Samsung AG042KSVANH, AG056KSVANH, AG070KSVANH Installation Manual

DVM CHILLER

Installation manual

AG042KSV✴✴✴ / AG056KSV✴✴✴ / AG070KSV✴✴✴ Series

ŷ Thank you for purchasing this Samsung Product.

ŷ Before operating this unit, please read this Insatallation manual carefully and retain it for future

reference.

2

English

Contents

INSTALLATION

Safety information 3

Preparing for installation 8

Specications of the non-pump models 8

Specications of the pump integrated models 9

DVM CHILLER Classication 10

Moving the product 10

Center location 11

Accessories (Basic specication) 11

Field Supply 11

Selecting installation location 12

Required space for installation 14

Base construction and installation 16

Supporting base construction 16

Product installation 17

Base mount and anchor bolt position 17

Examples of draining work 17

Installation precautions 18

Installing the wind/snow prevention duct 20

Installing the discharge duct around the obstacles 20

Installing the discharge duct in cold regions 20

Installing the discharge duct in regions with strong wind 21

Water pipe installation 22

Water pipe diagram 22

Water pipe installation 23

Securing water storage 26

Water pipe installation 26

Startup 27

Maintenance 27

Using the pump 27

Pump performance chart 28

Fault nding 29

ELECTRICAL WORK

Electrical wiring work 31

Circuit breaker and power cable specication 31

Power and communication cable conguration 32

Connecting the power cable 33

Connecting the communication cable 34

External contact wiring work 34

Selecting solderless ring terminal 40

Connecting the power terminal 41

Fixing the power cable 43

Fixing the ground cable 43

Withdrawing the power cable 44

Installing the Solution device 44

Grounding work 44

Setting key function 46

Setting hydro controller option 46

How to set hydro controller option 49

Setting inverter controller option 55

BEFORE OPERATION

Check points after installation 61

Trial operation 62

Trial operation for each CHILLER unit 63

MAINTENANCE

Maintenance 65

Name of the parts 65

Water pipe installation 66

Water maintenance standard 68

Maintaining plate type heat exchanger 70

Stopping during winter time 71

Stopping for a long time 71

Inspection for normal operation 72

Chilled/Heating water ow rate range 72

Chilled water management 73

Water temperature range 74

Freeze prevention 74

Error display 77

Error history display 80

Air tightness test and vacuuming 80

Important information regulation regarding the refrigerant used 81

Troubleshooting 83

Periodic maintenance 85

Quick Smart Features 88

COMMISSION REGULATION (EU) No 813/2013 I) 90

ECODESIGN REQUIREMENTS FOR SPACE HEATER

II)

90

COMMISSION DELEGATED REGULATION (EU) No 811/2013

i)

105

PRODUCT FICHE (ENERGY LABELLING OF SPACE HEATERS)

ii)

105

PRODUCT FICHE (ENERGY LABELLING OF PACKAGES OF SPACE HEATER)

iii)

105

PRODUCT FICHE (ENERGY LABELLING OF TEMPERATURE CONTROLS)

iv)

105

PRODUCT FICHE (ENERGY LABELLING OF SPACE HEATERS)

ii)

106

PRODUCT FICHE (ENERGY LABELLING OF PACKAGES OF SPACE HEATER)

iii)

106

PRODUCT FICHE (ENERGY LABELLING OF TEMPERATURE CONTROLS)

iv)

106

INSTALLATION

3

English

Safety information

DVM Chiller uses R-410A refrigerant.

ŷ When moisture or foreign substances enter into the

refrigerant pipe using R-410A, it may affect the

performance and reliability of the product. Safety

precautions must be obeyed when installing the

refrigerant pipe.

ŷ Since R-410A is an azeotrope refrigerant, it must be

charged in liquid phase. (A blend of the refrigerant

may change if you charge in vapor phase which

could cause product malfunction.)

The manufacturer is not responsible for any installation

or performance problem of the load side indoor unit

and water pipes.

ŷ Product for low temperature (below 5°C) must use

anti-freeze to manage freezing point (concentration

of anti-freeze) according to usage range.

ŷ Freezing point of anti-freeze should be checked

periodically after installation during usage. (once a

year or more)

ŷ Maintain the temperature of chilled/heating water to

recommended range for stable operation.

The manufacturer is not responsible for freezing and

bursting of heat exchanger occurred by errors on

installation.

After completing the installation and test operation,

explain to the user how to use and maintain the

product. Also, hand over this installation manual so that

it can be stored by the user.

The manufacturer of DVM Chiller is not responsible

for the incidents occurred by improper installation.

Installer is responsible for any installation related

claims from the user occurred by neglecting warnings

and cautions stated in this manual.

Generally, DVM Chiller should not be relocated after

installation. But when it has to be relocated for

inevitable reasons, please contact Samsung's qualied

dealers for DVM Chiller.

WARNING

Hazards or unsafe practices that may result in severe

personal injury or death.

CAUTION

Hazards or unsafe practices that may result in minor

personal injury or property damage.

Follow directions.

Do NOT attempt.

Make sure the machine is grounded to prevent

electric shock.

Unplug the power plug from the wall socket.

Do NOT disassemble.

For operation

WARNING

Do not use water containing chemicals such as

chlorine for chilled/heating water as it can cause

corrosion on stainless steel or copper.

ŷ This may result in product malfunction.

Do not block air inlet or outlet of the product.

ŷ It may cause performance decrease or

malfunction of the product.

Do not attempt to disassemble, modify, or repair

the product.

ŷ Failure to do so may result in water leakage,

electric shock or re. Contact the service center.

Do not use the product where oil particles such as

cooking oil and machine oil exist.

ŷ There are potential risks of electric shock or re.

Do not use the product where smokes consisted

by oil particles, such as kitchen, ammable gas,

corrosive gas, or metallic dust exist.

ŷ Failure to do so may result in re or

phenomenon.

INSTALLATION

Safety information

4

English

Do not operate the product with power switch or

circuit breaker.

ŷ Potential risk of electric shock or re.

ŷ If automatic blackout restore is set, fan may spin

suddenly and it may cause injury.

If fuse load switch is used, do not use fuse in

incorrect capacity.

ŷ Usage of wire may result in product malfunction

or re.

Do not use ammable gas (such as hair spray or

insecticide) near the product.

ŷ There are potential risks of electric shock or re.

If there is any problem (such as burning smell),

stop the operation and close the circuit breaker.

ŷ Otherwise, it may cause product malfunction,

electric shock, or re. Contact the service center.

Use chilled/heating water which is appropriate

according to water maintenance standard.

ŷ Deterioration of water may cause water leakage.

Contact the merchandise or service center to clean

inside of the product.

ŷ Error on selecting cleaner and cleaning the

product may harm rubber part and cause water

leakage.

ŷ If the cleaner reaches to electric parts or motor,

it may cause product malfunction, smoke, or re.

CAUTION

Do not use the product for specic purpose.

ŷ It may affect performance, quality, or life of

preservation of precision machinery, food, art

work, etc., and breeding animal or plants.

Do not use the holder which is worn out for

longtime usage.

ŷ It may cause injury due to falling down of the

product.

Do not step onto the product or place any objects

on the product.

ŷ It may cause injury due to falling down of the

product.

Do not operate the product with the cover of

exterior or electric box opened.

ŷ It may cause electric shock or re.

Do not place any objects that are not allowed to be

wet.

ŷ It may get wet by dripping water caused

by product or refrigerant pipe freezing,

contaminated air lter, blocked drain valve.

Do not change settings for protection device.

ŷ It may cause re.

Do not use chilled/heating water for drinking.

ŷ It is harmful for humans.

ŷ For hot water supply, use undirective heat

exchange.

Do not wash the product with water.

ŷ It may cause electric shock.

Do not operate protect devices forcibly.

ŷ This may result in re or explosion.

Do not touch high temperature part such as

compressor and refrigerant pipe.

ŷ It may cause burns.

Do not touch inlet or aluminum plate.

ŷ It may cause injury.

INSTALLATION

5

English

When outdoor temperatre drops below zero, take

appropriate countermeasures for frozen damage.

ŷ Freeze protection such as using brine, heater,

pump operation, etc. is necessary.

ŷ Drain all water and cut-off the power supply

when the product is not operated during winter

time.

Use appropriate refrigerant and refrigerant oil.

ŷ This may result in re or explosion.

Stop the operation and close the circuit breaker

while repair service.

ŷ Otherwise, it may cause electric shock or injury.

Be aware of step board while working on high

place.

ŷ This may result in injury by falling down if the

step board is not stable.

Use chilled/heating water which is appropriate

according to water maintenance standard.

(Refer to page 68 for water maintenance standard.)

ŷ Deterioration of water may cause water leakage.

Follow regulations for disposing brine, cleaner, and

refrigerant.

ŷ It is against the law to dispose illegally.

For installation

WARNING

Do not install the product by users.

ŷ It may result in water leakage, electric shock,

or re if installation is not precise. Contact the

merchandise or service center.

Consult qualied installer or dealer for installation.

ŷ When the installation is done by unqualied

people, it may cause water leakage, electric

shock or re.

Installation should be done by following the

installation manual accurately.

ŷ When installation is not done properly, it may

cause water leakage, electric shock or re.

Do not install the eld supply parts by users.

ŷ Do not use any other product other than the

manufacturer recommended. It may result in

water leakage, electric shock, or re if installation

is not precise. Contact the merchandise or

service center.

Do not move or reinstall the product by users.

ŷ It may result in water leakage, electric shock,

or re if installation is not precise. Contact the

merchandise or service center.

Do not close the circuit breaker for protect devices.

ŷ Otherwise, a re may occur.

Do not install power cables between the products.

ŷ It may cause re.

Make sure to install the product in a place strong

enough to withstand its weight.

ŷ Otherwise, it may result in falling down,

vibration, noise of the product.

Install the product securely to resist strong wind or

earthquake.

ŷ Otherwise, it may result in falling down,

vibration, noise of the product.

Fix the product securely to resist natural

phenomenon such as earthquake.

ŷ If the product is not properly xed, it may fall

down and cause an accident.

ŷ When installing the unit in a small area, take

measure to keep the refrigerant concentration

from exceeding allowable safety limits in case

of refrigerant leakage. Consult the dealer for

precautionary measure before the installation.

ŷ When refrigerant leaks and exceed dangerous

concentration level, it may cause suffocation

accidents.

INSTALLATION

Safety information

6

English

Check the followings before installation and repair/

maintenance service.

ŷ Before brazing, remove dangerous and/or

ammable things around workplace that may

cause an explosion and re.

ŷ Before brazing, remove the refrigerant within

the pipe or the product.

ŷ If you perform welding while refrigerant is in

the pipe, it may increase the pressure of the

refrigerant and cause the pipe to burst. If the

pipe bursts or explodes, it may cause severe

injury to the installer.

ŷ Use the nitrogen gas to eliminate oxide inside

the pipe during brazing.

Electric work must be done by qualied people,

complying the national wiring regulations and

installed according to the instruction stated in the

installation manual and must comply regulated

electrical specication.

ŷ Capacity shortage on the power circuit or

improper installation may cause electric shock or

re.

Wiring must be connected with the designated

wires and it must be xed securely so that it does

not apply any external force to the connection part

of the terminals.

ŷ If connection or xation is not properly done, it

may cause heat generation or re.

Neatly arrange the wires in the electrical parts to

make sure that electrical cover is closed securely

without any gaps.

ŷ If the cover is not properly closed, heat may

generate on the terminal and cause electric

shock or re.

Exclusive circuit breaker (MCCB, ELB) must be

installed to the power supply.

ŷ Use ELCB that has harmonic wave prevent

function since the product uses inverter

compressor.

ŷ If the auxiliary circuit breaker is not installed,

power will not be cutoff in case of overcurrent

or current leakage and cause electric shock or

re.

ŷ Do not use damaged parts. Otherwise, a re or

electric shock may occur.

You must cut-off the power before you work

on, or adjust any power supply part for product

installation, maintenance, repair or any other

services.

ŷ This may result in electric shock.

ŷ Even when the power is off, it is very dangerous

to touch the inverter PCB and the fan PCB since

high pressure DC voltage is charged for those

parts.

ŷ When replacing/repairing the PCB, cut-off

the power and wait until the DC voltage is

discharged before replacing/repairing them.

(Wait for more than 15 minutes to allow those

parts to be fully discharged.)

You must ventilate the room if the refrigerant gas

leaks during the installation.

ŷ Toxic gas can be generated when the refrigerant

gas gets in contact with ammable substance.

Use chilled/heating water which is appropriate

according to water maintenance standard.

(Refer to page 68 for water maintenance standard.)

ŷ Deterioration of water may cause water leakage.

Contact the merchandise for refrigerant stagnating.

ŷ When refrigerant leaks and exceed dangerous

concentration level, it may cause suffocation

accidents. When installing the unit in a small

area, take measure to keep the refrigerant

concentration from exceeding allowable safety

limits in case of refrigerant leakage.

Follow regulations for disposing brine, cleaner, and

refrigerant.

ŷ It is against the law to dispose illegally, and also

harmful for humans and environment.

INSTALLATION

7

English

Wiring must be connected with the designated

wires and it must be xed securely so that it does

not apply any external force to the connection part

of the terminals.

ŷ If connection or xation is not properly done, it

may cause heat generation or re.

Please connect ground wire.

ŷ If the ground wire is not properly xed, there is

potential risk of electric shock or re.

ŷ Do not connect the grounding cable to a gas

pipe, water pipe, lightening conductor or the

grounding cable of the telephone.

CAUTION

Drain system must be constructed according to this

installation manual so that condensation water

drains properly, and drain system should be kept

warm to prevent dew condensation.

ŷ When water management is not done properly,

water leakage may occur and cause property

damage.

Install the power cable and communication cable

of the product at least 1.5m away from the electric

appliances and install it at least 2m away from the

lightning conductor.

ŷ Even if the cables are installed more than 2 m

away from electronics, noise can be generated

from them depending on the status of the

electric wave.

Do not leave any obstacles around the inlet and

outlet of the product.

ŷ It may cause product failure or other accidents.

Do not install the product in following places.

ŷ A place where noise and warm air of the product

may disturb neighbors

- It may cause property loss.

ŷ A place full of mineral oil, place where oil

scatters or with oil vapors such as a kitchen

- Plastic parts may get damaged and cause

water leakage, or maybe even cause product

to fall down.

- The performance of the heat exchanger may

decrease or cause product failure.

ŷ A place near exhaust pipes or ventilation outlet

where corrosive gas such as ammonia gas or

sulfurous acid gas are being generated

- Copper pipe and connection parts may corrode

causing refrigerant leakage.

ŷ A place with a machine that generates

electromagnetic waves

- Electromagnetic waves may cause problems in

control system and product may not operate

normally.

ŷ A place where there is a danger of combustible

gas leakage or the place where thinner or

gasoline is handled

There is a risk of re or explosion.

ŷ A place with airborne carbon ber or ammable

dust

ŷ A place near seashore or hot spring where there

is risk of product corrosion

Install MCCB for each product.

ŷ Use ELCB that has harmonic wave prevent

function since the product uses inverter

compressor.

ŷ It may cause electric shock or re if more than

two products are installed on one MCCB.

Make sure to install drain pipe for draining

performed correctly.

ŷ If the installation is not done properly,

water leakage may occur and cause product

malfunction.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety. Children should be

supervised to ensure that they do not play with the

appliance.

