Samsung B1113JDW/XAC Service Manual

ٛ

ERVICE

WASHING MACHINE

CONTENTS

WASHING MACHINE

Caution for safety during servicing

1. SPECIFICATIONS

2. OVERVIEW OF THE WASHING MACHINE

3. OVERVIEW OF THE CONTROL PANEL

4. GENERAL ERROR FUNCTION

5. TROUBLE DIAGNOSIS

6. TEST MODE

7. DESIGNATION OF MAIN COMPONENTS

8. PCB SCHEMATIC DIAGRAM

PCB CIRCUIT DIAGRAM

9. ASSEMBLE AND DISASSEMBLE

10

.TOOLS FOR DISASSEMBLY AND ASSEMBLY

11.EXPLODED VIEW AND PARTS LIST

Manual

B1113JDW/XAC

- 1 -

Caution for safety during servicing

1. Do not allow the customer to repair the product.

The person may be injured or the product life may be shortened.

2. Execute A/S after unplugging the power supply unit.

Be careful of electric shocks.

3. Do not plug several plugs in the same outlet.

Itmaycausefireduetooverheat.

4. Check for damage, pressing or burning of the power plug or outlet.

Replace it promptly if it has a problem.(It may cause electric shocks or fire)

5. Do not clean the main body with water.

It may cause electric shocks and fire and shorten the product life.

6. The wiring of the harness shall be free from moisture and tightened during serving.

It shall not be deviated by certain impact.

7. Remove any dust or filth on the housing section,wiring section,connection section during servicing.

Protect frompossible cause of fire such as tracking,shortage etc.

8. Check for any marks of moisture on the electrical parts, harness section etc.

Replace the parts or remove the moisture..

9. Check the assembly status of the parts after servicing.

Maintain the status before servicing..

10. Pull out the power cord by holding the plug.

Be careful of electric shocks and fire when the cord is damaged.

11. Unplug t he power plug from the outlet when the washing machine is not used.

Be careful of electric shocks and fire due to the strike of lightning.

12. 12. Do not use or store sprays or flammable materials(including gasoline,alcohol etc.)

around the washing machine.

Be careful of explosions or fire due to electric sparks.

13. Do not put a bowl of water or wet laundry on the washing machine.

If the water has penetrated the washing machine, this may cause electric shocks or fire.

14. 14. Do not install the washing machine where it is exposed to bad weather.

It may cause the electric shock and fire and shorten the product life..

15. Do not push the control buttons with an awl,pin, or sharp materials.

It may cause electric shocks and damage.

16. Check that the washing machine is leveled horizontally and installed properly on the floor.

The vibration may shorten the product life..

17. Joint the wire by the connector correctly.

When the wire is jointed by tape, this may cause fire due to tracking.

18. When the washing machine is to be laid for service, put the pad on the floor and lay the

product on its side slowly.

If the washing machine is laid on its front, the relay may be damaged by the tub.

