Samsung APH180HD, APH180CD, APH180ED Service Manual

SERVICE

Manual

APH180HD/ED/CD

CONTENTSAIR CONDITIONER

1 . P re c a u t i o n s

2 . P roduct Specifications

3 . Operating Instru c t i o n s

4 . Disassembly and Reassembly

5 . Tro u b l e s h o o t i n g

6 . Exploded Views and Parts List

7 . Block Diagrams

8 . PCB Diagrams

9 . Wiring Diagrams

1 0 . Schematic Diagrams

PACKAGED AIR CONDITIONER

1) Turn off the the power.

Be sure to turn off the power before attempting to repair the

unit such as the disassembly of the unit.

2) Be careful of electric shock

When checking the circuit with the power connected in

unavoidable circumstances, take special care not to touch the

live parts. There is a danger of electric shock.

3) Use of appropriate parts

Be sure to use the genuine parts of the relevant model when

it is necessary to replace parts. (Replace parts instead of

repairing with regard to the malfunctioning of electric contact

areas. Never attempt to modify the unit. It is extremely dangerous for the consumer to attempt to repair the unit on

his(her) own.)

4) Use of proper tools

Use appropriate tools for repair, and use measuring equipment after accurate calibration. Using worn tools may result

in problems, including poor contact and poor connection.

5) Avoid damage to electric wire or electric cord.

Check the electric cord or electric wire for any damage during

repair.

Be sure to replace it if damaged.

6) Avoid intermediate connection of the electric cord.

Never attempt to make an intermediate connection by cutting

the middle area of the electric cord or make a connection to

the power receptacle as it is very dangerous, causing problems or fire.

7) Checking of insulation

Be sure to check the insulation resistance after completion of

the assembly work.

(Check whether the insulation resistance of the electric wire

and grounding terminal is over 30MΩ by using the insulation

resistance tester, and then connect the power source.)

8) Checking of grounding

Check the grounding condition, and perform repair if poorly

grounded.

9) Checking of installation condition

Check the installation condition of the unit, and perform

repair if there is any defective area.

If the unit remains in an unstable installing condition, install

it at a new site.

10) Be careful of children

As the repair of the unit involves a lot of dangerous elements,

do not allow children to approach nearby during repair work.

Samsung Electronics

1-1

1. Precautions

Turn off the sub power switch separately installed.

No connection with the power receptacle

Upon completion of the repair, clean the air

conditioner and surrounding area, and

inform the customer of completion of the repair.