For use in Europe : This appliance can be used by

children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

INSTALLATION

8

English

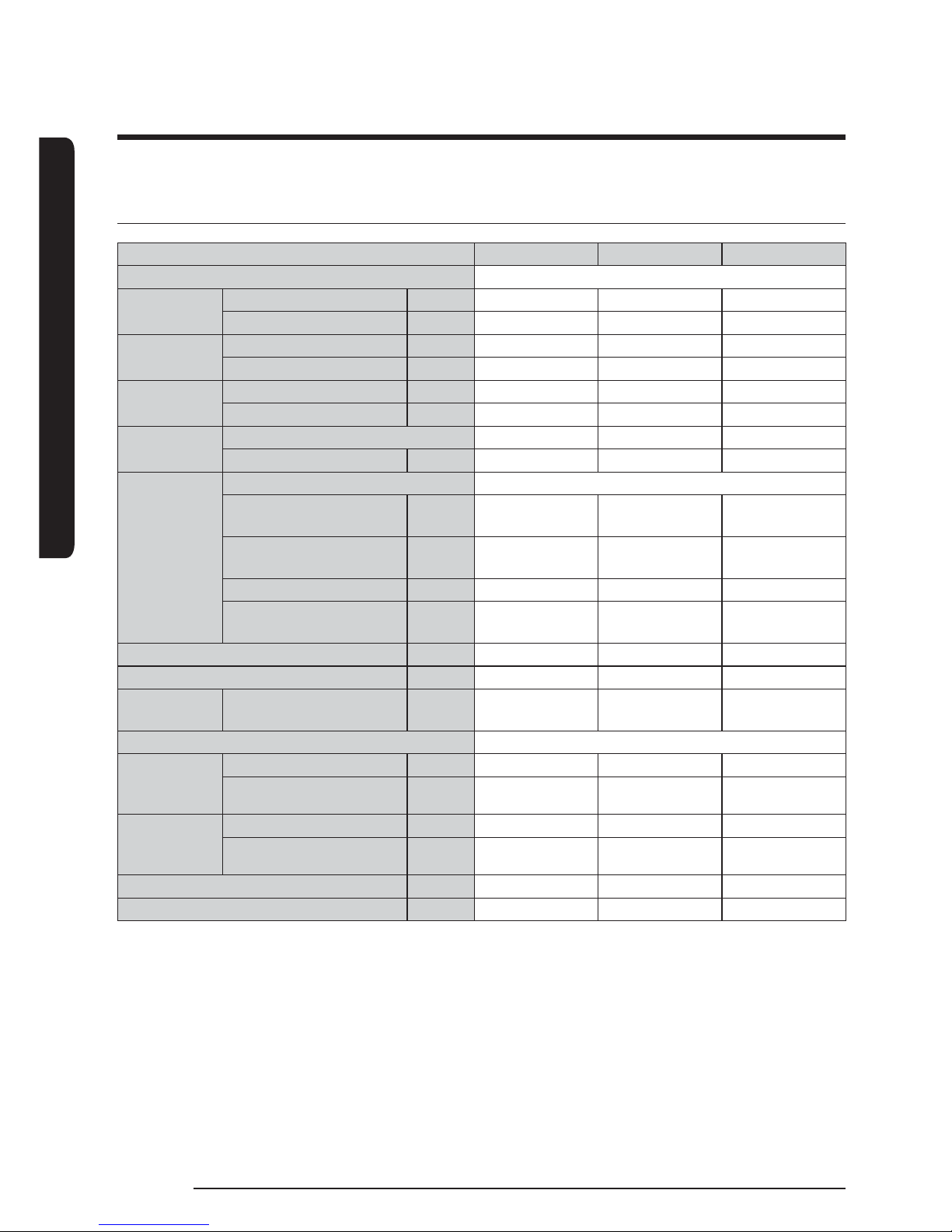

Preparing for installation

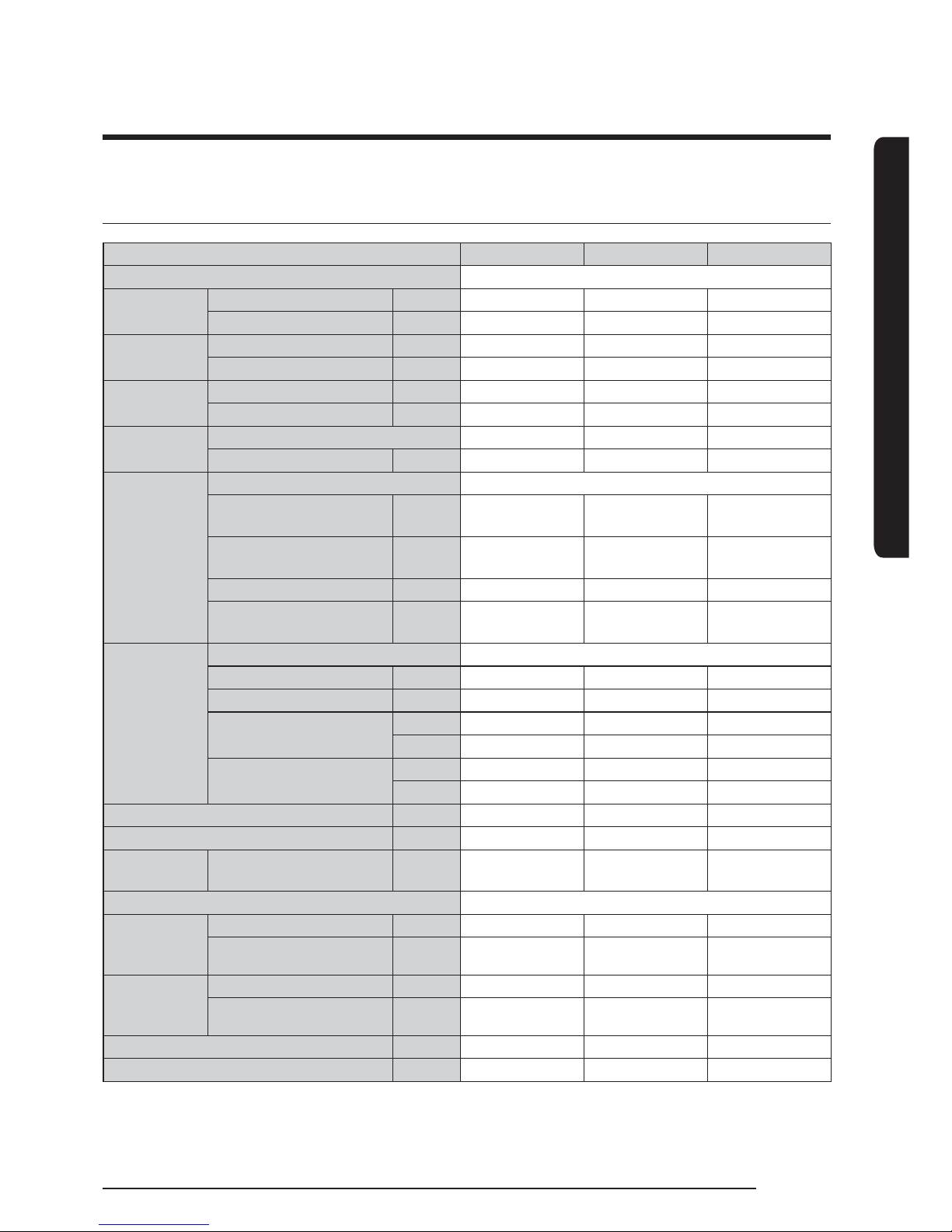

Specications of the non-pump models

Model AG042KSVANH AG056KSVANH AG070KSVANH

Power supply

3 Phase 4 Wires 380 ~ 415 V, 50/60 Hz

Capacity

Cooling (Rated) kW

42 56 65

Heating (Rated) kW

42 56 69.5

Power

consumption

Cooling (Rated) kW

12.35 18.67 26.0

Heating (Rated) kW

11.83 17.50 24.39

Operating

current

Cooling (Rated) A

19.6 29.6 41.2

Heating (Rated) A

18.8 27.8 38.7

Refrigerant

Type

R-410A R-410A R-410A

Charging amount kg

18 18 18

Water

side heat

exchanger

Type

Plate type heat exchanger

Flow rate

(Cooling/Heating)

LPM

120/120 160/160 186/200

Maximum operating

pressure

MPa

1.0 1.0 1.0

Head loss kPa

60 100 120

Inlet·Outlet connected

pipe size

A

40 40 50

Minimum water quantity L

294 392 490

Net weight kg

446 446 465

Net dimension W X H X D mm

1795 X 1695 X

765

1795 X 1695 X

765

1795 X 1695 X

765

Remote control

Module Control

Water outlet

temperature

range

Cooling (If using brine) °C

5 ~ 25 (-10 ~ 25) 5 ~ 25 (-10 ~ 25) 5 ~ 25 (-10 ~ 25)

Heating °C

25 ~ 55 25 ~ 55 25 ~ 55

Surrounding

temperature

range

Cooling °C

-15 ~ 48 -15 ~ 48 -15 ~ 48

Heating °C

-25 ~ 43 -25 ~ 43 -25 ~ 43

MCA A

32 46 58

MFA A

40 60 75

1) Standard for rated cooling capacity: chilled water inlet/outlet temperature 12/7°C, outdoor 35°C DB, 24°C WB

2) Standard for rated heating capacity: heating water inlet/outlet temperature 40/45°C, outdoor 7°C DB, 6°C WB

3) When using brine, maintain the concentration according to temperature. (Refer to page 76.)

INSTALLATION

9

English

Specications of the pump integrated models

Model AG042KSVGNH AG056KSVGNH AG070KSVGNH

Power supply

3 Phase 4 Wires 380 ~ 415 V, 50/60 Hz

Capacity

Cooling (Rated) kW

42 56 65

Heating (Rated) kW

42 56 69.5

Power

consumption

Cooling (Rated) kW

13.59 20.14 28.26

Heating (Rated) kW

12.77 18.48 25.84

Operating

current

Cooling (Rated) A

24.2 34.2 45.8

Heating (Rated) A

23.4 32.4 43.3

Refrigerant

Type

R-410A R-410A R-410A

Charging amount kg

18 18 18

Water

side heat

exchanger

Type

Plate type heat exchanger

Flow rate

(Cooling/Heating)

LPM

120/120 160/160 186/200

Maximum operating

pressure

MPa

1.0 1.0 1.0

Head loss kPa

60 100 120

Inlet·Outlet connected

pipe size

A

40 40 50

Pump

Type

End-Suction

Input x n kW

1.68 1.68 1.68

Output x n W

1.45 1.45 1.45

Normal Water Flow rate

(Cooling/Heating)

LPM

120/120 160/160 186/200

l/s

2.0/2.0 2.7/2.7 3.1/3.3

External Static Pressure

(Max.)

mAq

22.4 / 22.4 15.3 / 15.3 10.2 / 10.2

kPa

220 / 220 150 / 150 131 / 100

Minimum water quantity L

294 392 490

Net weight kg

472 472 493

Net dimension W X H X D mm

1795 X 1695 X

765

1795 X 1695 X

765

1795 X 1695 X

765

Remote control

Module Control

Water outlet

temperature

range

Cooling (If using brine) °C

5 ~ 25(-10 ~ 25) 5 ~ 25(-10 ~ 25) 5 ~ 25(-10 ~ 25)

Heating °C

25 ~ 55 25 ~ 55 25 ~ 55

Surrounding

temperature

range

Cooling °C

-15 ~ 48 -15 ~ 48 -15 ~ 48

Heating °C

-25 ~ 43 -25 ~ 43 -25 ~ 43

MCA A

39 53 65

MFA A

50 60 75

1) Standard for rated cooling capacity: chilled water inlet/outlet temperature 12/7°C, outdoor 35°C DB, 24°C WB

2) Standard for rated heating capacity: heating water inlet/outlet temperature 40/45°C, outdoor 7°C DB, 6°C WB

3) When using brine, maintain the concentration according to temperature. (Refer to page 76.)

INSTALLATION

Preparing for installation

10

English

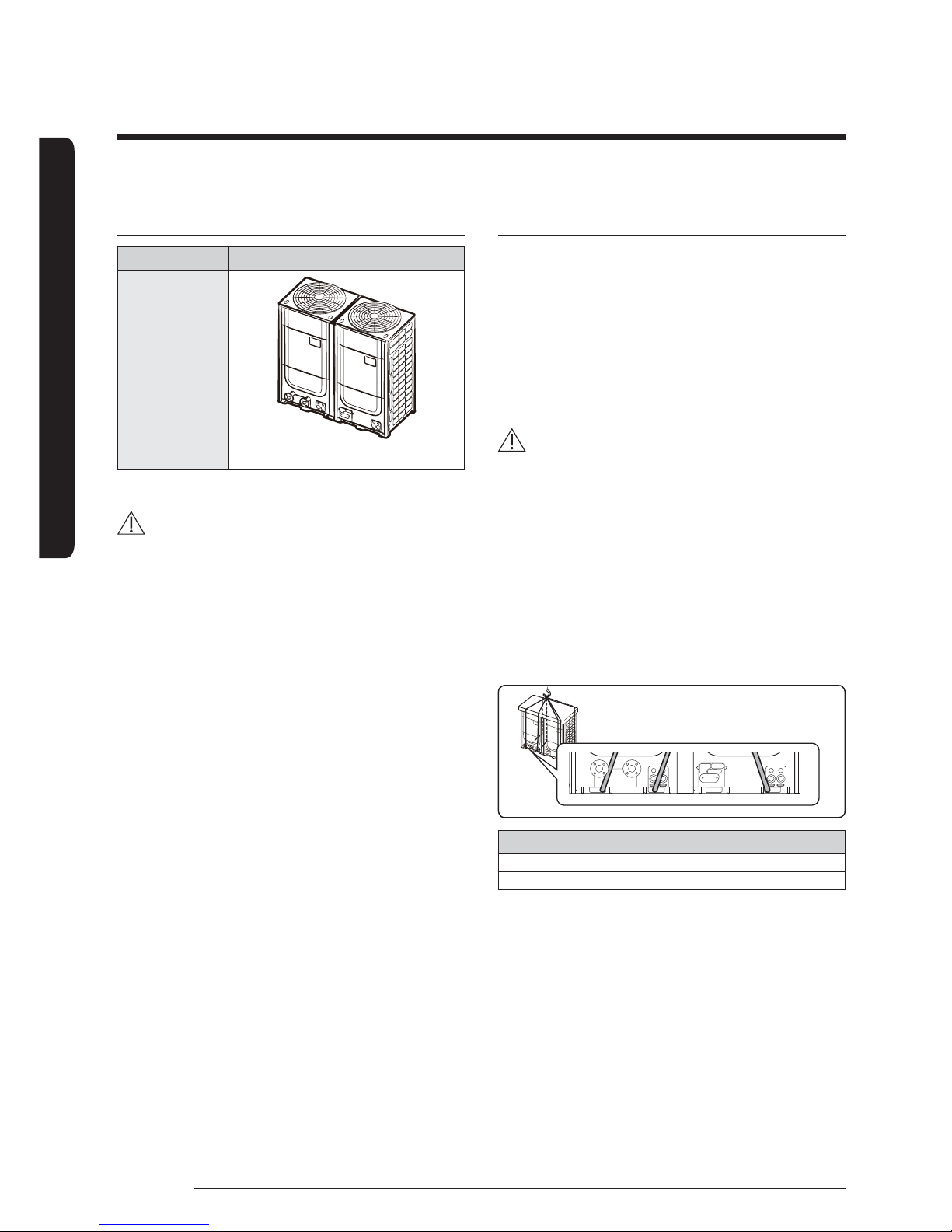

DVM CHILLER Classication

Classication DVM CHILLER

Appearance

Applied model

AG042/056/070KSV Series

CAUTION

ŷSafely store or dispose the packaging materials.

- Sharp metals such as nails or wooden material

packaging that may break into pieces become a

cause for personal injury.

- Make sure to store or dispose the vinyl type

packaging material to keep it out of reach of

children. Children may put them over their face,

which is very dangerous since it may lead them

to suffocation.

Moving the product

fSelect the moving path in advance.

fBe sure that moving path can support weight of the

product.

fDo not slant the product more than 30˚ when

carrying it.

(Do not lay the product down in sideways.)

fSurface of the heat exchanger is sharp. Be careful not

to get injured while moving the product.

CAUTION

ŷYou must use square holes in the base of the

product when moving the product.

1 When moving with a crane

fFasten the wire rope using square holes of the

product as shown in the gure.

- To protect damage or scratches, insert a piece of

cloth between the product and the wire rope.

