Samsung AE090MNYDEH, AE090MNYDGH, AE160MNYDEH, AE160MNYDGH Installation Manual

Air to Water Heat Pump -TDM PLUS Hydro Unit

Installation manual

AE090MNYDEH / AE090MNYDGH / AE160MNYDEH / AE160MNYDGH

• Thank you for purchasing this Samsung air conditioner.

• Before operating this unit, please read this manual carefully and retain it for future

reference.

2

English

Contents

PREPARATION 3

Safety precautions 3

Product Specifications 5

Typical application examples 9

Main components 11

Functional diagram 12

Dimensional drawing 13

INSTALLATION 14

Installing the unit 14

Pipe work 16

Wiring work 23

Self-test mode of wired remote controller 35

OTHERS 37

Troubleshooting 37

DHW tank 40

Mixing Valve 47

Concrete curing function 51

Installation option setting 53

How to connect your extended power cables 55

COMMISSION REGULATION (EU) No 813/2013 ᶦ⁾ 58

COMMISSION DELEGATED REGULATION (EU) No 811/2013

i)

83

3

English

PREPARATION

All materials supplied to this manual are indispensable for the

safety of equipment.

Users shall establish appropriate safety and health practices

and determine the applicability of regulatory limitation based

on following descriptions prior to use.

WARNING

• Always disconnect the air to water heat pump from the

power supply before servicing it or accessing its internal

components.

• Verify that installation and testing operations are

performed by qualified personnel.

• Verify that the air to water heat pump is not installed in an

easily accessible area.

GENERAL INFORMATION

WARNING

• Carefully read the content of this manual before installing the

air to water heat pump and store the manual in a safe place in

order to be able to use it as reference after installation.

• For maximum safety, installers shall always carefully read the

following warnings.

• Store the user and installation manual in a safe location and

remember to hand it over to the new owner if the air to water

heat pump is sold or transferred.

• This manual explains how to install SAMSUNG TDM Plus

product. The use of other types of units with different control

systems may damage the units and invalidate the warranty.

The manufacturer shall not be responsible for damages arising

from the use of non compliant units.

• The manufacturer shall not be responsible for damage

originating from unauthorized changes or the improper

connection of electric and hydraulic lines. Failure to comply

with these instructions or to comply with the requirements set

forth in the “Operating limits” table, included in the manual,

shall immediately invalidate the warranty.

• Do not use the units if damaged. If problems occur, switch the

unit off and disconnect it from the power supply.

• In order to prevent electric shocks, fires or injuries, always stop

the unit, disable the protection switch and contact SAMSUNG’s

technical support if the unit produces smoke, if the power cable

is hot or damaged or if the unit is very noisy.

• Always remember to inspect the unit, electric connections,

refrigerant tubes and protections regularly. These operations

should be performed by qualified personnel only.

• The unit contains moving parts, which should always be kept

out of the reach of children.

• Do not attempt to repair, move, alter or reinstall the unit. If

performed by unauthorized personnel, these operations may

cause electric shocks or fires.

• Do not place containers with liquids or other objects on the

unit.

• All the materials used for the manufacture and packaging of

the air to water heat pump are recyclable.

• The packing material and exhaust batteries of the remote

control(optional) must be disposed of in accordance with

current laws.

• The air to water heat pump contains a refrigerant must be

disposed in authorized center or returned to retailer as special

wastes.

• Do not disassemble and alter the heater at your own discretion.

INSTALLING THE UNIT

IMPORTANT: When installing the unit, always remember to

connect first the refrigerant tubes, then the electrical lines.

Always disassemble the electric lines before the refrigerant

tubes.

• Upon receipt, inspect the product to verify that it has not been

damaged during transport. If the product appears damaged,

DO NOT INSTALL it and immediately report the damage to the

carrier or retailer (if the installer or the authorized technician

has collected the material from the retailer.)

• After completing the installation, always carry out a functional

test and provide the instructions on how to operate the air to

water heat pump to the user.

• Do not use the air to water heat pump in environments with

hazardous substances or close to equipment that release free

flames to avoid the occurrence of fires, explosions or injuries.

Safety precautions

4

Safety precautions

English

PREPARATION

POWER SUPPLY LINE, FUSE OR CIRCUIT

BREAKER

• Always make sure that the power supply is compliant with

current safety standards. Always install the air to water heat

pump in compliance with current local safety standards.

• Always verify that a suitable grounding connection is

available.

• Verify that the voltage and frequency of the power supply

comply with the specifications and that the installed power

is sufficient to ensure the operation of any other domestic

appliance connected to the same electric lines.

• Always verify that the cut-off and protection switches are

suitably dimensioned.

• Verify that the air to water heat pump is connected to the

power supply in accordance with the instructions provided

in the wiring diagram included in the manual.

• Always verify that electric connections (cable entry, section

of leads, protections…) are compliant with the electric

specifications and with the instructions provided in the

wiring scheme. Always verify that all connections comply

with the standards applicable to the installation of air to

water heat pumps.

• Be sure not to perform power cable modification, extension

wiring, and multiple wire connection.

– It may cause electric shock or fire due to poor

connection, poor insulation, or current limit override.

– When extension wiring is required due to power line

damage, refer to "How to connect your extended power

cables" in the installation manual.

CAUTION

• Make sure that you earth the cables.

– Do not connect the earth wire to the gas pipe, water

pipe, lighting rod or telephone wire. If earthing is not

complete, electric shock or fire may occur.

• Install the circuit breaker.

– If the circuit breaker is not installed, electric shock or

fire may occur.

• Make sure that the condensed water dripping from the

drain hose runs out properly and safely.

• Install the power cable and communication cable of the

indoor and outdoor unit at least 1m away from the electric

appliance.

5

English

PREPARATION

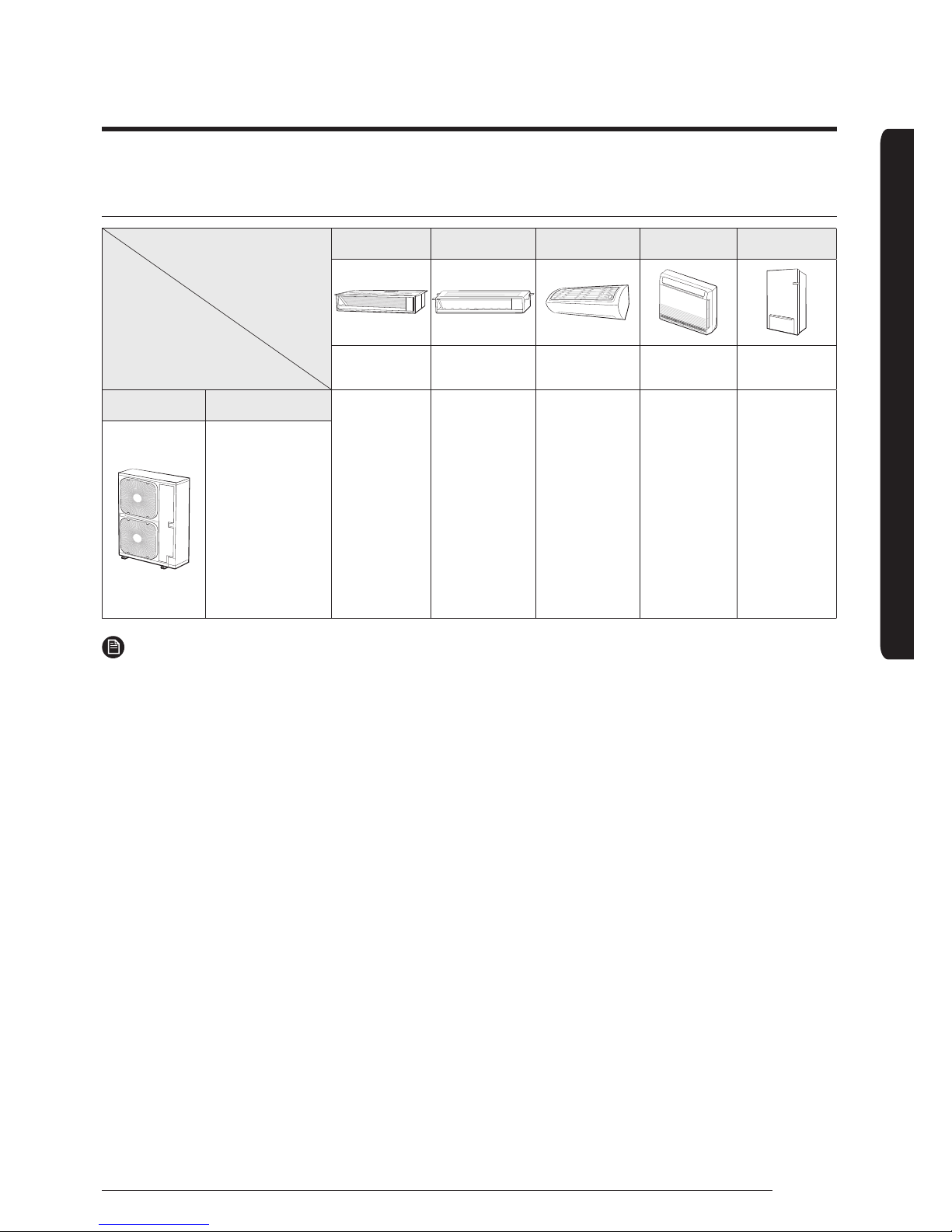

Product compatibility

Indoor unit

Outdoor unit

Slim Duct MSP Duct RAC Console Hydro Unit

2.2~5.6kW 7.1~9kW 2 . 2~7.1 kW 2.2~5.6kW 9/16kW

Classification Features

AE022MNLDEH

AE028MNLDEH

AE036MNLDEH

AE056MNLDEH

AE071MNMPEH

AE090MNMPEH

AE022MNADEH

AE028MNADEH

AE036MNADEH

AE056MNADEH

AE071MNADEH

AE022MNJDEH

AE028MNJDEH

AE036MNJDEH

AE056MNJDEH

AE090MNYDEH

AE160MNYDEH

AE090MNYDGH

AE160MNYDGH

- Heat pump for

heating and hot

water system

[Eco Heating Full

System]

- Outdoor unit:

4.4/6.6/9/12/16 kW

- Long pipe reliability:

75m

NOTE

• AE∗∗∗MXTP∗H and above EHS TDM Indoor units are applicable for EHS products only.

They are not compatible with EHS Split Hydro unit, CAC, DVM and FJM products.

• A2W: Air to Water, A2A: Air to Air

Product Specifications

6

Product Specifications

English

PREPARATION

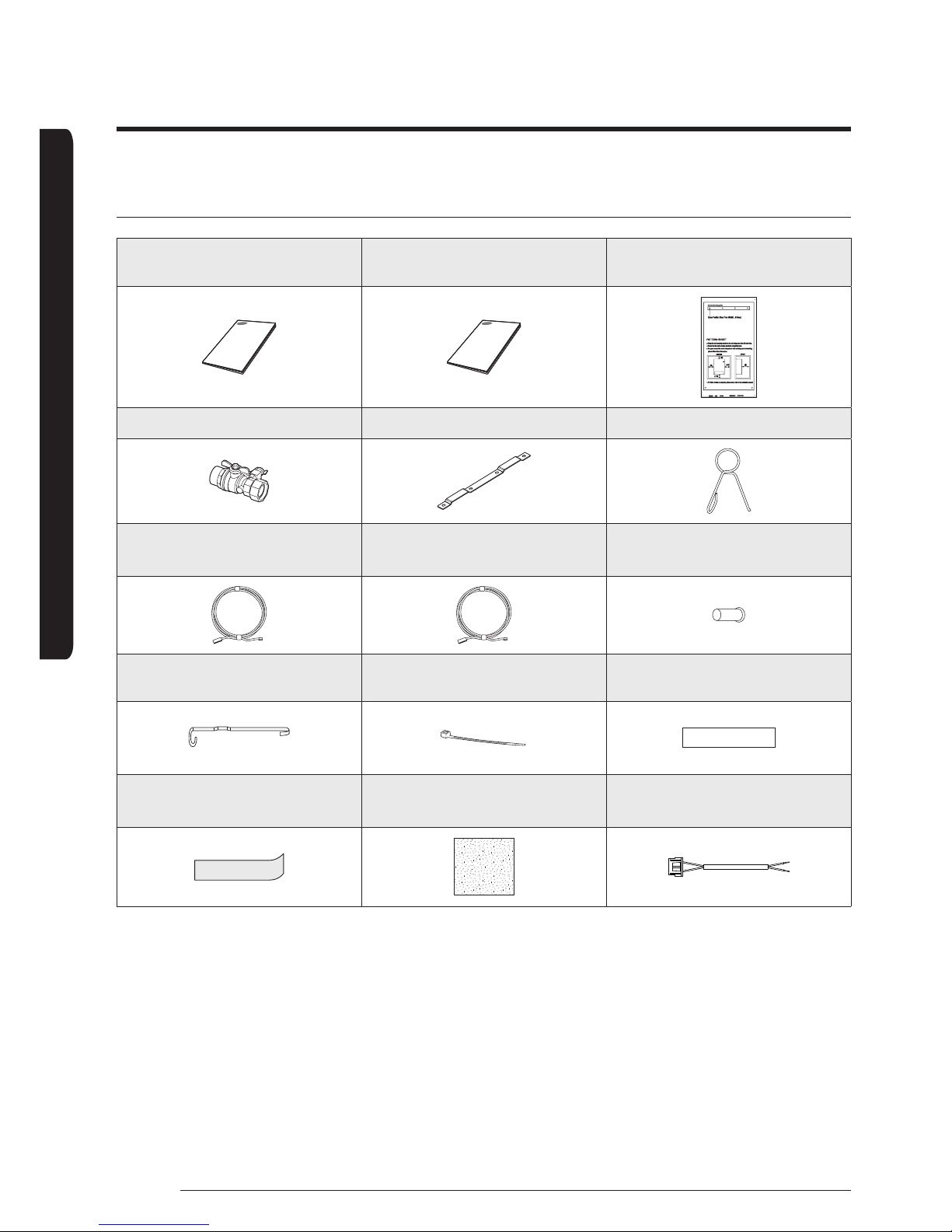

Accessories

Installation Manual(1) User Manual(1) Pattern Sheet(1)

Service Valve(2) Wall Mounting Bracket(1) Ring band (1)

Temperature Sensor for DHW Tank

(1x15m,YEL) (1)

Temperature Sensor for Mixing

Valve (1x15m, BLU) (1)

Sensor holder of mixing valve

(ID Ø6.8mm) (1)

Sensor clip for mixing Valve Sensor

(1)

Cable-tie for mixing valve (4) Aluminum tape for mixing valve (1)

Rubber tape for mixing Valve Sensor

(1)

Insulator for mixing valve (1)

Connector Wire -Smart Grid

(1x2m, RED) (1)

