Samsung AC-Series-KN4*EH, AC071KN4DEH, AC100KN4PEH, AC100KN4DEH, AC071KN4PEH Installation Manual

...

Air conditioner

Installation manual

AC✴✴✴KN4✴EH

• Thank you for purchasing this Samsung air conditioner.

• Before operating this unit, please read this manual carefully and retain it for future

reference.

360_AC_Indoor_IM_AU_ENG_EN.indb 1 2016-05-13 오후 5:01:31

2

English

Contents

Safety Information 3

Installation Procedure 5

Step 1 Checking and preparing accessories

Step 2 Choosing the installation location

Step 3 Optional: Insulating the body of the indoor unit

Step 4 Installing the indoor unit

Step 5 Purging inert gas from the indoor unit

Step 6 Cutting and flaring the pipes

Step 7 Connecting the assembly pipes to the refrigerant pipes

Step 8 Performing the gas leak test

Step 9 Insulating the refrigerant pipes

Step 10 Installing the drain hose and drain pipe

Step 11 Performing the drainage test

Step 12 Connecting the power and communication cables

Step 13 Optional: Extending the power cable

Step 14 Setting the indoor unit addresses and the installation options

Appendix 34

Troubleshooting

360_AC_Indoor_IM_AU_ENG_EN.indb 2 2016-05-13 오후 5:01:31

3

English

Safety Information

WARNING

• Hazards or unsafe practices that may result in severe

personal injury or death.

CAUTION

• Hazards or unsafe practices that may result in minor

personal injury or property damage.

• Carefully follow the precautions listed below because

they are essential to guarantee the safety of the

equipment.

WARNING

• Always disconnect the air conditioner from the power

supply before servicing it or accessing its internal

components.

• Verify that installation and testing operations are

performed by qualified personnel.

• Verify that the air conditioner is not installed in an easily

accessible area.

General information

WARNING

• Carefully read the content of this manual before

installing the air conditioner and store the manual in a

safe place in order to be able to use it as reference after

installation.

• For maximum safety, installers should always carefully

read the following warnings.

• Store the operation and installation manual in a safe

location and remember to hand it over to the new owner

if the air conditioner is sold or transferred.

• This manual explains how to install an indoor unit

with a split system with two SAMSUNG units. The use

of other types of units with different control systems

may damage the units and invalidate the warranty.

The manufacturer shall not be responsible for damages

arising from the use of non compliant units.

• The manufacturer shall not be responsible for damage

originating from unauthorized changes or the improper

connection of electric and requirements set forth in the

“Operating limits” table, included in the manual, shall

immediately invalidate the warranty.

• The air conditioner should be used only for the

applications for which it has been designed: the indoor

unit is not suitable to be installed in areas used for

laundry.

• Do not use the units if damaged. If problems occur,

switch the unit off and disconnect it from the power

supply.

• In order to prevent electric shocks, fires or injuries,

always stop the unit, disable the protection switch

and contact SAMSUNG’s technical support if the unit

produces smoke, if the power cable is hot or damaged or

if the unit is very noisy.

• Always remember to inspect the unit, electric

connections, refrigerant tubes and protections regularly.

These operations should be performed by qualified

personnel only.

• The unit contains moving parts, which should always be

kept out of the reach of children.

• Do not attempt to repair, move, alter or reinstall the

unit. If performed by unauthorized personnel, these

operations may cause electric shocks or fires.

• Do not place containers with liquids or other objects on

the unit.

• All the materials used for the manufacture and

packaging of the air conditioner are recyclable.

• The packing material and exhaust batteries of the

remote controller(optional) must be disposed of in

accordance with current laws.

• The air conditioner contains a refrigerant that has to be

disposed of as special waste. At the end of its life cycle,

the air conditioner must be disposed of in authorised

centres or returned to the retailer so that it can be

disposed of correctly and safely.

Safety Information

Safety Information

360_AC_Indoor_IM_AU_ENG_EN.indb 3 2016-05-13 오후 5:01:32

4

Safety Information

English

Safety Information

Installing the unit

WARNING

IMPORTANT: When installing the unit, always remember

to connect first the refrigerant tubes, then the electrical

lines.

• Always disassemble the electric lines before the

refrigerant tubes.

• Upon receipt, inspect the product to verify that it has not

been damaged during transport. If the product appears

damaged, DO NOT INSTALL it and immediately report the

damage to the carrier or retailer (if the installer or the

authorized technician has collected the material from the

retailer.)

• After completing the installation, always carry out a

functional test and provide the instructions on how to

operate the air conditioner to the user.

• Do not use the air conditioner in environments with

hazardous substances or close to equipment that release

free flames to avoid the occurrence of fires, explosions

or injuries.

• Our units should be installed in compliance with the

spaces shown in the installation manual, to ensure

accessibility from both sides and allow repairs

or maintenance operations to be carried out. The

unit’s components should be accessible and easy to

disassemble without endangering people and objects.

For this reason, when provisions of the installation

manual are not complied with, the cost required to

access and repair the units (in SAFETY CONDITIONS, as

set out in prevailing regulations) with harnesses, ladders,

scaffolding or any other elevation system will NOT be

considered part of the warranty and will be charged to

the end customer.

Power supply line, fuse or circuit

breaker

WARNING

• Always make sure that the power supply is compliant

with current safety standards. Always install the air

conditioner in compliance with current local safety

standards.

• Always verify that a suitable grounding connection is

available.

• Verify that the voltage and frequency of the power

supply comply with the specifications and that the

installed power is sufficient to ensure the operation of

any other domestic appliance connected to the same

electric lines.

• Always verify that the cut-off and protection switches

are suitably dimensioned.

• Verify that the air conditioner is connected to the power

supply in accordance with the instructions provided in

the wiring diagram included in the manual.