- Insert hanging softening material to prevent load

from the rope on top of the product.

AB C

Model name Rope's Location

AG

✴✴✴

KSVA Series B + C

AG

✴✴✴

KSVG Series A + C

INSTALLATION

11

English

CAUTION

ŷDo not hang the rope on side of the water pipe.

The rope may force the water pipe to deformed or

damaged.

2 When moving with a forklift

fCarefully insert the forklift forks into the forklift

holes at the palette.

fBe careful with the forklift from damaging the

product.

Center location

A

B

A

C

B

C

Model name A B C

AG042KSVANH 1020 380 590

AG056KSVANH 1020 380 590

AG070KSVANH 1020 380 590

AG042KSVGNH 950 370 550

AG056KSVGNH 950 370 550

AG070KSVGNH 950 370 550

Accessories (Basic specication)

fYou must keep following accessories not to be lost

during installation.

fHand over the installation manual to the customer

after nishing the installation.

Installation manual Installation check card

Field Supply

fStrainer

Maximum

operating

pressure

Water pipe connection part

AG042/056

✴✴

AG070

✴✴

1.0 MPa 40 A (1-1/2") 50 A (2")

Mesh size Material (Strainer/Mesh)

50 Mesh SUS304

INSTALLATION

12

English

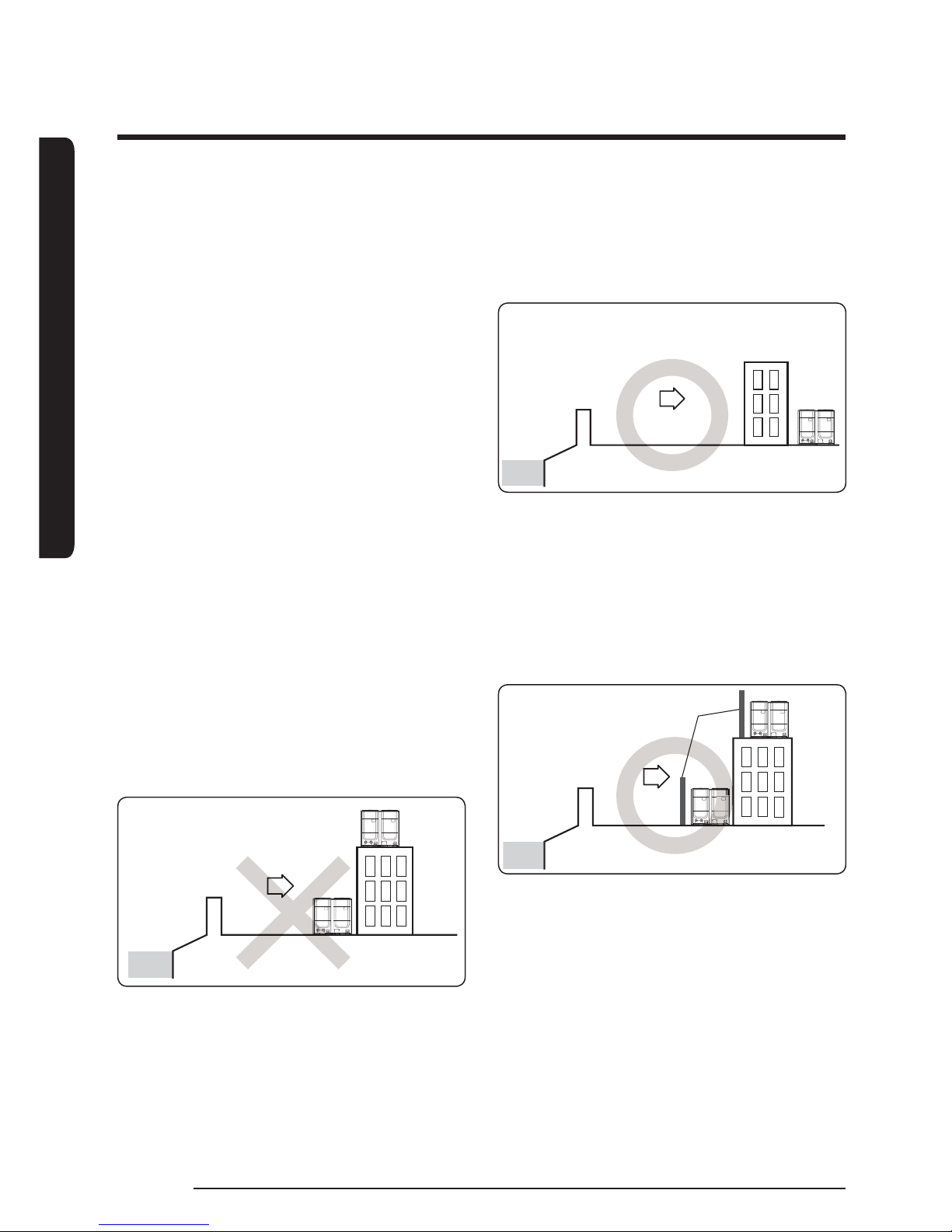

Decide the installation location, with the consideration

of the following conditions, under user's approval.

fPlace where hot discharge air or noise from the DVM

CHILLER may not disturb the neighbor (Especially in

residential areas, keep the operation hours in mind.)

fPlace where structure can bear the weight and

vibration of the DVM CHILLER

fPlace with at surface where rainwater does not

settle or leak

fPlace where it is not exposed to strong wind

fWell ventilated place with sufcient service place

for repairs and maintenance (Discharge duct can be

purchased separately)

fPlace where it allows easy waterproong and

draining work for the condensation water generated

from the DVM CHILLER during heating operation

fPlace where there is no risk of inammable gas

leakage

fPlace where there is no direct inuence of snow or

rain

fDo not install the product in a place where it will be

directly exposed to sea breeze.

- Consult an installation expert (or company)

since you will need to take extra anti-corrosion

measures if you need to install the product in

a place where it can be exposed to direct sea

breeze. (You have to remove dusts and salinity

on the heat exchanger and apply designated rust

inhibitor more than once a year.)

Sea

Sea breeze

DVM

CHILLER

DVM

CHILLER

fCaution when installing the product in seashore

- When installing the product in seashore, make

sure to install it behind a structure (such as

building) that can block the sea breeze or install

protection wall around the DVM CHILLER.

Sea

Sea breeze

DVM

CHILLER

- Make sure to install the product in a place where

it allows smooth drainage.

- Protection wall should be constructed with a

solid material that can block the sea breeze

and the height and width of the wall should

be 1.5times larger than the size of the

DVMCHILLER. (You must secure more than

700mm of space between the protection wall

and the DVMCHILLER for air circulation.)

Sea

Sea breeze

DVM

CHILLER

Protection wall

DVM

CHILLER

Selecting installation location

INSTALLATION

13

English

CAUTION

ŷIn regions with heavy snowfall, make sure to install

the DVM CHILLER where there is no concerns of

direct snowfall on the DVM CHILLER. Also, build

higher base support so that accumulated snow does

not block the air inlet or the heat exchanger.

ŷR-410A refrigerant is a safe, nontoxic and

nonammable refrigerant. However, if the place

holds any concerns for exceeding dangerous level

of refrigerant concentration in case of refrigerant

leakage, extra ventilation system is required.

ŷWhen you install the product in a high places such

as roof, install fence or guardrail around it. When

there is no fence or guardrail, service person could

fall.

ŷDo not install the product in places where corrosive

gases such as sulfur oxides, ammonia, and sulfurous

gases are produced. (e.g. Toilet outlet, ventilation

opening, sewage works, dyeing complex, cattle

shed, sulfuric hot spring, nuclear power plant, ship

etc.) When installing the product in those places,

contact an installation specialty store as the copper

pipe and brazing part will need additional corrosion

proof or anti-rust additive to prevent corrosion.

ŷMake sure to keep any inammable materials (such

as wooden materials, oil etc.) around the DVM

CHILLER. When there's re, those inammable

material will easily catch the re and may pass it on

to the product.

ŷDepending on the condition of power supply,

unstable power or voltage may cause malfunction

of the parts or control system.

(At the ship or places using power supply from

electric generator, etc.)

INSTALLATION

14

English

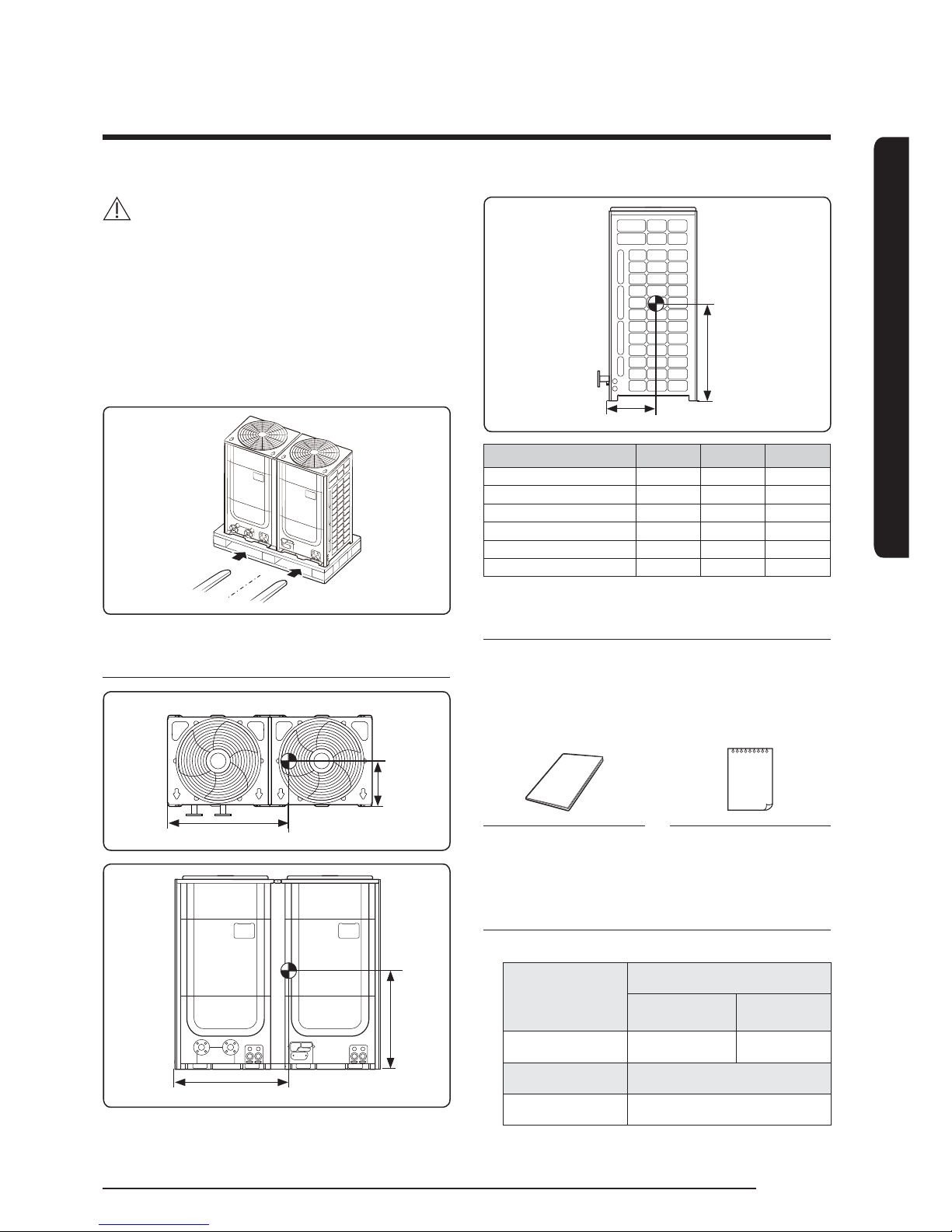

Required space for installation

fSpace requirement was decided based on the

following conditions; Cooling mode, outdoor

temperature of 35°C. Larger space is required if the

outdoor temperature is higher than 35°C or if the

place is heated easily by quantity of solar radiation.

fWhen you secure installation space, consider path for

people and the direction of the wind.

fSecure installation space as shown in the gure,

considering ventilation and the service space.

fIf the installation space is narrow, installer or other

worker may get injured during work and may also

cause a problem with the product.

fIf you install multiple number of DVM CHILLERs in

one space, make sure to secure enough ventilation

space if there's any walls around the product that

may disturb the air ow. If enough ventilation space

is not secured, the product may malfunction.

fYou could install the DVM CHILLERs with 100 mm

of space between each unit, but performance may

decrease depending on the installation environment.