7

English

PREPARATION

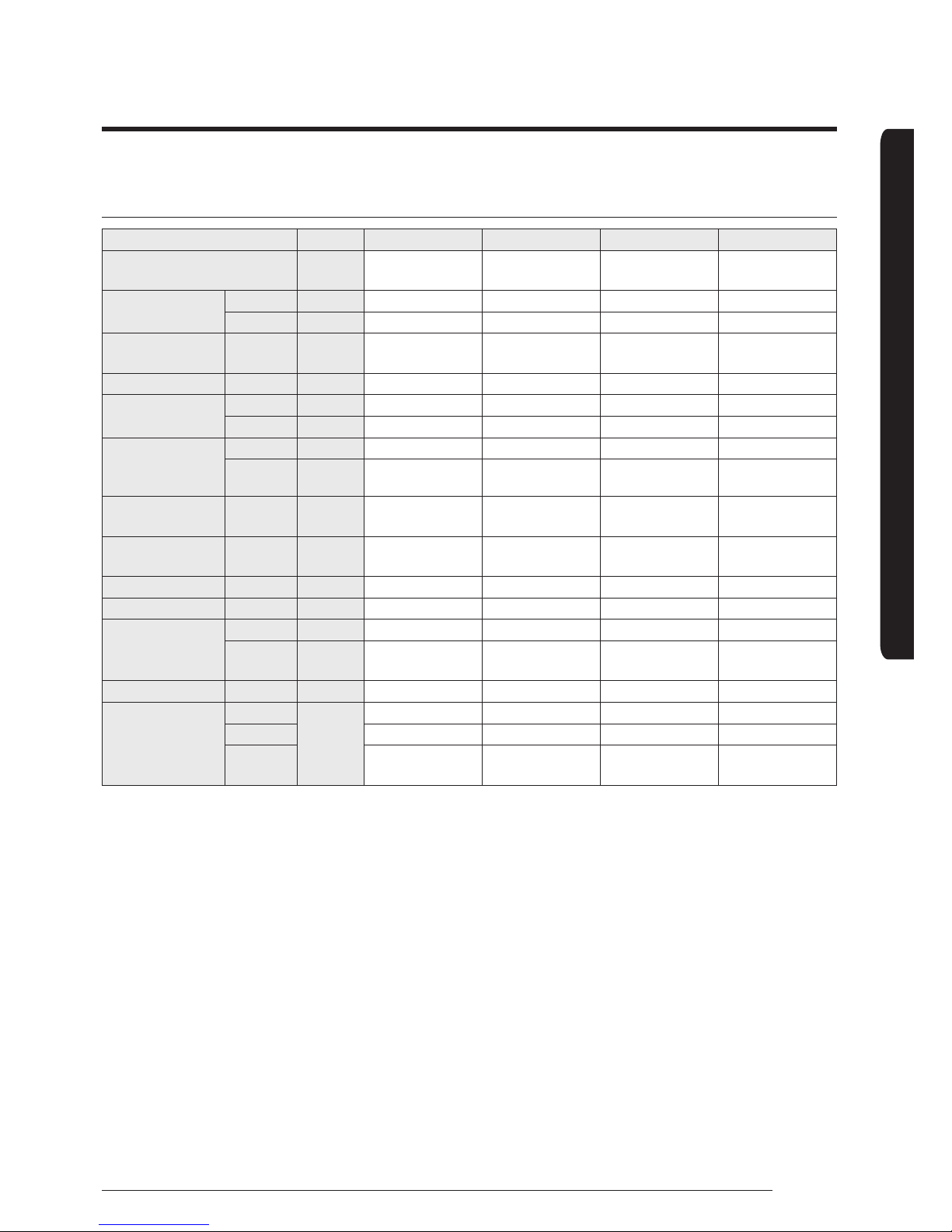

Specications

Type Unit AE090MNYDEH AE090MNYDGH AE160MNYDEH AE160MNYDGH

Power Source

V/Hz

1ø, 220-240V~,

50Hz

3ø, 380-415V~,

50Hz

1ø, 220-240V~,

50Hz

3ø, 380-415V~,

50Hz

Operation Range

[Water]

Cooling

°C 5~25 5~25 5~25 5~25

Heating

°C 15~55 15~55 15~55 15~55

Dimension

(WxHxD)

Net

mm 850 x 510 x 315 850 x 510 x 315 850 x 510 x 315 850 x 510 x 315

Weight Net

kg 45.5 46.5 46.5 46.5

Connecting Pipe

[Refrigerant]

Liquid

Inch 1/4 1/4 3/8 3/8

Gas

Inch 5/8 5/8 5/8 5/8

Service Valve

Connecting Pipe

[Water]

Inlet

Inch BSPP male 1 1/4 BSPP male 1 1/4 BSPP male 1 1/4 BSPP male 1 1/4

Outlet

Inch BSPP male 1 1/4 BSPP male 1 1/4 BSPP male 1 1/4 BSPP male 1 1/4

Water Pump

Max Vol

Flow

m3/h 3.5 3.5 5.0 5.0

Electric Heater

Input

power

W 4,000 6,000 6,000 6,000

Flow Switch Set Point

LPM 7±1.5 7±1.5 12±1.5 12±1.5

Expansion Vessel Volume

Liter 8.0 8.0 8.0 8.0

Pressure relief

valve

Size

Inch BSPP male 1/2 BSPP male 1/2 BSPP male 1/2 BSPP male 1/2

Relief

Pressure

bar 2.9 2.9 2.9 2.9

Air- vent Valve Size

inch BSPP male 3/8 BSPP male 3/8 BSPP male 3/8 BSPP male 3/8

Operating

Outdoor Temp.

Range

Heating

°C

-25 ~ 35 -25 ~ 35 -25 ~ 35 -25 ~ 35

Cooling

10 ~ 46 10 ~ 46 10 ~ 46 10 ~ 46

DHW

Water

-25 ~ 43 -25 ~ 43 -25 ~ 43 -25 ~ 43

∗ Heat pump operating range of DHW : -25 ~ 35 °C

∗ At the temperature -25°C ~ -20°C, operation is available but capacity cannot be guaranteed.

8

Product Specifications

English

PREPARATION

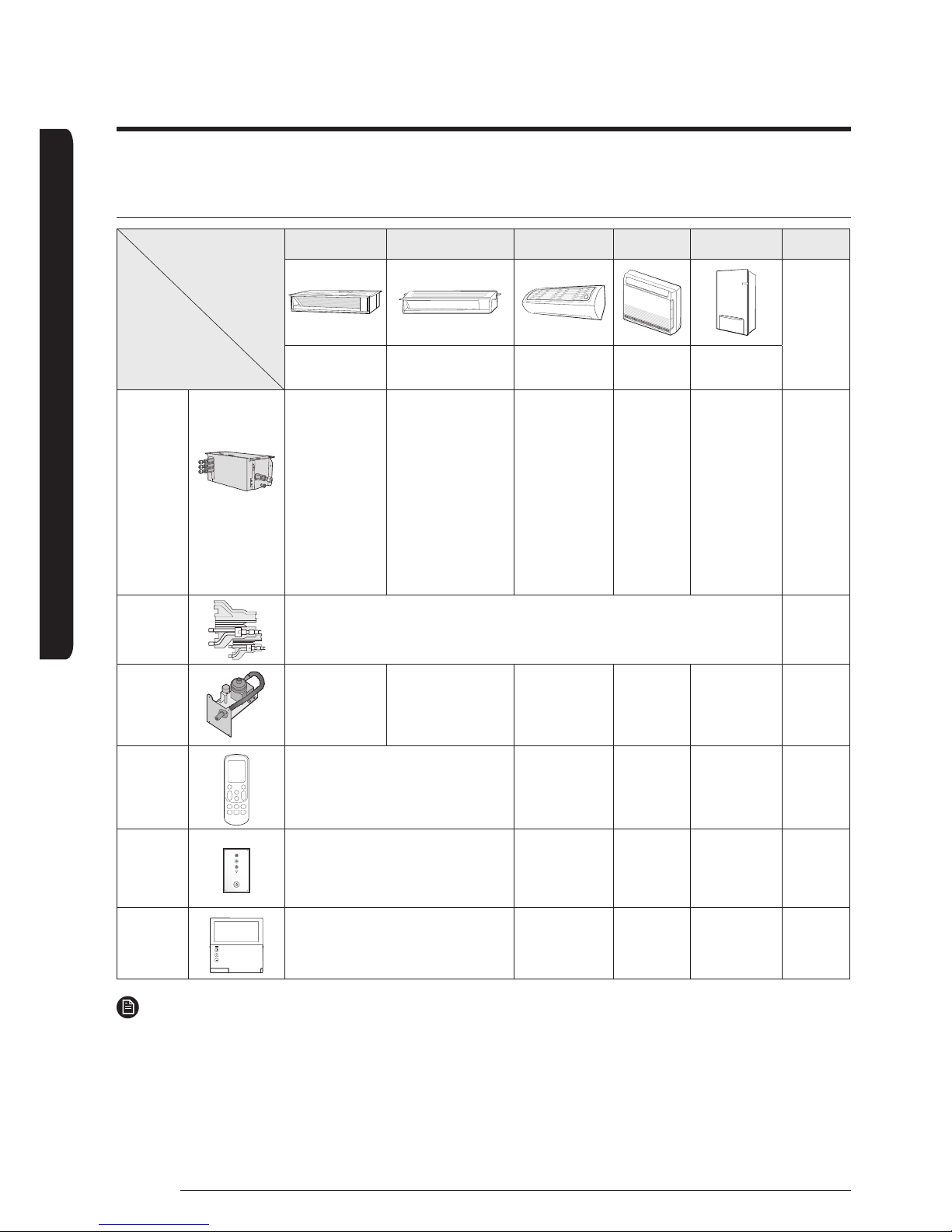

Subsidiary materials compatibility

Indoor unit

Subsidiary materials

Slim Duct MSP Duct RAC Console Hydro Unit Remark

2.2~5.6kW 7.1~9kW 2. 2~ 7.1kW 2.2~5.6kW 9/16kW

EEV Kit

EEV Kit for 1/2/3

room

- -

MEV-E24SA

MEV-E32SA

MXD-E24K132A

MXD-E24K200A

MXD-E24K232A

MXD-E24K300A

MXD-E32K200A

MXD-E32K224A

MXD-E32K300A

- - Requisite

Y-joint

MXJ-YA1509M

(≤15.0kW and below)

Requisite

Drain

Pump

MDP-

E075SEE3D

(Option,

Internal Type)

MDP-G075SP

(Option, External Type)

MDP-G075SQ

(Option, Internal Type)

- - -

Wireless

remote

controller

MR-EH00

(Option)

MR-EH00

(Included)

- -

Remote

controller

receive kit

MRK-A10N

(Option)

- - -

Wired

remote

controller

MWR-WE10N

(Option)

- -

MWR-

WW00N

(Included)

NOTE

• Subsidiary materials are compatible with DVM products.

• EEV KIT : Required installation. It is not included inside of product. Install distribution kit for 1, 2 or 3 indoor on the ceiling or

outdoor area.

• A2W: Air to Water, A2A: Air to Air

9

English

PREPARATION

Typical application examples

CAUTION

• The application examples given below are for illustration purposes only.

• When the SAMSUNG Air-to-Water Heat Pump system is used in series with another heat source (e.g. gas boiler), ensure that

the return water temperature not exceed 55°C.

• The unit is only to be used in a closed water system. Application in an open water circuit can lead to excessive corrosion of the

water piping.

• SAMSUNG can not be responsible put responsible for incorrect installations in the water system. Make sure that the boiler,

radiators, convectors, solar collectors, UFHs, FCUs, additional pumps, pipes, and controls in the water system are in accordance

with relevant local laws and regulations under the installer’s responsibility.

• SAMSUNG shall not be held liable for any damage resulting from not observing this rule.

• SAMSUNG do not provide specific water system components such as Pressure relief valve, Air vent valve, buffer tank and etc.

Installers and end-users shall consider how to install the above designated components in overall water system depending on

the installation conditions. If the components are not installed in appropriate location, the water system can not be operated

as designed.

∗ The below examples are for illustration purposes only.

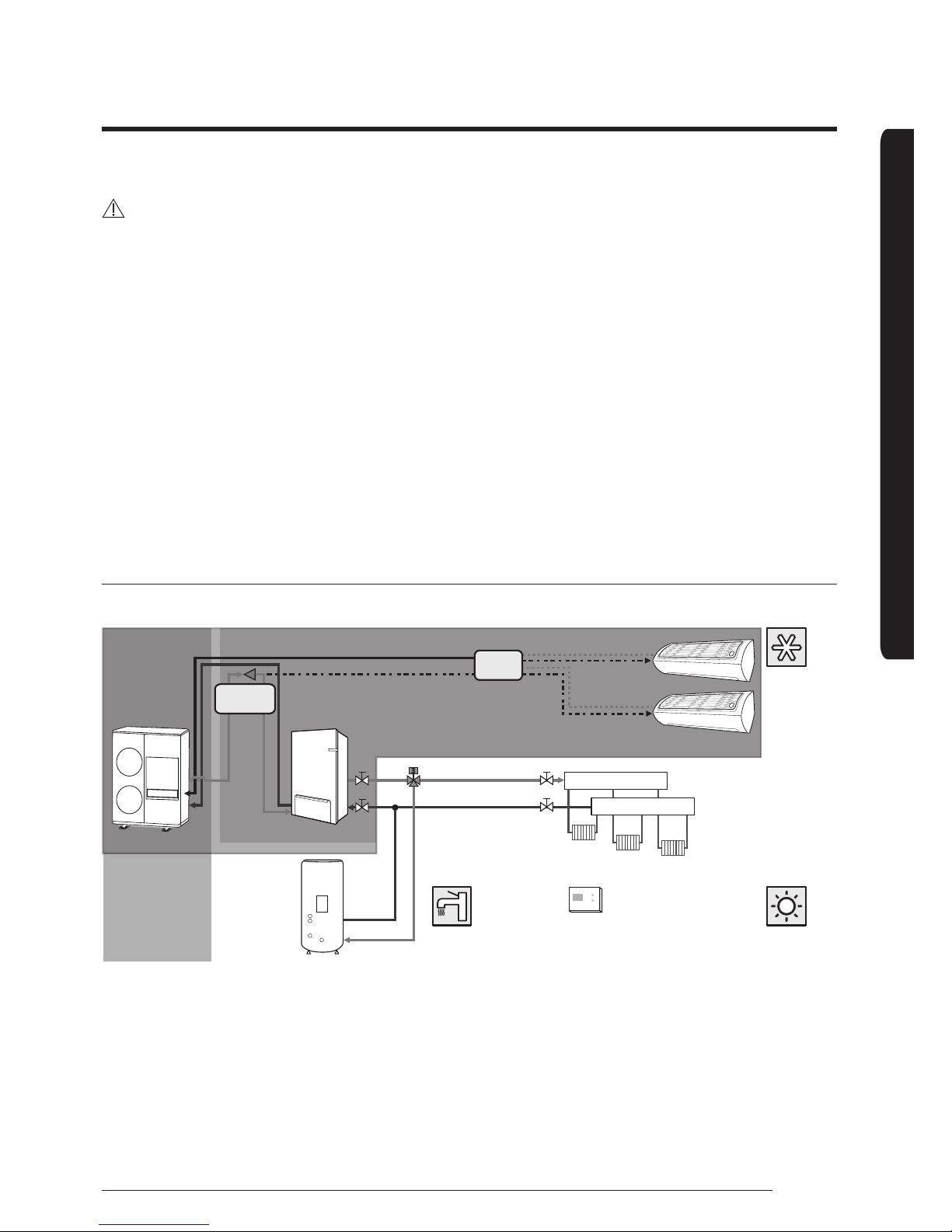

Application 1 : TDM(Time Division Multi)