• Always verify that electric connections (cable entry,

section of leads, protections…) are compliant with the

electric specifications and with the instructions provided

in the wiring scheme. Always verify that all connections

comply with the standards applicable to the installation

of air conditioners.

• Devices disconnected from the power supply should be

completely disconnected in the condition of overvoltage

category.

CAUTION

Make sure that you earth the cables.

• Do not connect the earth wire to the gas pipe, water

pipe, lighting rod or telephone wire. If earthing is not

complete, electric shock or fire may occur.

Install the circuit breaker.

• If the circuit breaker is not installed, electric shock or

fire may occur.

Make sure that the condensed water dripping from the

drain hose runs out properly and safely.

Install the power cable and communication cable of

the indoor and outdoor unit at least 1m away from the

electric appliance.

Install the indoor unit away from lighting apparatus

using the ballast.

• If you use the wireless remote control, reception error

may occur due to the ballast of the lighting apparatus.

360_AC_Indoor_IM_AU_ENG_EN.indb 4 2016-05-13 오후 5:01:32

5

Installation Procedure

English

Installation Procedure

Installation Procedure

Do not install the air conditioner in following places.

• Place where there is mineral oil or arsenic acid. Resin

parts flame and the accessories may drop or water may

leak. The capacity of the heat exchanger may reduce or

the air conditioner may be out of order.

• The place where corrosive gas such as sulphuric acid gas

generates from the vent pipe or air outlet.

• The copper pipe or connection pipe may corrode and

refrigerant may leak.

• The place where there is a machine that generates

electromagnetic waves. The air conditioner may not

operate normally due to control system.

• The place where there is a danger of existing

combustible gas, carbon fibre or flammable dust.

• The place where thinner or gasoline is handled. Gas may

leak and it may cause fire.

Step 1 Checking and preparing

accessories

The following accessories are supplied with the indoor

unit.

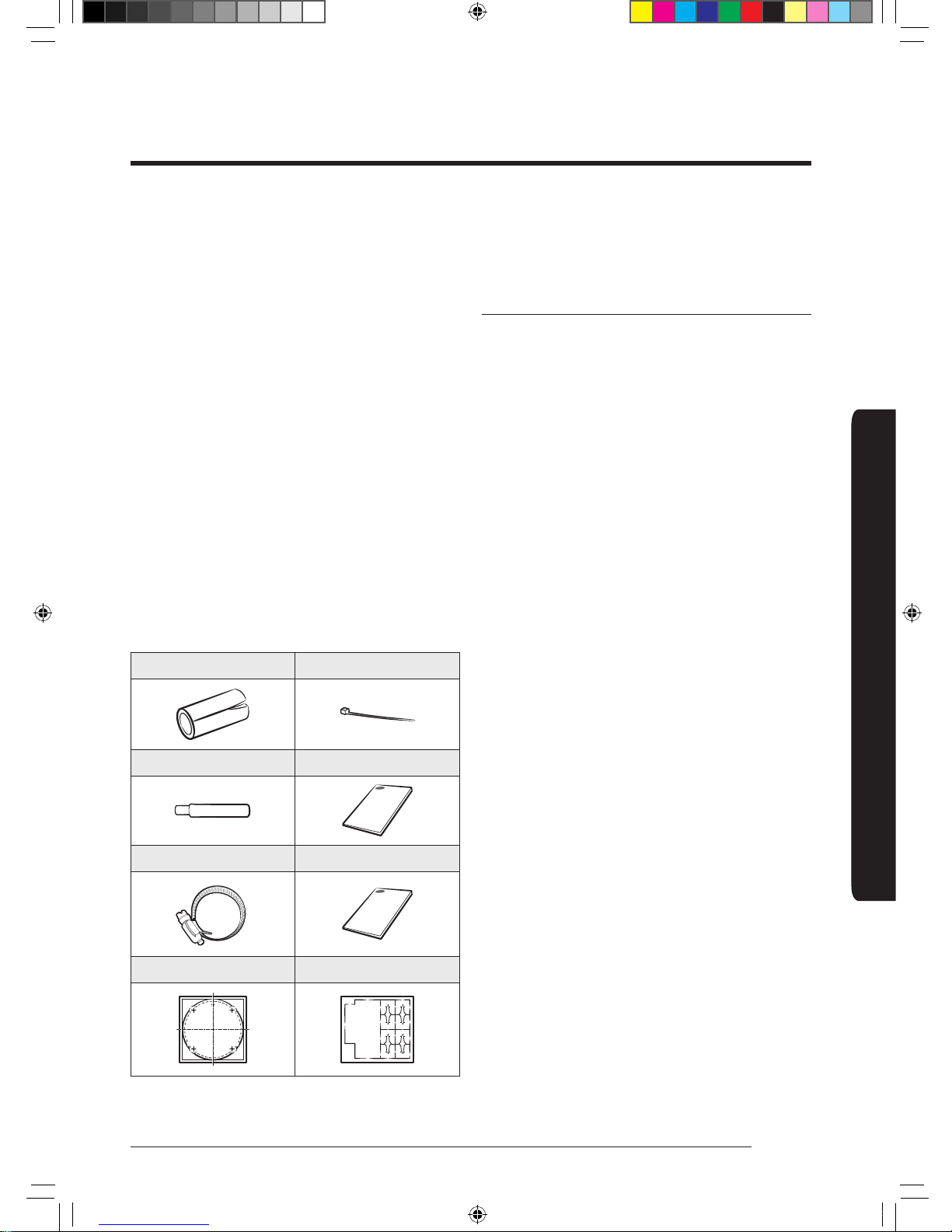

Insulation pipe (3 ea) Cable-tie (6 ea)

Drain hose (1 ea) Installation manual (1 ea)

Clamp (1 ea) User manual (1 ea)

Installation template (1 ea) Dimension gauge (1 ea)

Step 2 Choosing the installation

location

Installation location requirements

• There must be no obstacles near the air inlet and outlet.