Cleaning

Samsung Electronics

2-1

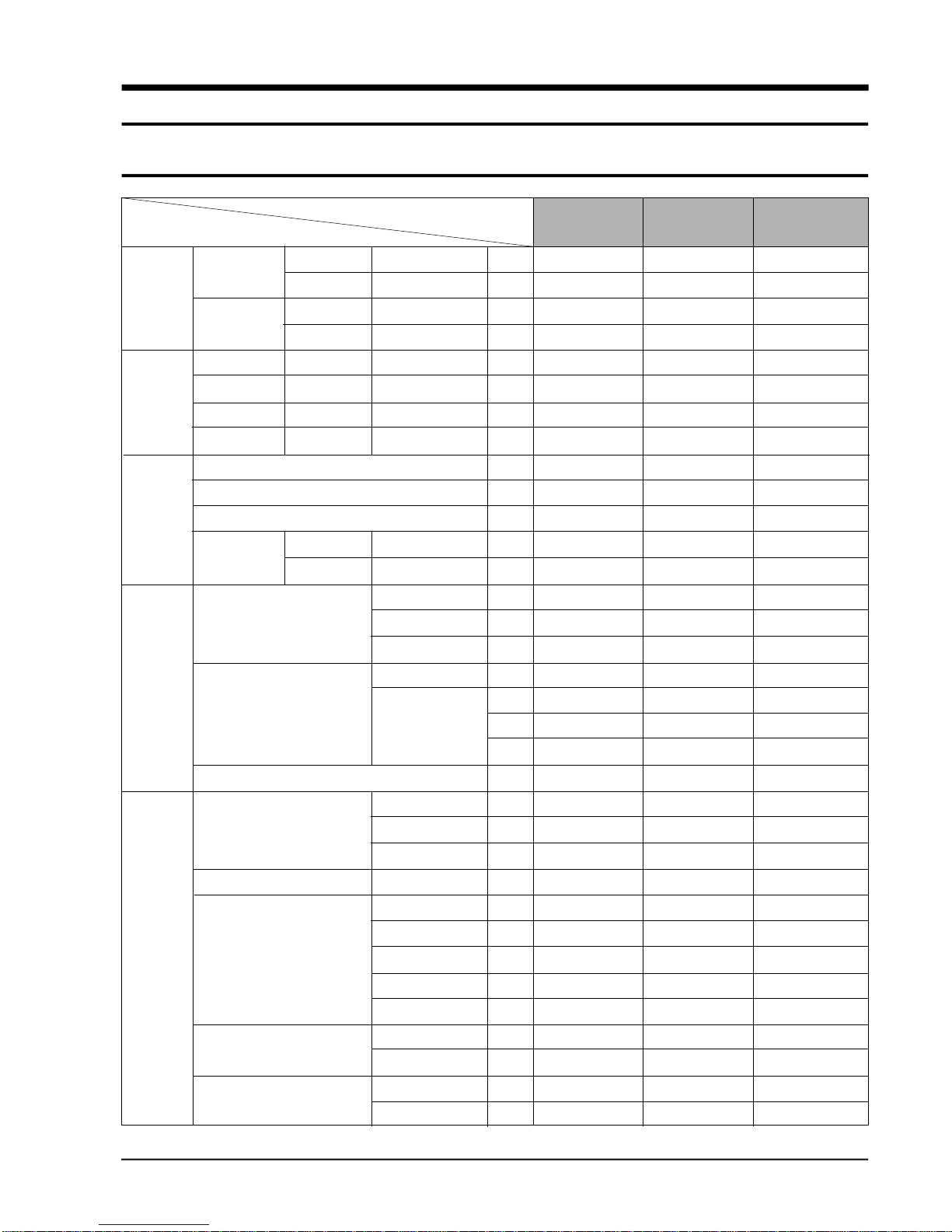

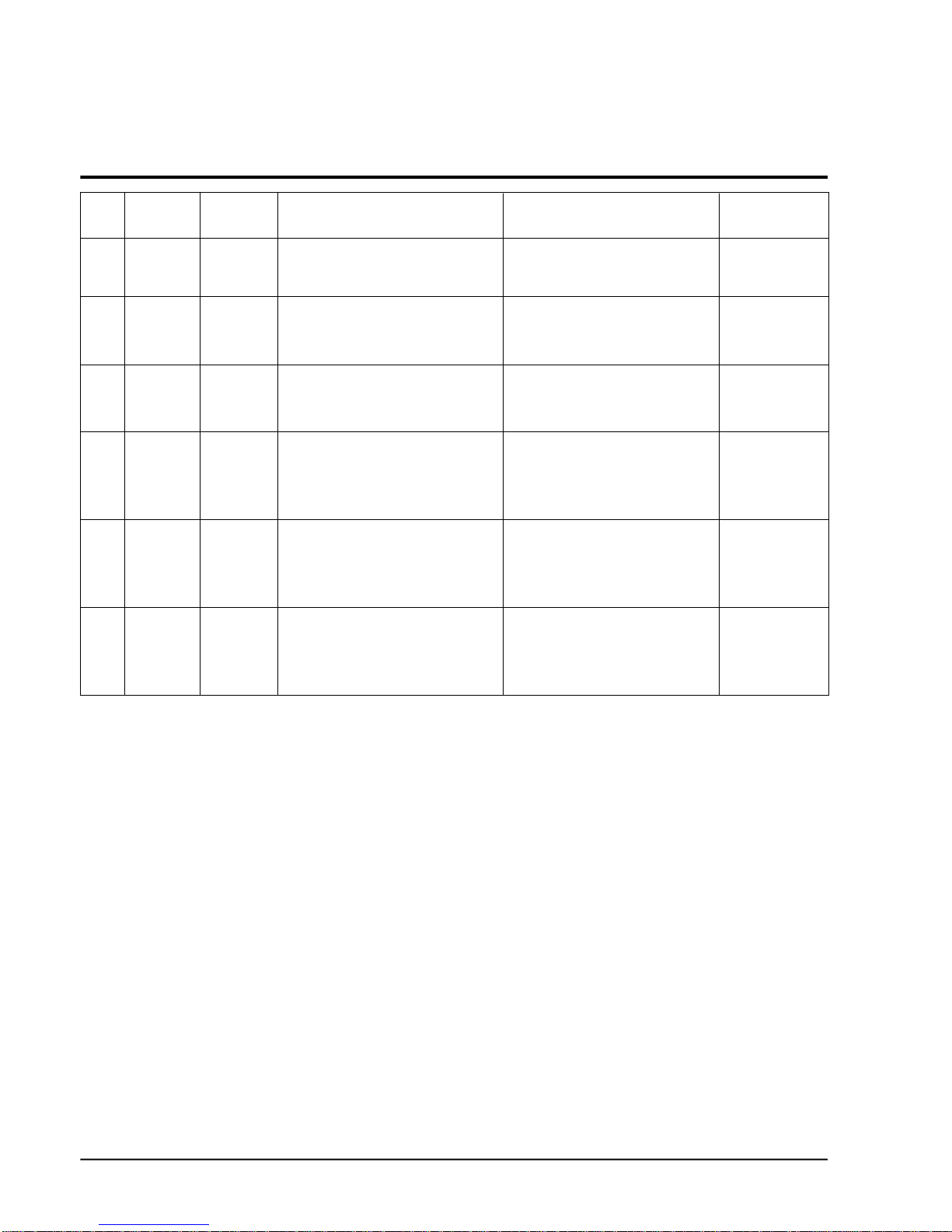

2. Product Specifications

2-1 Table

Model

Item

Unit Width x Height x Depth mm

Packed Width x Height x Depth mm

Unit Width x Height x Depth mm

Packed Width x Height x Depth mm

Unit kg

Packed kg

Unit kg

Packed kg

1. Capacity(Cooling /Heating) W

2. Power consumption(Cooling/Heating) W

3. Current consuption(Cooling/Heating) A

4. Noise Indoor unit High dBA

(Cooling/Heating) Outdoor unit dBA

1. Evaporator Construction Row x Step

Fin

Capillary tube

2. Blower motor Capacitor

RPM HIgh

Medium

Low

3. Fuse V/A

1. Condenser Construction Row x Step

Fin

Capillary tube

2. Refrigerant volume R22 g

3. Compressor Maker

Model

Type

Capacitor

Crankcase heater W

4. Fan motor Capacitor

RPM

5. Service v/v High pressure side inch

Low pressure side inch

APH180HD APH180ED APH180CD

500 x 1700 x 330 500 x 1700 x 330 500 x 1700 x 330

590 x 1785 x 465 590 x 1785 x 465 590 x 1785 x 465

765 x 532 x 280 765 x 532 x 280 765 x 532 x 280

884 x 593 x 380 884 x 593 x 380 884 x 593 x 380

35 38 35

41 44 41

40 40 38

46 46 44

4700/5600 4700/6400 4700

1900/1900 1900/2700 1900

9.5/9.5 9.5/14 9.5

45 45 45

55 55 55

2x24 2x24 2x24

WAVE 1.4 WAVE 1.4 WAVE 1.4

ø1.3x3 ø1.3x3 ø1.3x3

450V/4.0uF 450V/4.0uF 450V/4.5uF

500 500 530

450 450 480

400 400 430

250V 3.15A 250V 3.15A 250V 3.15A

2x20 2x20 2x20

D5 1.7 D5 1.7 D5 1.7

Ø2.0x1 Ø2.0x1 Ø2.0x1

1,450 1,450 1,200

SAMSUNG SAMSUNG SAMSUNG

48B 180MV 1E7 48B 180MV 1E7 48B 180MV 1E7

ROTARY ROTARY ROTARY

420V/45uF 420V/45uF 420V/45uF

40 40 -

450V/2.5uF 450V/2.5uF 450V/2.5uF

1050 1050 1050

3/8 3/8 1/4

1/2 1/2 1/2

Size

Weight

Indoor unit

Outdoor unit

Outdoor unit

Indoor unit

Electric

characteristics

Indoor unit

Outdoor unit

2-2

Samsung Electronics

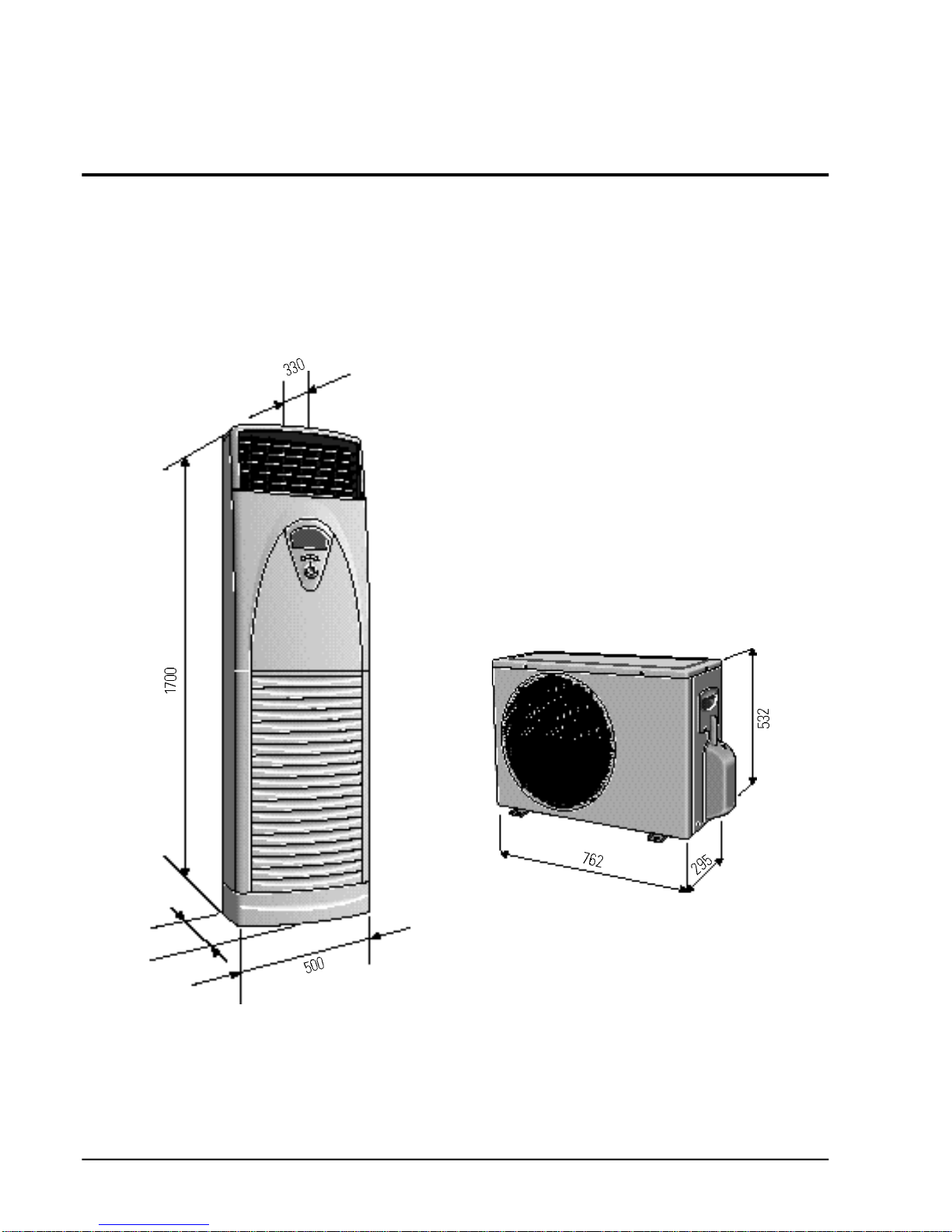

2-2 Dimensions

Indoor Unit

Outdoor Unit

unit : mm

330

Samsung Electronics

3-1

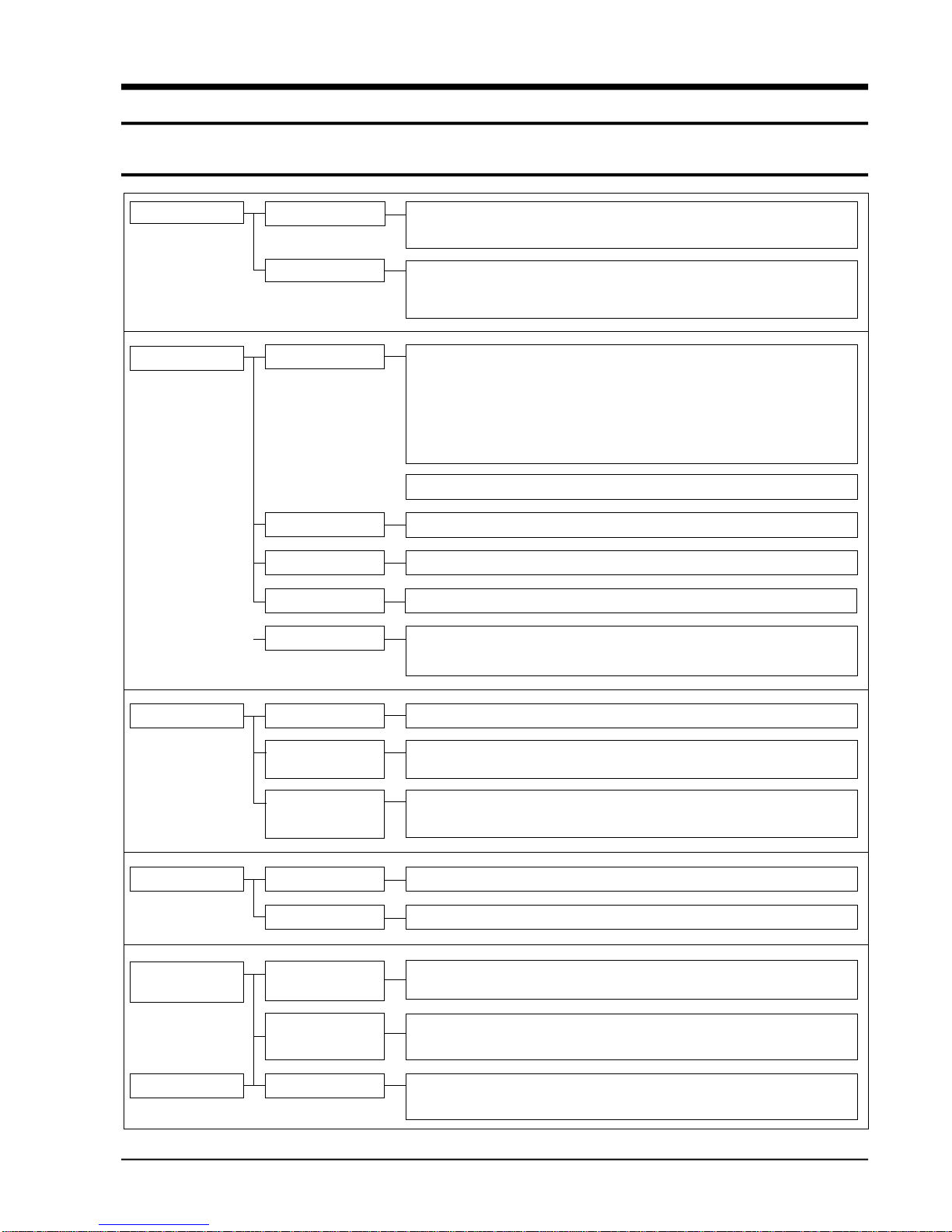

3. Operating Instructions

3-1 Control System Chart

Operation Mode

Operation selector mode

Fan speed selector mode

A i rflow selector mode

R e s e rvation operation

m o d e

Convenience function

Main switch operation