Outdoor Indoor

Outdoor unit

DHW Tank

Hydro-unit

RAC

Space

Cooling

Space

Heating

Room Controller

Supply Header

Return Header

Radiator or FCU

Water Heating

Samsung Supply Range

EEV Kit

Y joint

10

Typical application examples

English

PREPARATION

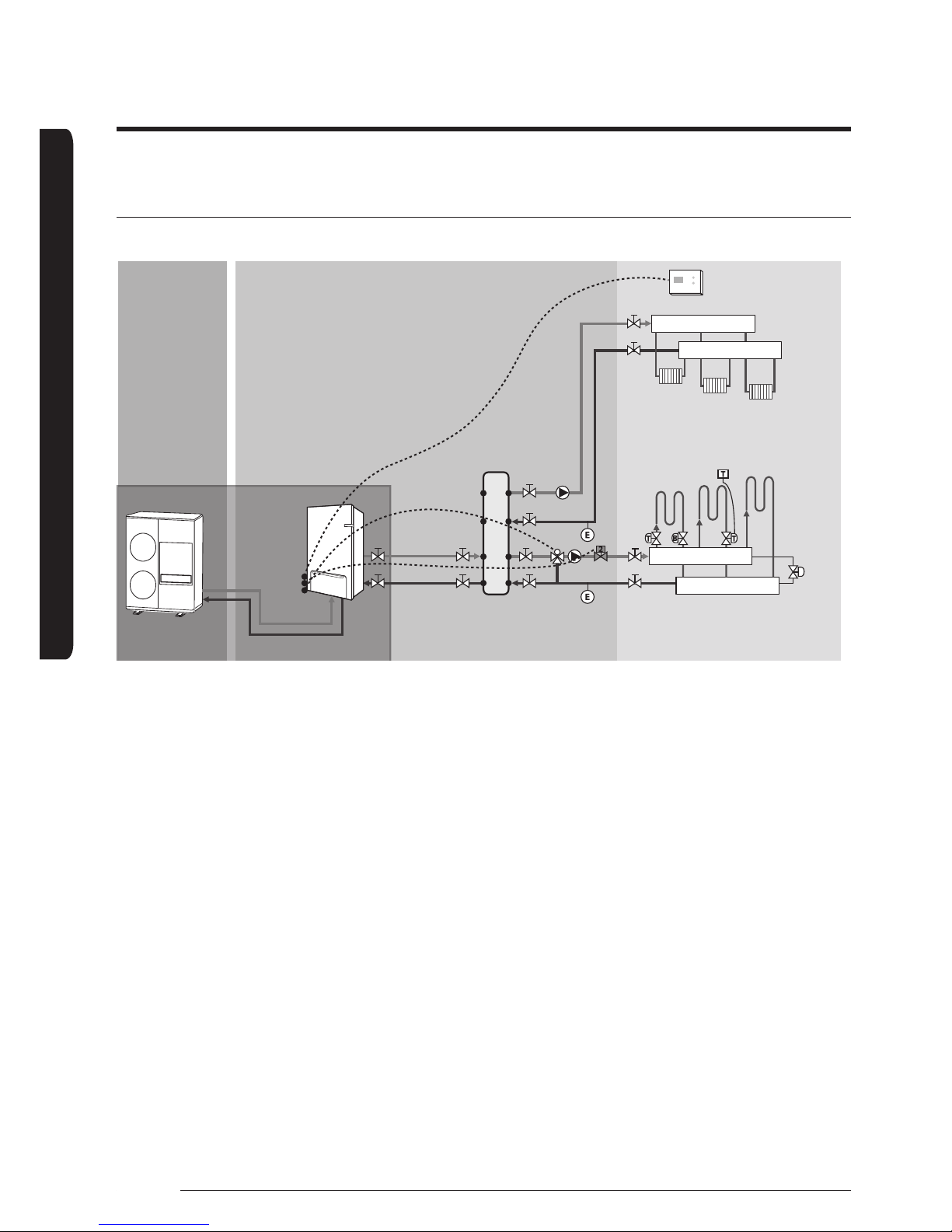

Application 2 : Space heating

Samsung Supply Range

Outdoor unit

Hydro-unit

Mixing Tank

Under-Floor Heating Coils

[Application #1]

Zone Thermostat & 2way Valve

[Application #2]

Thermostatic &

Balancing Valves

[Application #4]

Differential Pressure bypass Valve

[Application #3]

Room Thermosat &

Actuators

Supply Header

Supply Header

Return Header

Return Header

Bypass

valve

Room

Controller

Load Pump #1

Load Pump #2

40 °C

45 °C

Outdoor

Indoor

Radiators or Convectors

11

English

PREPARATION

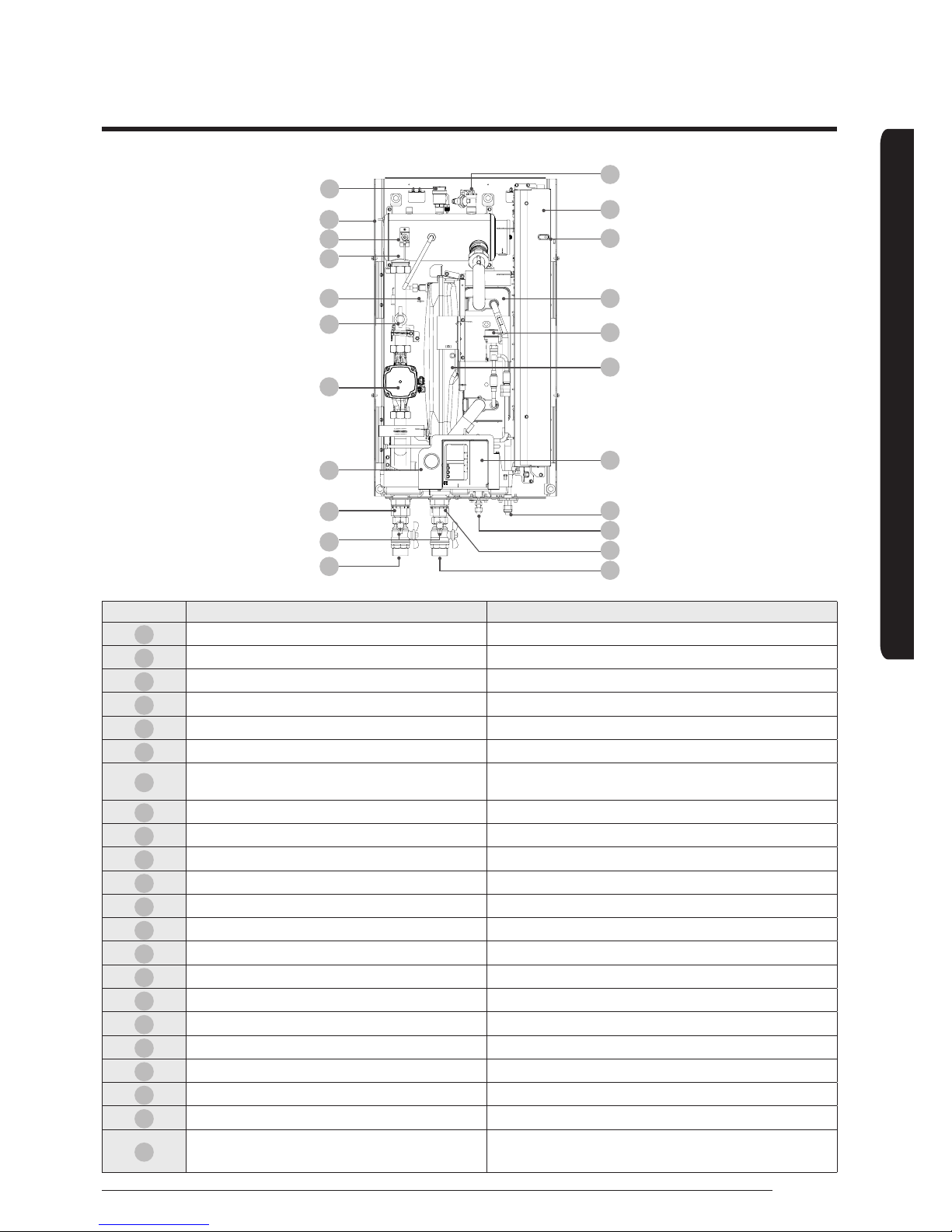

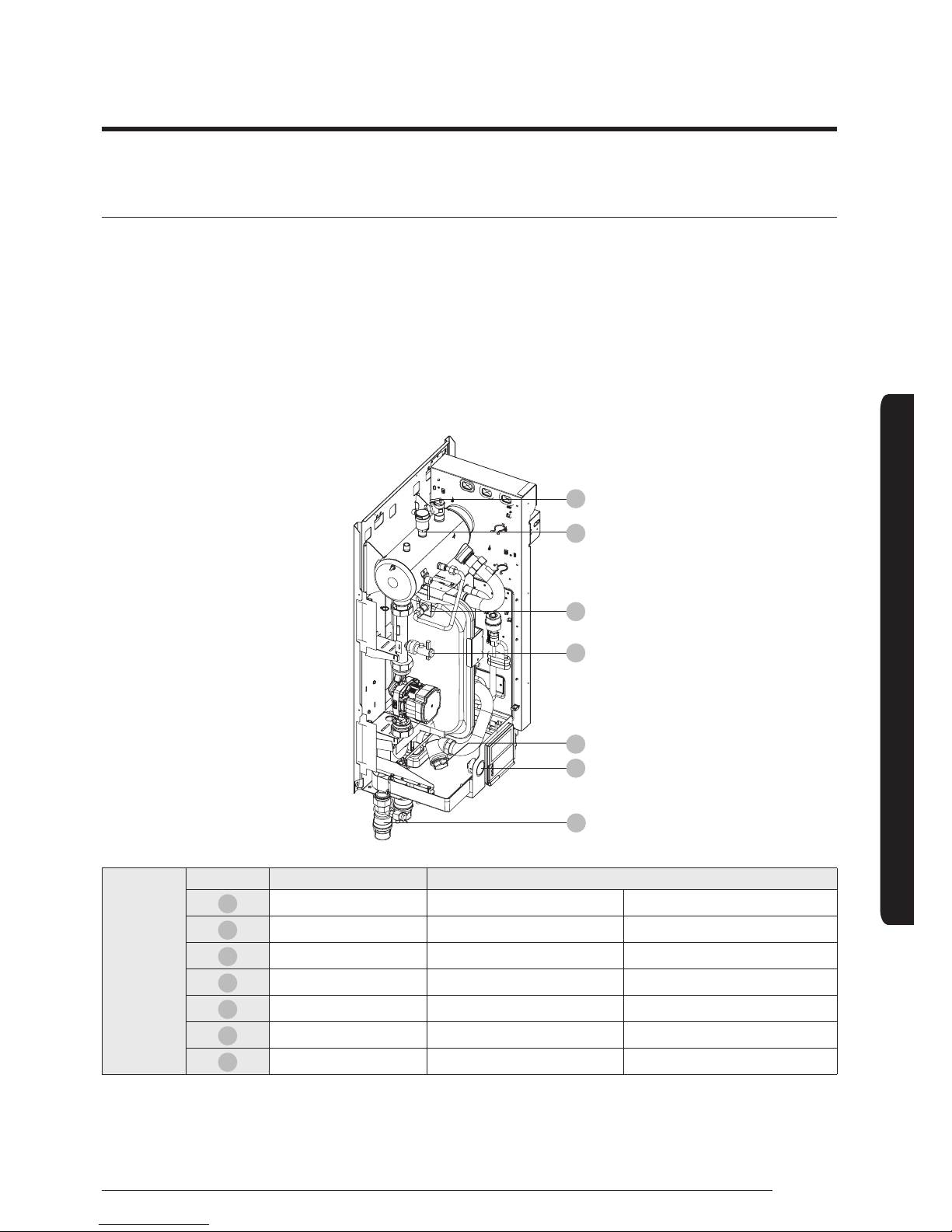

Main components

21

20

19

18

22

17

16

15

14

13

12

01

02

03

04

05

06

07

08

09

10

11

No. Name Note

01

Air vent 3/8” BSPP male 3/8”

02

Backup heater thermal fuse Thermal cut out 94°C (+0, -6°C)

03

Backup heater thermostat Disc. 65°C ±4°C

04

Backup Heater Element Incoloy 800, 4/6kW, 230V AC 50Hz

05

Drain Hose

06

Flow switch 9kW : 7LPM ± 1.5LPM / 16kW : 12LPM ± 1.5LPM

07

Water pump

AE090MNYD*H : 1P-230V-50Hz,26LPM x 65kPa

AE0160MNYD*H : 1P-230V-50/60Hz,46LPM x 60kPa

08

Manometer ø48, 0~4 bar

09

Water outlet pipe BSPP male 1 1/4"

10

Drain valves

11

Service valve (L) BSPP male, 1-1/4”

12

Service valve (R) BSPP male, 1-1/4”

13

Water inlet pipe BSPP male 1 1/4"

14

Refrigerant pipe 9kW : Ø6.35(1/4") / 16kW : Ø9.52(3/8")

15

Refrigerant pipe ø15.88 (5/8”)

16

Wire for controller length 15m

17

Expansion Vessel 8 Liter, Pre-charge gas : 0.1MPa, N2, BSPP male, 3/8”

18

Plate heat exchanger

19

LED display

20

Control box

21

Pressure relief valve 0.3MPa, BSPP 1/2”

22

Expansion valve

AE090MNYD∗H : EDM Type, DPF(O)3.2C

AE0160MNYD∗H : EDM Type, DPF(O)4.0C

12

English

PREPARATION

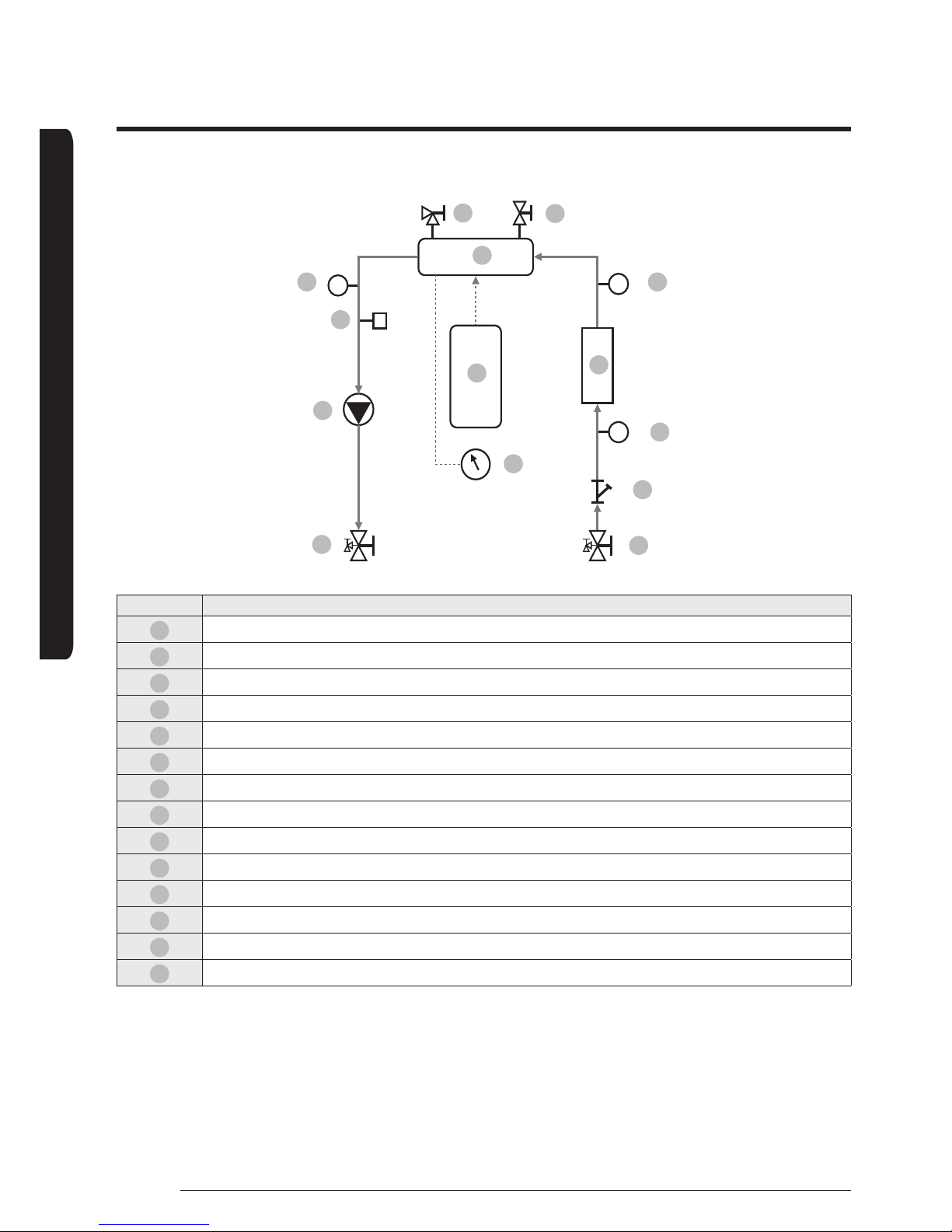

Functional diagram

Tw3

Tw2

Tw1

14 13

12

01

02

03

04

05

06

07

08

09

10

11

No. Note

01

Service valve(R)