• Install the indoor unit on a ceiling that can support its

weight.

• Maintain sufficient clearance around the indoor unit.

• Before installing the indoor unit, be sure to check

whether the chosen location is well-drained.

• The indoor unit must be installed such that it is beyond

public access and is not touchable by users.

360_AC_Indoor_IM_AU_ENG_EN.indb 5 2016-05-13 오후 5:01:33

6

Installation Procedure

Installation Procedure

English

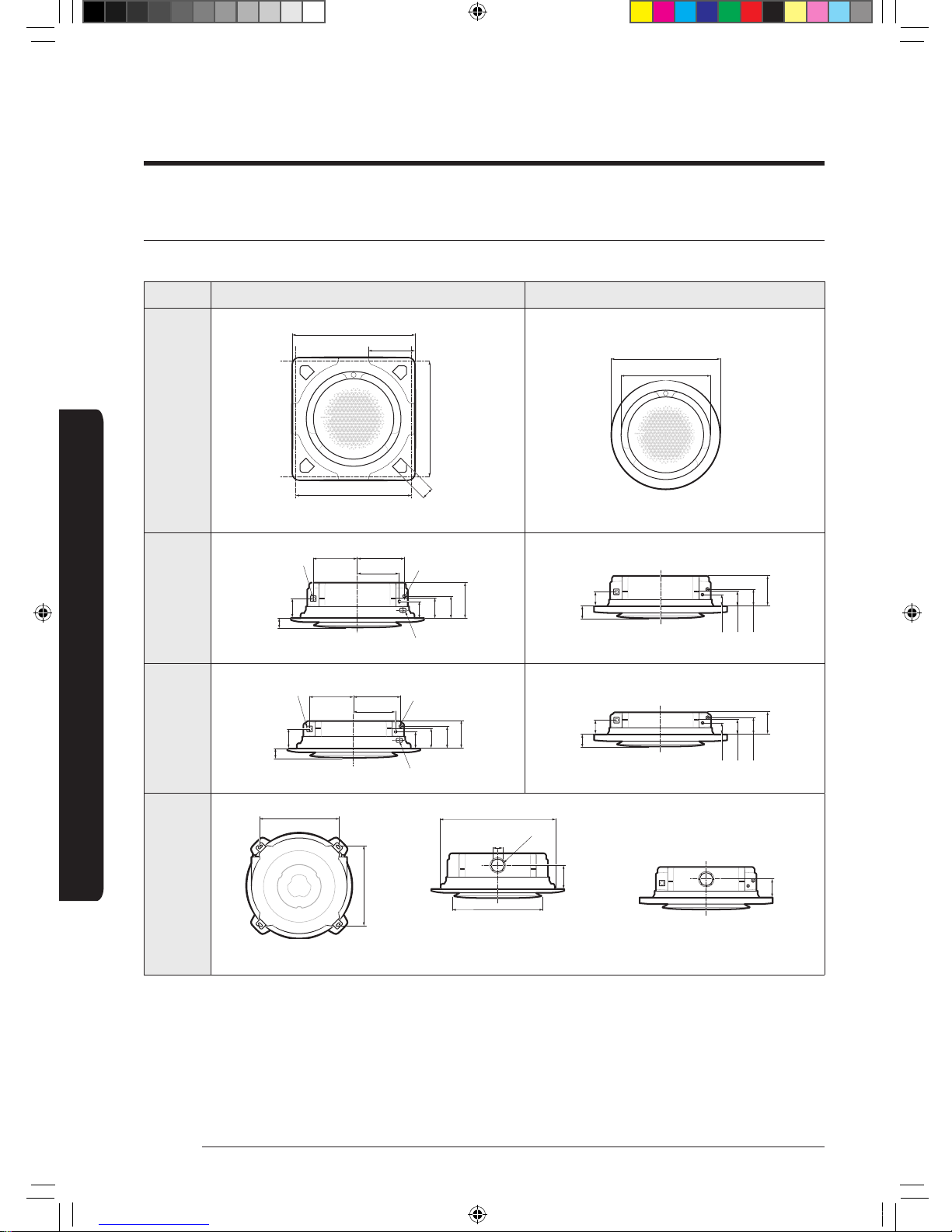

Indoor unit dimensions

(Unit: mm)

Category Square panel Circular panel

Front

1000

358

Ceiling opening dimension

960 (950 - 960)

Ceiling opening dimension

960 (950 - 960)