Remote control operation

Auto

Cooling operation

Dry operation

Heating operstion

Manual 3-step

Natural

Auto

Left/Right turn

UP/Down Turn

Start time

reservation

Stop time

reservation

Brief reservation

Operation/stop, operation selection, blow volme selection, turbo, temperature

control

Start/stop, operation selection, fan speed selection, turbo, temperature control, reservation operation, sleeping operation, left/light turning, up/down

turning, turbo/remote

Indoor temperature control according to the set temperature.

Indoor temperature control accoding to the set temperature(18°C<->30°C)

Decide the dry cydle by the difference in room temperature(18

°C-30°C)

Indoor temperature control according to the set temperature(16

°C<->30°C)

APH180HD/180ED=(0), APH180CD=(X)

High, Medium, Low(slectable at the cool and fan mode)

The hige, midium, low wind is automaticallly changed by CHAOS calculation.

In automatically operating, it is fixed with natural wind.

The automatic fan control according to the difference between the indoor and

the set temperatures.

Selectable only by the remote control and turn and turn/stop are possible only.

Selectable only by the remote control and turn and turn/stop are possible only.

Selectable only by the remote control and the time of operation ON is set..

Selectable only by the remote control and the time of operation OFF is set..

Selectable only by eremote control and the off reservation function is performed

after 30 minutes, 1,2,3 and 5 hours.

Cooling and heating control according to the set temperature

Room temperture≥21°C±2°C(remocon input)=cooling operation

Desired temperature=24°C±2°C

Room temperature<21°C±2°C(remocon input)=heating operation

Desired temperature=22°C±2°C

Fan operstion Operation of the indoor fan moter only(High, midium, low)

Operating Instructions

3-2

Samsung Electronics

Convenience

function

Long operation

Sleeping operation

The set temperature is set to the standard-1

°C and the fan speed is set to

turbo wind, and up and down rotating blades are positioned upward.

During the initial 1hour of the sleeping selection, when the indoor temperature reaches the set temperature +1

°C, the compressor is on and off at theset

temperature.

