Samsung AQ12AAMC, UQ12AAMC, AQ12AABMC, UQ12AABMC Service Manual

ROOM AIR CONDITIONER

INDOOR UNIT

AQ12AA(B)MC

SERVICE

OUTDOOR UNIT

UQ12AA(B)MC

Manual

CONTENTSAIR CONDITIONER

1. Installation

2. Disassembly and Reassembly

3. Troubleshooting

4. Exploded Views and Parts List

5. Refrigerating Cycle Block Diagrams

6. Wiring Diagrams

E DB98-05496A(1)

7. Schematic Diagrams

1. Installation

1-1 Refrigerant Refill Procedure

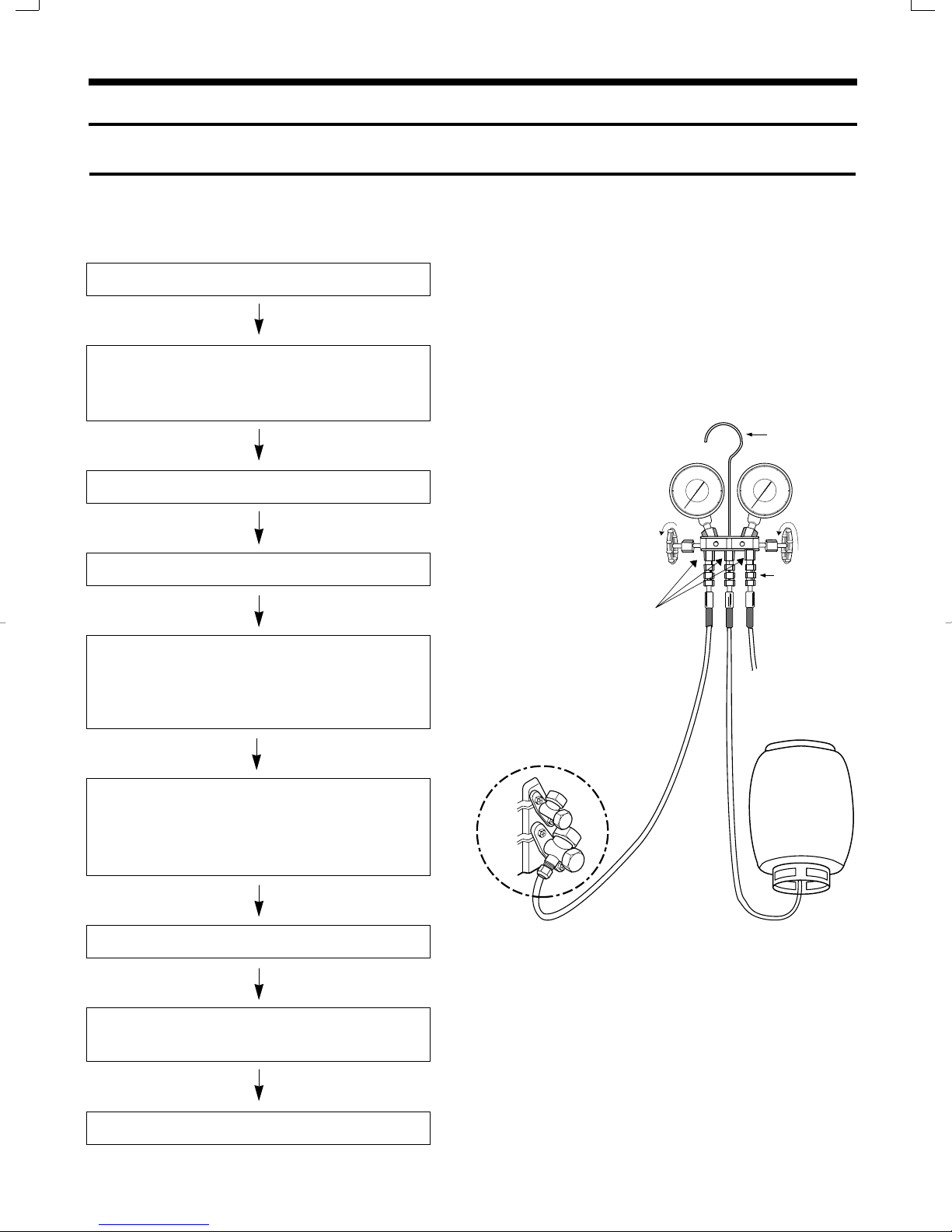

• Refill an air-conditioner with refrigerant when refrigerant has been leaked at installing or using