116

1050

883

Large+,

Large

385

166

66

357

404

128

181

190

317

Drain hose

connector

Refrigerant

pipe

Wire insert hole

100

153

162

289

138

94

Small

385

166

66

357

404

128

181

190

233

Drain hose

connector

Refrigerant

pipe

Wire insert hole

100

153

162

205

138

94

Common

646

646

942

787

80

ø100

H1

H1 → Large+, Large: 180, Small: 150

H2

→ Large+, Large: 152, Small: 122

H2

Square panel Circular panel

360_AC_Indoor_IM_AU_ENG_EN.indb 6 2016-05-13 오후 5:01:34

7

Installation Procedure

English

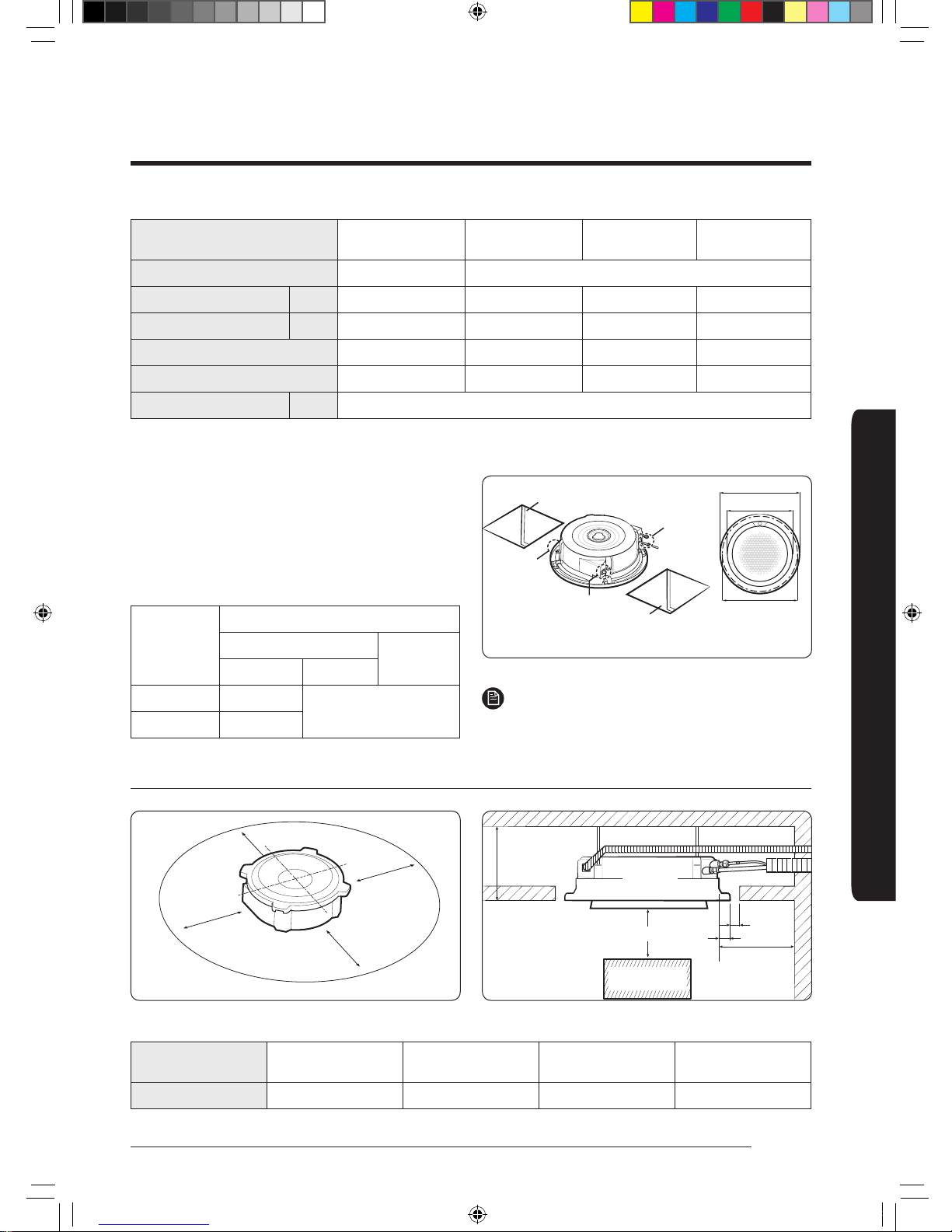

Spacing requirements

A

A : 1500 mm or more

A

A

A

'C'

Indoor unit

2500 mm or more

Obstruction

20 mm

1500 mm or

more

10 mm

• The circular panel is by default available in exposed

installation.

• Make inspection holes on the ceiling for easier

installation and maintenance, as shown in the following

table. (The size of an inspection hole must be at least

450 mm x 450 mm.)

• A suspended ceiling structure can substitute for the

inspection holes.

Category

Inspection hole

Recessed installation

Exposed

installation

Integrated suspended

Square panel

1 ea

-

Circular panel

2 ea

•

For the recessed installation of the circular panel

Refrigerant

pipe

Connection part of the

drain hose

Indoor unit

display

Inspection hole

1050

883

ø1010 to 1020

Ceiling opening diameter

ø1010 to 1020

Inspection hole

NOTE

The clearance between the panel and the inspection hole

is 15 to 20 mm on a side.

Model

AC071KN4PEH

AC071KN4DEH

AC100KN4PEH

AC100KN4DEH

AC125KN4PEH

AC140KN4PEH

AC140KN4DEH

Chassis Large Large+

Net dimension (W × D × H) mm 947 × 947 × 365 947 × 947 × 365 947 × 947 × 365 947 × 947 × 365

Net weight kg 24.0 26.0 26.0 26.0

Liquid pipe connection 6.35 9.52 9.52 9.52

Gas pipe connection 15.88 15.88 15.88 15.88

Drain hose connection mm Outer diameter: ø32, inner diameter: ø26.5

(Unit: mm)