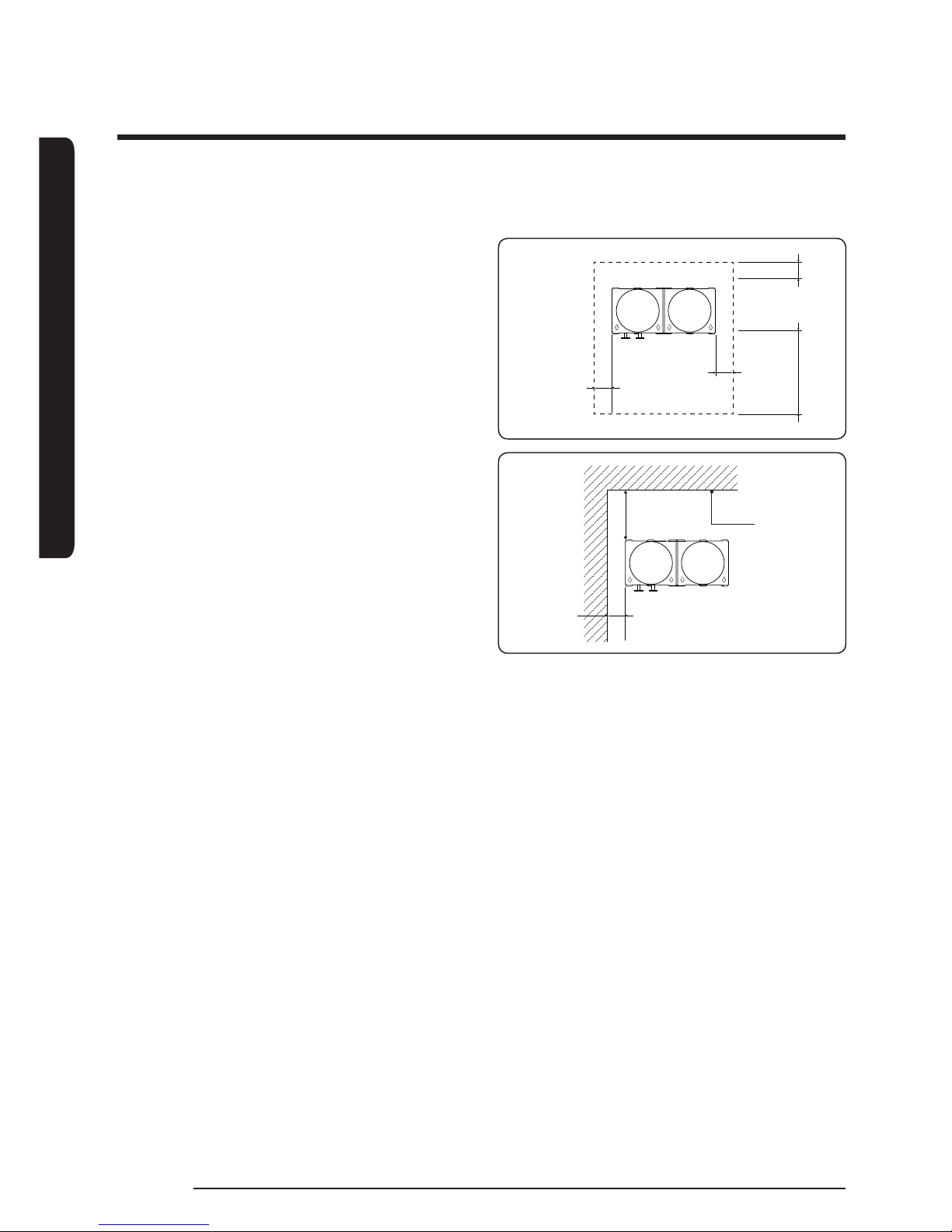

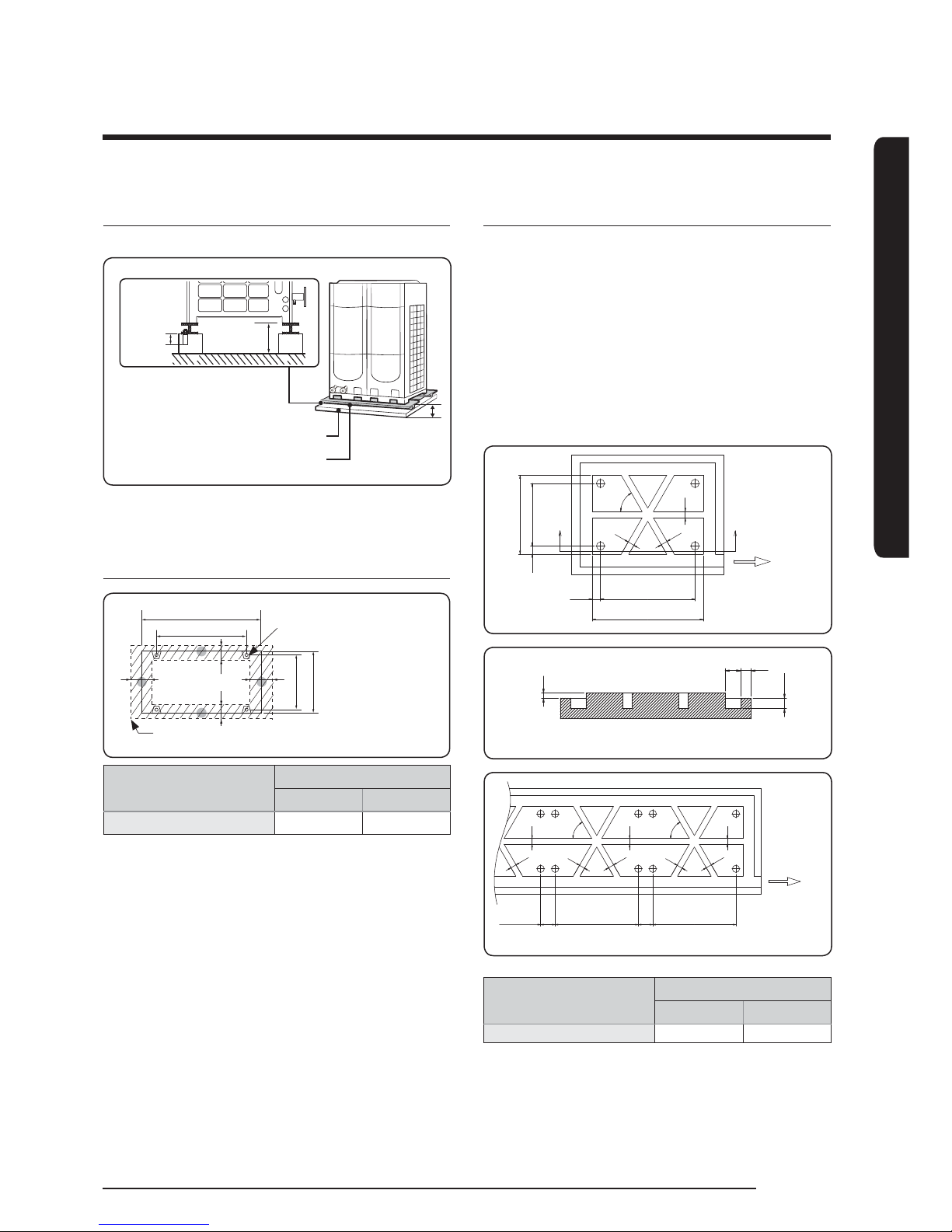

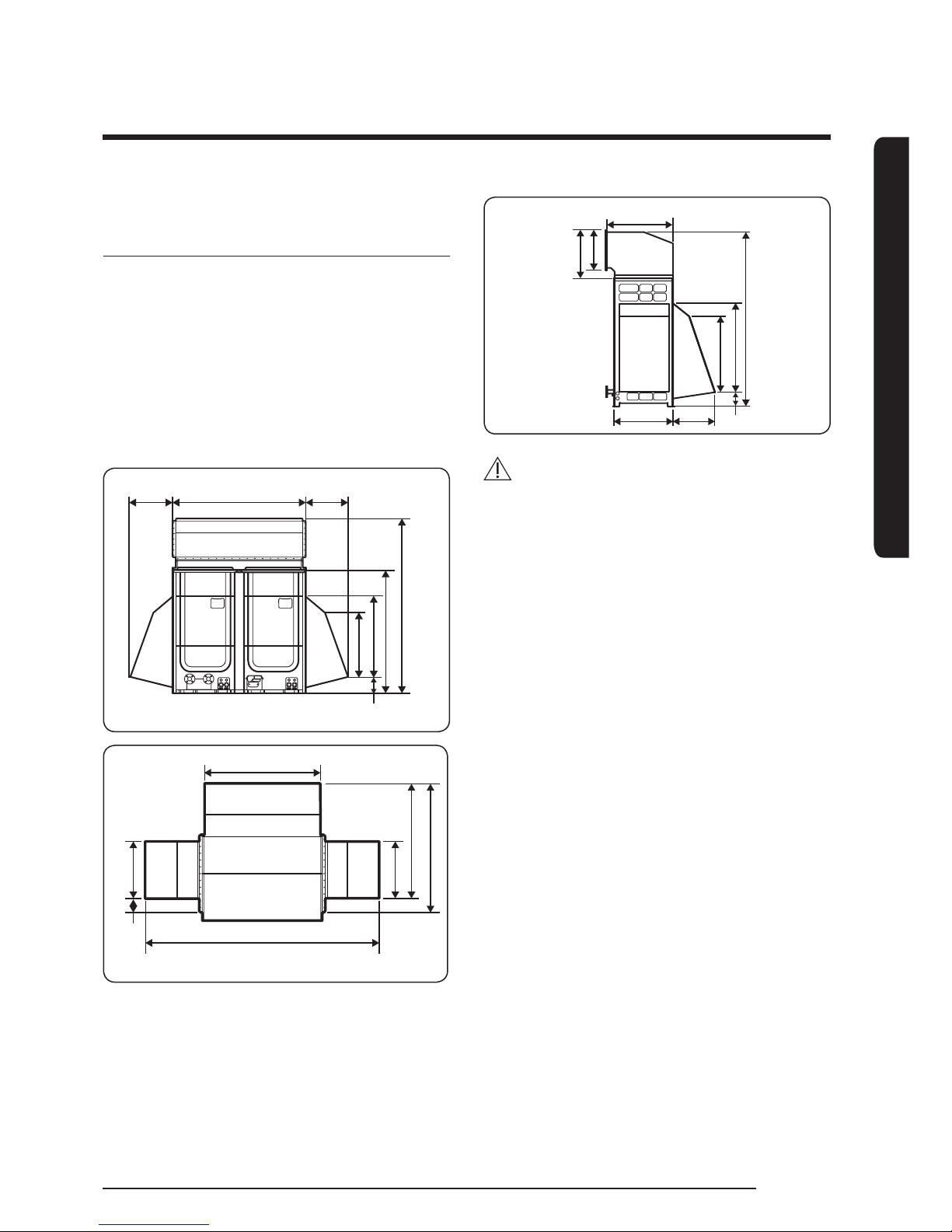

1 Single installation

Unit: mm

Front side

100 or more

100 or

more

500 or more (S1) 100 or

more (S2)

<Case 1>

Front side

100 or

more

300 or

more

Height of

the wall is

unlimited

<Case 2>

INSTALLATION

15

English

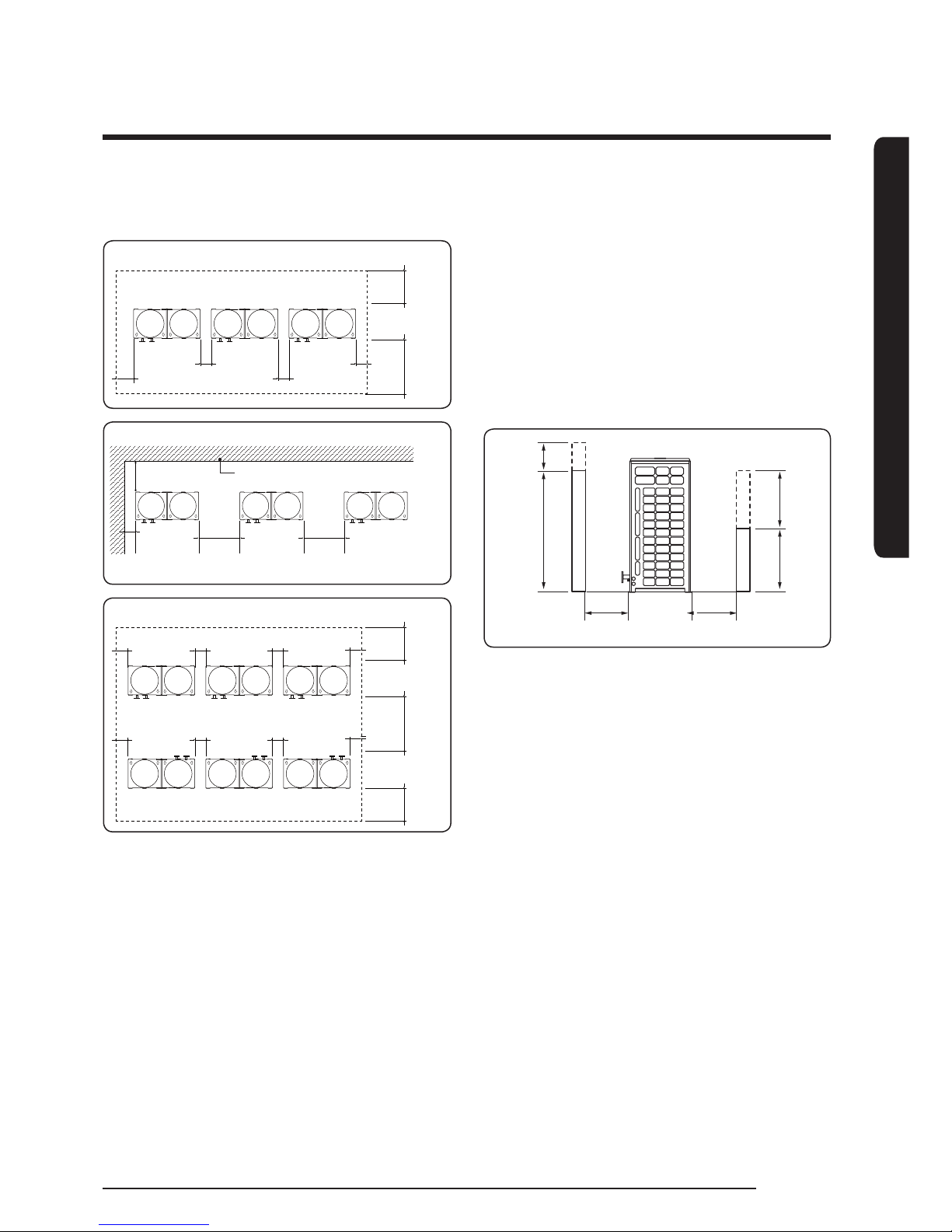

2 Module installation

Unit: mm

Front side

100 or more

200 or more 100 or more

100 or more

300 or

more (S2)

500 or

more (S1)

<Case 1>

<Case 2>

400 or

more

400 or

more

200 or

more

Front side

300 or more

Height of the wall is unlimited

Front side

Front side

100 or more

100 or more

100 or

more

100 or

more

100 or more

100 or more

100 or

more

100 or

more

500 or

more

500 or

more

600 or

more

<Case 3>

f Installing by <Case 1> or <Case 3>

- Height of the wall on the front side should not

be higher than 1500mm.

- Height of the wall on the air inlet side should not

be higher than 500mm.

- Height of the wall on the side is not limited.

- If the height of the wall exceeds by certain value

(h1, h2), additional clearance [(h1)/2, (h2)/2 : Half

of the exceeded distance] should be added to the

service space (S1, S2).

Unit: mm

1500 h1

500 h2

Front side

Air inlet side

S1+h1/2 S2+h2/2

INSTALLATION

16

English

WARNING

ŷMake sure to remove the wooden pallet before

installing the DVM CHILLER. If you do not remove

the wooden pallet, there is risk of re during

welding the pipes. If the DVMCHILLER is installed

with wooden pallet on, and it was used for long

period time, wooden palette may break and cause

electrical hazard or high pressure may damage the

pipes.

ŷFix DVMCHILLER rmly on the base ground with

anchor bolts.

CAUTION

ŷManufacturer is not responsible for the damage

occurred by not following the installation standards.

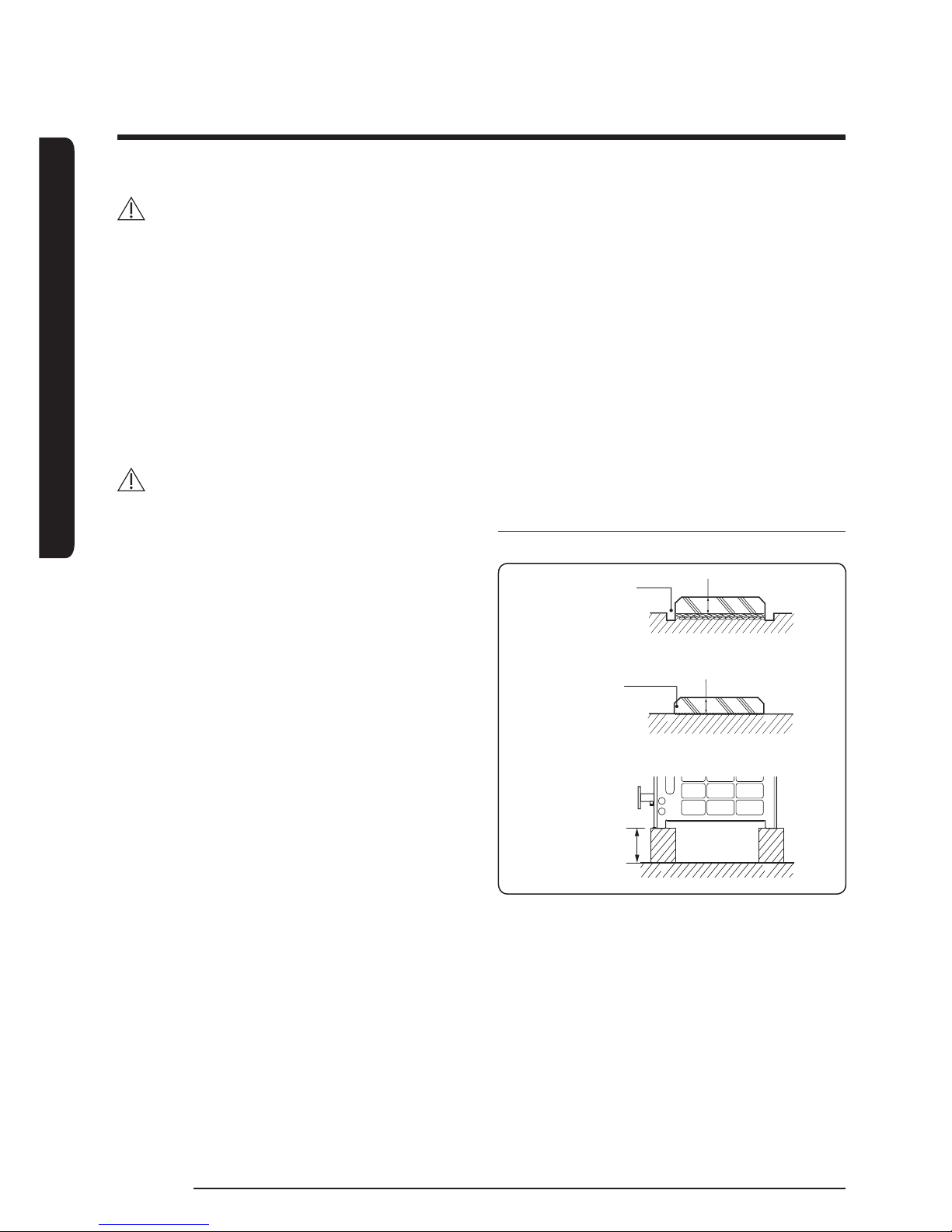

1 Make sure that the height of the base ground is

200mm or higher to protect the product from rain

water or other external conditions. Also, install

a drainage hole around the supporting base and

connect the drain pipe to the drainage pit.