1. Purge air(for new installation only).

2. Turn the 3-way valve clockwise to close,

connect the pressure gauge(low pressure side) to the

service valve, and open the 3-way valve again.

Suspension hook

3. Connect the tank to refill with Refrigerant

4. Set the unit to cool operation mode.

5. Check the pressure indicated by the pressure gauge(low

pressure side).

* Standard pressure is should be 64~78psi in a regular,

high operation mode.

6. Open the refrigerant tank and fill with refrigerant until

the rated pressure is reached.

* It is recommended not to pour the refrigerant in too

quickly, but gradually while operating a pressure valve.

Compound

gauge

For mounting

other and of

hose when

not in use

High

pressure

gauge

Hand

wheel

Finger tight

fittings

Connected to

high pressure

side

Charging

line

R-22

7. Stop operation of the air conditioner.

8. Close the 3-way valve, disconnect the pressure gauge,

and open the 3-way valve again.

9. Close the cap of each valve.

1

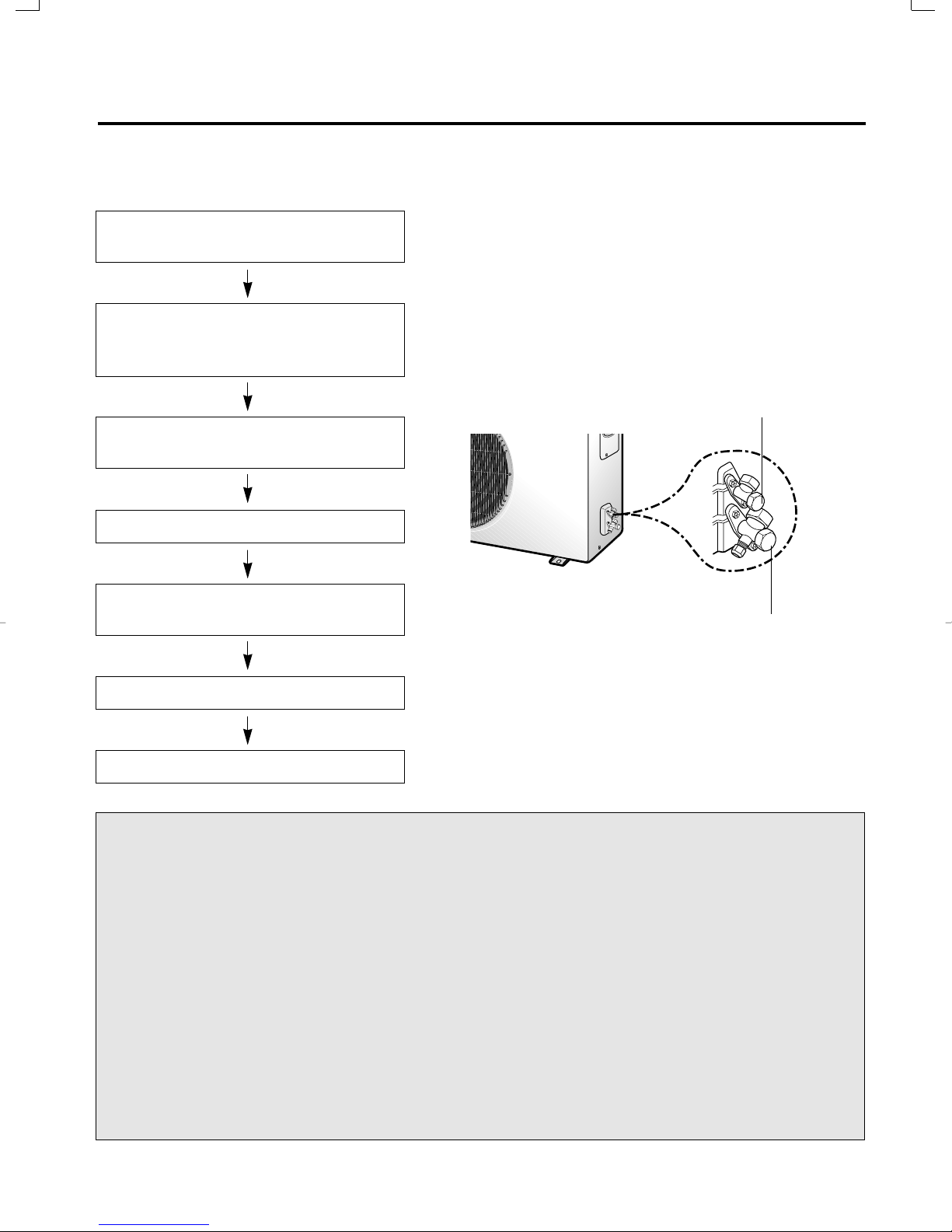

1-2 “Pump down” Procedure

• Pump down shall be carried out when an evaporator is replaced or when the unit is relocated in

another area.

1. Remove the caps from the 2-way valve and the

3-way valve.

2. Turn the 3-way valve clockwise to close and

connect a pressure gauge(low pressure side) to

the service valve, and open the 3-way valve again.

2-Way Valve

3. Set the unit to cool operation mode.

(Check if the compressor is operating.)

4. Turn the 2-way valve clockwise to close.

5. When the pressure gauge indicates "0" turn the

3-way valve clockwise to close.

6. Stop operation of the air conditioner.

7. Close the cap of each valve.

Relocation of the air conditioner

• Refer to this procedure when the unit is

relocated.

1. Carry out the pump down procedure (refer

to the details of 'pump down').

2. Remove the power cable.

3. Disconnect the assembly cable from the

indoor and outdoor units.

4. Remove the flare nut connecting the indoor

unit and the pipe.

At this time, cover the pipe of the indoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

3-Way Valve

5. Disconnect the pipe connected to the outdoor unit.

At this time, cover the valve of the outdoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

6. Make sure you do not bend the connection

pipes in the middle and store together with

the cables.

7. Move the indoor and outdoor units to a new

locatioon.

8. Remove the mounting plate for the indoor

unit and move it to a new location.