Model

AC071KN4PEH

AC071KN4DEH

AC100KN4PEH

AC100KN4DEH

AC125KN4PEH

AC140KN4PEH

AC140KN4DEH

C 345 345 345 345

360_AC_Indoor_IM_AU_ENG_EN.indb 7 2016-05-13 오후 5:01:35

8

Installation Procedure

Installation Procedure

English

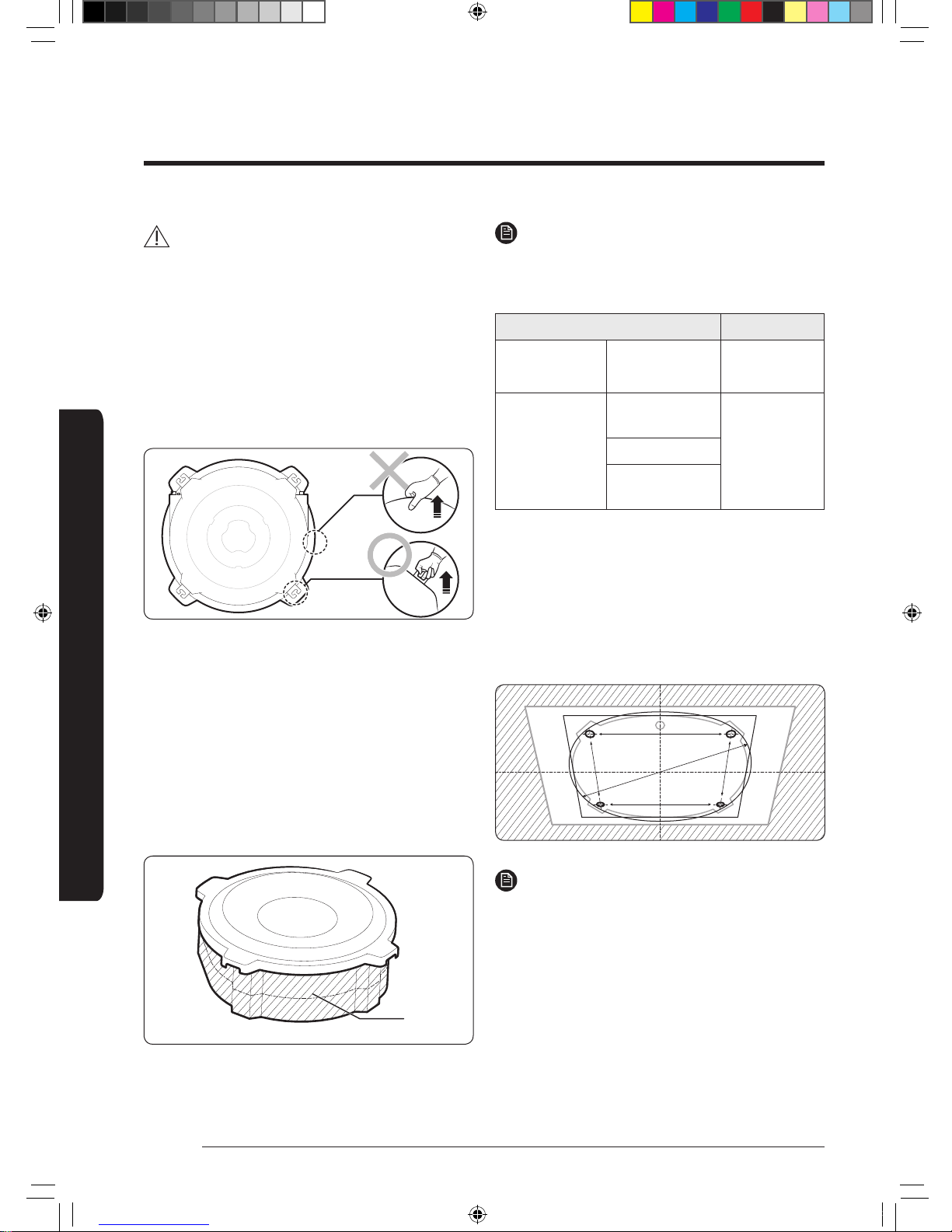

CAUTION

• The indoor unit must be installed according to the

specified distances in order to permit accessibility from

each side, to guarantee correct operation, maintenance,

and repair of the unit.

The components of the indoor unit must be reachable and

removable under safe conditions for people and the unit.

• Do not hold the discharge while carrying the indoor unit

to avoid the possibility of breakage.

• You must hold the hanger plate on the corner and carry

the indoor unit.

Step 3 Optional: Insulating the body

of the indoor unit

If you install a cassette type indoor unit on the ceiling

when temperature is over 27°C and humidity is over

80%, you must apply an extra 10 mm thick polyethylene

insulation or a similar type of insulation to the body of

the indoor unit.

Cut away the part where pipes are pulled out for the

insulating work.

A

Insulate the end of the pipe and some curved area by

using separate insulator.

NOTE

• A: Reference for the outer circumference of the unit

(When insulating the body of the indoor unit, use A as

the reference for its outer circumference.)

Indoor unit type and models Dimensions

360 cassette type

<L>

(947 x 947 x 365)

AC071KN4PEH

AC071KN4DEH

2610 × 215

360 cassette type

<L+>

(947 x 947 x 365)