2 Considering the vibration and weight of the product,

strength of the base ground must be strong to

prevent noise and the top surface of it should be at.

3 Area of the base ground should be 1.5 times larger

than the bottom of the product.

4 Product must be xed rmly so that it can withstand

the wind speed of 30m/s. If you cannot x the

DVMCHILLER on the supporting base, x it by side

or use extra structure.

5 In heating operation, defrost water may form

so you must really care about the drainage and

waterproong the oor. To prevent defrost water

from stagnating or freezing, construct a drainage pit

with over 1/50 slant. (Ice may form on the oor in

the winter time.)

6 It is necessary to add wire mesh or steel bar during

concrete construction for the base ground to prevent

damage or cracks.

7 When installing multiple DVM CHILLERs at the same

place, construct an H beam or a vibration-isolation

frame on the base ground to install the product.

8 After installing an H beam or a vibration-isolation

frame, apply corrosion protection and other

necessary coating.

9 When concrete construction for product installation is

complete, install an isolation pad (t = 20 mm or more)

or a vibration-isolation frame to prevent vibration of

the product from transferring to the supporting base.

10 Place the product on an H beam or a vibration

isolation frame and x it with the anchor bolt, nut

and washer. (The bearing capacity of the anchor bolt

has to be over 3.5 kN)

Supporting base construction

Unit: mm

When installing on the ground

Draining pit

200 or more

When installing on the roof

Bottom surface of

the supporting base

must be horizontally

leveled

200 or more

200 or more

Base construction and installation

INSTALLATION

17

English

Product installation

Unit: mm

200 or more

200 or

more

50 or

more

H beam or vibration-isolation frame

Supporting base

Base mount and anchor bolt

position

A

B

54

761

803

54

Product - vibration-isolation

frame (4 - Ø12)

Supporting base (H beam or vibraition-isolation frame)

Applied model

Net dimension

AB

AG042/056/070

✴✴

1,795 1,655

ŷWhen applying vibration-isolation frame additionally

on supporting base, specication of xed holes with

the base should be referred to specication of the

frame.

Examples of draining work

fUse concrete or steel bar for draining work to

prevent any damage or cracks.

fFor smooth draining of defrost water, make sure to

apply 1/50 slant.

fConstruct a drainage around the product to prevent

the defrost water (from the product) from stagnating,

overowing or freezing near the installation space.

fWhen the product is installed on the roof, check the

strength and waterproof status of the roof.

Unit: mm

960

760

100

80

80

80

60°

100

X

X’

Direction of the

drainage

(1/50 slant)

B

A

50

100

150 100

X-X’ SECTION

80

80

80

80

80

80

80

80

60°

60°

200

BB

200

Direction

of the

drainage

(1/50 slant)

Applied model

Net dimension

AB

AG042/045/070

✴✴

1,855 1,655

INSTALLATION

Base construction and installation

18

English

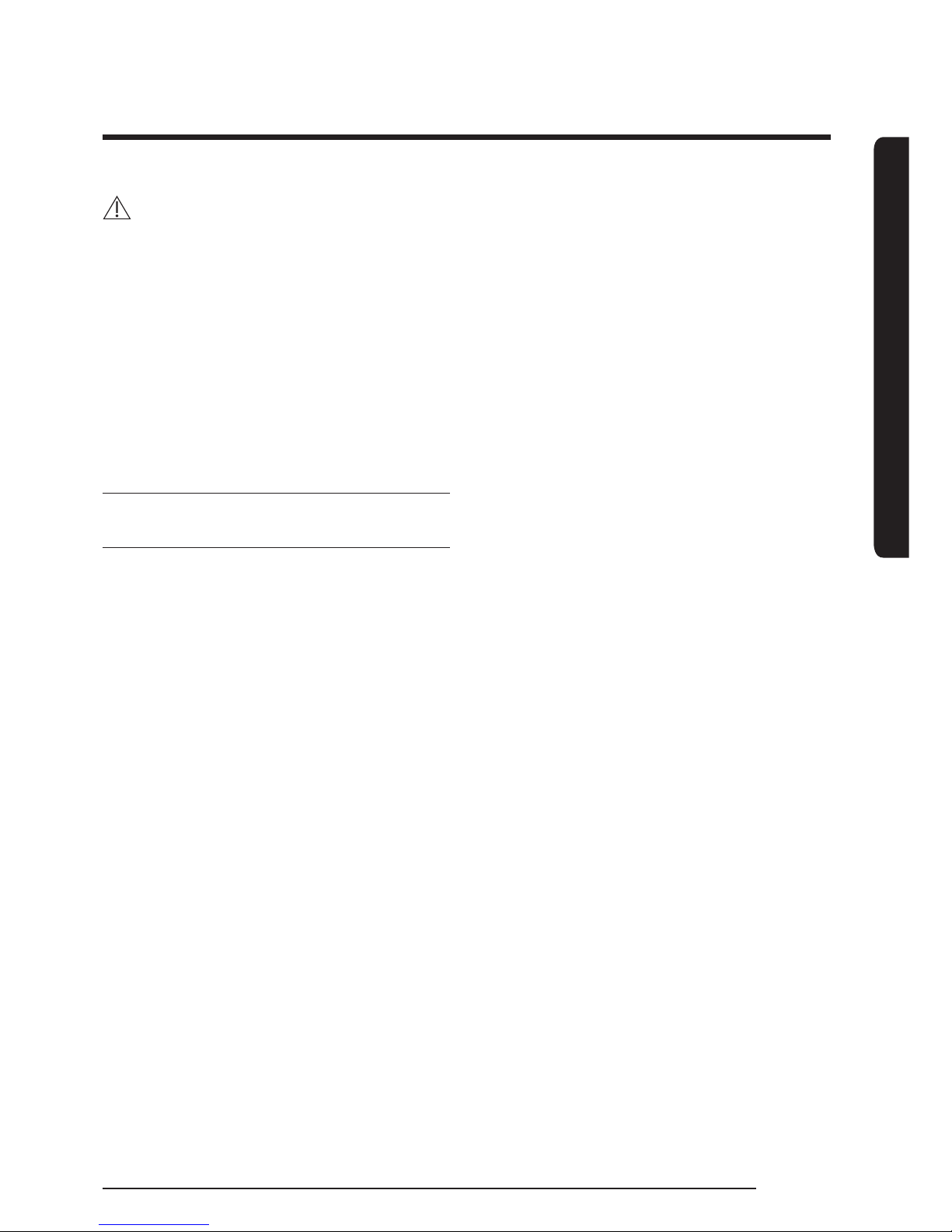

Installation precautions

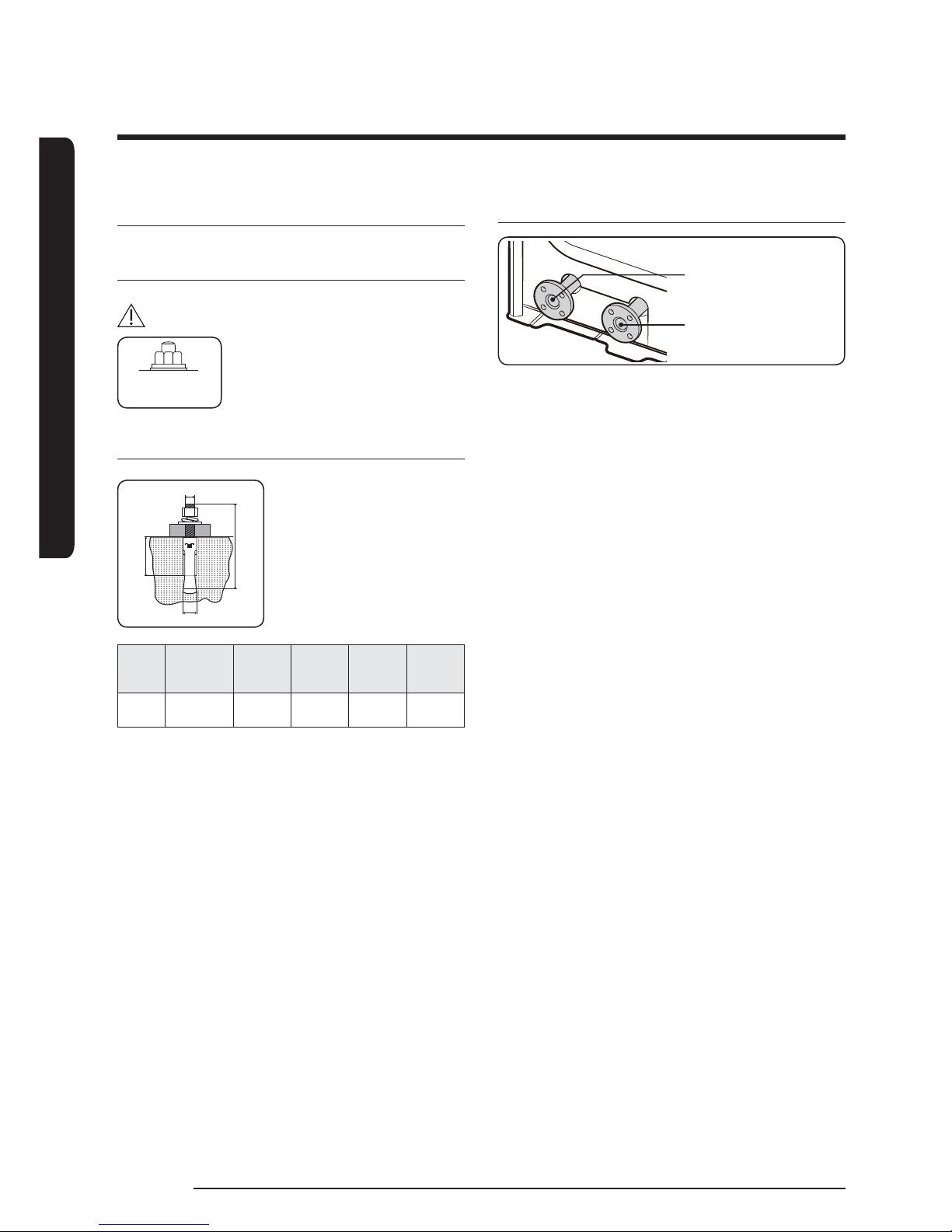

Connecting the anchor bolt

CAUTION

Plastic (rubber)

washer

ŷTighten the rubber washer to

prevent the bolt connection

part of the DVM CHILLER from

corroding.

Anchor specication

a

b

c

m

ŷUse the anchor bolts and nuts

that is zinc plated or made

of STS material. Regular

anchor bolts or nuts may get

damaged by corrosion.

Size

Diameter of

drill bit (a)

Anchor

length (b)

Sleeve

length (c)

Insertion

depth

Fastening

torque

ø10 14 mm 75 mm 40 mm 50 mm 30 N·m

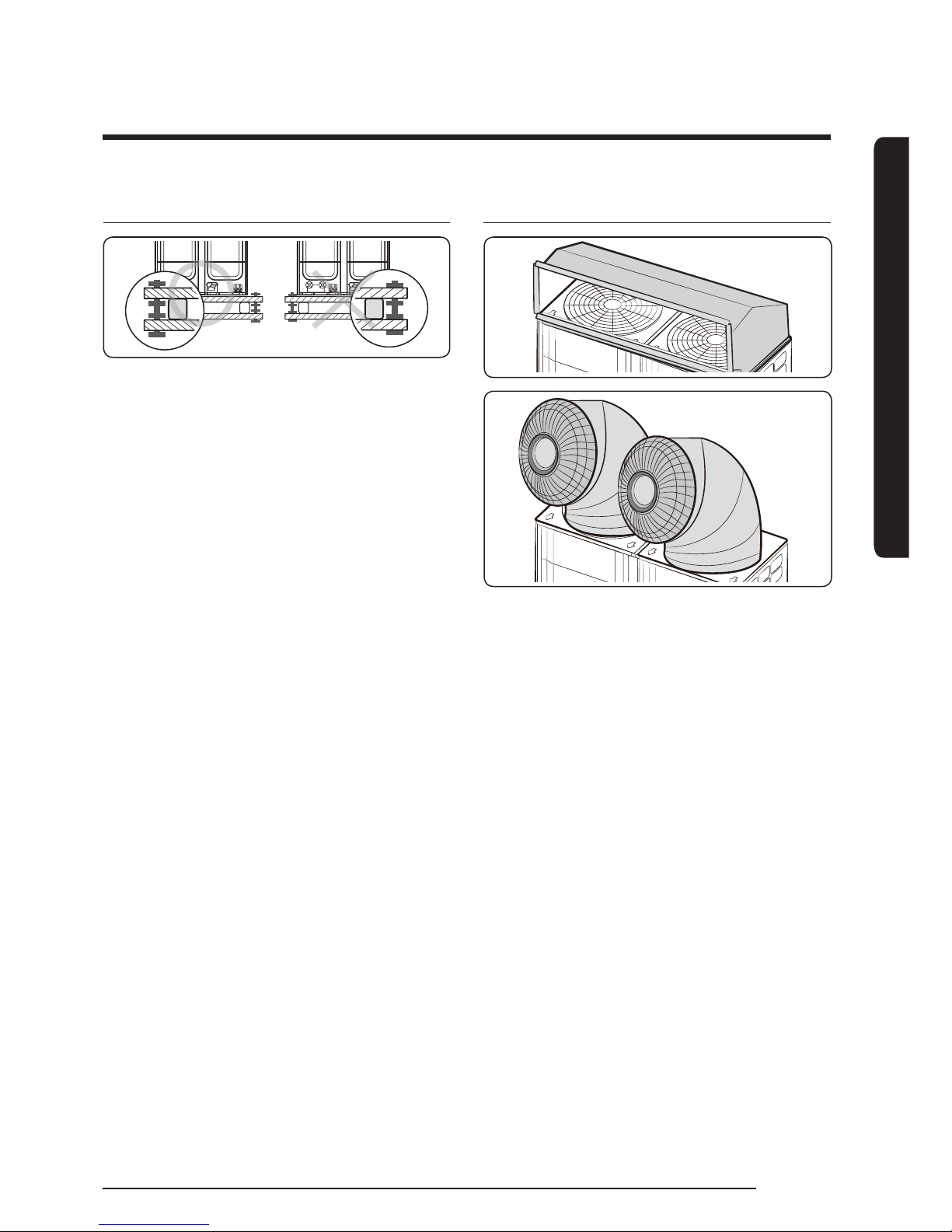

Connecting the pipe

Water inlet pipe

Water outlet pipe

fIf you install the DVMCHILLER on the rooftop,

check the strength and make sure to waterproof the

rooftop.

fConstruct draining pit around the supporting base

and pay attention to the drainage around the

product. (Condensation or defrost water may form

during product operation.)

fIf there's any possibility of small animals entering

into the product through pipe outlet, block the outlet.

INSTALLATION

19

English

Installing vibraiton-isolation frame

fDuring installation, make sure there is no gap

between the supporting base and the extra structures

such as vibration-isolation frame or H beam.

fSupporting base must be constructed strongly to

support the bottom part of the vibration-isolation

mount.

fAfter installing the vibration-isolation frame, unscrew

the xing part on the top and bottom part of the

frame.