It is on at the set temperature +2°C between 1hour and 2hours and off at the set

temperature +1°C.

After 2 hours, it is on at the temperature +3°C and off at the set temperation +2°C.

When 6hours pass after selection of sleeping operation, it stops.

Self diagnosis

function

“E 1” Displayed at the indoor temperature sensor operates abnormally.

“E 2” Displayed at the auto shutter operates abnormally.

“E 5” Displayed at the indoor evaporator temperature sensor operates abnormally.

“E 6” Displayed at the outdoor condensor temperature sensor operates abnormally.

“E 7” Displayed at the electric heater temperature sensor operates abnormally.

“ E C ” Displayed at the electric heater is overheated.

3-3

Samsung Electronics

3-2 Key Types and Functions

KEY

Operation and stop of operation

- Start durning turn on once, and stop durning turn on again

- Continous operation is impossible

Change of the operation mode

-Each one every turn on,

"AUTO" → "COOL" → "DRY" → "FAN" → "HEAT"is selected sequentially.

(standard = auto)

- continued operation is impossible.

The indoor fan motor speed is set.

-Cooling operation

Each one every turn on,

"LOW" → "MEDIUM" → "HIGH" → "AUTO" is selected sequentially. (standard = auto)

- In fan operation

"LOW" → "MEDIUM" → "HIGH" is selected sequentially. (standard = Low)

- In auto and dry operation, the fan speed is selscted with "Auto" or "Natural" so that the

key input is ignored.

- Continuous operation is impossible.

The set temperature is increased.

-Temperature:the set temperature is increased 1˚C each one every turn on.

Cooling operation:18˚C → 30˚C

Heating operation:16˚C → 30˚C

-The key operate only when the heat, cool, dry operation.

-One time and continuous operation is possible.

The set temperature is drcreased.

-Temperature:the set temperature is decreased 1˚C each one every turn on.

Cooling operation: 30˚C →18˚C

Heating operation:30˚C → 16˚C

-The key operate only when the heat, cool, dry operation.

-One time and continuous operation is possible.

Turbo function is on and off.

-Selectable all over operation mode.

-Continuous operation is impossible.

Temperature

setting

(decreasing)

Turbo

KEY NAME

Operation/

stop

Operation

selection

Fan speed

Temperature

setting

(increasing)

TACT

H e a t = A P H 1 8 0 C D ( X )

TACT

TACT

TACT

H e a t = A P H 1 8 0 C D ( X )

TACT

TACT

H e a t = A P H 1 8 0 C D ( X )

Kinds of Key

3-4

Samsung Electronics

3-3 Check and Test Operation

•

Be sure to check the following again after completion of installation.

•

After checking, read the owner's instructions care f u l l y, and perform a test operation.

Then deliver the unit to the customer.

(When delivering the unit, be sure to read carefully and follow the contents of the owner's

i n s t ru c t i o n s . )

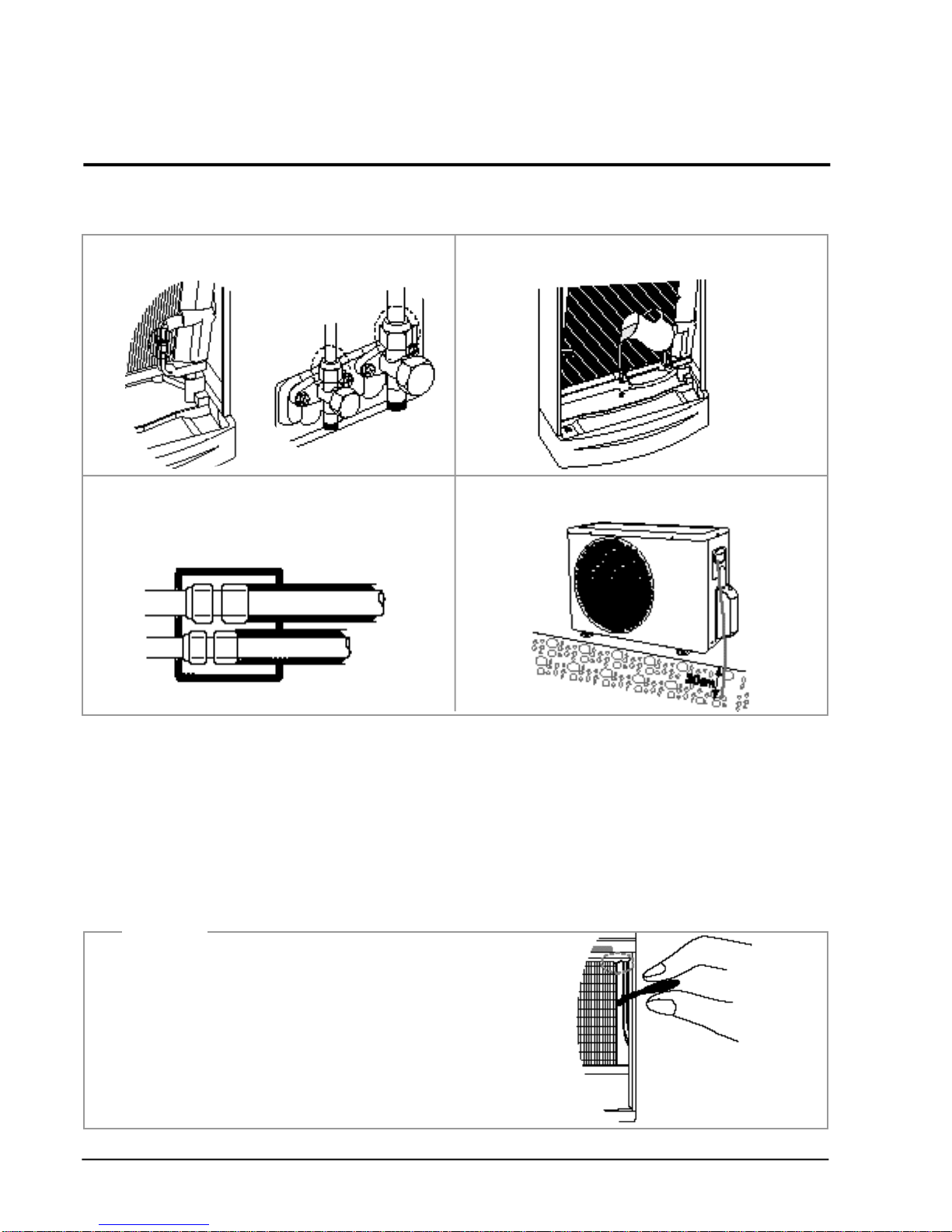

3-2-4(b) Test Operation

1. Be sure to check whether the service valve is opened before attempting to

perform the test operation.

2. Never attempt to start test operation by force pressing the electronic contactor

as it is very dangerous.

(This is very dangerous as the protective device does not work.)

3. Be sure to perform the test operation after installment.

It is easy to start the test operation in winter if you increase the sensor

temperature to 23°C ~25°C by holding the indoor temperature sensor (Cooling

operation)

Caution

Outdoor connection area

Indoor connection area

1. Check the piping connection area for any gas leakage.

3. Is the insulation of the piping in good condition? 4. Is grounding properly made?

(In case of disconnecting ground on electric panel board.)