2

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

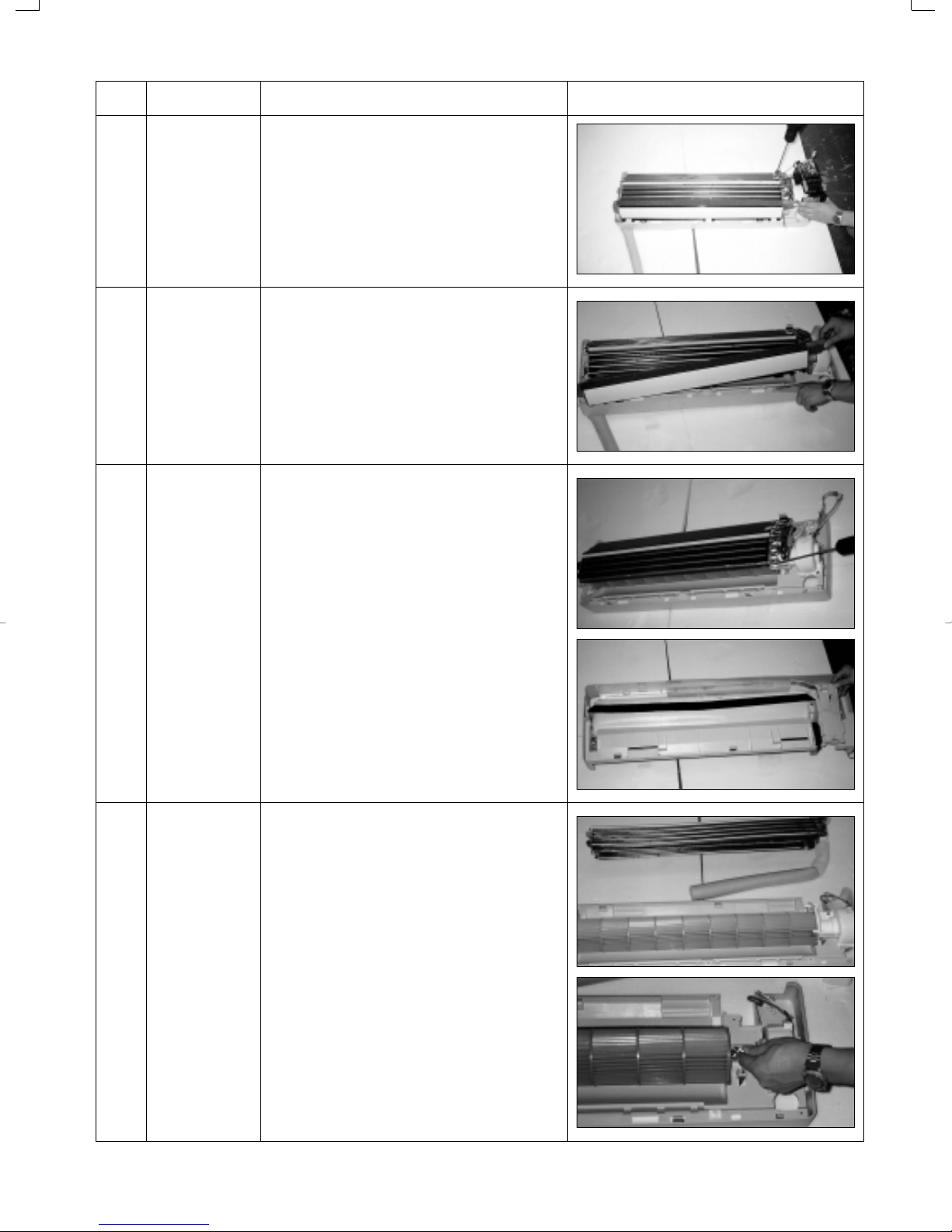

2-1 Indoor Unit

No Parts Procedure Remark

Front Grille1 1) Stop the air conditioner operation and block the

main power.

2) Separate tape of front panel upper.

3) Contract the second finger to the left, and right

handle and pull to open the inlet grille.

4) Take the left and right filter out.

*Taking off the deodorizing filter.

5) Loosen one of the right fixing screw and separate the terminal cover.

6) Loosen three fixing screws of front grille.

7) Pull the upper left and right of discharge softly

for the outside cover to be pulled out.

8) Pull softly the lower part of discharge and push

it up.

Caution;

Assemble the front panel and fix the

hooks of left and right.

3

No Parts Procedure Remark

Electrical Parts

2

(Main PCB)

1) Do “1”above.

2) Take all the connector of PCB upper side out.

(Inclusion Power cord)

3) Separate the outdoor unit connection wire from

the terminal block.

4) If pulling the Main PCB up. it will be taken out.

3

4

Ass’y Tray Drain.

Heat Exchanger

1) Do “1”, “2”, above.

Separate the drain hose from the extension

drain hose.

2) Pull tray drain out from the back body.

1) Do “1” and “2”, “3”, above.

2) Loosen two fixing earth screws of right side.

3) Separate the connection pipe.

4) Separate the holder pipe at the rearside.

5) Loosen the three fixing screws of right and left

side.

6) Lifting the heat exchanger up a little to push the

up side for separation from the indoor unit.

Fan Motor and

5

1) Do “1” “2” ”3” “4”, above.