- 2 -

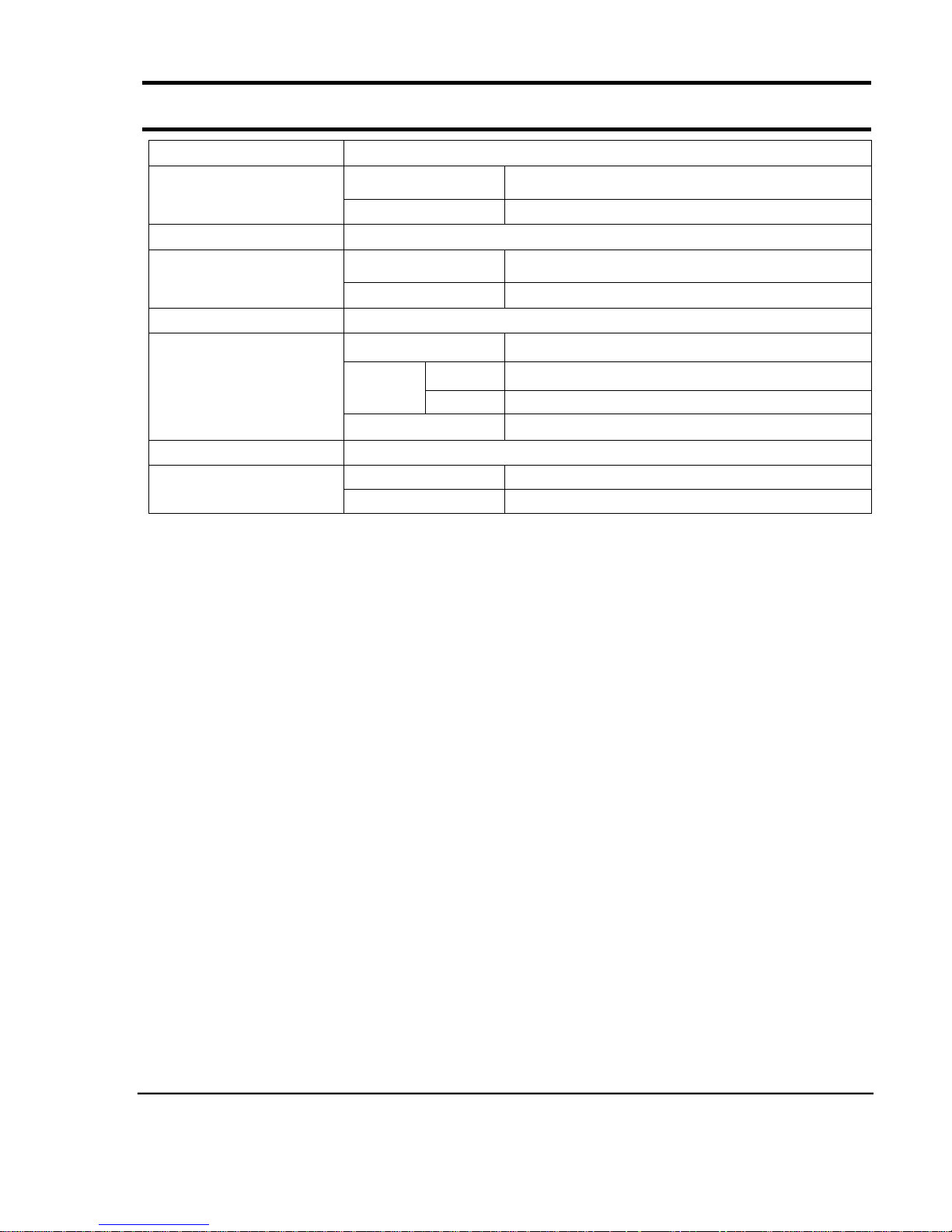

1. Specifications

WASH TYPE

FRONT LOADING TYPE

DIMENSIONS

GROSS W 680mm X D 665mm X H 890mm

NET W 598mm X D 550mm X H 844mm

WATER PRESSURE

50 kPa ~ 800 kPa

WEIGHT

GROSS 78 kg

NET 75 kg

WASH and SPIN CAPACITY

5.5 kg (DRY LAUNDRY)

POWER CONSUMPTION

WASHING 120V

SPIN

MODEL B1113J

120V 500W

PUMPING 34W

WATER CONSUMPTION

60l (STANDARD COURSE)