AC100KN4PEH

AC100KN4DEH

2610 × 215AC125KN4PEH

AC140KN4PEH

AC140KN4DEH

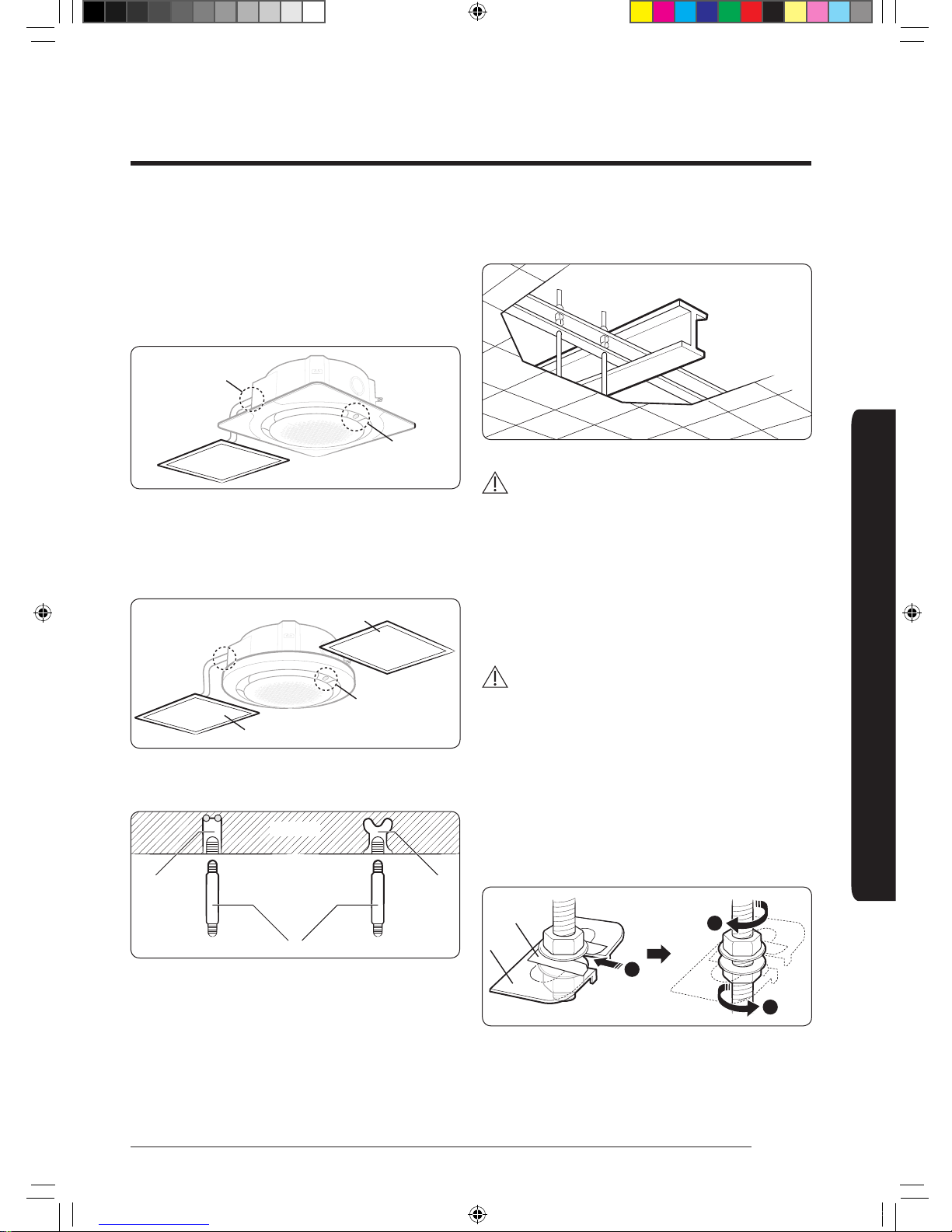

Step 4 Installing the indoor unit

When deciding on the location of the air conditioner the

following restrictions must be taken into account.

1 Determine the positions of the pipe and the drain hose

hole as shown in the pattern sheet, and drill the hole

with an inner diameter of 14 mm.

NOTE

• Since the diagram is made of paper, it may shrink or

stretch slightly due to temperature or humidity. For this

reason, before drilling the holes, be sure to maintain the

correct dimensions between the markings.

360_AC_Indoor_IM_AU_ENG_EN.indb 8 2016-05-13 오후 5:01:35

9

Installation Procedure

English

2 Perform the following steps to install inspection holes in

accordance with the panel type.

a For the recessed installation of the square panel.

• Install an inspection hole to the direction of

connection parts of the refrigerant pipe and the

drain hose. (1 point)

Indoor unit

display

Refrigerant pipe

Inspection hole

b For recessed installation of the circular panel

• Install inspection holes to both directions of the

connection part of the refrigerant pipe and the

drain hose and of the indoor unit display. (2 points)

Refrigerant pipe

Indoor unit display

Inspection hole

Inspection hole

3 Insert bolt anchors, use existing ceiling supports or

construct a suitable support as shown in figure.

Concrete

Hole in anchor

Hole in plug

Suspension bolt (M10) - eld supply

Insert

4 Install the suspension bolts, depending on the ceiling

type.

Ceiling support

CAUTION

• Make sure that the ceiling is strong enough to support

the weight of the indoor unit. Before hanging the unit,

test the strength of each attached suspension bolt.

• If the length of the suspension bolt is more than 1.5 m,

you are required to prevent vibration.

5 Screw eight pairs of nuts and washers to the suspension

bolts, making space for hanging the indoor unit.

CAUTION

• You must install all of the suspension rods.

• It is important to leave sufficient space in the false

ceiling to allow access for maintenance or repairs to

the drainage pipe connection, the refrigerant pipe

connection, or to remove the unit if necessary.

6 Hang the indoor unit to the suspension bolts between

two nuts. Cut a pad stopper and place it on the

suspension bolts to hold the washers. Remove the

stopper and screw the nuts to fix the unit.

1

2

2

360_AC_Indoor_IM_AU_ENG_EN.indb 9 2016-05-13 오후 5:01:36

10

Installation Procedure

Installation Procedure

English

7 Adjust the unit to the appropriate position, taking into

account the installation area for the front panel.

• Place the pattern sheet on the indoor unit.

• Adjust the space between the ceiling and the indoor

unit by using a dimension gauge.

• Fix the indoor unit securely after adjusting the level

of the unit by using a leveller.

• Remove the pattern sheet and install the front panel.

For the recessed installation

of the square panel: 11.5 mm

For the recessed installation

of the circular panel: 41.5 mm

Indoor unit

Ceiling

Gauge of dimensions

Step 5 Purging inert gas from the

indoor unit

The indoor unit comes with nitrogen gas (inert gas)

charged at the factory. Therefore, all inert gas must be

purged before connecting the assembly piping.