Insulation

2. Is the drain hose properly connected?

Temperature

Sensor

Samsung Electronics

4-1

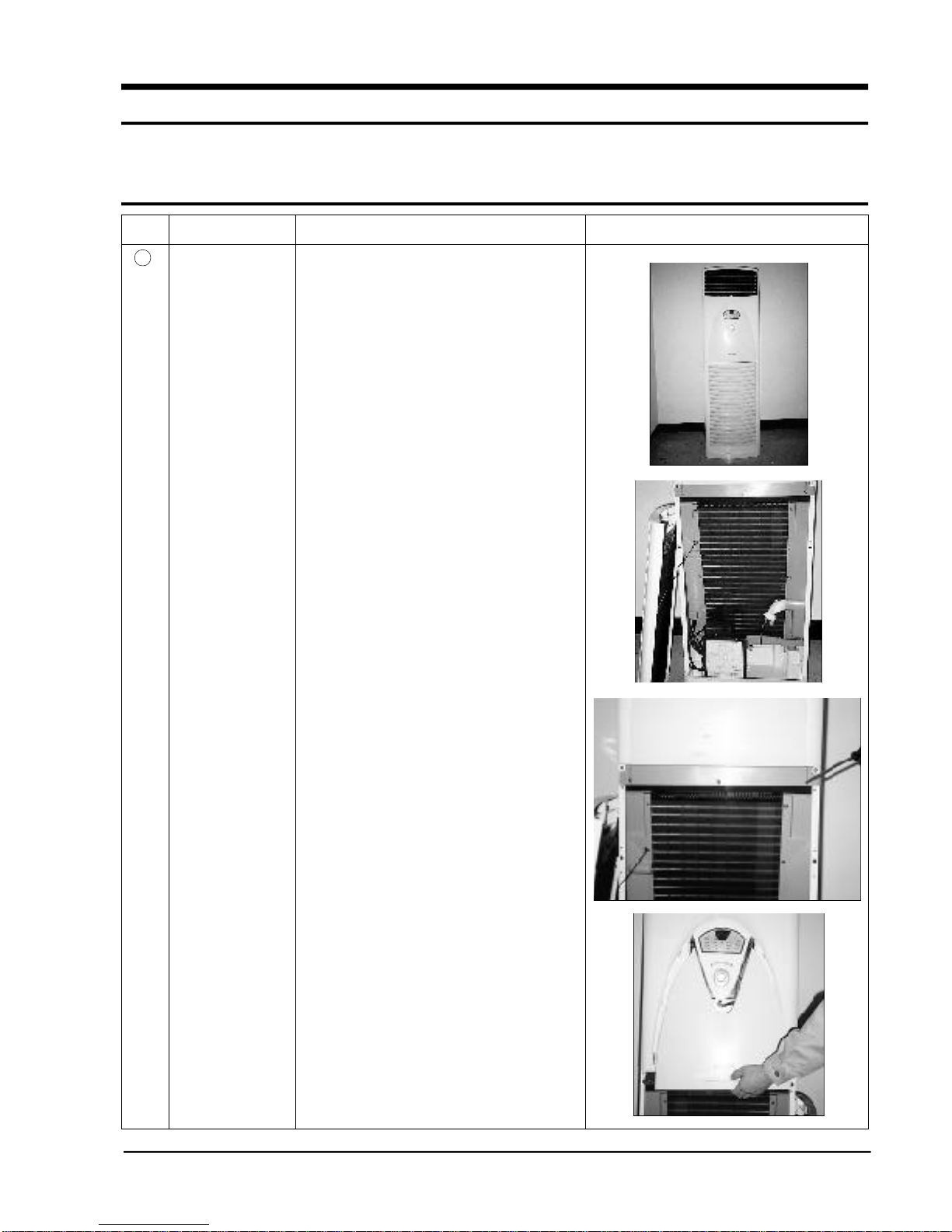

4. Disassembly and Reassembly

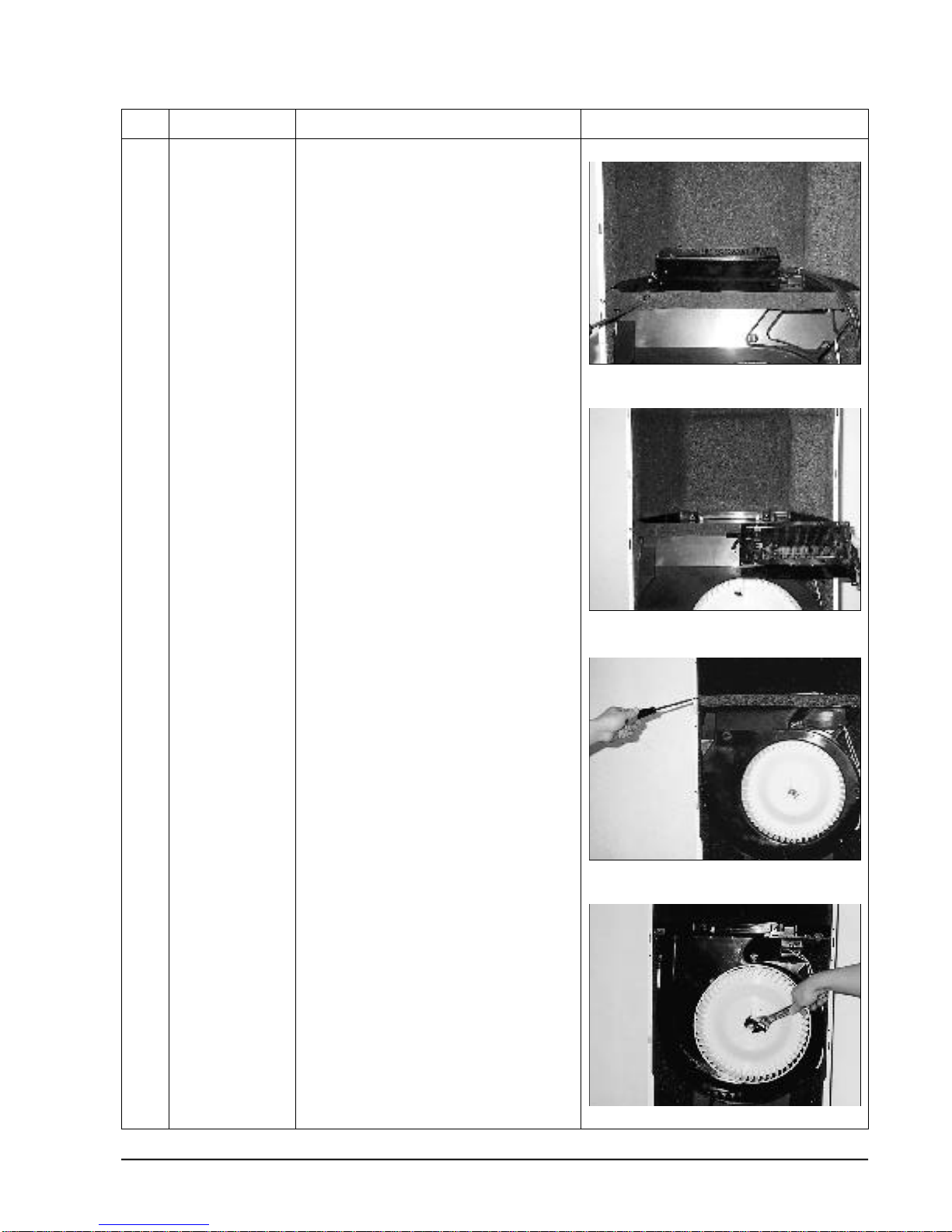

4-1 Indoor Unit

Stop operation of the air conditioner and remove the power before repairing the unit.