02

Strainer

03

Flow switch

04

Heat exchanger

05

Backup heater

06

Pressure relief valve

07

Air-vent valve

08

Variable Speed water pump

09

Expansion tank

10

Manometer

11

Service valve(L)

12

Water temp. sensor 1

13

Water temp. sensor 2

14

Water temp. sensor 3

13

English

PREPARATION

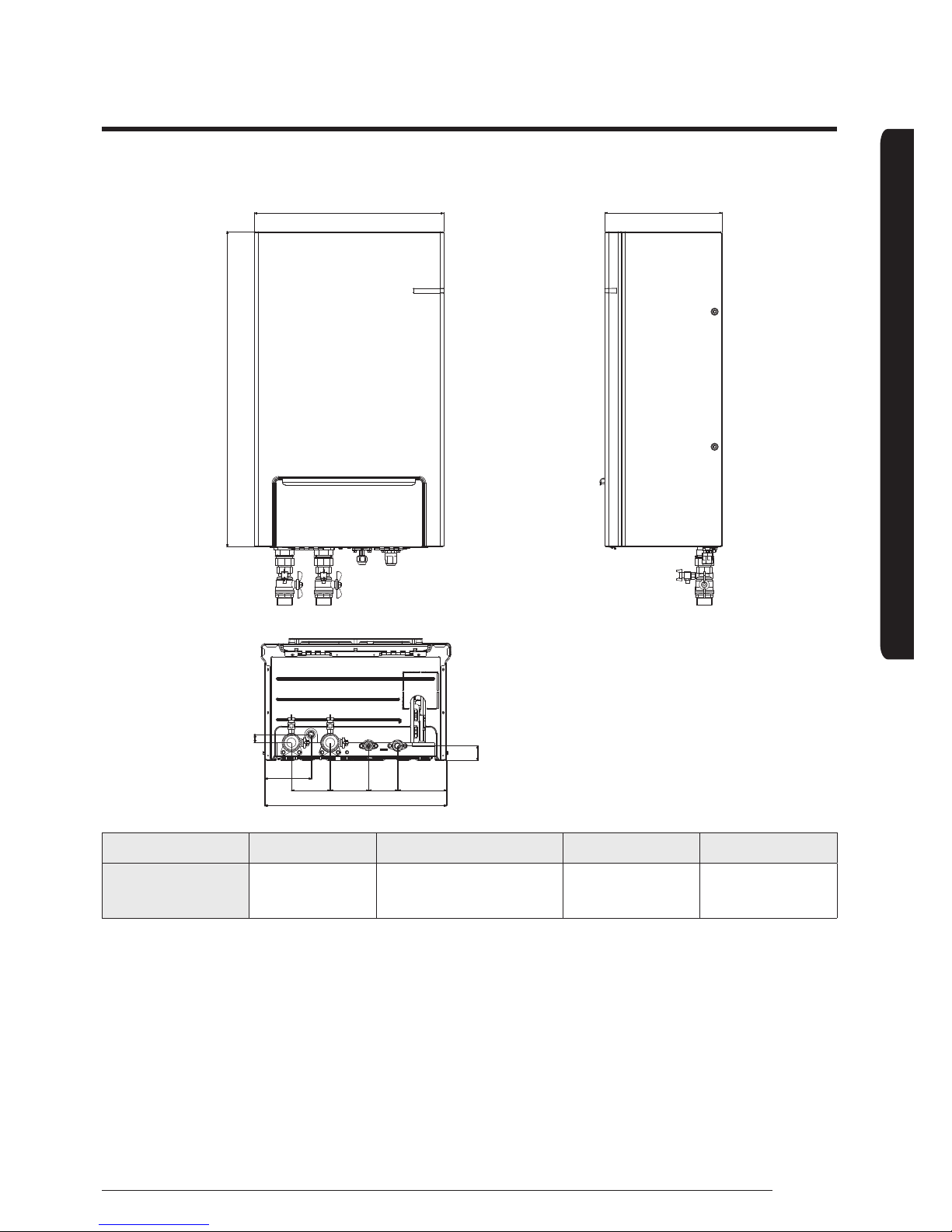

Dimensional drawing

510

850

125

104 103.7 78.5 131.7

490

22

39.2

314.6

Gas pipe (O.D.) Liquid pipe (O.D.) Water Inlet Water Outlet

Indoor unit 15.88mm (5/8inch)

9kW : 6.35mm (1/4inch)

16kW : 9.52mm (3/8inch)

BSPP male 1 1/4" BSPP male 1 1/4"

14

INSTALLATION

English

Installing the unit

Installation of the indoor unit

The indoor unit should be installed indoors and meet the following conditions.

• Installation site should be sheltered from frost.

• In area with suitable space for servicing.

• A place with adequate ventilation.

• Where there is no risk of leakage of flammable gases.

• There is a provision for condensate drain and pressure relief valve blow-off.

• The wall for installation is a flat, vertical and non-combustible wall, capable of supporting the operation weight of the unit.

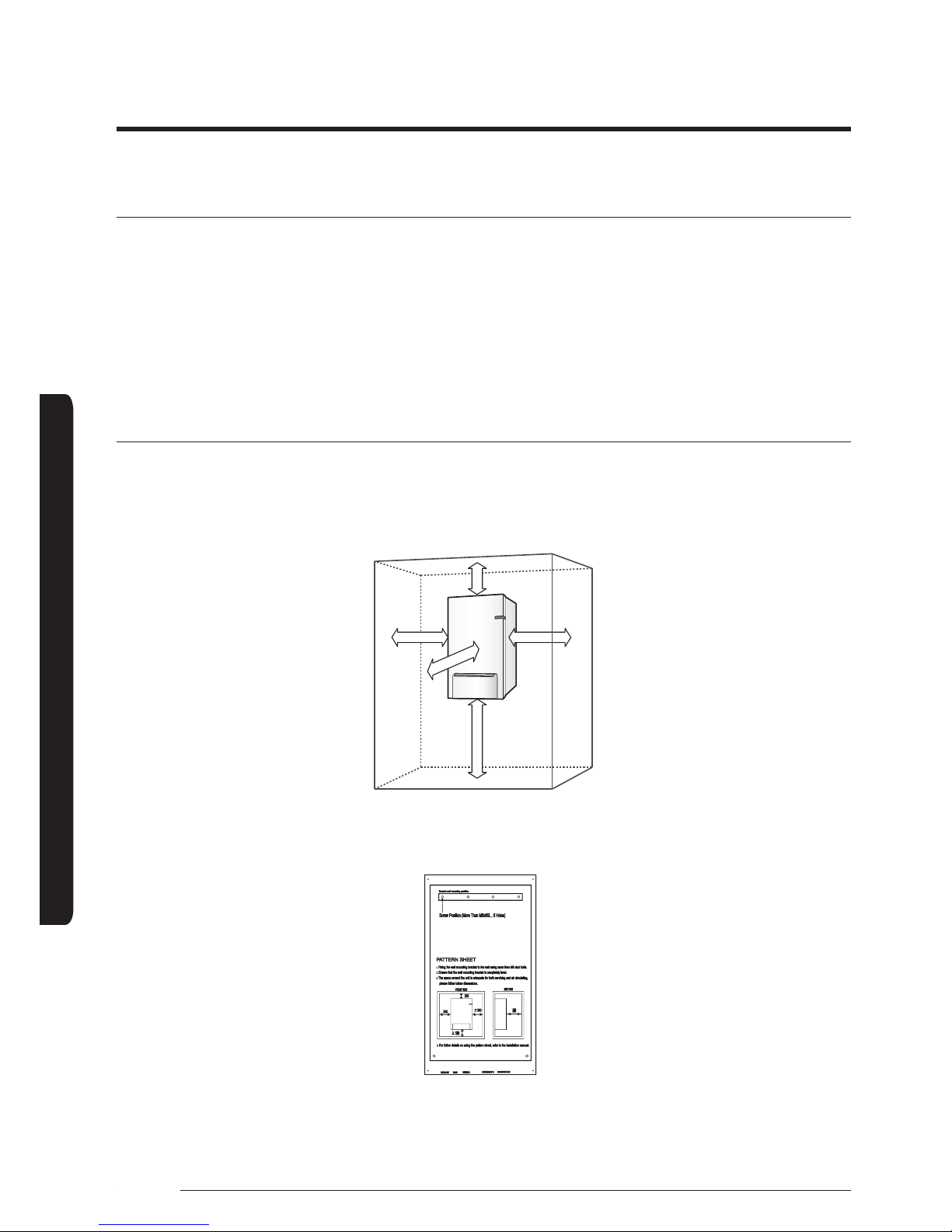

Installation space

• Ensure to leave the appropriate space as indicated in the drawing.

• Installation site should be secured with adequate ventilation so that the components of hydro unit will not be damaged from

overheating.

(Unit : mm )

300

500

200≥1200

≥350

• Before installing the indoor unit, fix the pattern sheet on the wall. This sheet has a function to take correct position for the wall

mounting bracket and screws.

Pattern Sheet

15

INSTALLATION

English

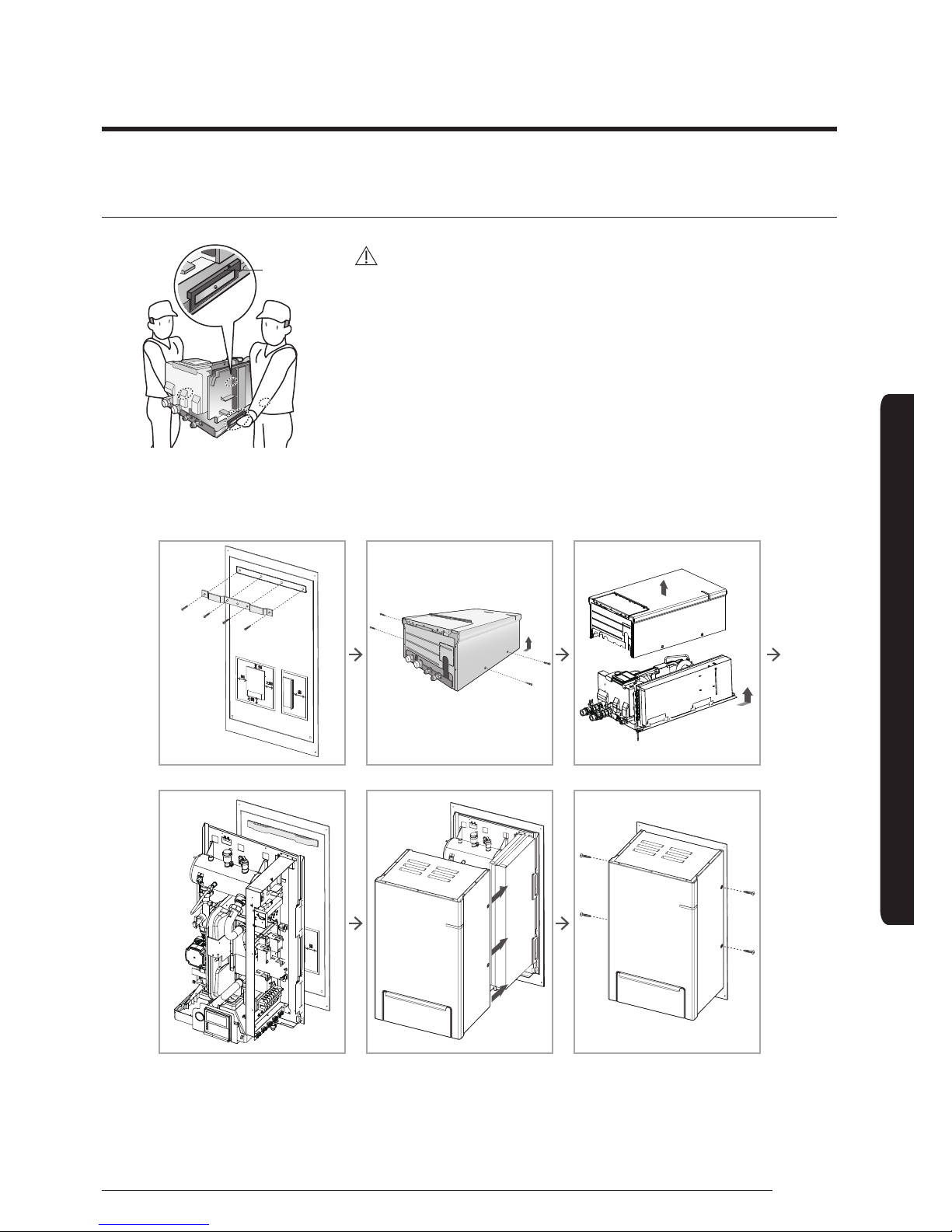

Mounting the indoor unit

Handle

CAUTION

• A minimum of two people should lift the unit by the handles and not by the

drain pan or pipe work.

• Drill 6 holes from the pattern sheet for fixing the wall bracket and unit. After completing holes, detach the pattern sheet.

• Fix the wall-mount-bracket to the wall using appropriate plugs and screws(Use over M8 6 screws).

• Hang the indoor unit on a wall-mount-bracket and fix a front cabinet on the unit by using 4 screws.

• Fix screw through base panel of the unit.

16

INSTALLATION

English

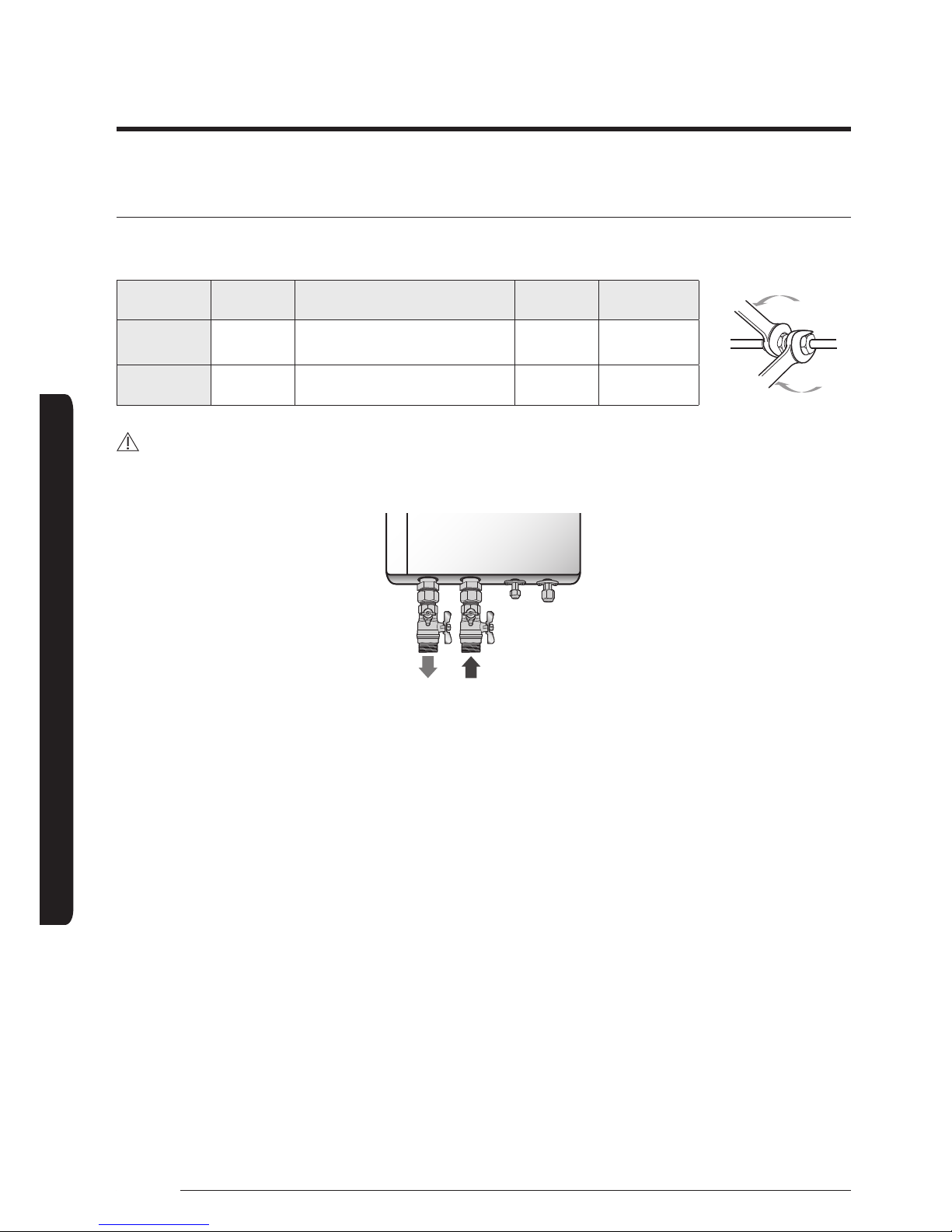

Refrigerant pipe work

For all guide lines, specifications regarding refrigerant pipe work between the indoor unit and the outdoor unit, please follow the

outdoor unit installation manual.