Cross Fan

2) Loosen the fixing two screws and separate the

motor holder.

3) Loosen the fixing screw of fan motor.

(By use of M3 wrench)

4) Separate the fan motor from the fan.

5) Separate the fan from the left holder bearing.

4

2-2 Outdoor Unit

■ UQ12AA(B)MC

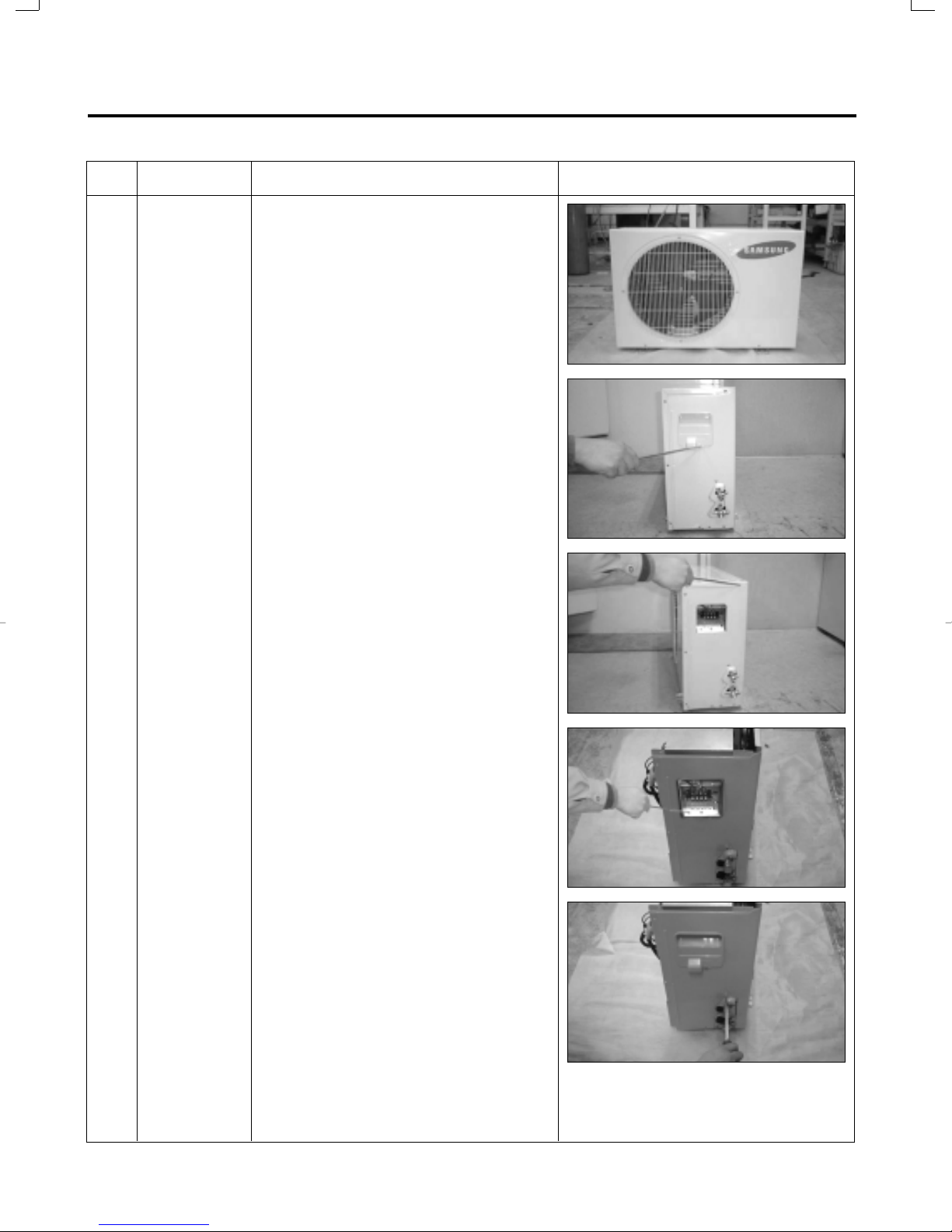

No Parts Procedure Remark

Common Work 1) Loosen the fixing one screws and separate the

1

COVER TERMINAL.