No Parts Procedure Remark

1 Front Grille

1) Packaged air conditioner indoor unit.

2) Open the inlet grille, and remove the

connector ring.

3) Loosen nine screws to remove the cover

connect and cover evap’L.

4) Loosen one screws and pull the

downward.

Disassembly and Reassembly

4-2

Samsung Electronics

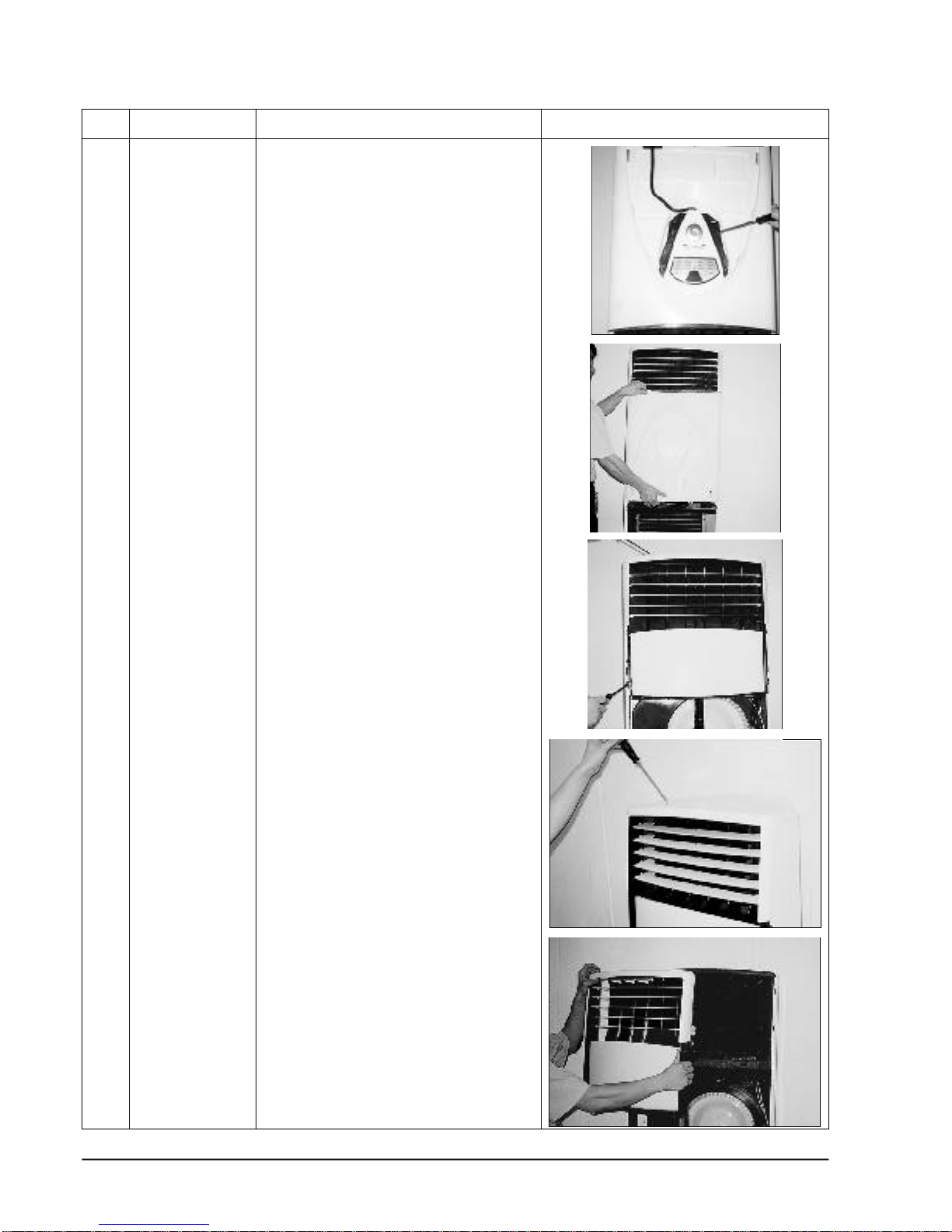

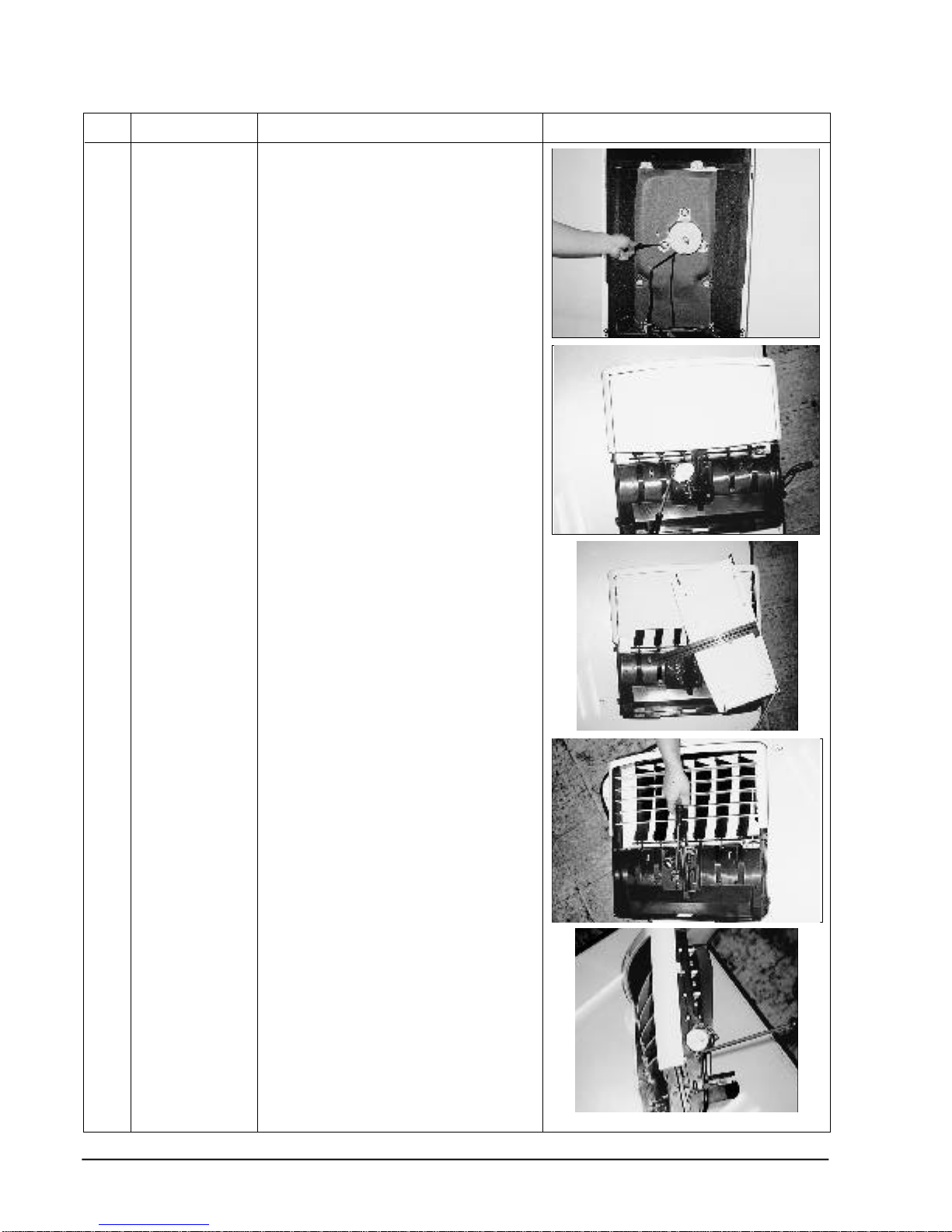

No Parts Procedure Remark

5) To remove the Deco Low, remove the right

and left side two screws, and then seperate the wire connector.