Gas pipe

(O.D.)

Liquid pipe (O.D.)

Tightening

Torque

Final Torque

Indoor unit

15.88mm

(5/8 inch)

9kW : 6.35mm (1/4 inch)

16kW : 9.52mm (3/8 inch)

400kg∙cm 450kg∙cm

Outdoor unit

15.88mm

(5/8 inch)

Φ9.52mm(3/8 inch) 700kg∙cm 750kg∙cm

CAUTION

• When connecting the refrigerant pipes, always use 2 wrenches/spanners for tightening or loosening nuts. If not, piping

connections can be damaged.

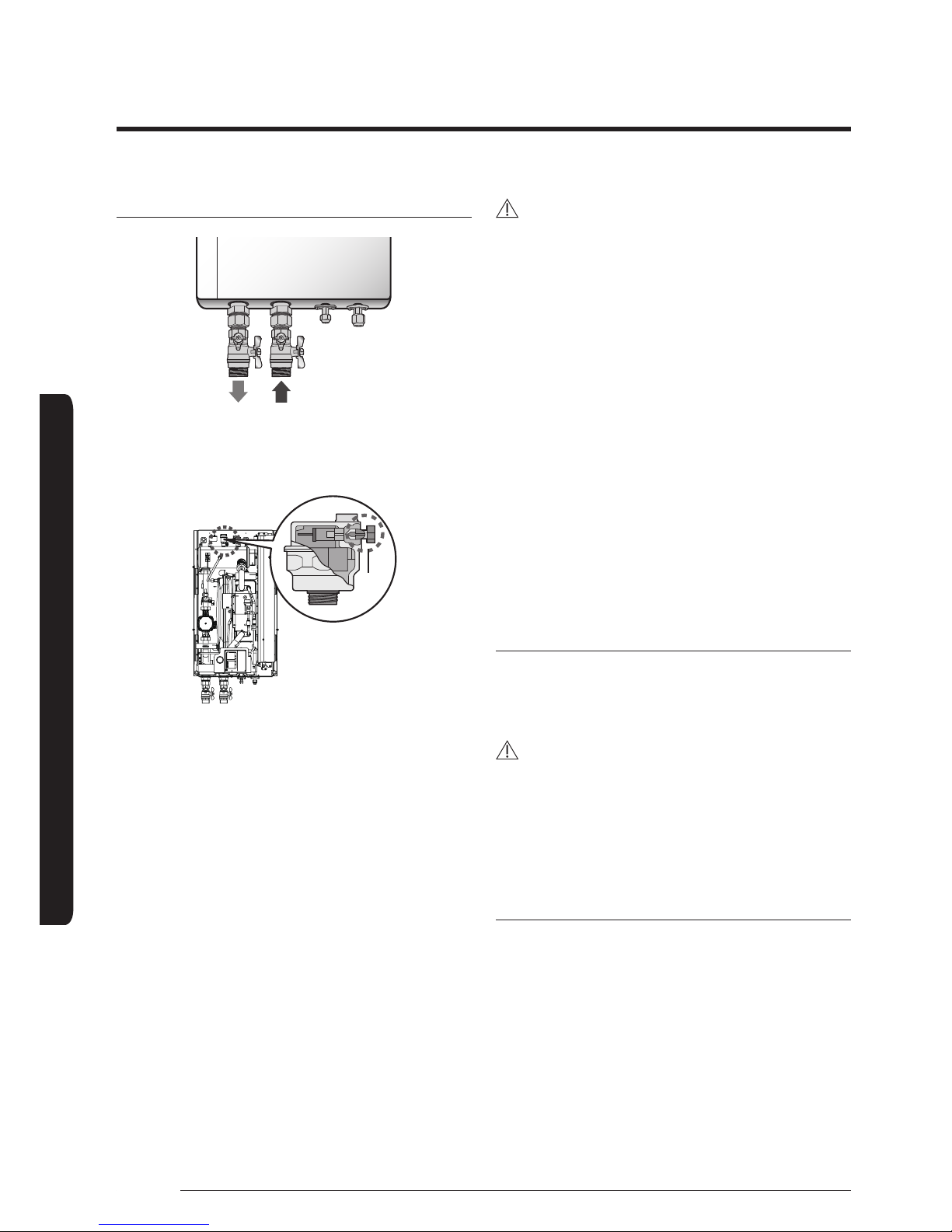

WATER

OUTLET

WATER

INLET

Liquid

pipe

Gas

pipe

Pipe work

17

INSTALLATION

English

Water pipe work

The hydro unit is equipped with components listed on the table below.

The hot and cold water supply connections are clearly marked on the unit with labels. And service valves are provided.

Whole water plumbing system including Hydro unit shall be installed by a qualified technician and must comply with all relevant

European and national regulations.

• Allowable water pressure of hydro unit is maximum 3.0 bar.

• 2 service valves are provided with the Hydro unit. To facilitate service and maintenance work, install R-Type service valve at the

water inlet of the hydro unit and L-Type service valve at the water outlet of the hydro unit.

• An air-vent valve is integrated on the hydro unit. Please check that air-vent valve is not overtightened so the air-vent valve can

release any air out of the system during system operation.

01

02

03

04

05

06

07

Hydro unit

No. Name Tightening Torque

01

1.25” BSPP 350 ~ 380 kgf•cm 34 ~ 37 N•m

02

3/8” BSPP 120 ~ 150 kgf•cm 12 ~ 15 N•m

03

Pressure relief valve 120 ~ 150 kgf•cm 12 ~ 15 N•m

04

Air-vent valve 120 ~ 150 kgf•cm 12 ~ 15 N•m

05

Manometer 92~ 102 kgf•cm 9 ~ 10 N•m

06

Flow switch 72 ~ 82 kgf•cm 7 ~ 8 N•m

07

Strainer 350 ~ 380 kgf•cm 34 ~ 37 N•m

18

Pipe work

INSTALLATION

English

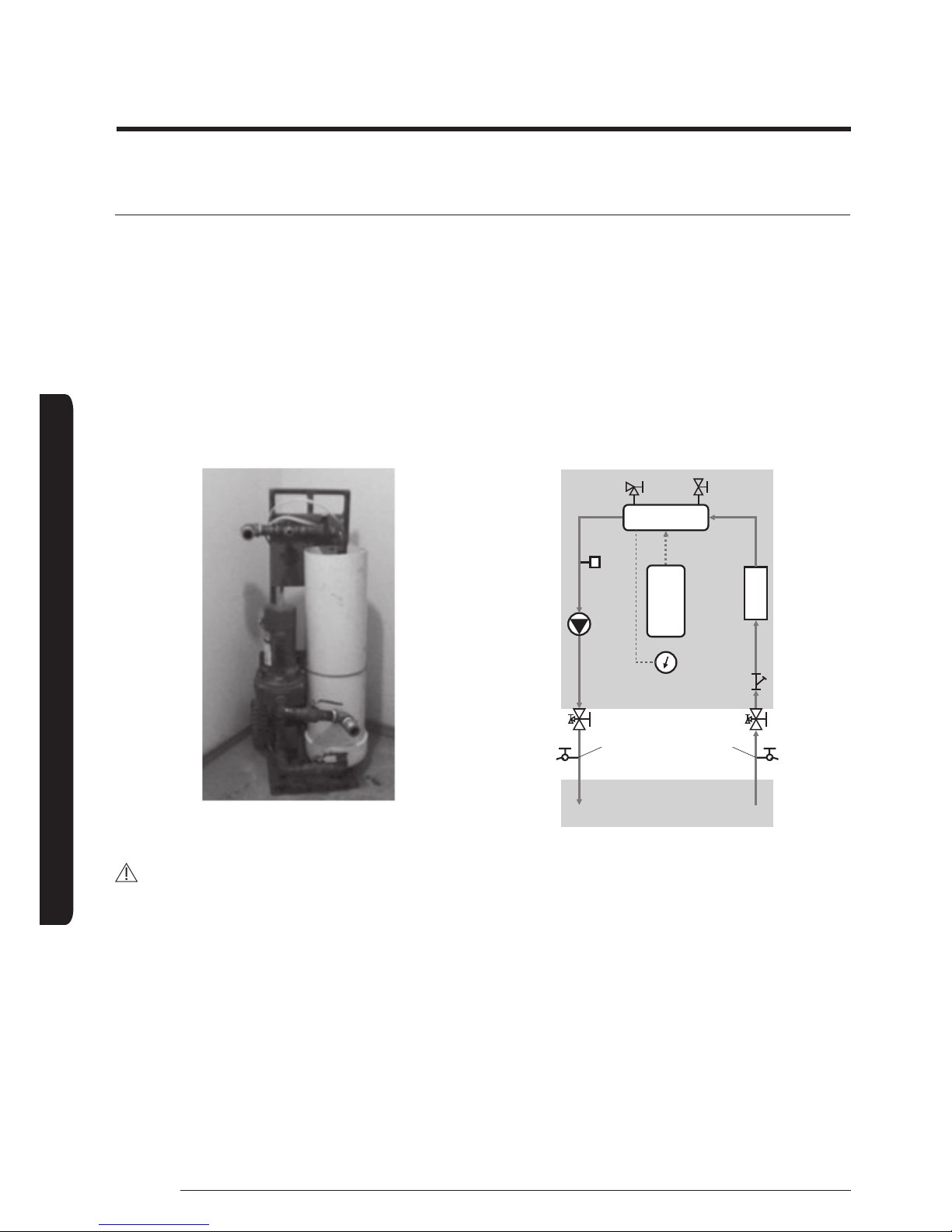

Flushing and air-purging

When filling water, the following start-up procedure should be followed.

1 All system components and pipes must be tested for the presence of leaks.

2 Preparation of a make-up water assembly or Flushing unit is recommended for installation and service.

3 3. Before connecting pipes to the hydro unit, Flush water pipes clean to remove contaminants during 1 hours using a flushing

unit or tap water pressure if it is adequate (at 2 to 3 bar)

4 Fill water into the hydro unit by opening service valves.

5 Purge the air. (Fill with a flushing unit with sufficient capacity: avoid aerating the water)

6 Circulate for long enough to ensure that all air has been bled from the complete water piping system.

After installations, Commissioning should be performed by qualified representatives.

Unless flushing and air-purging works are performed adequately, it might result in malfunctions.

Flushing unit (or purging cart)

Hydro unit

Water Out

Strainer

Out of Indoor

Service ports for flushing

& purging

Heater Vessel

CAUTION

• Check and clean strainer periodically.

• Replace strainer when necessary.

• It is recommended that you flush the system for 4 hours minimum once a per annum.

• Use chemical cleaning agents(Begin with acid , finish with alkali).

• Install Air vents on the top of the system

• Pressure of entering water(over 2.0 bar)

19

INSTALLATION

English

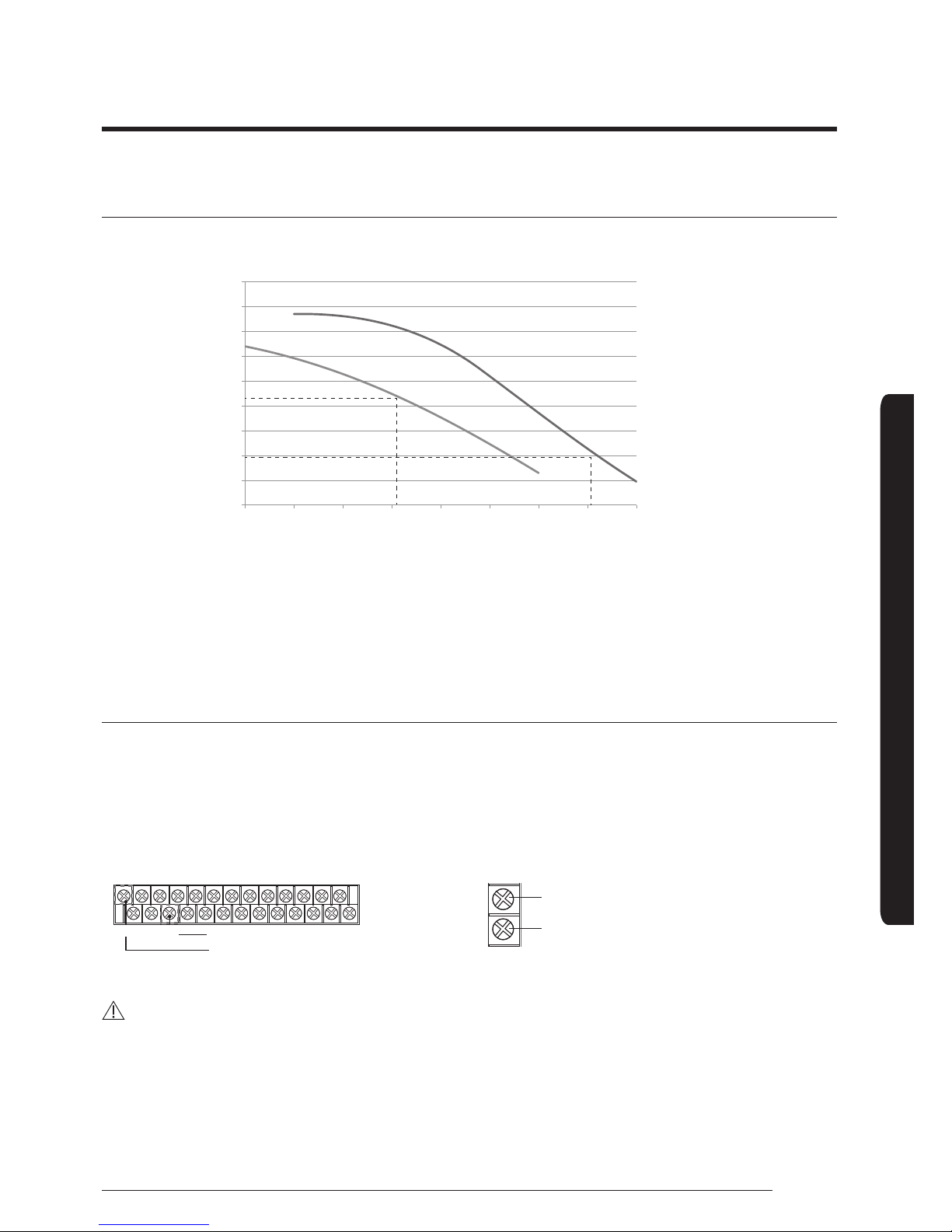

ESP(External Static Pressure) Diagram

The illustration below shows the external static pressure of the unit depending on the water flow and the pump setting.