2) Loosen the fixing one screws and seperate the

cover control.

3) Separate the connection wire from the terminal

block.

4) Loosen 13 fixing screws and separate the cabi

front.

5) Loosen the one fixing screw of Ass'y E-part.

6) Loosen 4 fixing screws and separate the cabi

side.

5

No Parts Procedure Remark

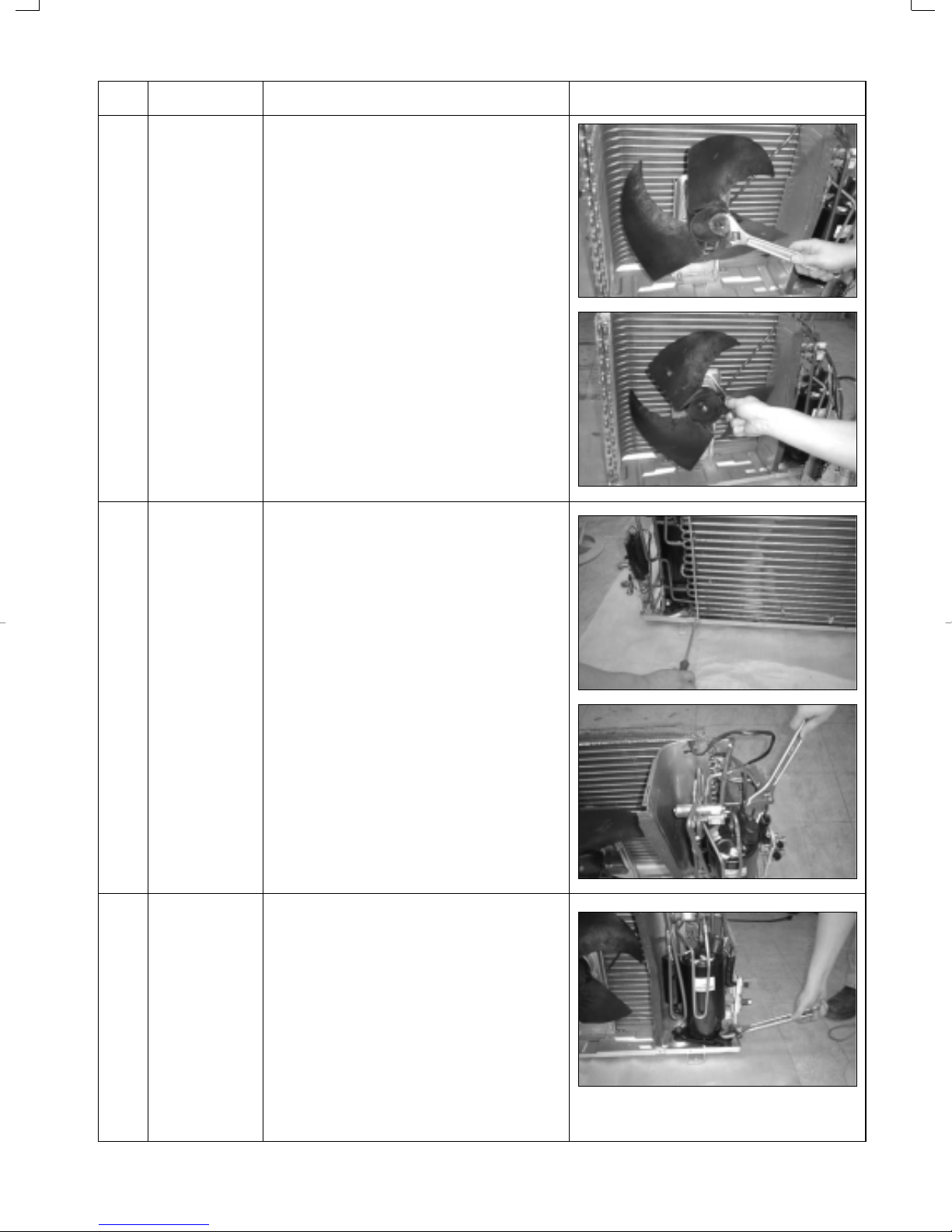

Fan and Motor

2

1) Do “1”, above.