Unscrew the pinch pipe at the end of each refrigerant

pipe.

Liquid side

Gas side

Insulator

NOTE

• To prevent dirt or foreign objects from getting into the

pipes during installation, do not remove the pinch pipe

completely until you are ready to connect the piping.

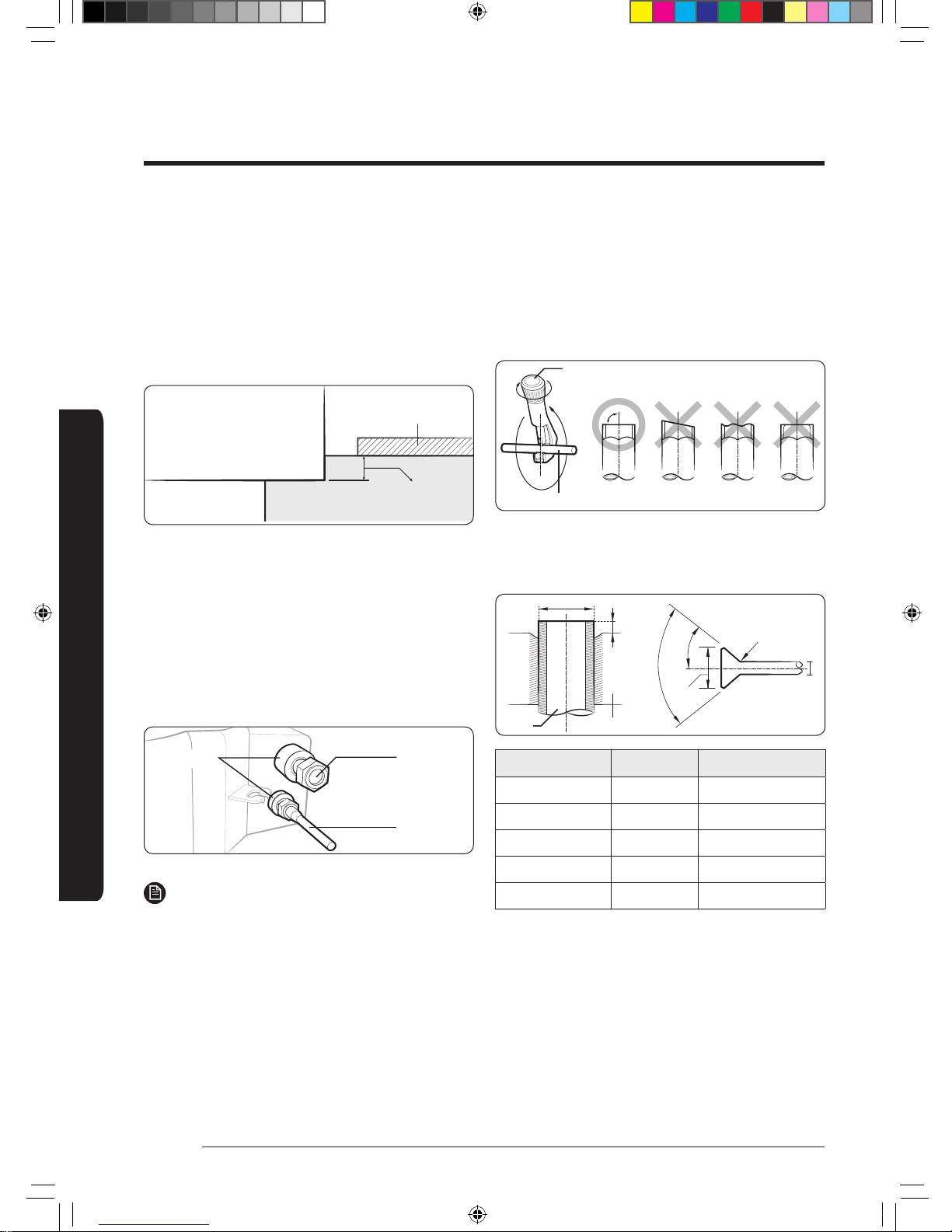

Step 6 Cutting and flaring the pipes

1 Make sure that you have the required tools available:

pipe cutter, reamer, flaring tool, and pipe holder.

2 If you wish to shorten the pipes, cut them with a pipe

cutter, ensuring that the cut edge remains at a 90° angle

to the side of the pipe. Refer to the illustrations below

for examples of edges cut correctly and incorrectly.

Pipe cutter

Pipe

Oblique

Rough

Burr

3 To prevent any gas from leaking out, remove all burrs at

the cut edge of the pipe, using a reamer.

4 Slide a flare nut on to the pipe and modify the flare.

Pipe

Flare

D

A

Flare

R 0.4 to 0.8 mm

D

L

90° ±2°

45° ±2°

Outer Diameter (D) Depth (A) Flare dimension (L)

Ø6.35 mm 1.3 mm 8.7 to 9.1 mm

Ø9.52 mm 1.8 mm 12.8 to 13.2 mm

Ø12.70 mm 2.0 mm 16.2 to 16.6 mm

Ø15.88 mm 2.2 mm 19.3 to 19.7 mm

Ø19.05 mm 2.2 mm 23.6 to 24.0 mm

360_AC_Indoor_IM_AU_ENG_EN.indb 10 2016-05-13 오후 5:01:36

11

Installation Procedure

English

5 Check that the flaring is correct, referring to the

illustrations below for examples of incorrect flaring.