16 kW

Flow [l/min]

ESP [kPa]

9 kW

Water flow rate

9 kW : 26 LPM

Water flow rate

16 kW : 46 LPM

0

10

20

30

40

43

50

60

70

80

90

10

15 20 2526 30 35 40 4546 50

If the pressure loss of total system is over 43(9kW) or 20(16kW)kPa, additional water pump should be installed in series.

Otherwise, the flow rate might decreased, causing insufficient heating or cooling.

When ESP is not enough, additional pump should be installed. In this case, install the PWM control external type pump (Heating

type) additionally.

Connection guide of additional pump

Case 1) INV. pump

Connect the PWM control external type pump to PWM terminal block and power cable to the external contact terminal.

The maximum number of additional pump installation is one inverter pumps (Input power 100W).

1 Power supply (INV. Pump) 2 PWM control (for INV. Pump only)

Live additional pump

Neutral additional pump

B6

B1

Reference (GND)

PWM signal (SIG)

CAUTION

• If there is wrong wiring between PWM and reference, INV. Water Pump may not work or wrong operation.

20

Pipe work

INSTALLATION

English

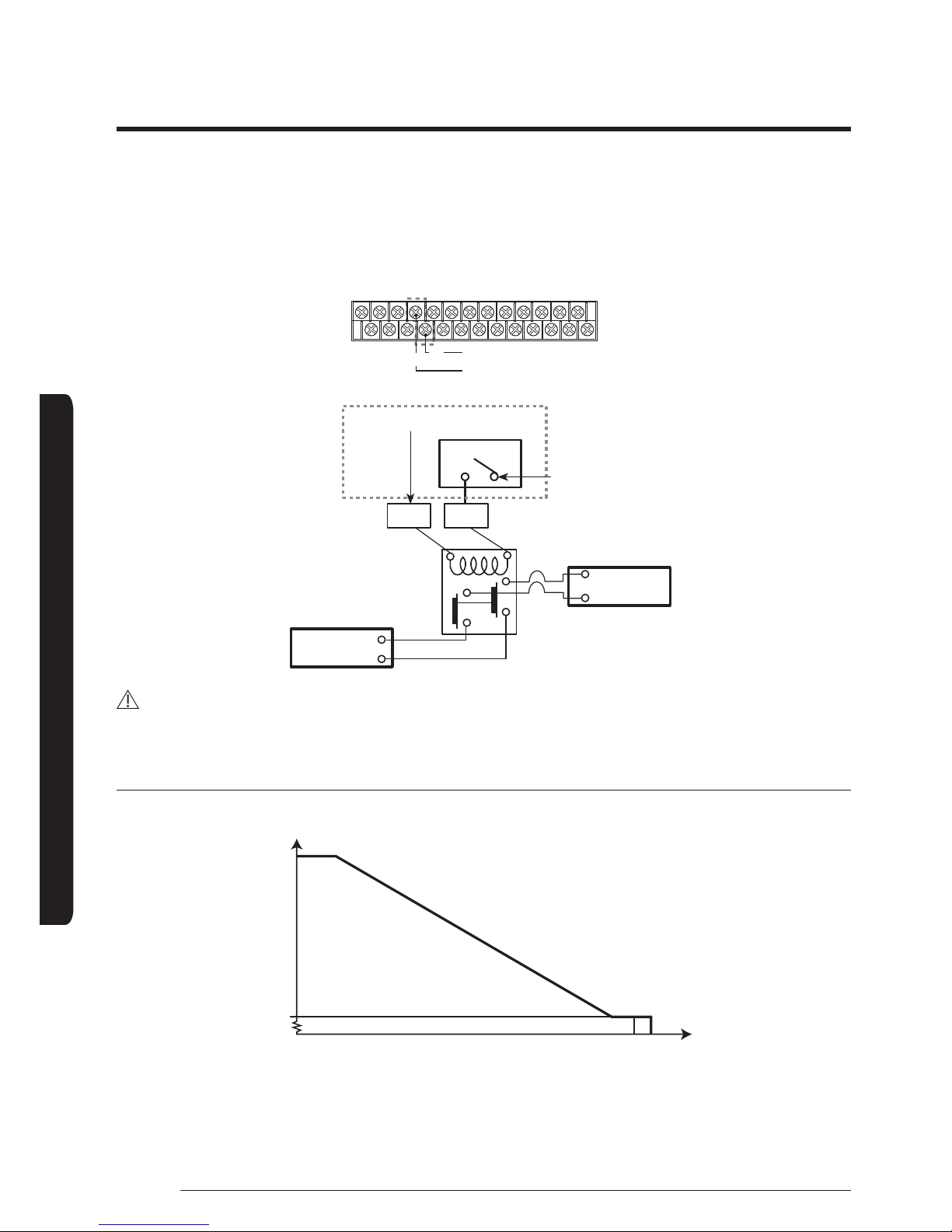

Case 2) AC pump

The maximum number of additional pump installation is one AC pumps (Input power 100W).

1 Power supply (AC Pump)

Live additional pump

Neutral additional pump

B7

B8

L

N

M/C

PCB

Terminal block

Neutral additional pump

Live additional pump

B7 B8

Pump

Power

CAUTION

• Terminal of this product is for additional water pump and the maximum allowable current is 0.5 A.

PWM characteristic curve

PWM input signal(%)

Max.

Speed

The additional pump should be the same type of product as the above graph.

Recommendation

• 9kW (AE090∗∗∗) : GRUNDFOS UPM3 25-75 (Heating Type)

• 16kW (AE160∗∗∗) : WILO STRATOS PARA 25/1-9 (Heating Type)

21

INSTALLATION

English

Setting the pre-pressure of the expansion vessel

When it is required to change the default pre-pressure of the expansion vessel(1 bar), keep in mind the following guidelines:

• Use only dry nitrogen to set the expansion vessel pre-pressure.

• Inappropriate setting of the expansion vessel pre-pressure will lead to malfunction of the system. Therefore, the pre-pressure

should only be adjusted by a licensed installer.

[Lit]

50 100 150 200 250 300 350 400

14.00

12.00

10.00

8.00

6.00

4.00

2.00

0.00

Water volume (Litre) in total system including pipes

Operation range

Norminal

Expansion Vessel capacity (Liter)

CAUTION

• Water volume of total system for reliable performance is minimum 50 liters.

Installation height

difference

a)

Water volume

< 220 Litres > 220 Litres

< 7m No pre-pressure adjustment required.

Actions required:

• Pre-pressure must be decreased, calculate

according to “Calculating the pre-pressure

of the expansion vessel”.

• Check if the water volume is lower than

maximum allowed water volume

> 7m

Actions required:

• Pre-pressure must be increased, calculate

the appropriate value following by

“Calculating the pre-pressure of the

expansion vessel”.

• Check if the water volume is lower than

maximum allowed water volume

Expansion vessel of the unit too small for the

installation.

a) Installation height difference: height difference(m) between the highest point of the water circuit and the indoor unit. If the

indoor unit is located at the highest point of the installation, the installation height is considered 0m.

Calculating the pre-pressure of the expansion vessel

The pre-pressure(Pg) to be set depends on the maximum installation height difference(H) and is calculated as below:

Pg=(H/10+0.3) bar

22

Pipe work

INSTALLATION

English

Charging water

WATER

OUTLET

WATER

INLET

Liquid

pipe

Gas

pipe

Air-vent valve

Cap

After installation is completed the following procedures shall

be used to charge water into the hydro unit.

• Connect water lines to water connections of hydro unit.

• The air-vent valve shall be opened at least 2 turns and

drain valves shall be closed.

• Open the service valve in the water supply connection.

• Water pressure of supply line shall be over 2.0 bar for good

charging work.

• Stop water supply when the pressure gauge of hydro unit

indicates 2.0 bar.

CAUTION

• Service space should be secured.

• Water pipe and connections must be cleaned using water.

• If internal water pump capacity is not enough, install

external water pump.

• Do not connect electric wire while water charging.

• When initial installation or re-installation required, open

the cap to prevent air trap in the unit while charging water.

• The back-up heater vessel shall be full of water before

heater is turned on. Confirm if the vessel is empty by

opening the pressure relief valve of hydro unit. (OK if water

is flowing out)

• It is recommended to install the make-up water

assembly to feed small quantities of water to the system

automatically, replacing the minor water losses and

maintaining the system pressure. This assembly usually

consists of a pressure-reducing valve, water filter, check-

valve and shut-off valves. In this case, Check-valve must be

installed to prevent from contaminating city water.

Pressure relief valve

A pressure relief valve is integrated on heater vessel of hydro

unit and shall work in abnormal condition for protecting the

hydro unit.

CAUTION

• The pressure relief valve will operate releasing the

pressure by flowing out some water through the drain

hose.

• Make certain that the discharged water out of drain pan

can not contact any electrical parts.

Piping insulation

The complete water circuit, including all piping must be

insulated to prevent condensation forming on the surface of

the pipe and heat loss to external environment.

23

INSTALLATION

English

Wiring work

CAUTION

• Field-supplied electrical components such as power switch, circuit breakers, wires, terminal blocks, etc must be properly

chosen with compliance with national legislation or regulation.

• Switch off the power supply before making any connections.

• All field wiring and components must be installed by a licensed electrician.

• Use a dedicated power supply.

• All power connections must be protected from dew condensation by thermal insulation.

• The system shall be earthed. Do not earth the unit to a utility pipe, surge absorber or telephone earth. Incomplete earth may

cause electrical problems.

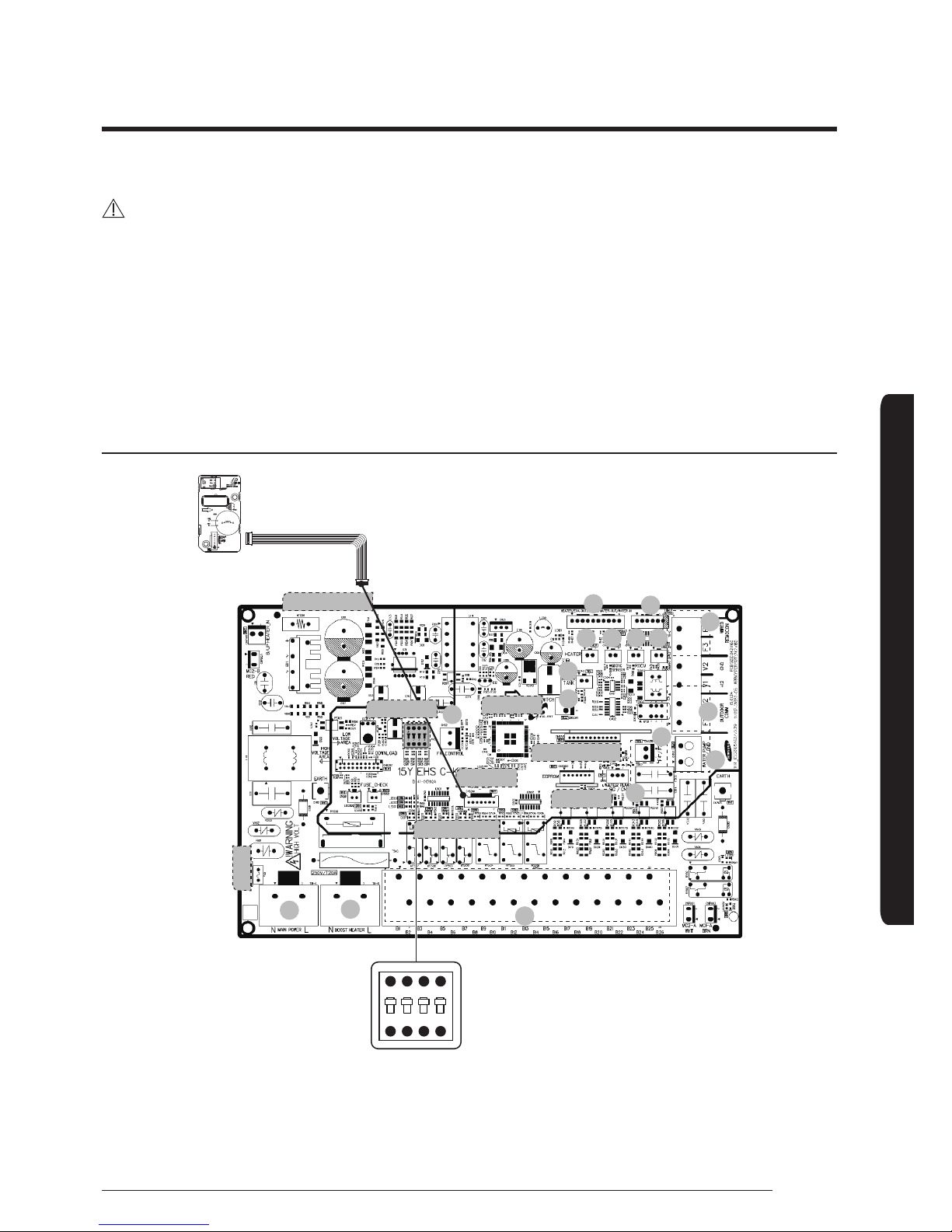

Layout of PCB

1ON2 3 4

SMPS circuit

Micom

LED

EEPROM

2-WIRE COMM

Load control

Fuse

01

02

03

04

05 06

07

08

09

10

11

17

16

15

14

13

12

DIP switch

24

Wiring work

INSTALLATION

English

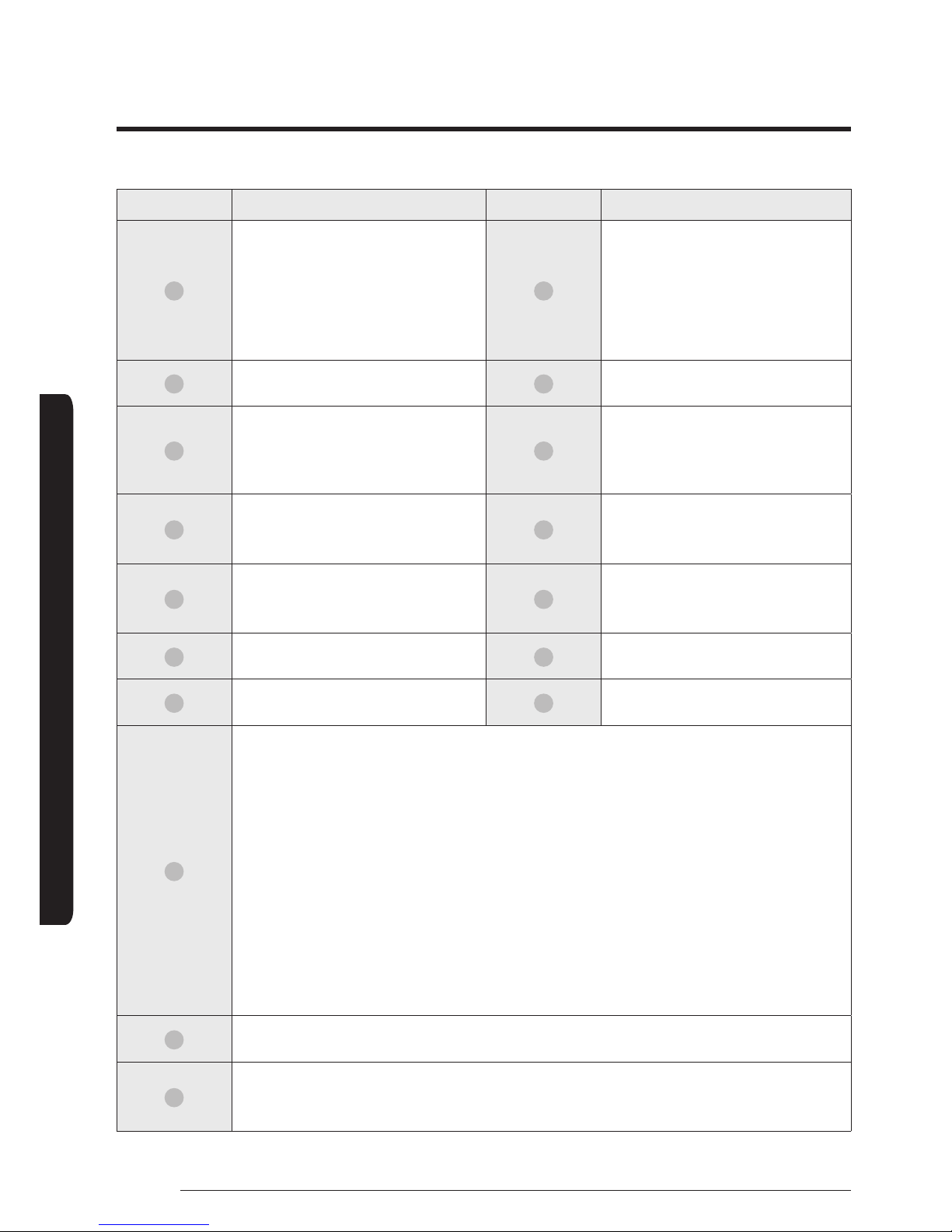

No. Note No. Note

01

FR Control

CNS2(Green)