Installing discharge duct

fStatic pressure of the discharge duct should be within

the standard specication (80 kPa) when installing

the duct.

fIf you remove the fan guard to install the discharge

duct, make sure to install a safety net on the duct

outlet.

Foreign substance may enter into the product and

there could be a risk of personal injury.

fWear protection equipment at all times when making

galvanized sheet metal duct, since the worker may

get injured by the sharp parts.

fWhen installing the product under the tree or

near forest, leafs may get into the product and

cause problems on the product. Therefore, install

a discharge duct to prevent foreign substance

inltration.

INSTALLATION

20

English

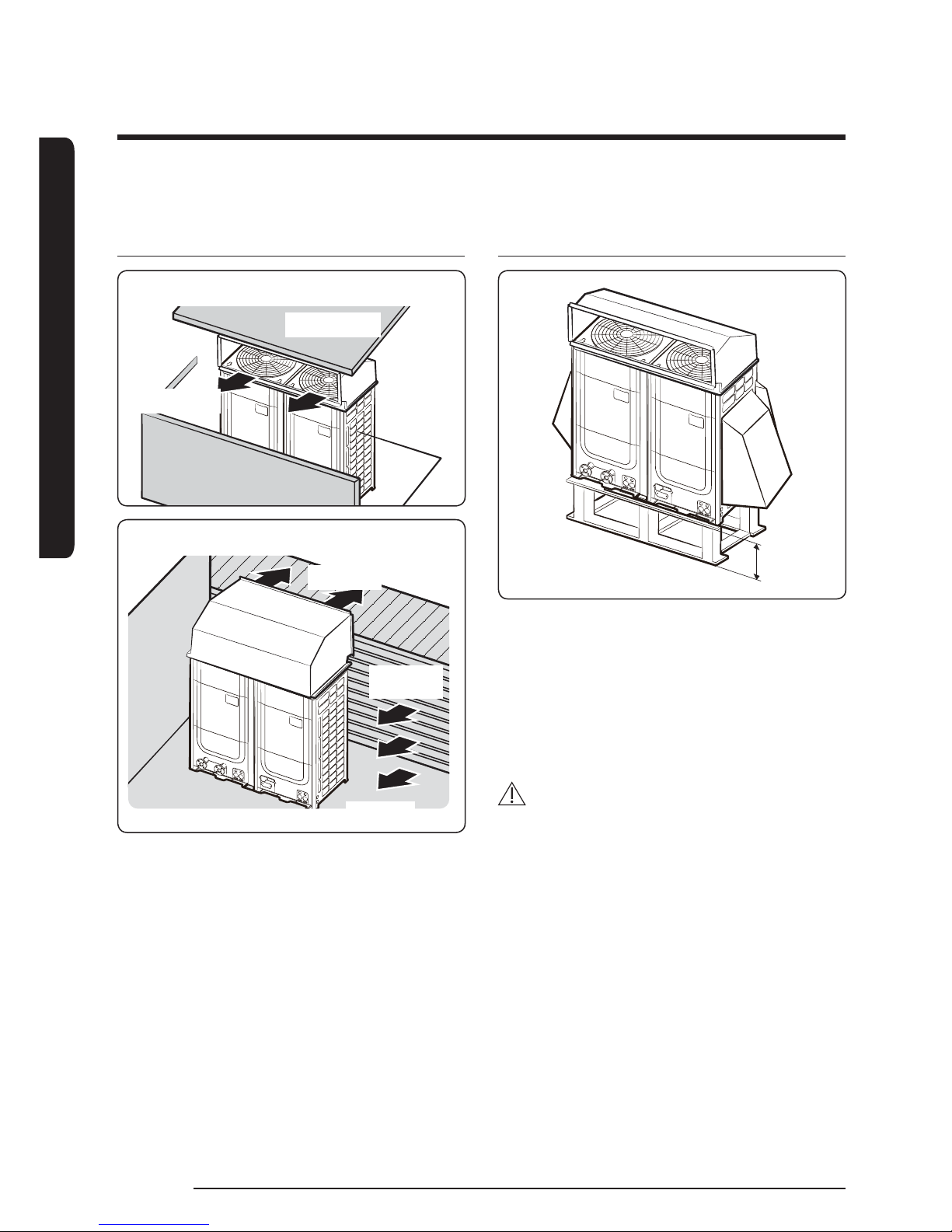

Installing the discharge duct

around the obstacles

Ex.) Balcony

Upper oor

Discharged air

Ex.) Mechanical room

Discharged

air

Grille/

louver

Suction air

fIt is necessary to install a wind/snow prevention

duct (eld supply) to direct exhaust from the fan

horizontally, when it is difcult to provide a minimum

space of 2m between the air outlet and a nearby

obstacle.

Installing the discharge duct in

cold regions

h

fIn cold regions with lots of snowfall, install a snow

prevention duct, as a sufcient countermeasure, to

prevent snow from accumulating on the product.

When the snow prevention duct is not installed

properly, frost may accumulate on the heat exchanger

and heating operation may not work normally.

fAir outlet of the duct should not be directed to the

enclosed space.

CAUTION

Cautions regarding on installing the frame and selecting

the base ground

ŷHeight (h) of the frame and the base ground should

be higher than the "heaviest expected snowfall".

ŷArea of the frame and the supporting base should

not be larger than the area of the product. Snow

may accumulate if the area of the frame or the base

ground is larger.

Installing the wind/snow prevention duct

INSTALLATION

21

English

Installing the discharge duct in

regions with strong wind

fIn windy regions such as near sea shores, protection

wall or wind protection duct must be installed

for normal operation of the product. (Refer to the

illustration of the snow prevention duct, for installing

the wind protection duct.)

fInstall the wind prevention duct with the

consideration of major wind direction. If the direction

of the discharge part is same as major direction

of the wind, it could cause product's performance

decrease.

1795560 560

2300

1695

1150

180

980

1697

2915

593

612

1210

1318

127

871

550765

668

532

2271

1134

965

180

CAUTION

Cautions regarding on installing the frame and selecting

the base ground

ŷThe base ground must be solid and the product

must be xed with anchor bolts.

ŷMake sure to install the product in a place strong

enough to withstand its weight.

If the place cannot withstand the weight of the

product, product may fall and cause personal injury.

ŷWhen installing on a rooftop subject to strong wind,

countermeasures must be taken to prevent the

product from falling down.

ŷUse a frame that is resistant to corrosion.

INSTALLATION

22

English

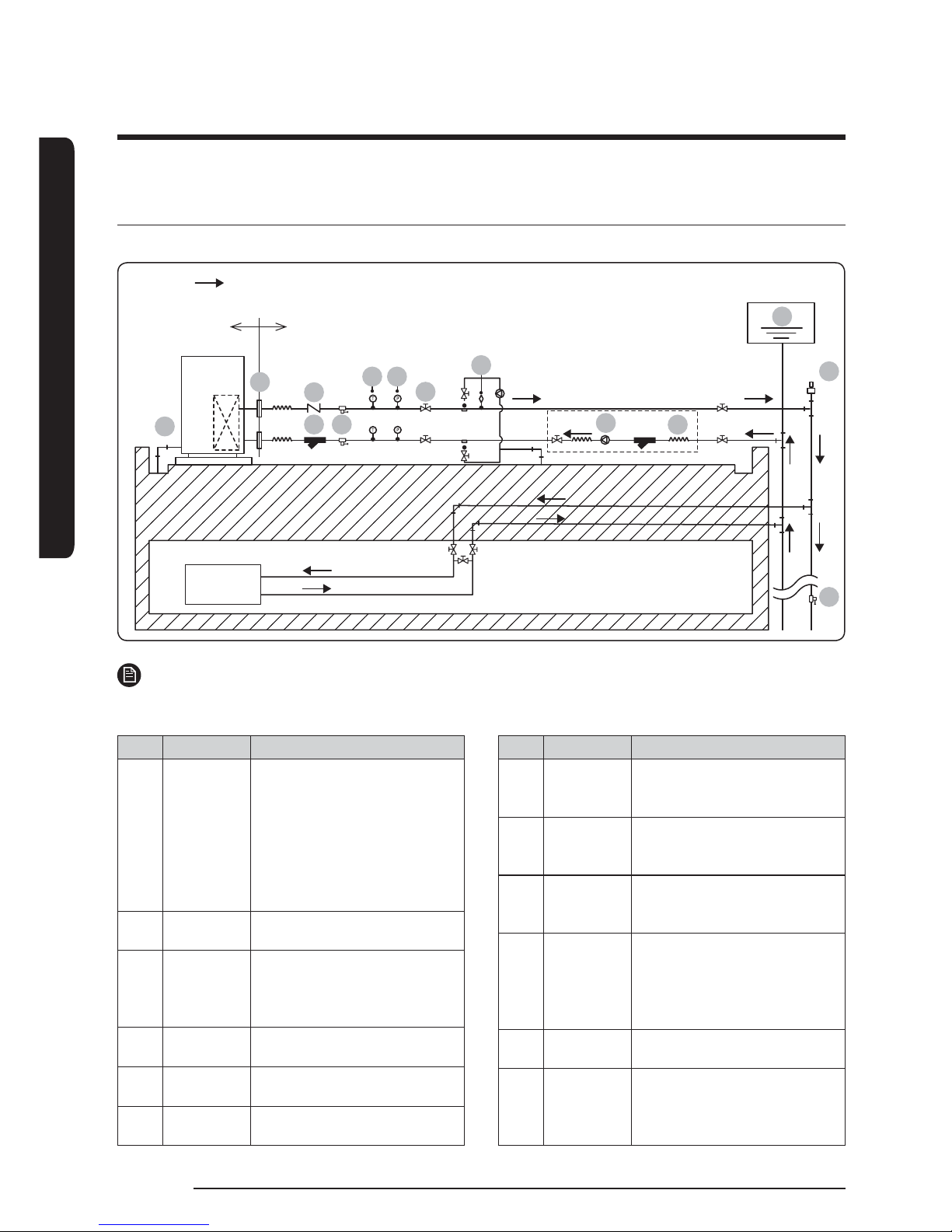

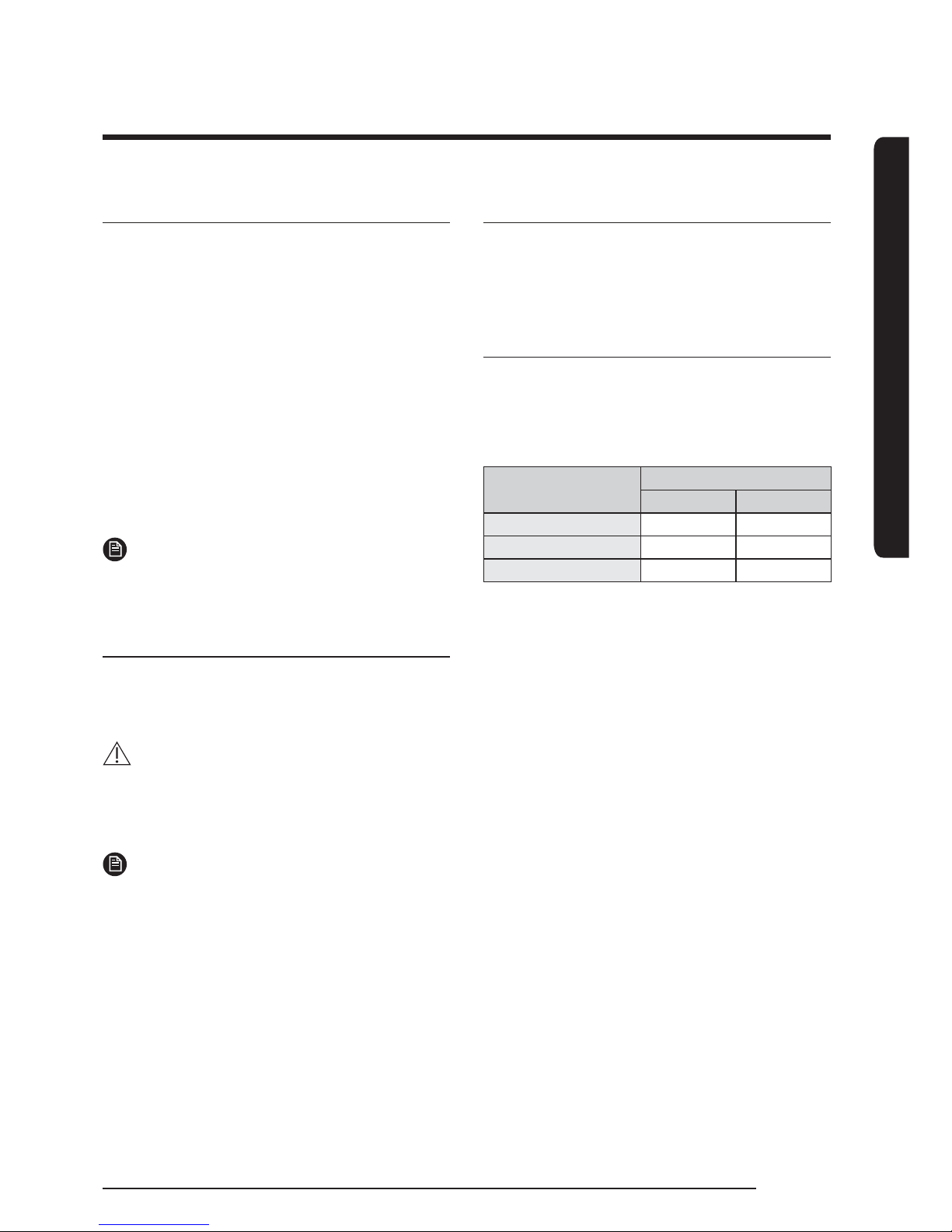

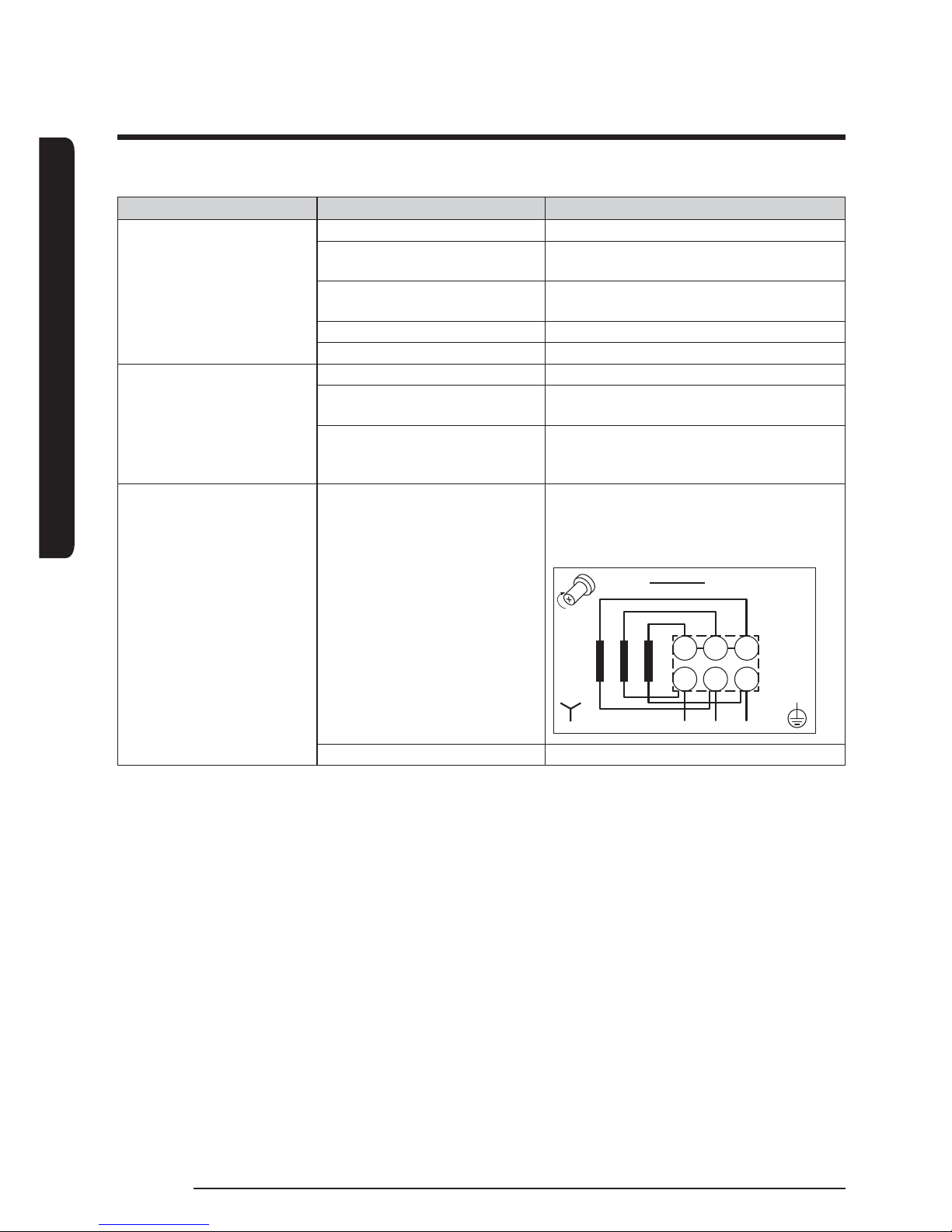

Water pipe diagram

Install the water system according to the diagram.