SPIN REVOLUTION

MODEL B1113J

rpm 1100

- 3 -

2. Overview of the Washing Machine

- 4 -

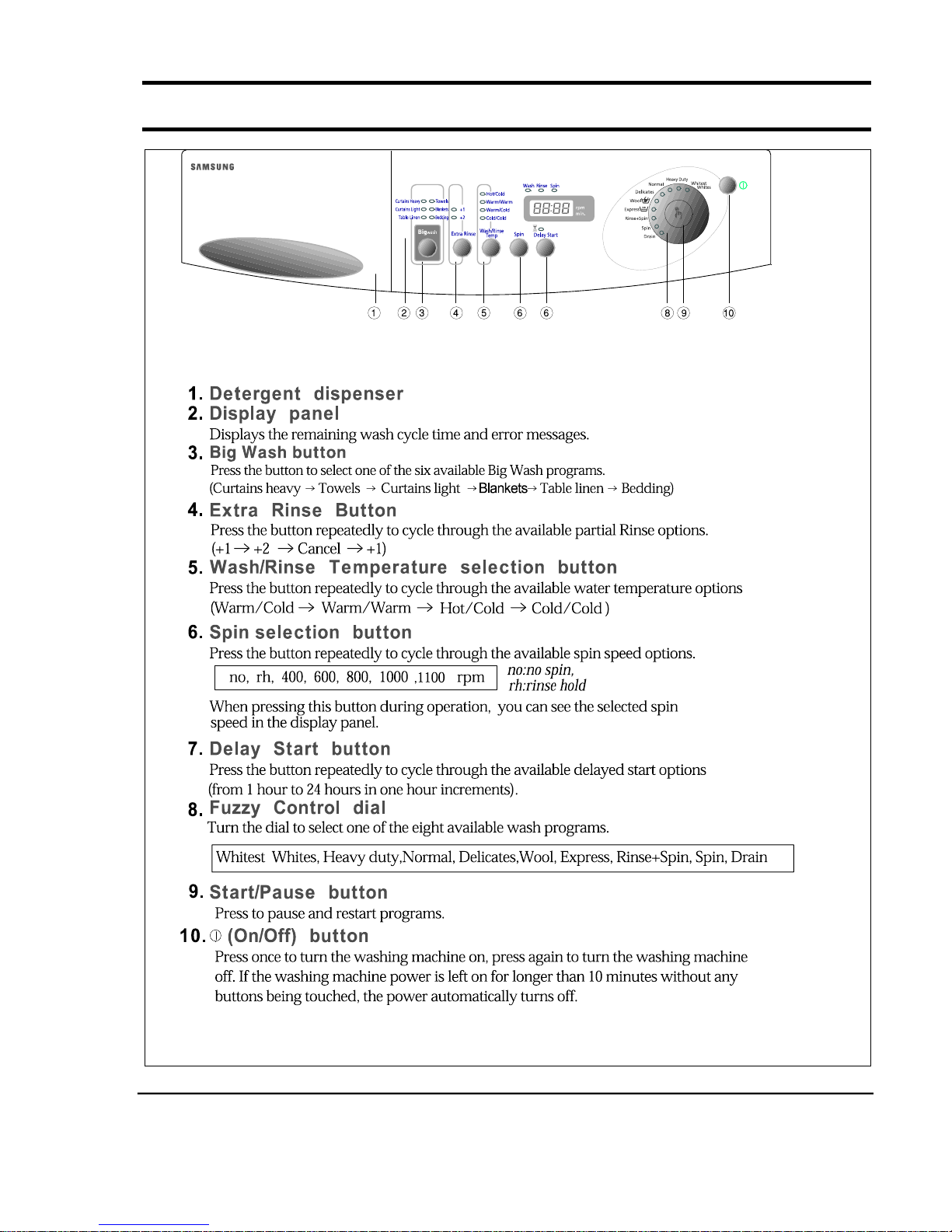

3. Overview of the control panel

- 5 -

4. General Error Function

- When an error occurs, this function starts to keep generating error melody sounds and displays error indicators as

shown in the followings per corresponding error by blinking in 0.5sec intervals until the error status is completely cleared out.

In this case, all the driving devices are turned off until the error is cleared out.

1. WATER SUPPLY ERROR

- Display shows ‘ E1’ .

- Water Supply Error occurs when water level frequency does not show changes more than 100Hz or water is not supplied

up to the water level presetting for 20 min or more at the time of initial water supply.

- The error status can be cleared by turning POWER S/W OFF and resuming the POWER ON initial status.

2. WATER DRAIN ERROR

- Display shows ‘ E2’ .

- In case the water level frequency is 25.5KHz or less in the initial phase of UNB-detecting cycle.

- Water Drain error can be cleared by turning POWER S/W OFF and resuming the POWER ON initial status.

3. OVER-FLOW ERROR

- Display shows ‘ E3’ .

- Over-Flow error occurs when the water level is in abnormal operation. It can be cleared by turning POWER S/W OFF.

Water is drained prior to POWER S/W OFF and it is forced to be drained for 2 min if a frequency of more than 25.24

KHz is detected.

4. DOOR OPEN ERROR

- Display shows ‘ door’

- Door Open error can be cleared by closing the door.