08

CNS043(White)

1-2:Heater Out

3-4:Eva Out

5-6:Eva in

7-8:Water Out

9-10:Water In

02

Flow Switch

CNS041(Blue)

09

EEV

CNS063(Blue)

03

Water Tank

CNS042(Yellow)

10

TB-C (Black)

F3-F4:COMM2 (Wired remote controller)

INPUT/OUTPUT, DC, 210 mA (per each

controller)

04

Heater Out(Mono)

CNS047(Black)

11

TB-C (Black)

F1-F2:COMM1 (IN-OUT COMM)

INPUT/OUTPUT, DC, 10 mA

05

Mixing Sensor

CNS045(Blue)

12

CNS1(White)

1:Signal

3:Gnd

06

Room Sensor

CNS044(White)

13

Boost Heater TB-A1 (Black)

L-N, OUTPUT AC

07

Smart Grid

CNS046(Red)

14

Main Power TB-A(Black)

L-N, INPUT, AC

15

TB-B(Black)

B1:Neutral_INV PUMP,

OUTPUT, AC

B2:Mixing Valve_CW,

OUTPUT, AC

B3:Mixing Valve_CCW,

OUTPUT, AC

B4:Boiler, OUTPUT, AC

B5:Neutral, OUTPUT,

AC

B6:Lived_INV

PUMP, OUTPUT,

AC

B7:Neutral,

OUTPUT, AC

B8:Lived, OUTPUT,

AC

B9:2WAY1_NO,

OUTPUT, AC

B10:2WAY1_NC,

OUTPUT, AC

B11:Neutral,

OUTPUT, AC

B12:Lived,

OUTPUT, AC

B13:2WAY2_NO,

OUTPUT, AC

B14:2WAY2_NC,

OUTPUT, AC

B15:Neutral,

OUTPUT, AC

B16:Lived,

OUTPUT, AC

B17:3WAY_NO,

OUTPUT, AC

B18:3WAY_NC,

OUTPUT, AC

B19:Neutral,

OUTPUT, AC

B20:Lived, OUTPUT,

AC

B21:THERM01_C,

INPUT, AC

B22:THERM01_H,

INPUT, AC

B23:THERM02_C,

INPUT, AC

B24:THERM02_H,

INPUT, AC

B25:Solar/

Thermostat_N,

INPUT, AC

B26:Solar/

Thermostat_L,

INPUT, AC

16

CNS304(RED)

F3-F4:COMM2 (Wired Remote controller)

17

CNS3(Black)

1:Signal

2:Gnd

25

INSTALLATION

English

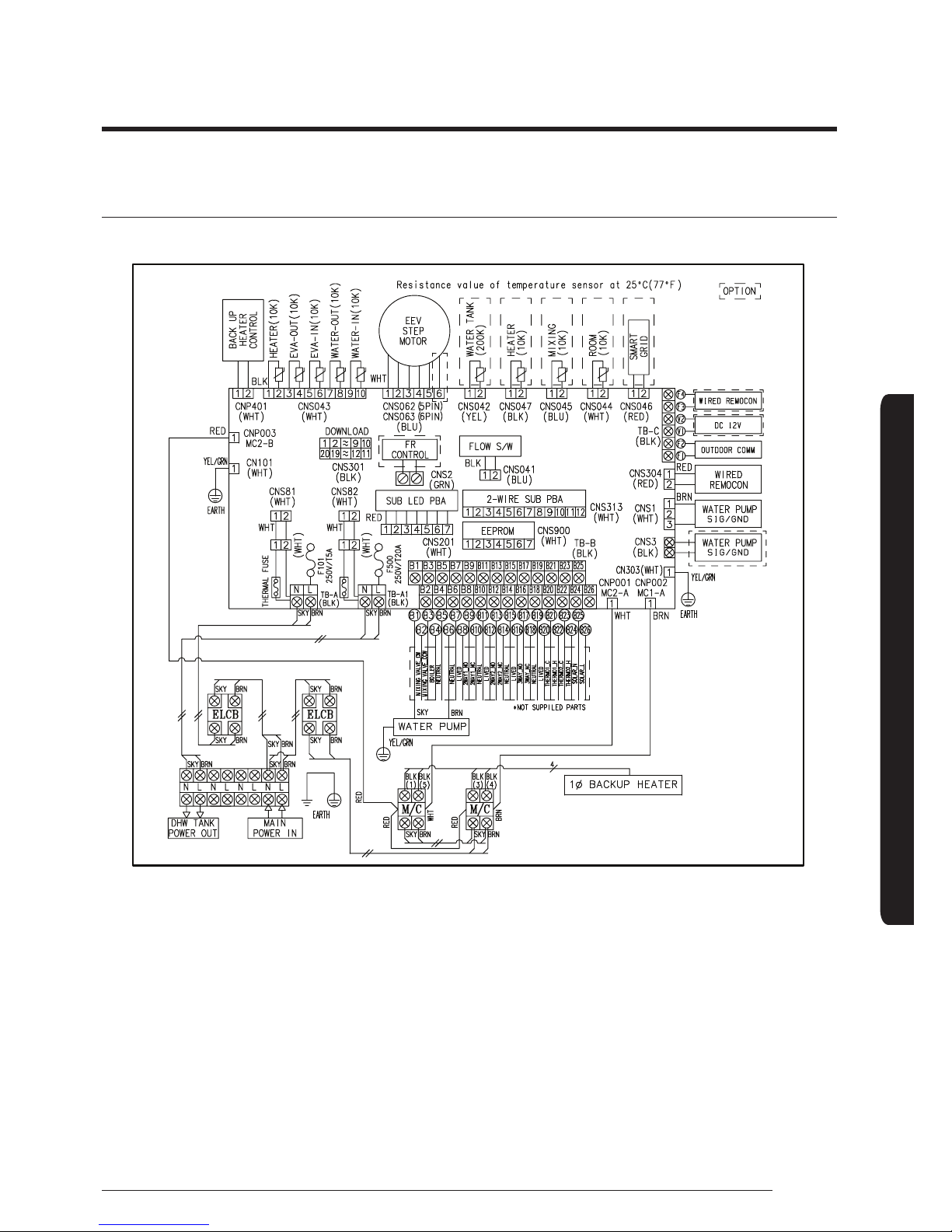

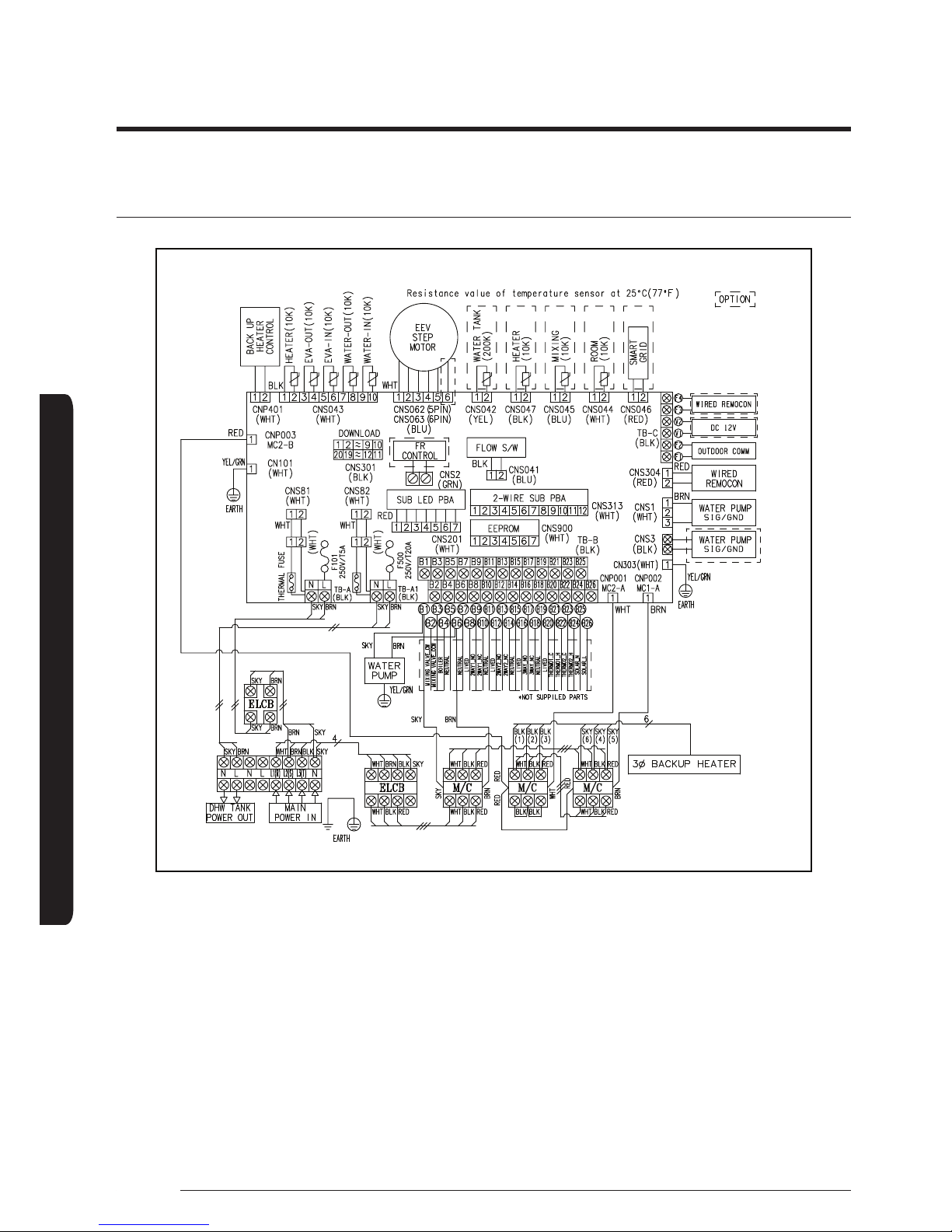

Wiring diagram (AE090MNYDEH/AE160MNYDEH) 1-Phase

26

Wiring work

INSTALLATION

English

Wiring diagram ( AE090MNYDGH/AE160MNYDGH) 3-Phase

27

INSTALLATION

English

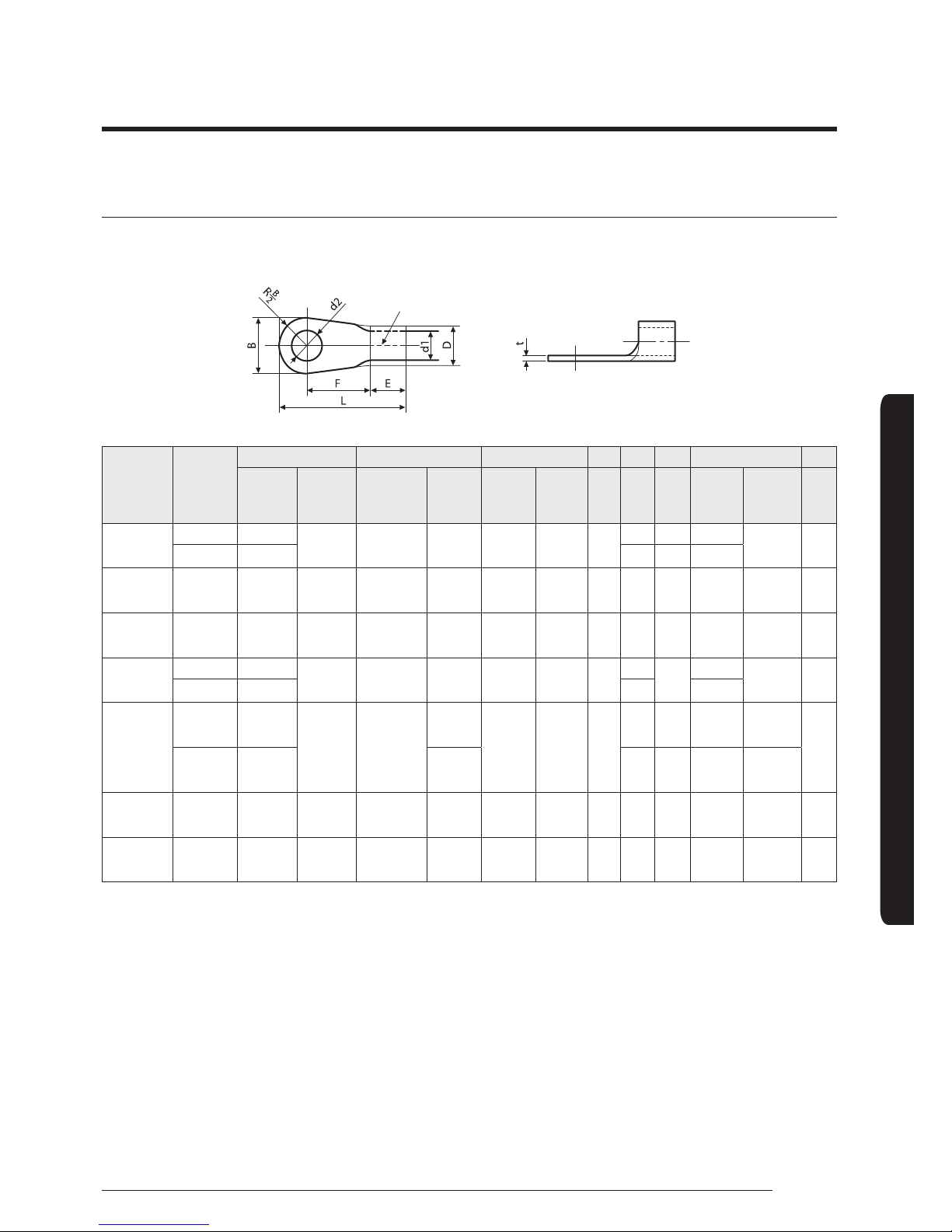

Selecting solderless ring terminal

• Select a solderless ring terminal of a connecting power cable based on a nominal dimensions for cable.

• Cover a solderless ring terminal and a connector part of the power cable and then connect it.

Nominal

dimensions

for cable

(mm

2

)

Nominal

dimensions

for screw

(mm)

B D d1 E F L d2 t

Standard

dimension

(mm)

Allowance

(mm)

Standard

dimension

(mm)

Allowance

(mm)

Standard

dimension

(mm)

Allowance

(mm)

Min. Min. Max.

