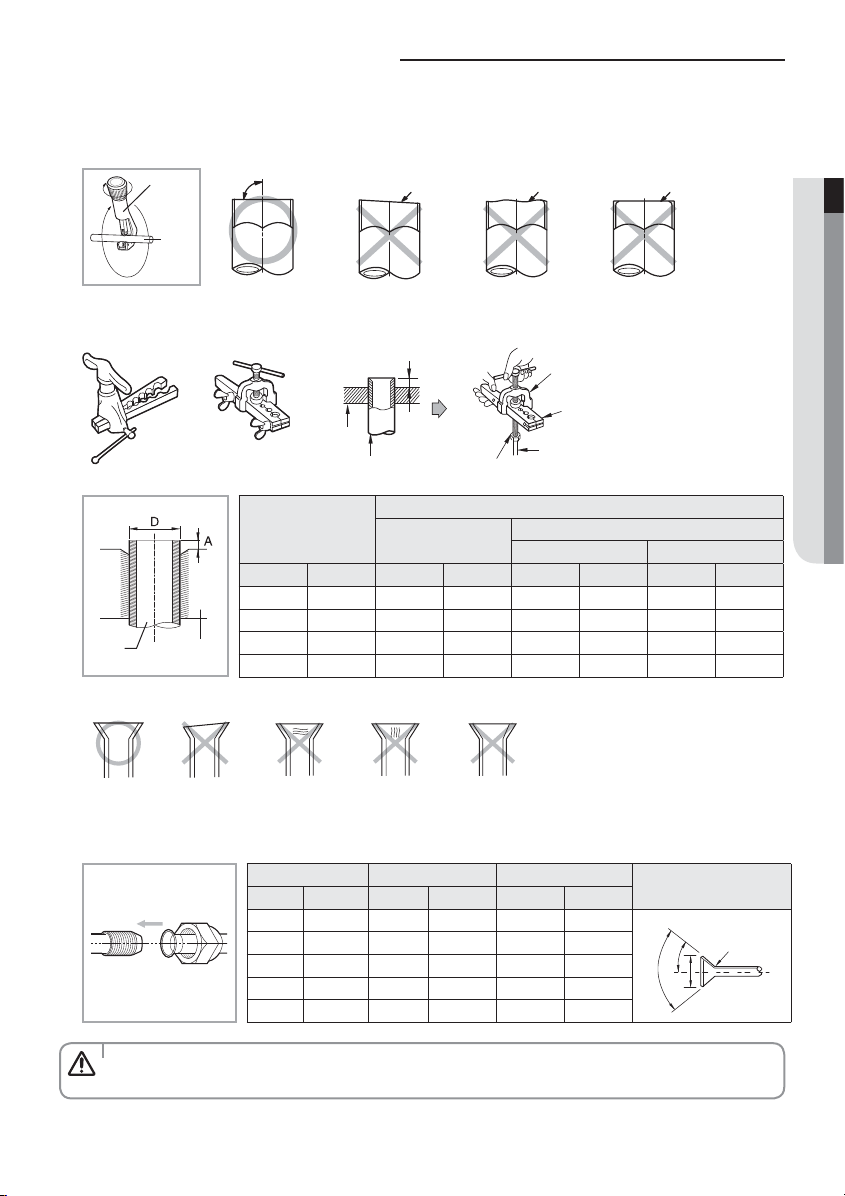

Cutting/Flaring the Pipes

1. Make sure that you prepared the required tools. (pipe cutter, reamer, aring tool and pipe holder)

2. If you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains at 90° with the side of the

pipe. There are some examples of correct and incorrect cut edges below.

Pipe

cutter

Pipe

3. To prevent a gas leak, remove all burrs at the cut edge of the pipe using a reamer.

4. Carr y out aring work using aring tool as shown below.

Flaring tool

Clutch type Wing nut type

Oblique90° Rough Burr

Die

Copper pipe

A

Flare nut

Yor k

Die

Copper pipe

ENGLISH

Depth of aring part [A]

Using conventional aring tool

Clutch type Wing nut type

Pipe

Flare

Pipe diameter

[D]

mm inch mm inch mm inch mm inch

6.35 1/4 0~0.5 0~0.02 1.0~1.5 0.04~0.06 1.5~2.0 0.06~0.08

9.52 3/8 0~0.5 0~0.02 1.0~1.5 0.04~0.06 1.5~2.0 0.06~0.08

12.7 1/2 0~0.5 0~0.02 1.0~1.5 0.04~0.06 1.5~2.0 0.06~0.08

15.88 5/8 0~0.5 0~0.02 1.0~1.5 0.04~0.06 1.5~2.0 0.06~0.08

Using aring tool

for R-410A

5. Check if you ared the pipe correctly. There are some examples of incorrectly ared pipes below.

InclinedCorrect

Surface

CrackedDamaged

Uneven

Thickness

6. Align the pipes and tighten the are nuts rst manually and then with a torque wrench, applying the following torque.

Outer diameter (D) Torque (A) Flare dimension (L)

mm inch N•m lbf.ft mm inch

6.35 1/4 14~18 10.3~13.3 8.7~9.1 0.34~0.36

9.52 3/8 34~42 25.1~31.0 12.8~13.2 0.50~0.52

12.7 1/2 49~61 36.1~45.0 16.2~16.6 0.64~0.65

15.88 5/8 68~82 50.2~60.5 19.3~19.7 0.76~0.78

19.05 3/4 100~120 73.8~88.5 23.6~24.0 0.93~0.94

• In case of needing brazing, you must work with Nitrogen gas blowing.

CAUTION

Flare shape

mm(inch)

R 0.4~0.8

(0.016~0.032)

LD

45° ±2°

90° ±2°

11

Performing leak test & insulation

Leak test

LEAK TEST WITH NITROGEN (before opening valves)

In order to detect basic refrigerant leaks, before recreating the vacuum

and recirculating the R-410A, it’s responsibility of installer to pressurize the

whole system with nitrogen (using a pressure regulator) at a pressure above

4.1MPa(594.7 psig) (gauge).

LEAK TEST WITH R-410A (after opening valves)

Before opening valves, discharge all the nitrogen into the system and create

vacuum. After opening valves check leaks using a leak detector for refrigerant

R-410A.

• Discharge all the nitrogen to create a vacuum and charge the system.

CAUTION

Insulation

Once you have checked that there are no leaks in the system, you can insulate the piping and hose.

Leak check

1. To avoid condensation problems, place T13.0 (1/2") or thicker Acrylonitrile

Butadien Rubber separately around each refrigerant pipe.

• Always make the seam of pipes face upwards.

NOTE

2. Wind insulating tape around the pipes and drain hose avoiding to compress

the insulation too much.

3. Finish wrapping insulating tape around the rest of the pipes leading to the

outdoor unit.

4. The pipes and electrical cables connecting the indoor unit with the outdoor

unit must be xed to the wall with suitable ducts.

• All refrigerant connection must be accessible, in order to permit

either unit maintenance or removing it completely.

CAUTION

Insulation cover pipe

Indoor unit

• Must t tightly against

body without any gap.

CAUTION

No gap

NBR

(T13.0 (1/2") or thicker)

Insulation pipe

Be sure to overlap the

insulation

12

Loading...

Loading...