6) Remove the four screws, and remove the

cover top. Then seperate the connector

wire

7) Remove the six screws, and pull the

upward cover top PCB.

Disassembly and Reassembly

4-3

Samsung Electronics

No Parts Procedure Remark

8) Loosen the right and left side two screws,

and then push the upward cover front.

9) Remove the five screws,and then remove

the seven screws on the Duct up.

Disassembly and Reassembly

4-4

Samsung Electronics

No Parts Procedure Remark

10) Loosen one bolt to remove the blower.

11) Loosen the five locking screws, and

remove the lower duct on the front side.

Remove the left and right side two screws,

and the upper side two screws.

And then seperate the shutter body

4-5

Samsung Electronics

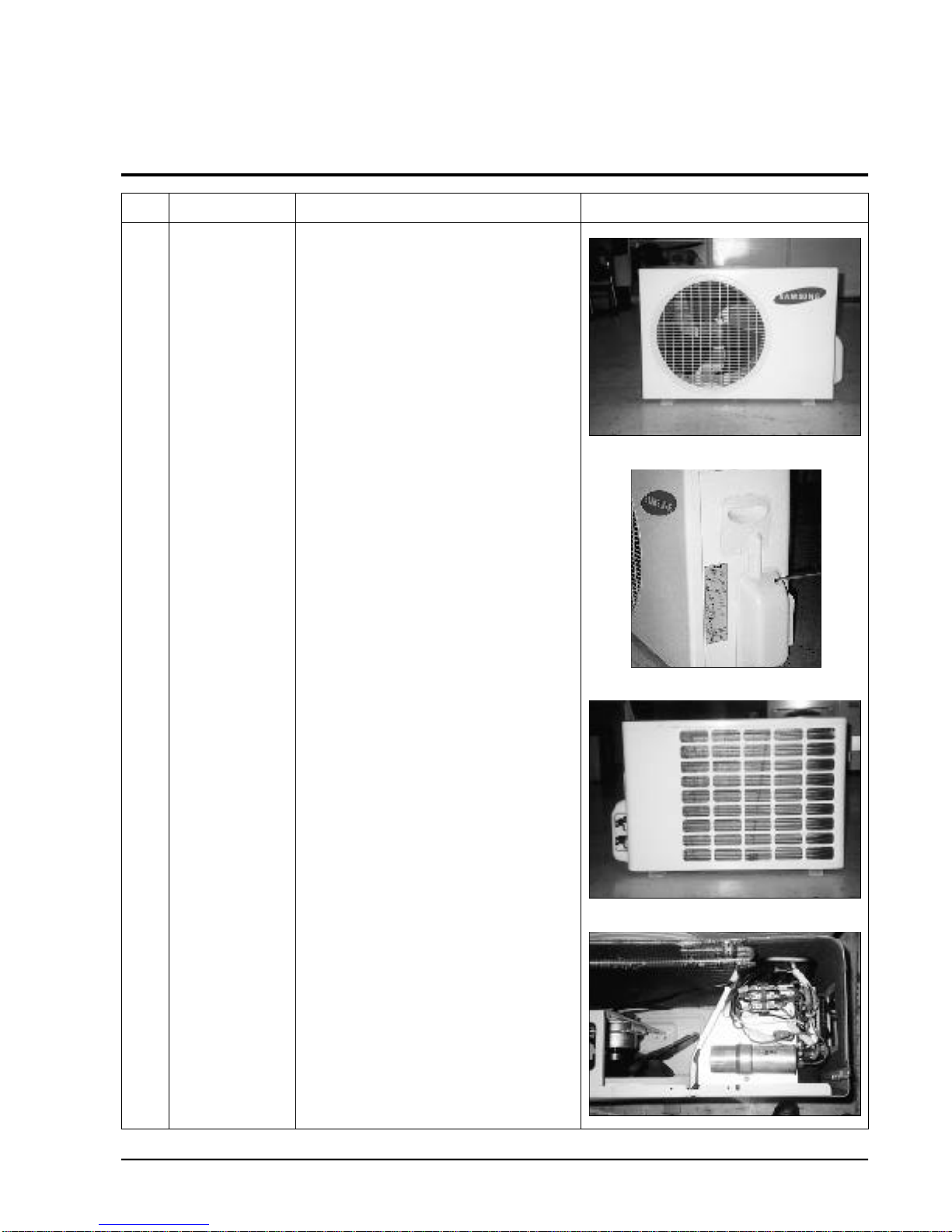

4-2 Outdoor Unit

No Parts Procedure Remark

1) Loosen the seven screws on the cover top,

and remove the cover top.

2) Loosen the two screws on the cover

control, and remove the cover control.

3) Loosen the six screws in the side cabinet,

and remove the side cabinet.

4) Connection of the control box wiring.