5. UNBALANCE ERROR

- Display shows ‘ E4’ .

- Laundry load is unbalanced; loosen any tangled laundry.

- If only one item of clothing needs washing, such as a bathrobe or jeans, the final spin result might be unsatisfactory and an

“ E4” error message will be shown in the display window.

- Unbalance error is cleared by POWER S/W OFF and by resuming the POWER ON initial status.

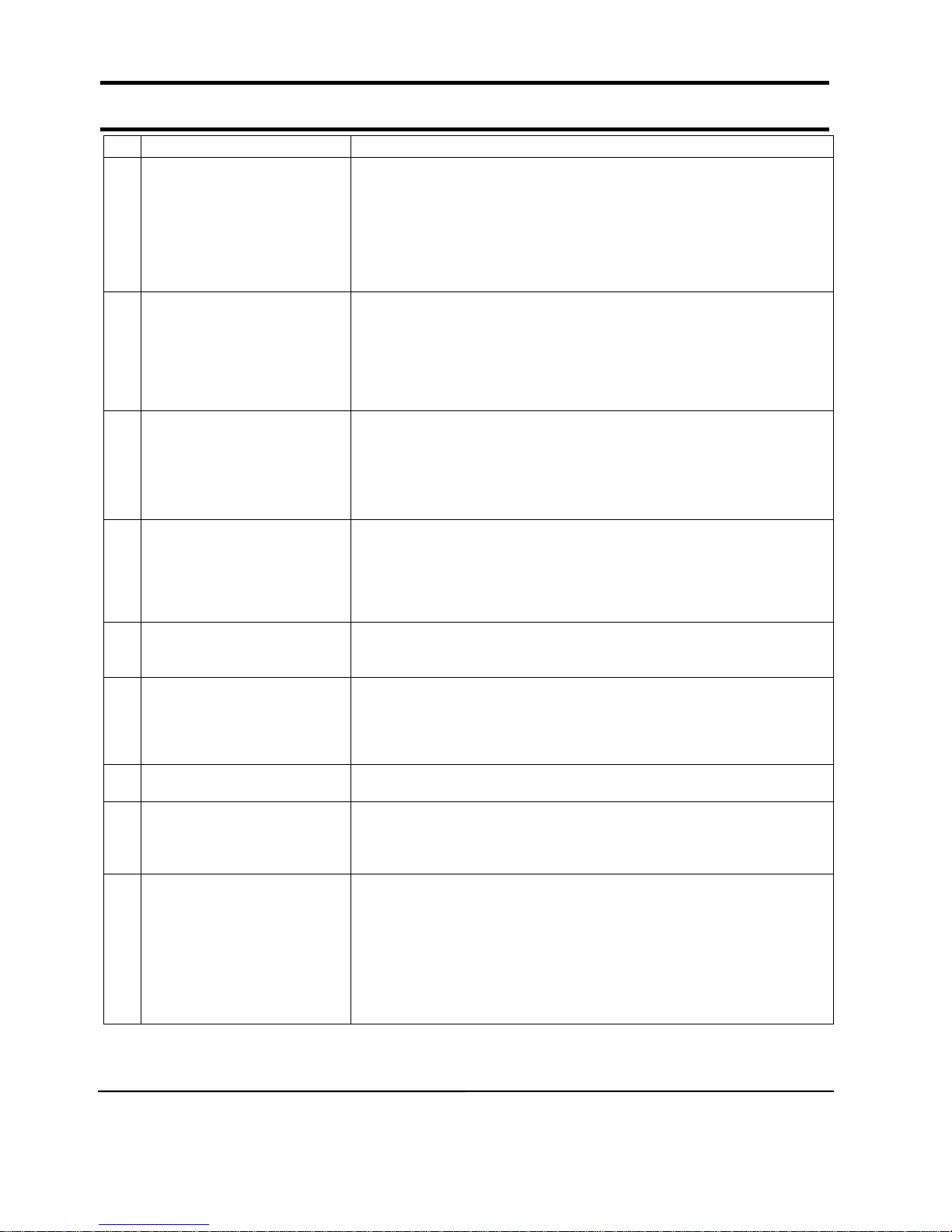

6. ASS’ Y PRESSURE S/W ERROR

* Generated Frequency Signal of WATER LEVEL(W/L) S/W (KHz)

- If the same signal as the above table is detected for more than 5 seconds, it is a PRESSURE S/W Error.