Correct

Inclined

Damaged

Surface

Cracked

Uneven

Thickness

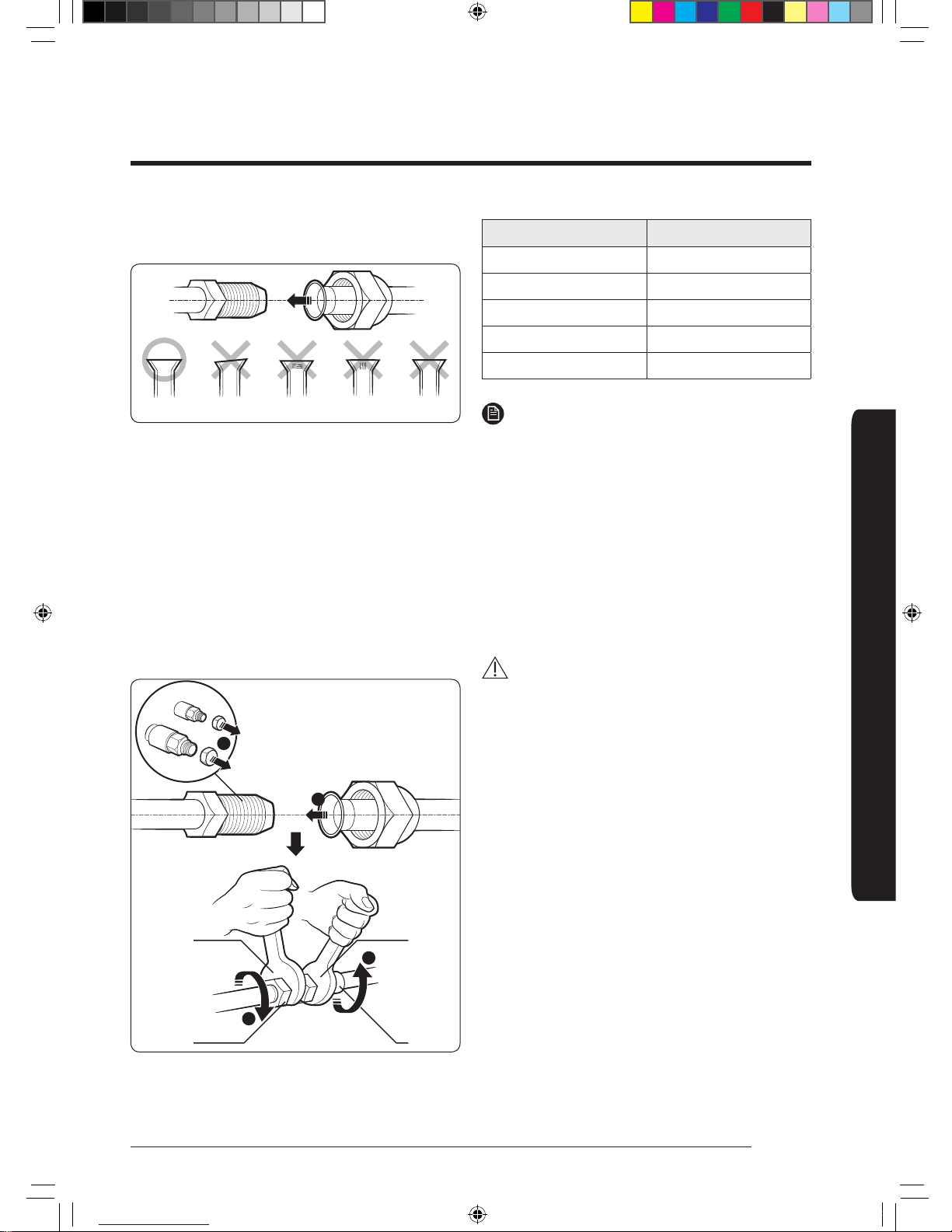

Step 7 Connecting the assembly

pipes to the refrigerant pipes

There are two refrigerant pipes of different diameters :

• A smaller one for the liquid refrigerant.

• A larger one for the gas refrigerant. The inside of copper

pipe must be clean and has no dust.

1 Remove the pinch pipe on the pipes and connect the

assembly pipes to each pipe, tightening the nuts, first

manually and then with a torque wrench, a spanner

applying the following torque.

2

3

3

1

Torque

wrench

Flare nut

Spanner

Union

Outer diameter (mm) Torque (N•m)

Ø6.35 14 to18

Ø9.52 34 to 42

Ø12.70 49 to 61

Ø15.88 68 to 82

Ø19.05 100 to 120

NOTE

• If the pipes must be shortened, see Step 6 Cutting and

flaring the pipes on page 10.

2 Be sure to use an insulator thick enough to cover the

refrigerant tube to protect the condensate water on the

outside of the pipe falling onto the floor and to improve

the efficiency of the unit.

3 Cut off any excess foam insulation.

4 Make sure that there are no cracks or waves on the bent

area.

5 It would be necessary to double the insulation thickness

(10 mm or more) to prevent condensation even on the

insulator when if the installed area is warm and humid.

CAUTION

• Connect the indoor and outdoor units using pipes with

flared connections (not supplied). For the lines, use

insulated, unwelded, degreased and deoxidized copper

pipe (Cu DHP type to ISO 1337 or UNI EN 12735-1),

suitable for operating pressures of at least 4.2 MPa and

for a burst pressure of at least 20.7 MPa. Copper pipe for

hydro-sanitary applications is completely unsuitable.

• For sizing and limits (height difference, line length, max.

bends, refrigerant charge, etc.) see the outdoor unit

installation manual.

• All refrigerant connection must be accessible, in order

to permit either unit maintenance or removing it

completely.

• If the pipes require brazing, make sure that oxygen free

nitrogen (OFN) is flowing through the system.

• Nitrogen blowing pressure range is 0.02 to 0.05 MPa.

(1N•m=10kgf•cm)

360_AC_Indoor_IM_AU_ENG_EN.indb 11 2016-05-13 오후 5:01:37

Loading...

Loading...