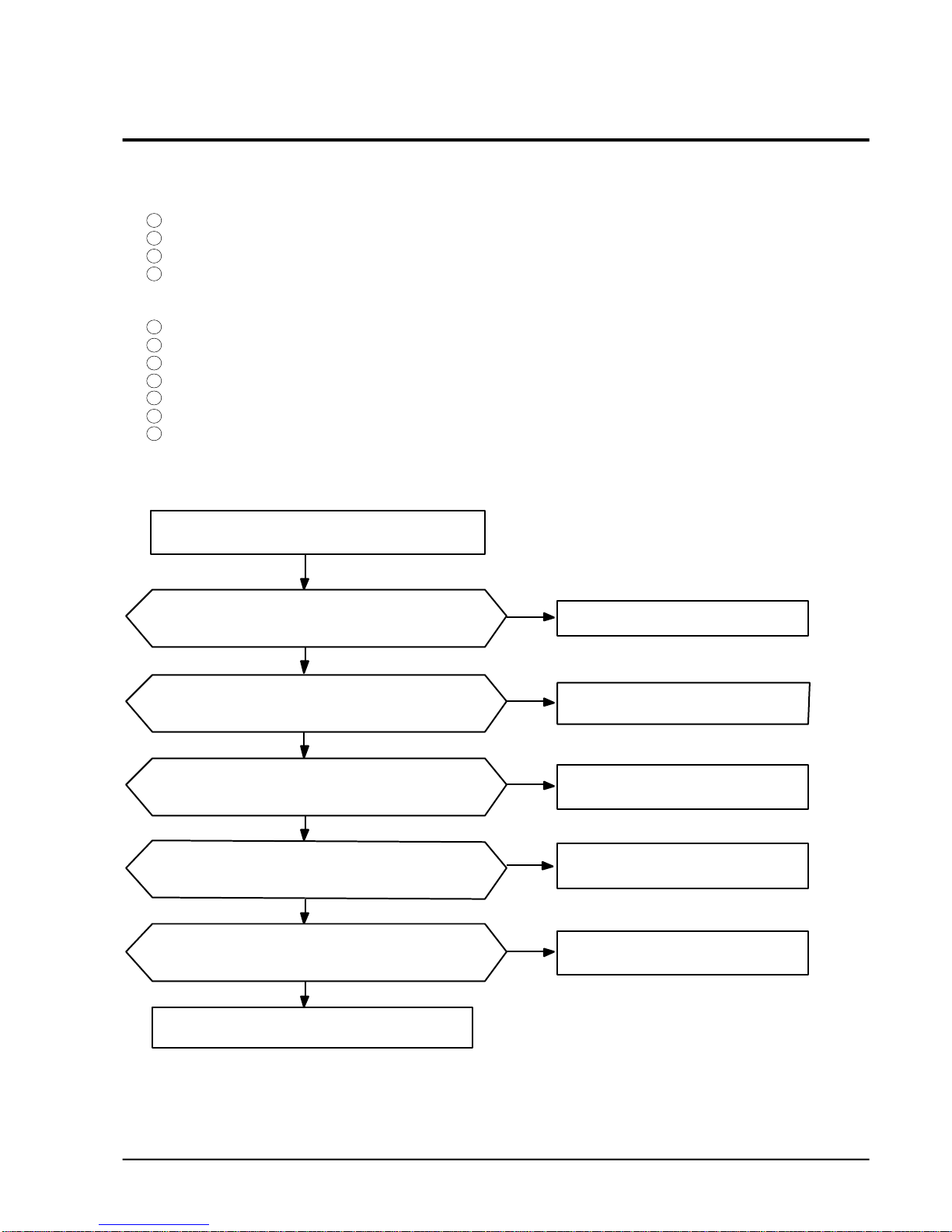

Troubleshooting pro c e d u re s

1 • Check the items to check first time.

2 • Check the self-diagnostic mode and action method.

3 •

Check in detail the troubled parts according to the sequence of ”trouble shooting by the phenomena”.

Samsung Electronics

5-1

5. Troubleshooting

5-1 The items to be checked first time

1) Is proper the power voltage ?

The power voltage shall be of 187V-253V 50Hz.

2) Is the cable connected correctly between the indoor and outdoor unit?

The indoor and outdoor units shall be connected with 8wires including the gro u n d i n g .

Check whether the wires of indoor and outdoor units are connected with the correct wire no. and

terminal board no.

3) The phenomena in the following table is not related to the fault of air conditioner.

No

1

2

3

4

5

6

7

- Durning the heating, the compressor and outdoor

unit fan motor operate but indoor unit fan motor

does not operate.

- Durning the heating, the outdoor unit fan motor

repeats start/stop or even the compressor repeats

the starts the start snd stop.

- Durning the heating operation, the lamp “on deice”

is on at the control panel and the compressor

oprates.

-The compressor repeates the stop and start with the

interval of several minutes durning dry.

- The temperature is not adjusted durning the auto,

dry, turbo and long and fan operation.

- Fan speed is not adjusted durning the auto, dry, turbo

and long operation.

-

Heating operaation

The compressor does not operated even though the set

t e m p e r a t u re is set higher than the indoor temperature.

-

Cooling operation

The compressor does not operated even though the set

t e m p e r a t u re is set lower than the indoor temperature .

Phenomena

-This is the function to prevent the cooling air incoming to the

indoor, where the temperature of indoor evaporator reaches 27°C,

the indoor fan motor operates.

- It is the function to prevent the overheating of the indoor

evapolator, where the temperature of indoor unit heat exchanger

reaches 52°C, the normal operation is done.

- The deice operation is being performed in order to melt the frost

by outdoor unit and its maximum time is 9 minutes.

- At the dry operation, the set temperature and the indoor

temperature are compared to adjust the compressor start/stop

time in order to dehumidify.

- The set temperature is automatically set durning the auto, dry

and long operation.

- The wind blow operation is the mode to circulate the indoor air.

-

The fan speed is automatically adjusted durning the auto, dry,

turo and long operation.

-

The operation of compressor is delayed for 3minutes for the

protection of compressor when it is off and on again.

- The compressor operates nomally after 3 minutes even the lnitial

power is on.

Description

Samsung Electronics

5-2

5-2 Display of the result of self-diagnostic and check items on the control panel

1

2

3

4

5

6

Flickering

(1Hz)

Flickering

(1Hz)

Flickering

(1Hz)

Flickering

(1Hz)

Flickering

(1Hz)

Flickering

(1Hz)

Power

lamp

No.

Te m p e r a t u re

d i s p l a y

Cause Counter measure Remark

E1

E2

E5

E6

E7

EC

- Indoor temperature sensor open

- Indoor temperature sensor short

- Shutter motor defect

- Shutter sensor defact

- Connector wire contact bad

- Indoor evaporator sensor open

- Indoor evaporator sensor short

- Indoor condensor sensor open

- Indoor condensor sensor short

- Connector wire contact bad

- Electric heater sensor open

- Electric heater sensor short

- Electric heater overheated

- Indoor fan motor stocked

- Indoor fan motor fault

“E1”AND “E2” ARE DISPLAYED ON THE TEMPERATURE DISPLAY ONLY WHEN THE OPERATION STOPS.

- Check short/open of PCB parts

- Replacement of temperature sensor

- Replacement of shutter motor

- Replacement of shutter sensor

- Replacement of connector wire

- Check short/open of PCB parts

- Replacement of temperature sensor

- Check short/open of PCB parts

- Replacement of temperature sensor

- Check the overheating sensor

- Remove the cause of the indoor fan

motor stocking

- Replacement of indoor fan motor

- Check short/open of PCB parts

- Replacement of sensor

- Replacement of connector wire

APH180CD

APH180HD

APH180ED

APH180CD

APH180HD

APH180ED

APH180HD

APH180ED

APH180HD

APH180ED

APH180ED

APH180ED

Samsung Electronics

5-3

5-3 Trouble shooting by phenomena

5-3-1 When it is not Power on.(When it is not display)

1) Trouble cause

1 When the power voltage is out the operating range or the power cable contact is bad.

2 The transformer is defect or it’s connection is bad.

3 The fuse of main PCB is broken or the PCB with a defect.

4 The panel PCB has it’s defect.

• The knob switch with a poor assembly, V.F-display defect.

2) Check items

1 Is the power voltage normal?(AC 187V~AC 253V)

2 Is the contact of power cable good?

3 Is the power fuse(F701, F702) AND PCB fuse(F101)not disconnected?

4 Is the contact of connector at primary and secondary side of power transformer?

5 Is the output voltage of IC08(KA7812) normal?(DC 11.5~DC 12.5V)

6 Is the output voltage of IC09(KA7805) normal?(DC 4.5~DC 5.5V)

7 Is the connection of harness(wire connector- c o n t rol)of main PCB panel good?

3) Sequence of check

Tu rn off the power, and then turn it on in 5 seconds.

Is the display part on dose the door operate

when pressing the start key?

Is the voltage of the power input part(CN71 red-white)

AC 187~AC 253V?

Is the output voltage of IC08, and IC09 normal?

(IC08=12V, RIC09=5V)

Is the secondary voltage of power transformer correct?

blue-white:AC14~17V,red-red:AC4~5V black-white:AC14~17V

Dose the remocon receive the singnal correctly?

Normal operation of set.

Y

N

N

N

N

N

Y

Y

Y

N

Check the connection harness of indoor and

replace.

Check the power trancsfornmer and replace it.

Check the main PBC and replace it.

Check the knob key.

Replace it due to the defact of main PCB.

Loading...

Loading...