Standard

dimension

(mm)

Allowance

(mm)

Min.

4/6

4 9.5

±0.2 5.6

+0.3

-0.2

3.4 ±0.2 6

5 20 4.3 +0.2

0

0.9

8 15 9 28.5 8.4

10 8 15 ±0.2 7.1

+0.3

-0.2

4.5 ±0.2 7.9 9 30 8.4

+0.4

0

1.15

16 8 16 ±0.2 9

+0.3

-0.2

5.8 ±0.2 9.5 13 33 8.4

+0.4

0

1.45

25

8 12

±0.3 11.5

+0.5

-0.2

7.7 ±0.2 11

15

34

8.4 +0.4

0

1.7

8 16.5 13 8.4

35

8 16

±0.3 13.3

+0.5

-0.2

9.4 ±0.2 12.5

13 38 8.4

+0.4

0

1.8

8 22

+0.5

-0.2

13 43 8.4

+0.4

0

50 8 22 ±0.3 13.5

+0.5

-0.2

11.4 ±0.3 17. 5 14 50 8.4

+0.4

0

1.8

70 8 24 ±0.4 1 7.5

+0.5

-0.4

13.3 ±0.4 18.5 20 51 8.4

+0.4

0

2

28

Wiring work

INSTALLATION

English

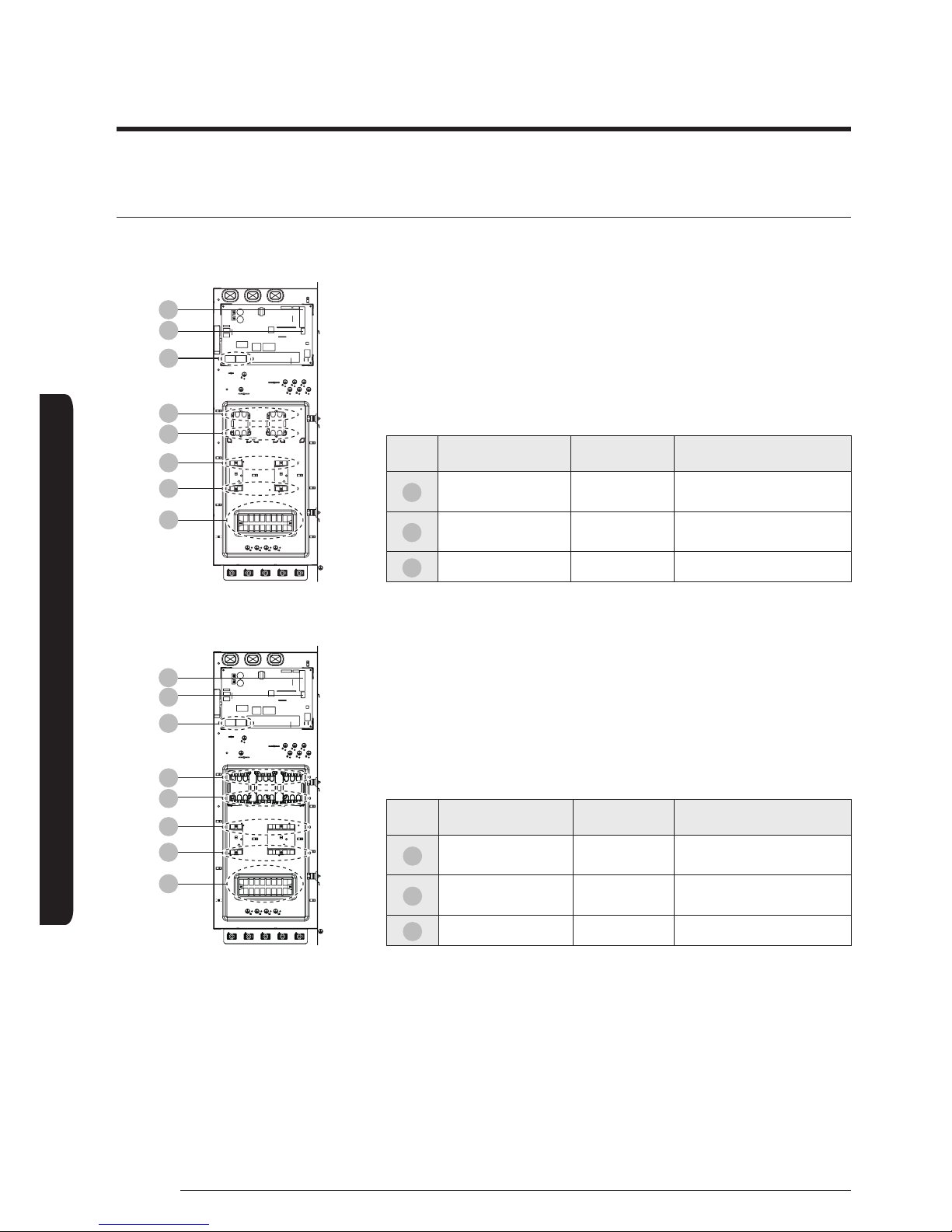

Torque requirements

1 Phase

01

02

03

03

03

03

03

03

No. Terminal name Specification Tightening Torque (N · m)

01

PWM control

(INV. Pump)

M3 0.5 ~ 0.75

02

Communication &

External contact

M3.5 0.8 ~ 1.2

03

Power M4 1.2 ~ 1.8

3 Phase

01

02

03

03

03

03

03

03

No. Terminal name Specification Tightening Torque (N · m)

01

PWM control

(INV. Pump)

M3 0.5 ~ 0.75

02

Communication &

External contact

M3.5 0.8 ~ 1.2

03

Power M4 1.2 ~ 1.8

29

INSTALLATION

English

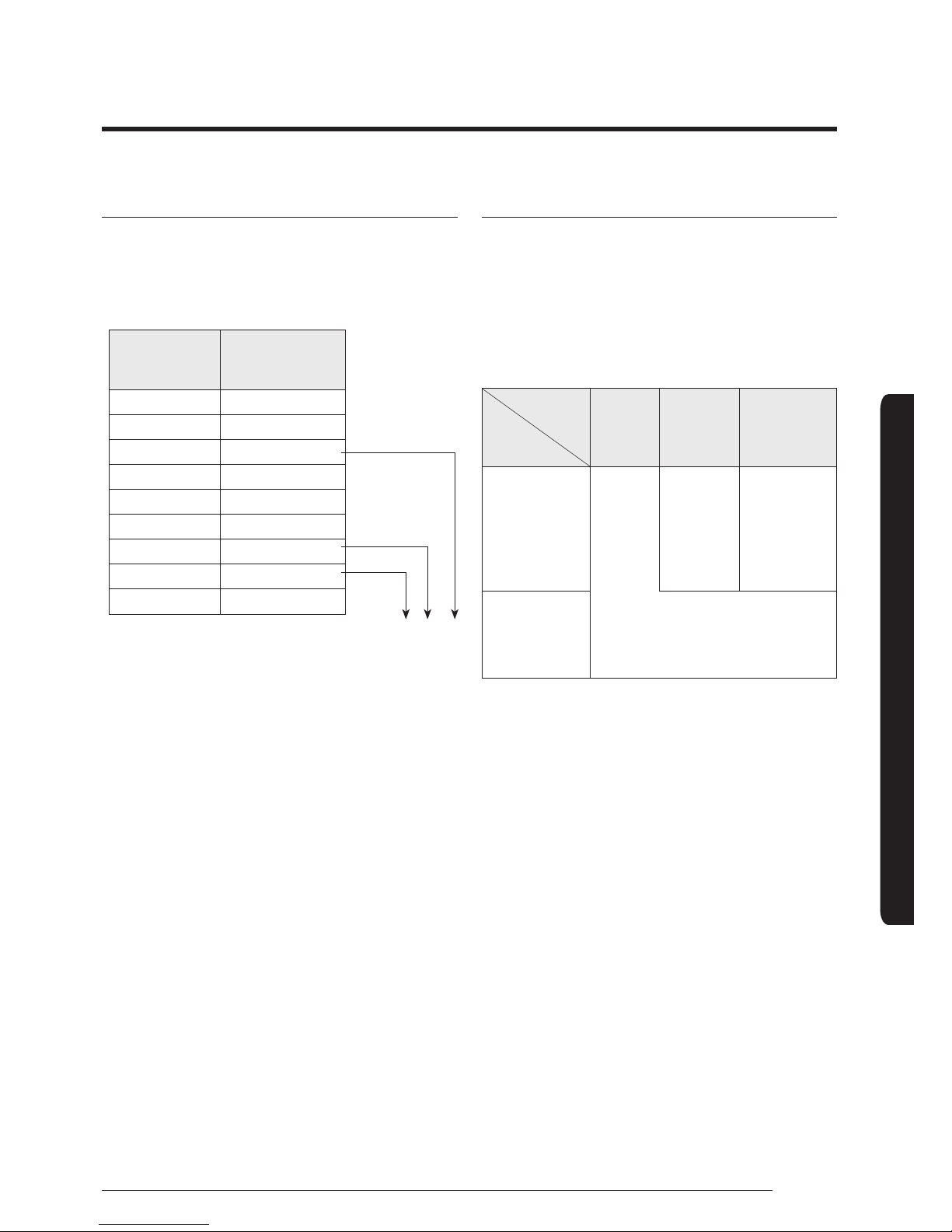

Types of allowable current

Conductors of supply cord shall have a nominal cross-sectional

area not less than that shown in the table below.

Minimum cross-sectional area of conductors

Rated current

of appliance (A)

Nominal

cross-sectional

area (mm2)

≤0.2 Tinsel cord

a)

≤0.2 and ≤3 0.5

a)

>3 and ≤6 0.75

>6 and ≤10 1.0(0.75)

b)

>10 and ≤16 1.5(1.0)

b)

>16 and ≤25 2.5

>25 and ≤32 4

>32 and ≤40 6

>40 and ≤63 10

a) These cords may only be used if their length does not

exceed 2m between the point where the cord or cord

guard enters the appliance and the entry to the plug.

b) Cords having the cross-sectional areas indicated in the

parentheses may be used for portable appliances if their

length does not exceed 2m.

Grounding work

• Grounding must be done by a qualified installer for your

safety.

Grounding the power cable

• The standard of grounding may vary according to the rated

voltage and installation place of a heating pump.

• Ground the power cable according to the following.

Installation

place

Power

condition

High

humidity

Average

humidity

Low humidity

Electrical

potential of

lower than 150V

Perform

the

grounding

work 3.

Note 1)

Perform the

grounding

work 3 if

possible for

your safety.

Note 1)

Electrical

potential of

higher than

150V

Must perform the grounding work 3.

Note 1)

(In case of installing circuit breaker)

∗ Note 1) Grounding work 3

• Grounding must be done by your installation specialist.

• Check if the grounding resistance is lower than 100Ω.

When installing a circuit breaker that can cut the electric

circuit in case of a short circuit, the allowable grounding

resistance can be 30~500Ω.

Exterior connection

DHW Power IN/OUT

Main power

30

Wiring work

INSTALLATION

English

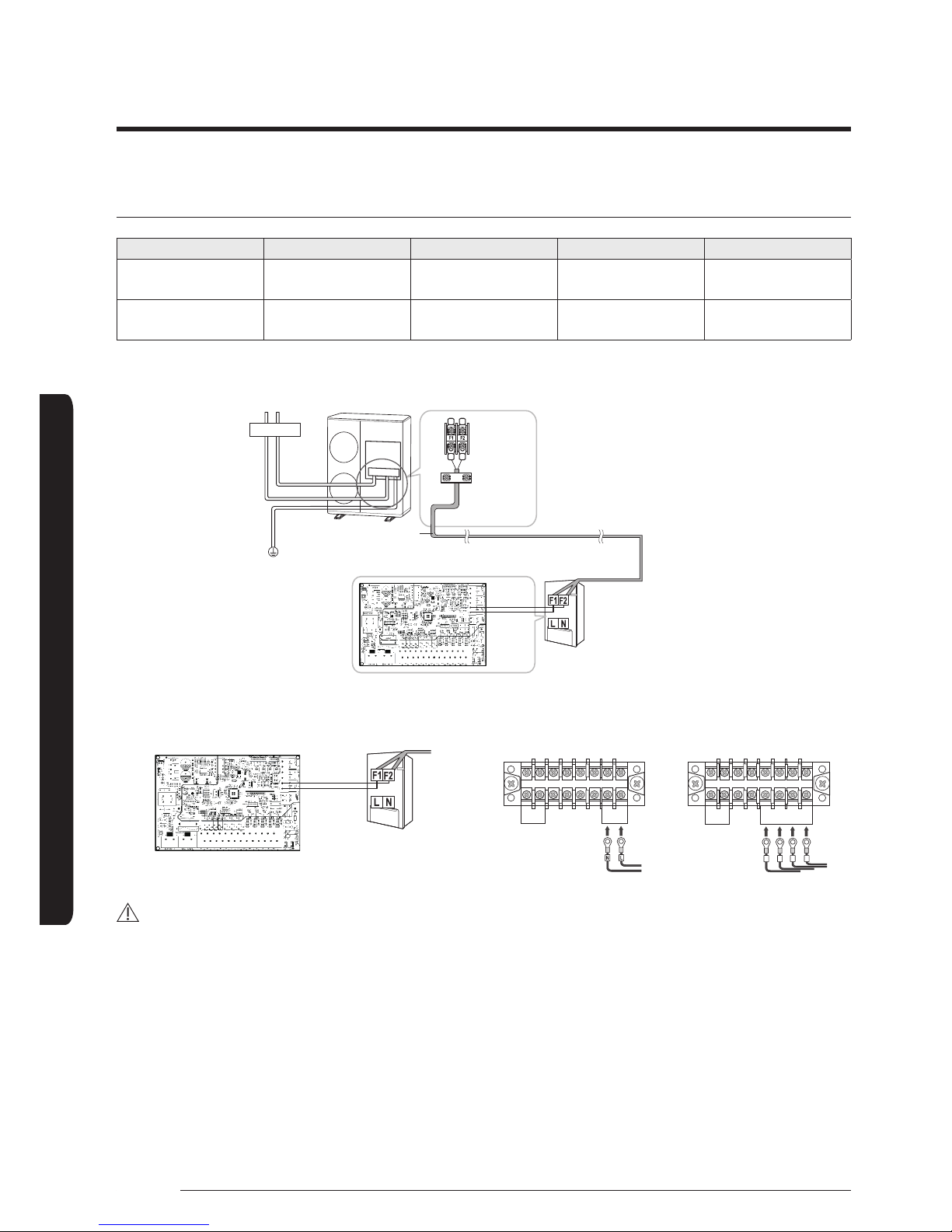

Connection of the power supply and communication cable

Description No. of wires Max. A Thickness Supply Scope

Main power 2+ground 32A

4.0mm

2

H05RN-F or

H07RN-F

Field supply

(230V~, Input)

Communication 2 6A

0.75mm

2

H05RN-F or

H07RN-F

7Vdc data

2 wires for communication cable

Earth

Communication cable

between indoor and

outdoor units

Communication

cable

Hydro unit

Circuit breaker

Communication cable connection Power wire connection

N

N L

N L

L N L N L

DHW TANK

POWER OUT

MAIN

POWER IN

1 phase

N

N

L

T N

L N L T N

R S

R S

T N

R S

DHW TANK

POWER OUT

MAIN POWER IN

3 phase

CAUTION

• If the supply cable is damaged, it must be replaced by a special cable or assembly available from the manufacturer or installer.

• Circuit Breaker (ELCB, ELB, MCCB etc.) for outdoor and indoor units shall be installed by installers because they are not sub-

parts in the units. But you don't need to install for hydro unit (Built-in ELCB).

– ELCB : Earth leakage circuit breaker

– ELB : Earth leakage breaker

– MCCB : Molded case circuit breaker

Loading...

Loading...