Direction of water ow

Expansion vessel

Cleaning and ushing pipe

(Install when cleaning)

Load unit

AHU or

Fancoil

DVM CHILLER

Field scope

Water side heat

exchanger

030704

10

11

09

12

08

01

04

0605

02

08

NOTE

ŷThe part shown in the dotted line is an installation example of AG

✴✴✴

KSVA series (non-pump models).

No. Name Remarks

01 Drain plug

Make 1/100 ~ 1/200 for drain

to ow by height difference. To

prevent freezing in winter time,

make slope steep and distance of

level side short as possible. Take

appropriate countermeasures

such as drain heater to prevent

freezing in cold region.

02 Flange

Install ange to allow unit

exchange.

03 Strainer

Install strainer at the nearest

place of the product to prevent

foreign materials ow into water

side heat exchanger. (50Mesh)

04 Drain valve

Install drain valve to drain water

for service.

05

Temperature

gauge

It is recommended for checking

ability and operation.

06

Pressure

gauge

It is recommended for checking

operation status.

No. Name Remarks

07 Valve

Install valves for services such

as owmeter exchange and

cleaning.

08

Air vent

valve

Install air vent valve where

there is a risk of air remaining.

(Auto air valve usable)

09 Check valve

Install check valve to prevent

water owing backward when

pump is stopped.

10 Pump

Install pump which holds amount

for keeping the head loss and

delivering enough water amount

to the product. (Refer to water

ow rate range on page 25.)

11 Flexible joint

It is recommended to prevent

noise and vibration of pump.

12

Expansion

vessel

To absorb the water volume

change caused by temperature

variation, be sure to install the

expansion vessel.

Water pipe installation

INSTALLATION

23

English

WARNING

ŷThe maximum operation water pressure of the

product is 1.0 MPa.

ŷThe water strainer is not included in the product.

You must install 50 Mesh stainless strainer (eld

supply). If the strainer is not installed, it may cause

breakdown of the product.

ŷThe strainer needs periodical maintenance. Work on

pipes considering space for maintenance.

ŷCompanion ange (eld supply) should be made of

SUS304, DIN PN10 standardized product.

Water pipe installation

Installation precautions

fHeat source water with high level of foreign

substances can cause corrosion or creation of water

scale on plate type heat exchanger and pipe, so

select installation place where the heat source water

is qualied according to water maintenance standard

for air conditioning equipment. (Refer to page 68 for

water maintenance standard table.)

fInstall strainer (eld supply) on heat source water

inlet.

fIf sand, dust, corroded particles ow into water

system, heat exchanger may get damaged because of

sedimentation of metallic particles and blocking the

heat exchanger. (Refer to page 11 for specication of

strainer.)

fBe careful not to change inlet/outlet of chilled/

heating water.

fFor normal operation, supply chilled/heating water

regularly to keep operation conditions stable.

fInstall valves at inlet/outlet of water pipes for

services.

fInstall temperature gauge and pressure gauge at

inlet/outlet of water pipes to check operation status.

fInsulate pipes to prevent thermal loss of water pipes

and freezing of pipe surface.

fWhen insulation is not done thoroughly, you will

waste energy caused by thermal loss and may get

property damage during cold seasons when water

pipe freezes. If the product is stopped at night or not

operated for long time during winter time, solution

for water pipe freezing may be necessary. Freezing

may cause product damage, so take appropriate

countermeasures such as pump operation, water

drainage, or heating by heater depending on the

situation.

fInstall exible joints at water pipes to prevent

vibrations.

fSupport water pipes with holders so that too much

weight is not loaded on pipes.

fInstall valves to drain water when the product is not

used for a long time or outdoor temperature is below

freezing point. Use drain valve to drain water left in

plate type heat exchanger and inside the product.

fInstall pipe returning to the pump inside the water

to prevent bubbles when thermal storage or tank is

installed. If dissolved oxygen is increased, corrosion

on water side heat exchanger and pipe can be faster.

INSTALLATION

Water pipe installation

24

English

Installing strainer

fInstall strainer (Field scope: 50 Mesh) that cleaning

is possible at the inlet of DVM CHILLER to prevent

foreign substances such as bolt and stones from

owing into water side heat exchanger.

- If strainer is not installed or the mesh is too

wide, foreign substances may ow into the

system and cause damage by freezing.

fInstall drain valves at inlet/outlet pipes to drain water

from water side heat exchanger for services.

fInstall extra strainer that cleaning is possible near

inlet pipe of the water pump.

Maintaining circulating water amount

fIf the product is operated below minimum amount

of circulating water (more than 50 % of rated ow

rate), plate type heat exchanger may freeze and get

damage. Use the product within circulating water

amount.

fMaintain for water level since it may decrease

by blocked strainer, remaining air, malfunction of

circulating pump.

Drainage during winter time

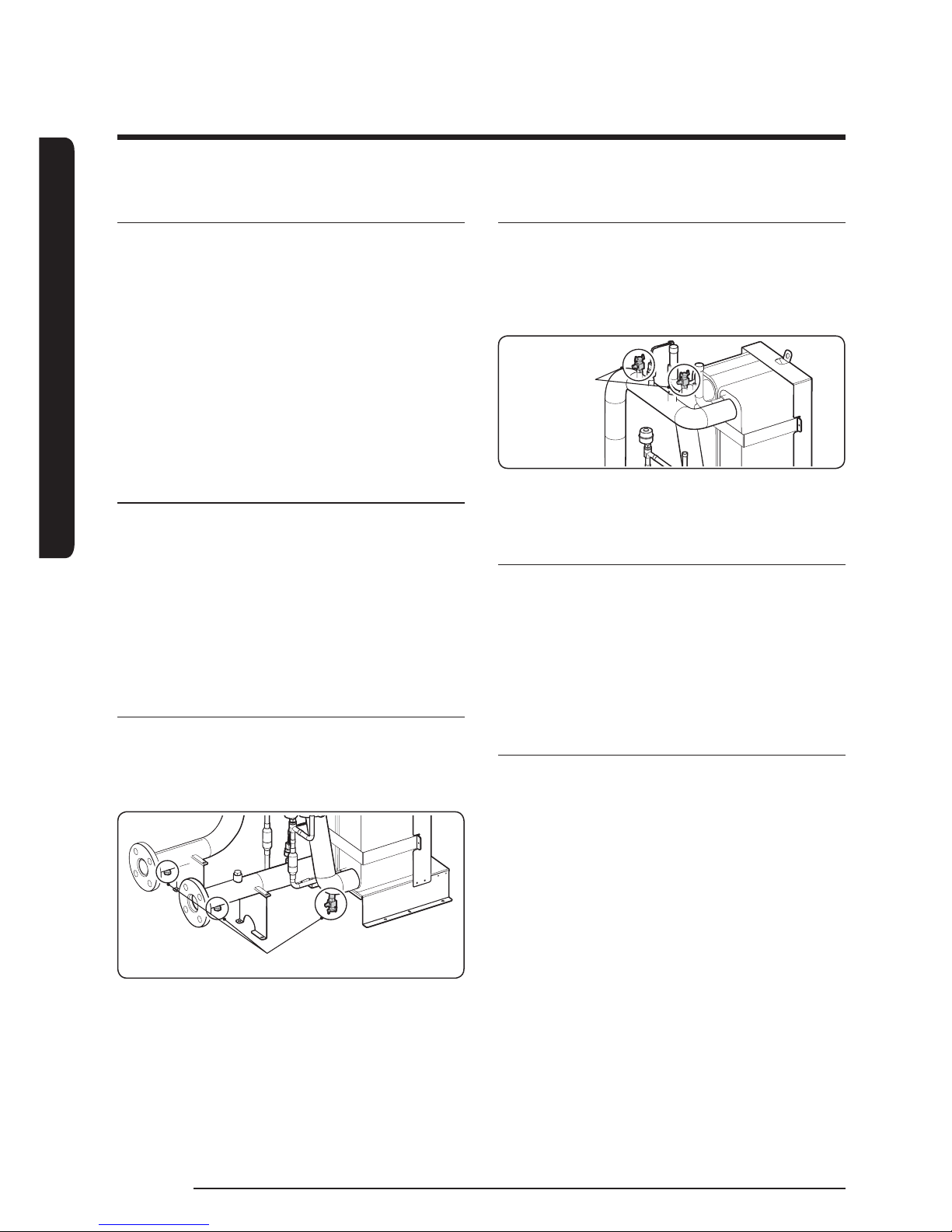

fWhen DVM CHILLER is not operated during winter

time, drain all water by opening drain valves in

CHILLER shown in gure and drain valves in the

pipes.

Drain valve

Air venting

fVent air by opening two air vent valves on inlet and

middle of the pipe of water side heat exchanger.

If air venting is not done properly, it is difcult to

maintain rated ow rate, and pipe corrosion or noise

by remaining oxygen may occur.

Air vent valve

fWhen venting air, be aware to prevent water get in

to the box.

Solution for freeze protection device

When freeze protection device is activated, plate heat

exchanger may freeze. Operate the product after

taking care of the cause. If you operate the product

before the problem has been taken care of, plate type

heat exchanger will be frozen and damaged, causing

refrigerant leakage or water may enter into the

refrigerant cycle.

Solution for pump vibration noise

Install exible joints at inlet/outlet and use vibration

proof rubber on the pump since noise may occur when

pump vibration is transferred to pipes.

INSTALLATION

25

English

Maintaining contamination

Foreign substances included in chilled/heating water by

small particles pass strainers, and they may be stuck or

stacked inside plate type heat exchanger. Some parts of

water pipes inside the plate type heat exchanger, and

the performance may decrease or it may freeze and get

damage. Therefore, clean the plate type heat exchanger

periodically.

Turbidity is a standard for water pollution level, and

standard water pollution set by Corrosion Prevention

Association is under turbidity 4. If the turbidity is high

or foreign substance is ew in too much, clean the

plate type heat exchanger periodically and maintain

the turbidity under 4. If it is over 4, clean the product

in about 1 year period since the rst operation of the

product.

NOTE

ŷRefer to page 68 for water maintenance standard

table.

Solution for water level decrease

When tank or thermal storage is installed open, select

pump which can acquire required water amount

concerning head loss other than pipe resistance.

CAUTION

ŷThe product should be operated for 3 minute after

it is stopped to protect water side heat exchanger

(plate type heat exchanger) from freezing.

NOTE

ŷExpansion vessel is to buffer expanded water and

also to purge air in water pipes. The capacity of

expansion vessel should be 2 ~ 2.5 times larger

than amount of water expansion or 4 ~ 5 % of total

amount of circulating water.

Freeze protection operation

Forced pump operation may be operated periodically

to protect water side heat exchanger (plate type heat

exchanger) from freezing in winter time or night time

when the pump is stopped. Be careful not to be injured.

Water ow rate range

Refer to the table to maintain minimum amount of

circulating water. If circulating amount is not enough,

the product will not only operate in best performance

but also affect the life of the product. Keep the amount

above the minimum level.

Model name

Flow rate range (LPM)

Min. Max.

AG042KSV Series 60 240

AG056KSV Series 80 320

AG070KSV Series 93 400

INSTALLATION

Water pipe installation

26

English

Securing water storage

Minimum water storage

Chilled/

heating

water pump

Buffer tank

Fan coil

fIf the length of water pipe is too short, water storage

within the system becomes lower and ON/OFF

operation of the compressor occurs more often. For

stable operation, maintain certain water storage by

applying header or Buffer tank.

CAUTION

ŷWhen installing tank, inlet pipe of the tank must be

installed under the water level.

fIf total water storage becomes under the minimum

storage, install another tank to retain more water

storage.

- In case of variable ow system, retain certain

amount of water by bypass pipe system.

Model name Minimum water storage (L)

AG042KSV Series 294

AG056KSV Series 392

AG070KSV Series 490

NOTE

ŷTotal water storage in the system = water storage

within the water pipe + water storage in DVM

CHILLER + water storage in AHU (or fan coil)

ŷMinimum capacity of buffer tank = Minimum

water storage - Total water storage in the system

excluding buffer tank

ŷSelect the capacity of buffer tank according to

system installation condition of the eld.

Water amount within the DVM CHILLER: AG042

✴✴✴

,

AG056

✴✴✴

: 12liter / AG070

✴✴✴

: 15.3 liter

Water pipe installation

Connecting water pipe

Chilled/heating water inlet

Chilled/heating water outlet

Flange

fCompanion ange is not supplied. Use eld supplied

one in DIN standardized product.

fWhen connecting the water pipe, use companion

ange and bolt made of SUS304, DIN PN10

standardized product.

fMaintain the tightening torque for ange as the table.

Water pipe

size

Allowable torque for

ange (N·m)

Material of

gasket

40 A

6.8 EPDM

50 A

12.7 EPDM

D

C

G

t

f

d

Size D

t

W.N. Slip-On Blind

DIN PN10

40 150 16 16 16

50 165 18 18 18

Gfd

Bolting

C

Diameter of

holes

Bolt size

DIN PN10

88 3 44.5 110 18 4-M16

102 3 57 125 18 4-M16

INSTALLATION

27

English

Using the pump

NOTE

ŷThe description below applies to AG

✴✴✴

KSVG series

models only.

Startup

CAUTION

ŷDo not start the pump until it has been lled with

liquid.

WARNING

ŷPay attention to the direction of the vent hole,

and make sure that the escaping hot or cold liquid

does not cause injury to persons or damage to the

equipment.