- When the error occurs, water drain pump will operate for 3 min. and then turn off the water drain pump.

Then the display shows ‘ E7’ indicating a pressure s/w error indicator.

7. WATER LEAKAGE ERROR (E9)

- Water Leakage error occurs when water is drained naturally after washing program starts.

8. Tacho Error

- This error occurs in case motor thaco is out of order or tacho siganals inputted are fewer than 2

- "EA" displayed

- This error can be cleared by power s/w off

9. Motor Triac short Error

- This error occurs in case over 300 per 1 sec tacho signals are inputted power S/w should be off.

- "Eb" diplayed.

- This error can be cleared by power s/w off

Level Low Level High Level

Abnormal W/L Frequency 30.00 KHz 15.00 KHz

- 6 -

5. Trouble Diagnosis

*

As the micom washing machine is configured of a complicated structure, there might be a need for a

service call. The information below is prepared for exact trouble diagnosis and suitable repair guide.

Caution for the Repair and Replacement

1) As some electronic components are damaged by the charged static electricity from the resin part of wash

machine or the human body, prepare the human body earth or remove the potential difference of the

human body and wash machine by contacting the power supply plug when the work contacting to PCB is

executed.

2) Since AC120V is applied to the triac T1 and T2 on P.C.B, electric shock may occur by touching

and be careful that the strong and weak electricity are not mixed.

3) As the P.C.B assembly is designed for easy handling, do not replace the P.C.B assembly by the wrong

diagnosis and follow the procedure of trouble diagnosis when the micom is not operated normally.

Please follow instructions below for trouble diagnosis and parts replacement.

- 7 -

5-1. Trouble Diagnosis

No Item Cause and treatment

1

The power is not supplied - Is the PCB connector connected well?

- Is the voltage normal?

- Is the power supply plug connected well?

- Is the noise filter connected well?

- Is the secondary output of the power supply transformation normal?

- Is the fuse disconnected? (option)

• If above points are not found, the PCB assembly is out of order.

Replace it.

2

The water is not supplied. - Is the knob open?

- Did you push START/PAUSE button after selecting the course?

- Is the water supply valve connected well?

- Is the winding of the water supply valve continuous?

- Is the connection and operation of the pressure switch normal?

• If above points are not found, the PCB assembly is out of order.

Replace it.

3

The wash does not start though

the water supply is stopped.

- Is the connection and operation of the pressure switch normal?

- Is the pressure switch hose damaged so that the air is leaked?

- Is the pressure switch hose bent?

- Check the operation of the water level switch.

• If above points are not found, the PCB assembly is out of order.

Replace it.

4

The drum does not rotate during

washing.

- Is the belt connected well?

- Is the winding of the motor continuous?

(Rotor winding, stator winding, generator)

- Is the motor protector normal?

• If above points are not found, the PCB assembly is out of order.

Replace it.

5

The drum rotates in one direction

during washing. (The drum rotates

in one direction for SPIN.)

- The PCB assembly is out of order. Replace it.

(Inversion relay open trouble)

6

Drainage problem. - Is the drainage hose bent?

- Is the winding of the drainage pump continuous?

- Is the drain filter clogged by waste?

• If above points are not found, the PCB assembly is out of order.

Replace it.

7

Dehydration problem. - Unbalance is detected.

- Put in the laundry uniformly and start again.

8

Abnormal noise during SPIN.

- Is the pulley nut loose?

- Is the transport safety device removed?

- Is the product installed on a level and stable surface?

(Little noise may be generated during the high-speed SPIN.)

9

Leak breaker or current/leak

breaker is down during washing.

<When the leak breaker and current breaker is installed separately>

- When the leak breaker is down, check and make sure it is grounded.

- When the current is down, the current is leaked.

<Is the breaker down when the leak/current breaker is combined?>

- Check the rated capacity of the current and leak breaker.

The current breaker may be down due to the lack of current when the

washing machine and other apparatus are used.

In this case, execute a cold water wash to check whether the current capacity

is lacking.

Loading...

Loading...