2) Remove the nut flange (Turn to the right to

remove, as it is a left hand screw)

3) Separate the fan.

4) Loosen four fixing screws to separate the motor.

5) Loosen five fixing screws and seperate the

motor bracket from the base.

Heat Exchanger

3

1) Do “1”, “2” above.

2) Loosen two fixing screws of left and right side.

3) Disassemble the inlet and outlet pipe by

welding.

4) Separate the heat exchanger.

4

Compressor

1) Do “1”, “2”, “3” above.

2) Open the terminal cover of compressor and

unscrew the connection terminal.

3) Disassemble the inlet and outlet pipe of compressor by welding.

4) Loosen the three bolts of the lower part.

5) Separate the compressor.

6

3. Troubleshooting

3-1 Items to be checked first

1) The input voltage should be rating voltage ±10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2) Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 6 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of

cables.

Otherwise the airconditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below it is a symptom not related to

the malfunction of the airconditioner.

NO

1 The STD operation indication LED blinks when a

power plug of the indoor unit is plugged in for the first time.

2 In a COOL operation mode, the compressor does not

operate at a room temperature higher than the setting

temperature that the INDOOR FAN should operate.

In a HEAT operation mode, the compressor does not

operate at a room temperature lower than the setting

temperature that indoor fan should operate.

3 Fan speed setting is not allowed in AUTO or DRY mode.

4 Compressor stops operation intermittently in DRY mode.

5 Compressor of the outdoor unit is operating although it is

turned off in a HEAT mode.

6 Timer LED only of the indoor unit lights up and the

air conditioner does not operate.

7 The compressor and indoor fan stop intermittently in HEAT

mode.

8 Indoor fan and outdoor fan stop operation intermittently in

a HEAT mode.

9 The compressor stops intermittently in a COOL mode or DRY

mode, and fan speed of the indoor unit decreases.

Operation of air conditioner

Explanation

It indicates power is on. The LED stops blinking if the operation

ON/OFF button on the remote control unit is pushed.

In happens after a delay of 3 minutes when the compressor is reoperated. The same phenomenon occurs when a power is on.

As a phenomenon that the compressor is reoperated after a delay of

3 minutes, the indoor fan is adjusted automatically with reference

to a temperature of the air blew.

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

When the unit is turned off while de-ice is activated, the compressor

continues operation for up to 9 minutes (maximum) until the deice is

completed.

Timer is being activated and the unit is in ready mode.

The unit operates normally if the timer operation is cancelled.

The compressor and indoor fan stop intermittently if room temperature exceeds a setting temperature in order to protect the compressor from overheated air in a HEAT mode.

The compressor operates in a reverse cycle to remove exterior ice in

a HEAT mode, and indoor fan and outdoor fan do not operate intermittently for within 20% of the total heater operation

The compressor stops intermittently or the fan speed of the indoor

unit decreases to prevent inside/outside air frozen depending on the

inside/outside air temperature.

4) Indoor unit observes operation condition of the air conditioner, and displays self diagnosis

details on the display panel.

NO

1 STD LED blinking (1Hz)

2 TIMER LED blinking (1Hz)

3 STD and TIMER LED blinking (1Hz)

4 NATURE LED blinking (1Hz)

Display

Self Diagnosis

Restore from power failure (input initial power)

Indoor unit Room sensor Error (open or short)

Indoor unit heat exchanger temperature sensor Error (open or short)

Indoor fan malfunctioning (for spead is Below 450rpm)

7

Loading...

Loading...