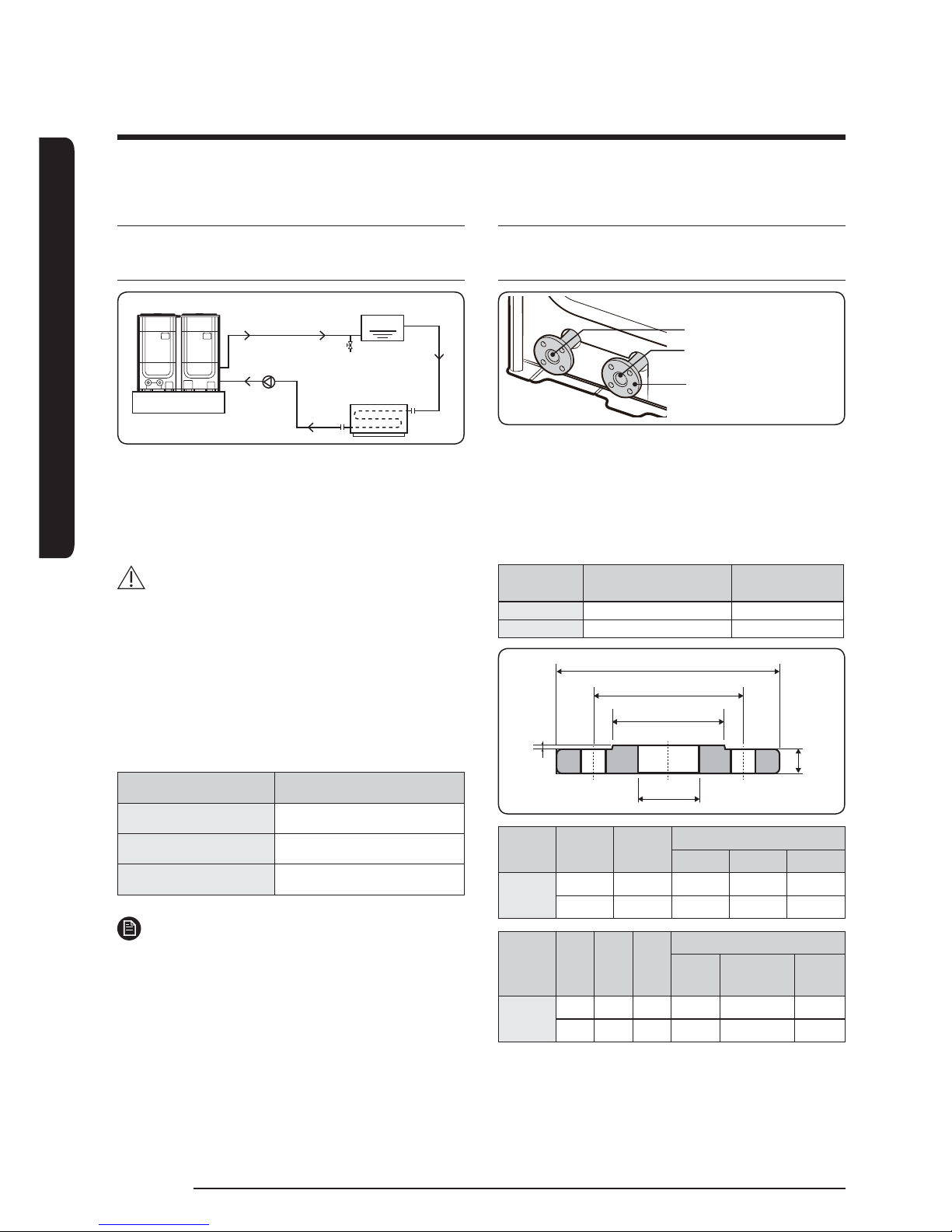

Checking the direction of rotation

NOTE

ŷThe description below applies to three-phase

motors only.

The motor fan cover has an installation indicator. See

g. 1. Based on the motor cooling air, it indicates the

direction of rotation of the motor.

Before the motor is started for the rst time or if

the position of the indicator has been changed, the

indicator function should be checked, for instance by

moving the indicator eld with a nger.

To determine whether the direction of rotation is

correct or wrong, compare the indication with the table

below.

Indicator eld Direction of rotation

Black Correct

White/reecting Wrong*

* To reverse the direction of rotation, switch off

the power supply and interchange any two of the

incoming supply wires.

Indicator eld

Fig. 1 Installation indicator

You can place the indicator in various positions on the

motor, but do not place it between the cooling ns close

to the screws that hold the fan cover.

The correct direction of rotation is also shown by

arrows on the motor fan cover.

Maintenance

WARNING

ŷBefore starting work on the pump, switch off the

power supply. Make sure that the power supply

cannot be accidentally switched on.

ŷMake sure that the escaping water does not cause

injury to persons or damage to the equipment.

The internal pump parts are maintenance-free. You

must keep the motor clean in order to ensure adequate

cooling of the motor. If the pump is installed in dusty

environments, clean and check the pump regularly.

Take the enclosure class of the motor into account when

cleaning.

The motor has maintenance-free, greased-for-life

bearings.

INSTALLATION

Using the pump

28

English

Frost protection

Pumps which are not being used during periods of frost

must be drained to avoid damage.

Remove the lling and drain plugs from the pump.

Do not ret the plugs until the pump is taken into

operation again.

CAUTION

ŷBefore startup after a period of inactivity, the pump

and the suction pipe must be completely lled with

liquid. See Start up (27).

Cleaning

Prior to a long period of inactivity, ush the pump with

clean water to prevent corrosion and deposits in the

pump.

Use acetic acid to remove possible lime deposits from

the pump.

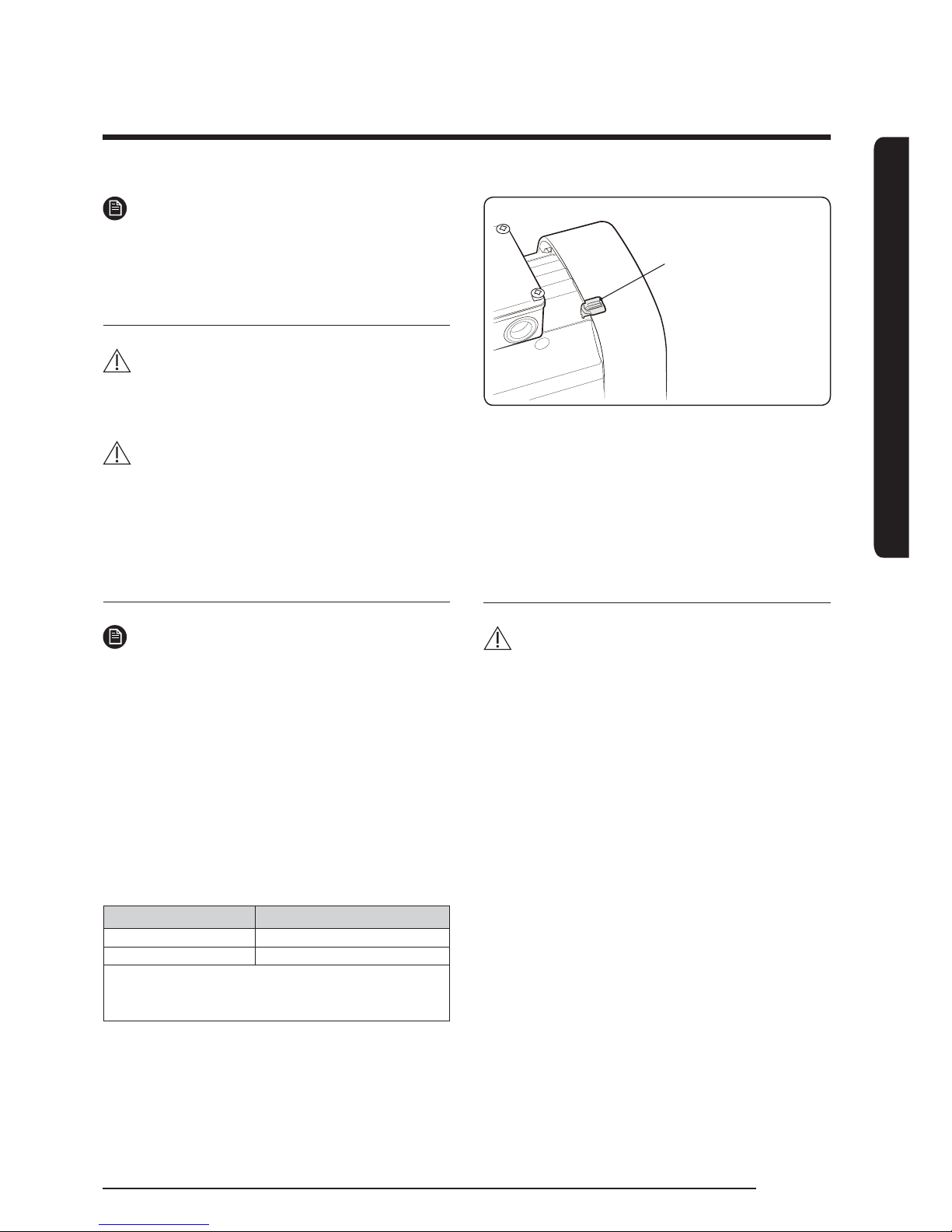

Repairing the pump and connecting the

pipe

We recommend that

you t isolating valves

on either side of the

pump. It is thus not

necessary to drain the

system if the pump

needs service.

The pump must not

be stressed by the

pipework.

Coupling bolt torque: 200 ± 10% kgfcm

The torque must not be exceeded.

WARNING

ŷAfter product inspection, if the compressor is

operated while the refrigerant piping is leaked,

air may enter inside the compressor. It may cause

abnormal high pressure to develop inside the

compressor, leading to product malfunction or an

explosion.

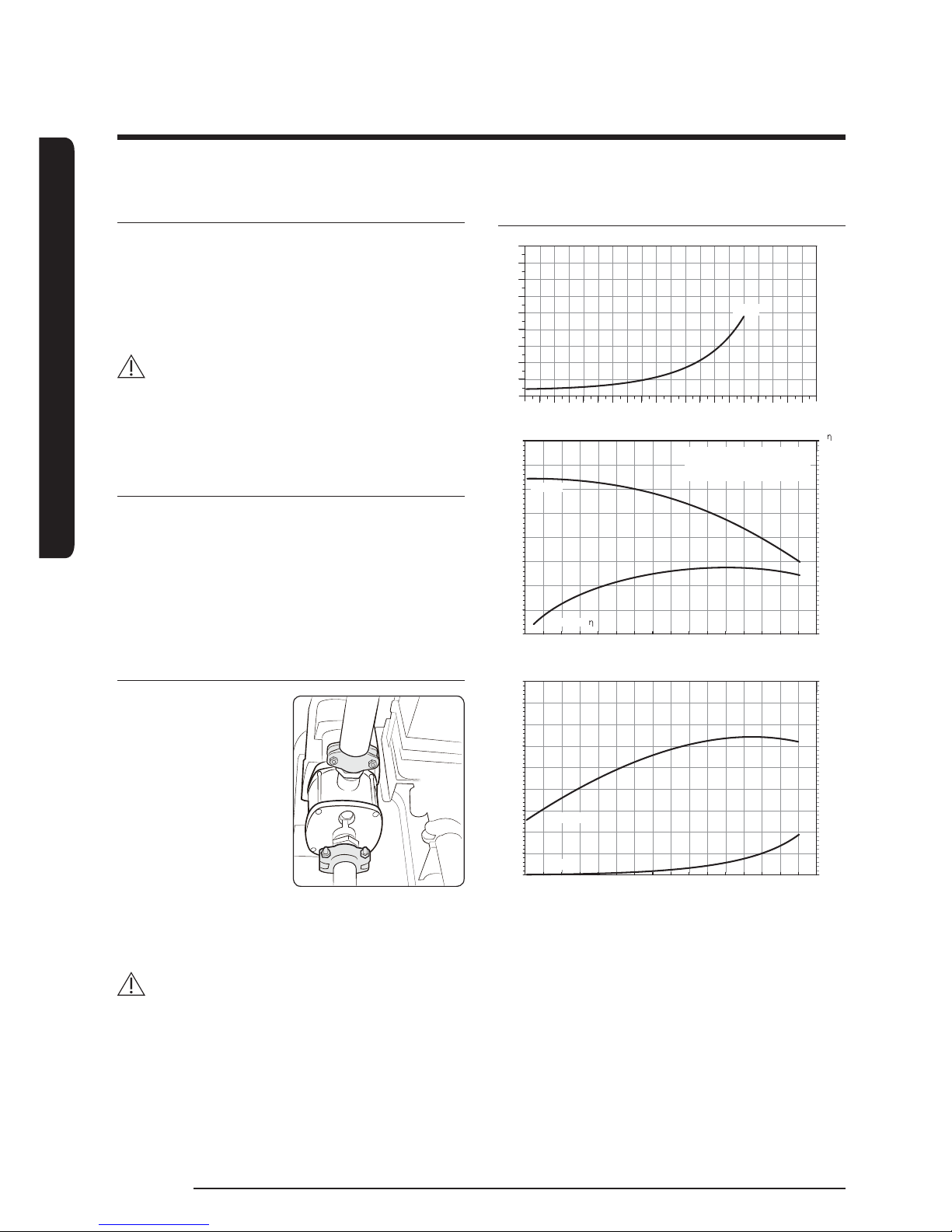

Pump performance chart

NPSH

[m]

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Q [m³/h]

2

4

6

8

10

12

14

16

50Hz

H

[m]

30

35

25 100

20

15

10

0

5

[%]

120

140

80

60

40

0

20

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Q [m³/h]15

efciency,

Head, H

P

[kW]

1.2

1.6

1.4

1.0 25

0.8

0.6

0.4

0

0.2

NPSH

[m]

30

40

35

20

15

10

0

5

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Q [m³/h]15

NPSH

Power, P

ŷNPSH = Net Positive Suction Head

ŷNPSH is the requirement to keep enough pressure

on the system to prevent cavitation.

ŷCavitation : ashing the moving uid into a gas

ŷFrequency : 50Hz

Pumped liquid = Water

Liquid temperature = 20°C

Density = 998.2 kg/m³

INSTALLATION

29

English

Fault nding

WARNING

ŷBefore removing the terminal box cover, switch off the power supply. Make sure that the power supply cannot

be accidentally switched on.

ŷThe pumped liquid may be scalding hot and under high pressure. Before any removal or dismantling of the

pump, the system must therefore be drained, or the isolating valves on either side of the pump must be closed.

Fault Cause Remedy

1. The pump does not run. a) Supply power failure. Switch on the switch.

Check cables and cable connections for defects

and loose connections.

b) Motor protection tripped. See 2. a), b), c), d), e).

c) Control-current circuit defective. Repair or replace the control-current circuit.

2. Motor-protective circuit

breaker has tripped (trips

immediately when power

supply is switched on).

a) Contacts of the motor-protective

circuit breaker or magnet coil

defective.

Replace the contacts of the motor-protective

circuit breaker, the magnet coil or the entire

motor-protective circuit breaker.

b) Cable connection is loose or

faulty.

Check cables and cable connections for

defects, and replace the fuses.

c) Motor winding is defective. Repair or replace the motor.

d) The pump is mechanically

blocked.

Switch off the power supply, and clean or

repair the pump.

e) The setting of the motor-

protective circuit breaker is too

low.

Set the motor-protective circuit breaker

according to the rated current of the motor.

See nameplate.

3. The motor-protective circuit

breaker trips occasionally.

a) The setting of the motor-

protective circuit breaker is too

low.

See 2. e).

b) Periodic supply fault. See 2. b).

c) Periodically low voltage. Check cables and cable connections for defects

and loose connections. Check that the power

supply cable of the pump is correctly sized.

4. The motor-protective circuit

breaker has not tripped, but

the pump is inadvertently

out of operation.

a) See 1. a), b), c) and 2. d).

5. The pump performance is

unstable.

a) Pump inlet pressure too low. Check the inlet conditions of the pump.

b) Suction pipe is partly blocked

by impurities.

Remove and clean the suction pipe.

c) Leakage in suction pipe. Remove and repair the suction pipe.

d) Air in suction pipe or pump. Vent the suction pipe or pump. Check the inlet

conditions of the pump.

INSTALLATION

Using the pump

30

English

Fault Cause Remedy

6. The pump runs, but gives

no water.

a) Pump inlet pressure too low. See 5. a).

b) The suction pipe is partly

clogged by impurities.

See 5. b).

c) The foot or non-return valve is

stuck in its closed position.

Remove and clean, repair or replace the valve.

d) Leakage in suction pipe. See 5. c).

e) Air in suction pipe or pump. See 5. d).

7. The pump runs backwards

when switched off.

a) Leakage in suction pipe. See 5. c).

b) Foot or non-return valve

defective.

See 6. c).

c) The foot valve is stuck in

completely or partly open

position.

See 6. c).

8. The pump runs with

reduced performance.

a) Wrong direction of rotation. Switch off the power supply with the external

circuit breaker, and interchange two phases

in the pump terminal box. See Checking the

direction of rotation on page 27.

W2 U2 V2

U1 V1 W1

HIGH VOLTAGE

DIRECTION OF ROTATION

b) See 5. a), b), c), d).

Loading...

Loading...